1J” SUZUKI SWIFT 2005 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 894 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-12 Power Assisted Steering System:

Scan Tool Data Definitions

Battery Voltage

This parameter indicates battery positive voltage.

TQS Power Supply (Torque Sensor Power Supply, V)

This parameter indicates the power supply voltage which

the P/S control module supplies to the torque sensor.

TQS Main Torque (Torque Sensor Main Torque, N ⋅m)

The torque sensor is installed to detect the steering force

and the steering directio n. It consists of two

potentiometers and the main torque sensor is one of

these.

TQS Sub Torque (Torque Sensor Sub Torque, N ⋅m)

The torque sensor is installed to detect the steering force

and the steering directio n. It consists of two

potentiometers and the sub-torque sensor is one of

these. Its output characteristics are compared with those

of the main torque sensor.

Assist Torque (N ⋅m)

This parameter is an internal parameter of the P/S

control module. It is obtained by computing the torque

sensor input signal. Motor Control (Motor Control Current, A)

Based on the input signal, the P/S control module

determines the assist amount

and controls the current to

the motor suitable for that a ssist amount. This parameter

indicates that control value.

Motor Monitor (Motor Monitor Current, A)

This parameter indicates the actually measured value of

the current flowing to the motor. The motor circuit

condition is diagnosed by co mparing this parameter with

“Motor Control” parameter described previously.

Vehicle Speed (km/h, MPH)

Vehicle speed signal is fed from BCM. P/S control

module determines the amount of power assist based on

this vehicle speed signal and the torque sensor signal.

Engine Speed (rpm)

Engine speed signal is fed from the ECM so that it can

be used for trouble diagnos is of the electric power

steering system.

Motor Volt (V)

This parameter indicates the voltage between motor

terminals.

Ignition switch (ON, OFF)

This parameter indicates the condition of the power

supply through the ignition switch.

Visual InspectionS7RS0B6304007

Visually check the following pats and system.

P/S System Symptom DiagnosisS7RS0B6304008

This section describes trouble diagnosis of the P/S system parts whose trouble is not indicated by the on-board

diagnostic system (self-diagnostic functi on). When no malfunction is indicated by the on-board diagnostic system

(self-diagnosis function) and those stee ring basic parts as described in “Steering Symptom Diagnosis in Section 6A”

are all in good condition, check the following power steer ing system parts which may be a possible cause for each

symptom of the steering. Inspection Item Referring section

Battery Level, leakage, color “Batte ry Description in Section 1J”

Connectors of electric wire

harness Disconnection friction “Intermittent and Poor

Connection Inspection in Section 00”

Fuses Burning “Cautions in Body Electric al System Servicing in Section 9A”

Parts Installation, damage

Other parts that can be checked visually

Condition Possible cause Correction / Reference Item

Steering wheel feels

heavy (Perform “Steering

Force Check” before

diagnosis.) Steering wheel installed improperly

(twisted)

Install steering wheel correctly.

Poor performance of torque sensor Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Poor performance of P/S motor Check motor referring to “P/S Motor and Its

Circuit Inspection”.

Steering gear case assembly faulty Replace.

Poor performance of vehicle speed

signal from ECM Check vehicle speed signal circuit referring to

“DTC C1121 / C1123 / C1124: VSS Circuit

Failure”.

Page 914 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-32 Power Assisted Steering System:

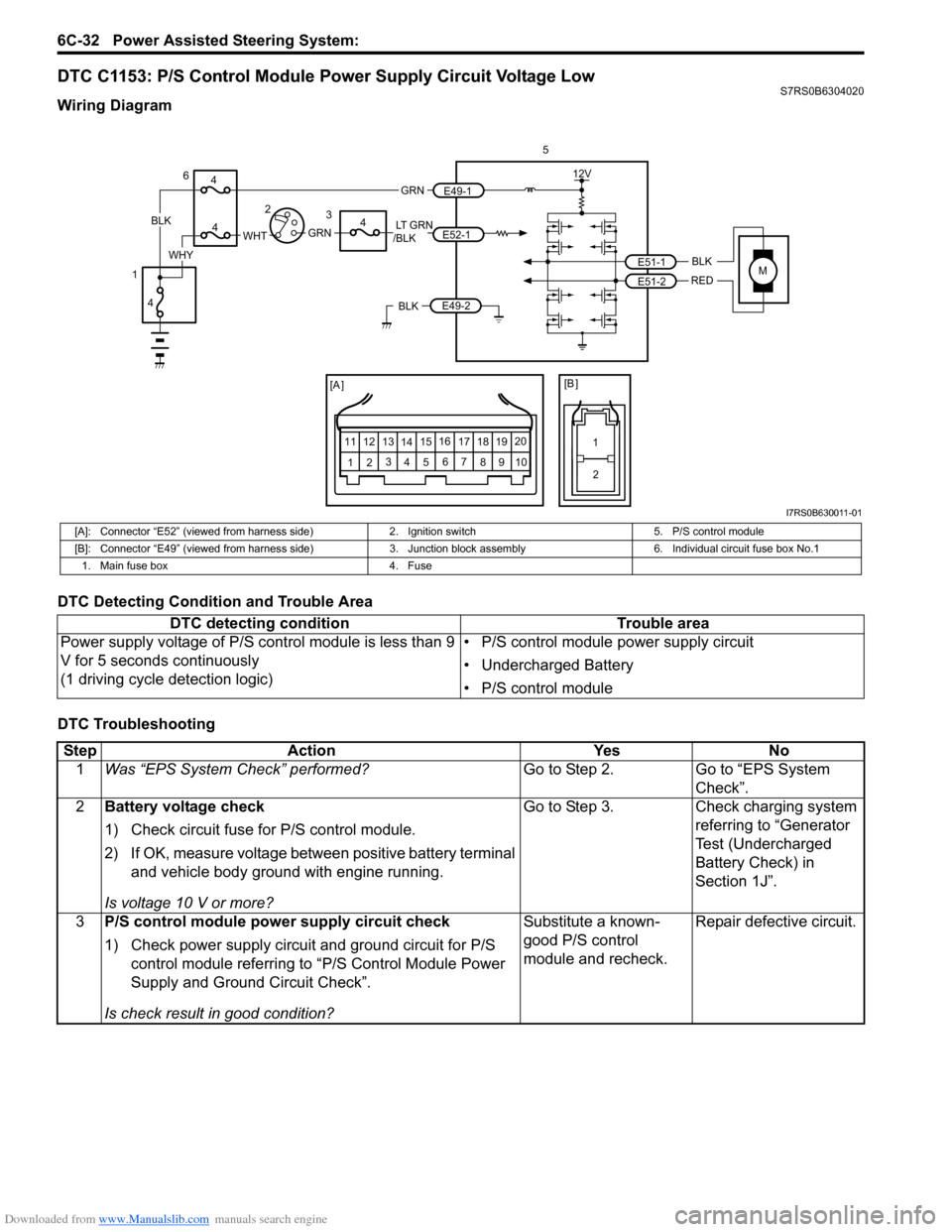

DTC C1153: P/S Control Module Power Supply Circuit Voltage LowS7RS0B6304020

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

MBLK

REDE51-1

E51-2

12V

5

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

[B ]

1

2

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

6

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630011-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch5. P/S control module

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly 6. Individual circuit fuse box No.1

1. Main fuse box 4. Fuse

DTC detecting condition Trouble area

Power supply voltage of P/S control module is less than 9

V for 5 seconds continuously

(1 driving cycle detection logic) • P/S control module power supply circuit

• Undercharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 Battery voltage check

1) Check circuit fuse for P/S control module.

2) If OK, measure voltage between positive battery terminal

and vehicle body ground with engine running.

Is voltage 10 V or more? Go to Step 3.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

3 P/S control module power supply circuit check

1) Check power supply circuit and ground circuit for P/S

control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition? Substitute a known-

good P/S control

module and recheck.

Repair defective circuit.

Page 915 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-33

DTC C1155: P/S Control Module FailureS7RS0B6304021

Wiring Diagram

Refer to “DTC C1153: P/S Control Module Power Supply Circuit Voltage Low”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting DTC detecting condition Trouble area

Internal memory (EEPROM) is data error.

(In this case, MIL does not light up)

or

Internal circuit is faulty.

or

Power supply voltage of P/S control module exceeded

17.5 V.

(1 driving cycle detection logic) • Overcharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 P/S control module power supply and ground circuit

check

Check power supply circuit and ground circuit for P/S control

module referring to “P/S Control Module Power Supply and

Ground Circuit Check”.

Is check result in good condition? Go to Step 3.

Repair or replace

defective circuit.

3 Battery voltage check

1) Check voltage between positive (+) battery terminal and

vehicle body ground with engine speed at 3000 rpm.

Is voltage 15.5 V or less? Replace P/S control

module.

Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

Page 1057 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-19

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

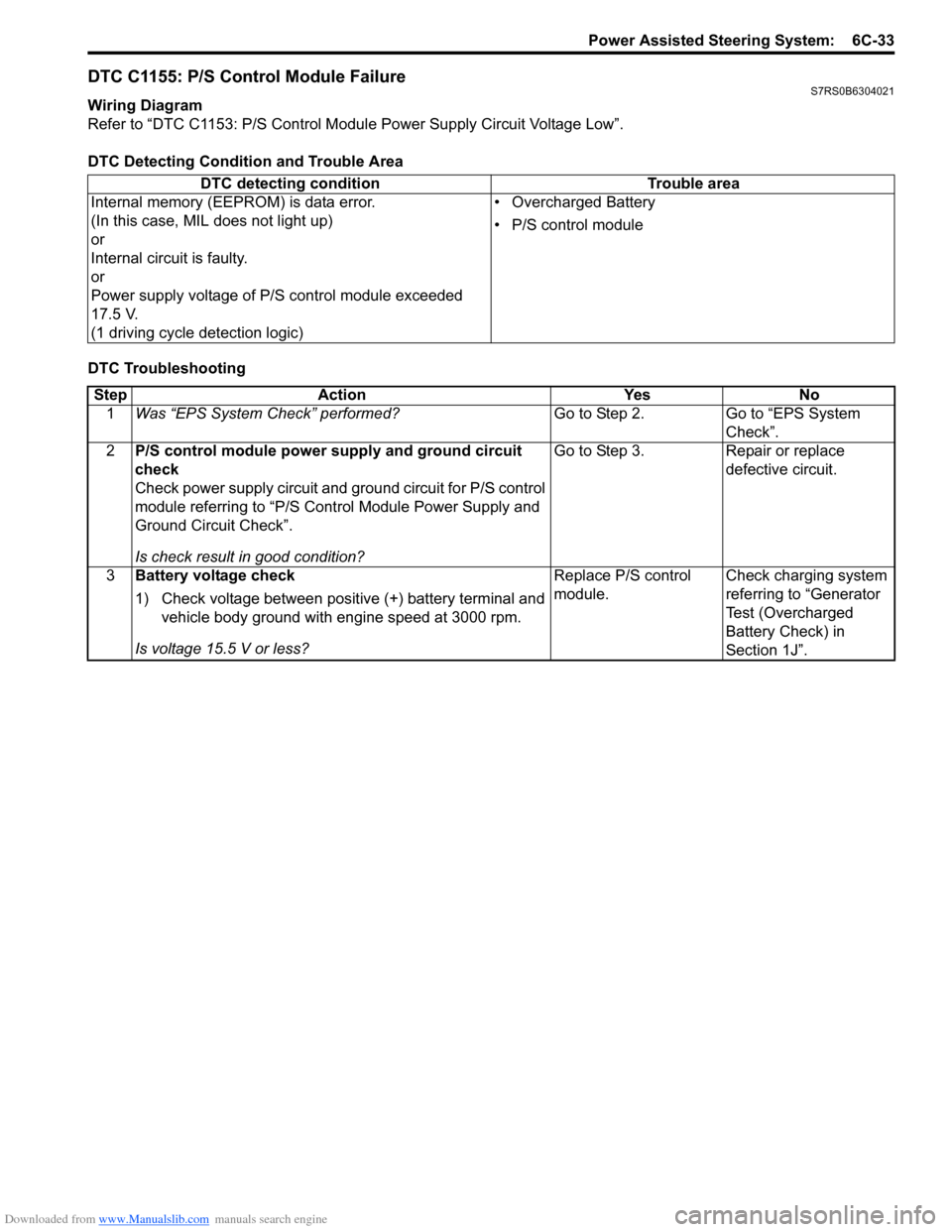

DTC Will Set when

The power source voltage to SDM is above an approx. 21 V for specified time.

Flow Test Description

Step 1: Check if voltage applie d to SDM is within normal range.

Step 2: Check if DTC B1016 still exists.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

Step Action YesNo

1 1) With ignition switch OFF, disconnect SDM connector.

2) Check proper connection to SDM at “L29-27” terminal.

3) If OK, turn ignition switch ON and then check voltage between “L29-27” terminal on SDM connector and body

ground.

Special tool

(A): 09932-76010

Is voltage 14 V or less? Go to Step 2.

Check charging system

and repair as necessary

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

2 1) With ignition switch OFF, reconnect SDM connector. With ignition switch ON , is DTC B1016 indicated? Substitute a known-

good SDM and recheck.

Intermittent trouble.

Check for intermittent

trouble referring to

“Inspection of

Intermittent and Poor

Connections” If OK,

substitute a known-

good SDM and recheck.

(A)

"L29-27"

I7RS0A820005-08

Page 1058 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-20 Air Bag System:

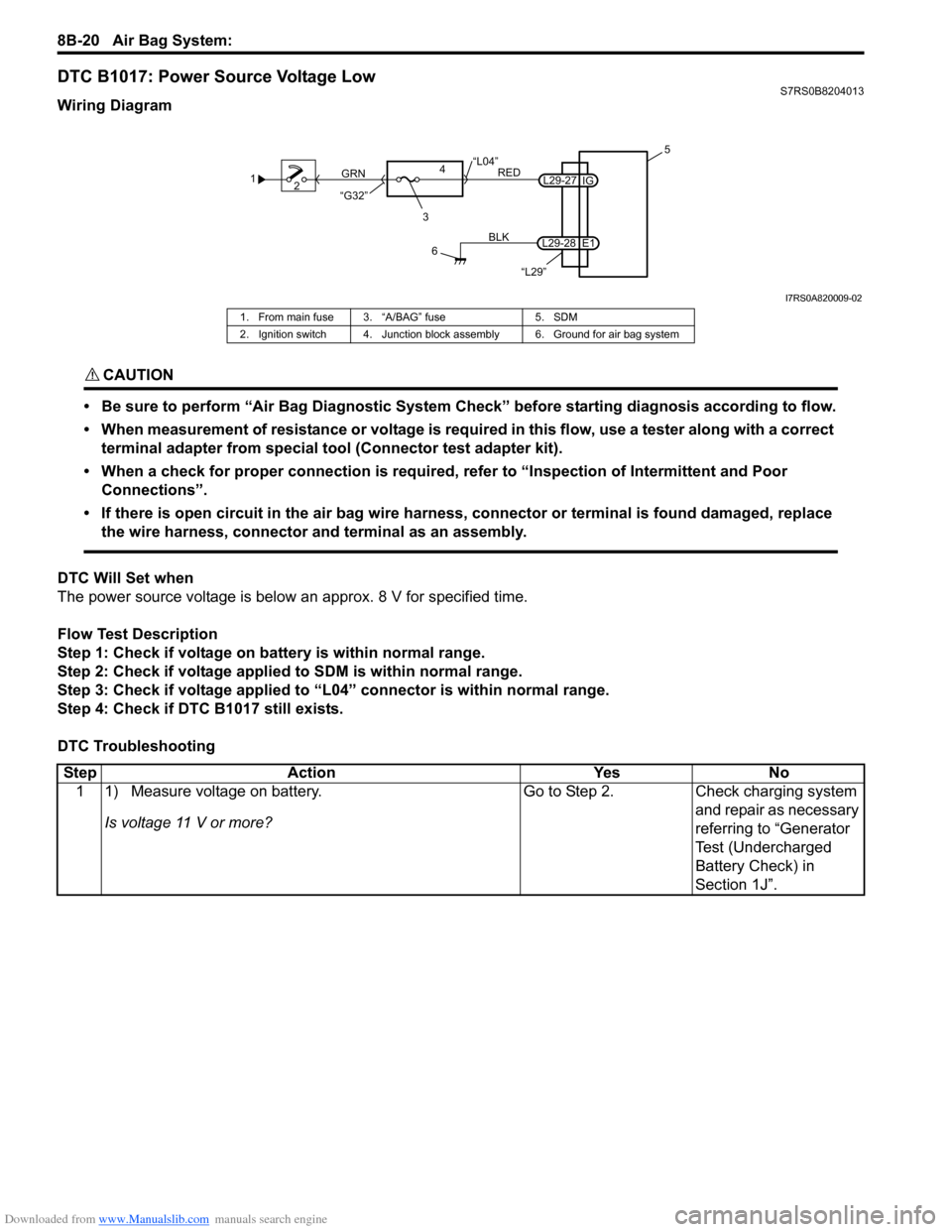

DTC B1017: Power Source Voltage LowS7RS0B8204013

Wiring Diagram

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The power source voltage is below an approx. 8 V for specified time.

Flow Test Description

Step 1: Check if voltage on ba ttery is within normal range.

Step 2: Check if voltage applie d to SDM is within normal range.

Step 3: Check if voltage applied to “L04” connector is within normal range.

Step 4: Check if DTC B1017 still exists.

DTC Troubleshooting

1 2

3

GRN

RED

6

BLK

L29-27

L29-28 IG

E1 5

4

“L29”

“L04”

“G32”

I7RS0A820009-02

1. From main fuse 3. “A/BAG” fuse 5. SDM

2. Ignition switch 4. Junction block assembly 6. Ground for air bag system

Step Action YesNo

1 1) Measure voltage on battery.

Is voltage 11 V or more? Go to Step 2.

Check charging system

and repair as necessary

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

Page 1059 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-21

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

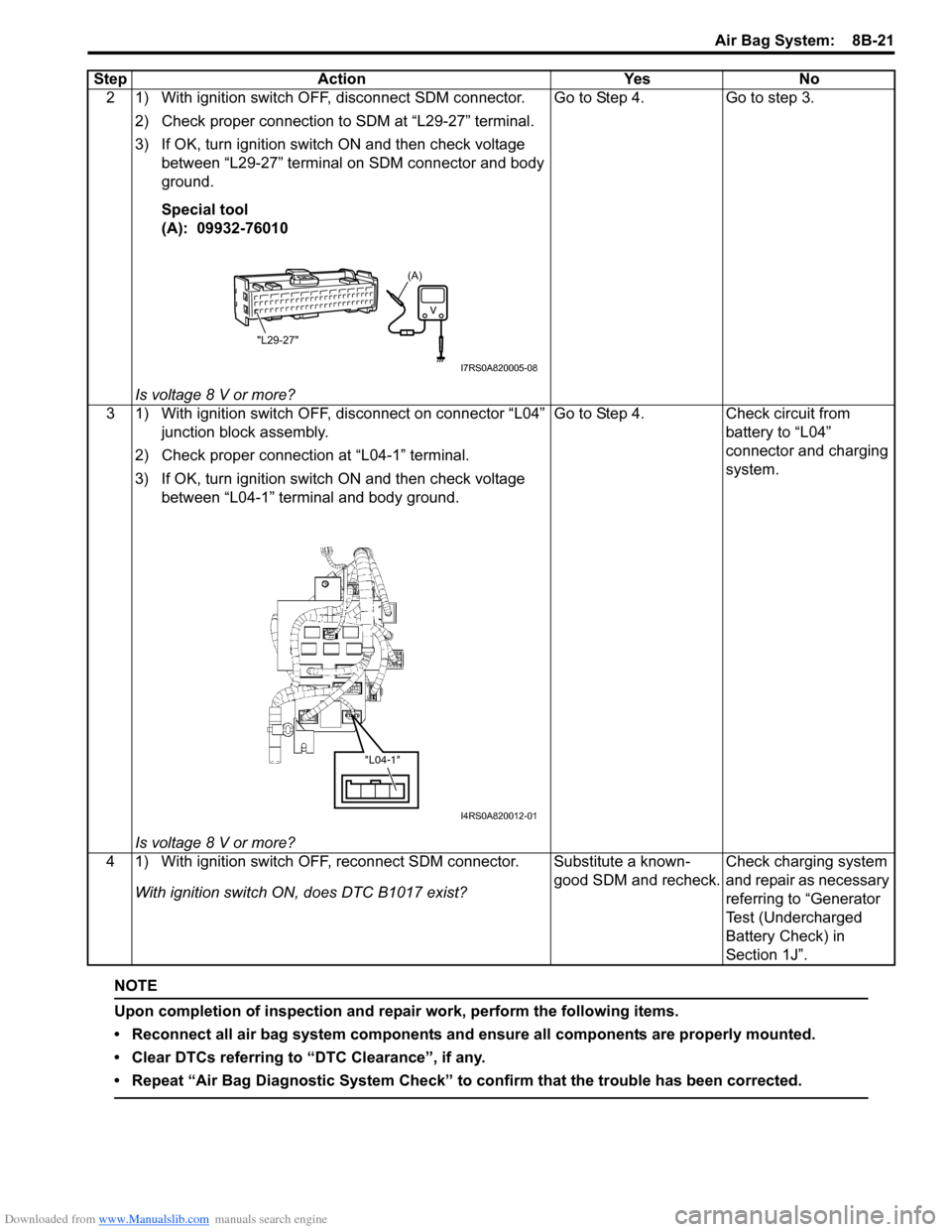

2 1) With ignition switch OFF, disconnect SDM connector.2) Check proper connection to SDM at “L29-27” terminal.

3) If OK, turn ignition switch ON and then check voltage between “L29-27” terminal on SDM connector and body

ground.

Special tool

(A): 09932-76010

Is voltage 8 V or more? Go to Step 4. Go to step 3.

3 1) With ignition switch OFF, disconnect on connector “L04” junction block assembly.

2) Check proper connection at “L04-1” terminal.

3) If OK, turn ignition switch ON and then check voltage between “L04-1” terminal and body ground.

Is voltage 8 V or more? Go to Step 4. Check circuit from

battery to “L04”

connector and charging

system.

4 1) With ignition switch OFF, reconnect SDM connector. With ignition switch ON, does DTC B1017 exist? Substitute a known-

good SDM and recheck.

Check charging system

and repair as necessary

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

Step Action Yes No

(A)

"L29-27"

I7RS0A820005-08

"L04-1"

I4RS0A820012-01

Page 1284 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-2 Lighting Systems:

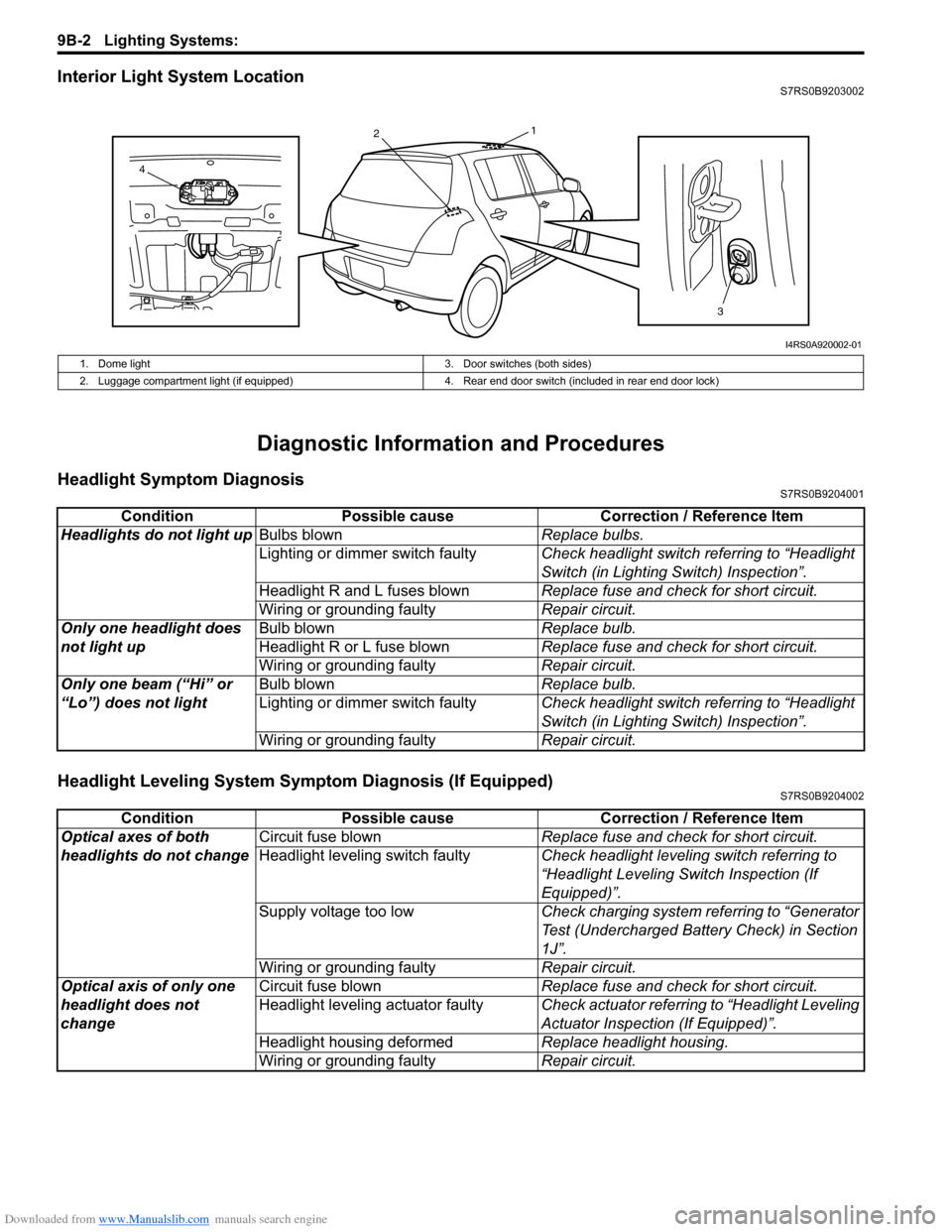

Interior Light System LocationS7RS0B9203002

Diagnostic Information and Procedures

Headlight Symptom DiagnosisS7RS0B9204001

Headlight Leveling System Symptom Diagnosis (If Equipped)S7RS0B9204002

13

2

4

I4RS0A920002-01

1. Dome light 3. Door switches (both sides)

2. Luggage compartment light (if equipped) 4. Rear end door switch (included in rear end door lock)

ConditionPossible cause Correction / Reference Item

Headlights do not light up Bulbs blown Replace bulbs.

Lighting or dimmer switch faulty Check headlight switch referring to “Headlight

Switch (in Lighting Switch) Inspection”.

Headlight R and L fuses blown Replace fuse and check for short circuit.

Wiring or grounding faulty Repair circuit.

Only one headlight does

not light up Bulb blown

Replace bulb.

Headlight R or L fuse blown Replace fuse and check for short circuit.

Wiring or grounding faulty Repair circuit.

Only one beam (“Hi” or

“Lo”) does not light Bulb blown

Replace bulb.

Lighting or dimmer switch faulty Check headlight switch referring to “Headlight

Switch (in Lighting Switch) Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

Optical axes of both

headlights do not change Circuit fuse blown

Replace fuse and check for short circuit.

Headlight leveling switch faulty Check headlight leveling switch referring to

“Headlight Leveling Switch Inspection (If

Equipped)”.

Supply voltage too low Check charging system referring to “Generator

Test (Undercharged Battery Check) in Section

1J”.

Wiring or grounding faulty Repair circuit.

Optical axis of only one

headlight does not

change Circuit fuse blown

Replace fuse and check for short circuit.

Headlight leveling actuator faulty Check actuator referring to “Headlight Leveling

Actuator Inspection (If Equipped)”.

Headlight housing deformed Replace headlight housing.

Wiring or grounding faulty Repair circuit.

Page 1420 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-17 Body Electrical Control System:

DTC B1133 (DTC No. 1133): Battery Voltage Too HighS7RS0BA204008

Wiring Diagram

Refer to “BCM Power Circuit and Ground Circuit Check”.

DTC Detecting Conditi on and Possible Cause

Flow Test Description

Step 1: Check charging system

DTC Troubleshooting 3

Power supply circuit check

1) Check for proper connection to junction block assembly

connector at terminals “G32-2” and “G32-5”.

2) If OK, turn ignition switch ON.

3) Measure voltage between following terminals. • Between “G32-2” terminal of junction block assembly connector and vehicle body ground

• Between “G32-5” terminal of junction block assembly connector and vehicle body ground

Is each voltage 10 – 14 V? Go to Step 4. Repair power supply

circuit.

4 Ground circuit check

1) Turn ignition switch to OFF position.

2) Check for proper connection to junction block assembly

connector at terminals “G33-3”, “G34-9” and “L05-4”.

3) If OK, then measure resistance between following terminals.

• Between “G33-3” terminal of junction block assembly connector and vehicle body ground

• Between “G34-9” terminal of junction block assembly connector and vehicle body ground

• Between “L05-4” terminal of junction block assembly connector and vehicle body ground

Is each resistance 2

Ω or less? BCM power supply

circuit and ground circuit

are in good condition.

Repair ground circuit.

Step Action Yes No

DTC detecting condition

Possible cause

Power voltage supplied from battery to BCM is

higher than 16V. • Charging system malfunction

• BCM malfunction

Step

Action YesNo

1 Charging system operation check

1) Check generator for operation referring to “Generator

Test (Overcharged Battery Check) in Section 1J”.

Is it in good condition? Substitute a known

good BCM (included in

junction block

assembly) and recheck.

Repair charging system.