Harness SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1376 of 1496

Downloaded from www.Manualslib.com manuals search engine 9J-7 Hood / Fenders / Doors:

WARNING!

Handling of Rear End Door Balancer

(Damper)

• Handle balancer carefully. Do not scar or scratch exposed surface of its piston rod,

and never allow any paint or oil to stick to

its surface.

• Do not turn piston rod with balancer fully extended.

• Do not disassemble balancer (1) because its cylinder is filled with gas.

Discarding of Rear End Door Balancer

(Damper)

• The gas itself in balancer is harmless but it may issue out of the hole together with

chips generated by th e drill (2). Therefore,

be sure to wear goggle when drilling.

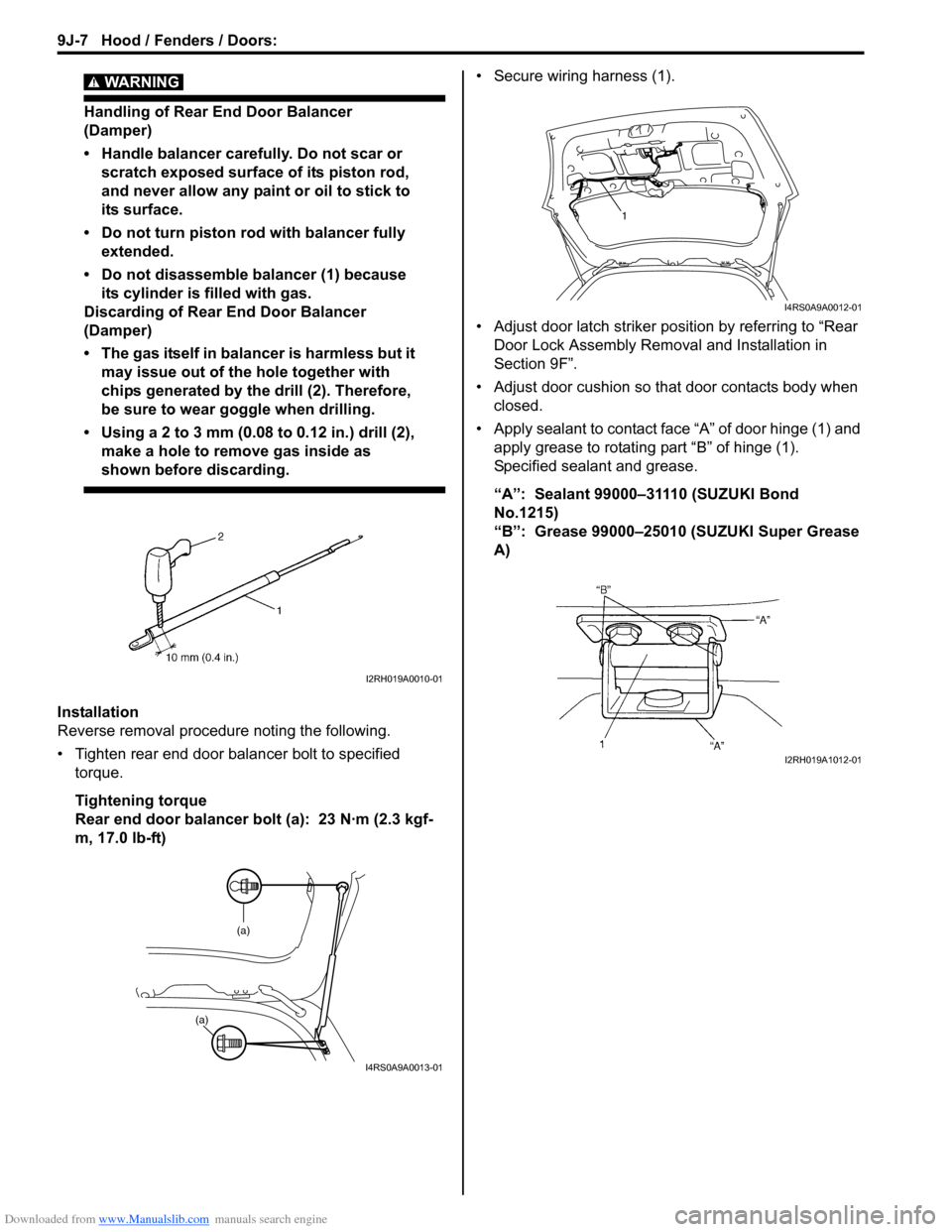

• Using a 2 to 3 mm (0.08 to 0.12 in.) drill (2),

make a hole to remove gas inside as

shown before discarding.

Installation

Reverse removal procedure noting the following.

• Tighten rear end door balancer bolt to specified torque.

Tightening torque

Rear end door balancer bolt (a): 23 N·m (2.3 kgf-

m, 17.0 lb-ft) • Secure wiring harness (1).

• Adjust door latch striker position by referring to “Rear

Door Lock Assembly Removal and Installation in

Section 9F”.

• Adjust door cushion so that door contacts body when closed.

• Apply sealant to contact face “A” of door hinge (1) and apply grease to rotating part “B” of hinge (1).

Specified sealant and grease.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

“B”: Grease 99000–25010 (SUZUKI Super Grease

A)

I2RH019A0010-01

(a)

(a)

I4RS0A9A0013-01

1

I4RS0A9A0012-01

I2RH019A1012-01

Page 1410 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-7 Body Electrical Control System:

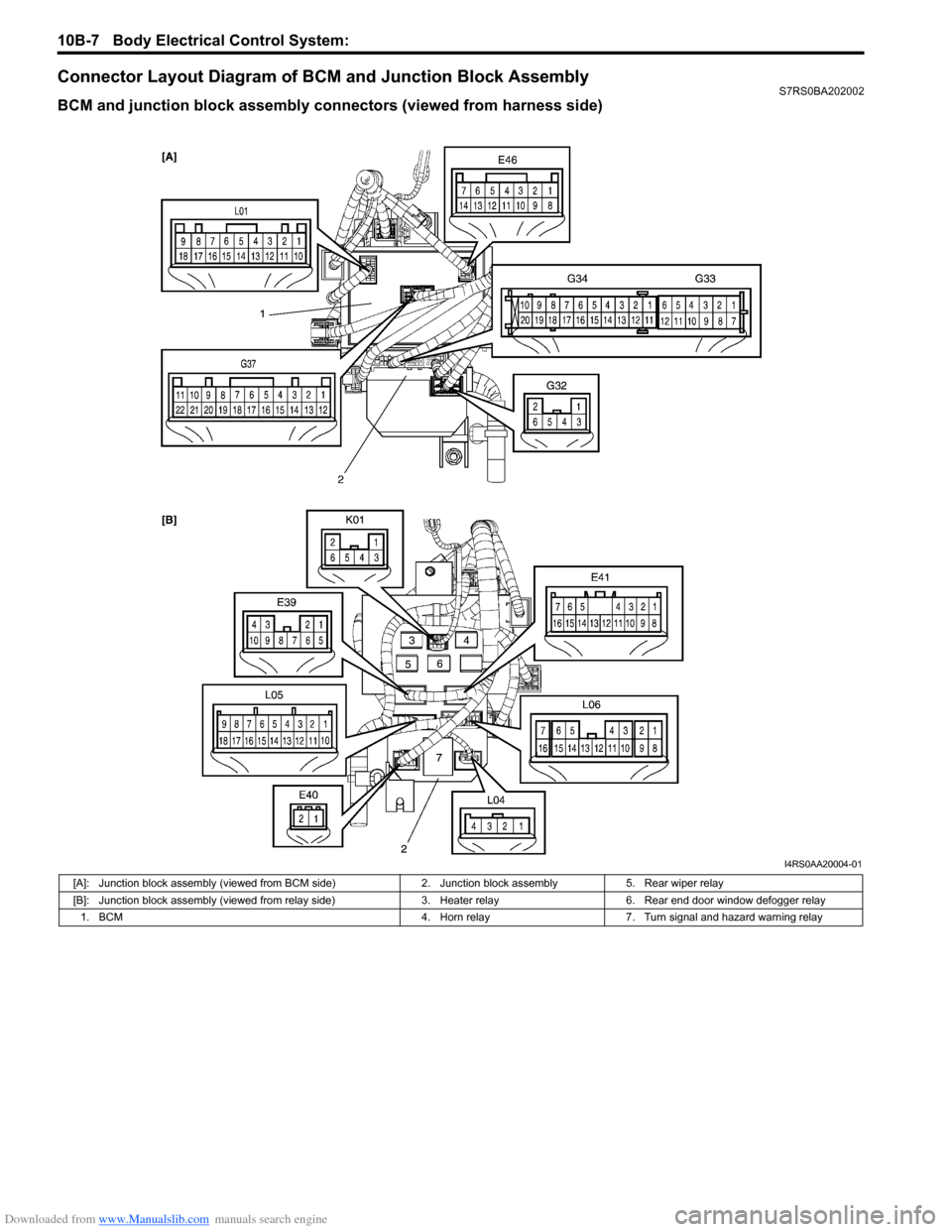

Connector Layout Diagram of BCM and Junction Block AssemblyS7RS0BA202002

BCM and junction block assembly connectors (viewed from harness side)

I4RS0AA20004-01

[A]: Junction block assembly (viewed from BCM side)2. Junction block assembly5. Rear wiper relay

[B]: Junction block assembly (viewed from relay side) 3.Heater relay 6. Rear end door window defogger relay

1. BCM 4. Horn relay7. Turn signal and hazard warning relay

Page 1414 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-11 Body Electrical Control System:

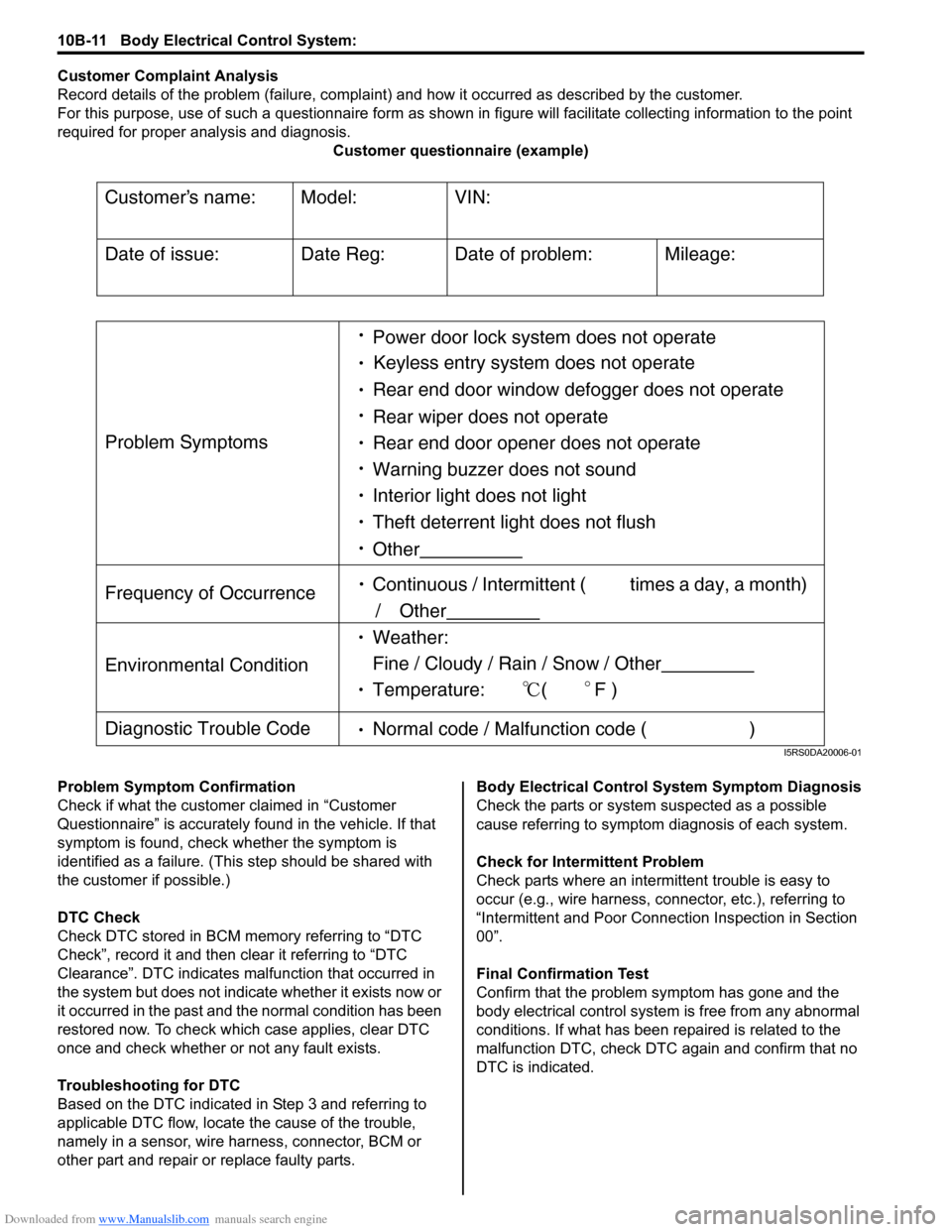

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in figure will facilitate collectin g information to the point

required for proper analysis and diagnosis. Customer questionnaire (example)

Problem Symptom Confirmation

Check if what the custom er claimed in “Customer

Questionnaire” is accurately f ound in the vehicle. If that

symptom is found, check whether the symptom is

identified as a failure. (This step should be shared with

the customer if possible.)

DTC Check

Check DTC stored in BCM me mory referring to “DTC

Check”, record it and then clear it referring to “DTC

Clearance”. DTC indicates malfunction that occurred in

the system but does not indicate whether it exists now or

it occurred in the past and the normal condition has been

restored now. To check which case applies, clear DTC

once and check whether or not any fault exists.

Troubleshooting for DTC

Based on the DTC indicated in Step 3 and referring to

applicable DTC flow, locate the cause of the trouble,

namely in a sensor, wire harness, connector, BCM or

other part and repair or replace faulty parts. Body Electrical Control System Symptom Diagnosis

Check the parts or system

suspected as a possible

cause referring to symptom diagnosis of each system.

Check for Intermi ttent Problem

Check parts where an intermit tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00”.

Final Confirmation Test

Confirm that the problem symptom has gone and the

body electrical control system is free from any abnormal

conditions. If what has been repaired is related to the

malfunction DTC, check DTC again and confirm that no

DTC is indicated.

Customers name:

Model:

VIN:

Date of issue:

Date Reg:

Date of problem:

Mileage:

Problem Symptoms

Power door lock system does not operate

Keyless entry system does not operate

Rear end door window defogger does not operate

Rear wiper does not operate

Rear end door opener does not operate

Other

Frequency of Occurrence

Continuous / Intermittent ( times a day, a month)

/ Other

Environmental Condition

Weather:

Fine / Cloudy / Rain / Snow / Other

Temperature: (F )

Diagnostic Trouble Code Normal code / Malfunction code ( )

Warning buzzer does not sound

Interior light does not light

Theft deterrent light does not flush

I5RS0DA20006-01

Page 1419 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-16

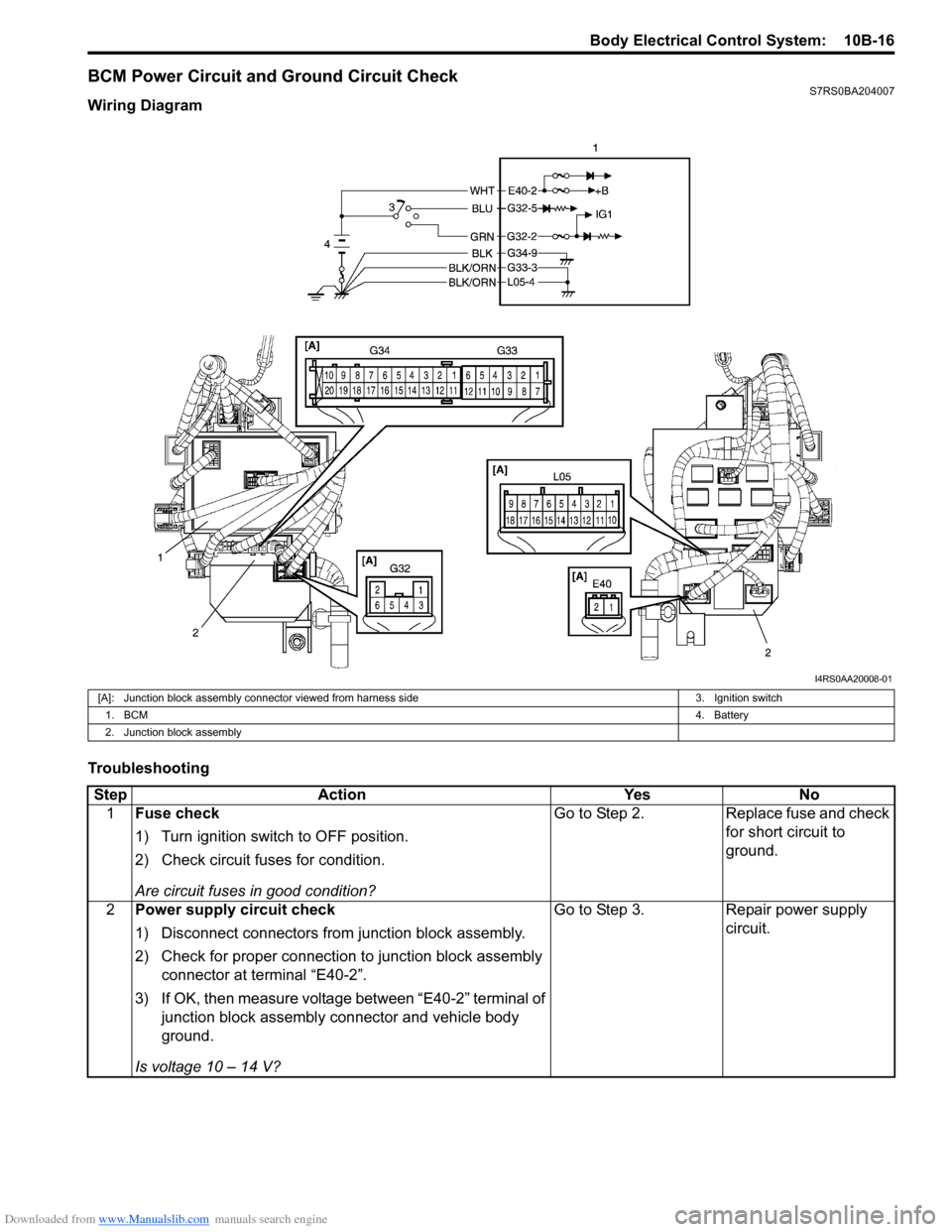

BCM Power Circuit and Ground Circuit CheckS7RS0BA204007

Wiring Diagram

Troubleshooting

I4RS0AA20008-01

[A]: Junction block assembly connector viewed from harness side3. Ignition switch

1. BCM 4. Battery

2. Junction block assembly

Step Action YesNo

1 Fuse check

1) Turn ignition switch to OFF position.

2) Check circuit fuses for condition.

Are circuit fuses in good condition? Go to Step 2.

Replace fuse and check

for short circuit to

ground.

2 Power supply circuit check

1) Disconnect connectors from junction block assembly.

2) Check for proper connection to junction block assembly

connector at terminal “E40-2”.

3) If OK, then measure voltage between “E40-2” terminal of junction block assembly connector and vehicle body

ground.

Is voltage 10 – 14 V? Go to Step 3.

Repair power supply

circuit.

Page 1421 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-18

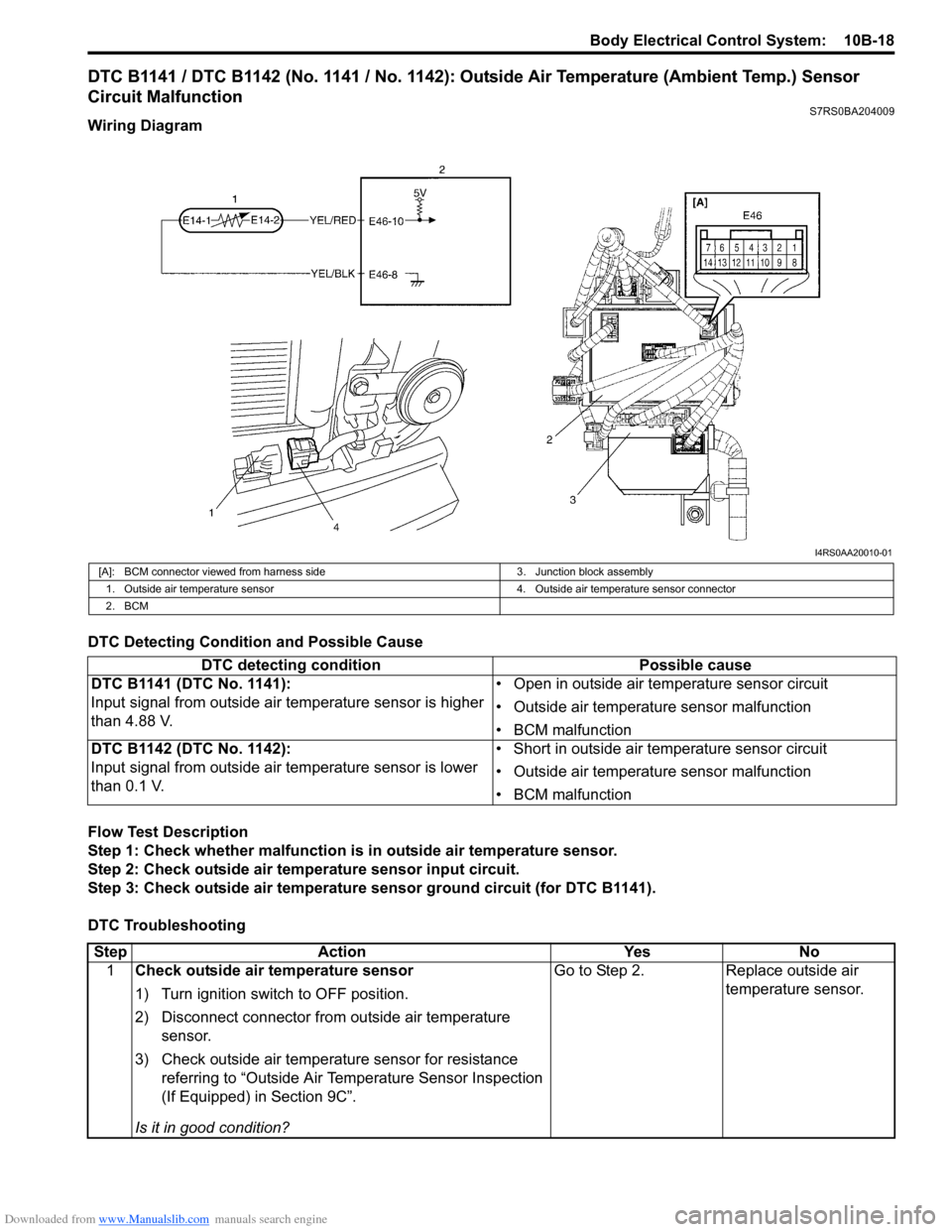

DTC B1141 / DTC B1142 (No. 1141 / No. 1142): Outside Air Temperature (Ambient Temp.) Sensor

Circuit Malfunction

S7RS0BA204009

Wiring Diagram

DTC Detecting Condition and Possible Cause

Flow Test Description

Step 1: Check whether malfunction is in outside air temperature sensor.

Step 2: Check outside air temperature sensor input circuit.

Step 3: Check outside air temperature sensor ground circuit (for DTC B1141).

DTC Troubleshooting

I4RS0AA20010-01

[A]: BCM connector viewed from harness side 3. Junction block assembly

1. Outside air temperature sensor 4. Outside air temperature sensor connector

2. BCM

DTC detecting condition Possible cause

DTC B1141 (DTC No. 1141):

Input signal from outside air temperature sensor is higher

than 4.88 V. • Open in outside air temperature sensor circuit

• Outside air temperature sensor malfunction

• BCM malfunction

DTC B1142 (DTC No. 1142):

Input signal from outside air temperature sensor is lower

than 0.1 V. • Short in outside air temperature sensor circuit

• Outside air temperature sensor malfunction

• BCM malfunction

Step

Action YesNo

1 Check outside air temperature sensor

1) Turn ignition switch to OFF position.

2) Disconnect connector from outside air temperature

sensor.

3) Check outside air temperature sensor for resistance referring to “Outside Air Temperature Sensor Inspection

(If Equipped) in Section 9C”.

Is it in good condition? Go to Step 2.

Replace outside air

temperature sensor.

Page 1422 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-19 Body Electrical Control System:

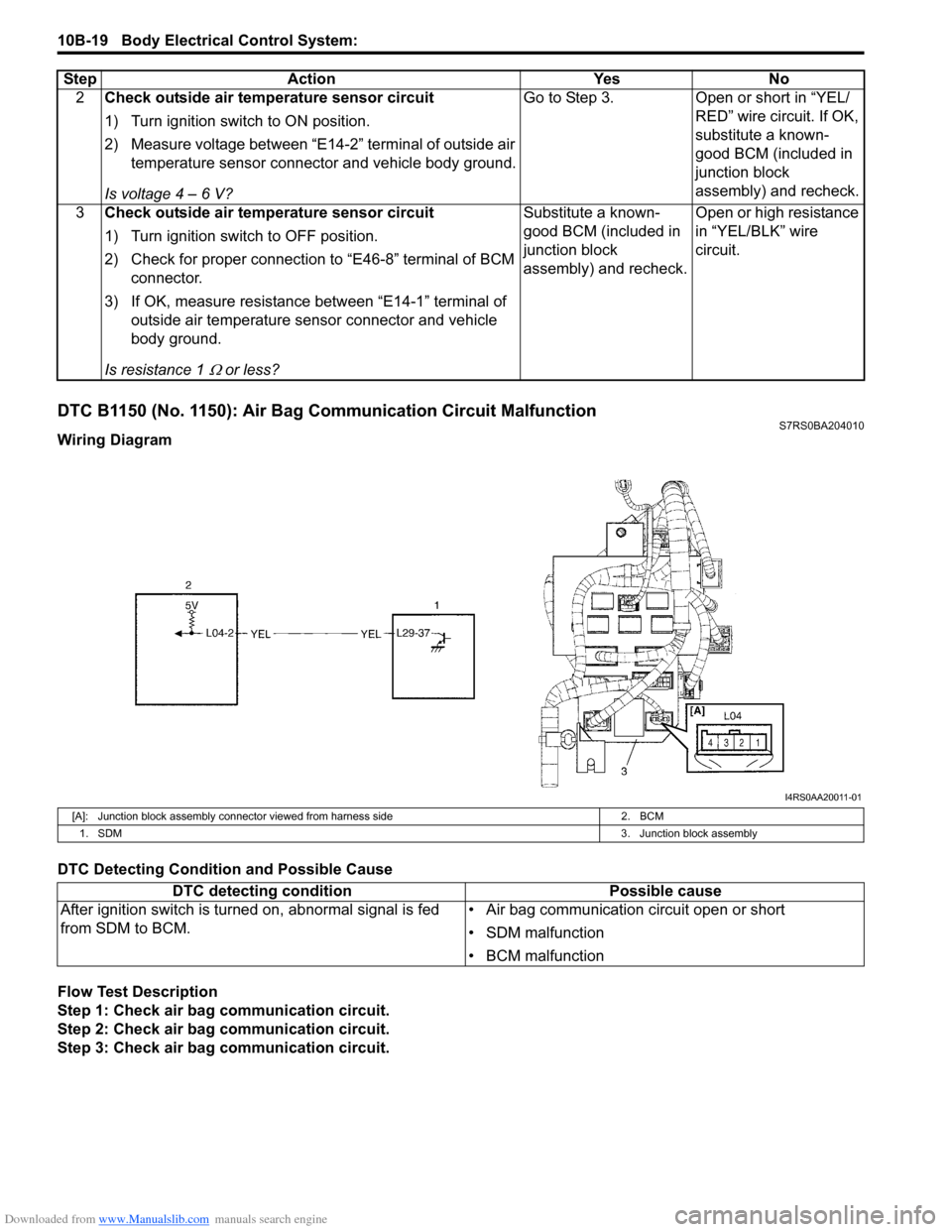

DTC B1150 (No. 1150): Air Bag Communication Circuit MalfunctionS7RS0BA204010

Wiring Diagram

DTC Detecting Condition and Possible Cause

Flow Test Description

Step 1: Check air bag communication circuit.

Step 2: Check air bag communication circuit.

Step 3: Check air bag communication circuit. 2

Check outside air temperature sensor circuit

1) Turn ignition switch to ON position.

2) Measure voltage between “E14-2” terminal of outside air

temperature sensor connector and vehicle body ground.

Is voltage 4 – 6 V? Go to Step 3. Open or short in “YEL/

RED” wire circuit. If OK,

substitute a known-

good BCM (included in

junction block

assembly) and recheck.

3 Check outside air temperature sensor circuit

1) Turn ignition switch to OFF position.

2) Check for proper connection to “E46-8” terminal of BCM

connector.

3) If OK, measure resistance between “E14-1” terminal of outside air temperature sens or connector and vehicle

body ground.

Is resistance 1

Ω or less? Substitute a known-

good BCM (included in

junction block

assembly) and recheck.

Open or high resistance

in “YEL/BLK” wire

circuit.

Step Action Yes No

I4RS0AA20011-01

[A]: Junction block assembly connect

or viewed from harness side 2. BCM

1. SDM 3. Junction block assembly

DTC detecting conditionPossible cause

After ignition switch is turned on, abnormal signal is fed

from SDM to BCM. • Air bag communication circuit open or short

• SDM malfunction

• BCM malfunction

Page 1424 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-21 Body Electrical Control System:

DTC B1170 (No. 1170): EEPROM Access ErrorS7RS0BA204012

DTC Detecting Condition and Possible Cause

DTC Troubleshooting

NOTE

Before performing steps below, be sure to perform “Body Electrical Control System Check”.

1) Ignition switch OFF.

2) Replace BCM.

3) Repeat BCM Check Flow Table.

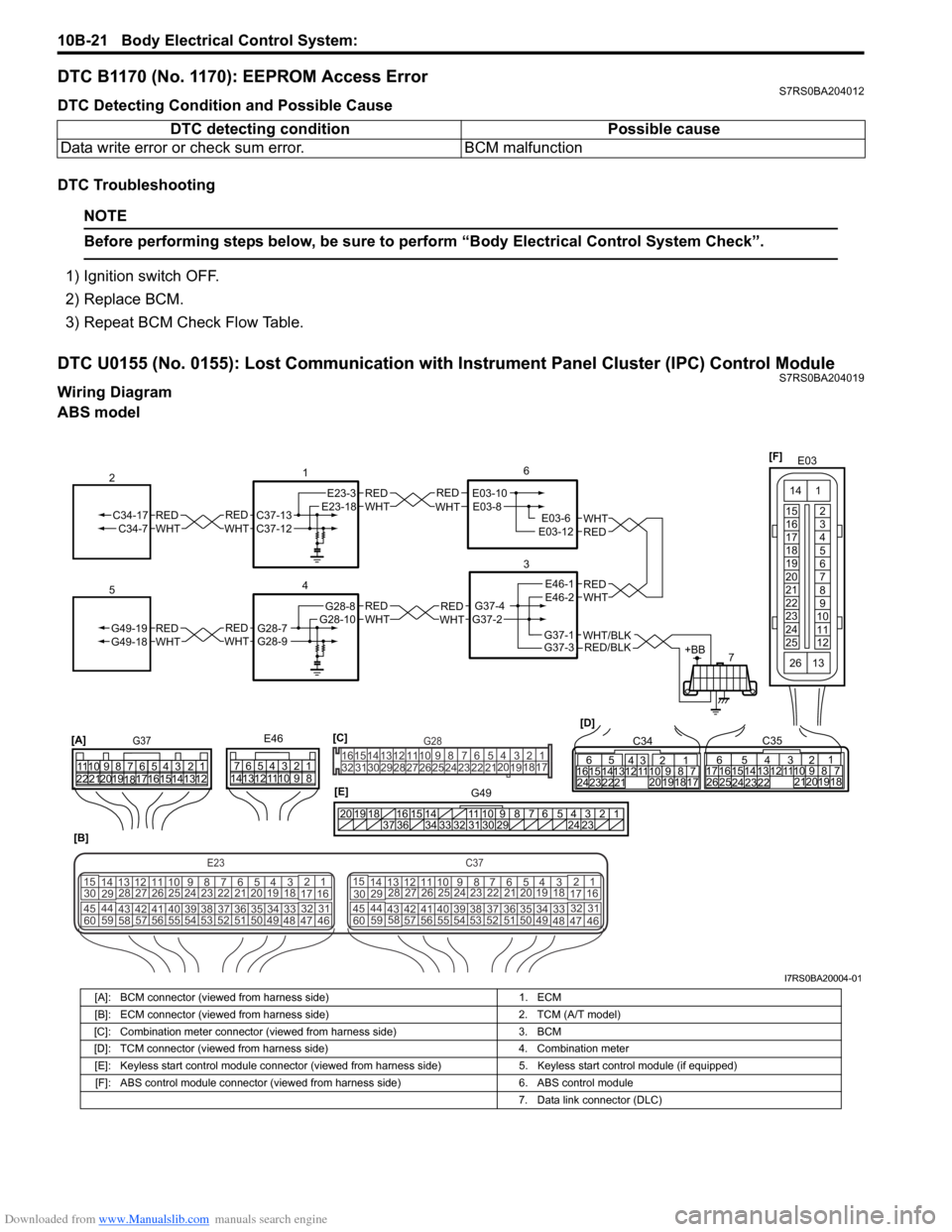

DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control ModuleS7RS0BA204019

Wiring Diagram

ABS model DTC detecting condition Possible cause

Data write error or check sum error. BCM malfunction

REDWHTE03-6E03-12

6

3

7

REDWHT

1

[B]

[A]

G37E46

1234567

1234567

8910

11

8910

11

121314 121314

151617

18

19202122 [D]65

1615 141312 11 43

2423 2122 10 9 8 7

21

1920 1817

C3417 16

26 2515 14

65 3

42

13 12

23 2224 1110 9

212019 87

18

1

C35

[E]

REDWHTC37-13C37-12REDWHTC34-17C34-7

2

12345678910

11

141516

36 34 33 32 31 30 29 24 23

37

181920

[C] [F]

G49

E23-3E23-18

4

REDWHTG28-7G28-9REDWHTG49-19G49-18

5

REDWHTE03-10E03-8

G37-4G37-2

REDWHTE46-1E46-2REDWHTREDWHTG28-8G28-10

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 33 1

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

G281234567

8

910111213141516

1718

19

20

212223242526272829303132

RED/BLKWHT/BLKG37-3G37-1+BB

I7RS0BA20004-01

[A]: BCM connector (viewed from harness side) 1. ECM

[B]: ECM connector (viewed from harness side) 2. TCM (A/T model)

[C]: Combination meter connector (viewed from harness side) 3. BCM

[D]: TCM connector (viewed from harness side) 4. Combination meter

[E]: Keyless start control module connector (viewed from harness side) 5. Keyless start control module (if equipped)

[F]: ABS control module connector (viewed from harness side) 6. ABS control module

7. Data link connector (DLC)

Page 1425 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-22

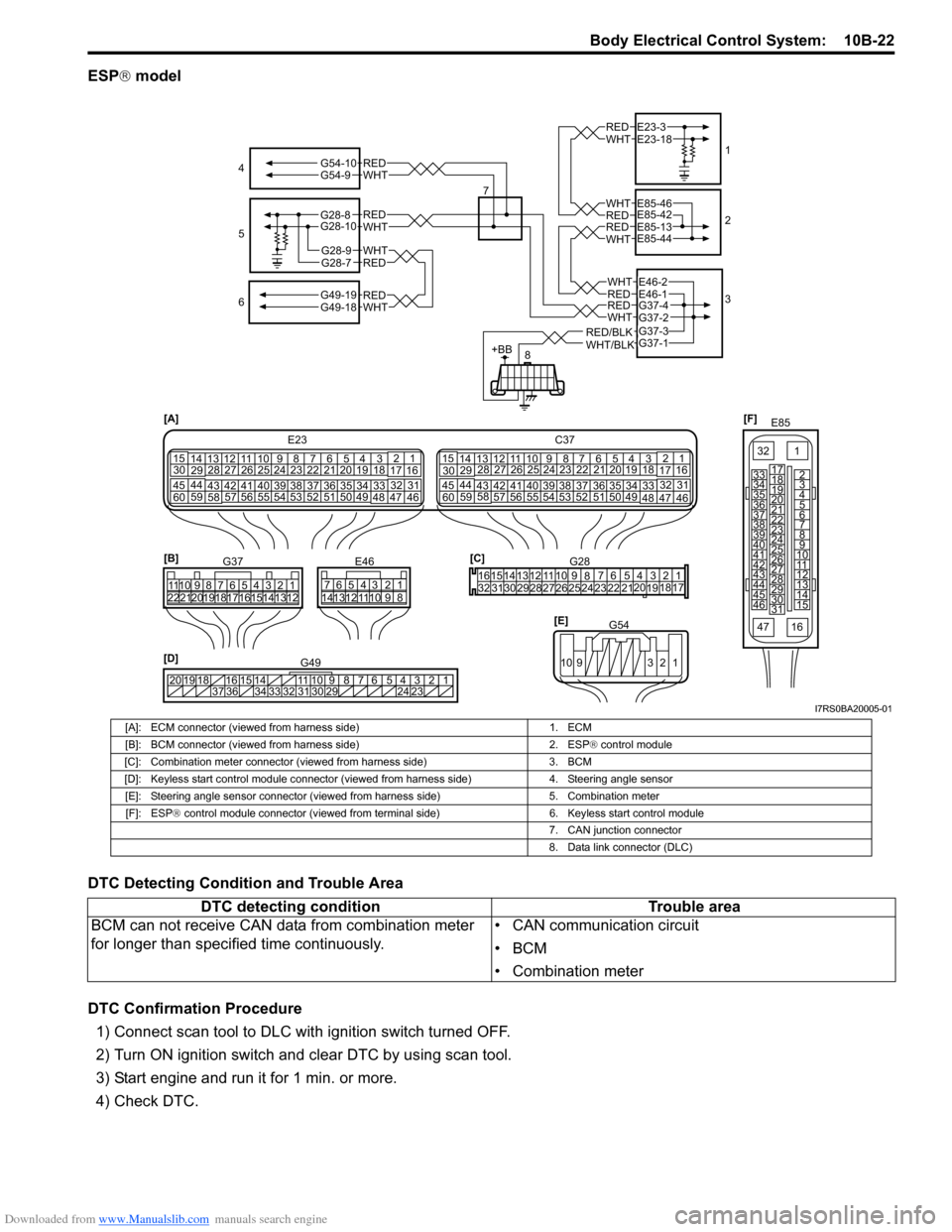

ESP® model

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

[F] E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

[D] 12345678910

11

141516

36 34 33 32 31 30 29 24 23

37

181920

G49

[A]

E23

C37

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

12

13

238

[C]G28

1234567

8

910

11

1213141516

1718

19

20

212223242526272829303132

[E] G54

109 321

[B]

G37E46

1234567 1234567

8910

11

8910

11

121314 121314

1516171819202122

4

6 1

2

3

REDWHT

REDWHT

REDWHT

REDWHT

E23-3E23-18

E85-42E85-46

E85-13E85-44

G37-4G37-2

REDWHT

REDWHTG49-19G49-18

5

7

WHTG54-9REDG54-10

G28-8G28-10

G28-7REDG28-9WHT

RED/BLKWHT/BLK

REDWHTE46-1E46-2

G37-1G37-3

+BB8

I7RS0BA20005-01

[A]: ECM connector (viewed from harness side)

1. ECM

[B]: BCM connector (viewed from harness side) 2. ESP® control module

[C]: Combination meter connector (viewed from harness side) 3. BCM

[D]: Keyless start control module connector (viewed from harness side) 4. Steering angle sensor

[E]: Steering angle sensor connector (viewed from harness side) 5. Combination meter

[F]: ESP ® control module connector (viewed from terminal side) 6. Keyless start control module

7. CAN junction connector

8. Data link connector (DLC)

DTC detecting condition Trouble area

BCM can not receive CAN data from combination meter

for longer than specif ied time continuously. • CAN communication circuit

•BCM

• Combination meter

Page 1442 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-39 Body Electrical Control System:

Repair Instructions

BCM (Included in Junction Block Assembly)

Removal and Installation

S7RS0BA206001

CAUTION!

Do not attempt removal of BCM from junction

block assembly as it may cause contact

failure.

If there is faulty condition in BCM, replace

junction block assembly.

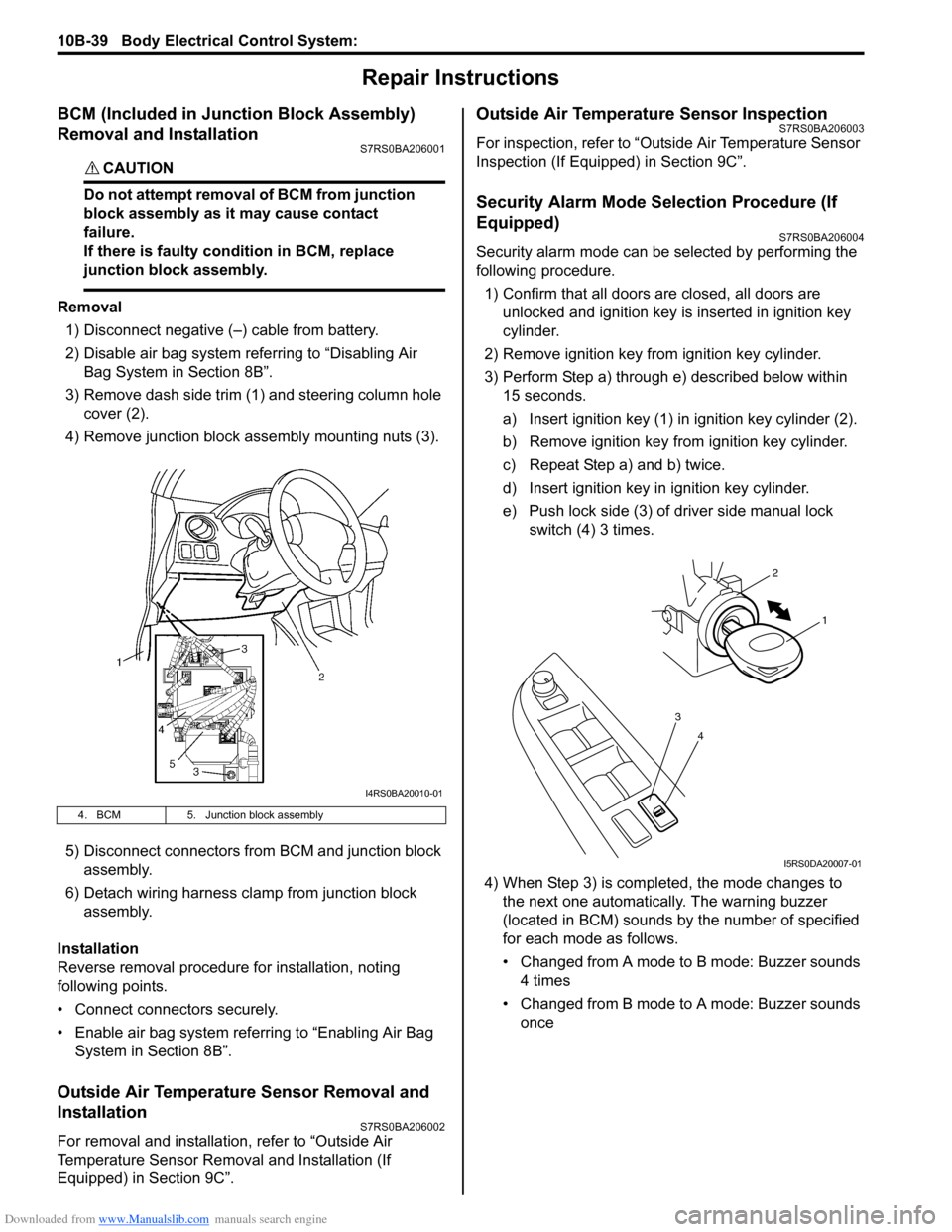

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove dash side trim (1) and steering column hole cover (2).

4) Remove junction block assembly mounting nuts (3).

5) Disconnect connectors from BCM and junction block assembly.

6) Detach wiring harness clamp from junction block assembly.

Installation

Reverse removal procedure for installation, noting

following points.

• Connect connectors securely.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Outside Air Temperature Sensor Removal and

Installation

S7RS0BA206002

For removal and installation, refer to “Outside Air

Temperature Sensor Removal and Installation (If

Equipped) in Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0BA206003

For inspection, refer to “Outside Air Temperature Sensor

Inspection (If Equipped) in Section 9C”.

Security Alarm Mode Selection Procedure (If

Equipped)

S7RS0BA206004

Security alarm mode can be selected by performing the

following procedure.

1) Confirm that all doors are closed, all doors are unlocked and ignition key is inserted in ignition key

cylinder.

2) Remove ignition key from ignition key cylinder.

3) Perform Step a) through e) described below within 15 seconds.

a) Insert ignition key (1) in ignition key cylinder (2).

b) Remove ignition key from ignition key cylinder.

c) Repeat Step a) and b) twice.

d) Insert ignition key in ignition key cylinder.

e) Push lock side (3) of driver side manual lock switch (4) 3 times.

4) When Step 3) is completed, the mode changes to the next one automatically. The warning buzzer

(located in BCM) sounds by the number of specified

for each mode as follows.

• Changed from A mode to B mode: Buzzer sounds 4 times

• Changed from B mode to A mode: Buzzer sounds once

4. BCM 5. Junction block assembly

I4RS0BA20010-01

4

3

1

2

I5RS0DA20007-01

Page 1444 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-1 Immobilizer Control System:

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing TroublesS7RS0BA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

• Communication of ECM, BCM, keyless start control module (if equipped), ABS / ESP ® control module,

steering angle sensor (ESP ® model), combination

meter and TCM (A/T model) is established by CAN

(Controller Area Network). Therefore, handle CAN

communication lines with care referring to “Precaution

for CAN Communication System in Section 00”. For

CAN communication system, refer to description on

“CAN Communication System Description in Section

1A”.

Precaution in Replacing ECMS7RS0BA300002

• If ECM is replaced with new or used one without immobilizer control function , the engine will not be

started. In case of the above, check if the newly

installed ECM has immobilizer control function.

• After ECM is replaced with new one or used one, the transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

Precautions in Handling Immobilizer Control

System

S7RS0BA300003

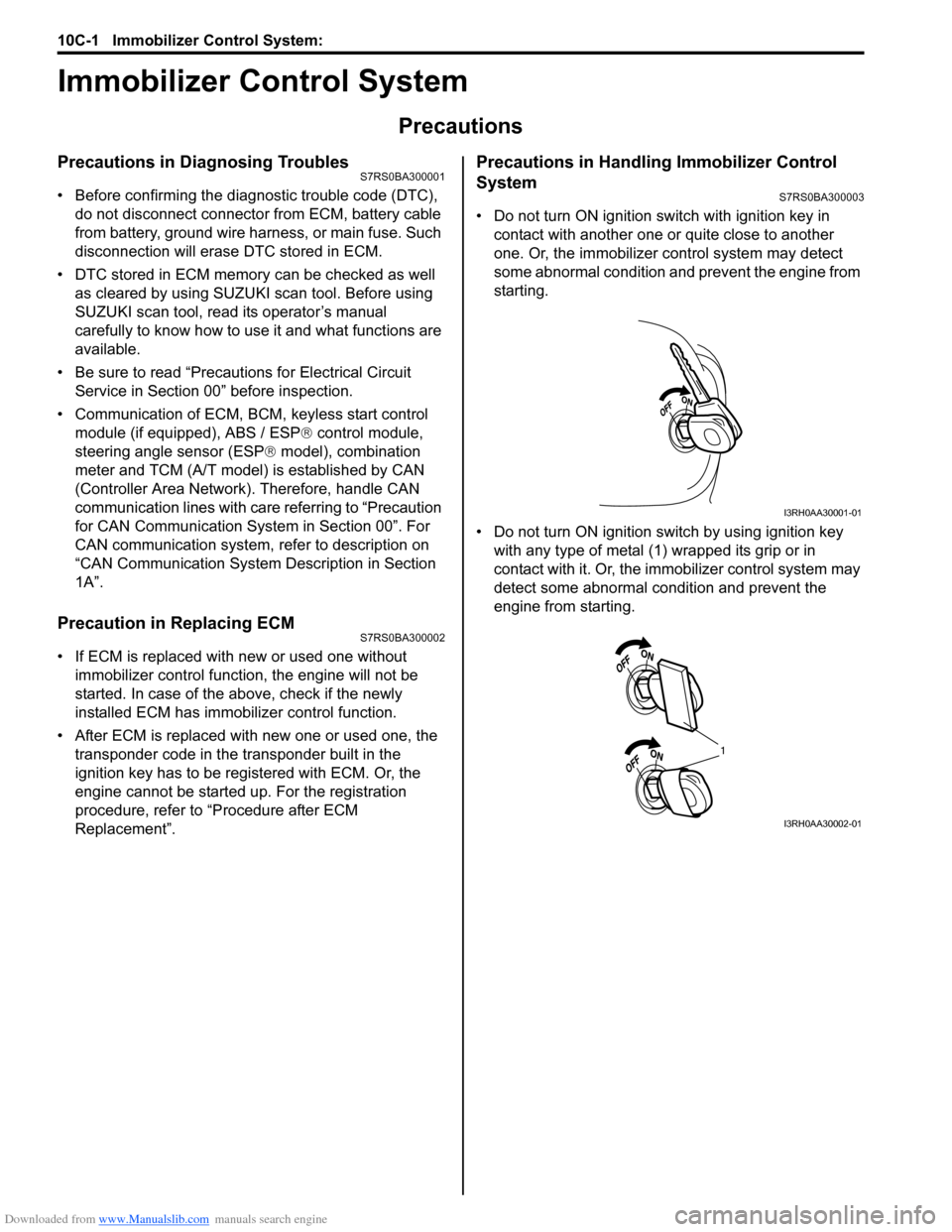

• Do not turn ON ignition sw itch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer co ntrol system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key with any type of metal (1) wrapped its grip or in

contact with it. Or, the i mmobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

I3RH0AA30001-01

1

I3RH0AA30002-01