air con test SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1133 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-95

Inspection of Intermittent and Poor

Connections

S7RS0B8204048

Most intermittents are caused by faulty electrical

connections or wiring. When a check for proper

connection is requested in a diagnostic flow, perform

careful check of suspect circuits.

If any abnormality is found, repair or replace as a wire

harness assembly.

• Poor mating of connector halves, or terminals not fully seated in the connector body (backed out).

• Dirt or corrosion on the terminals. The terminals must be clean and free of any foreign material which could

impede proper terminal contact.

However, cleaning the terminal with a sand paper or

the like is prohibited.

• Damaged connector body, exposing the terminals to moisture and dirt, as well as not maintaining proper

terminal orientation with the component or mating

connector.

• Improperly formed or damaged terminals. Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal included in the

connector test adapter kit (special tool).

If contact tension is not e nough, reform the terminal to

increase contact tension or replace it.

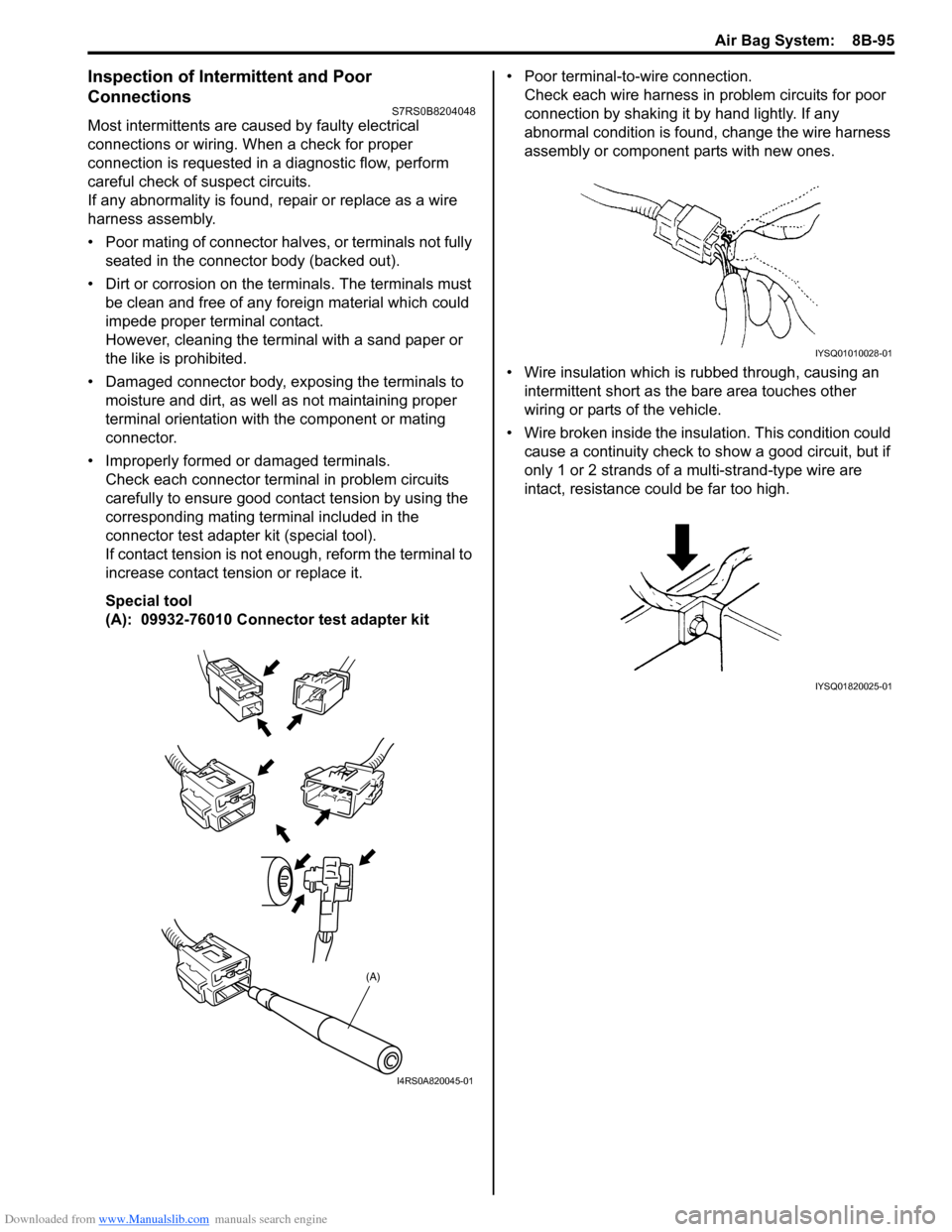

Special tool

(A): 09932-76010 Connector test adapter kit • Poor terminal-to-wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, change the wire harness

assembly or component parts with new ones.

• Wire insulation which is rubbed through, causing an intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wire broken inside the insulation. This condition could cause a continuity check to show a good circuit, but if

only 1 or 2 strands of a multi-strand-type wire are

intact, resistance could be far too high.

(A)

I4RS0A820045-01

IYSQ01010028-01

IYSQ01820025-01

Page 1139 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-101

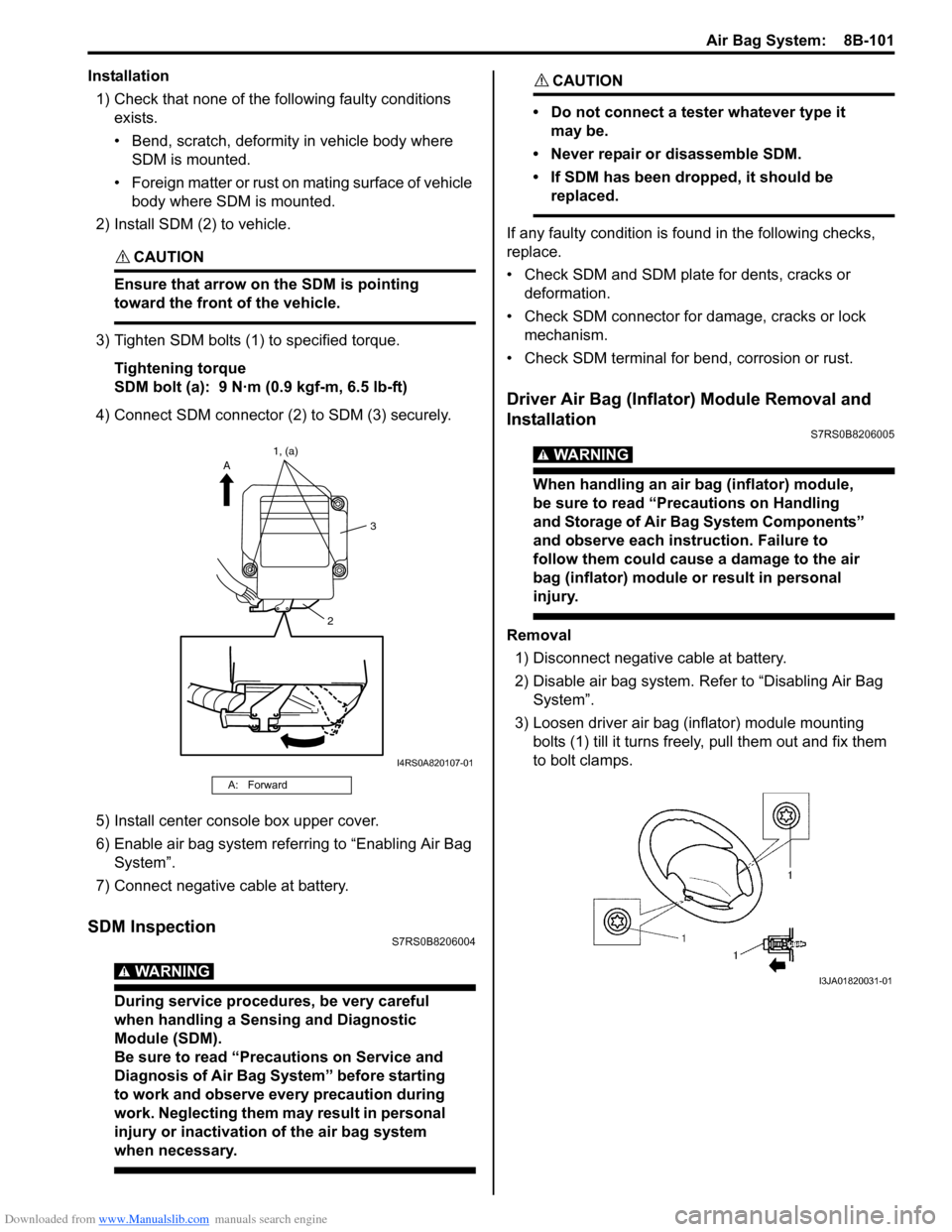

Installation1) Check that none of the following faulty conditions exists.

• Bend, scratch, deformity in vehicle body where SDM is mounted.

• Foreign matter or rust on mating surface of vehicle body where SDM is mounted.

2) Install SDM (2) to vehicle.

CAUTION!

Ensure that arrow on the SDM is pointing

toward the front of the vehicle.

3) Tighten SDM bolts (1) to specified torque.

Tightening torque

SDM bolt (a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

4) Connect SDM connector (2) to SDM (3) securely.

5) Install center console box upper cover.

6) Enable air bag system referring to “Enabling Air Bag System”.

7) Connect negative cable at battery.

SDM InspectionS7RS0B8206004

WARNING!

During service procedures, be very careful

when handling a Sensing and Diagnostic

Module (SDM).

Be sure to read “Precautions on Service and

Diagnosis of Air Bag System” before starting

to work and observe every precaution during

work. Neglecting them ma y result in personal

injury or inactivation of the air bag system

when necessary.

CAUTION!

• Do not connect a tester whatever type it may be.

• Never repair or disassemble SDM.

• If SDM has been dropped, it should be replaced.

If any faulty condition is fo und in the following checks,

replace.

• Check SDM and SDM plate for dents, cracks or deformation.

• Check SDM connector for damage, cracks or lock mechanism.

• Check SDM terminal for bend, corrosion or rust.

Driver Air Bag (Inflator) Module Removal and

Installation

S7RS0B8206005

WARNING!

When handling an air bag (inflator) module,

be sure to read “Precautions on Handling

and Storage of Air Bag System Components”

and observe each instruction. Failure to

follow them could cause a damage to the air

bag (inflator) module or result in personal

injury.

Removal 1) Disconnect negative cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System”.

3) Loosen driver air bag (inflator) module mounting bolts (1) till it turns freely, pull them out and fix them

to bolt clamps.

A: Forward

2 3

A

1, (a)

I4RS0A820107-01

I3JA01820031-01

Page 1163 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-125

Specifications

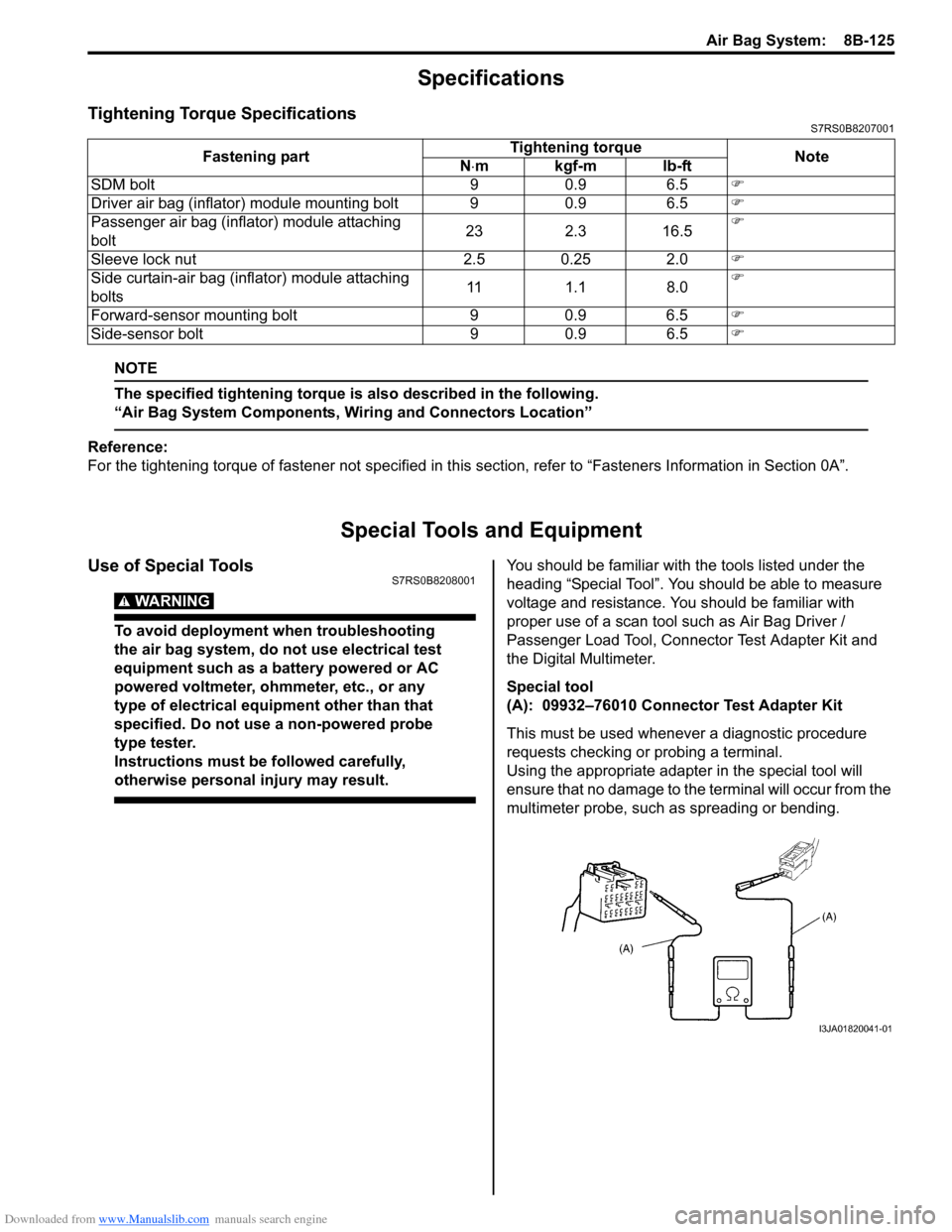

Tightening Torque SpecificationsS7RS0B8207001

NOTE

The specified tightening torque is also described in the following.

“Air Bag System Components, Wiring and Connectors Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Use of Special ToolsS7RS0B8208001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified. Do not use a non-powered probe

type tester.

Instructions must be followed carefully,

otherwise personal injury may result.

You should be familiar with the tools listed under the

heading “Special Tool”. You should be able to measure

voltage and resistance. You should be familiar with

proper use of a scan tool such as Air Bag Driver /

Passenger Load Tool, Connector Test Adapter Kit and

the Digital Multimeter.

Special tool

(A): 09932–76010 Connector Test Adapter Kit

This must be used whenever a diagnostic procedure

requests checking or probing a terminal.

Using the appropriate adapter in the special tool will

ensure that no damage to the terminal will occur from the

multimeter probe, such as spreading or bending.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

SDM bolt 9 0.9 6.5 �)

Driver air bag (inflator) module mounting bolt 9 0.9 6.5 �)

Passenger air bag (inflator) module attaching

bolt 23 2.3 16.5�)

Sleeve lock nut 2.5 0.25 2.0 �)

Side curtain-air bag (inflator) module attaching

bolts 11 1.1 8.0�)

Forward-sensor mounting bolt 9 0.9 6.5 �)

Side-sensor bolt 9 0.9 6.5 �)

I3JA01820041-01

Page 1164 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-126 Air Bag System:

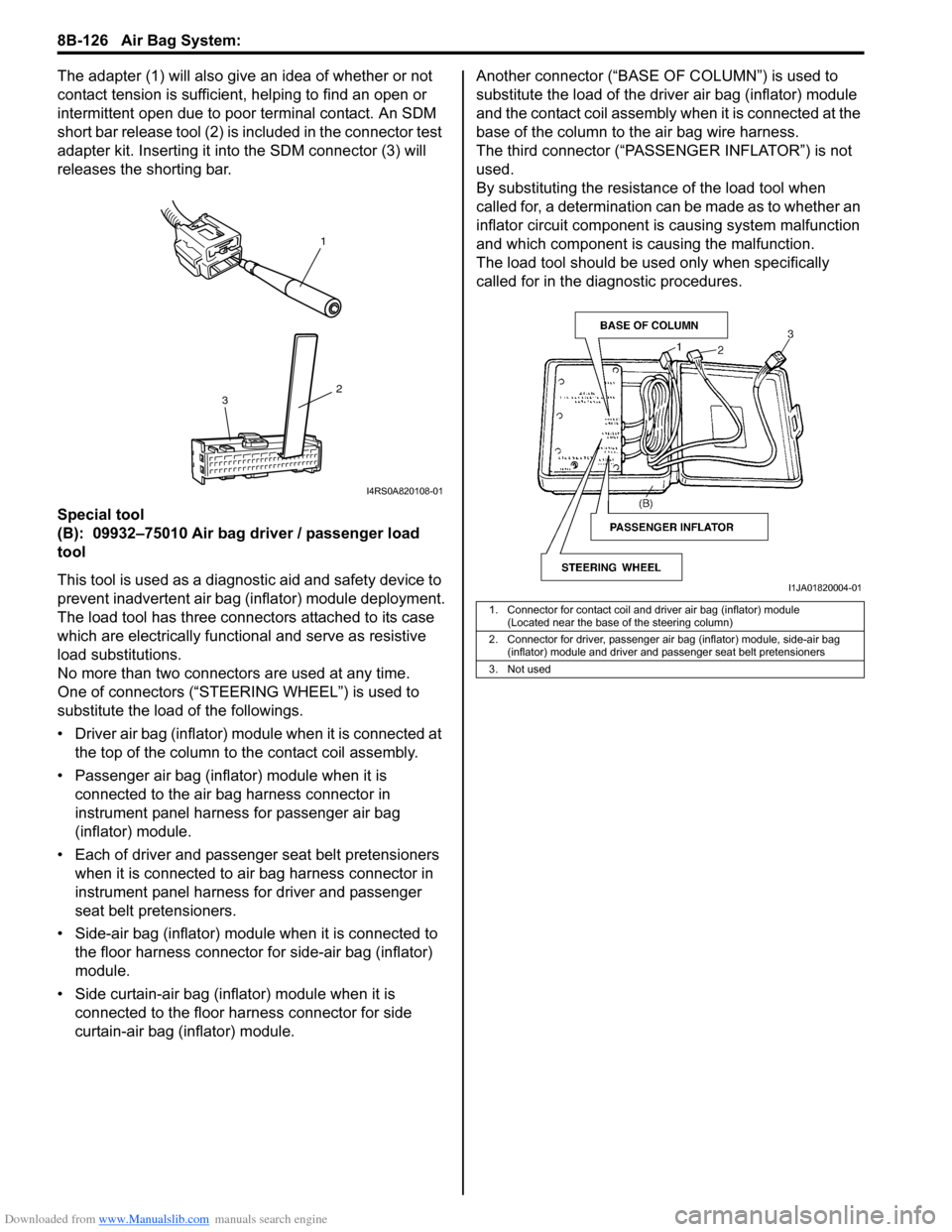

The adapter (1) will also give an idea of whether or not

contact tension is sufficient, helping to find an open or

intermittent open due to poor terminal contact. An SDM

short bar release tool (2) is included in the connector test

adapter kit. Inserting it in to the SDM connector (3) will

releases the shorting bar.

Special tool

(B): 09932–75010 Air bag driver / passenger load

tool

This tool is used as a diagno stic aid and safety device to

prevent inadvertent air bag (inflator) module deployment.

The load tool has three connectors attached to its case

which are electrically functional and serve as resistive

load substitutions.

No more than two connectors are used at any time.

One of connectors (“STEER ING WHEEL”) is used to

substitute the load of the followings.

• Driver air bag (inflator) module when it is connected at the top of the column to the contact coil assembly.

• Passenger air bag (inflator) module when it is connected to the air bag harness connector in

instrument panel harness for passenger air bag

(inflator) module.

• Each of driver and passen ger seat belt pretensioners

when it is connected to air bag harness connector in

instrument panel harness for driver and passenger

seat belt pretensioners.

• Side-air bag (inflator) module when it is connected to the floor harness connector for side-air bag (inflator)

module.

• Side curtain-air bag (inflator) module when it is connected to the floor harness connector for side

curtain-air bag (inflator) module. Another connec

tor (“BASE OF COLUMN ”) is used to

substitute the load of the driver air bag (inflator) module

and the contact coil assembly when it is connected at the

base of the column to the air bag wire harness.

The third connector (“PASSENGER INFLATOR”) is not

used.

By substituting the resistan ce of the load tool when

called for, a determination can be made as to whether an

inflator circuit component is causing system malfunction

and which component is causing the malfunction.

The load tool should be used only when specifically

called for in the diagnostic procedures.

1

2

3

I4RS0A820108-01

1. Connector for contact coil and driver air bag (inflator) module

(Located near the base of the steering column)

2. Connector for driver, passenger air bag (inflator) module, side-air bag (inflator) module and driver and passenger seat belt pretensioners

3. Not used

I1JA01820004-01

Page 1165 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-127

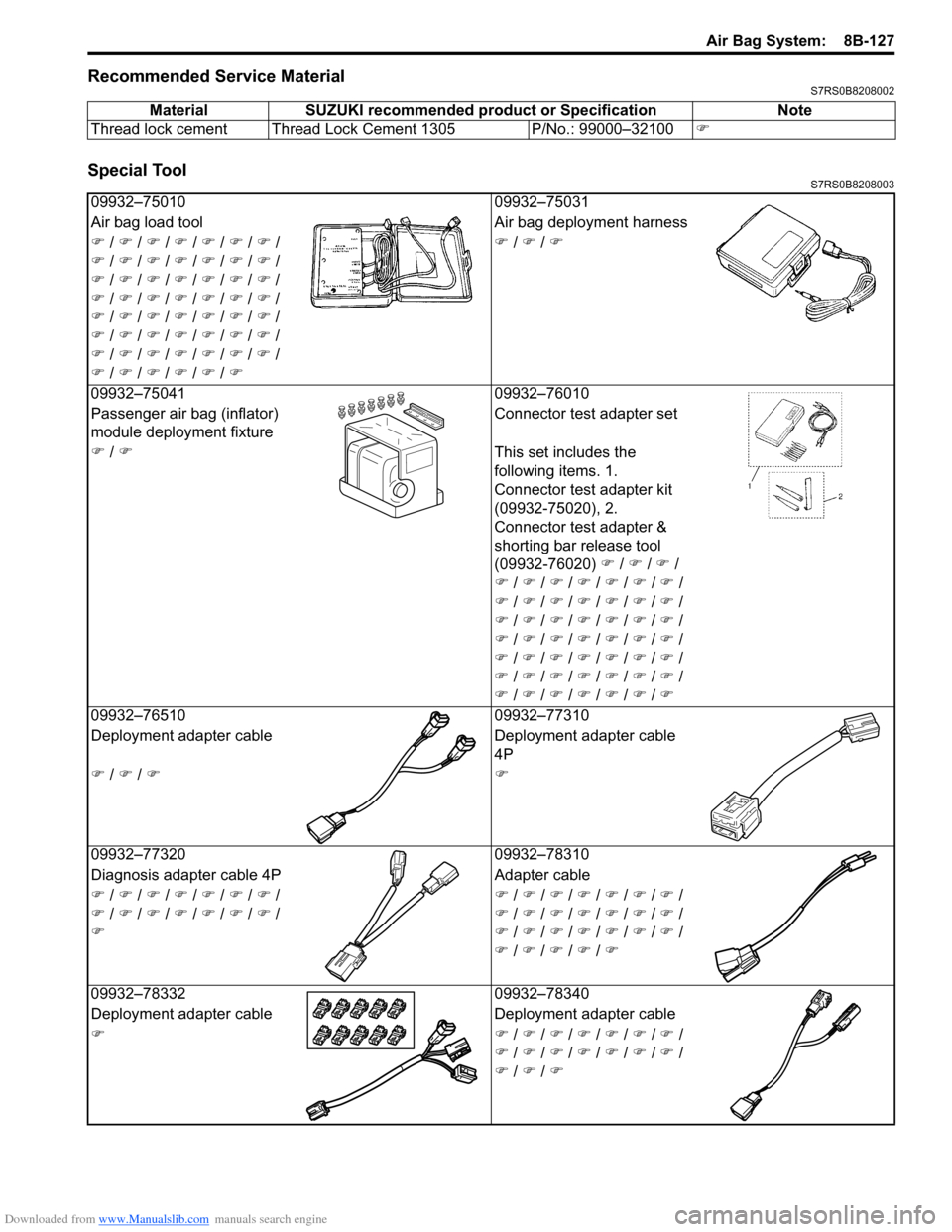

Recommended Service MaterialS7RS0B8208002

Special ToolS7RS0B8208003

MaterialSUZUKI recommended product or Specification Note

Thread lock cement Thread Lock Cement 1305 P/No.: 99000–32100 �)

09932–7501009932–75031

Air bag load tool Air bag deployment harness

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) �)

/ �) / �)

0

9932–75041 09932–76010

Passenger air bag (inflator)

module deployment fixture Connector test adapter set

�) / �) This set includes the

following items. 1.

Connector test adapter kit

(09932-75020), 2.

Connector test adapter &

shorting bar release tool

(09932-76020) �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �)

0

9932–76510 09932–77310

Deployment adapter cable Deployment adapter cable

4P

�) / �) / �)�)

09932–77320 09932–78310

Diagnosis adapter cable 4P Adapter cable

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) �)

/ �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �)

0

9932–78332 09932–78340

Deployment adapter cable Deployment adapter cable

�)�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �)

Page 1284 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-2 Lighting Systems:

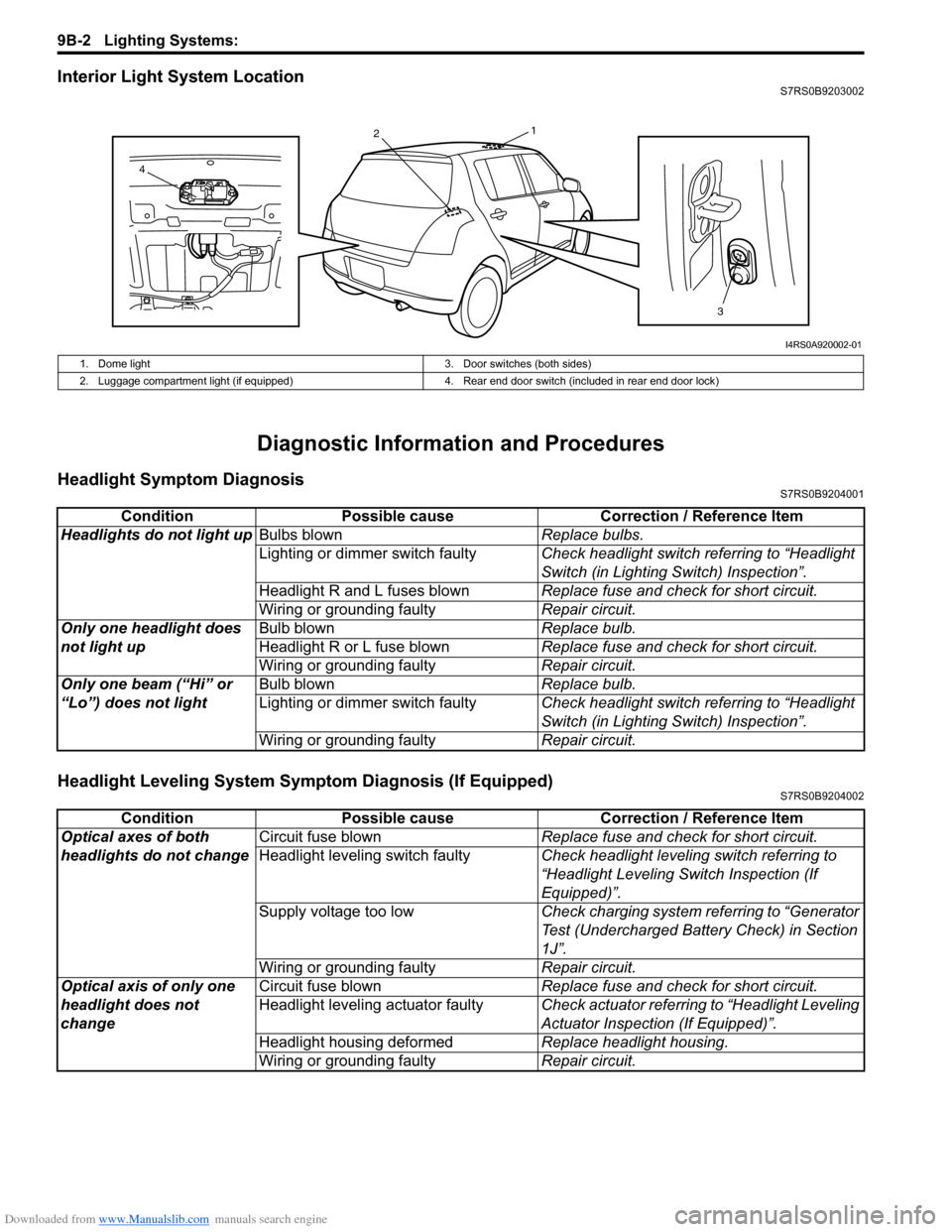

Interior Light System LocationS7RS0B9203002

Diagnostic Information and Procedures

Headlight Symptom DiagnosisS7RS0B9204001

Headlight Leveling System Symptom Diagnosis (If Equipped)S7RS0B9204002

13

2

4

I4RS0A920002-01

1. Dome light 3. Door switches (both sides)

2. Luggage compartment light (if equipped) 4. Rear end door switch (included in rear end door lock)

ConditionPossible cause Correction / Reference Item

Headlights do not light up Bulbs blown Replace bulbs.

Lighting or dimmer switch faulty Check headlight switch referring to “Headlight

Switch (in Lighting Switch) Inspection”.

Headlight R and L fuses blown Replace fuse and check for short circuit.

Wiring or grounding faulty Repair circuit.

Only one headlight does

not light up Bulb blown

Replace bulb.

Headlight R or L fuse blown Replace fuse and check for short circuit.

Wiring or grounding faulty Repair circuit.

Only one beam (“Hi” or

“Lo”) does not light Bulb blown

Replace bulb.

Lighting or dimmer switch faulty Check headlight switch referring to “Headlight

Switch (in Lighting Switch) Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

Optical axes of both

headlights do not change Circuit fuse blown

Replace fuse and check for short circuit.

Headlight leveling switch faulty Check headlight leveling switch referring to

“Headlight Leveling Switch Inspection (If

Equipped)”.

Supply voltage too low Check charging system referring to “Generator

Test (Undercharged Battery Check) in Section

1J”.

Wiring or grounding faulty Repair circuit.

Optical axis of only one

headlight does not

change Circuit fuse blown

Replace fuse and check for short circuit.

Headlight leveling actuator faulty Check actuator referring to “Headlight Leveling

Actuator Inspection (If Equipped)”.

Headlight housing deformed Replace headlight housing.

Wiring or grounding faulty Repair circuit.

Page 1285 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-3

Turn Signal and Hazard Warning Light Symptom DiagnosisS7RS0B9204003

Clearance, Tail and License Plate Light Symptom DiagnosisS7RS0B9204004

ConditionPossible cause Correction / Reference Item

Flash rate high or one

side only flashes Bulb blown on “flash rate high”-side

Replace bulb.

Incorrect bulb Replace bulb.

Turn signal / hazard warning relay faulty Check turn signal / hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection”.

Open circuit or high resistance existing

either; between turn signal switch and

non lighting bulb, or between hazard

warning switch and non lighting bulb Repair circuit.

Wiring or grounding faulty Repair circuit.

No flashing

NOTE

• Use of SUZUKI scan tool makes it easy to

check whether a faulty

condition is on the

input side or output

side of BCM. For

checking procedure,

refer to “Diagnosis

Using Output Test

Function of SUZUKI

Scan Tool” under

“Scan Tool Data in

Section 10B”.

• Check each part in the order from the top of

the following list.

Circuit fuse(s) blown Replace fuse(s) and check for short circuit.

Turn signal / hazard warning relay faulty Check turn signal / hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection”.

Turn signal light switch faulty Check turn signal light switch referring to “Turn

Signal Light Switch (in Lighting Switch)

Inspection”.

Hazard warning switch faulty Check hazard warning switch referring to

“Hazard Warning Switch Inspection”.

Open circuit or high resistance existing

between battery and switch Repair circuit.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Flash rate low Supply voltage low Check charging system.

Turn signal / hazard warning relay faulty Check turn signal / hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection”.

ConditionPossible cause Correction / Reference Item

All lights do not light up Circuit fuse blown Replace fuse and check for short circuit.

Lighting and dimmer switch of

combination switch faulty Check lighting and dimmer switch referring to

“Headlight Switch (in Lighting Switch)

Inspection”.

Wiring or grounding faulty Repair circuit.

Some lights do not light

up Bulb(s) blown

Replace bulb(s).

Wiring or grounding faulty Repair circuit.

Page 1287 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-5

Interior Light Symptom DiagnosisS7RS0B9204008

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Repair Instructions

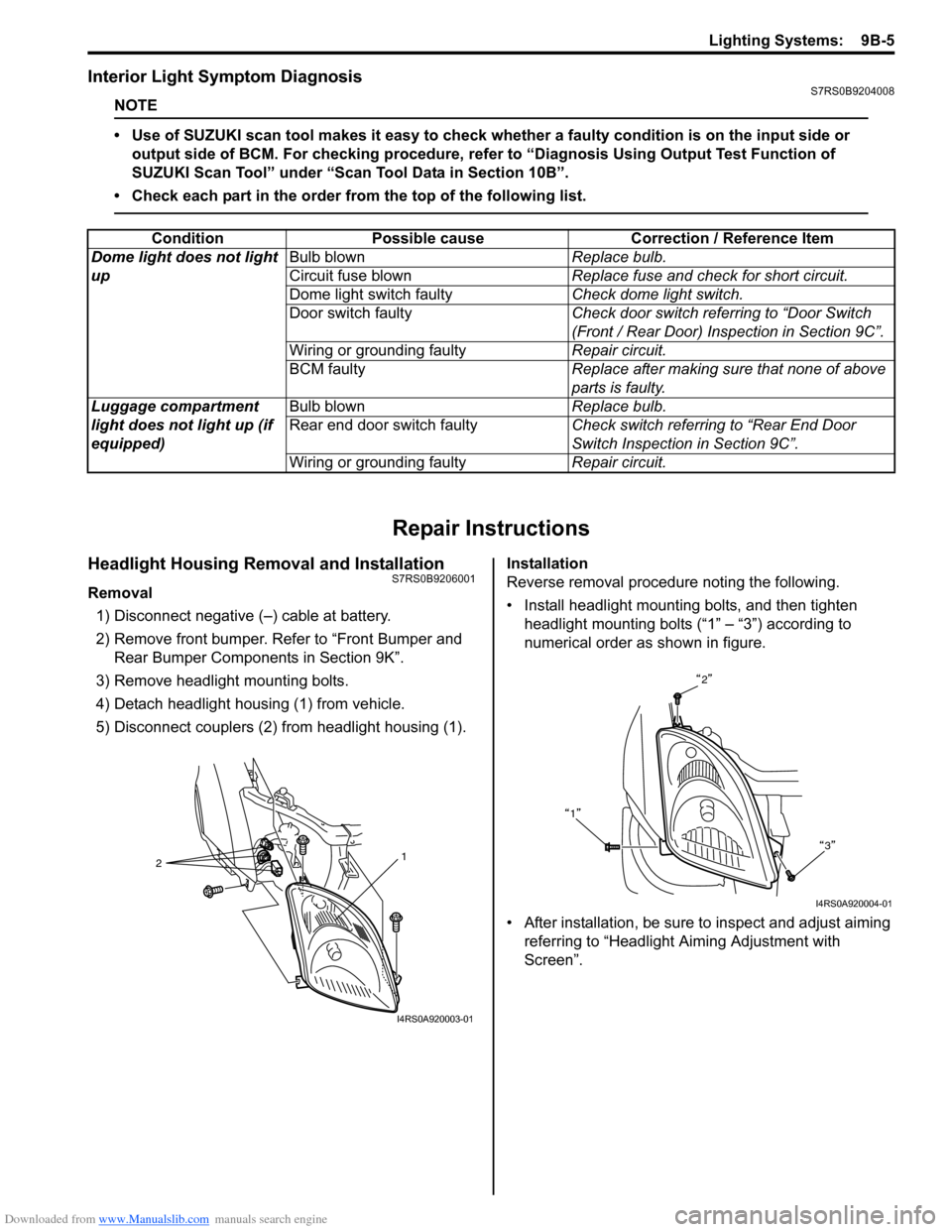

Headlight Housing Removal and InstallationS7RS0B9206001

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper. Refer to “Front Bumper and Rear Bumper Componen ts in Section 9K”.

3) Remove headlight mounting bolts.

4) Detach headlight housing (1) from vehicle.

5) Disconnect couplers (2) from headlight housing (1). Installation

Reverse removal procedure noting the following.

• Install headlight mounting bolts, and then tighten

headlight mounting bolts (“1” – “3”) according to

numerical order as shown in figure.

• After installation, be sure to inspect and adjust aiming referring to “Headlight Aiming Adjustment with

Screen”.

Condition Possible cause Correction / Reference Item

Dome light does not light

up Bulb blown

Replace bulb.

Circuit fuse blown Replace fuse and check for short circuit.

Dome light switch faulty Check dome light switch.

Door switch faulty Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Luggage compartment

light does not light up (if

equipped) Bulb blown

Replace bulb.

Rear end door switch faulty Check switch referring to “Rear End Door

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

2 1

I4RS0A920003-01

2

1 3

I4RS0A920004-01

Page 1305 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-10

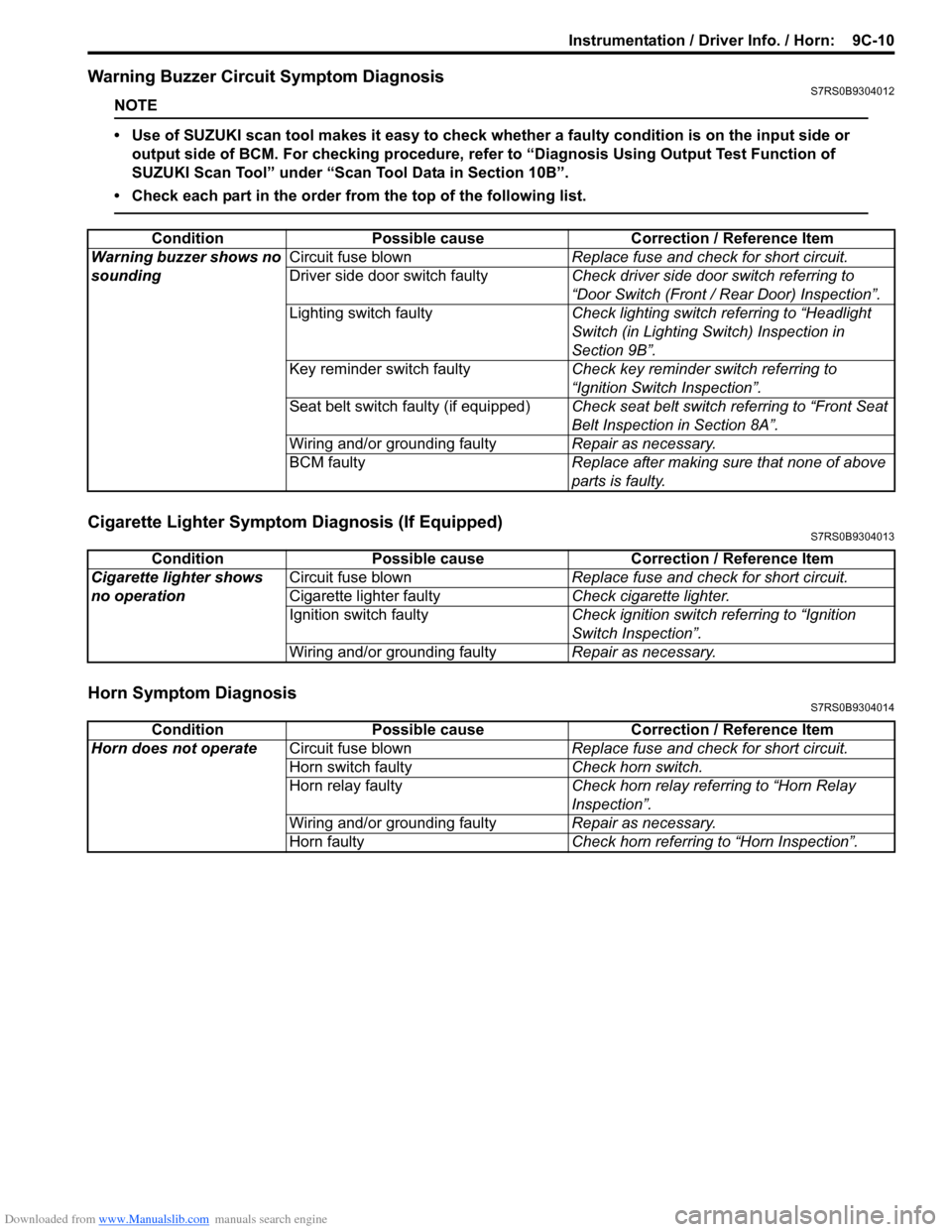

Warning Buzzer Circuit Symptom DiagnosisS7RS0B9304012

NOTE

• Use of SUZUKI scan tool makes it easy to check wh ether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Cigarette Lighter Symptom Diagnosis (If Equipped)S7RS0B9304013

Horn Symptom DiagnosisS7RS0B9304014

Condition Possible cause Correction / Reference Item

Warning buzzer shows no

sounding Circuit fuse blown

Replace fuse and check for short circuit.

Driver side door switch faulty Check driver side door switch referring to

“Door Switch (Front / Rear Door) Inspection”.

Lighting switch faulty Check lighting switch referring to “Headlight

Switch (in Lighting Switch) Inspection in

Section 9B”.

Key reminder switch faulty Check key reminder switch referring to

“Ignition Switch Inspection”.

Seat belt switch faulty (if equipped) Check seat belt switch referring to “Front Seat

Belt Inspection in Section 8A”.

Wiring and/or grounding faulty Repair as necessary.

BCM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

Cigarette lighter shows

no operation Circuit fuse blown

Replace fuse and check for short circuit.

Cigarette lighter faulty Check cigarette lighter.

Ignition switch faulty Check ignition switch referring to “Ignition

Switch Inspection”.

Wiring and/or grounding faulty Repair as necessary.

ConditionPossible cause Correction / Reference Item

Horn does not operate Circuit fuse blown Replace fuse and check for short circuit.

Horn switch faulty Check horn switch.

Horn relay faulty Check horn relay referring to “Horn Relay

Inspection”.

Wiring and/or grounding faulty Repair as necessary.

Horn faulty Check horn referring to “Horn Inspection”.

Page 1307 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-12

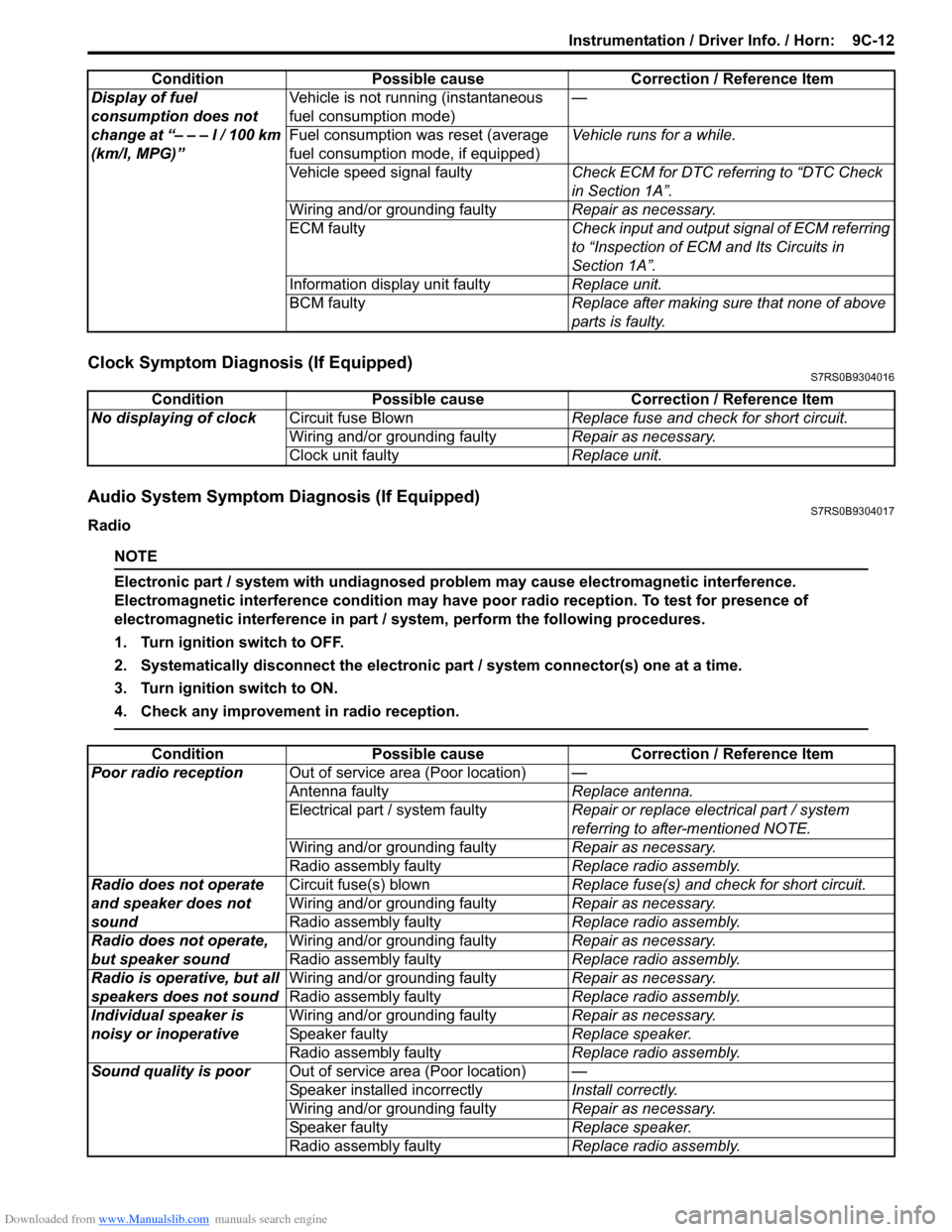

Clock Symptom Diagnosis (If Equipped)S7RS0B9304016

Audio System Symptom Diagnosis (If Equipped)S7RS0B9304017

Radio

NOTE

Electronic part / system with undiagnosed pr oblem may cause electromagnetic interference.

Electromagnetic interference condition may have poor radio reception. To test for presence of

electromagnetic interference in part / system, perform the following procedures.

1. Turn ignition switch to OFF.

2. Systematically disconnect the electronic part / system connector(s) one at a time.

3. Turn ignition switch to ON.

4. Check any improvement in radio reception.

Display of fuel

consumption does not

change at “– – – l / 100 km

(km/l, MPG)” Vehicle is not running (instantaneous

fuel consumption mode)

—

Fuel consumption was reset (average

fuel consumption mo de, if equipped)Vehicle runs for a while.

Vehicle speed signal faulty Check ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring and/or grounding faulty Repair as necessary.

ECM faulty Check input and output signal of ECM referring

to “Inspection of ECM and Its Circuits in

Section 1A”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

No displaying of clock Circuit fuse Blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Clock unit faulty Replace unit.

ConditionPossible cause Correction / Reference Item

Poor radio reception Out of service area (Poor location) —

Antenna faulty Replace antenna.

Electrical part / system faulty Repair or replace electrical part / system

referring to after-mentioned NOTE.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate

and speaker does not

sound Circuit fuse(s) blown

Replace fuse(s) and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate,

but speaker sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio is operative, but all

speakers does not sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Individual speaker is

noisy or inoperative Wiring and/or grounding faulty

Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Sound quality is poor Out of service area (Poor location) —

Speaker installed incorrectly Install correctly.

Wiring and/or grounding faulty Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.