Automatic transaxle fluid SUZUKI SWIFT 2005 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 755 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-111

8) Remove fluid cooler pipes (1) and pipe union (2).

9) Remove fluid level gauge (3) and fluid filler tube (4).

10) Remove oil pan (1) and oil pan gasket (2).

NOTE

• For removal of oil pan, do not turn transaxle over as this will contaminate

valve body with foreign materials in

bottom of oil pan.

• When removing oil pan, tap around it lightly with plastic ha mmer. Do not force it

off by using screwdriver or the like.

11) Remove oil strain er assembly (1). 12) Disconnect connectors (2) from solenoid valves and

transmission fluid temperature sensor (1).

13) Remove valve body assembly bolts.

CAUTION!

Be careful not to let manual valve fall off

when removing valve body assembly.

NOTE

There are five kinds of bolts (bolts A (1), B (2),

C (3), D (4) and E (5)) fixing valve body

assembly.

14) Remove manual valve rod (1) from manual valve lever (2), then remove valve body assembly (3).

1 2

4

3

I3RM0B510059-01

I2RH0B510086-01

I2RH0B510087-01

1 2I4RS0A510027-01

I2RH0B510089-01

I2RH0B510090-01

Page 756 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-112 Automatic Transmission/Transaxle:

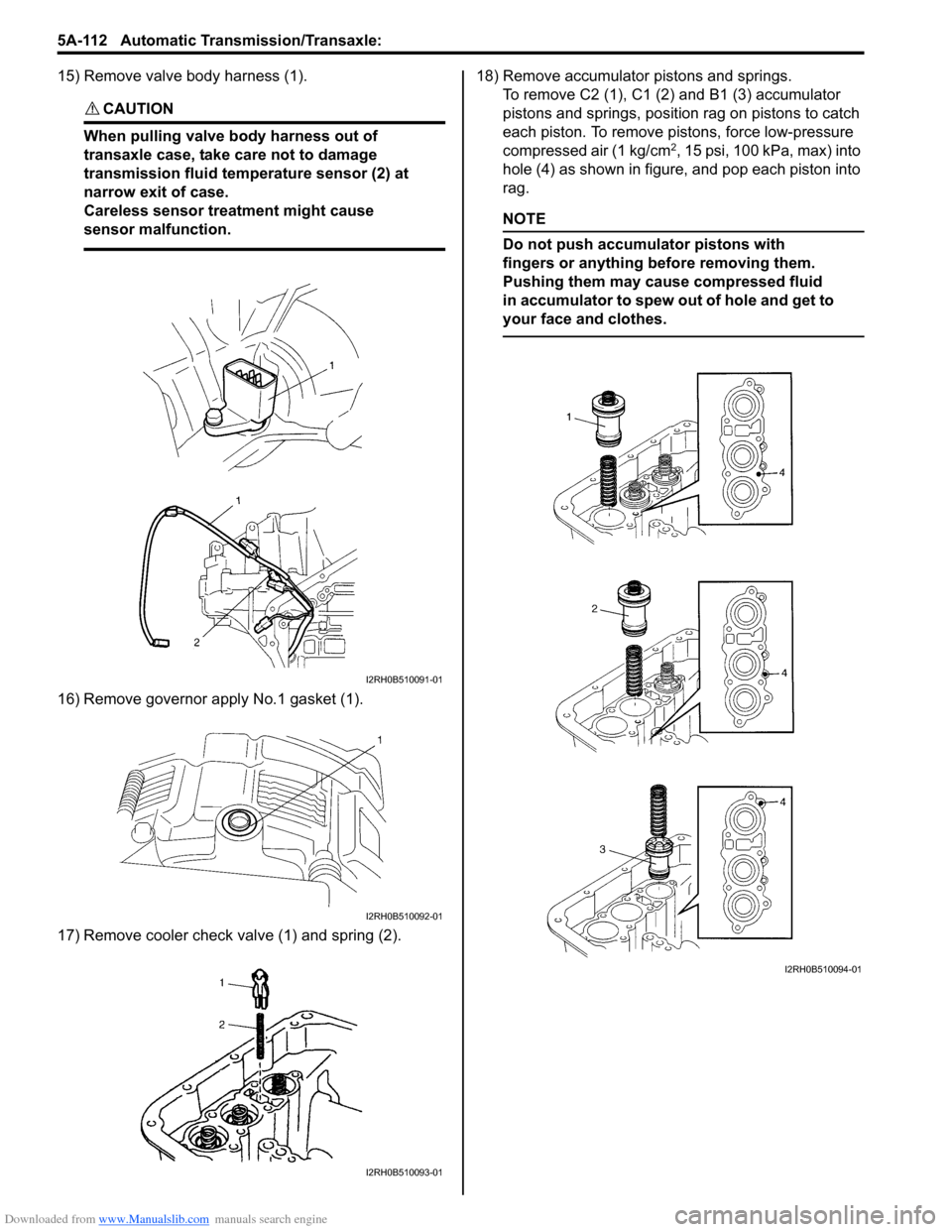

15) Remove valve body harness (1).

CAUTION!

When pulling valve body harness out of

transaxle case, take care not to damage

transmission fluid temperature sensor (2) at

narrow exit of case.

Careless sensor treatment might cause

sensor malfunction.

16) Remove governor apply No.1 gasket (1).

17) Remove cooler check valve (1) and spring (2).18) Remove accumulator pistons and springs.

To remove C2 (1), C1 (2) and B1 (3) accumulator

pistons and springs, position rag on pistons to catch

each piston. To remove pistons, force low-pressure

compressed air (1 kg/cm

2, 15 psi, 100 kPa, max) into

hole (4) as shown in figure, and pop each piston into

rag.

NOTE

Do not push accumulator pistons with

fingers or anything before removing them.

Pushing them may cause compressed fluid

in accumulator to spew out of hole and get to

your face and clothes.

I2RH0B510091-01

I2RH0B510092-01

I2RH0B510093-01

I2RH0B510094-01

Page 758 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-114 Automatic Transmission/Transaxle:

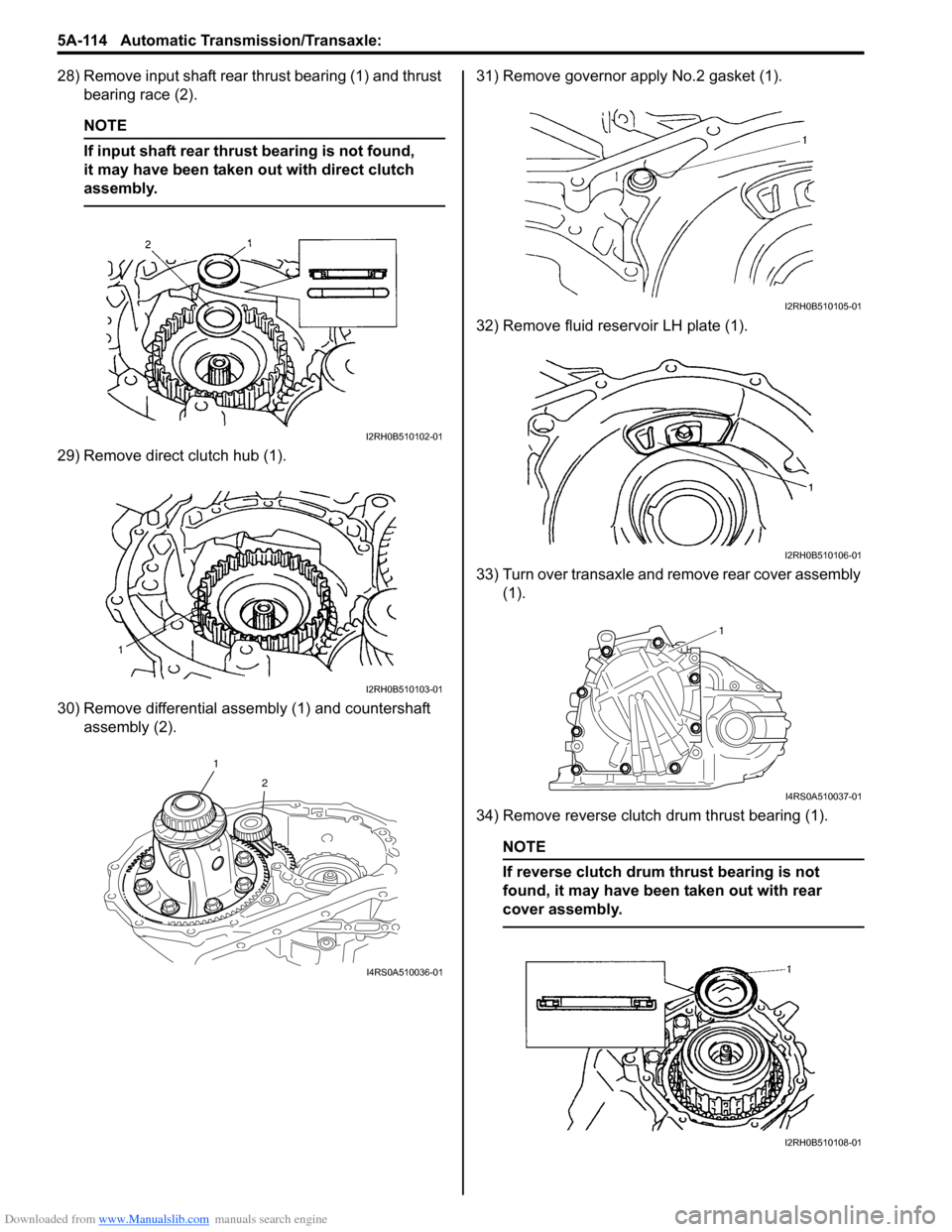

28) Remove input shaft rear thrust bearing (1) and thrust bearing race (2).

NOTE

If input shaft rear thrust bearing is not found,

it may have been taken out with direct clutch

assembly.

29) Remove direct clutch hub (1).

30) Remove differential assembly (1) and countershaft assembly (2). 31) Remove governor apply No.2 gasket (1).

32) Remove fluid reservoir LH plate (1).

33) Turn over transaxle and remove rear cover assembly

(1).

34) Remove reverse clutch drum thrust bearing (1).

NOTE

If reverse clutch drum thrust bearing is not

found, it may have been taken out with rear

cover assembly.

I2RH0B510102-01

I2RH0B510103-01

1 2

I4RS0A510036-01

I2RH0B510105-01

I2RH0B510106-01

1

I4RS0A510037-01

I2RH0B510108-01

Page 765 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-121

74) Remove manual detent spring (1).75) Remove manual shift shaft oil seal (1).

Oil Pump Assembly ComponentsS7RS0B5106034

I2RH0B510146-01I2RH0B510147-01

I2RH0B510148-01

1. Oil seal

: Apply grease 99000-25030 to oil seal lip. 5. Oil pump drive gear : Apply automatic transaxle fluid.

2. O-ring 6. Stator shaft assembly : Tightening torque

3. Oil pump body 7. Oil pump subassembly bolts : Do not reuse.

4. Oil pump driven gear

Page 766 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-122 Automatic Transmission/Transaxle:

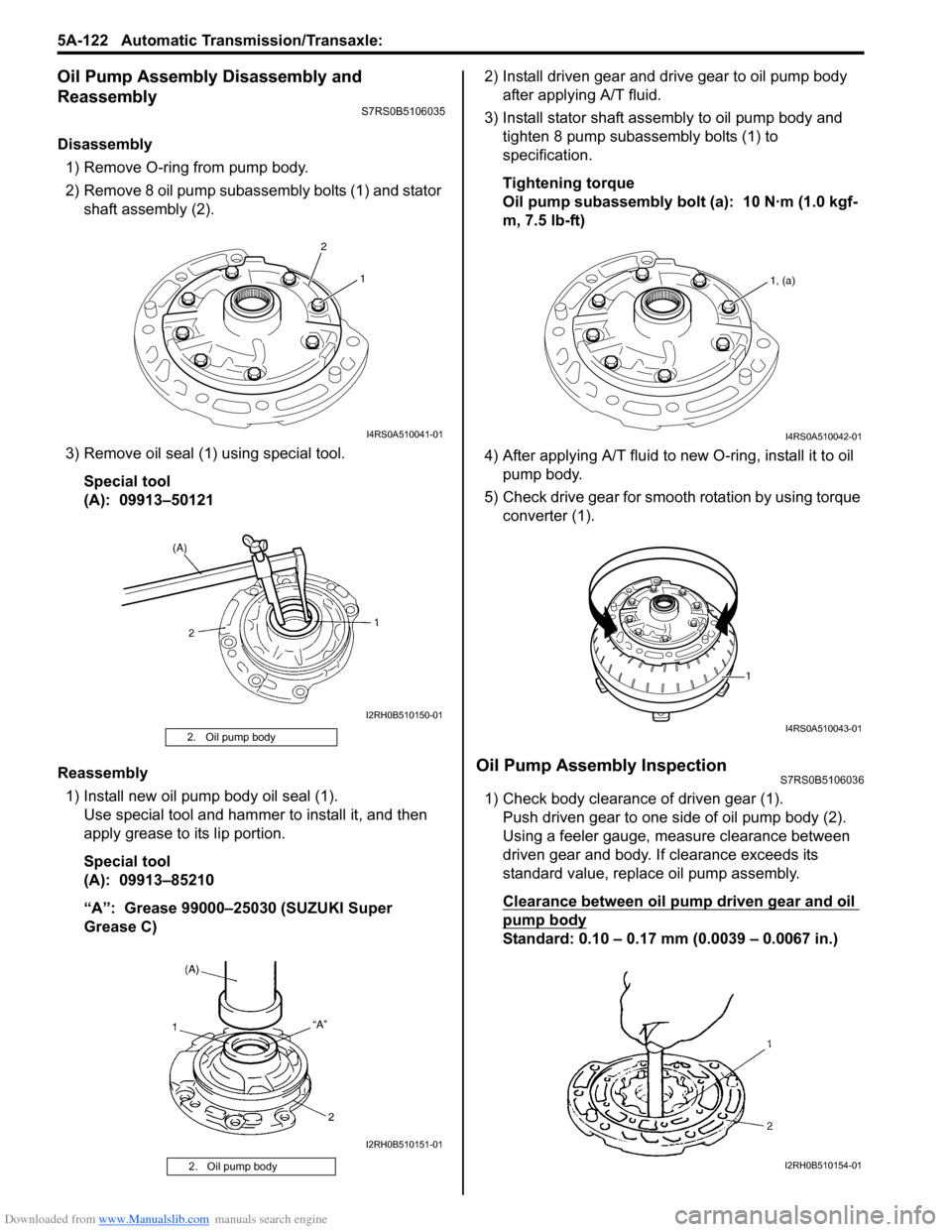

Oil Pump Assembly Disassembly and

Reassembly

S7RS0B5106035

Disassembly1) Remove O-ring from pump body.

2) Remove 8 oil pump subassembly bolts (1) and stator shaft assembly (2).

3) Remove oil seal (1) using special tool. Special tool

(A): 09913–50121

Reassembly 1) Install new oil pump body oil seal (1). Use special tool and hammer to install it, and then

apply grease to its lip portion.

Special tool

(A): 09913–85210

“A”: Grease 99000–25030 (SUZUKI Super

Grease C) 2) Install driven gear and drive gear to oil pump body

after applying A/T fluid.

3) Install stator shaft assembly to oil pump body and tighten 8 pump subassembly bolts (1) to

specification.

Tightening torque

Oil pump subassembly bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

4) After applying A/T fluid to new O-ring, install it to oil pump body.

5) Check drive gear for smooth rotation by using torque converter (1).

Oil Pump Assembly InspectionS7RS0B5106036

1) Check body clearance of driven gear (1).Push driven gear to one side of oil pump body (2).

Using a feeler gauge, m easure clearance between

driven gear and body. If clearance exceeds its

standard value, replace oil pump assembly.

Clearance between oil pump driven gear and oil

pump body

Standard: 0.10 – 0.17 mm (0.0039 – 0.0067 in.)

2. Oil pump body

2. Oil pump body

2 1

I4RS0A510041-01

I2RH0B510150-01

I2RH0B510151-01

1, (a)

I4RS0A510042-01

1

I4RS0A510043-01

I2RH0B510154-01

Page 768 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-124 Automatic Transmission/Transaxle:

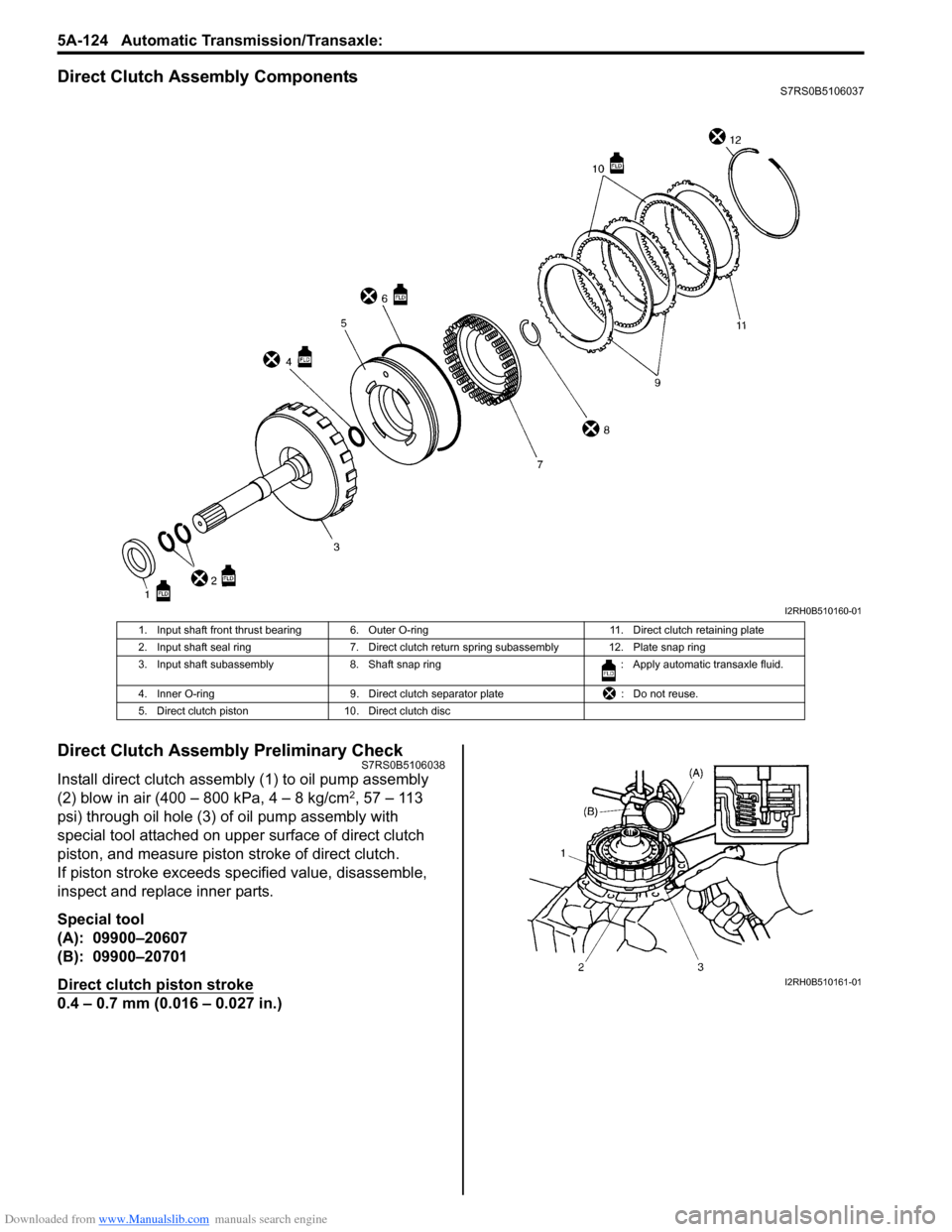

Direct Clutch Assembly ComponentsS7RS0B5106037

Direct Clutch Assembly Preliminary CheckS7RS0B5106038

Install direct clutch assembly (1) to oil pump assembly

(2) blow in air (400 – 800 kPa, 4 – 8 kg/cm2, 57 – 113

psi) through oil hole (3) of oil pump assembly with

special tool attached on uppe r surface of direct clutch

piston, and measure piston stroke of direct clutch.

If piston stroke exceeds sp ecified value, disassemble,

inspect and replace inner parts.

Special tool

(A): 09900–20607

(B): 09900–20701

Direct clutch piston stroke

0.4 – 0.7 mm (0.016 – 0.027 in.)

I2RH0B510160-01

1. Input shaft front thrust bearing 6. Outer O-ring 11. Direct clutch retaining plate

2. Input shaft seal ring 7. Direct clutch return spring subassembly 12. Plate snap ring

3. Input shaft subassembly 8. Shaft snap ring : Apply automatic transaxle fluid.

4. Inner O-ring 9. Direct clutch separator plate : Do not reuse.

5. Direct clutch piston 10. Direct clutch disc

I2RH0B510161-01

Page 770 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-126 Automatic Transmission/Transaxle:

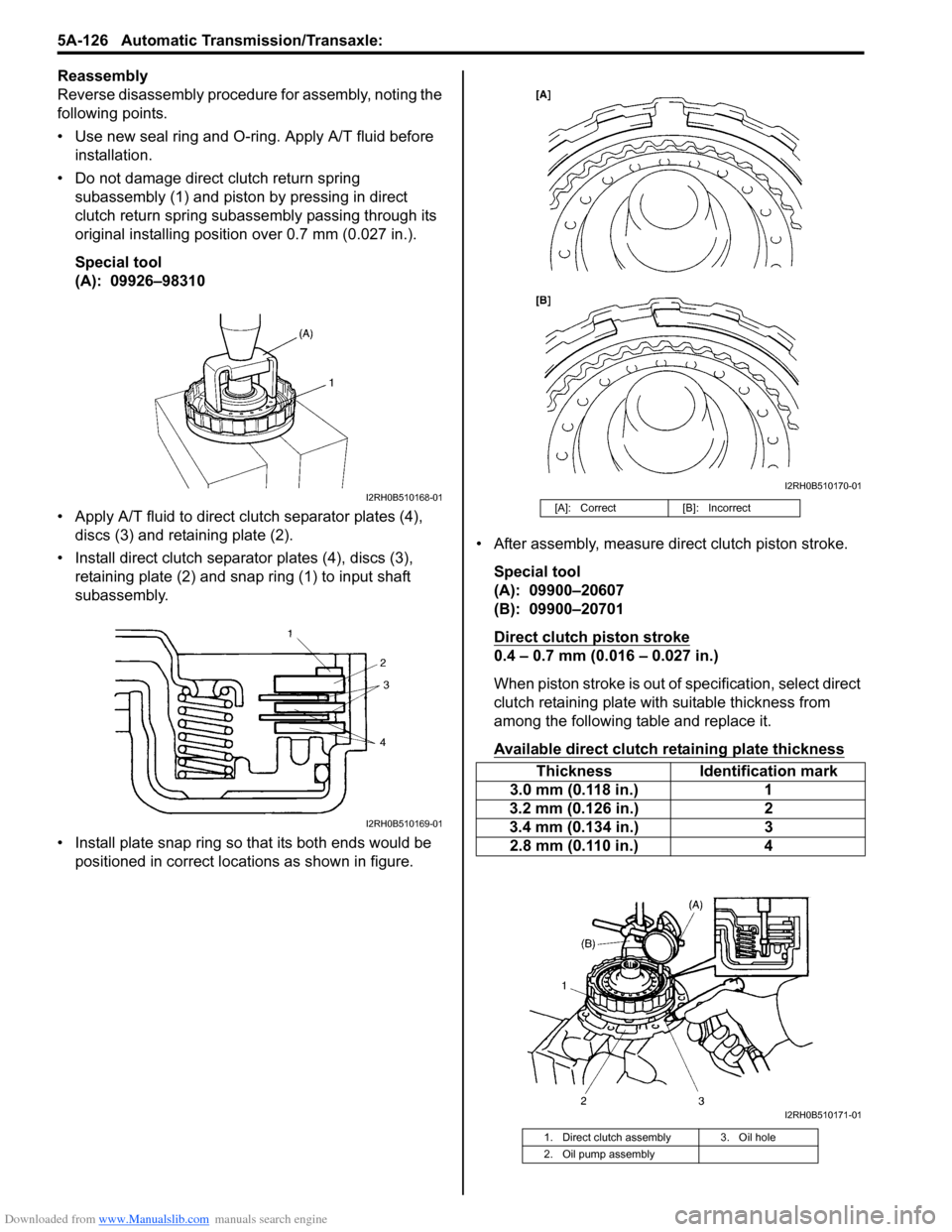

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Use new seal ring and O-ring. Apply A/T fluid before installation.

• Do not damage direct clutch return spring subassembly (1) and piston by pressing in direct

clutch return spring subassembly passing through its

original installing position over 0.7 mm (0.027 in.).

Special tool

(A): 09926–98310

• Apply A/T fluid to direct cl utch separator plates (4),

discs (3) and retaining plate (2).

• Install direct clutch separator plates (4), discs (3), retaining plate (2) and snap ring (1) to input shaft

subassembly.

• Install plate snap ring so that its both ends would be positioned in correct locations as shown in figure. • After assembly, measure direct clutch piston stroke.

Special tool

(A): 09900–20607

(B): 09900–20701

Direct clutch piston stroke

0.4 – 0.7 mm (0.016 – 0.027 in.)

When piston stroke is out of specification, select direct

clutch retaining plate with suitable thickness from

among the following table and replace it.

Available direct clutch retaining plate thickness

I2RH0B510168-01

I2RH0B510169-01

[A]: Correct [B]: Incorrect

ThicknessIdentification mark

3.0 mm (0.118 in.) 1

3.2 mm (0.126 in.) 2

3.4 mm (0.134 in.) 3

2.8 mm (0.110 in.) 4

1. Direct clutch assembly 3. Oil hole

2. Oil pump assembly

I2RH0B510170-01

I2RH0B510171-01

Page 771 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-127

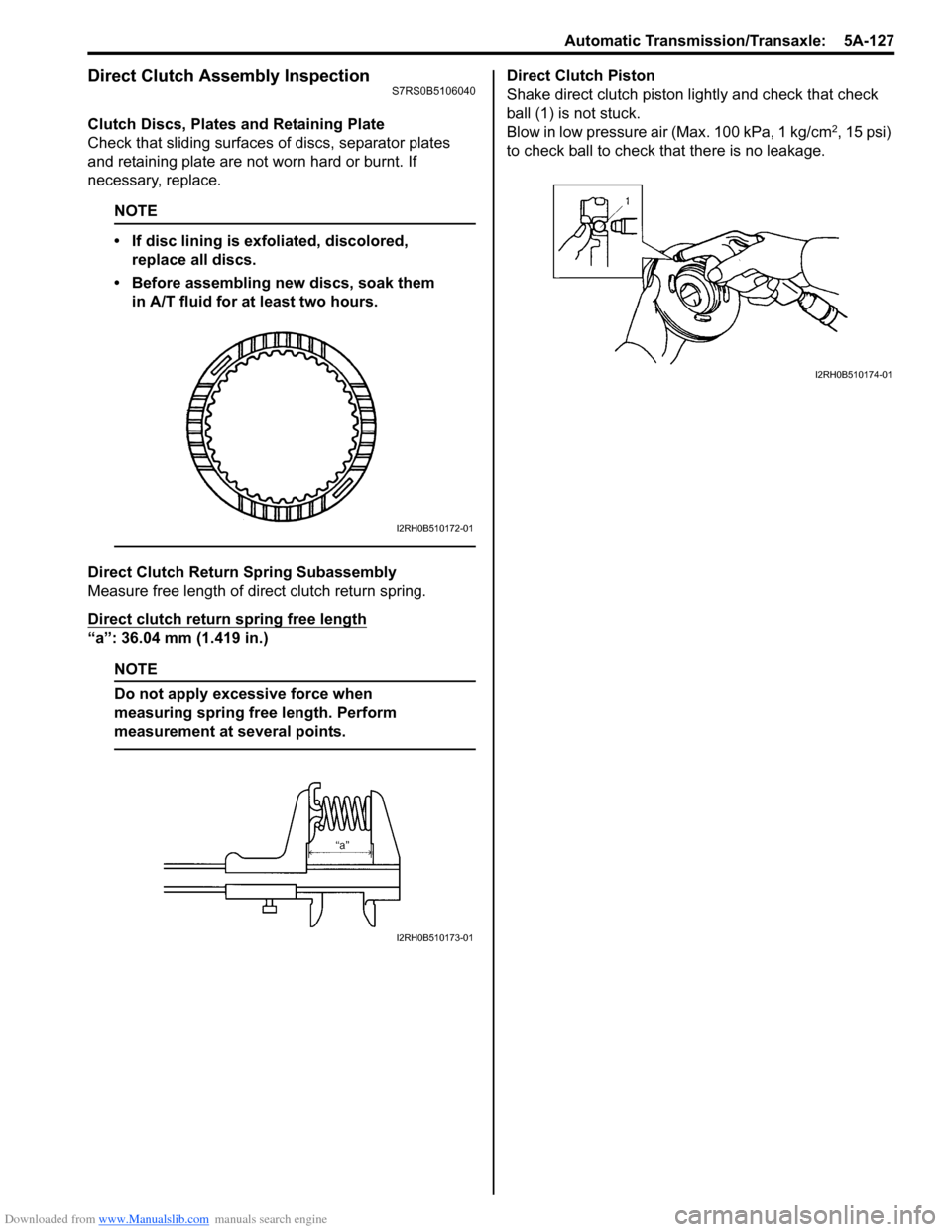

Direct Clutch Assembly InspectionS7RS0B5106040

Clutch Discs, Plates and Retaining Plate

Check that sliding surfaces of discs, separator plates

and retaining plate are not worn hard or burnt. If

necessary, replace.

NOTE

• If disc lining is exfoliated, discolored, replace all discs.

• Before assembling new discs, soak them in A/T fluid for at least two hours.

Direct Clutch Return Spring Subassembly

Measure free length of direct clutch return spring.

Direct clutch return spring free length

“a”: 36.04 mm (1.419 in.)

NOTE

Do not apply excessive force when

measuring spring free length. Perform

measurement at several points.

Direct Clutch Piston

Shake direct clutch piston lightly and check that check

ball (1) is not stuck.

Blow in low pressure air (Max. 100 kPa, 1 kg/cm

2, 15 psi)

to check ball to check that there is no leakage.

I2RH0B510172-01

I2RH0B510173-01

I2RH0B510174-01

Page 772 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-128 Automatic Transmission/Transaxle:

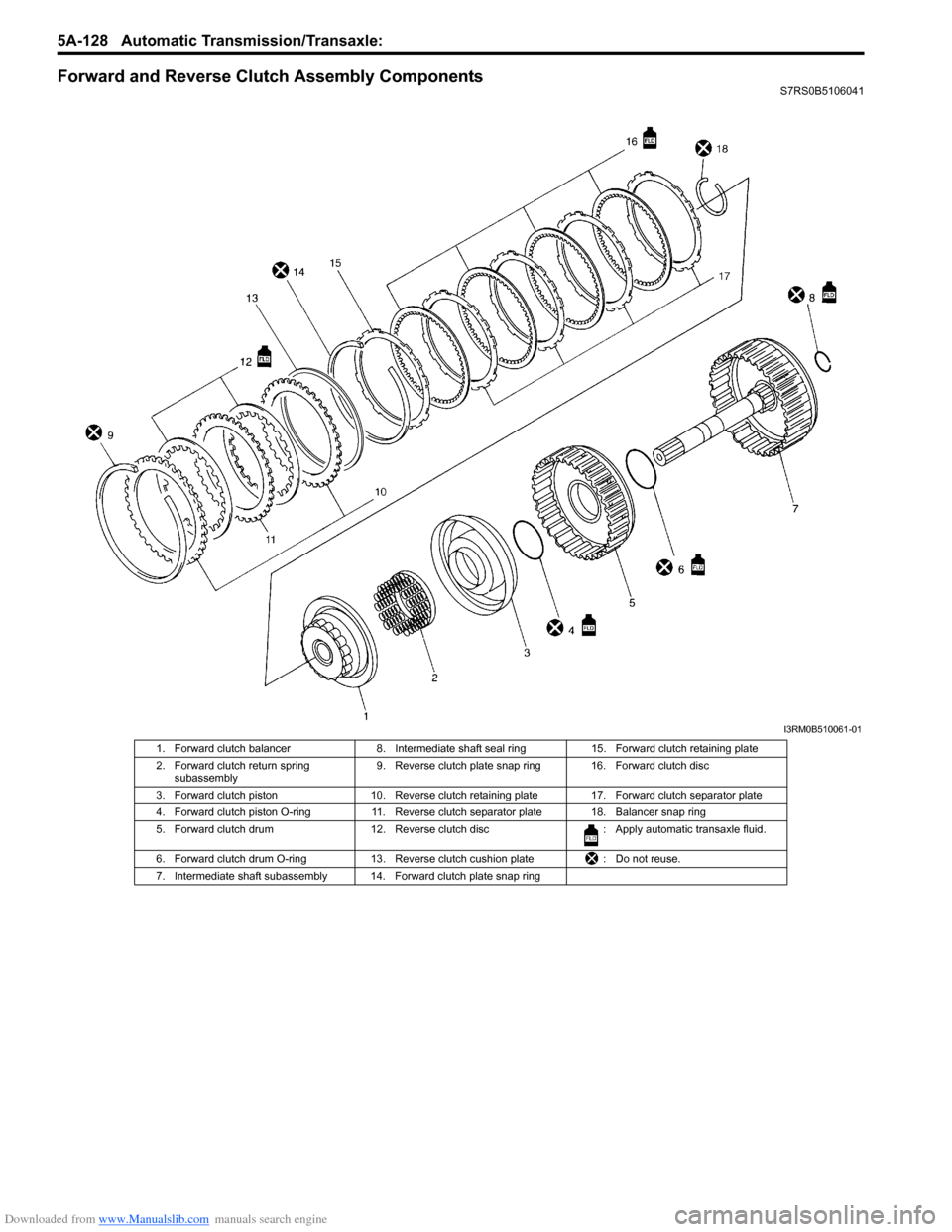

Forward and Reverse Clutch Assembly ComponentsS7RS0B5106041

I3RM0B510061-01

1. Forward clutch balancer8. Intermediate shaft seal ring15. Forward clutch retaining plate

2. Forward clutch return spring subassembly 9. Reverse clutch plate snap ring 16. Forward clutch disc

3. Forward clutch piston 10. Reverse clutch retaining plate 17. Forward clutch separator plate

4. Forward clutch piston O-ring 11. Reverse clutch separator plate 18. Balancer snap ring

5. Forward clutch drum 12. Reverse clutch disc : Apply automatic transaxle fluid.

6. Forward clutch drum O-ring 13. Reverse clutch cushion plate : Do not reuse.

7. Intermediate shaft subassembly 14. Forward clutch plate snap ring

Page 775 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-131

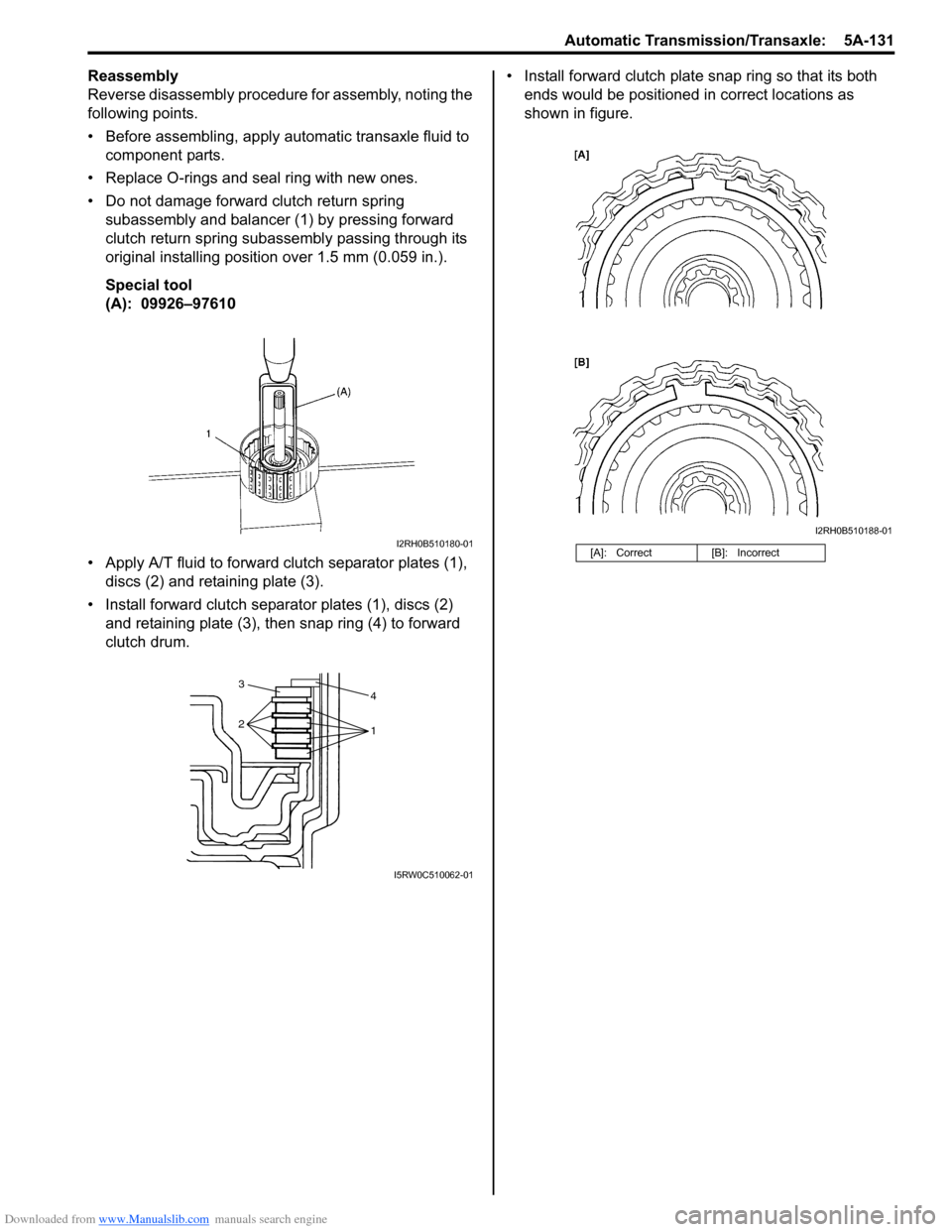

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Before assembling, apply automatic transaxle fluid to component parts.

• Replace O-rings and seal ring with new ones.

• Do not damage forward clutch return spring subassembly and balancer (1) by pressing forward

clutch return spring subassembly passing through its

original installing position over 1.5 mm (0.059 in.).

Special tool

(A): 09926–97610

• Apply A/T fluid to forward clutch separator plates (1), discs (2) and retaining plate (3).

• Install forward clutch separator plates (1), discs (2) and retaining plate (3), then snap ring (4) to forward

clutch drum. • Install forward clutch plate snap ring so that its both

ends would be positioned in correct locations as

shown in figure.

I2RH0B510180-01

4

1

2 3

I5RW0C510062-01

[A]: Correct

[B]: Incorrect

I2RH0B510188-01