air con test SUZUKI SWIFT 2005 2.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 995 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-47

Scan Tool Data Definitions

TEMP CONT SWITCH (TEMPERATURE SELECTOR): Position of temperature control

selector of HVAC control module

CABIN TEMPERATURE: In-car temperature detected

by inside air temperature sensor installed in HVAC

control module

OUTSIDE AIR TEMP (OUTSIDE AIR TEMPERATURE): Outside air temperature

detected by outside air temperature sensor installed

in front bumper member

EVAPORATOR TEMP (EVAPORATOR TEMPERATURE): Temperature of air passed

through evaporator

COOLANT TEMP (ENGINE COOLANT TEMPERATURE): Engine coolant temperature

detected by engine coolant temperature sensor

SUN LOAD: Amount of sunlight detected by sunload

sensor installed on the driver side on the dashboard

MODE CONT SWITCH (MODE (AIR FLOW) SELECTOR): Position of air flow selector of HVAC

control module

FAN CONT SWITCH (BLOWER SPEED SELECTOR): Position of blower speed selector of HVAC control

module

FAN DESIRED VOLT: Voltage for blower motor AIR MIX POS SEN (TEMPERATURE CONTROL

ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in temperature control actuator

MODE POS SENSOR (AIR FLOW CONTROL ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in air flow control actuator

A/C CONT SIG (A/C SWITCH SIGNAL, ON or OFF): State of A/C switch

BLOWER LOAD SIG (BLO WER FAN LOAD SIGNAL,

ON or OFF): ON: Position of blower speed selector

is 1st position or more / OFF: Position of blower

speed selector is OFF position.

AIR INTAKE MODE (AUTO, FRE or REC): State of air

intake mode

REFRIGERANT PRESSURE (A/C REFRIGERANT ABSOLUTE PRESSURE): This parameter

indicates A/C refrigerant absolute pressure

calculated by ECM

A/C COMP CLUTCH (A/C COMPRESSOR MAGNET CLUTCH, ON or OFF): This parameter indicates

the state of the A/C switch

DFR INDICATOR (DEFROSTER INDICATOR LAMP, ON or OFF): State of defroster indicator lamp

VEHICLE SPEED: It is computed based on pulse

signals from vehicle speed sensor

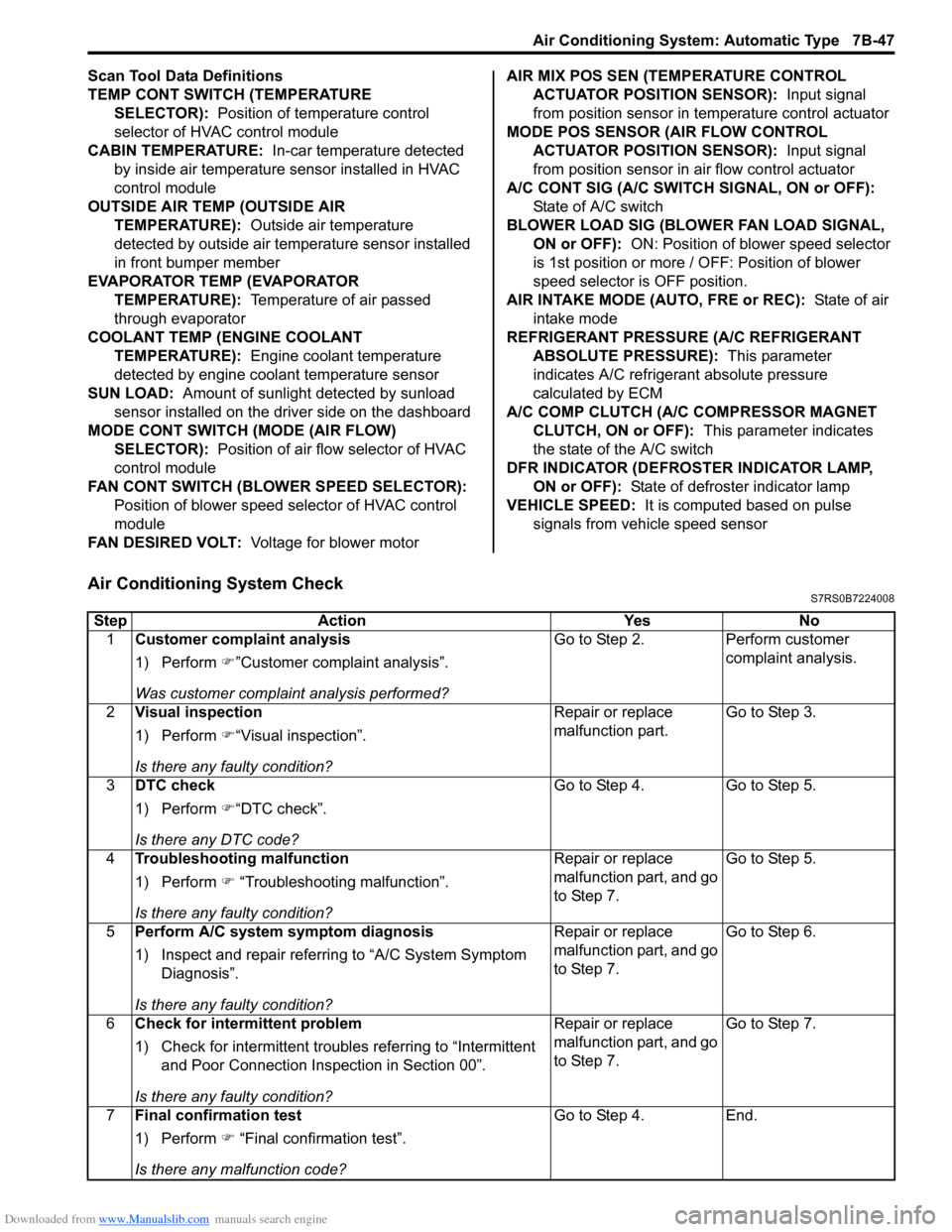

Air Conditioning System CheckS7RS0B7224008

Step Action YesNo

1 Customer complaint analysis

1) Perform �)”Customer complaint analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 Visual inspection

1) Perform �)“Visual inspection”.

Is there any faulty condition? Repair or replace

malfunction part.

Go to Step 3.

3 DTC check

1) Perform �)“DTC check”.

Is there any DTC code? Go to Step 4.

Go to Step 5.

4 Troubleshooting malfunction

1) Perform �) “Troubleshooting malfunction”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 5.

5 Perform A/C system symptom diagnosis

1) Inspect and repair referri ng to “A/C System Symptom

Diagnosis”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 6.

6 Check for intermittent problem

1) Check for intermittent troubles referring to “Intermittent

and Poor Connection Inspection in Section 00”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 7.

7 Final confirmation test

1) Perform �) “Final confirmation test”.

Is there any malfunction code? Go to Step 4.

End.

Page 997 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-49

Step 7. Final confirmation test

Confirm if the problem symptom is troubleshoot and the A/C system is free from any abnormal conditions. If there

existed DTC, clear the DTC. Then , check if the DTC is still detected and if there is any other DTC.

Visual InspectionS7RS0B7224009

Check visually the following parts and systems.

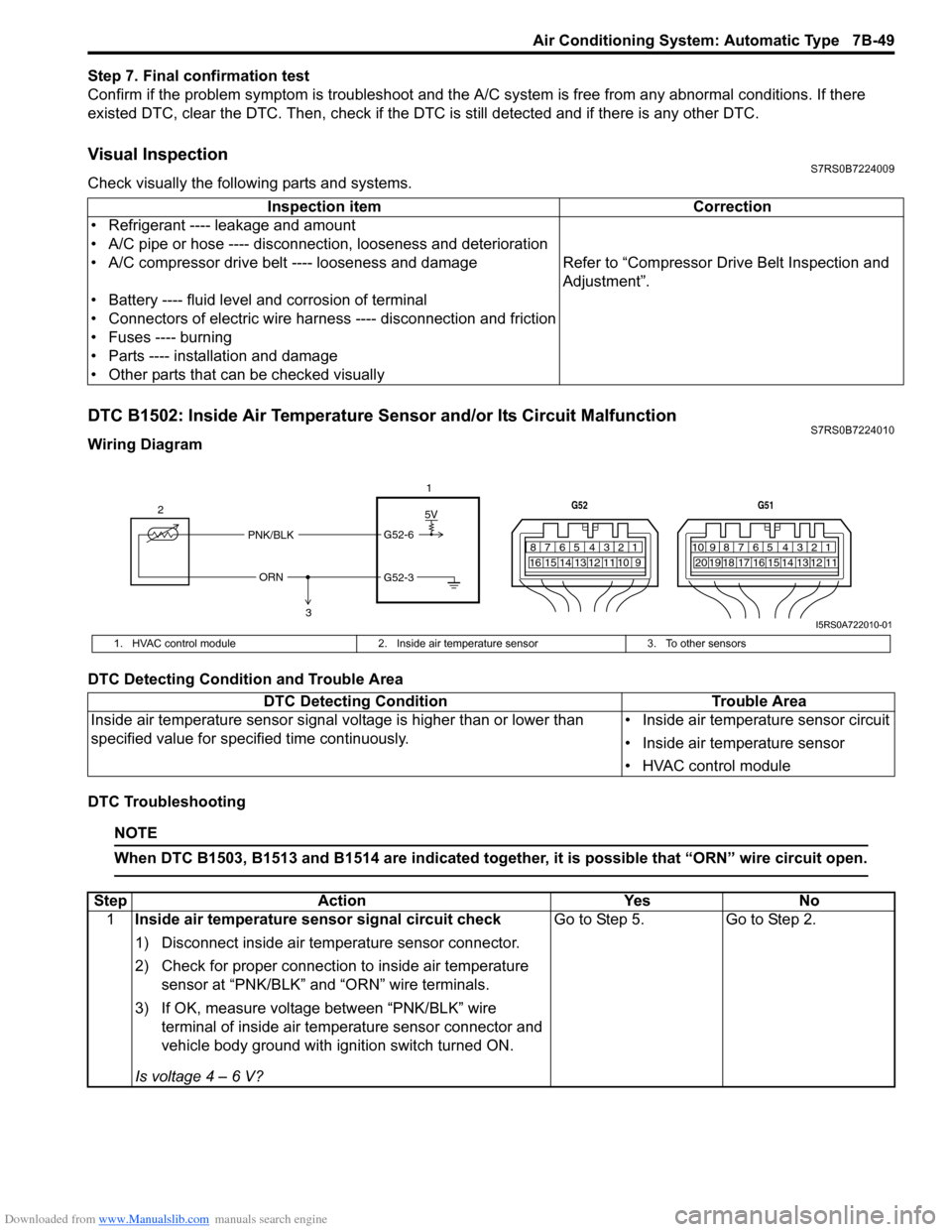

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit MalfunctionS7RS0B7224010

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

When DTC B1503, B1513 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

Inspection item Correction

• Refrigerant ---- leakage and amount

• A/C pipe or hose ---- disconnection, looseness and deterioration

• A/C compressor drive belt ---- looseness and damage Refer to “Compressor Drive Belt Inspection and

Adjustment”.

• Battery ---- fluid level and corrosion of terminal

• Connectors of electric wire harn ess ---- disconnection and friction

• Fuses ---- burning

• Parts ---- installation and damage

• Other parts that can be checked visually

5V

PNK/BLK

ORN G52-6

G52-3

2

1

3

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722010-01

1. HVAC control module

2. Inside air temperature sensor 3. To other sensors

DTC Detecting Condition Trouble Area

Inside air temperature sensor signal voltage is higher than or lower than

specified value for specified time continuously. • Inside air temperature sensor circuit

• Inside air temperature sensor

• HVAC control module

Step

Action YesNo

1 Inside air temperature sensor signal circuit check

1) Disconnect inside air temperature sensor connector.

2) Check for proper connection to inside air temperature

sensor at “PNK/BLK” and “ORN” wire terminals.

3) If OK, measure voltage between “PNK/BLK” wire terminal of inside air temp erature sensor connector and

vehicle body ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

Page 1018 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-70 Air Conditioning System: Automatic Type

A/C System Performance InspectionS7RS0B7224027

Refer to “A/C System Performance Inspection”.

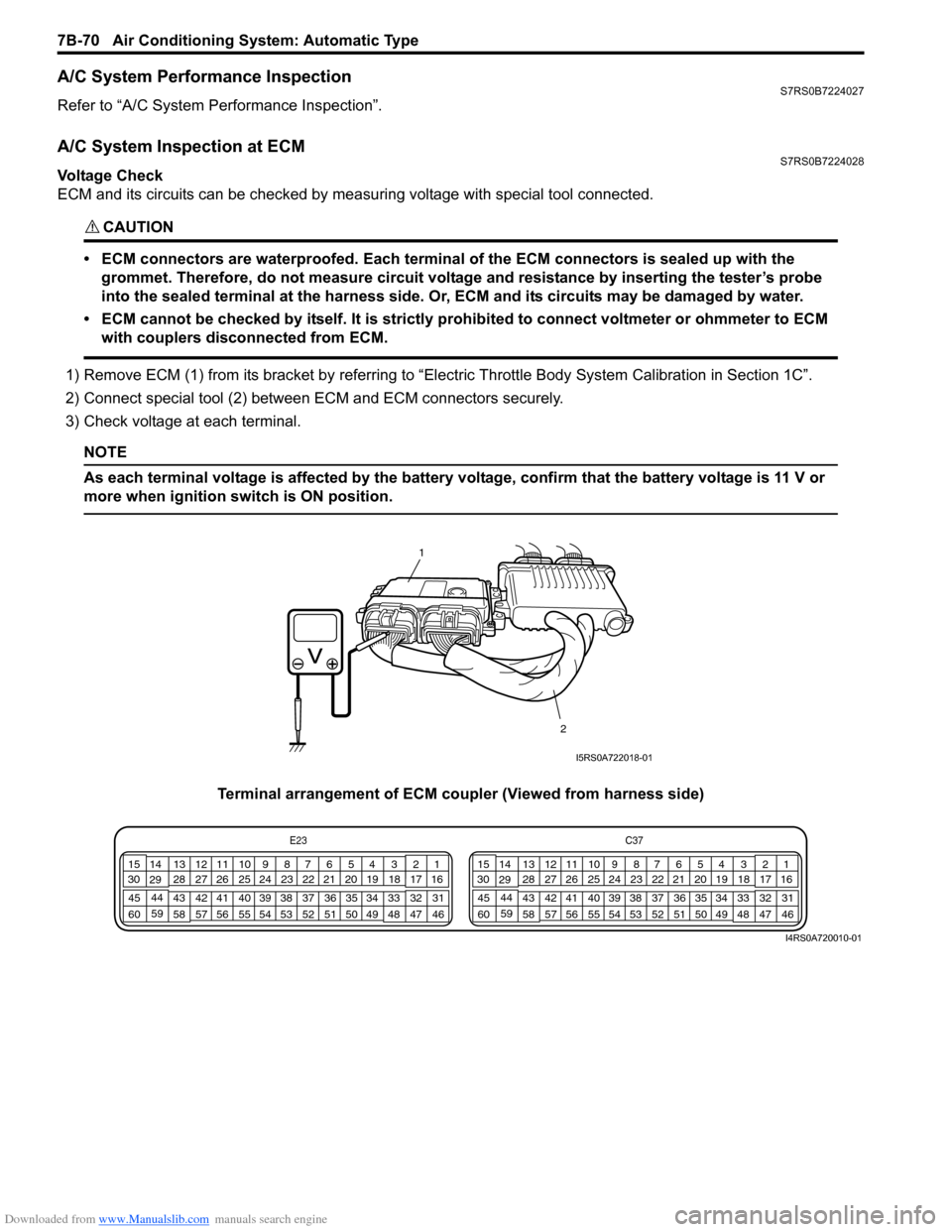

A/C System Inspection at ECMS7RS0B7224028

Voltage Check

ECM and its circuits can be checked by measuring voltage with special tool connected.

CAUTION!

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the

grommet. Therefore, do not measure circuit voltage and resistance by inserting the tester’s probe

into the sealed terminal at the harness side. Or, ECM and its circuits may be damaged by water.

• ECM cannot be checked by itself. It is strictly prohibited to connect voltmeter or ohmmeter to ECM with couplers disconnected from ECM.

1) Remove ECM (1) from its bracket by referring to “Electric Throttle Body System Calibration in Section 1C”.

2) Connect special tool (2) between ECM and ECM connectors securely.

3) Check voltage at each terminal.

NOTE

As each terminal voltage is affected by the battery voltage, confirm that the battery voltage is 11 V or

more when ignition sw itch is ON position.

Terminal arrangement of ECM coupler (Viewed from harness side)

1

2

I5RS0A722018-01

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A720010-01

Page 1040 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-2 Air Bag System:

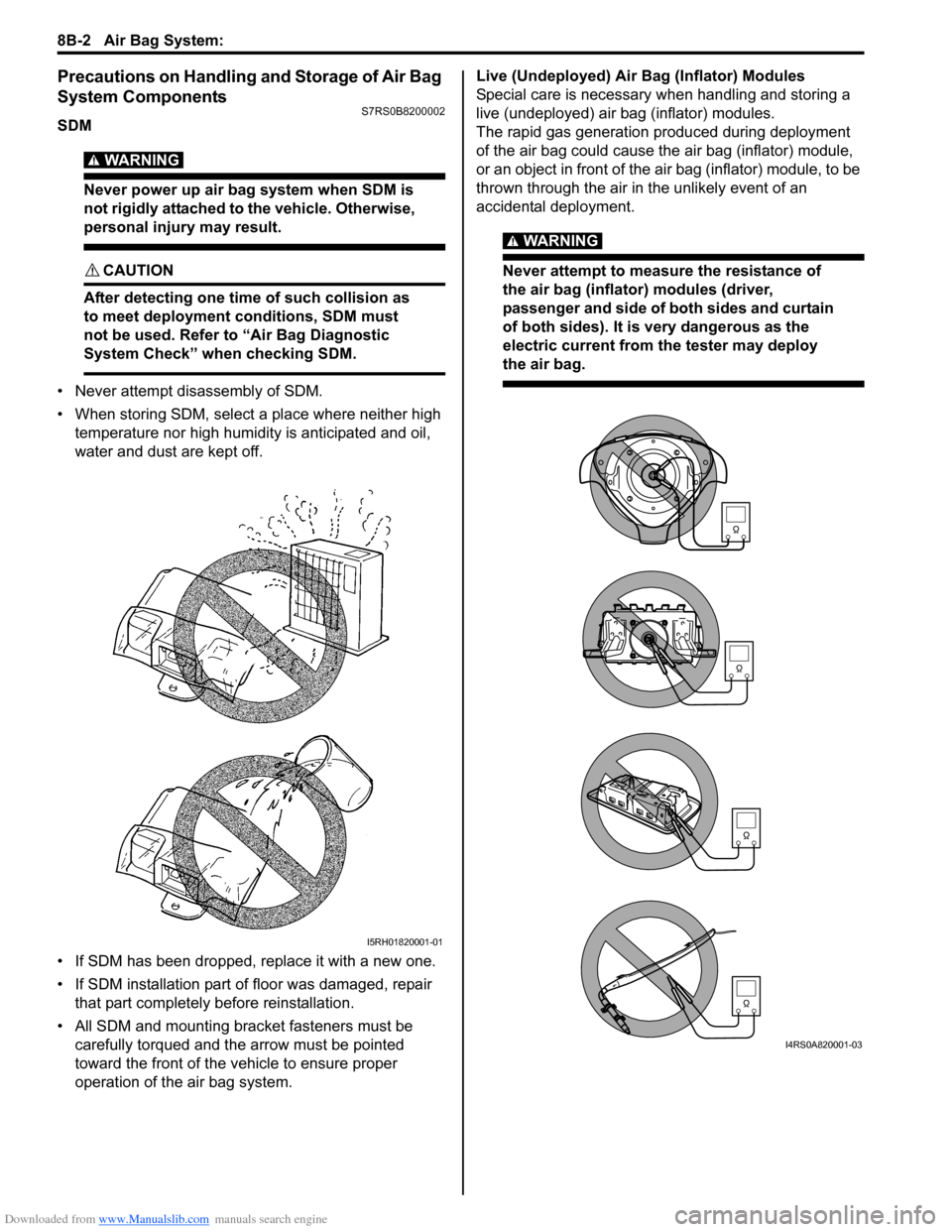

Precautions on Handling and Storage of Air Bag

System Components

S7RS0B8200002

SDM

WARNING!

Never power up air bag system when SDM is

not rigidly attached to the vehicle. Otherwise,

personal injury may result.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, SDM must

not be used. Refer to “Air Bag Diagnostic

System Check” when checking SDM.

• Never attempt disassembly of SDM.

• When storing SDM, select a place where neither high temperature nor high humidity is anticipated and oil,

water and dust are kept off.

• If SDM has been dropped, replace it with a new one.

• If SDM installation part of floor was damaged, repair that part completely before reinstallation.

• All SDM and mounting bracket fasteners must be carefully torqued and the arrow must be pointed

toward the front of the vehicle to ensure proper

operation of the air bag system. Live (Undeployed) Air Bag (Inflator) Modules

Special care is necessary when handling and storing a

live (undeployed) air bag (inflator) modules.

The rapid gas generation produced during deployment

of the air bag could cause the air bag (inflator) module,

or an object in front of the air bag (inflator) module, to be

thrown through the air in the unlikely event of an

accidental deployment.

WARNING!

Never attempt to measure the resistance of

the air bag (inflator) modules (driver,

passenger and side of both sides and curtain

of both sides). It is

very dangerous as the

electric current from the tester may deploy

the air bag.

I5RH01820001-01

I4RS0A820001-03

Page 1042 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-4 Air Bag System:

WARNING!

Never attempt to measure the resistance of

the seat belt pretensioners. It is very

dangerous as the electric current from the

tester may activate pretensioner.

• Never attempt to disassemble the seat belt

pretensioners (retractor assembly).

• If any abnormality is found, be sure to replace it with

new one as an assembly.

• When an abnormality is noted as existing in the live (inactivated) seat belt preten sioner, be sure to activate

it before discarding it.

• When grease, cleaning agent oil, water, etc., got on the seat belt pretensioners (r etractor assembly), wipe

it off immediately with a dry cloth.

• If seat belt pretensioner was dropped from a height of 30 cm (1 ft) or more, it should be replaced with a new

one as an assembly.

WARNING!

• For handling and storage of a live seat belt pretensioner, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

• Never carry the seat belt pretensioner by webbing.

• When placing a live seat belt pretensioner on the workbench or other surface, be sure

not to lay it with its exhaust hole (1)

provided side facing down. It is also

prohibited to put something on its face

with an exhaust hole (1) or to put a seat

belt pretensioner on top of another.

Otherwise, personal injury may result.

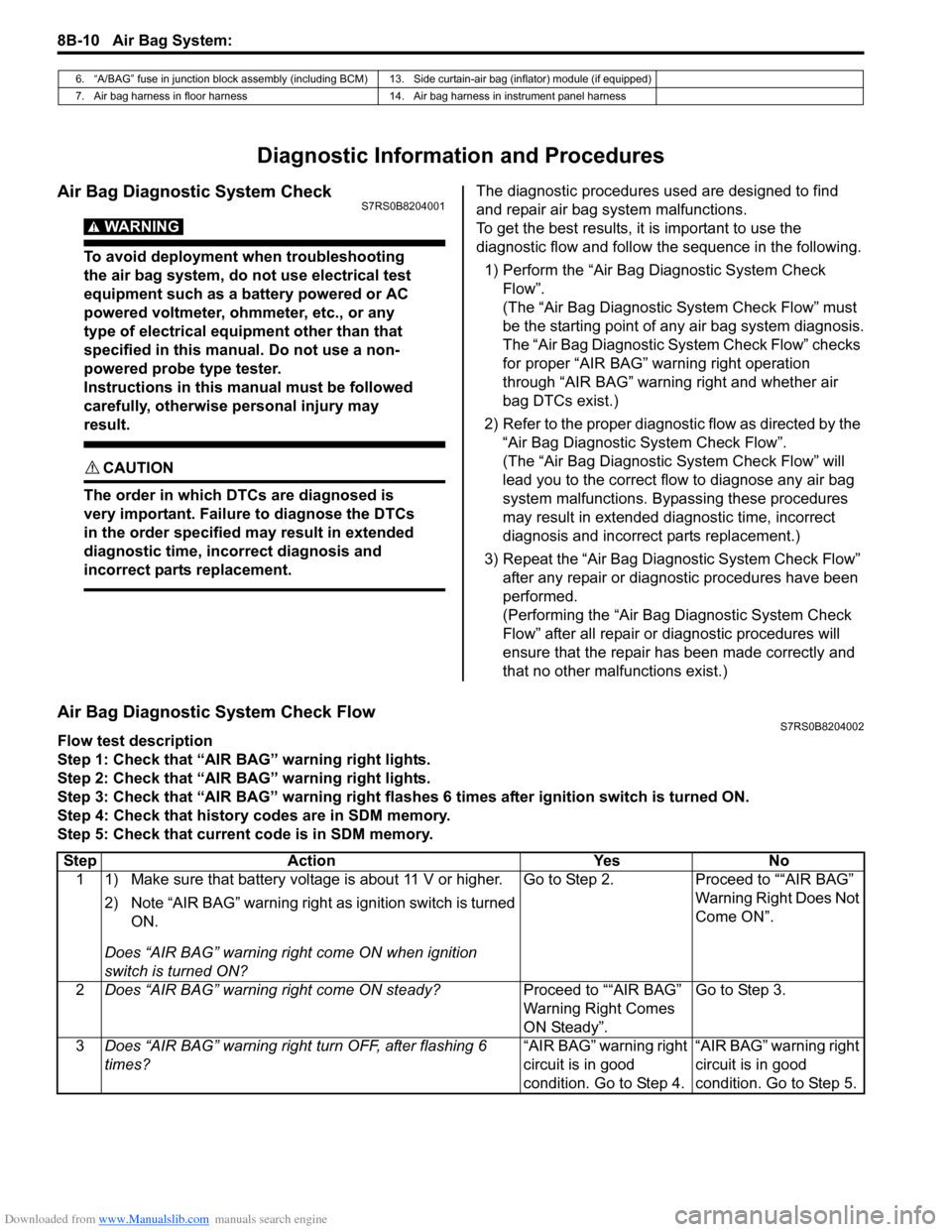

Deployed Air Bag (Inflator) Module and Activated

Seat Belt Pretensioner

WARNING!

• The air bag (inflator) module and seat belt

pretensioner immediately after

deployment/activation is very hot. Wait for

at least 30 minutes to cool it off before

proceeding the work.

• Do not apply water, oil, etc. to deployed air bag (inflator) module and to activate seat

belt pretensioner.

• After an air bag (inflator) module has been deployed, the surface of the air bag may

contain a powdery residue. This powder

consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-

products of the chemical reaction. As with

many service procedures, gloves and

safety glasses should be worn.

• Wash your hands with mild soap and water after completing the work.

Refer to the procedure described under “Deployed Air

Bag (Inflator) Module and Activated Seat Belt

Pretensioner Disposal” for disposal.

Air Bag Wire Harness and Connector

Air bag wire harness is includ ed in main harness (1),

instrument panel harness (4), floor harness (3) and seat

harness (5). Air bag wire harness can be identified easily

as the part of connector side wire harness is covered

with a yellow protection tube. Be very careful when

handling it.

I2RH01820047-01

1

I2RH01820048-01

Page 1048 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-10 Air Bag System:

Diagnostic Information and Procedures

Air Bag Diagnostic System CheckS7RS0B8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

The order in which DTCs are diagnosed is

very important. Failure to diagnose the DTCs

in the order specified may result in extended

diagnostic time, incorrect diagnosis and

incorrect parts replacement.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.1) Perform the “Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning right operation

through “AIR BAG” warning right and whether air

bag DTCs exist.)

2) Refer to the proper diagnost ic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow” after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

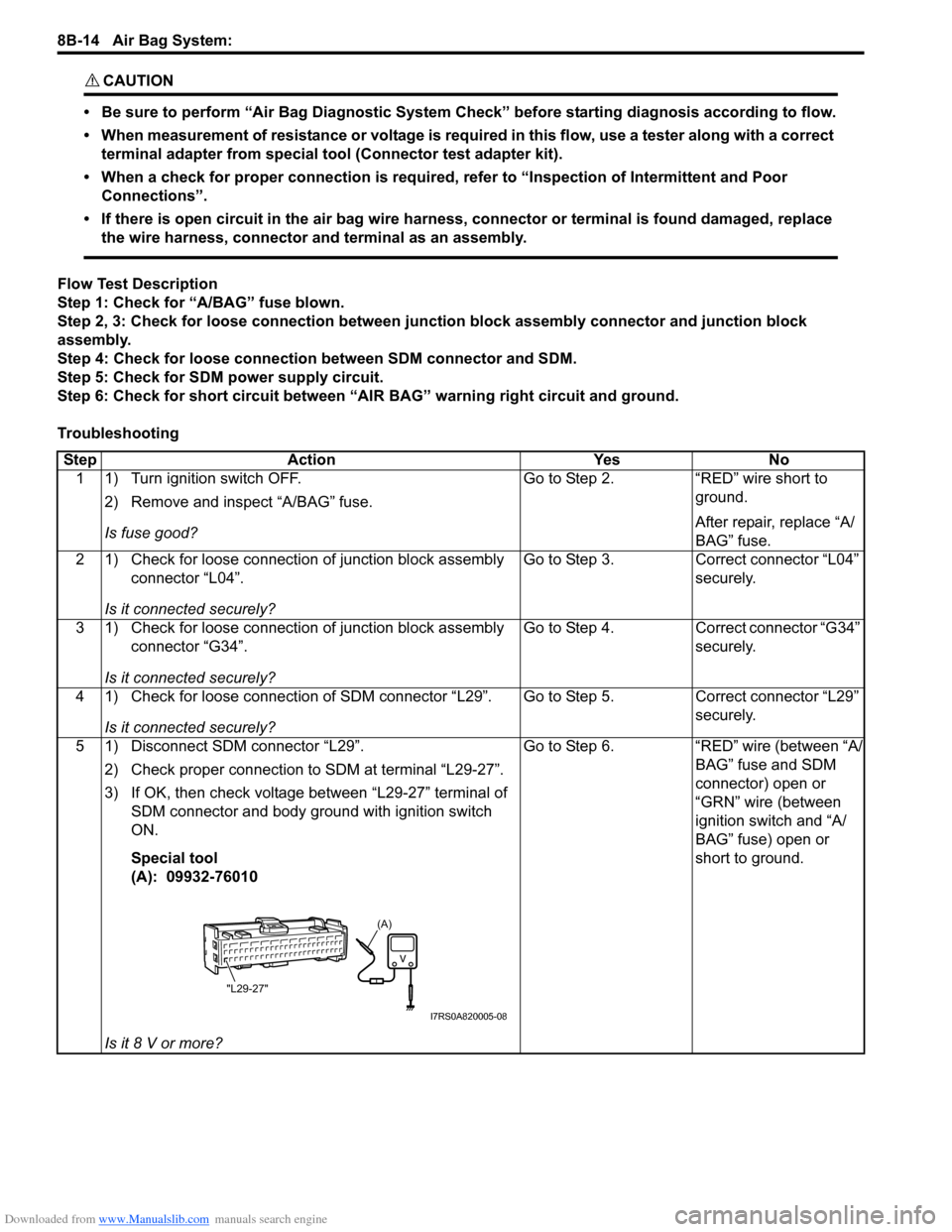

Air Bag Diagnostic System Check FlowS7RS0B8204002

Flow test description

Step 1: Check that “AIR BAG” warning right lights.

Step 2: Check that “AIR BAG” warning right lights.

Step 3: Check that “AIR BAG” warning right flas hes 6 times after ignition switch is turned ON.

Step 4: Check that history codes are in SDM memory.

Step 5: Check that current code is in SDM memory.

6. “A/BAG” fuse in junction block assembly (including BCM) 13. Side curtain-air bag (inflator) module (if equipped)

7. Air bag harness in floor harness 14. Air bag harness in instrument panel harness

Step Action YesNo

1 1) Make sure that battery voltage is about 11 V or higher.

2) Note “AIR BAG” warning right as ignition switch is turned

ON.

Does “AIR BAG” warning ri ght come ON when ignition

switch is turned ON? Go to Step 2.

Proceed to ““AIR BAG”

Warning Right Does Not

Come ON”.

2 Does “AIR BAG” warning right come ON steady? Proceed to ““AIR BAG”

Warning Right Comes

ON Steady”.Go to Step 3.

3 Does “AIR BAG” warning right turn OFF, after flashing 6

times? “AIR BAG” warning right

circuit is in good

condition. Go to Step 4.“AIR BAG” warning right

circuit is in good

condition. Go to Step 5.

Page 1052 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-14 Air Bag System:

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Flow Test Description

Step 1: Check for “A/BAG” fuse blown.

Step 2, 3: Check for loose connection between junction block assembly connector and junction block

assembly.

Step 4: Check for loose connection between SDM connector and SDM.

Step 5: Check for SDM power supply circuit.

Step 6: Check for short circuit between “A IR BAG” warning right circuit and ground.

Troubleshooting Step Action YesNo

1 1) Turn ignition switch OFF.

2) Remove and inspect “A/BAG” fuse.

Is fuse good? Go to Step 2.

“RED” wire short to

ground.

After repair, replace “A/

BAG” fuse.

2 1) Check for loose connection of junction block assembly connector “L04”.

Is it connected securely? Go to Step 3.

Correct connector “L04”

securely.

3 1) Check for loose connection of junction block assembly connector “G34”.

Is it connected securely? Go to Step 4.

Correct connector “G34”

securely.

4 1) Check for loose connection of SDM connector “L29”. Is it connected securely? Go to Step 5.

Correct connector “L29”

securely.

5 1) Disconnect SDM connector “L29”. 2) Check proper connection to SDM at terminal “L29-27”.

3) If OK, then check voltage between “L29-27” terminal of SDM connector and body ground with ignition switch

ON.

Special tool

(A): 09932-76010

Is it 8 V or more? Go to Step 6.

“RED” wire (between “A/

BAG” fuse and SDM

connector) open or

“GRN” wire (between

ignition switch and “A/

BAG” fuse) open or

short to ground.

(A)

"L29-27"

I7RS0A820005-08

Page 1054 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-16 Air Bag System:

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Flow Test Description

Step 1: Check combination meter power feed circuit.

Step 2: Check “AIR BAG” warning right circuit.

Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

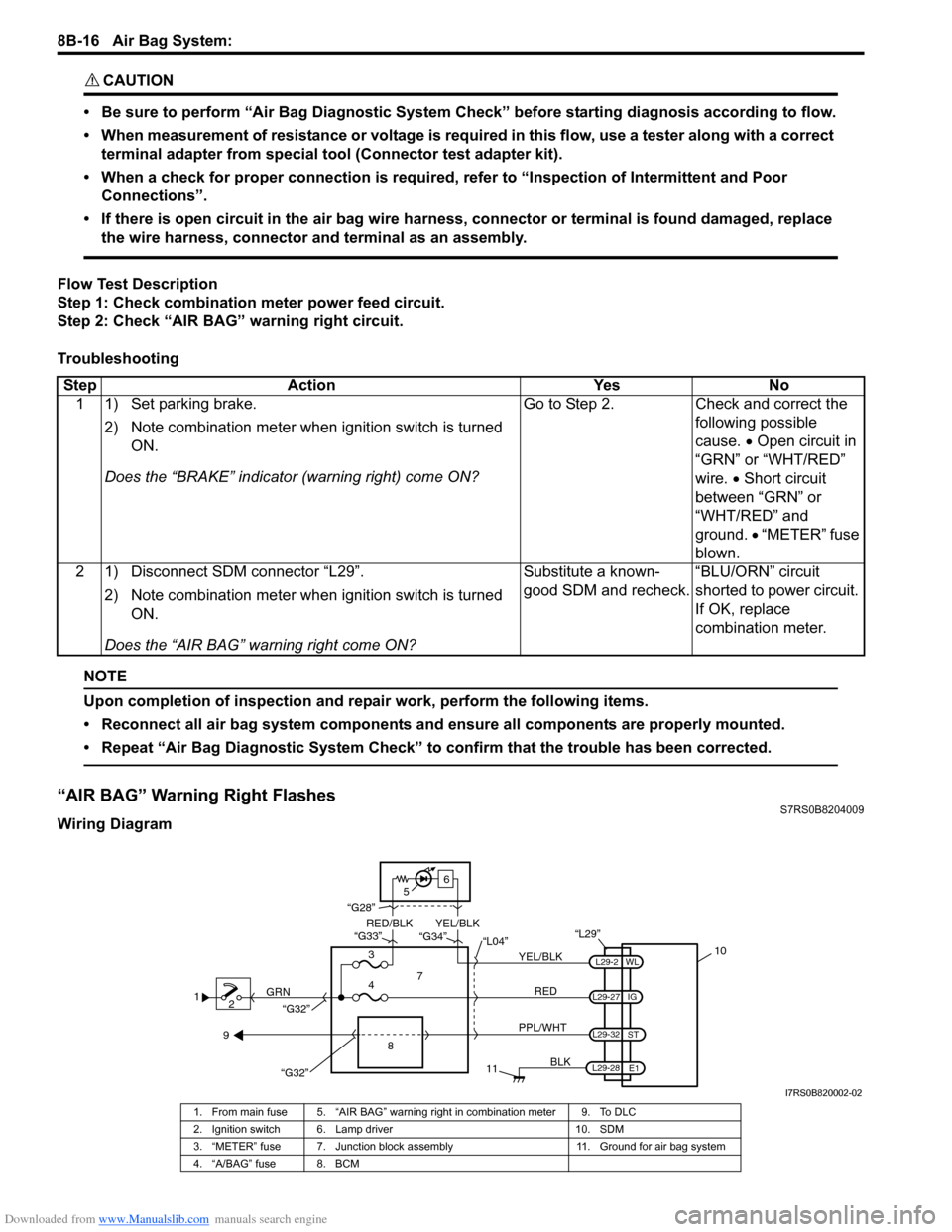

“AIR BAG” Warning Right FlashesS7RS0B8204009

Wiring Diagram Step Action Yes No

1 1) Set parking brake.

2) Note combination me ter when ignition switch is turned

ON.

Does the “BRAKE” in dicator (warning right) come ON? Go to Step 2. Check and correct the

following possible

cause. • Open circuit in

“GRN” or “WHT/RED”

wire. • Short circuit

between “GRN” or

“WHT/RED” and

ground. • “METER” fuse

blown.

2 1) Disconnect SDM connector “L29”.

2) Note combination me ter when ignition switch is turned

ON.

Does the “AIR BAG” warning right come ON? Substitute a known-

good SDM and recheck.

“BLU/ORN” circuit

shorted to power circuit.

If OK, replace

combination meter.

1

2 GRN

11

BLK

L29-27

L29-2

L29-28 WL

E1

IG

L29-32

ST

10

8

“L29”

RED

PPL/WHT

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

“G32”

YEL/BLK

YEL/BLK

RED/BLK

9

I7RS0B820002-02

1. From main fuse 5. “AIR BAG” warning right in combination meter 9. To DLC

2. Ignition switch 6. Lamp driver 10. SDM

3. “METER” fuse 7. Junction block assembly 11. Ground for air bag system

4. “A/BAG” fuse 8. BCM

Page 1055 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-17

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Flow Test Description

Check for short circuit between diag nosis switch circuit and ground.

Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1013: SDM faultS7RS0B8204010

DTC Will Set when

An internal SDM fault is detected by SDM.

NOTE

DTC B1013 can never be cleared once it has been set.

DTC Troubleshooting 1) Turn ignition switch OFF.

2) Replace SDM.

3) Repeat “Air Bag Diagnostic System Check”.

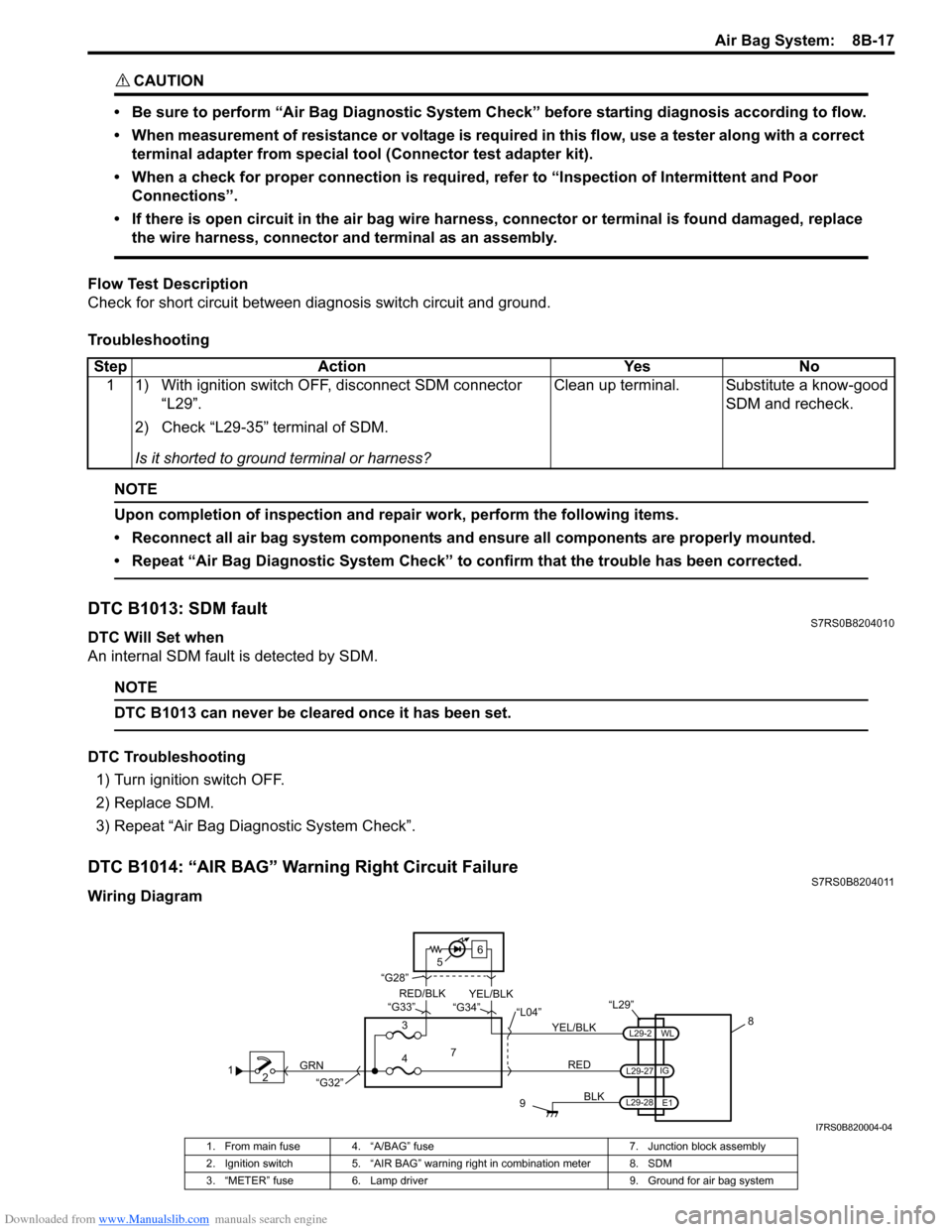

DTC B1014: “AIR BAG” Warning Right Circuit FailureS7RS0B8204011

Wiring DiagramStep Action Yes No

1 1) With ignition switch OFF, disconnect SDM connector “L29”.

2) Check “L29-35” terminal of SDM.

Is it shorted to ground terminal or harness? Clean up terminal. Substitute a know-good

SDM and recheck.

12 GRN

9

BLK

L29-2

L29-27

L29-28 IG

E1

WL

8

“L29”

RED

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

YEL/BLK

YEL/BLK

RED/BLK

I7RS0B820004-04

1. From main fuse 4. “A/BAG” fuse

7. Junction block assembly

2. Ignition switch 5. “AIR BAG” warning right in combination meter 8. SDM

3. “METER” fuse 6. Lamp driver 9. Ground for air bag system

Page 1056 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-18 Air Bag System:

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage at the “AIR BAG” warning right circuit term inal “L29-2” does not match the commanded state of the

warning right driver for specified time.

Flow Test Description

Step 1: This test rechecks “AIR BAG” warning right operation.

Step 2: This test rechecks whether an abnormality is in SDM.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1016: Power Source Voltage HighS7RS0B8204012

Wiring Diagram Step Action Yes No

1 1) This DTC is set when there is a trouble in “AIR BAG” warning right circuit. Failure to properly perform “Air Bag

Diagnostic System Check” may also result in

misdiagnosis. Therefore, check “AIR BAG” warning right

circuit again according to “Air Bag Diagnostic System

Check”.

Is “AIR BAG” warning right circuit in good condition? Go to Step 2. Repair “AIR BAG”

warning right circuit.

2 1) Clear DTC referring to “DTC Clearance”. 2) Check DTC referring to “DTC Check”.

Is DTC B1014 set? Substitute a known-

good SDM and recheck.

Recheck air bag system

referring to “Air Bag

Diagnostic System

Check”.

1

2

3

GRN

RED

6

BLK

L29-27

L29-28 IG

E1 5

4

“L29”

“L04”

“G32”

I7RS0A820009-02

1. From main fuse 3. “A/BAG” fuse 5. SDM

2. Ignition switch 4. Junction block assembly 6. Ground for air bag system