Fuel pump SUZUKI SWIFT 2005 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 94 of 1496

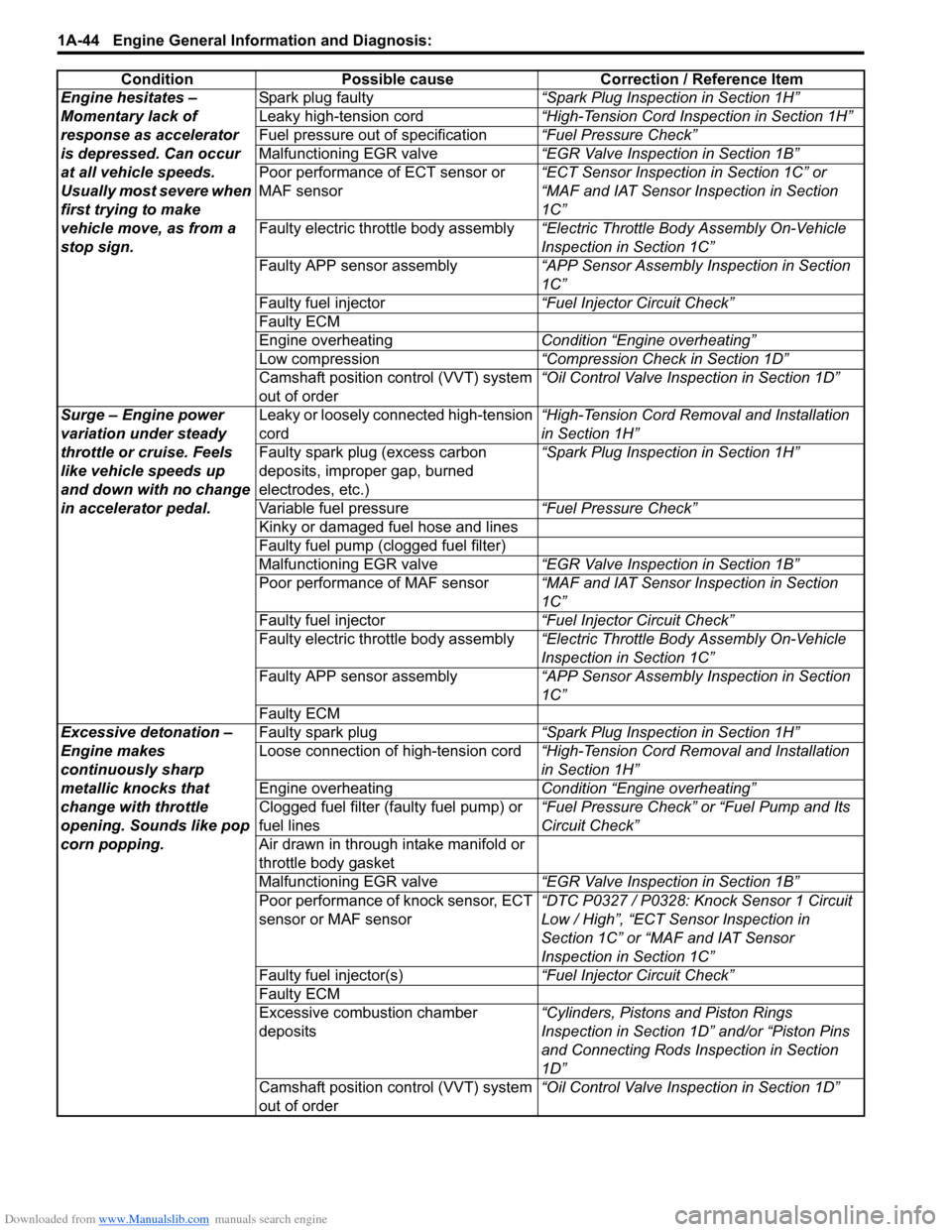

Downloaded from www.Manualslib.com manuals search engine 1A-44 Engine General Information and Diagnosis:

Engine hesitates –

Momentary lack of

response as accelerator

is depressed. Can occur

at all vehicle speeds.

Usually most severe when

first trying to make

vehicle move, as from a

stop sign.Spark plug faulty

“Spark Plug Inspection in Section 1H”

Leaky high-tension cord “High-Tension Cord Inspection in Section 1H”

Fuel pressure out of specification “Fuel Pressure Check”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector “Fuel Injector Circuit Check”

Faulty ECM

Engine overheating Condition “Engine overheating”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Surge – Engine power

variation under steady

throttle or cruise. Feels

like vehicle speeds up

and down with no change

in accelerator pedal. Leaky or loosely connected high-tension

cord

“High-Tension Cord Removal and Installation

in Section 1H”

Faulty spark plug (excess carbon

deposits, improper gap, burned

electrodes, etc.) “Spark Plug Inspection in Section 1H”

Variable fuel pressure “Fuel Pressure Check”

Kinky or damaged fuel hose and lines

Faulty fuel pump (clogged fuel filter)

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of MAF sensor “MAF and IAT Sensor Inspection in Section

1C”

Faulty fuel injector “Fuel Injector Circuit Check”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECM

Excessive detonation –

Engine makes

continuously sharp

metallic knocks that

change with throttle

opening. Sounds like pop

corn popping. Faulty spark plug

“Spark Plug Inspection in Section 1H”

Loose connection of high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Engine overheating Condition “Engine overheating”

Clogged fuel filter (faulty fuel pump) or

fuel lines “Fuel Pressure Check” or “Fuel Pump and Its

Circuit Check”

Air drawn in through intake manifold or

throttle body gasket

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of knock sensor, ECT

sensor or MAF sensor “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High”, “ECT Sensor Inspection in

Section 1C” or “MAF and IAT Sensor

Inspection in Section 1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Excessive combustion chamber

deposits “Cylinders, Pistons and Piston Rings

Inspection in Section 1D” and/or “Piston Pins

and Connecting Rods In

spection in Section

1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Condition Possible cause Correction / Reference Item

Page 95 of 1496

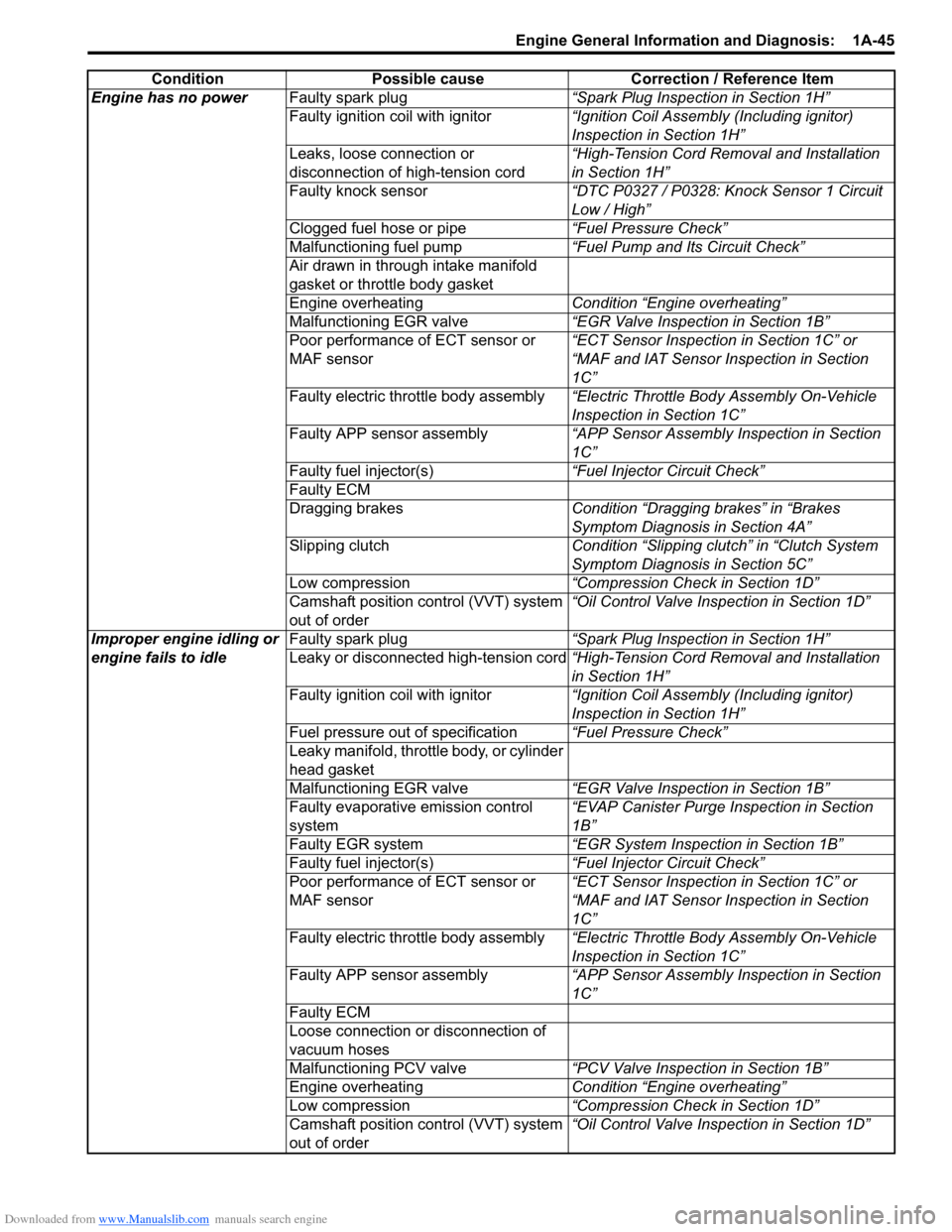

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-45

Engine has no powerFaulty spark plug “Spark Plug Inspection in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Leaks, loose connection or

disconnection of high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty knock sensor “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High”

Clogged fuel hose or pipe “Fuel Pressure Check”

Malfunctioning fuel pump “Fuel Pump and Its Circuit Check”

Air drawn in through intake manifold

gasket or throttle body gasket

Engine overheating Condition “Engine overheating”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Improper engine idling or

engine fails to idle Faulty spark plug

“Spark Plug Inspection in Section 1H”

Leaky or disconnected high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Fuel pressure out of specification “Fuel Pressure Check”

Leaky manifold, throttle body, or cylinder

head gasket

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Faulty evaporative emission control

system “EVAP Canister Purge Inspection in Section

1B”

Faulty EGR system “EGR System Inspection in Section 1B”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECM

Loose connection or disconnection of

vacuum hoses

Malfunctioning PCV valve “PCV Valve Inspection in Section 1B”

Engine overheating Condition “Engine overheating”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Condition Possible cause Correction / Reference Item

Page 205 of 1496

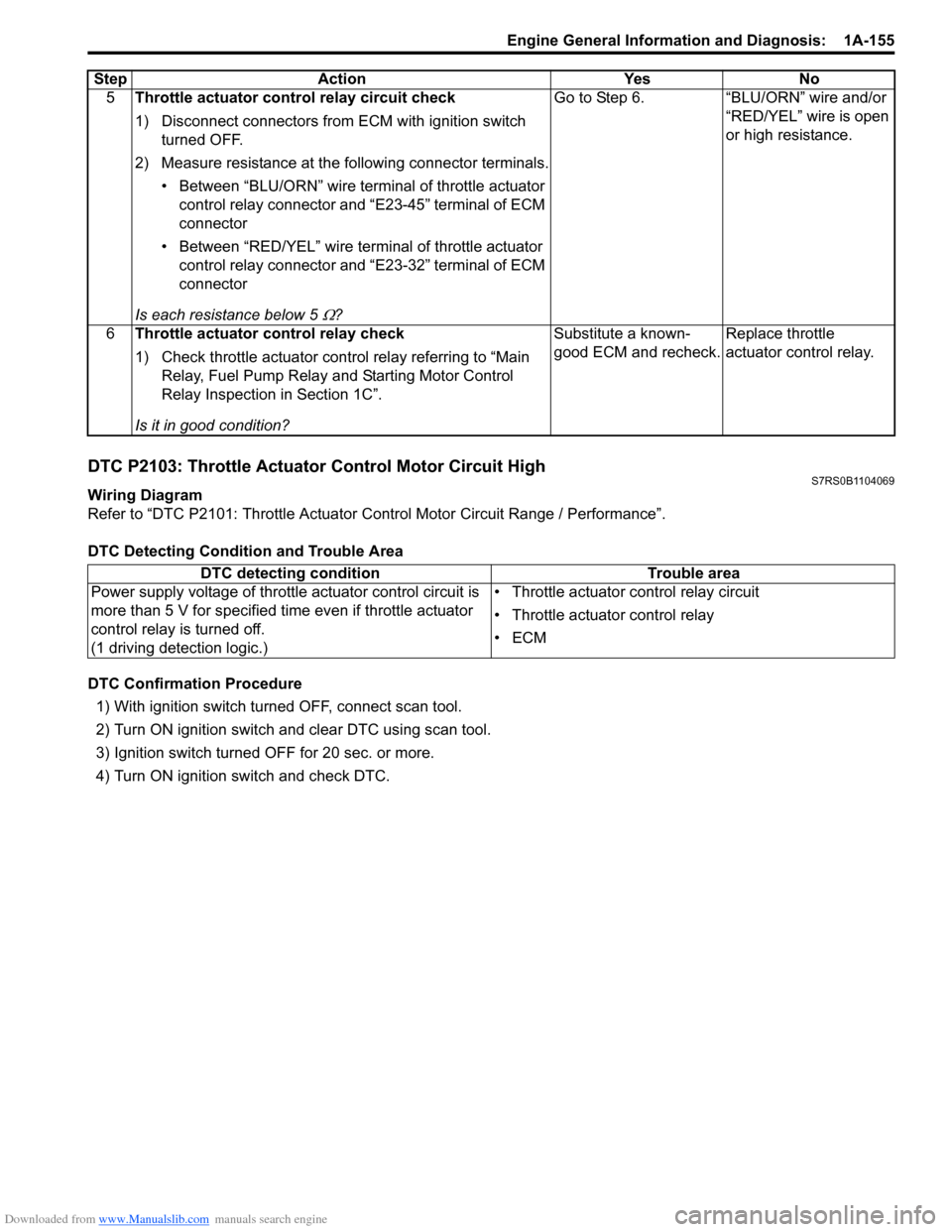

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-155

DTC P2103: Throttle Actuator Control Motor Circuit HighS7RS0B1104069

Wiring Diagram

Refer to “DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Ignition switch turned OFF for 20 sec. or more.

4) Turn ON ignition switch and check DTC. 5

Throttle actuator cont rol relay circuit check

1) Disconnect connectors from ECM with ignition switch turned OFF.

2) Measure resistance at the following connector terminals. • Between “BLU/ORN” wire termin al of throttle actuator

control relay connector and “E23-45” terminal of ECM

connector

• Between “RED/YEL” wire terminal of throttle actuator control relay connector and “E23-32” terminal of ECM

connector

Is each resistance below 5

Ω? Go to Step 6. “BLU/ORN” wire and/or

“RED/YEL” wire is open

or high resistance.

6 Throttle actuator control relay check

1) Check throttle actuator control relay referring to “Main Relay, Fuel Pump Relay an d Starting Motor Control

Relay Inspection in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace throttle

actuator control relay.

Step

Action YesNo

DTC detecting condition Trouble area

Power supply voltage of throttle actuator control circuit is

more than 5 V for specified time even if throttle actuator

control relay is turned off.

(1 driving detection logic.) • Throttle actuator control relay circuit

• Throttle actuator control relay

•ECM

Page 206 of 1496

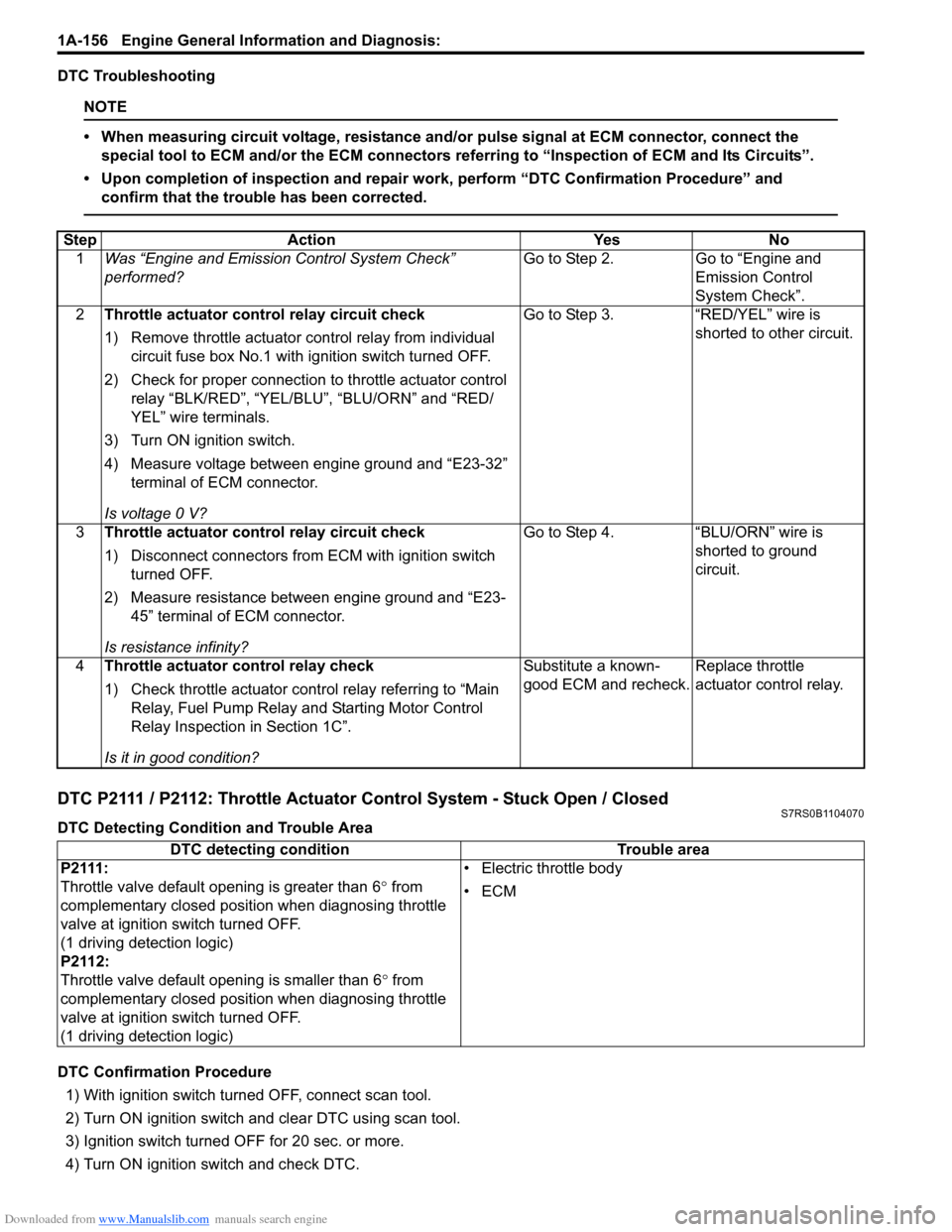

Downloaded from www.Manualslib.com manuals search engine 1A-156 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC P2111 / P2112: Throttle Actuator Control System - Stuck Open / ClosedS7RS0B1104070

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Ignition switch turned OFF for 20 sec. or more.

4) Turn ON ignition switch and check DTC.

Step Action Yes No

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2 Throttle actuator cont rol relay circuit check

1) Remove throttle actuator co ntrol relay from individual

circuit fuse box No.1 with ignition switch turned OFF.

2) Check for proper connection to throttle actuator control relay “BLK/RED”, “YEL/BLU”, “BLU/ORN” and “RED/

YEL” wire terminals.

3) Turn ON ignition switch.

4) Measure voltage between engine ground and “E23-32” terminal of ECM connector.

Is voltage 0 V? Go to Step 3. “RED/YEL” wire is

shorted to other circuit.

3 Throttle actuator cont rol relay circuit check

1) Disconnect connectors from ECM with ignition switch turned OFF.

2) Measure resistance between engine ground and “E23- 45” terminal of ECM connector.

Is resistance infinity? Go to Step 4. “BLU/ORN” wire is

shorted to ground

circuit.

4 Throttle actuator control relay check

1) Check throttle actuator control relay referring to “Main Relay, Fuel Pump Relay an d Starting Motor Control

Relay Inspection in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace throttle

actuator control relay.

DTC detecting condition

Trouble area

P2111:

Throttle valve default opening is greater than 6 ° from

complementary closed position when diagnosing throttle

valve at ignition switch turned OFF.

(1 driving detection logic)

P2112:

Throttle valve default opening is smaller than 6 ° from

complementary closed position when diagnosing throttle

valve at ignition switch turned OFF.

(1 driving detection logic) • Electric throttle body

•ECM

Page 231 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-181

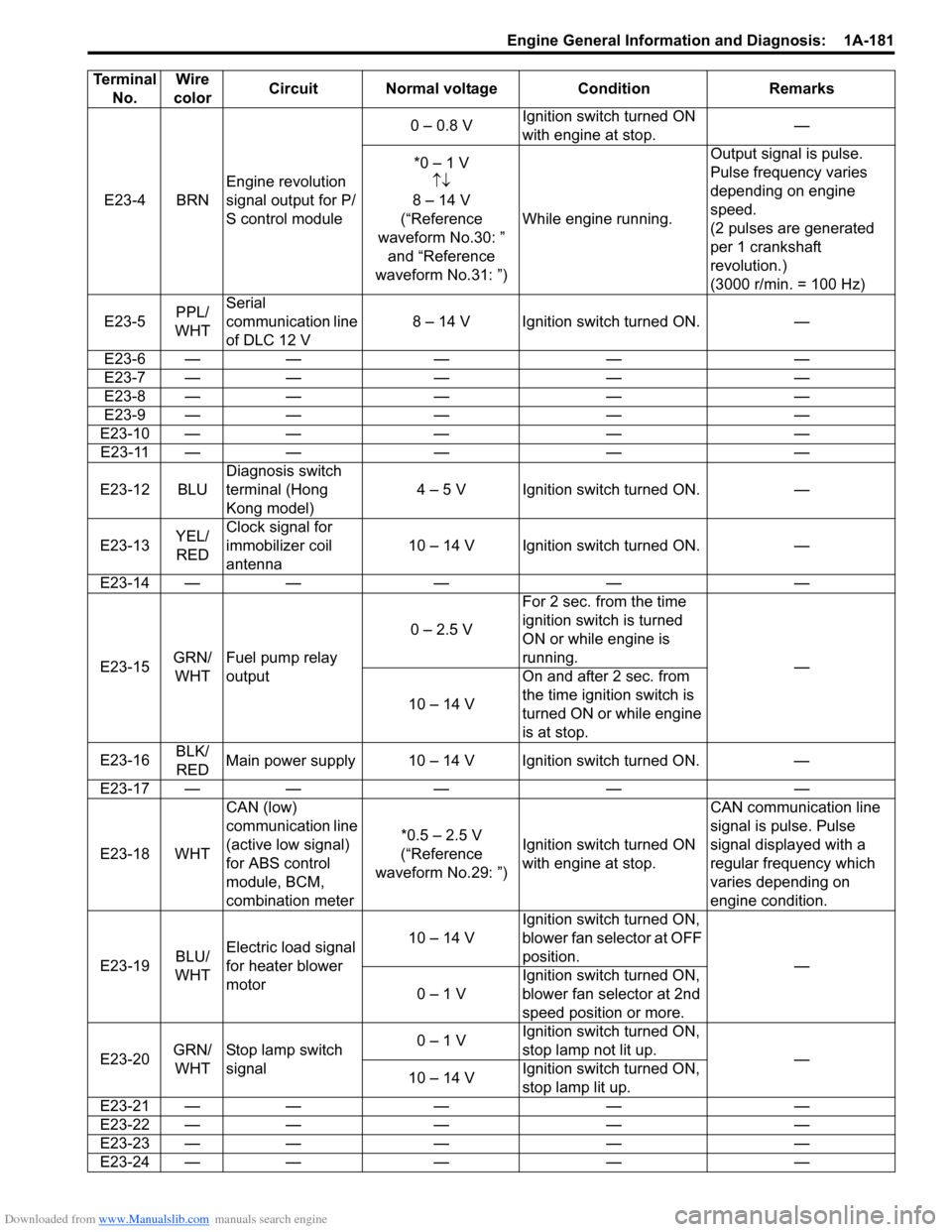

E23-4 BRNEngine revolution

signal output for P/

S control module 0 – 0.8 V

Ignition switch turned ON

with engine at stop. —

*0 – 1 V ↑↓

8 – 14 V

(“Reference

waveform No.30: ” and “Reference

waveform No.31: ”) While engine running. Output signal is pulse.

Pulse frequency varies

depending on engine

speed.

(2 pulses are generated

per 1 crankshaft

revolution.)

(3000 r/min. = 100 Hz)

E23-5 PPL/

WHT Serial

communication line

of DLC 12 V

8 – 14 V Ignition switch turned ON. —

E23-6 — — — — —

E23-7 — — — — —

E23-8 — — — — —

E23-9 — — — — —

E23-10 — — — — — E23-11 — — — — —

E23-12 BLU Diagnosis switch

terminal (Hong

Kong model) 4 – 5 V Ignition switch turned ON. —

E23-13 YEL/

RED Clock signal for

immobilizer coil

antenna

10 – 14 V Ignition switch turned ON. —

E23-14 — — — — —

E23-15 GRN/

WHT Fuel pump relay

output 0 – 2.5 V

For 2 sec. from the time

ignition switch is turned

ON or while engine is

running.

—

10 – 14 V On and after 2 sec. from

the time ignition switch is

turned ON or while engine

is at stop.

E23-16 BLK/

RED Main power supply 10 – 14 V Ignition switch turned ON. —

E23-17 — — — — —

E23-18 WHT CAN (low)

communication line

(active low signal)

for ABS control

module, BCM,

combination meter *0.5 – 2.5 V

(“Reference

waveform No.29: ”) Ignition switch turned ON

with engine at stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition.

E23-19 BLU/

WHT Electric load signal

for heater blower

motor 10 – 14 V

Ignition switch turned ON,

blower fan selector at OFF

position.

—

0 – 1 V Ignition switch turned ON,

blower fan selector at 2nd

speed position or more.

E23-20 GRN/

WHT Stop lamp switch

signal 0 – 1 V

Ignition switch turned ON,

stop lamp not lit up.

—

10 – 14 V Ignition switch turned ON,

stop lamp lit up.

E23-21 — — — — —

E23-22 — — — — —

E23-23 — — — — —

E23-24 — — — — —

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Page 243 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-193

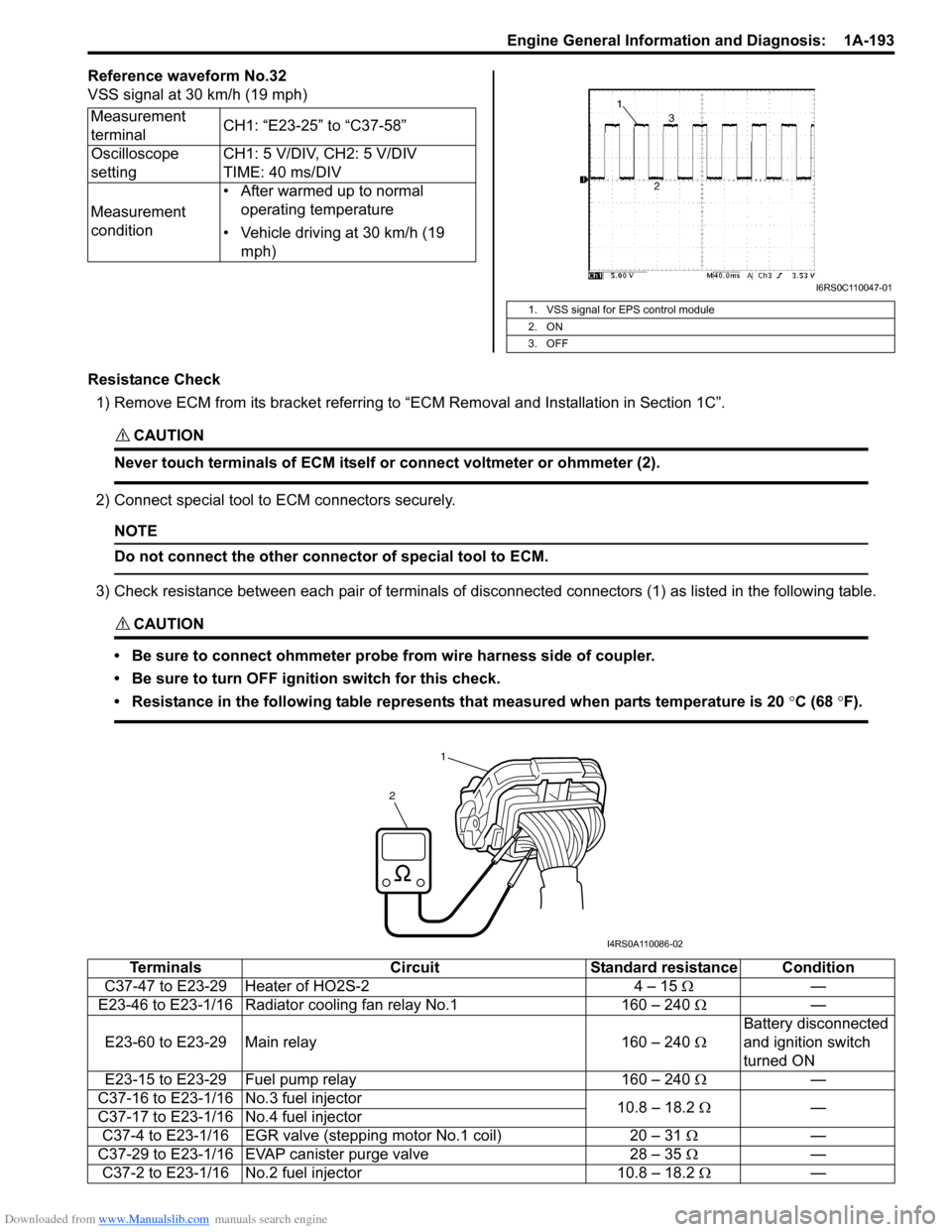

Reference waveform No.32

VSS signal at 30 km/h (19 mph)

Resistance Check1) Remove ECM from its bracket referring to “ECM Removal and Installation in Section 1C”.

CAUTION!

Never touch terminals of ECM itself or connect voltmeter or ohmmeter (2).

2) Connect special tool to ECM connectors securely.

NOTE

Do not connect the other connector of special tool to ECM.

3) Check resistance between each pair of terminals of disconnected connectors (1) as listed in the following table.

CAUTION!

• Be sure to connect ohmmeter probe from wire harness side of coupler.

• Be sure to turn OFF ignition switch for this check.

• Resistance in the following table represents that measured when parts temperature is 20 °C (68 °F).

Measurement

terminal CH1: “E23-25” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Vehicle driving at 30 km/h (19 mph)

1. VSS signal for EPS control module

2. ON

3. OFF

I6RS0C110047-01

1

2

I4RS0A110086-02

Terminals CircuitStandard resistance Condition

C37-47 to E23-29 Heater of HO2S-2 4 – 15 Ω—

E23-46 to E23-1/16 Radiator cooling fan relay No.1 160 – 240 Ω —

E23-60 to E23-29 Main relay 160 – 240 ΩBattery disconnected

and ignition switch

turned ON

E23-15 to E23-29 Fuel pump relay 160 – 240 Ω —

C37-16 to E23-1/16 No.3 fuel injector 10.8 – 18.2 Ω —

C37-17 to E23-1/16 No.4 fuel injector

C37-4 to E23-1/16 EGR valve (st epping motor No.1 coil) 20 – 31 Ω —

C37-29 to E23-1/16 EVAP canister purge valve 28 – 35 Ω —

C37-2 to E23-1/16 No.2 fuel injector 10.8 – 18.2 Ω—

Page 247 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-197

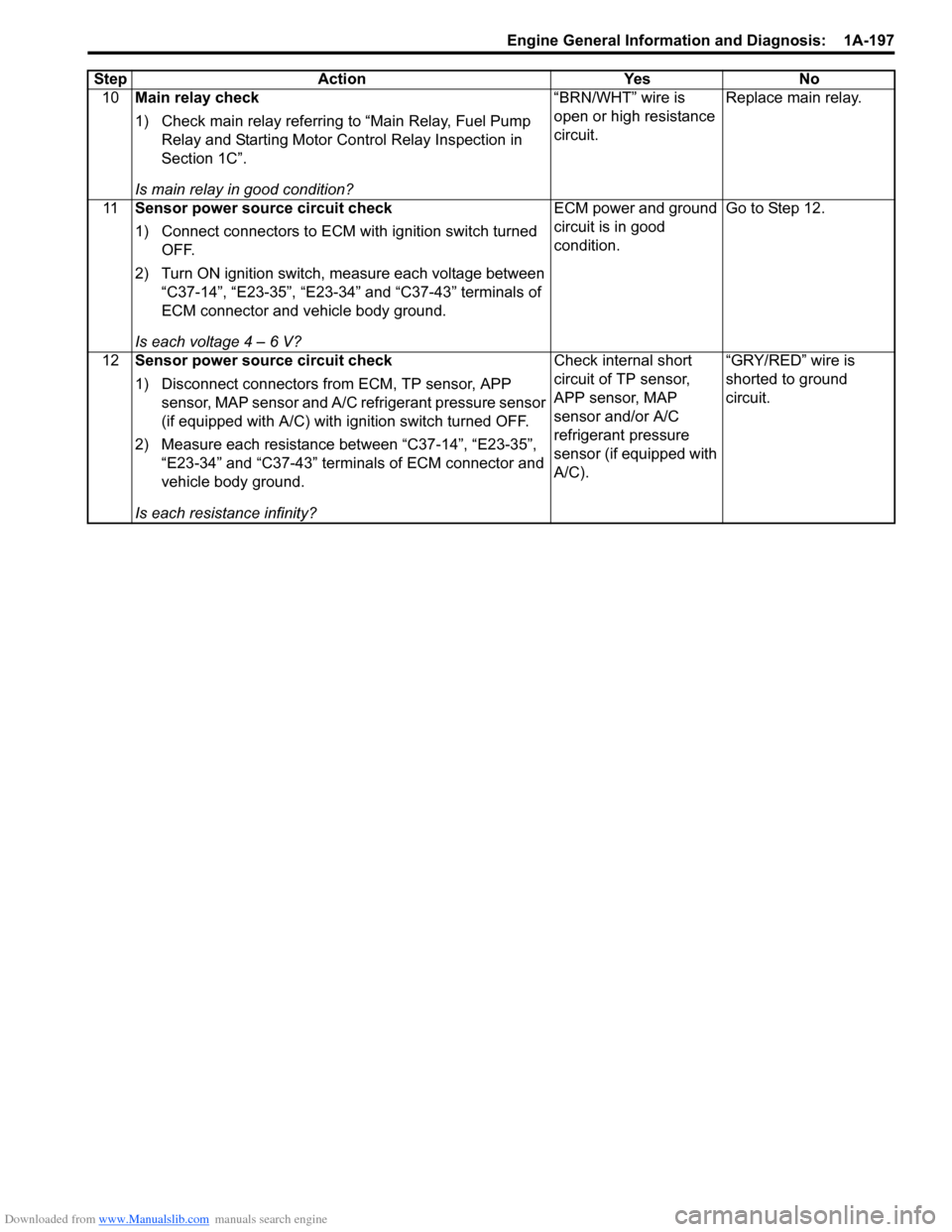

10Main relay check

1) Check main relay referring to “Main Relay, Fuel Pump

Relay and Starting Motor Control Relay Inspection in

Section 1C”.

Is main relay in good condition? “BRN/WHT” wire is

open or high resistance

circuit.

Replace main relay.

11 Sensor power source circuit check

1) Connect connectors to ECM with ignition switch turned

OFF.

2) Turn ON ignition switch, measure each voltage between “C37-14”, “E23-35”, “E23-34” and “C37-43” terminals of

ECM connector and vehicle body ground.

Is each voltage 4 – 6 V? ECM power and ground

circuit is in good

condition.

Go to Step 12.

12 Sensor power source circuit check

1) Disconnect connectors from ECM, TP sensor, APP

sensor, MAP sensor and A/C refrigerant pressure sensor

(if equipped with A/C) with i gnition switch turned OFF.

2) Measure each resistance between “C37-14”, “E23-35”, “E23-34” and “C37-43” terminals of ECM connector and

vehicle body ground.

Is each resistance infinity? Check internal short

circuit of TP sensor,

APP sensor, MAP

sensor and/or A/C

refrigerant pressure

sensor (if equipped with

A/C).

“GRY/RED” wire is

shorted to ground

circuit.

Step Action Yes No

Page 250 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-200 Engine General Information and Diagnosis:

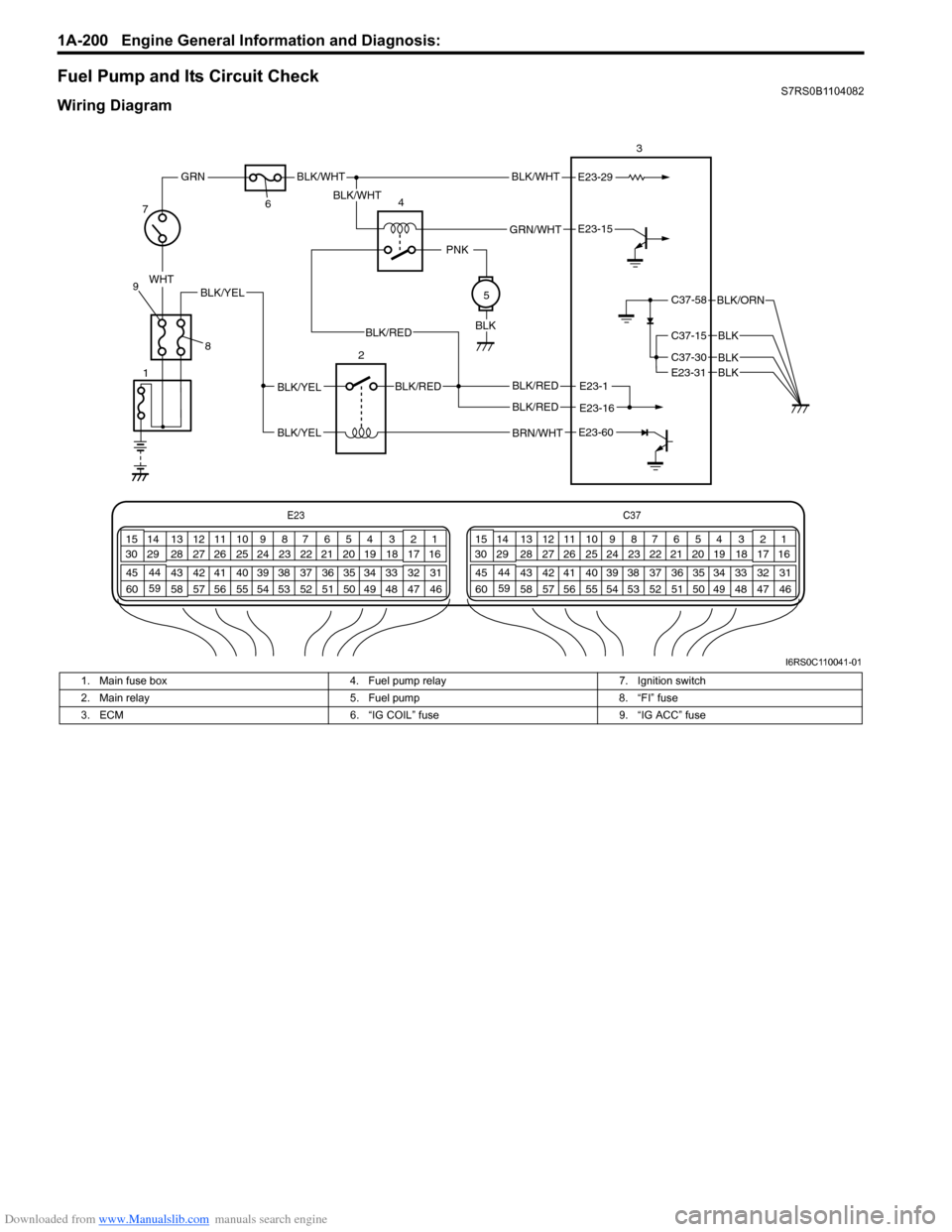

Fuel Pump and Its Circuit CheckS7RS0B1104082

Wiring Diagram

E23-1

E23-60

E23-15

BRN/WHT

BLK/REDBLK/YEL

BLK/YEL

BLK/RED

E23-29BLK/WHT

GRN/WHT

BLK/WHT

BLK/WHT

PNK

BLK

WHT

GRN

C37-58

C37-15

C37-30

BLK/ORN

BLK

BLKE23-31BLK

78

9 6

4 3

2 5

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 48 32 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/YEL

1

E23-16BLK/RED

BLK/RED

I6RS0C110041-01

1. Main fuse box 4. Fuel pump relay 7. Ignition switch

2. Main relay 5. Fuel pump 8. “FI” fuse

3. ECM 6. “IG COIL” fuse 9. “IG ACC” fuse

Page 251 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-201

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Fuel pump control system check for operation

Is fuel pump heard to operate 2 sec. after ignition switch is

turned ON? Fuel pump circuit is in

good condition.

Go to Step 2.

2 Fuel pump relay po wer supply check

1) Disconnect fuel pump relay from individual circuit fuse box No.1 with ignition switch turned OFF.

2) Check for proper connection to fuel pump relay at each terminal.

3) If OK, turn ON ignition switch, measure voltage between “BLK/WHT” wire terminal of fuel pump relay connector

and engine ground.

Is voltage 10 – 14 V? Go to Step 3.

“BLK/WHT” wire is open

or shorted to ground

circuit.

3 Fuel pump relay po wer supply check

1) Turn ON ignition switch, measure voltage between “BLK/ RED” wire terminal of fuel pump relay connector and

engine ground.

Is voltage 10 – 14 V? Go to Step 4.

“BLK/RED” wire is open

circuit.

4 Fuel pump relay check

1) Check fuel pump relay referring to “Main Relay, Fuel

Pump Relay and Starting Moto r Control Relay Inspection

in Section 1C”.

Is relay in good condition? Go to Step 5.

Faulty relay.

5 Fuel pump relay drive signal check

1) Connect fuel pump relay to individual circuit fuse box

No.1.

2) Connect voltmeter between “E23-15” terminal of ECM connector and vehicle body ground.

3) Measure voltage 2 second after ignition switch is turned ON.

Is voltage 10 – 14 V? Go to Step 6.

“GRN/WHT” wire is

open circuit or shorted

to ground circuit.

I2RH01110132-01

Page 252 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-202 Engine General Information and Diagnosis:

6Fuel pump relay drive signal check

1) Measure voltage within 2 second after ignition switch is

turned ON.

Is voltage 0 – 1 V? Go to Step 7. Substitute a known-

good ECM and recheck.

7 Wire circuit check

1) Turn OFF ignition switch.

2) Detach fuel tank referring to “Fuel Tank Removal and

Installation in Section 1G”.

3) Disconnect connector from fuel pump.

4) Measure resistance between “PNK” wire terminal of fuel pump connector and vehicle body ground.

Is resistance infinity? Go to Step 8. “PNK” wire is shorted to

ground.

8 Fuel pump circuit check

1) Connect service wire between “E23-15” terminal of ECM

connector and vehicle body ground.

2) Turn ON ignition switch, measure voltage between “PNK” terminal at fuel pump connector and vehicle body

ground.

Is voltage 10 – 14 V? Go to Step 9. “PNK” wire is open

circuit.

9 Fuel pump circuit check

1) Turn OFF ignition switch.

2) Measure resistance between “BLK” wire terminal at fuel

pump connector and vehicle body ground.

Is resistance less than 5

Ω? Faulty fuel pump. “BLK” wire is open

circuit.

Step Action Yes No