steering wheel control SUZUKI SWIFT 2005 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 595 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-21

Stability control (ACTIVE, INACTIVE): This indicates

stability control in acti vation / deactivation.

TCS control (brake) ( ACTIVE, INACTIVE): This

indicates brake function of TCS in activation /

deactivation.

TCS control (engine) (ACTIVE, INACTIVE): This

indicates torque control of TCS in activation /

deactivation. ESP®

off state (cont) (ESP ® ON, ESP ® OFF): State

of ESP ® OFF switch.

Steering angle Sen (Neutral, NON newtral): This

indicates steering wheel angle measured by steering

angle sensor is in straight-ahead or not.

Visual InspectionS7RS0B4604059

Check the following parts and systems visually.

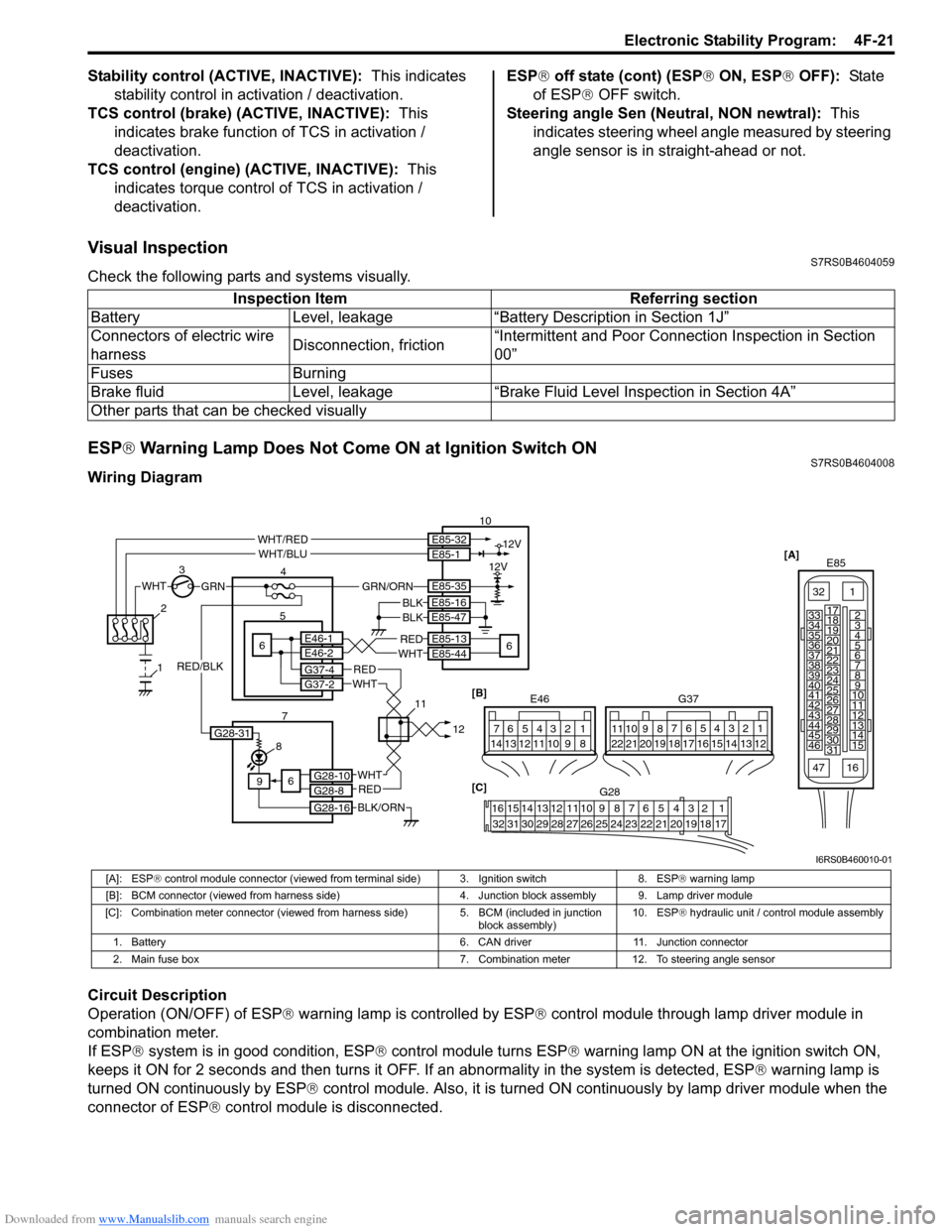

ESP ® Warning Lamp Does Not Come ON at Ignition Switch ONS7RS0B4604008

Wiring Diagram

Circuit Description

Operation (ON/OFF) of ESP ® warning lamp is controlled by ESP ® control module through lamp driver module in

combination meter.

If ESP ® system is in good condition, ESP ® control module turns ESP ® warning lamp ON at the ignition switch ON,

keeps it ON for 2 seconds and then turns it OFF. If an abnormality in the system is detected, ESP ® warning lamp is

turned ON continuously by ESP ® control module. Also, it is turned ON continuously by lamp driver module when the

connector of ESP ® control module is disconnected.Inspection Item Referring section

Battery Level, leakage “Battery Description in Section 1J”

Connectors of electric wire

harness Disconnection, friction“Intermittent and Poor Connec

tion Inspection in Section

00”

Fuses Burning

Brake fluid Level, leakage “Brake Fluid Level Inspection in Section 4A”

Other parts that can be checked visually

[A] E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

WHTGRN

3

E85-13

E85-44REDWHT6 5E46-1E46-2

4 10

6

E85-16

E85-47BLKBLK

8

9

BLK/ORN

REDWHT

REDWHT

G37-4G37-2

G28-10G28-8

G28-16

12V

12VE85-32E85-1

E85-35

WHT/REDWHT/BLU

GRN/ORN

6

2

1

7 1112[B]

G37

E46124

53

67

891011121314124

53

67

891011

1213141516171819202122

[C] G28

12345678910111213141516

17181920212223242526272829303132

G28-31

RED/BLK

I6RS0B460010-01

[A]: ESP ® control module connector (viewed from terminal side) 3. Ignition switch 8. ESP ® warning lamp

[B]: BCM connector (viewed from harness side) 4. Junction block assembly 9. Lamp driver module

[C]: Combination meter connector (viewed from harness side) 5. BCM (included in junction

block assembly) 10. ESP

® hydraulic unit / control module assembly

1. Battery 6. CAN driver 11. Junction connector

2. Main fuse box 7. Combination meter 12. To steering angle sensor

Page 608 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-34 Electronic Stability Program:

DTC C1024: Steering Angle Sensor Circuit FailureS7RS0B4604029

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

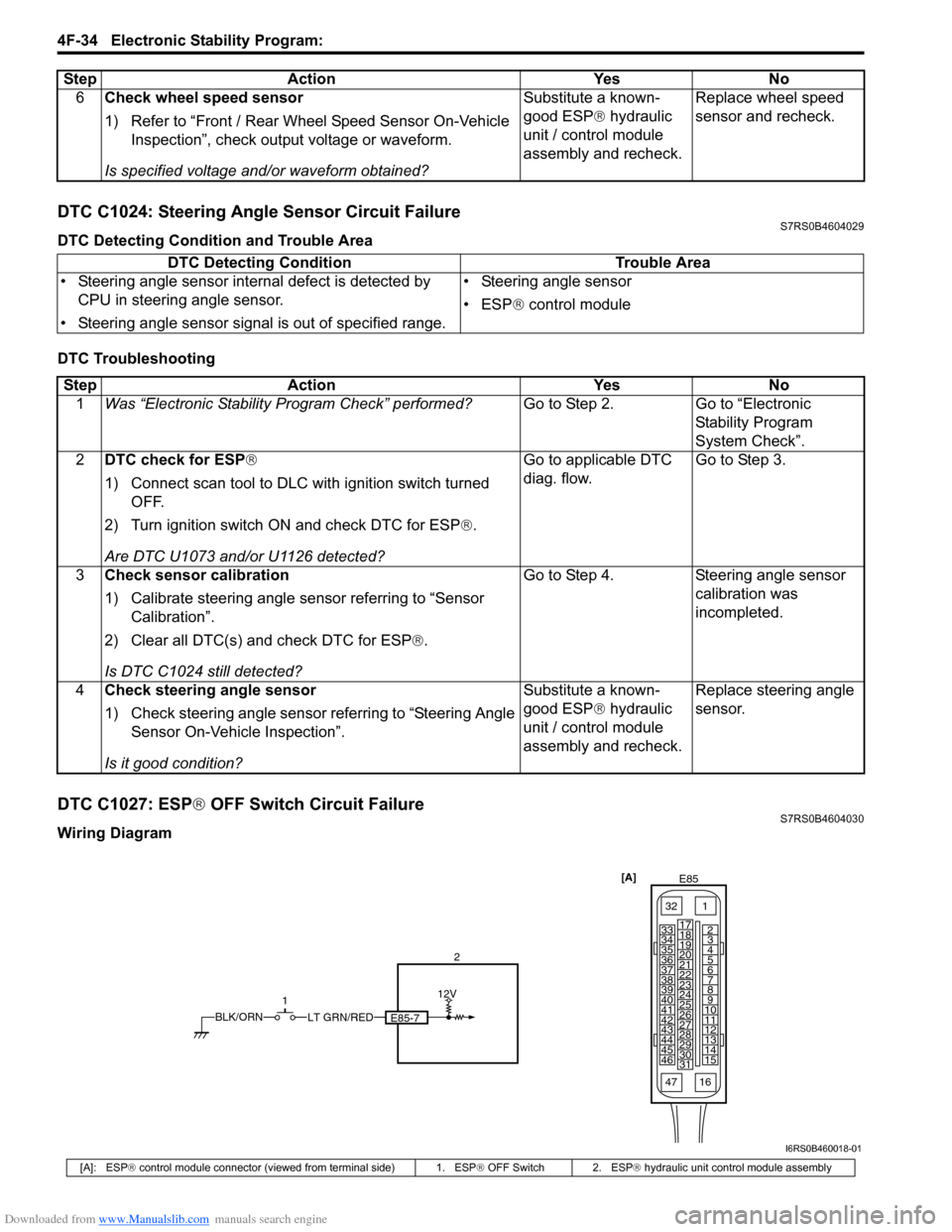

DTC C1027: ESP® OFF Switch Circuit FailureS7RS0B4604030

Wiring Diagram 6

Check wheel speed sensor

1) Refer to “Front / Rear Wheel Speed Sensor On-Vehicle

Inspection”, check output voltage or waveform.

Is specified voltage and/or waveform obtained? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Replace wheel speed

sensor and recheck.

Step

Action YesNo

DTC Detecting Condition Trouble Area

• Steering angle sensor internal defect is detected by CPU in steering angle sensor.

• Steering angle sensor signal is out of specified range. • Steering angle sensor

• ESP

® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC for ESP ®.

Are DTC U1073 and/or U1126 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

3 Check sensor calibration

1) Calibrate steering angle sensor referring to “Sensor

Calibration”.

2) Clear all DTC(s) and check DTC for ESP ®.

Is DTC C1024 still detected? Go to Step 4.

Steering angle sensor

calibration was

incompleted.

4 Check steering angle sensor

1) Check steering angle sensor referring to “Steering Angle

Sensor On-Vehicle Inspection”.

Is it good condition? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Replace steering angle

sensor.

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

LT GRN/REDBLK/ORN

12V

E85-7

1 2

I6RS0B460018-01

[A]: ESP

® control module connector (viewed from terminal side) 1. ESP ® OFF Switch 2. ESP ® hydraulic unit control module assembly

Page 628 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-54 Electronic Stability Program:

Repair Instructions

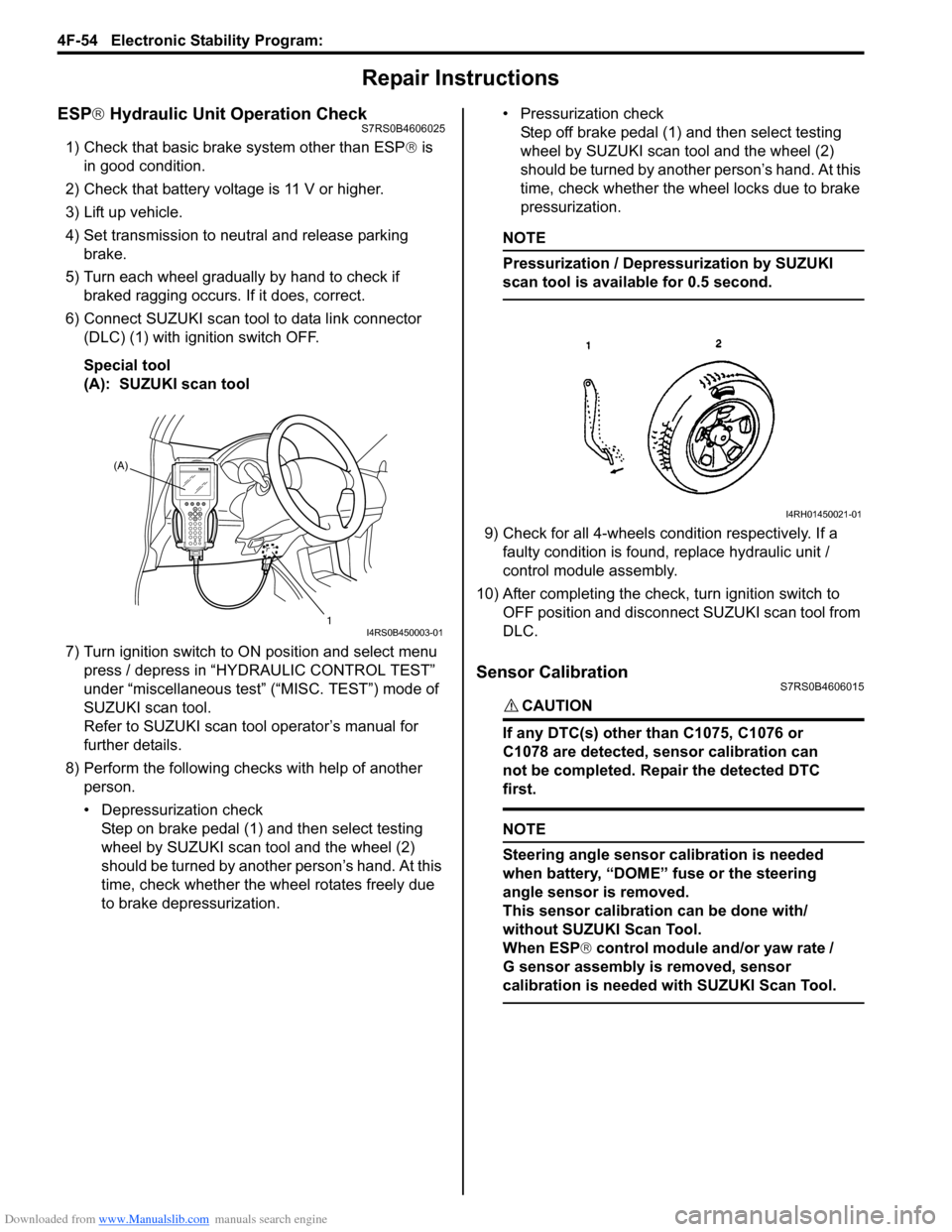

ESP® Hydraulic Unit Operation CheckS7RS0B4606025

1) Check that basic brake system other than ESP ® is

in good condition.

2) Check that battery voltage is 11 V or higher.

3) Lift up vehicle.

4) Set transmission to neutral and release parking brake.

5) Turn each wheel gradually by hand to check if braked ragging occurs. If it does, correct.

6) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

7) Turn ignition switch to ON position and select menu press / depress in “HYDRAULIC CONTROL TEST”

under “miscellaneous test” (“MISC. TEST”) mode of

SUZUKI scan tool.

Refer to SUZUKI scan tool operator’s manual for

further details.

8) Perform the following checks with help of another person.

• Depressurization checkStep on brake pedal (1) and then select testing

wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check whether the wheel rotates freely due

to brake depressurization. • Pressurization check

Step off brake pedal (1) and then select testing

wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check whether the wheel locks due to brake

pressurization.

NOTE

Pressurization / Depressurization by SUZUKI

scan tool is available for 0.5 second.

9) Check for all 4-wheels condition respectively. If a faulty condition is found, replace hydraulic unit /

control module assembly.

10) After completing the check, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

Sensor CalibrationS7RS0B4606015

CAUTION!

If any DTC(s) other than C1075, C1076 or

C1078 are detected, sensor calibration can

not be completed. Repair the detected DTC

first.

NOTE

Steering angle sensor calibration is needed

when battery, “DOME” fuse or the steering

angle sensor is removed.

This sensor calibration can be done with/

without SUZUKI Scan Tool.

When ESP ® control module and/or yaw rate /

G sensor assembly is removed, sensor

calibration is needed with SUZUKI Scan Tool.

(A)

1

I4RS0B450003-01

I4RH01450021-01

Page 629 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-55

Sensor Calibration (Using SUZUKI Scan Tool)1) Set steering wheel in straight-ahead position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position and confirm that

only any of DTC(s) C1075, C1076 and/or C1077 is

detected. If any other DTC are detected, repair the

detected DTC.

4) Park and level the vehicle with parking brake, stop engine with ignition switch ON, set steering in

straight and without step ping on the brake pedal.

NOTE

Hold the above condition in Step 4) to

calibrate sensor correctly until sensor

calibration is completed.

5) Select menu “SENSOR CALIBRATION” under

“MISC. TEST” mode of SUZUKI scan tool and

calibrate sensor. Refer to scan tool operator's

manual for further derails.

6) After completing the calibra tion, turn ignition switch

to OFF position and disconnect SUZUKI scan tool

from DLC. Steering Angle Sensor Calibration (Not Using

SUZUKI Scan Tool)

1) Set steering wheel in straight-ahead position.

2) Connect battery terminals and/or fuse and start engine.

NOTE

When power is not supplied to the steering

angle sensor by removing battery or fuse,

DTC C1075 is detected and SLIP indicator

lamp (1) flashes.

If DTC other than C1075 is detected, SLIP

indicator lamp flushes and other indicator

illuminate. In that case, repair the detected

DTC first.

3) Drive vehicle straight on level ground at 15 km/h (9.5 mph) or above for few seconds without spinning

wheels. And confirm that SLIP indicator lamp is OFF.

ESP ® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection

S7RS0B4606027

CAUTION!

Never disassemble ESP ® hydraulic unit /

control module assembly, loosen blind plug

or remove motor. Pe rforming any of these

prohibited services will affect original

performance of ESP ® hydraulic unit / control

module assembly.

Check hydraulic unit for fluid leakage.

If any, repair or replace.

(A)

1

I4RS0B450003-01

1

I6RS0B460028-02

Page 637 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-63

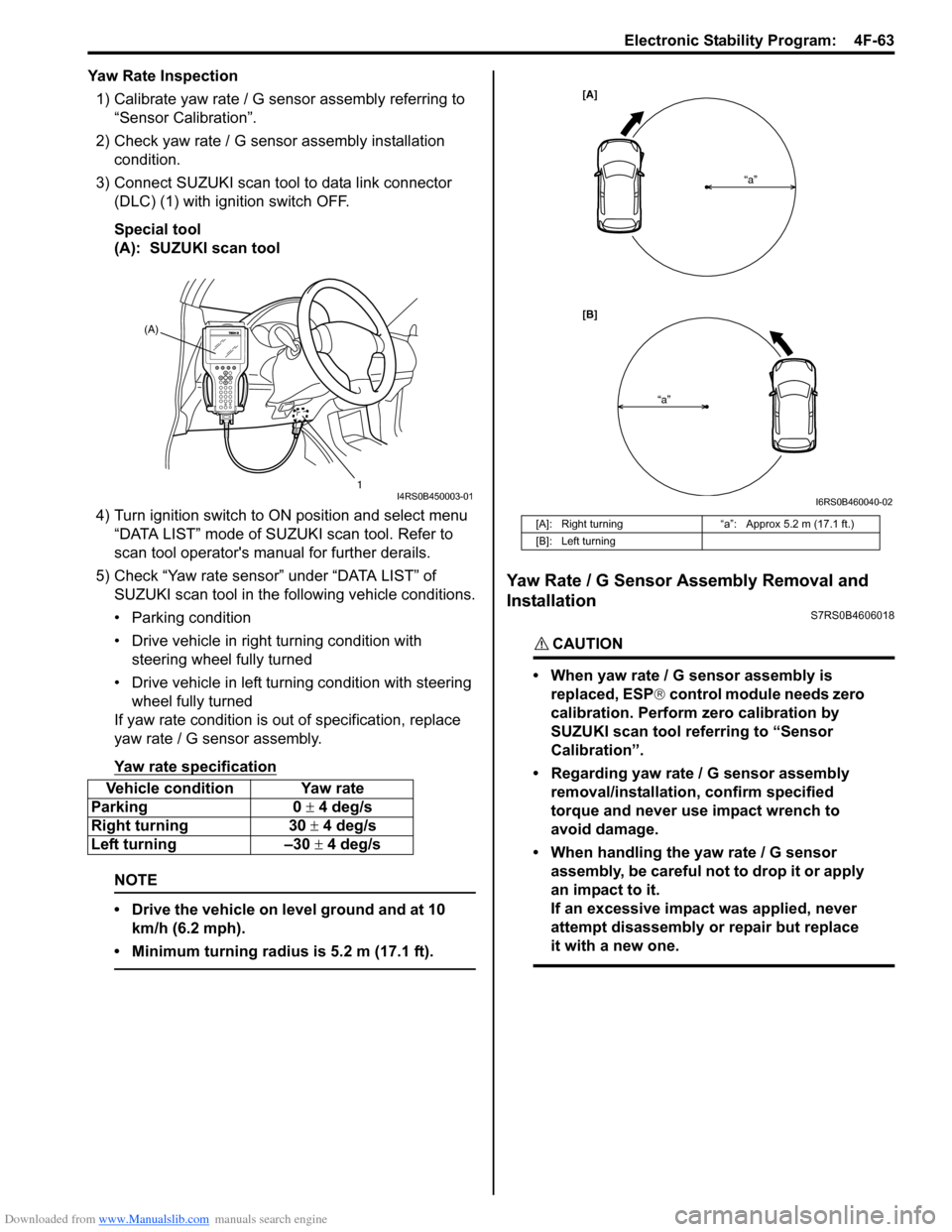

Yaw Rate Inspection1) Calibrate yaw rate / G sens or assembly referring to

“Sensor Calibration”.

2) Check yaw rate / G sensor assembly installation

condition.

3) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

4) Turn ignition switch to ON position and select menu

“DATA LIST” mode of SUZUKI scan tool. Refer to

scan tool operator's manual for further derails.

5) Check “Yaw rate sensor” under “DATA LIST” of SUZUKI scan tool in the following vehicle conditions.

• Parking condition

• Drive vehicle in right turning condition with steering wheel fully turned

• Drive vehicle in left tu rning condition with steering

wheel fully turned

If yaw rate condition is ou t of specification, replace

yaw rate / G sensor assembly.

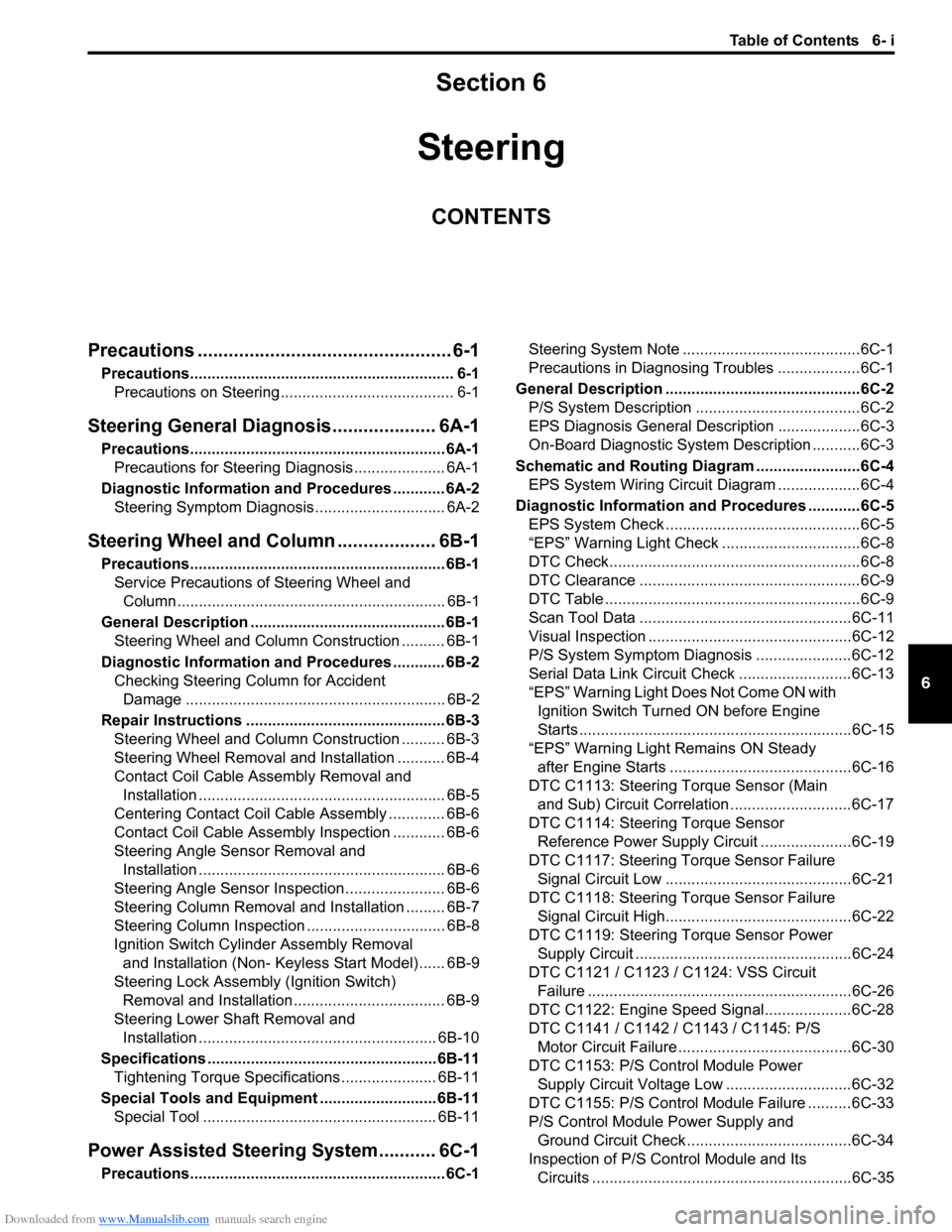

Yaw rate specification

NOTE

• Drive the vehicle on level ground and at 10 km/h (6.2 mph).

• Minimum turning radius is 5.2 m (17.1 ft).

Yaw Rate / G Sensor Assembly Removal and

Installation

S7RS0B4606018

CAUTION!

• When yaw rate / G sensor assembly is replaced, ESP ® control module needs zero

calibration. Perform zero calibration by

SUZUKI scan tool referring to “Sensor

Calibration”.

• Regarding yaw rate / G sensor assembly removal/installation, confirm specified

torque and never use impact wrench to

avoid damage.

• When handling the yaw rate / G sensor assembly, be careful not to drop it or apply

an impact to it.

If an excessive impact was applied, never

attempt disassembly or repair but replace

it with a new one.

Vehicle condition Yaw rate

Parking 0 ± 4 deg/s

Right turning 30 ± 4 deg/s

Left turning –30 ± 4 deg/s

(A)

1

I4RS0B450003-01

[A]: Right turning“a”: Approx 5.2 m (17.1 ft.)

[B]: Left turning

[A]

[B] “a”

“a”

I6RS0B460040-02

Page 867 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 6- i

6

Section 6

CONTENTS

Steering

Precautions ................................................. 6-1

Precautions............................................................. 6-1

Precautions on Steering........................................ 6-1

Steering General Diagnosi s.................... 6A-1

Precautions........................................................... 6A-1

Precautions for Steering Diagnosis ..................... 6A-1

Diagnostic Information and Procedures ............ 6A-2 Steering Symptom Diagnosis .............................. 6A-2

Steering Wheel and Column ................... 6B-1

Precautions........................................................... 6B-1

Service Precautions of Steering Wheel and Column.............................................................. 6B-1

General Description ............................................. 6B-1 Steering Wheel and Column Construction .......... 6B-1

Diagnostic Information and Procedures ............ 6B-2 Checking Steering Column for Accident Damage ............................................................ 6B-2

Repair Instructions .............................................. 6B-3 Steering Wheel and Column Construction .......... 6B-3

Steering Wheel Removal and Installation ........... 6B-4

Contact Coil Cable Assembly Removal and Installation ......................................................... 6B-5

Centering Contact Coil Cable Assembly ............. 6B-6

Contact Coil Cable Assembly Inspection ............ 6B-6

Steering Angle Sensor Removal and Installation ......................................................... 6B-6

Steering Angle Sensor Inspection ....................... 6B-6

Steering Column Removal and Installation ......... 6B-7

Steering Column Inspecti on ................................ 6B-8

Ignition Switch Cylinder Assembly Removal and Installation (Non- Keyless Start Model)...... 6B-9

Steering Lock Assembly (Ignition Switch) Removal and Installation................................... 6B-9

Steering Lower Shaft Removal and Installation ....................................................... 6B-10

Specifications ..................................................... 6B-11

Tightening Torque Specifications ...................... 6B-11

Special Tools and Equipmen t ........................... 6B-11

Special Tool ...................................................... 6B-11

Power Assisted Steering System........... 6C-1

Precautions........................................................... 6C-1 Steering System Note .........................................6C-1

Precautions in Diagnosing Troubles ...................6C-1

General Description .............................................6C-2 P/S System Description ......................................6C-2

EPS Diagnosis General Descr iption ...................6C-3

On-Board Diagnostic System Description ...........6C-3

Schematic and Routing Diagram ........................6C-4 EPS System Wiring Circuit Diagram ...................6C-4

Diagnostic Information and Procedures ............6C-5 EPS System Check .............. ...............................6C-5

“EPS” Warning Light Check . ...............................6C-8

DTC Check..........................................................6C-8

DTC Clearance ...................................................6C-9

DTC Table ...........................................................6C-9

Scan Tool Data .................................................6C-11

Visual Inspection ...............................................6C-12

P/S System Symptom Diagnosis ......................6C-12

Serial Data Link Circuit Check ..........................6C-13

“EPS” Warning Light Do es Not Come ON with

Ignition Switch Turn ed ON before Engine

Starts ...............................................................6C-15

“EPS” Warning Light Remains ON Steady after Engine Starts ..........................................6C-16

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit Correlation ............................6C-17

DTC C1114: Steering Torque Sensor Reference Power Supply Circuit .....................6C-19

DTC C1117: Steering Torque Sensor Failure Signal Circuit Low ...........................................6C-21

DTC C1118: Steering Torque Sensor Failure Signal Circuit High...........................................6C-22

DTC C1119: Steering Torque Sensor Power Supply Circuit ..................................................6C-24

DTC C1121 / C1123 / C1124: VSS Circuit

Failure .............................................................6C-26

DTC C1122: Engine Speed Signal....................6C-28

DTC C1141 / C1142 / C1143 / C1145: P/S Motor Circuit Failure ........................................6C-30

DTC C1153: P/S Control Module Power Supply Circuit Voltage Low .............................6C-32

DTC C1155: P/S Control Module Failure ..........6C-33

P/S Control Module Power Supply and Ground Circuit Check ......................................6C-34

Inspection of P/S Control Module and Its Circuits ............................................................6C-35

Page 868 of 1496

Downloaded from www.Manualslib.com manuals search engine 6-ii Table of Contents

Steering Wheel Play Check ..............................6C-39

Steering Force Check .......................................6C-39

Repair Instructions ........... .................................6C-40

Steering Gear Case Assembly Components ....6C-40

Tie-Rod End Boot On-Vehic le Inspection .........6C-41

Tie-Rod End Removal and Installation..............6C-41

Tie-Rod End Inspection.....................................6C-42

Steering Shaft Joint On-Vehicle Inspection.......6C-42

Steering Gear Case Assembly Removal and Installation .......................................................6C-42

Steering Rack Boot Inspec tion ..........................6C-43

Tie-Rod / Rack Boot Removal and Installation ..6C-43 Steering Rack Plunger Removal and

Installation .......................................................6C-45

Steering Rack Plunger Inspection .....................6C-45

P/S Control Module Removal and Installation...6C-46

Torque Sensor and Its Circuit Inspection ..........6C-46

P/S Motor and Its Circuit Inspection ..................6C-47

Specifications ..................... ................................6C-48

Tightening Torque Specifications ......................6C-48

Special Tools and Equipmen t ...........................6C-49

Recommended Service Material .......................6C-49

Special Tool ......................................................6C-49

Page 871 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering General Diagnosis: 6A-2

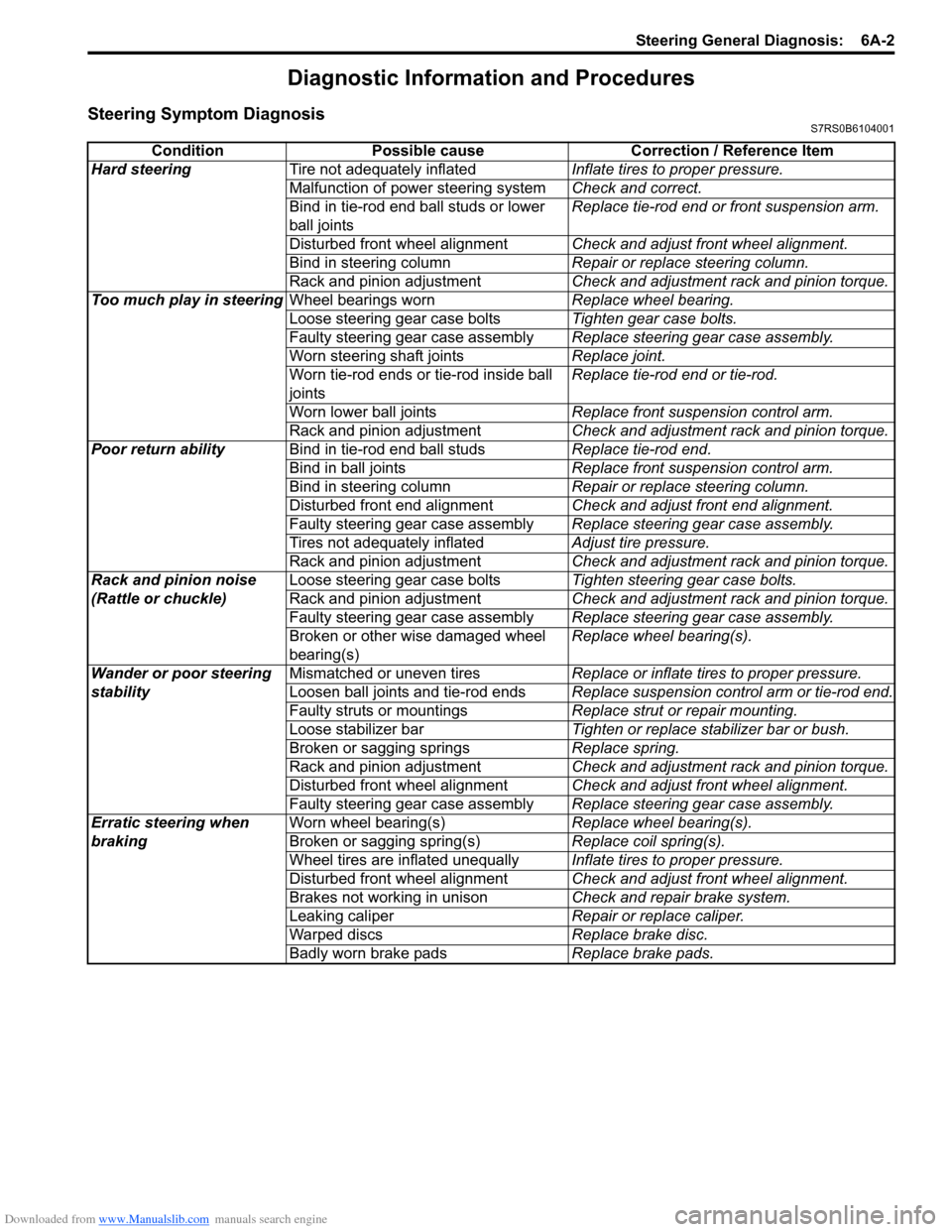

Diagnostic Information and Procedures

Steering Symptom DiagnosisS7RS0B6104001

ConditionPossible cause Correction / Reference Item

Hard steering Tire not adequately inflated Inflate tires to proper pressure.

Malfunction of power steering system Check and correct.

Bind in tie-rod end ball studs or lower

ball joints Replace tie-rod end or front suspension arm.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Bind in steering column Repair or replace steering column.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Too much play in steering Wheel bearings worn Replace wheel bearing.

Loose steering gear case bolts Tighten gear case bolts.

Faulty steering gear case assembly Replace steering gear case assembly.

Worn steering shaft joints Replace joint.

Worn tie-rod ends or tie-rod inside ball

joints Replace tie-rod end or tie-rod.

Worn lower ball joints Replace front suspension control arm.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Poor return ability Bind in tie-rod end ball studs Replace tie-rod end.

Bind in ball joints Replace front suspension control arm.

Bind in steering column Repair or replace steering column.

Disturbed front end alignment Check and adjust front end alignment.

Faulty steering gear case assembly Replace steering gear case assembly.

Tires not adequately inflated Adjust tire pressure.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Rack and pinion noise

(Rattle or chuckle) Loose steering gear case bolts

Tighten steering gear case bolts.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Faulty steering gear case assembly Replace steering gear case assembly.

Broken or other wise damaged wheel

bearing(s) Replace wheel bearing(s).

Wander or poor steering

stability Mismatched or uneven tires

Replace or inflate tires to proper pressure.

Loosen ball joints and tie-rod ends Replace suspension control arm or tie-rod end.

Faulty struts or mountings Replace strut or repair mounting.

Loose stabilizer bar Tighten or replace stabilizer bar or bush.

Broken or sagging springs Replace spring.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Faulty steering gear case assembly Replace steering gear case assembly.

Erratic steering when

braking Worn wheel bearing(s)

Replace wheel bearing(s).

Broken or sagging spring(s) Replace coil spring(s).

Wheel tires are inflated unequally Inflate tires to proper pressure.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Brakes not working in unison Check and repair brake system.

Leaking caliper Repair or replace caliper.

Warped discs Replace brake disc.

Badly worn brake pads Replace brake pads.

Page 874 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-3 Steering Wheel and Column:

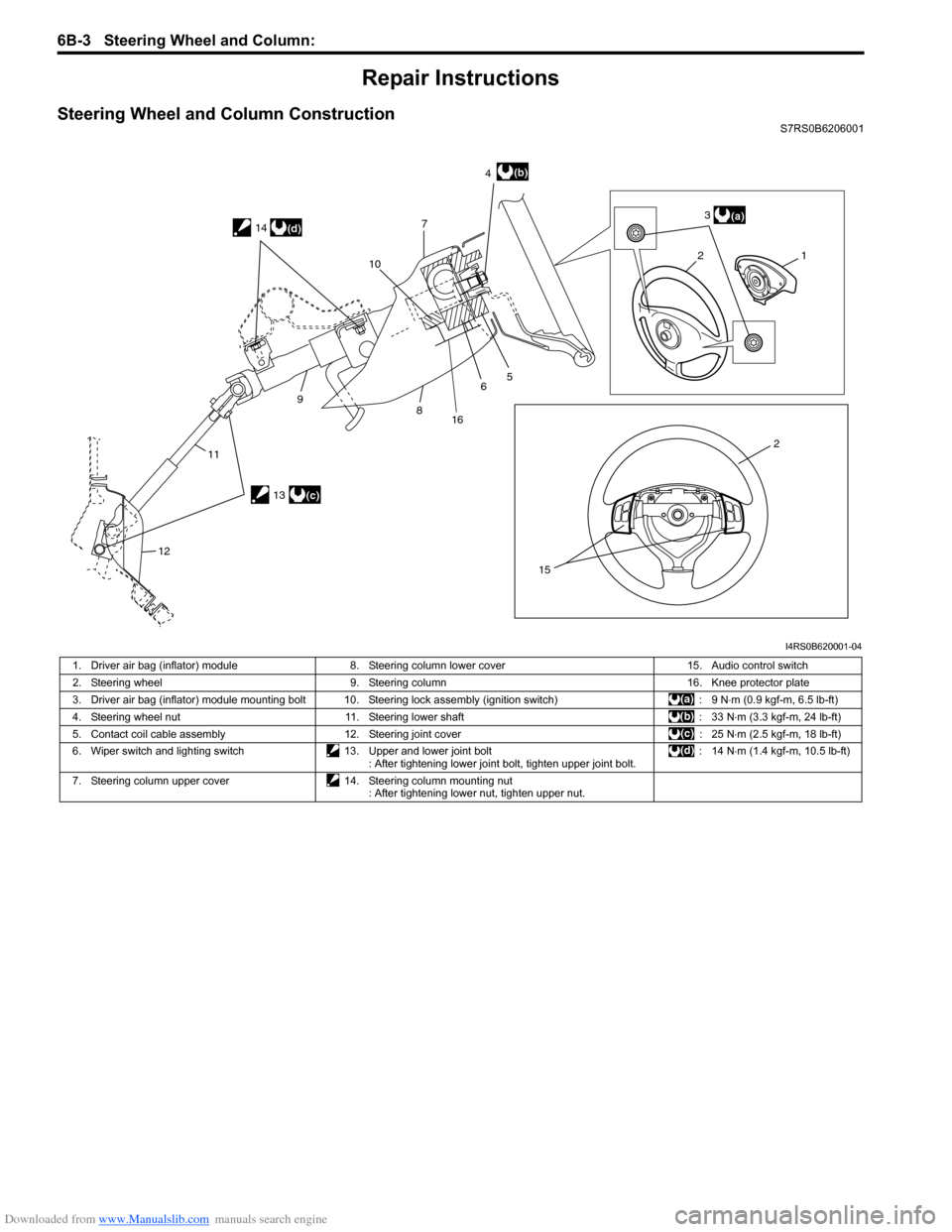

Repair Instructions

Steering Wheel and Column ConstructionS7RS0B6206001

21

2 3

4

7

5

6

8

9

11

12 10

15

(a)

(b)

13(c)

14

(d)

16

I4RS0B620001-04

1. Driver air bag (inflator) module

8. Steering column lower cover 15. Audio control switch

2. Steering wheel 9. Steering column 16. Knee protector plate

3. Driver air bag (inflator) module mounting bolt 10. Steering lock assembly (ignition switch) : 9 N⋅m (0.9 kgf-m, 6.5 lb-ft)

4. Steering wheel nut 11. Steering lower shaft : 33 N⋅m (3.3 kgf-m, 24 lb-ft)

5. Contact coil cable assembly 12. Steering joint cover : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

6. Wiper switch and lighting switch 13. Upper and lower joint bolt

: After tightening lower joint bolt, tighten upper joint bolt. : 14 N

⋅m (1.4 kgf-m, 10.5 lb-ft)

7. Steering column upper cover 14. Steering column mounting nut

: After tightening lower nut, tighten upper nut.

Page 875 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-4

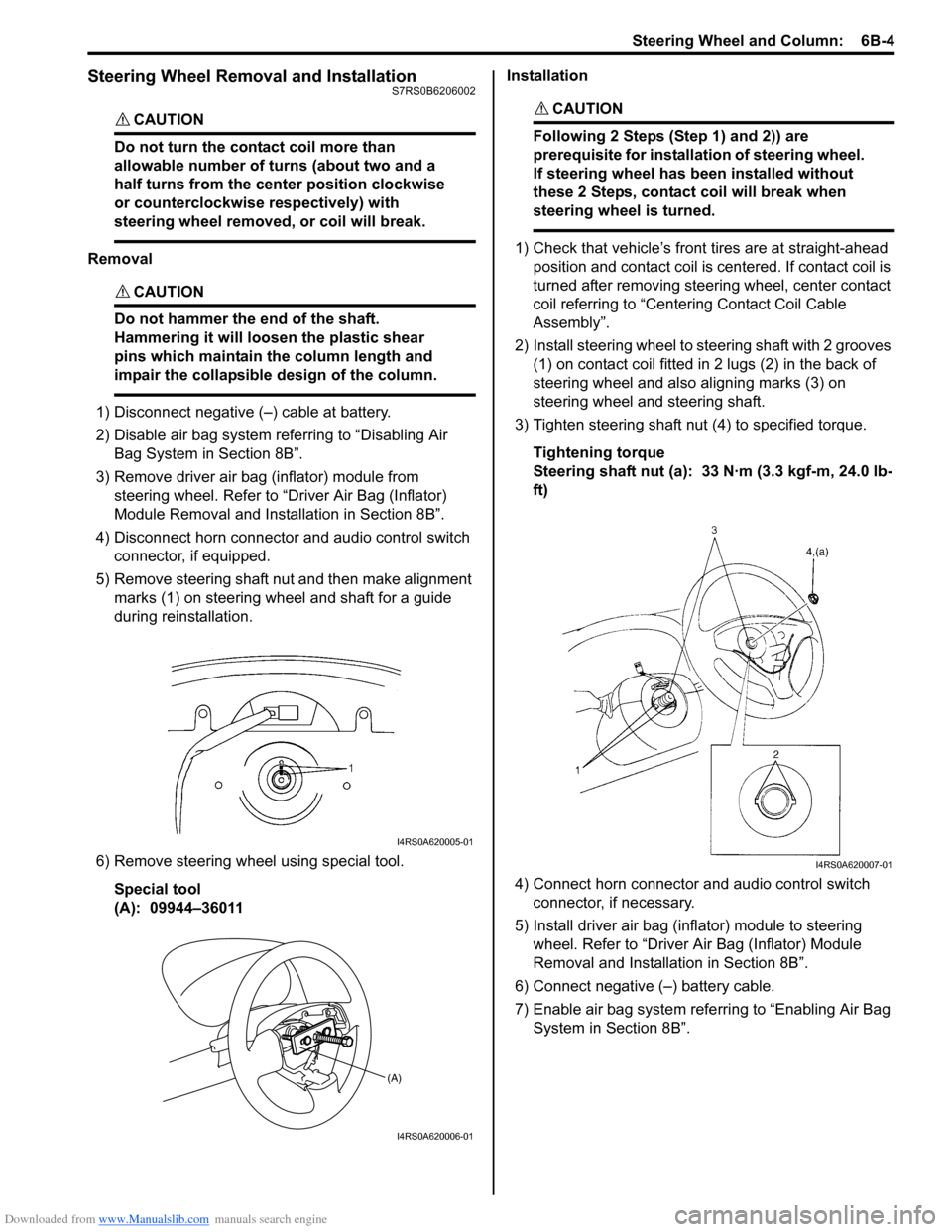

Steering Wheel Removal and InstallationS7RS0B6206002

CAUTION!

Do not turn the contact coil more than

allowable number of turns (about two and a

half turns from the center position clockwise

or counterclockwise respectively) with

steering wheel removed, or coil will break.

Removal

CAUTION!

Do not hammer the end of the shaft.

Hammering it will loosen the plastic shear

pins which maintain the column length and

impair the collapsible design of the column.

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove driver air bag (inflator) module from steering wheel. Refer to “Driver Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Disconnect horn connector and audio control switch connector, if equipped.

5) Remove steering shaft nut and then make alignment marks (1) on steering wheel and shaft for a guide

during reinstallation.

6) Remove steering wheel using special tool. Special tool

(A): 09944–36011 Installation

CAUTION!

Following 2 Steps (Step 1) and 2)) are

prerequisite for installation of steering wheel.

If steering wheel has

been installed without

these 2 Steps, contact coil will break when

steering wheel is turned.

1) Check that vehicle’s front tires are at straight-ahead position and contact coil is centered. If contact coil is

turned after removing steering wheel, center contact

coil referring to “Centering Contact Coil Cable

Assembly”.

2) Install steering wheel to steering shaft with 2 grooves (1) on contact coil fitted in 2 lugs (2) in the back of

steering wheel and also aligning marks (3) on

steering wheel and steering shaft.

3) Tighten steering shaft nut (4) to specified torque.

Tightening torque

Steering shaft nut (a): 33 N·m (3.3 kgf-m, 24.0 lb-

ft)

4) Connect horn connector and audio control switch connector, if necessary.

5) Install driver air bag (inflator) module to steering wheel. Refer to “Driver Air Bag (Inflator) Module

Removal and Installati on in Section 8B”.

6) Connect negative (–) battery cable.

7) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

I4RS0A620005-01

(A)

I4RS0A620006-01

I4RS0A620007-01