air cond SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1306 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-11 Instrumentation / Driver Info. / Horn:

Information Display Symptom Diagnosis (If Equipped)S7RS0B9304015

NOTE

This thermometer indicates the ambient temperature in back of front bumper member. Under any one

of the following listed conditions, however, even when the ambient temperature goes up, the

thermometer display does not rise so as to correct the rise of the ambient temperature caused by the

radiant heat of the engine. When the ambient temperature drops, the thermometer reading follows the

change in the temperature.

Be sure to bear this in mind when diagnosing trouble.

• The vehicle speed is 30 km/h (18 mph) or lower.

• Vehicle speed signal is faulty.

• The ignition switch is turned on again within 2 hours.

ConditionPossible cause Correction / Reference Item

No displaying of

information display Circuit fuse Blown

Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Information display unit faulty Replace unit.

Incorrect thermometer

display Outside air temperature sensor faulty

Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Vehicle speed signal faulty Check ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring and/or grounding faulty Repair as necessary.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Display of thermometer

does not change at –30

°C Outside air temperature is –30

°C (–22

° F) or less —

Outside air temperature sensor faulty Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Display of thermometer

does not change at 50

°C Outside air temperature is 50

°C (122

° F) or more —

Outside air temperature sensor faulty Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Display of thermometer

does not change at “– – –

°C” Outside air temperature sensor faulty

Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Outside air temperature sensor circuit is

open or short Repair as necessary.

Wiring and/or grounding faulty Repair as necessary.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Page 1307 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-12

Clock Symptom Diagnosis (If Equipped)S7RS0B9304016

Audio System Symptom Diagnosis (If Equipped)S7RS0B9304017

Radio

NOTE

Electronic part / system with undiagnosed pr oblem may cause electromagnetic interference.

Electromagnetic interference condition may have poor radio reception. To test for presence of

electromagnetic interference in part / system, perform the following procedures.

1. Turn ignition switch to OFF.

2. Systematically disconnect the electronic part / system connector(s) one at a time.

3. Turn ignition switch to ON.

4. Check any improvement in radio reception.

Display of fuel

consumption does not

change at “– – – l / 100 km

(km/l, MPG)” Vehicle is not running (instantaneous

fuel consumption mode)

—

Fuel consumption was reset (average

fuel consumption mo de, if equipped)Vehicle runs for a while.

Vehicle speed signal faulty Check ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring and/or grounding faulty Repair as necessary.

ECM faulty Check input and output signal of ECM referring

to “Inspection of ECM and Its Circuits in

Section 1A”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

No displaying of clock Circuit fuse Blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Clock unit faulty Replace unit.

ConditionPossible cause Correction / Reference Item

Poor radio reception Out of service area (Poor location) —

Antenna faulty Replace antenna.

Electrical part / system faulty Repair or replace electrical part / system

referring to after-mentioned NOTE.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate

and speaker does not

sound Circuit fuse(s) blown

Replace fuse(s) and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate,

but speaker sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio is operative, but all

speakers does not sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Individual speaker is

noisy or inoperative Wiring and/or grounding faulty

Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Sound quality is poor Out of service area (Poor location) —

Speaker installed incorrectly Install correctly.

Wiring and/or grounding faulty Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Page 1308 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-13 Instrumentation / Driver Info. / Horn:

CD Player

Auto Volume Control System

Remote Audio Control Switch Symptom Diagnosis (If Equipped)S7RS0B9304018

ConditionPossible cause Correction / Reference Item

CD-ROM does not insert Another CD-ROM already inserted Eject CD-ROM.

Circuit fuse blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Extraneous material come to be mixed

CD player Clear extraneous material from CD player or

replace radio assembly.

Radio assembly faulty Replace radio assembly.

CD-ROM does not eject Circuit fuse blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Extraneous material come to be mixed

in CD player Clear extraneous material from CD player or

replace radio assembly.

Radio assembly faulty Replace radio assembly.

CD player does not load

CD-ROM CD-ROM faulty

—

CD-ROM inserted wit h incorrect side upInsert correctly.

Temperature in cabin is too hot —

Water droplets form on internal lens Dry about 1 hour with power on.

Radio assembly faulty Replace radio assembly.

Sound skips or is noisy CD-ROM faulty —

Driving vibration —

Water droplets form on internal lens Dry about 1 hour with power on.

Radio assembly installed incorrectly Install correctly.

Radio assembly faulty Replace radio assembly.

CD player is operative,

but all speakers does not

sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Individual speaker is

noisy or inoperative Wiring and/or grounding faulty

Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Sound quality or volume

is poor CD-ROM faulty

—

Wiring and/or grounding faulty Repair as necessary.

Speaker installed incorrectly Install correctly.

Speaker faulty Replace speaker.

ConditionPossible cause Correction / Reference Item

Sound volume does not

vary according to

changes of vehicle speed Auto volume control system is “OFF”

mode

Select auto volume control.

Vehicle speed signal faulty Check vehicle speed signal referring to

“Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)”.

Wiring and/or grounding faulty Repair as necessary.

ECM faulty Check input and output signal of ECM referring

to “Inspection of ECM and Its Circuits in

Section 1A”

Radio assembly faulty Replace radio assembly.

ConditionPossible cause Correction / Reference Item

Audio system is

operative, but remote

control switch does not

control audio system Remote audio control switch faulty

Check remote audio control switch referring to

“Remote Audio Control Switch Inspection (If

Equipped)”.

Contact coil faulty Replace contact coil.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Page 1309 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-14

Navigation Symptom Diagnosis (If Equipped)S7RS0B9304019

Repair Instructions

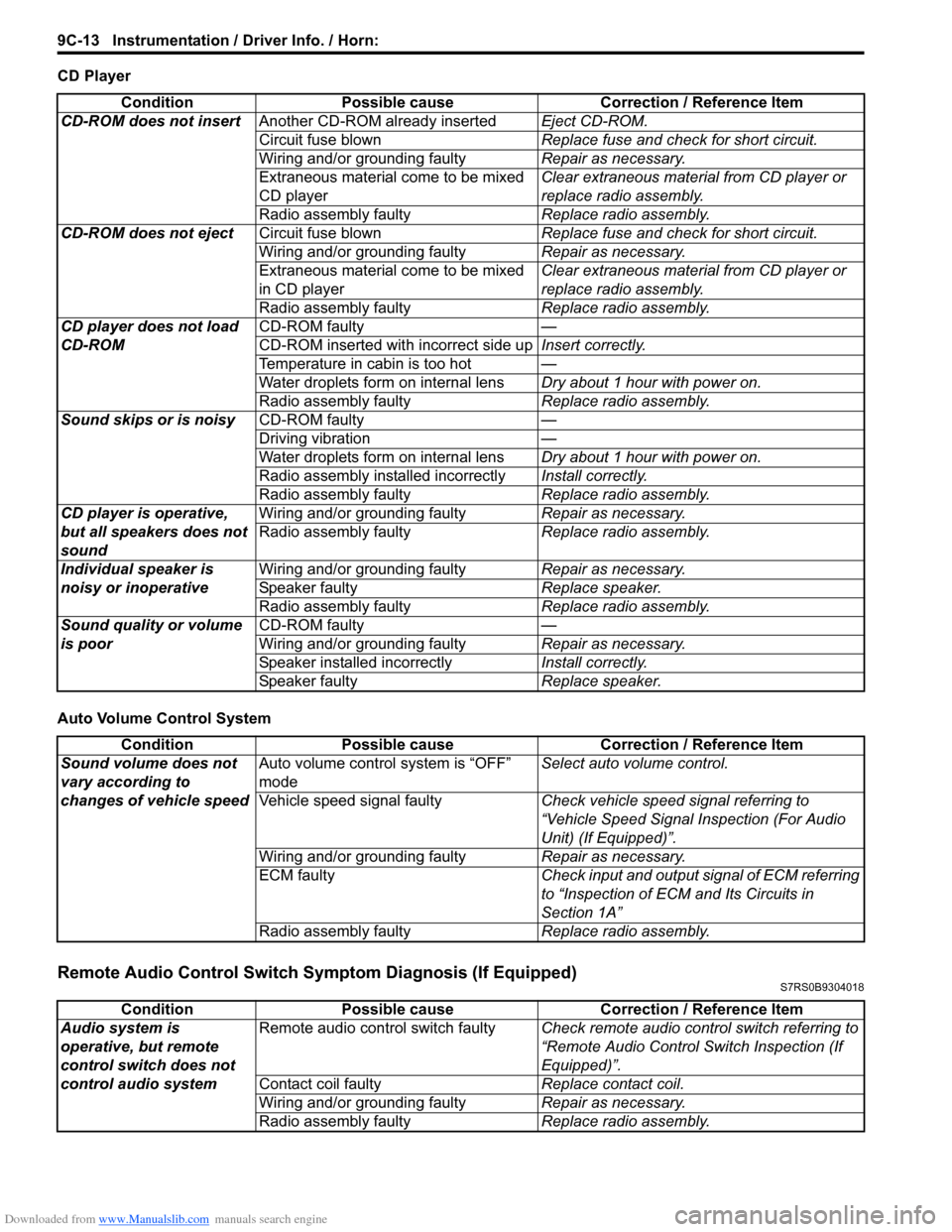

Ignition Switch Removal and InstallationS7RS0B9306001

Removal

1) Disconnect negative (–) cable at battery.

2) Confirm that ignition key is removed.

3) Remove steering column hole cover (1).

4) Turn steering wheel to remove steering column cover screws (3) and then remove steering column

covers (2).

5) Disconnect couplers (1) from ignition switch (2).

6) Remove ignition switch (2) from key cylinder (3).

Installation

Reverse removal procedure.

Ignition Switch InspectionS7RS0B9306002

• Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Condition Possible cause Correction / Reference Item

No displaying of

navigation Circuit fuse Blown

Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Navigation unit faulty Replace unit.

1

32

I4RS0B920004-02

1 1

2

3

I4RS0A930008-01

PositionTerminal

LOCK

ACC

ON

START

OUT

INK2K1ST

IG2

IG1

ACC

B1 B2

Ignition knob switch

(with keyless start system only)

ACC

IG1 IG2

ST

B2

B1 K2

K1

P2

P1

Terminal

OFF (ignition knob switch released) ON (ignition knob switch pushsed)P1 P2

Key

I5RS0D930003-02

Page 1317 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-22

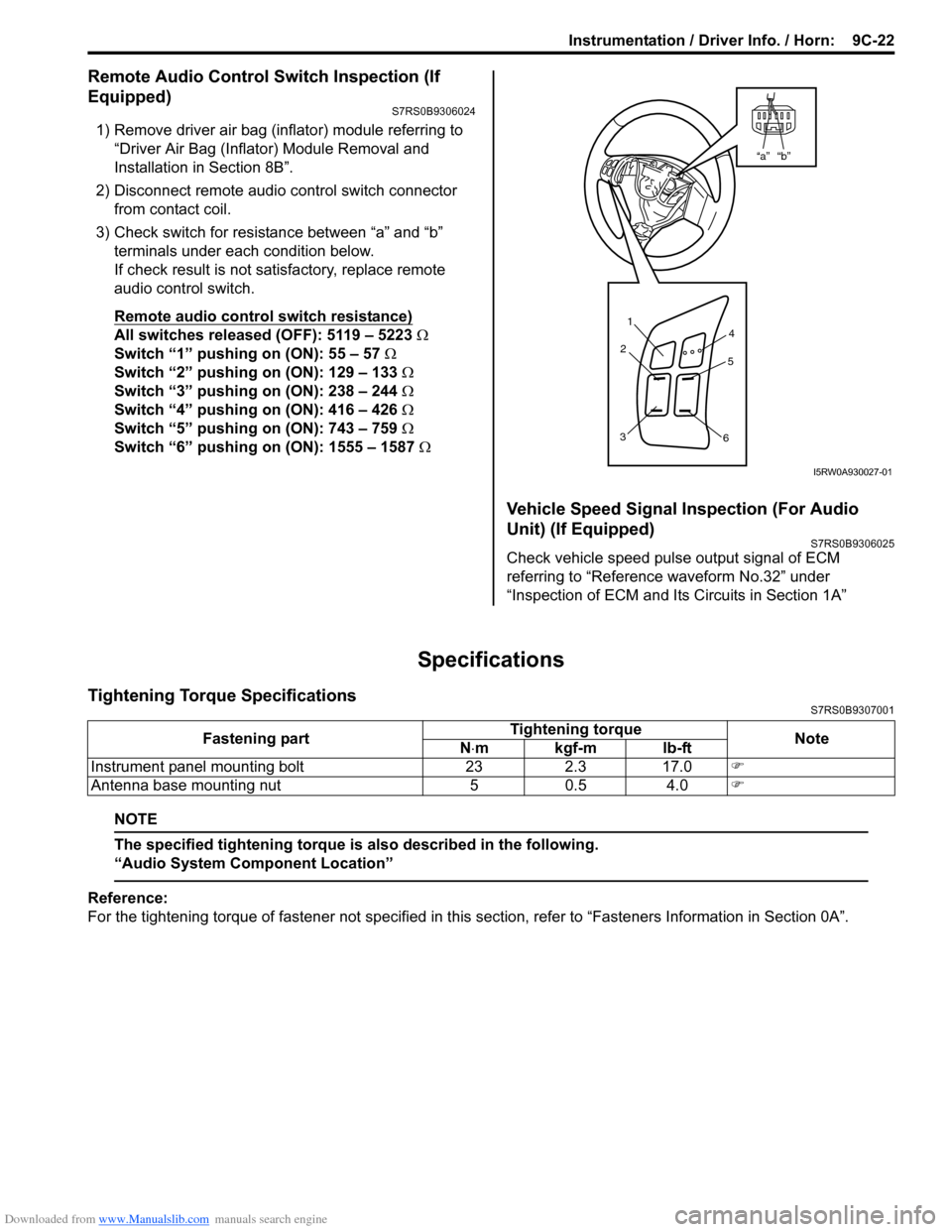

Remote Audio Control Switch Inspection (If

Equipped)

S7RS0B9306024

1) Remove driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

2) Disconnect remote audio control switch connector

from contact coil.

3) Check switch for resistance between “a” and “b” terminals under each condition below.

If check result is not satisfactory, replace remote

audio control switch.

Remote audio control switch resistance)

All switches released (OFF): 5119 – 5223 Ω

Switch “1” pushing on (ON): 55 – 57 Ω

Switch “2” pushing on (ON): 129 – 133 Ω

Switch “3” pushing on (ON): 238 – 244 Ω

Switch “4” pushing on (ON): 416 – 426 Ω

Switch “5” pushing on (ON): 743 – 759 Ω

Switch “6” pushing on (ON): 1555 – 1587 Ω

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)

S7RS0B9306025

Check vehicle speed pulse output signal of ECM

referring to “Reference waveform No.32” under

“Inspection of ECM and Its Circuits in Section 1A”

Specifications

Tightening Torque SpecificationsS7RS0B9307001

NOTE

The specified tightening torque is also described in the following.

“Audio System Component Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

“b”“a”

1

2

3 4

5

6

I5RW0A930027-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Instrument panel mounting bolt 23 2.3 17.0 �)

Antenna base mounting nut 5 0.5 4.0 �)

Page 1318 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-1 Wipers / Washers:

Body, Cab and Accessories

Wipers / Washers

Diagnostic Information and Procedures

Front Wiper and Washer Symptom DiagnosisS7RS0B9404001

Rear Wiper and Washer Symptom DiagnosisS7RS0B9404002

ConditionPossible cause Correction / Reference Item

Wiper malfunctions Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Windshield

Wiper Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

Wiper malfunctions

NOTE

• Use of SUZUKI scan tool makes it easy to

check whether a faulty

condition is on the

input side or output

side of BCM. For

checking procedure,

refer to “Diagnosis

Using Output Test

Function of SUZUKI

Scan Tool” under

“Scan Tool Data in

Section 10B”.

• Check each part in the order from the top of

the following list.

Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Rear Wiper

Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Rear Wiper

and Washer Switch Inspection”.

Rear wiper relay faulty Check rear wiper relay referring to “Rear Wiper

Relay Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Rear Wiper

and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Page 1329 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-2

• Eyeleteer

• Piano string

• Windshield knife

• Brush for primer application (2 pcs)

•Knife

• Rubber sucker grip

• Sealant gun (for filling adhesive)

• Putty spatula (for correcting adhered parts)

Diagnostic Information and Procedures

Rear End door Window Defogger Symptom DiagnosisS7RS0B9504001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Window Control System Symptom DiagnosisS7RS0B9504002

Condition Possible cause Correction / Reference Item

Rear end door window

defogger does not

operate Circuit fuse blown

Replace fuse and check for short circuit.

Rear end door window defogger switch

faulty Check rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faulty Check rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Defogger wire faulty Check defogger wire referring to “Rear End

Door Window Defogger Wire Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

All power windows do not

operate Circuit fuse blown

Replace fuse and check for short circuit.

Power window main switch faulty Check power window main switch referring to

“Power Window Main Switch Inspection”.

Ignition switch faulty Check ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

Only one power window

does not operate Power window main switch faulty

Check power window main switch referring to

“Power Window Main Switch Inspection”.

Power window sub switch faulty Check power window sub switch referring to

“Power Window Sub Switch Inspection”.

Wiring and/or coupler faulty Check wiring and/or coupler.

Power window regulator faulty Check window regulator.

Power window motor faulty Check power window motor.

Wiring or grounding faulty Repair circuit.

Page 1330 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-3 Glass / Windows / Mirrors:

Power Door Mirror Control System Symptom DiagnosisS7RS0B9504003

Door Mirror Heater Symptom Diagnosis (If Equipped)S7RS0B9504004

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Condition Possible cause Correction / Reference Item

All power mirrors do not

operate Circuit fuse blown

Replace fuse and check for short circuit.

Power door mirror switch faulty Check power door mirror switch referring to

“Power Door Mirror Switch Inspection”.

Wiring or grounding faulty Repair circuit.

One power mirror does

not operate Power door mirror switch faulty

Check power door mirror switch referring to

“Power Door Mirror Switch Inspection”.

Power door mirror actuator faulty Check actuator refraining to “Power Door

Mirror Actuator Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

All door mirror heaters

does not operate Circuit fuse blown

Replace fuse and check for short circuit.

Rear end door window defogger switch

faulty Check rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faulty Check rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Only one door mirror

heater does not operate Door mirror heater faulty

Check door mirror heater referring to “Door

Mirror Heater Inspection (If Equipped)”.

Wiring or grounding faulty Repair circuit.

Page 1342 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-15 Glass / Windows / Mirrors:

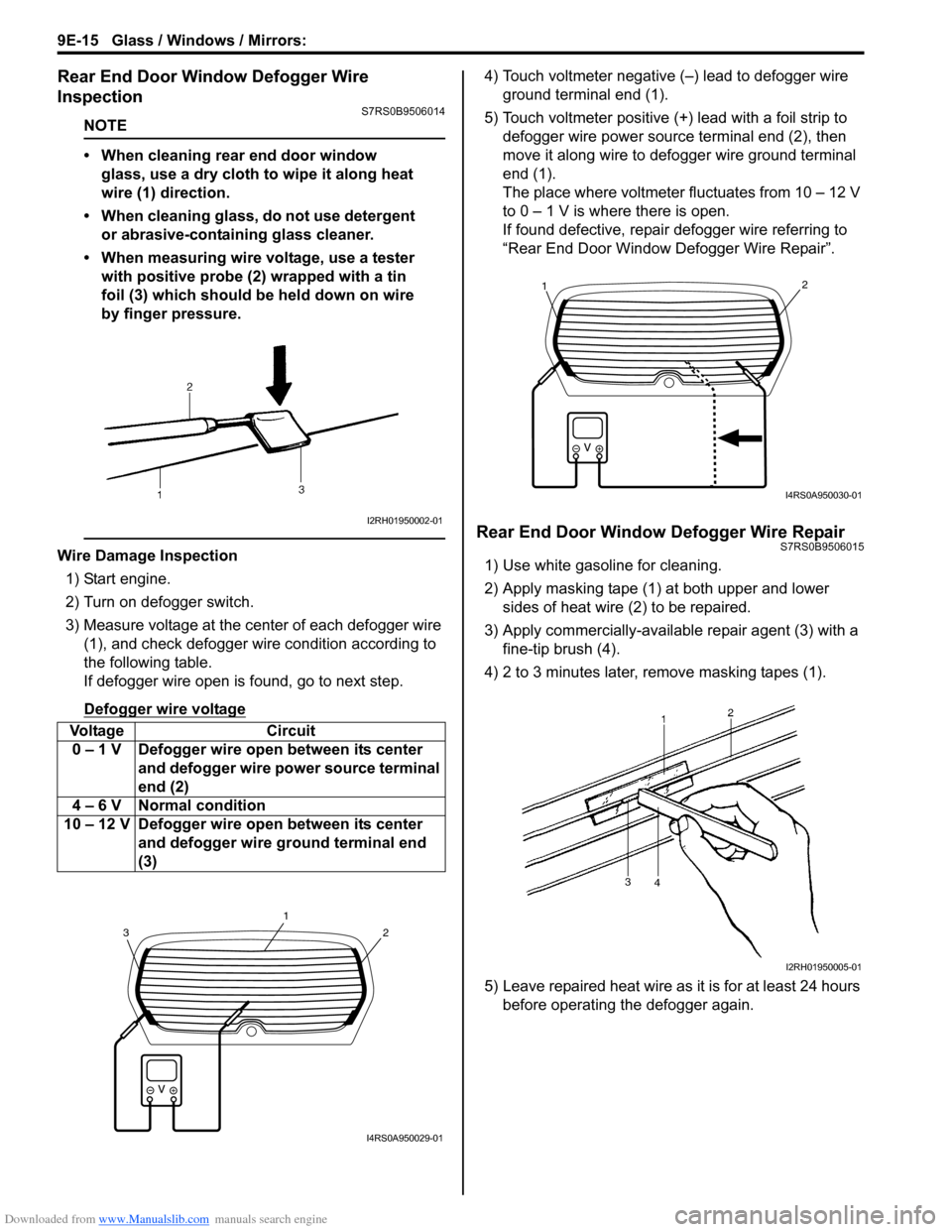

Rear End Door Window Defogger Wire

Inspection

S7RS0B9506014

NOTE

• When cleaning rear end door window glass, use a dry cloth to wipe it along heat

wire (1) direction.

• When cleaning glass, do not use detergent or abrasive-containing glass cleaner.

• When measuring wire voltage, use a tester with positive probe (2) wrapped with a tin

foil (3) which should be held down on wire

by finger pressure.

Wire Damage Inspection

1) Start engine.

2) Turn on defogger switch.

3) Measure voltage at the center of each defogger wire (1), and check defogger wire condition according to

the following table.

If defogger wire open is found, go to next step.

Defogger wire voltage

4) Touch voltmeter negative (–) lead to defogger wire ground terminal end (1).

5) Touch voltmeter positive (+) lead with a foil strip to defogger wire power source terminal end (2), then

move it along wire to defogger wire ground terminal

end (1).

The place where voltmeter fluctuates from 10 – 12 V

to 0 – 1 V is where there is open.

If found defective, repair defogger wire referring to

“Rear End Door Window Defogger Wire Repair”.

Rear End Door Window Defogger Wire RepairS7RS0B9506015

1) Use white gasoline for cleaning.

2) Apply masking tape (1) at both upper and lower sides of heat wire (2) to be repaired.

3) Apply commercially-available repair agent (3) with a fine-tip brush (4).

4) 2 to 3 minutes later, remove masking tapes (1).

5) Leave repaired heat wire as it is for at least 24 hours before operating the defogger again.

Voltage Circuit

0 – 1 V Defogger wire open between its center and defogger wire power source terminal

end (2)

4 – 6 V Normal condition

10 – 12 V Defogger wire open between its center and defogger wire ground terminal end

(3)

I2RH01950002-01

2

1

3

I4RS0A950029-01

21

I4RS0A950030-01

I2RH01950005-01

Page 1349 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-3

Diagnostic Information and Procedures

Power Door Lock System Symptom DiagnosisS7RS0B9604001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Door Lock System Operation InspectionS7RS0B9604002

1) Check the following operation:

a) Turn the driver side key cylinder is turned LOCK once, check all doors lock.

b) Turn the driver side door key cylinder is turned UNLOC K position with door key twice, check all doors unlock.

If malfunction is found, go to “Power Door Lock System Symptom Diagnosis”.

Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by all of

switches Circuit fuse blown

Replace fuse and check for short circuit.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only power

door lock switch Circuit fuse blown

Replace fuse and check for short circuit.

Power door lock switch faulty Check power door lock switch referring to

“Power Door Lock Switch Inspection”.

Wiring harness connected to power door

lock switch faulty Repair.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only key

cylinder switch Circuit fuse blown

Replace fuse and check for short circuit.

Key cylinder switch faulty Check key cylinder switch referring to “Door

Key Cylinder Switch Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Only one door can not be

locked / unlocked Power door lock actuator faulty

Check actuator referring to “Power Door Lock

Actuator Inspection”.

Wiring harness connected to applicable

door lock actuator faulty Repair.

BCM faulty Replace after making sure that none of above

parts is faulty.