air cond SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1020 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-72 Air Conditioning System: Automatic Type

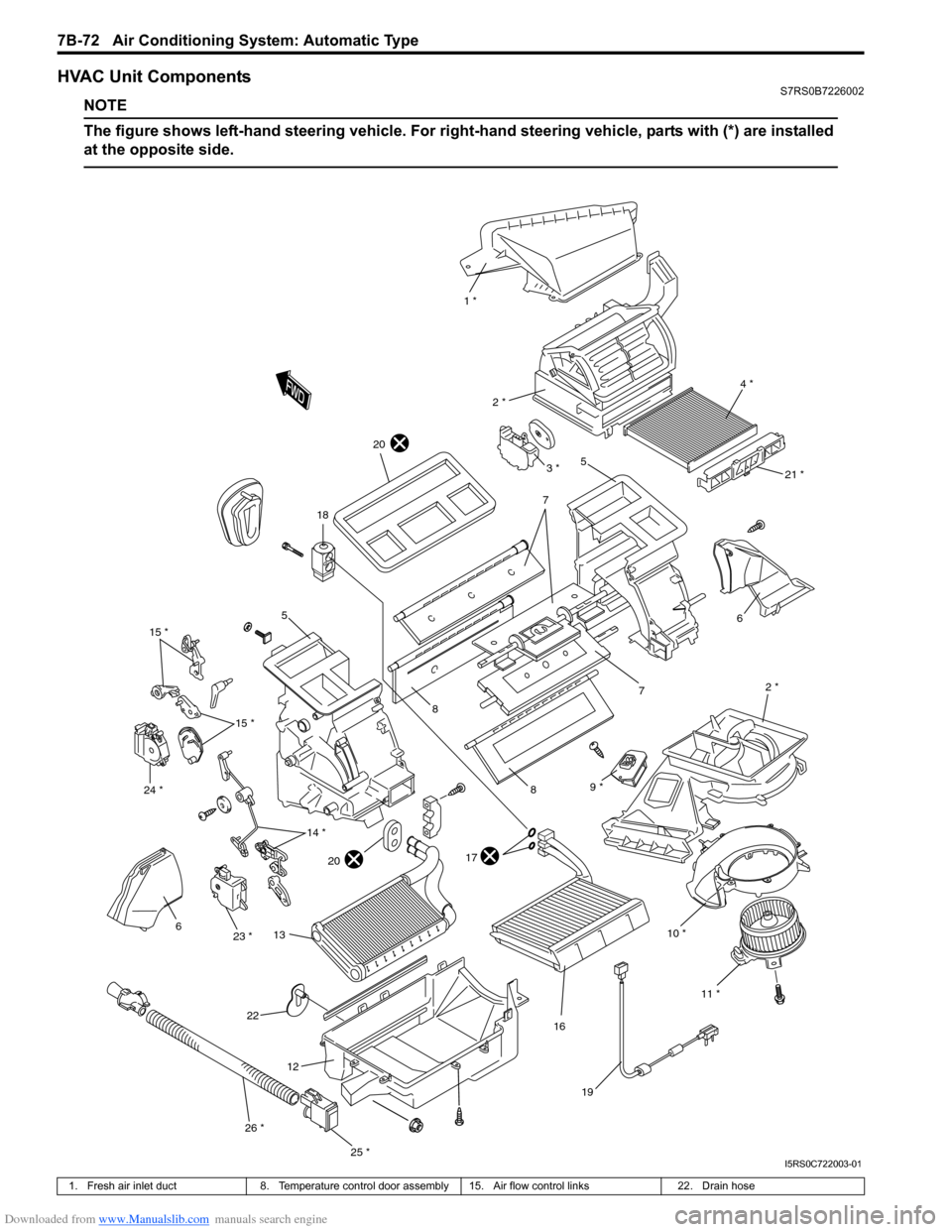

HVAC Unit ComponentsS7RS0B7226002

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

10 * 2 *

6

7

1 *

4 *

2 *

5

7

8

8

17

16

18

19

6

12

11 *

21 *

20

20

22

9 *

13

3 *

5

15 *

14 *

15 *

23 *

24 *

25 *

26 *

I5RS0C722003-01

1. Fresh air inlet duct

8. Temperature control door assembly 15. Air flow control links 22. Drain hose

Page 1021 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-73

HVAC Unit Removal and InstallationS7RS0B7226003

Refer to “HVAC Unit Removal and Installation”.

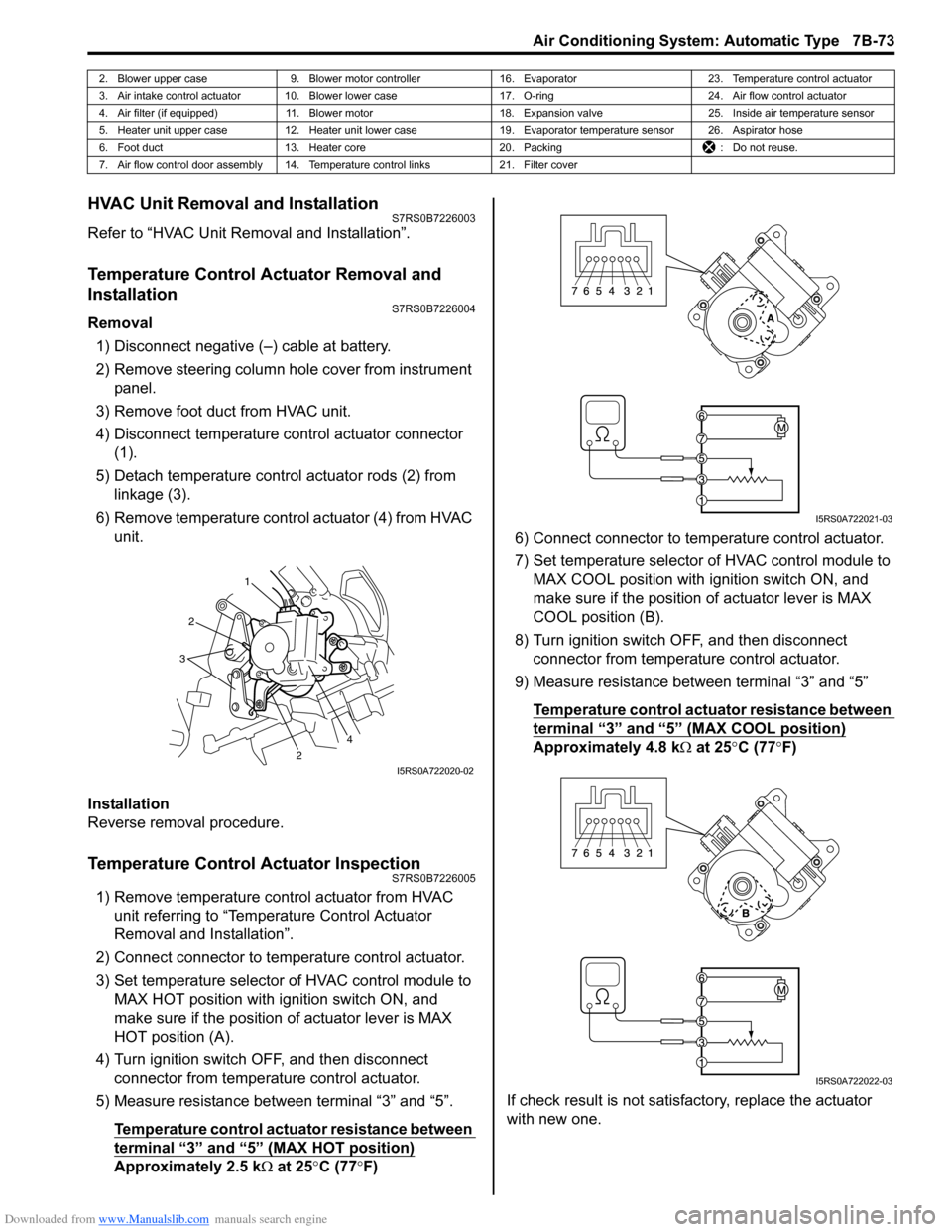

Temperature Control Actuator Removal and

Installation

S7RS0B7226004

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hol e cover from instrument

panel.

3) Remove foot duct from HVAC unit.

4) Disconnect temperature control actuator connector (1).

5) Detach temperature control actuator rods (2) from linkage (3).

6) Remove temperature control actuator (4) from HVAC unit.

Installation

Reverse removal procedure.

Temperature Control Actuator InspectionS7RS0B7226005

1) Remove temperature control actuator from HVAC unit referring to “Temperature Control Actuator

Removal and Installation”.

2) Connect connector to temperature control actuator.

3) Set temperature selector of HVAC control module to MAX HOT position with ignition switch ON, and

make sure if the position of actuator lever is MAX

HOT position (A).

4) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

5) Measure resistance between terminal “3” and “5”.

Temperature control actuator resistance between

terminal “3” and “5” (MAX HOT position)

Approximately 2.5 k Ω at 25 °C (77 °F) 6) Connect connector to tem

perature control actuator.

7) Set temperature selector of HVAC control module to MAX COOL position with ignition switch ON, and

make sure if the position of actuator lever is MAX

COOL position (B).

8) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

9) Measure resistance between terminal “3” and “5”

Temperature control actuator resistance between

terminal “3” and “5” (MAX COOL position)

Approximately 4.8 k Ω at 25 °C (77 °F)

If check result is not satisfactory, replace the actuator

with new one.

2. Blower upper case 9. Blower motor controller 16. Evaporator 23. Temperature control actuator

3. Air intake control actuator 10. Blower lower case 17. O-ring24. Air flow control actuator

4. Air filter (if equipped) 11. Blower motor 18. Expansion valve25. Inside air temperature sensor

5. Heater unit upper case 12. Heater unit lower case 19. Evaporator temperature sensor 26. Aspirator hose

6. Foot duct 13. Heater core 20. Packing : Do not reuse.

7. Air flow control door assembly 14. Temperature control links 21. Filter cover

1

2

2

3

4

I5RS0A722020-02

I5RS0A722021-03

I5RS0A722022-03

Page 1022 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-74 Air Conditioning System: Automatic Type

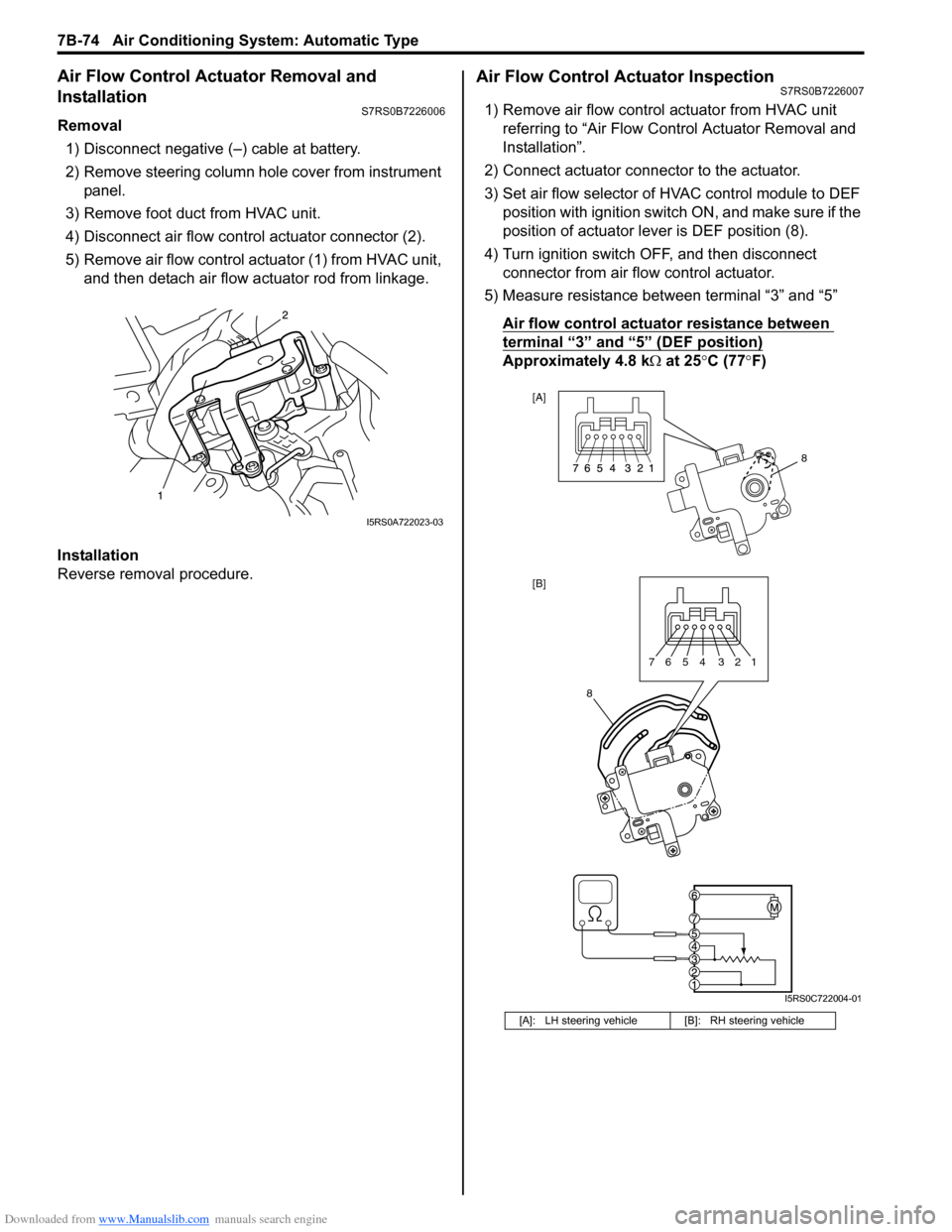

Air Flow Control Actuator Removal and

Installation

S7RS0B7226006

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hol e cover from instrument

panel.

3) Remove foot duct from HVAC unit.

4) Disconnect air flow contro l actuator connector (2).

5) Remove air flow control actuator (1) from HVAC unit, and then detach air flow actuator rod from linkage.

Installation

Reverse removal procedure.

Air Flow Control Actuator InspectionS7RS0B7226007

1) Remove air flow control actuator from HVAC unit referring to “Air Flow C ontrol Actuator Removal and

Installation”.

2) Connect actuator connector to the actuator.

3) Set air flow selector of HVAC control module to DEF position with ignition switch ON, and make sure if the

position of actuator lever is DEF position (8).

4) Turn ignition switch OFF, and then disconnect connector from air flow control actuator.

5) Measure resistance between terminal “3” and “5”

Air flow control actuator resistance between

terminal “3” and “5” (DEF position)

Approximately 4.8 k Ω at 25 °C (77 °F)

I5RS0A722023-03

[A]: LH steering vehicle [B]: RH steering vehicle

8

[A]

[B]

8

7654 321

I5RS0C722004-01

Page 1023 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-75

6) Connect connector to air flow control actuator.

7) Set air flow selector of HVAC control module to VENT position with ignition switch ON, and make

sure if the position of act uator lever is VENT position

(8).

8) Turn ignition switch OFF, and then disconnect connector from air flow control actuator.

9) Measure resistance between terminal “3” and “5”.

Air flow control actuator resistance between

terminal “3” and “5” (VENT position)

Approximately 2.0 k Ω at 25 °C (77 °F)

If check result is not satisfactory, replace the actuator

with new one.

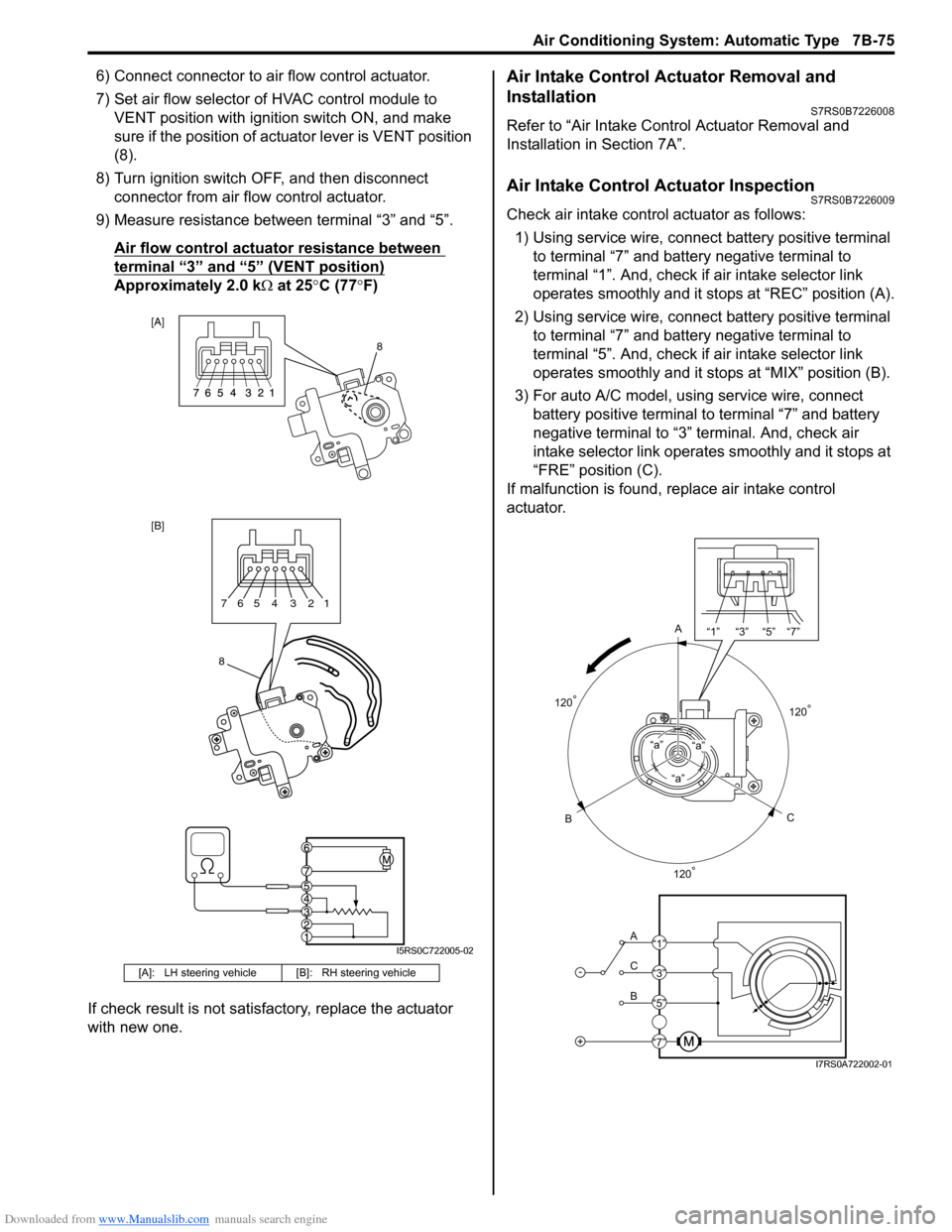

Air Intake Control Actuator Removal and

Installation

S7RS0B7226008

Refer to “Air Intake Control Actuator Removal and

Installation in Section 7A”.

Air Intake Control Actuator InspectionS7RS0B7226009

Check air intake contro l actuator as follows:

1) Using service wire, connect battery positive terminal

to terminal “7” and battery negative terminal to

terminal “1”. And, check if air intake selector link

operates smoothly and it stops at “REC” position (A).

2) Using service wire, connect battery positive terminal

to terminal “7” and battery negative terminal to

terminal “5”. And, check if air intake selector link

operates smoothly and it stops at “MIX” position (B).

3) For auto A/C model, using service wire, connect battery positive terminal to terminal “7” and battery

negative terminal to “3” terminal. And, check air

intake selector link operates smoothly and it stops at

“FRE” position (C).

If malfunction is found, replace air intake control

actuator.

[A]: LH steering vehicl e [B]: RH steering vehicle

[A]

[B]

8

8765 4 3 21

I5RS0C722005-02

A

C

B“a”

“a”“a”

-

+

A

C

B “1” “3” “5” “7”

“1”

“3”

“5”

“7”

120

°

120° 120

°

I7RS0A722002-01

Page 1024 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-76 Air Conditioning System: Automatic Type

Actuator Linkage InspectionS7RS0B7226010

• Check if each actuator linkage operates smoothly.

• Check actuator rod for bend.

• Check each actuator linkage for breakage.

• Make sure if there is not any obstruction in operating range of actuator linkage.

If any malfunction is found, repair or replace faulty

part(s).

Blower Motor Controller Removal and

Installation

S7RS0B7226011

Refer to “Blower Motor Resistor Removal and

Installation in Section 7A”.

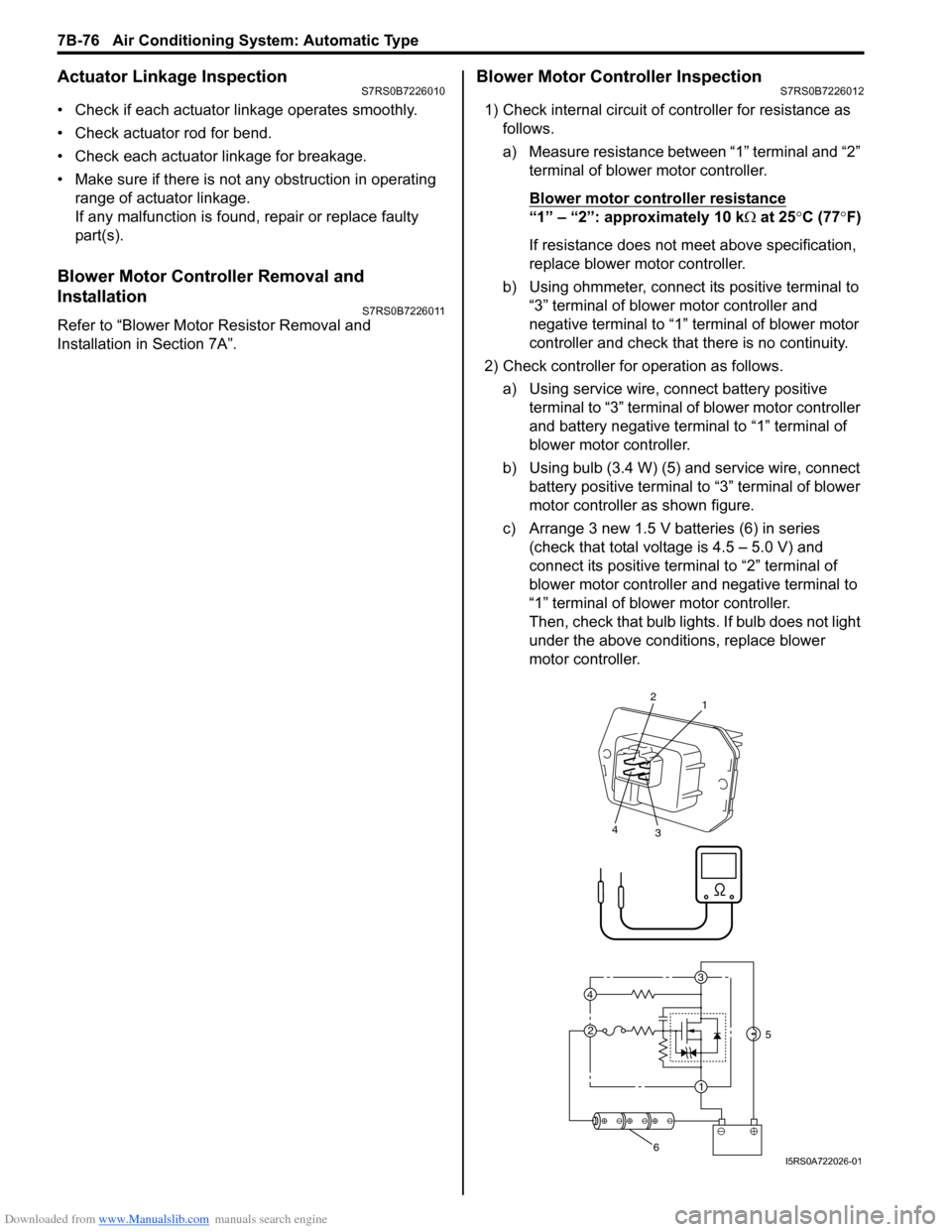

Blower Motor Controller InspectionS7RS0B7226012

1) Check internal circuit of controller for resistance as follows.

a) Measure resistance between “1” terminal and “2” terminal of blower motor controller.

Blower motor cont roller resistance

“1” – “2”: approximately 10 k Ω at 25 °C (77 °F)

If resistance does not meet above specification,

replace blower motor controller.

b) Using ohmmeter, connect its positive terminal to “3” terminal of blower motor controller and

negative terminal to “1” terminal of blower motor

controller and check that there is no continuity.

2) Check controller for operation as follows. a) Using service wire, connect battery positive terminal to “3” terminal of blower motor controller

and battery negative terminal to “1” terminal of

blower motor controller.

b) Using bulb (3.4 W) (5) and service wire, connect battery positive terminal to “3” terminal of blower

motor controller as shown figure.

c) Arrange 3 new 1.5 V batteries (6) in series (check that total voltage is 4.5 – 5.0 V) and

connect its positive term inal to “2” terminal of

blower motor controller and negative terminal to

“1” terminal of blower motor controller.

Then, check that bulb lights. If bulb does not light

under the above conditions, replace blower

motor controller.

3

1

2

4

2

1

3

4

5

6I5RS0A722026-01

Page 1025 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-77

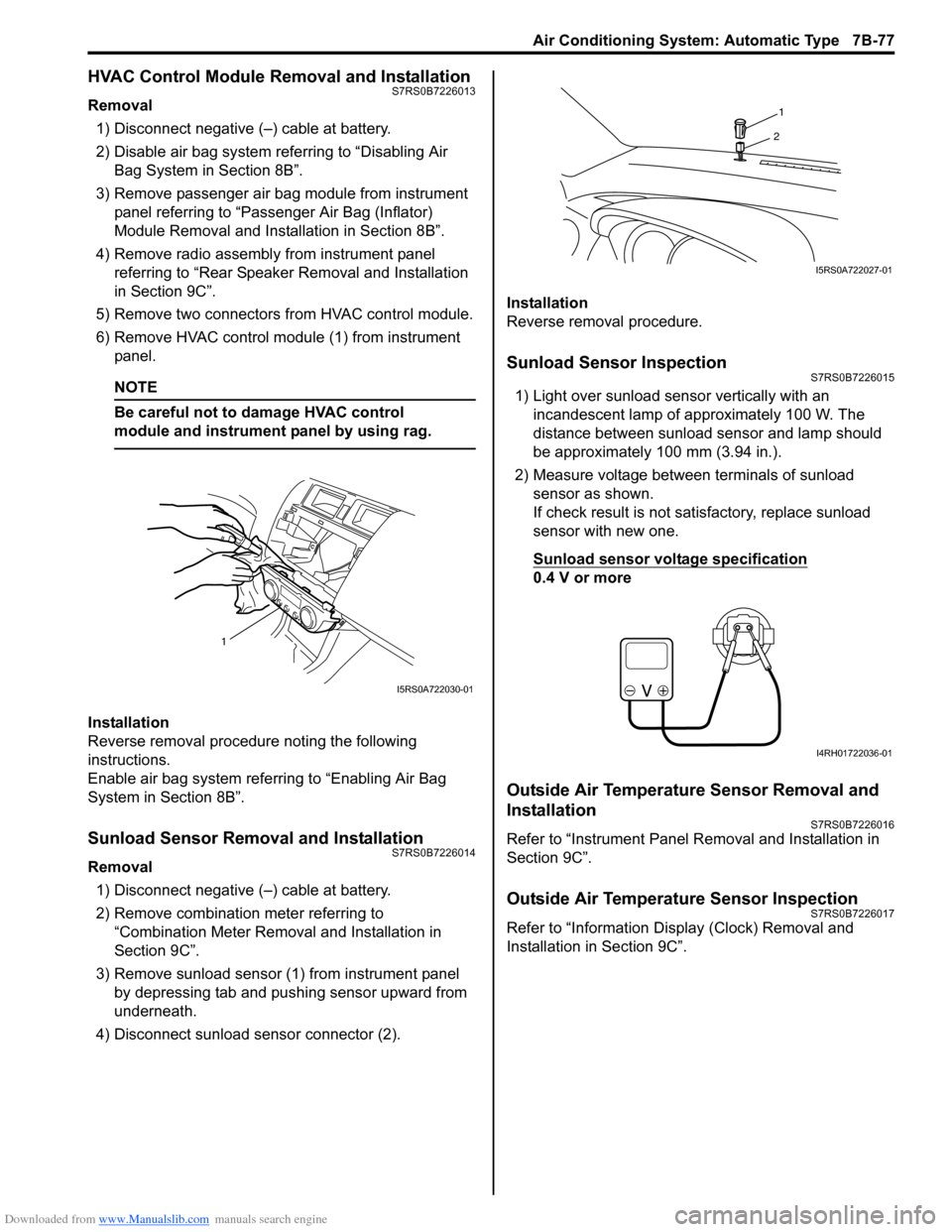

HVAC Control Module Removal and InstallationS7RS0B7226013

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Rear Speaker Removal and Installation

in Section 9C”.

5) Remove two connectors fr om HVAC control module.

6) Remove HVAC control modu le (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control

module and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Sunload Sensor Removal and InstallationS7RS0B7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter referring to “Combination Meter Removal and Installation in

Section 9C”.

3) Remove sunload sensor (1) from instrument panel by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2). Installation

Reverse removal procedure.

Sunload Sensor InspectionS7RS0B7226015

1) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W. The

distance between sunload sensor and lamp should

be approximately 100 mm (3.94 in.).

2) Measure voltage between terminals of sunload sensor as shown.

If check result is not satisfactory, replace sunload

sensor with new one.

Sunload sensor voltage specification

0.4 V or more

Outside Air Temperature Sensor Removal and

Installation

S7RS0B7226016

Refer to “Instrument Panel Re moval and Installation in

Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0B7226017

Refer to “Information Display (Clock) Removal and

Installation in Section 9C”.

1

I5RS0A722030-01

1

2

I5RS0A722027-01

I4RH01722036-01

Page 1026 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-78 Air Conditioning System: Automatic Type

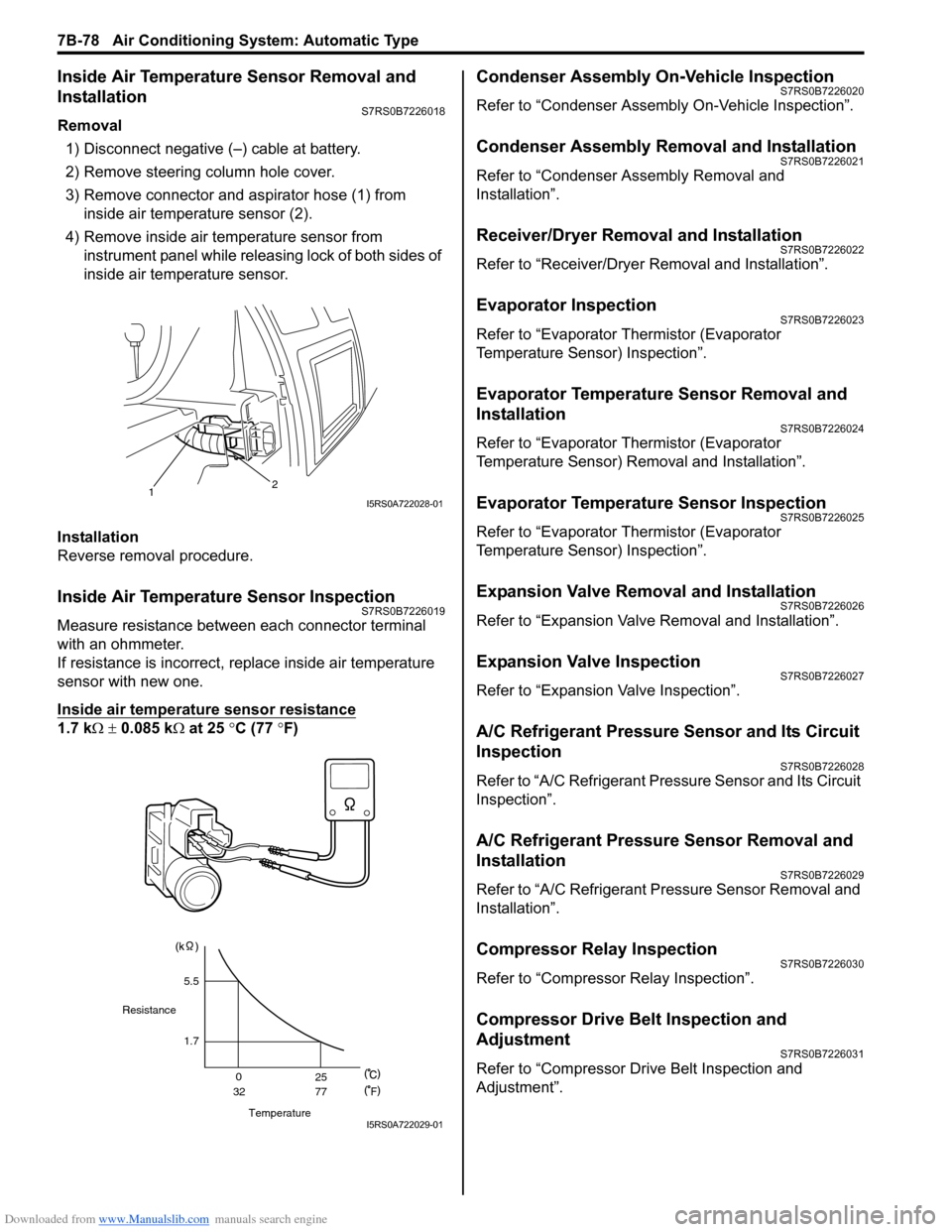

Inside Air Temperature Sensor Removal and

Installation

S7RS0B7226018

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover.

3) Remove connector and aspirator hose (1) from inside air temperature sensor (2).

4) Remove inside air temperature sensor from instrument panel while releas ing lock of both sides of

inside air temperature sensor.

Installation

Reverse removal procedure.

Inside Air Temperature Sensor InspectionS7RS0B7226019

Measure resistance between each connector terminal

with an ohmmeter.

If resistance is incorrect, replace inside air temperature

sensor with new one.

Inside air temperature sensor resistance

1.7 k Ω ± 0.085 k Ω at 25 °C (77 ° F)

Condenser Assembly On-Vehicle InspectionS7RS0B7226020

Refer to “Condenser Assembly On-Vehicle Inspection”.

Condenser Assembly Removal and InstallationS7RS0B7226021

Refer to “Condenser Assembly Removal and

Installation”.

Receiver/Dryer Removal and InstallationS7RS0B7226022

Refer to “Receiver/Dryer Removal and Installation”.

Evaporator InspectionS7RS0B7226023

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator Temperature Sensor Removal and

Installation

S7RS0B7226024

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Removal and Installation”.

Evaporator Temperature Sensor InspectionS7RS0B7226025

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Expansion Valve Removal and InstallationS7RS0B7226026

Refer to “Expansion Valve Removal and Installation”.

Expansion Valve InspectionS7RS0B7226027

Refer to “Expansion Valve Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7226028

Refer to “A/C Refrigerant Pressure Sensor and Its Circuit

Inspection”.

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7226029

Refer to “A/C Refrigerant Pressure Sensor Removal and

Installation”.

Compressor Relay InspectionS7RS0B7226030

Refer to “Compressor Relay Inspection”.

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7226031

Refer to “Compressor Drive Belt Inspection and

Adjustment”.

12I5RS0A722028-01

Temperature

Resistance

1.7

0

32 25

77

F

5.5

I5RS0A722029-01

Page 1027 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-79

Compressor Drive Belt Removal and

Installation

S7RS0B7226032

Refer to “Compressor Drive Belt Removal and

Installation”.

Compressor Assembly Removal and

Installation

S7RS0B7226033

Refer to “Compressor Assembly Removal and

Installation”.

Compressor Assembly ComponentsS7RS0B7226034

Refer to “Compressor Assembly Components”.

Magnet Clutch Removal and InstallationS7RS0B7226035

Refer to “Magnet Clutch Removal and Installation”.

Magnet Clutch InspectionS7RS0B7226036

Refer to “Magnet Clutch Inspection”.

Relief Valve InspectionS7RS0B7226039

Refer to “Relief Valve Inspection”.

Special Tools and Equipment

Special ToolS7RS0B7228001

SUZUKI scan tool

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12.�) / �)

Page 1028 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-80 Air Conditioning System: Automatic Type

Page 1032 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-1 Seat Belts:

Restraint

Seat Belts

Precautions

Precautions on Service and Diagnosis of Seat

Belt

S7RS0B8100001

WARNING!

If replacing seat belt is necessary, replace

buckle and seat belt assembly together as a

set. This is for the reason of ensuring locking

of tongue plate with buckle. If these parts are

replaced individually, such a locking

condition may become unreliable. For this

reason, SUZUKI will supply only the spare

buckle and seat belt assembly in a set part.

Before servicing or replacing seat belts, refer to the

following precautionary items.

• Seat belts should be normal relative to strap retractor and buckle portions. • Keep sharp edges and damaging objects away from

belts.

• Avoid bending or damaging any portion of belt buckle or latch plate.

• Do not bleach or dye belt webbing. (Use only mild soap and lukewarm water to clean it.)

• When installing a seat belt anchor bolt, it should be tightened by hand at first to prevent cross-threading

and then to specified torque.

• Do not attempt any repair s on retractor mechanisms

or retractor covers. Replace defective assemblies with

new replacement parts.

• Keep belts dry and clean at all times.

• If there exist any parts in question, replace such parts.

• Replace belts whose webbing is cut or otherwise damaged.

• Do not put anything into trim panel opening which seat belt webbing passes through.

General Description

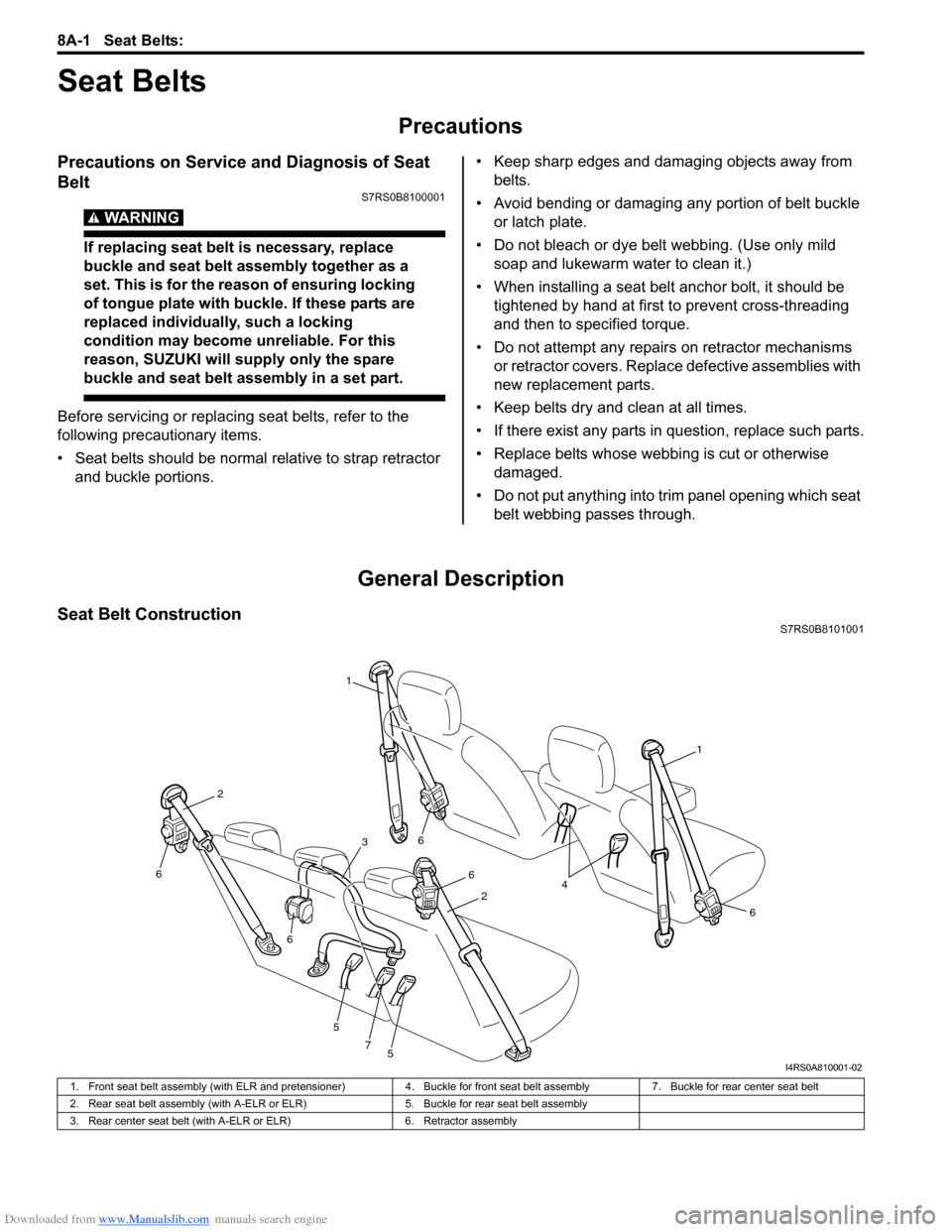

Seat Belt ConstructionS7RS0B8101001

1

1

6

6

6

5

5

7

6

6

2

2

3

4

I4RS0A810001-02

1. Front seat belt assembly (with ELR and pretensioner) 4. Buckle for front seat belt assembly7. Buckle for rear center seat belt

2. Rear seat belt assembly (with A-ELR or ELR) 5. Buckle for rear seat belt assembly

3. Rear center seat belt (with A-ELR or ELR) 6. Retractor assembly