suspension SUZUKI SWIFT 2005 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 451 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-18

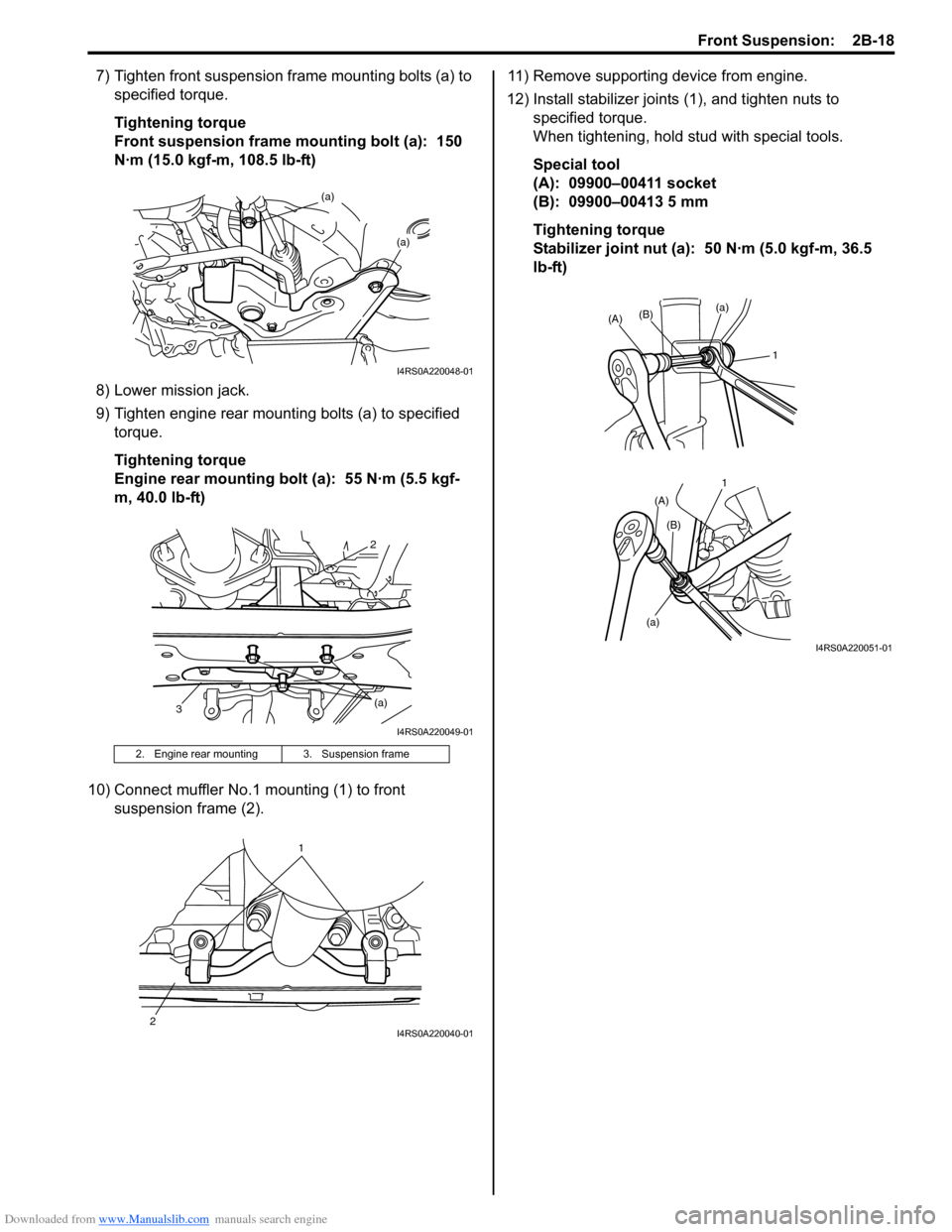

7) Tighten front suspension frame mounting bolts (a) to specified torque.

Tightening torque

Front suspension frame mounting bolt (a): 150

N·m (15.0 kgf-m, 108.5 lb-ft)

8) Lower mission jack.

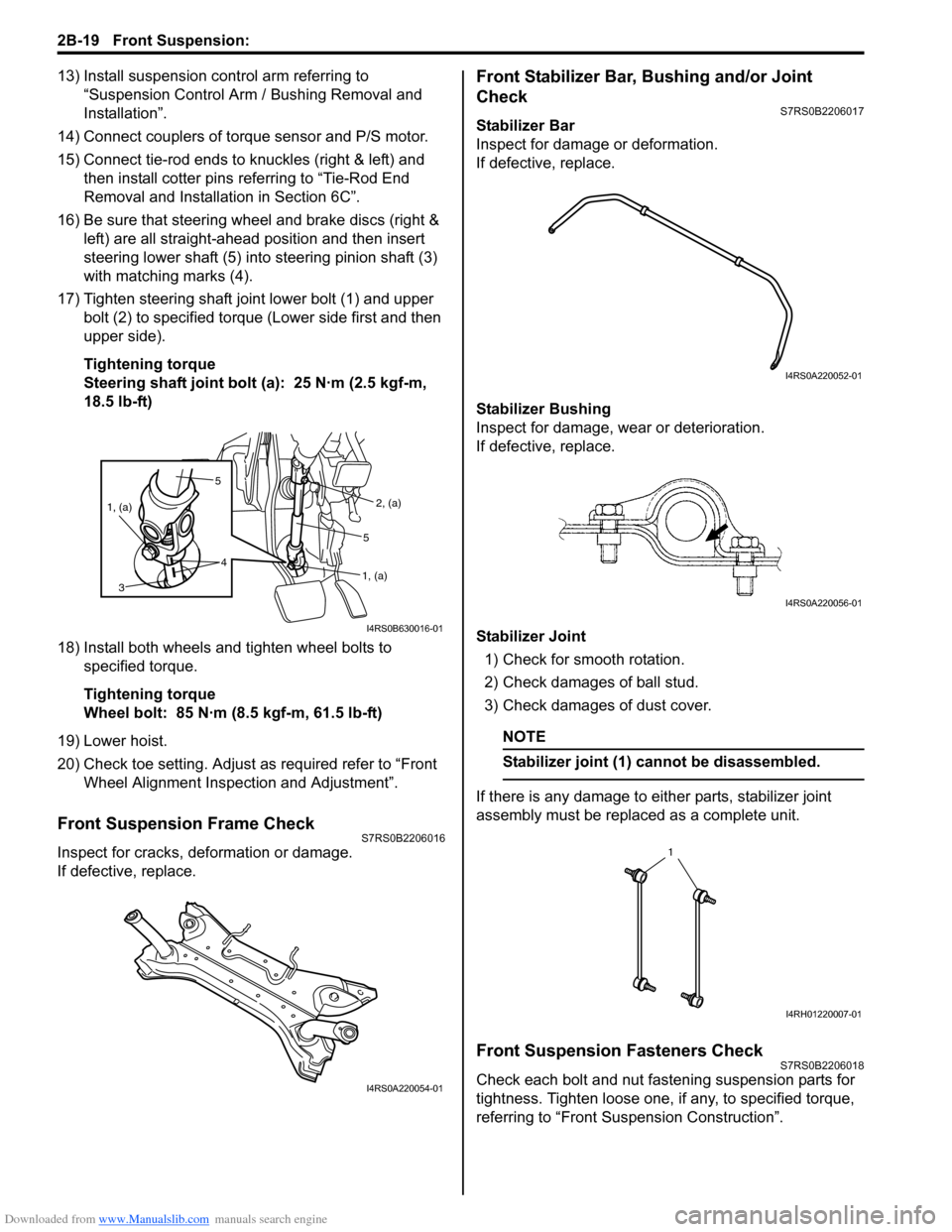

9) Tighten engine rear mounting bolts (a) to specified torque.

Tightening torque

Engine rear mounting bolt (a): 55 N·m (5.5 kgf-

m, 40.0 lb-ft)

10) Connect muffler No.1 mounting (1) to front suspension frame (2). 11) Remove supporting device from engine.

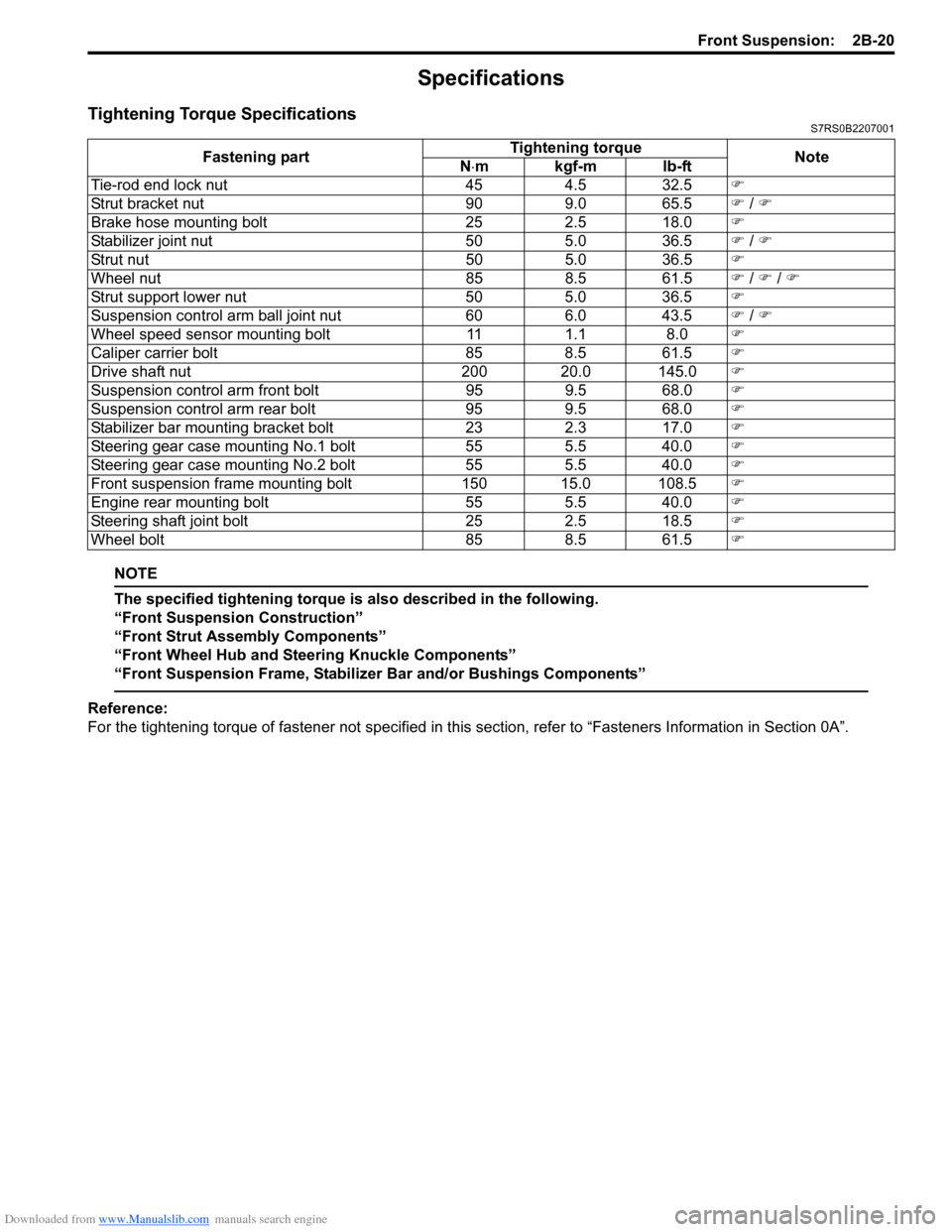

12) Install stabilizer joints (1), and tighten nuts to

specified torque.

When tightening, hold stud with special tools.

Special tool

(A): 09900–00411 socket

(B): 09900–00413 5 mm

Tightening torque

Stabilizer joint nut (a): 50 N·m (5.0 kgf-m, 36.5

lb-ft)

2. Engine rear mounting 3. Suspension frame

(a)

(a)

I4RS0A220048-01

2

3 (a)

I4RS0A220049-01

1

2

I4RS0A220040-01

1 1

(A)

(A)

(a) (a)

(B)

(B)

I4RS0A220051-01

Page 452 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-19 Front Suspension:

13) Install suspension control arm referring to

“Suspension Control Arm / Bushing Removal and

Installation”.

14) Connect couplers of torque sensor and P/S motor.

15) Connect tie-rod ends to knuckles (right & left) and then install cotter pins referring to “Tie-Rod End

Removal and Installa tion in Section 6C”.

16) Be sure that steering wheel and brake discs (right & left) are all straight-ahead position and then insert

steering lower shaft (5) into steering pinion shaft (3)

with matching marks (4).

17) Tighten steering shaft joint lower bolt (1) and upper bolt (2) to specified torque (Lower side first and then

upper side).

Tightening torque

Steering shaft joint bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft)

18) Install both wheels and tighten wheel bolts to specified torque.

Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

19) Lower hoist.

20) Check toe setting. Adjust as required refer to “Front Wheel Alignment Inspection and Adjustment”.

Front Suspension Frame CheckS7RS0B2206016

Inspect for cracks, deformation or damage.

If defective, replace.

Front Stabilizer Bar, Bushing and/or Joint

Check

S7RS0B2206017

Stabilizer Bar

Inspect for damage or deformation.

If defective, replace.

Stabilizer Bushing

Inspect for damage, wear or deterioration.

If defective, replace.

Stabilizer Joint

1) Check for smooth rotation.

2) Check damages of ball stud.

3) Check damages of dust cover.

NOTE

Stabilizer joint (1) cannot be disassembled.

If there is any damage to either parts, stabilizer joint

assembly must be replaced as a complete unit.

Front Suspension Fasteners CheckS7RS0B2206018

Check each bolt and nut fastening suspension parts for

tightness. Tighten loose one, if any, to specified torque,

referring to “Front Suspension Construction”.

5

4

1, (a)

3

2, (a)

1, (a)

5

I4RS0B630016-01

I4RS0A220054-01

I4RS0A220052-01

I4RS0A220056-01

1

I4RH01220007-01

Page 453 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-20

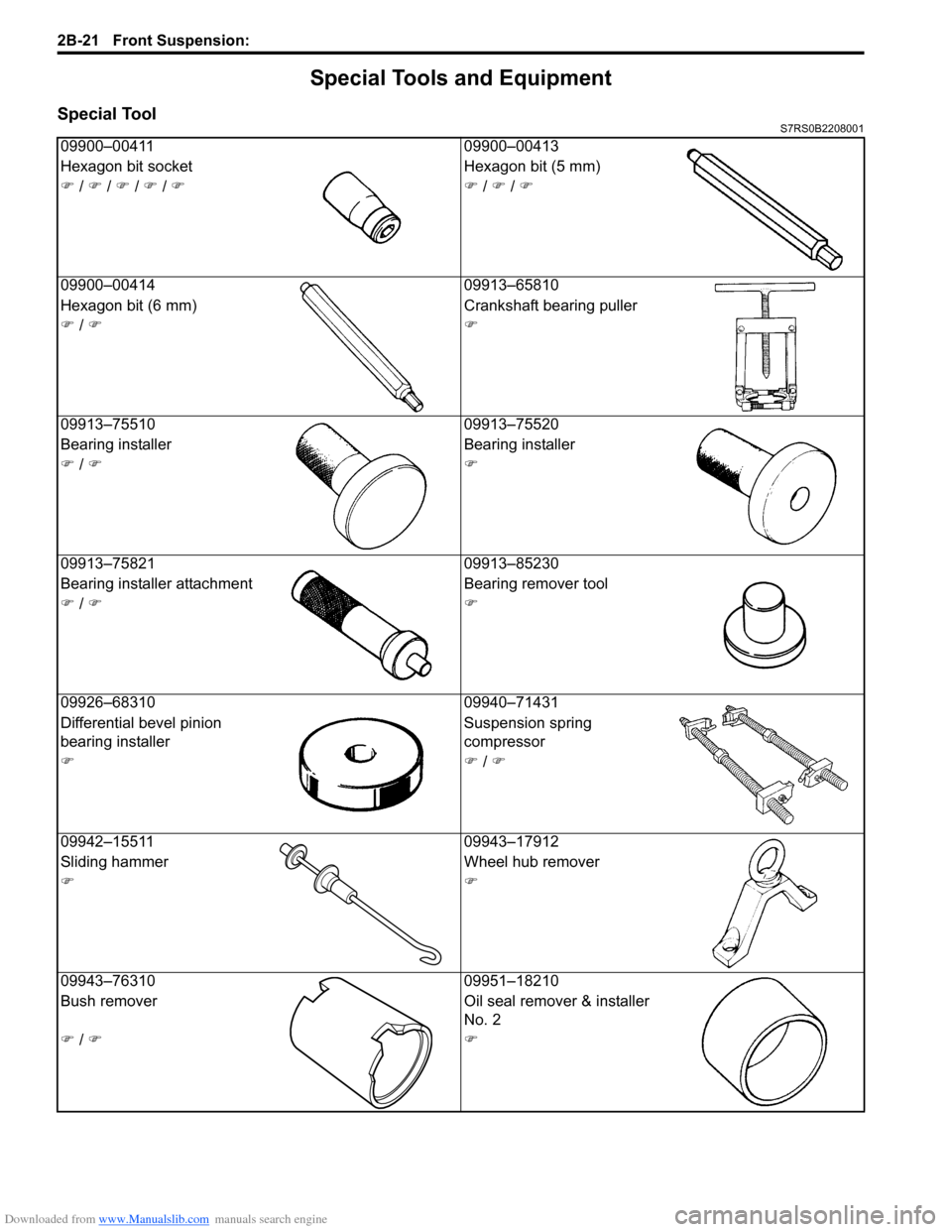

Specifications

Tightening Torque SpecificationsS7RS0B2207001

NOTE

The specified tightening torque is also described in the following.

“Front Suspension Construction”

“Front Strut Assembly Components”

“Front Wheel Hub and Steering Knuckle Components”

“Front Suspension Frame, Stabilizer Bar and/or Bushings Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Tie-rod end lock nut 454.5 32.5 �)

Strut bracket nut 909.0 65.5 �) / �)

Brake hose mounting bolt 252.5 18.0 �)

Stabilizer joint nut 505.0 36.5 �) / �)

Strut nut 505.0 36.5 �)

Wheel nut 858.5 61.5 �) / �) / �)

Strut support lower nut 505.0 36.5 �)

Suspension control arm ball joint nut 606.0 43.5 �) / �)

Wheel speed sensor mounting bolt 111.1 8.0 �)

Caliper carrier bolt 858.5 61.5 �)

Drive shaft nut 200 20.0 145.0�)

Suspension control arm front bolt 959.5 68.0 �)

Suspension control arm rear bolt 959.5 68.0 �)

Stabilizer bar mounting bracket bolt 232.3 17.0 �)

Steering gear case mounting No.1 bolt 555.5 40.0 �)

Steering gear case mounting No.2 bolt 555.5 40.0 �)

Front suspension frame mounting bolt 150 15.0 108.5�)

Engine rear mounting bolt 555.5 40.0 �)

Steering shaft joint bolt 252.5 18.5 �)

Wheel bolt 858.5 61.5 �)

Page 454 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-21 Front Suspension:

Special Tools and Equipment

Special ToolS7RS0B2208001

09900–0041109900–00413

Hexagon bit socket Hexagon bit (5 mm)

�) / �) / �) / �) / �)�) / �) / �)

09900–00414 09913–65810

Hexagon bit (6 mm) Crankshaft bearing puller

�) / �)�)

09913–75510 09913–75520

Bearing installer Bearing installer

�) / �)�)

09913–75821 09913–85230

Bearing installer attachment Bearing remover tool

�) / �)�)

09926–68310 09940–71431

Differential bevel pinion

bearing installer Suspension spring

compressor

�)�) / �)

09942–15511 09943–17912

Sliding hammer Wheel hub remover

�)�)

09943–76310 09951–18210

Bush remover Oil seal remover & installer

No. 2

�) / �)�)

Page 455 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-1

Suspension

Rear Suspension

General Description

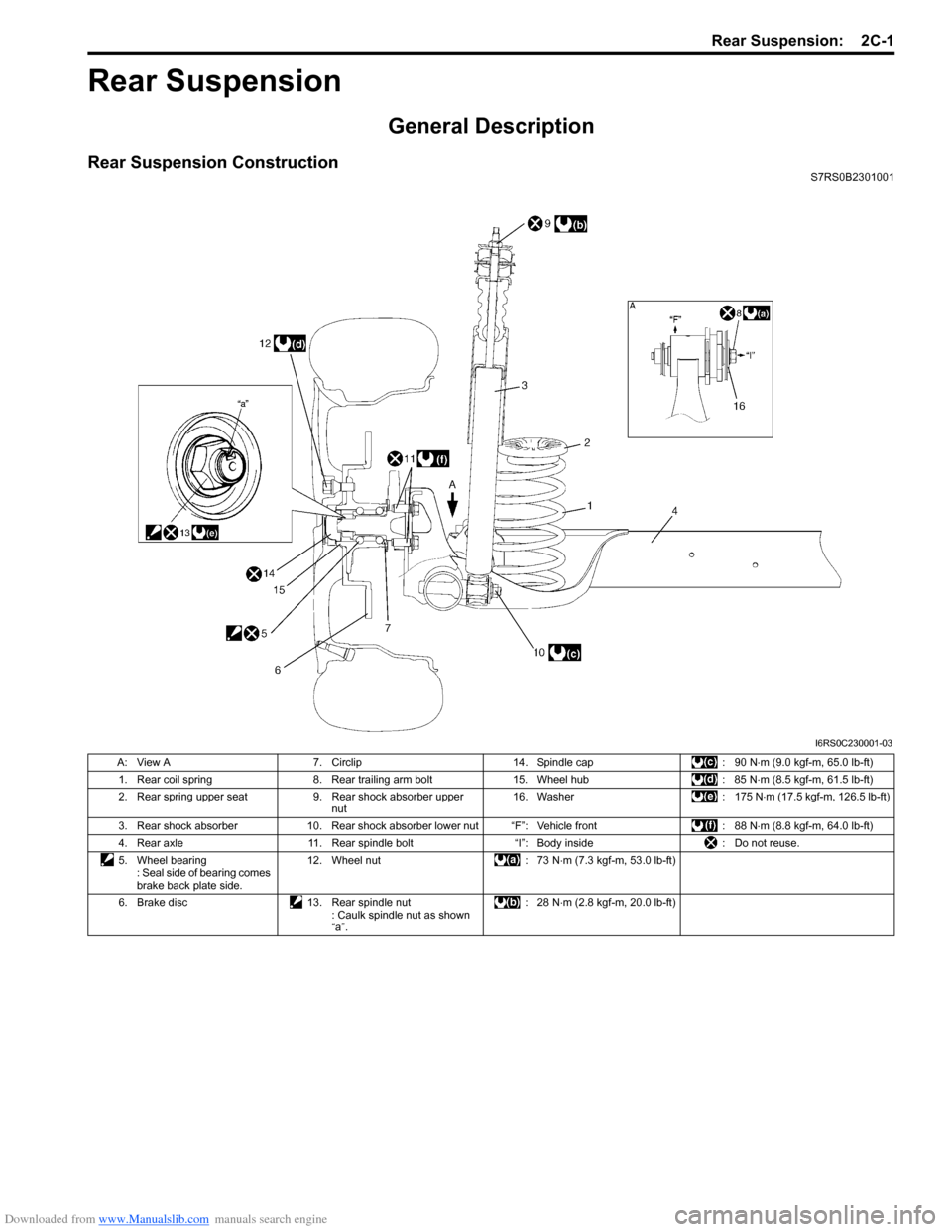

Rear Suspension ConstructionS7RS0B2301001

I6RS0C230001-03

A: View A7. Circlip 14. Spindle cap : 90 N⋅m (9.0 kgf-m, 65.0 lb-ft)

1. Rear coil spring 8. Rear trailing arm bolt 15. Wheel hub : 85 N⋅m (8.5 kgf-m, 61.5 lb-ft)

2. Rear spring upper seat 9. Rear shock absorber upper

nut 16. Washer

: 175 N⋅m (17.5 kgf-m, 126.5 lb-ft)

3. Rear shock absorber 10. Rear shock absorber lower nut “F”: Vehicle front : 88 N⋅m (8.8 kgf-m, 64.0 lb-ft)

4. Rear axle 11. Rear spindle bolt “I”: Body inside : Do not reuse.

5. Wheel bearing : Seal side of bearing comes

brake back plate side. 12. Wheel nut

: 73 N⋅m (7.3 kgf-m, 53.0 lb-ft)

6. Brake disc 13. Rear spindle nut

: Caulk spindle nut as shown

“a”. :28 N

⋅m (2.8 kgf-m, 20.0 lb-ft)

Page 456 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-2 Rear Suspension:

Repair Instructions

Rear Wheel Alignment InspectionS7RS0B2306017

Measure toe and camber referring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

NOTE

Rear suspension is not adjustable structure.

Rear toe (total)

: IN 3.8 ± 3.8 mm (IN 0.1969 ± 0.1969 in)

Rear camber

: –1 ° ± 1

If measured value is out of specified value, check

following items for damage, deformation and crack.

• Rear axle (torsion beam)

• Spindle, wheel hub or wheel bearing

• Vehicle body

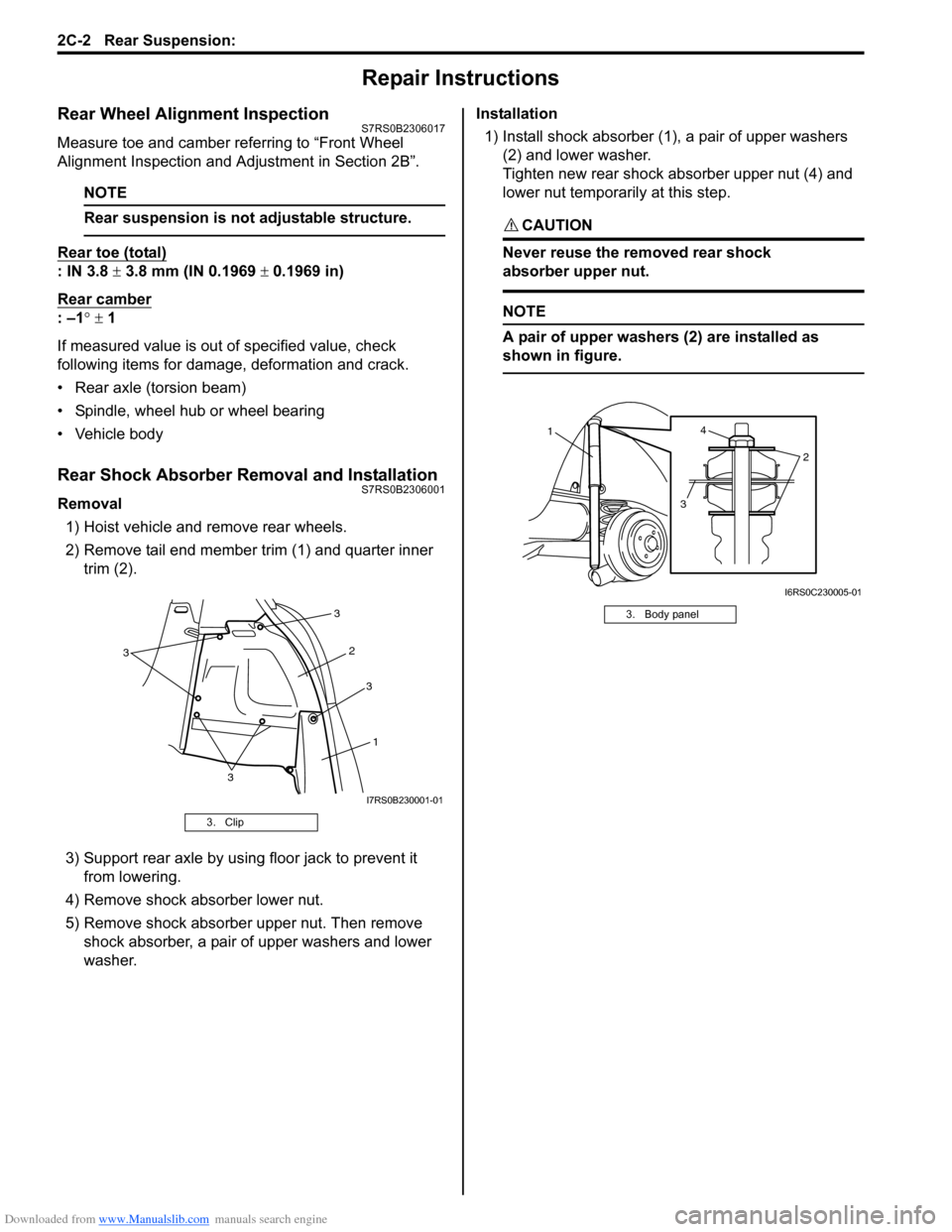

Rear Shock Absorber Removal and InstallationS7RS0B2306001

Removal 1) Hoist vehicle and remove rear wheels.

2) Remove tail end member trim (1) and quarter inner trim (2).

3) Support rear axle by using floor jack to prevent it from lowering.

4) Remove shock absorber lower nut.

5) Remove shock absorber upper nut. Then remove shock absorber, a pair of upper washers and lower

washer. Installation

1) Install shock absorber (1), a pair of upper washers (2) and lower washer.

Tighten new rear shock absorber upper nut (4) and

lower nut temporarily at this step.

CAUTION!

Never reuse the removed rear shock

absorber upper nut.

NOTE

A pair of upper washers (2) are installed as

shown in figure.

3. Clip

3

3 2

3

1

3

I7RS0B230001-01

3. Body panel

14

3 2

I6RS0C230005-01

Page 457 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-3

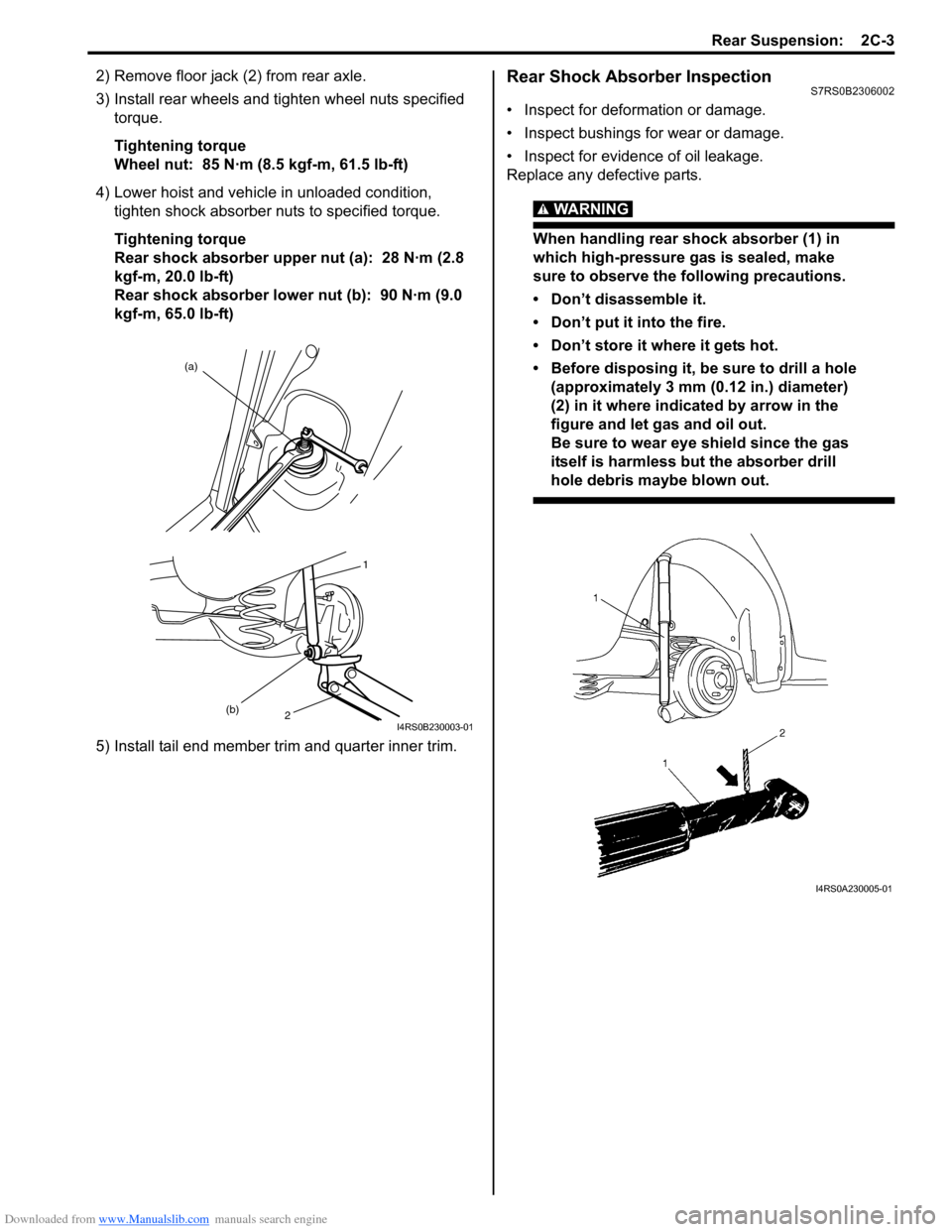

2) Remove floor jack (2) from rear axle.

3) Install rear wheels and tighten wheel nuts specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

4) Lower hoist and vehicle in unloaded condition, tighten shock absorber nuts to specified torque.

Tightening torque

Rear shock absorber upper nut (a): 28 N·m (2.8

kgf-m, 20.0 lb-ft)

Rear shock absorber lower nut (b): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

5) Install tail end member trim and quarter inner trim.Rear Shock Absorber InspectionS7RS0B2306002

• Inspect for deformation or damage.

• Inspect bushings for wear or damage.

• Inspect for evidence of oil leakage.

Replace any defective parts.

WARNING!

When handling rear shock absorber (1) in

which high-pressure gas is sealed, make

sure to observe the following precautions.

• Don’t disassemble it.

• Don’t put it into the fire.

• Don’t store it where it gets hot.

• Before disposing it, be sure to drill a hole (approximately 3 mm (0.12 in.) diameter)

(2) in it where indicated by arrow in the

figure and let gas and oil out.

Be sure to wear eye shield since the gas

itself is harmless but the absorber drill

hole debris maybe blown out.

(a)

1

(b) 2

I4RS0B230003-01

I4RS0A230005-01

Page 458 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-4 Rear Suspension:

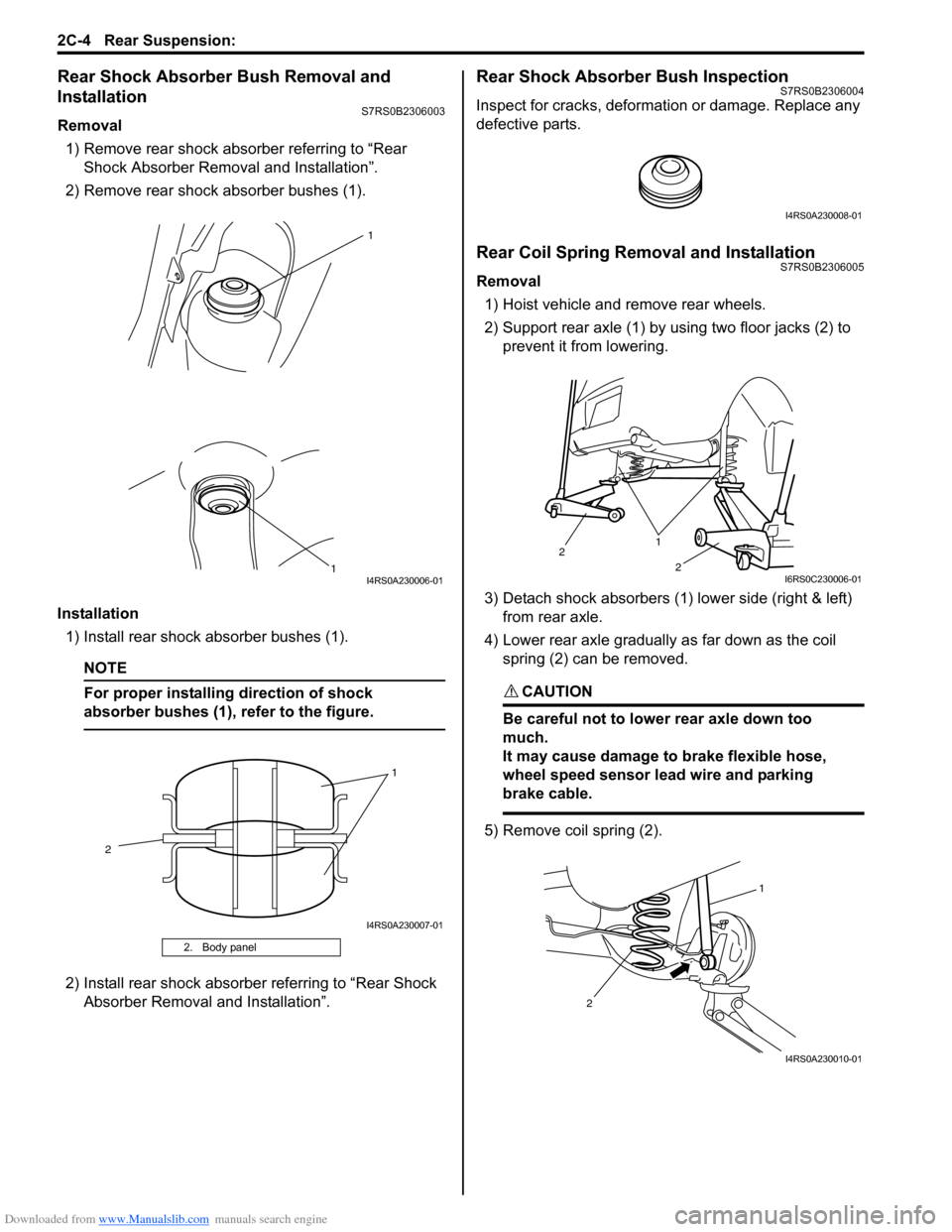

Rear Shock Absorber Bush Removal and

Installation

S7RS0B2306003

Removal1) Remove rear shock absorber referring to “Rear Shock Absorber Remova l and Installation”.

2) Remove rear shock absorber bushes (1).

Installation 1) Install rear shock absorber bushes (1).

NOTE

For proper installing direction of shock

absorber bushes (1), refer to the figure.

2) Install rear shock absorber referring to “Rear Shock Absorber Removal and Installation”.

Rear Shock Absorber Bush InspectionS7RS0B2306004

Inspect for cracks, deformation or damage. Replace any

defective parts.

Rear Coil Spring Removal and InstallationS7RS0B2306005

Removal

1) Hoist vehicle and remove rear wheels.

2) Support rear axle (1) by using two floor jacks (2) to prevent it from lowering.

3) Detach shock absorbers (1) lower side (right & left) from rear axle.

4) Lower rear axle gradually as far down as the coil spring (2) can be removed.

CAUTION!

Be careful not to lowe r rear axle down too

much.

It may cause damage to brake flexible hose,

wheel speed sensor lead wire and parking

brake cable.

5) Remove coil spring (2).

2. Body panel

1

1

I4RS0A230006-01

1

2

I4RS0A230007-01

I4RS0A230008-01

1

2

2

I6RS0C230006-01

1

2

I4RS0A230010-01

Page 459 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-5

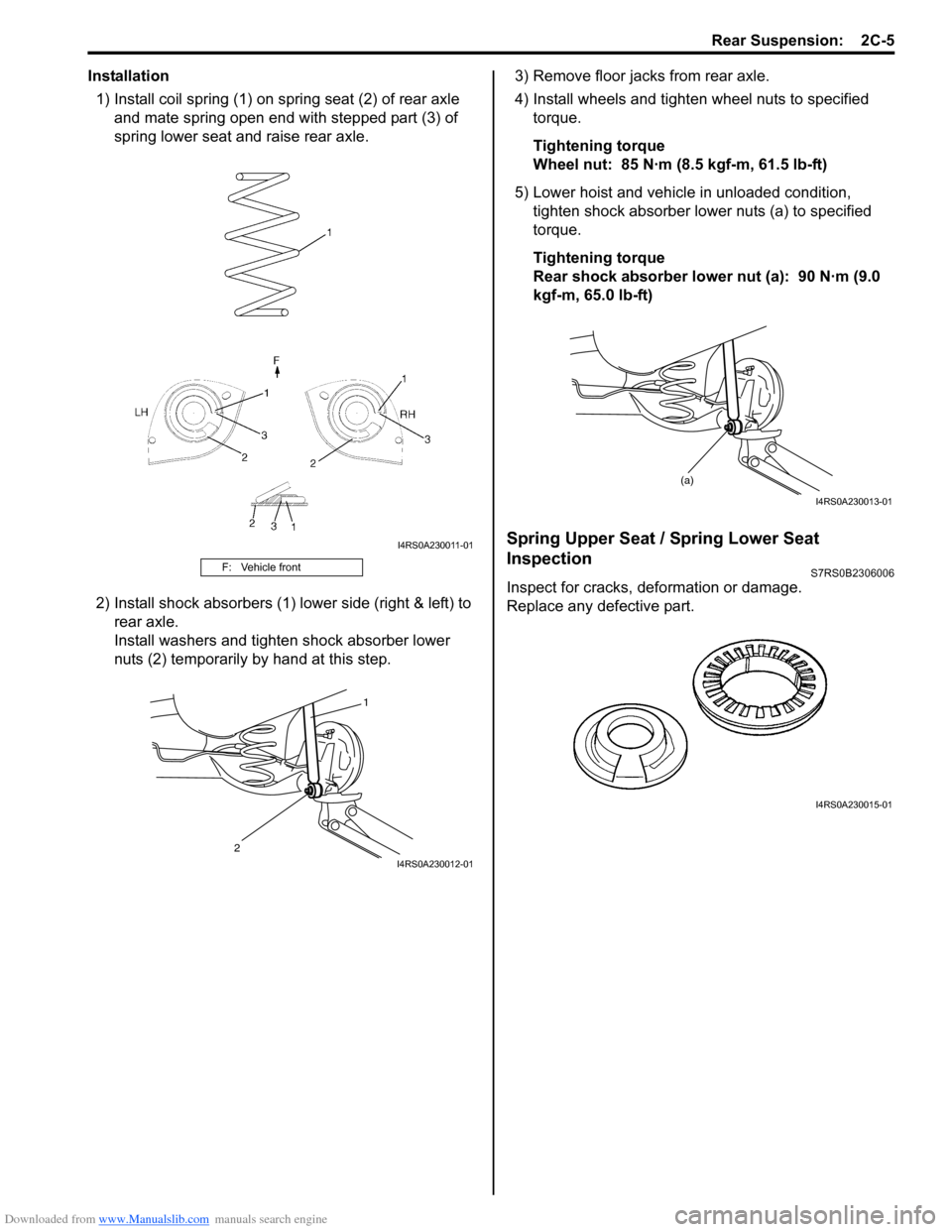

Installation1) Install coil spring (1) on spring seat (2) of rear axle and mate spring open end with stepped part (3) of

spring lower seat and raise rear axle.

2) Install shock absorbers (1) lower side (right & left) to rear axle.

Install washers and tighten shock absorber lower

nuts (2) temporarily by hand at this step. 3) Remove floor jacks from rear axle.

4) Install wheels and tighten wheel nuts to specified

torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

5) Lower hoist and vehicle in unloaded condition, tighten shock absorber lower nuts (a) to specified

torque.

Tightening torque

Rear shock absorber lower nut (a): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

Spring Upper Seat / Spring Lower Seat

Inspection

S7RS0B2306006

Inspect for cracks, deformation or damage.

Replace any defective part.

F: Vehicle front

I4RS0A230011-01

1

2

I4RS0A230012-01

(a)

I4RS0A230013-01

I4RS0A230015-01

Page 460 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-6 Rear Suspension:

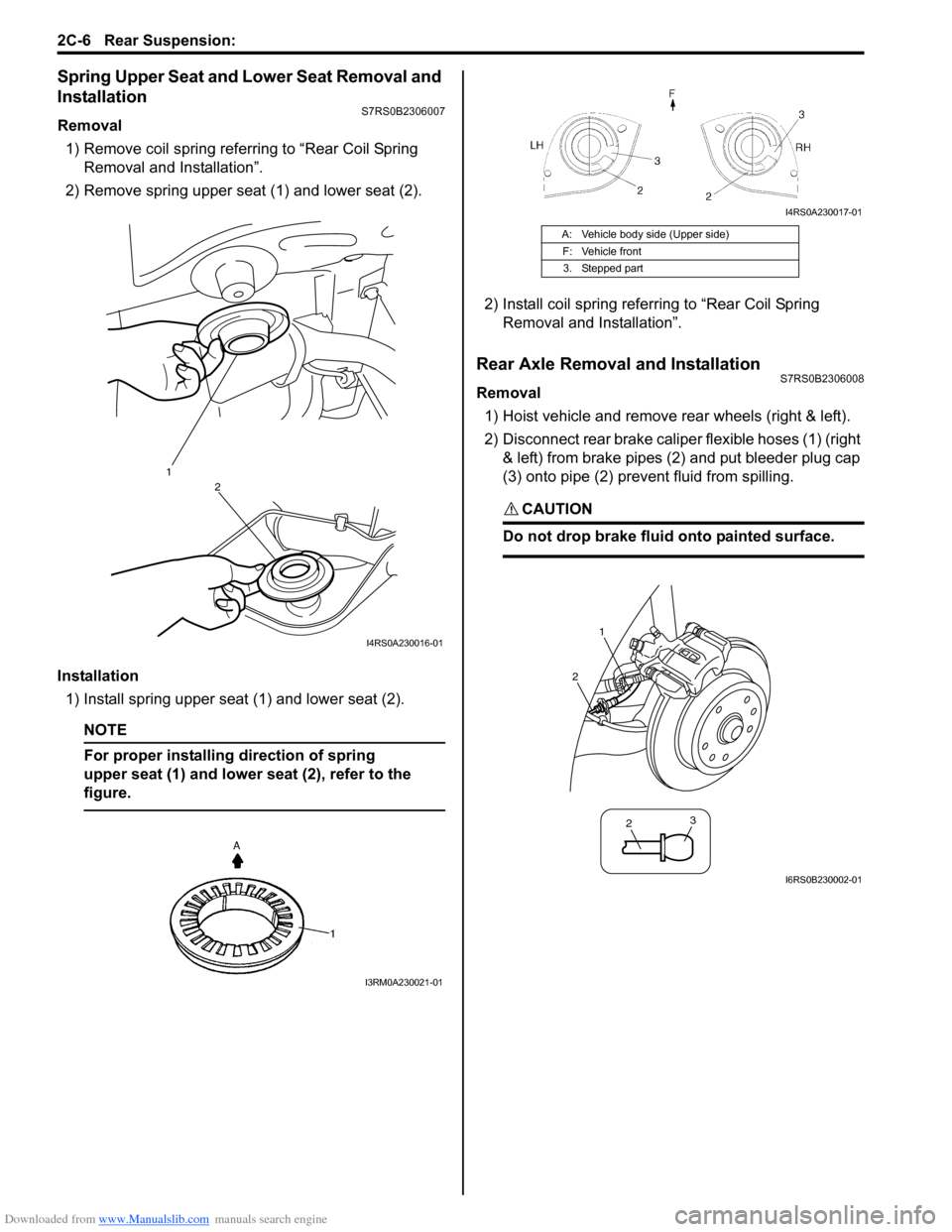

Spring Upper Seat and Lower Seat Removal and

Installation

S7RS0B2306007

Removal1) Remove coil spring referring to “Rear Coil Spring Removal and Installation”.

2) Remove spring upper seat (1) and lower seat (2).

Installation 1) Install spring upper seat (1) and lower seat (2).

NOTE

For proper installing direction of spring

upper seat (1) and lower seat (2), refer to the

figure.

2) Install coil spring referr ing to “Rear Coil Spring

Removal and Installation”.

Rear Axle Removal and InstallationS7RS0B2306008

Removal

1) Hoist vehicle and remove rear wheels (right & left).

2) Disconnect rear brake caliper flexible hoses (1) (right & left) from brake pipes (2) and put bleeder plug cap

(3) onto pipe (2) prevent fluid from spilling.

CAUTION!

Do not drop brake fluid onto painted surface.

1

2

I4RS0A230016-01

I3RM0A230021-01

A: Vehicle body side (Upper side)

F: Vehicle front3. Stepped part

I4RS0A230017-01

1

2

2 3

I6RS0B230002-01