gear SUZUKI SWIFT 2005 2.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 750 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-106 Automatic Transmission/Transaxle:

Automatic Transaxle Unit Dismounting and

Remounting

S7RS0B5106031

Dismounting1) Take down transaxle with engine. For its procedure, refer to “Engine Assembly Removal and Installation

in Section 1D”.

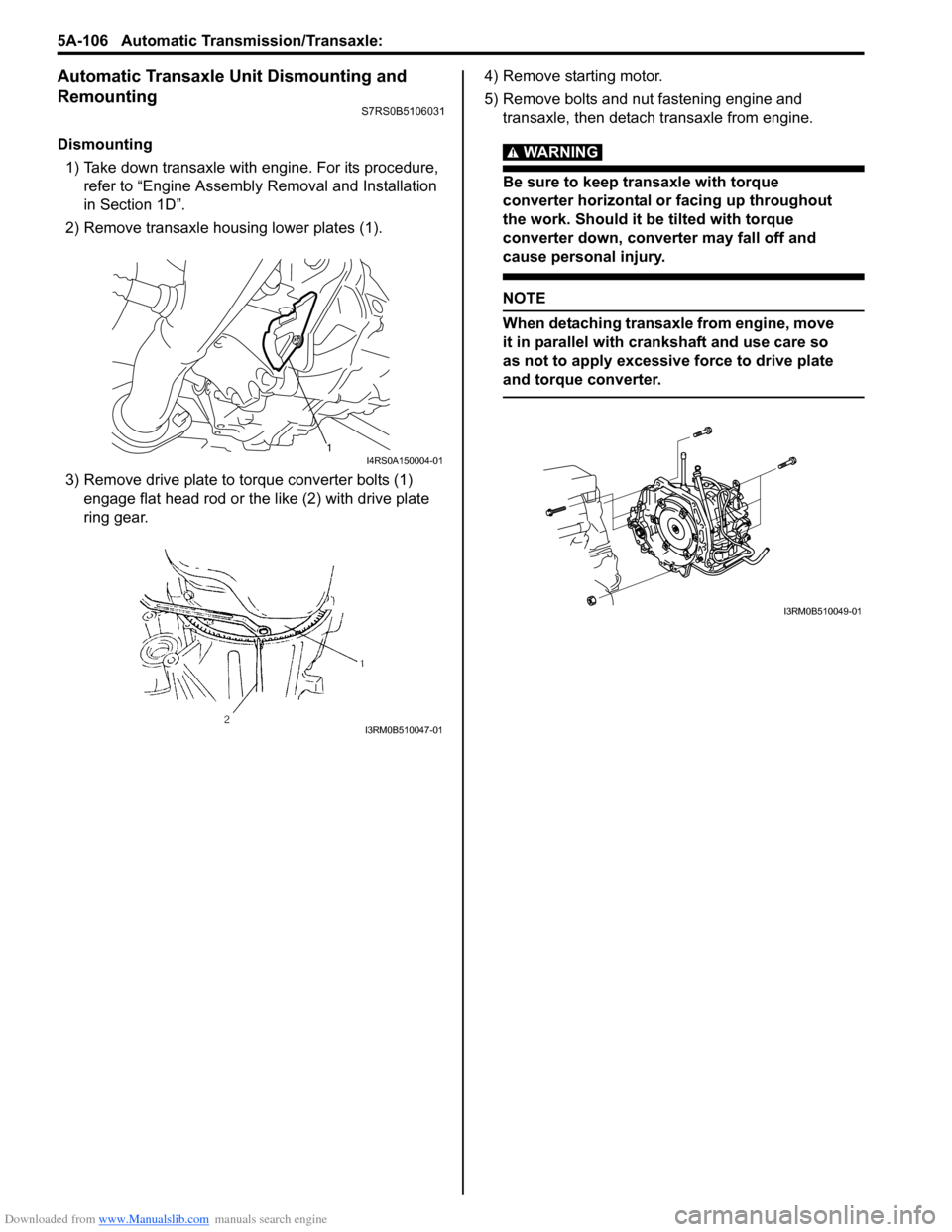

2) Remove transaxle housing lower plates (1).

3) Remove drive plate to torque converter bolts (1) engage flat head rod or the like (2) with drive plate

ring gear. 4) Remove starting motor.

5) Remove bolts and nut fastening engine and

transaxle, then detach transaxle from engine.WARNING!

Be sure to keep transaxle with torque

converter horizontal or facing up throughout

the work. Should it be tilted with torque

converter down, converter may fall off and

cause personal injury.

NOTE

When detaching transaxle from engine, move

it in parallel with cranks haft and use care so

as not to apply excessive force to drive plate

and torque converter.

1I4RS0A150004-01

I3RM0B510047-01

I3RM0B510049-01

Page 751 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-107

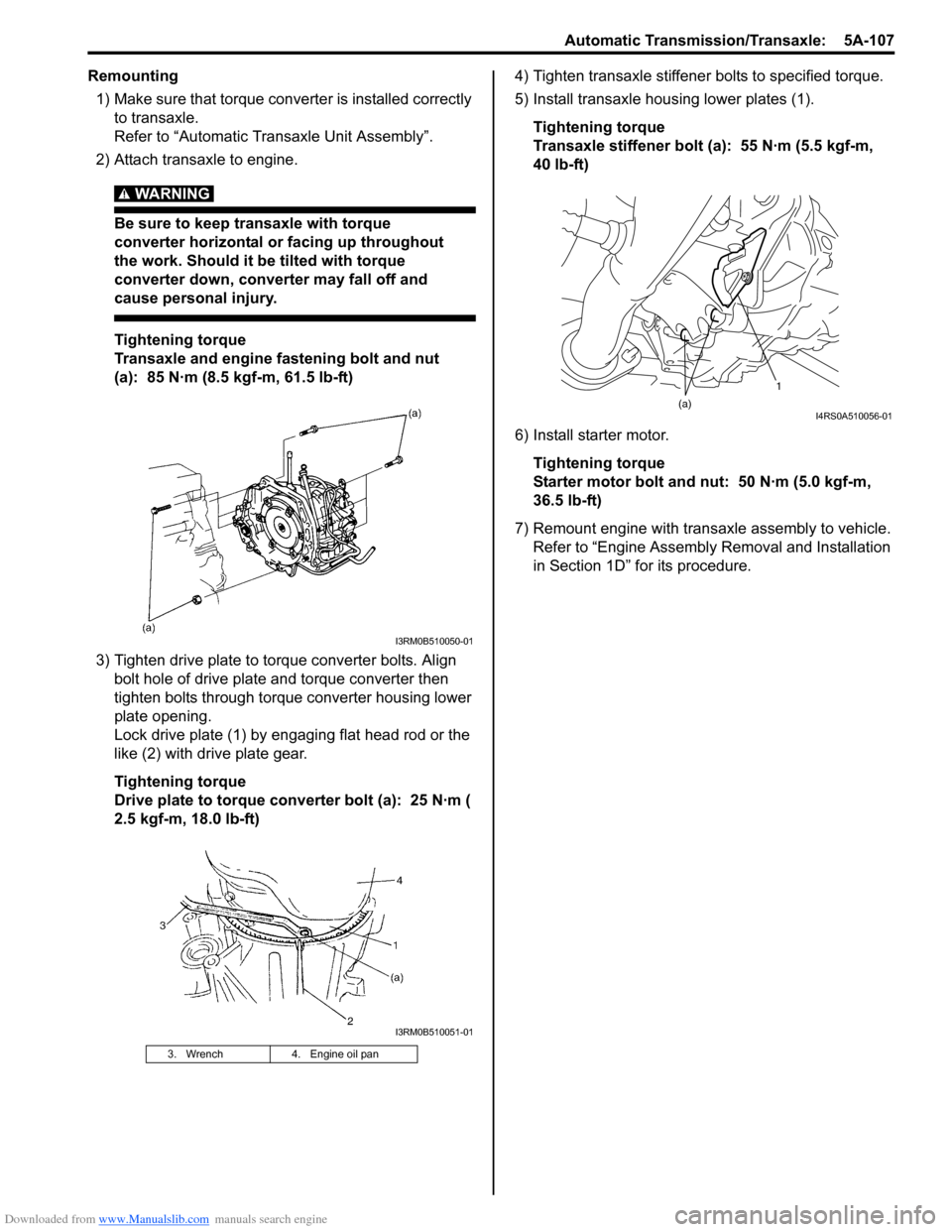

Remounting1) Make sure that torque converter is installed correctly to transaxle.

Refer to “Automatic Transaxle Unit Assembly”.

2) Attach transaxle to engine.

WARNING!

Be sure to keep transaxle with torque

converter horizontal or facing up throughout

the work. Should it be tilted with torque

converter down, converter may fall off and

cause personal injury.

Tightening torque

Transaxle and engine fastening bolt and nut

(a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

3) Tighten drive plate to torque converter bolts. Align bolt hole of drive plate and torque converter then

tighten bolts through torque converter housing lower

plate opening.

Lock drive plate (1) by engaging flat head rod or the

like (2) with drive plate gear.

Tightening torque

Drive plate to torque converter bolt (a): 25 N·m (

2.5 kgf-m, 18.0 lb-ft) 4) Tighten transaxle stiffener bolts to specified torque.

5) Install transaxle housing lower plates (1).

Tightening torque

Transaxle stiffener bolt (a): 55 N·m (5.5 kgf-m,

40 lb-ft)

6) Install starter motor. Tightening torque

Starter motor bolt and nut: 50 N·m (5.0 kgf-m,

36.5 lb-ft)

7) Remount engine with transaxle assembly to vehicle. Refer to “Engine Assembly Removal and Installation

in Section 1D” for its procedure.

3. Wrench 4. Engine oil pan

I3RM0B510050-01

I3RM0B510051-01

1

(a)

I4RS0A510056-01

Page 753 of 1496

Downloaded from www.Manualslib.com manuals search engine A u to m a tic Tra n s m is s io n /Tra n s a x le : 5 A -1 0 9

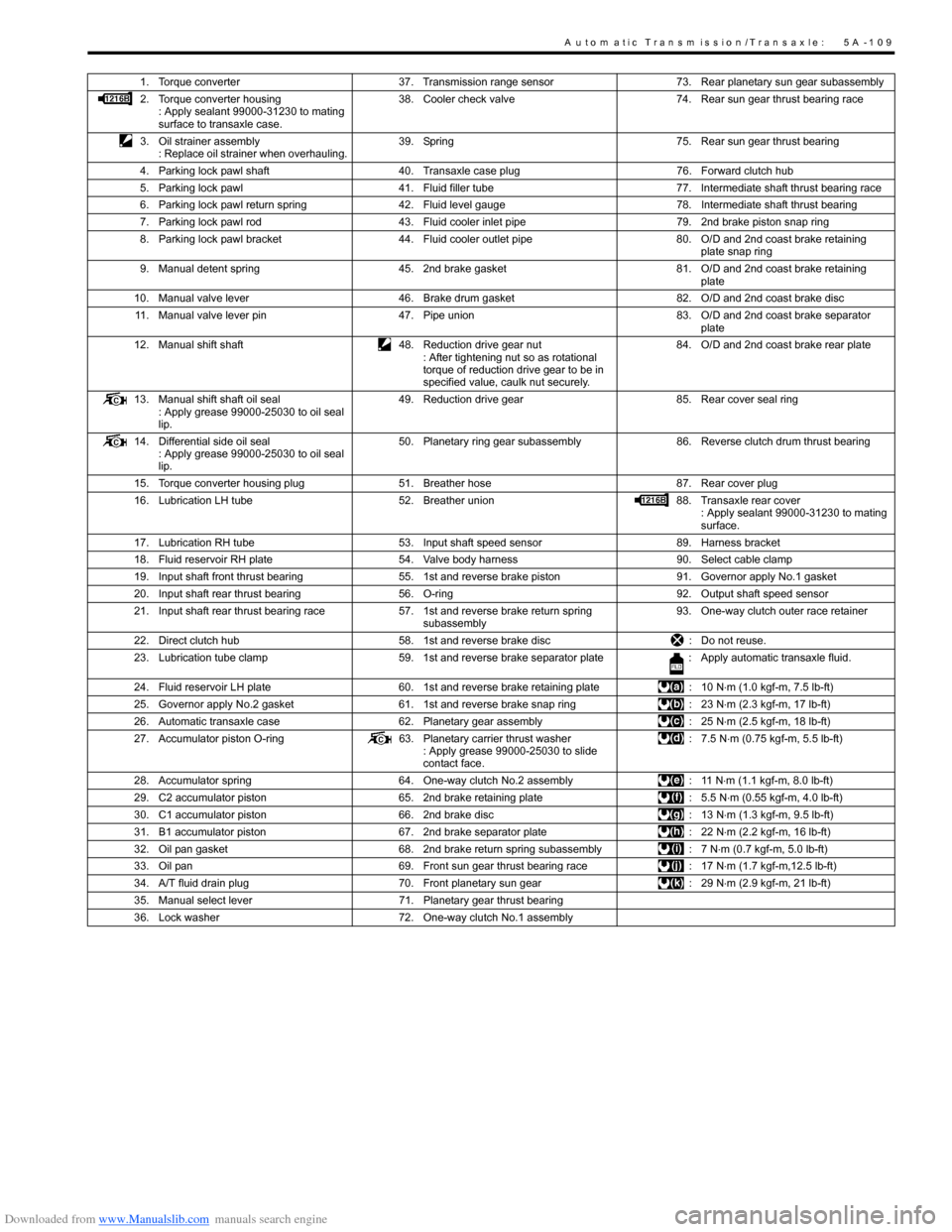

1. Torque converter37. Transmission range sensor 73. Rear planetary sun gear subassembly

2. Torque converter housing : Apply sealant 99000-31230 to mating

surface to transaxle case. 38. Cooler check valve

74. Rear sun gear thrust bearing race

3. Oil strainer assembly : Replace oil strainer when overhauling. 39. Spring

75. Rear sun gear thrust bearing

4. Parking lock pawl shaft 40. Transaxle case plug 76. Forward clutch hub

5. Parking lock pawl 41. Fluid filler tube 77. Intermediate shaft thrust bearing race

6. Parking lock pawl return spring 42. Fluid level gauge 78. Intermediate shaft thrust bearing

7. Parking lock pawl rod 43. Fluid cooler inlet pipe 79. 2nd brake piston snap ring

8. Parking lock pawl bracket 44. Fluid cooler outlet pipe 80. O/D and 2nd coast brake retaining

plate snap ring

9. Manual detent spring 45. 2nd brake gasket 81. O/D and 2nd coast brake retaining

plate

10. Manual valve lever 46. Brake drum gasket 82. O/D and 2nd coast brake disc

11. Manual valve lever pin 47. Pipe union 83. O/D and 2nd coast brake separator

plate

12. Manual shift shaft 48. Reduction drive gear nut

: After tightening nut so as rotational

torque of reduction drive gear to be in

specified value, caulk nut securely. 84. O/D and 2nd coast brake rear plate

13. Manual shift shaft oil seal : Apply grease 99000-25030 to oil seal

lip. 49. Reduction drive gear

85. Rear cover seal ring

14. Differential side oil seal : Apply grease 99000-25030 to oil seal

lip. 50. Planetary ring gear subassembly

86. Reverse clutch drum thrust bearing

15. Torque converter housing plug 51. Breather hose 87. Rear cover plug

16. Lubrication LH tube 52. Breather union 88. Transaxle rear cover

: Apply sealant 99000-31230 to mating

surface.

17. Lubrication RH tube 53. Input shaft speed sensor 89. Harness bracket

18. Fluid reservoir RH plate 54. Valve body harness 90. Select cable clamp

19. Input shaft front thrust bearing 55. 1st and reverse brake piston 91. Governor apply No.1 gasket

20. Input shaft rear thrust bearing 56. O-ring 92. Output shaft speed sensor

21. Input shaft rear thrust bearing race 57. 1st and reverse brake return spring

subassembly 93. One-way clutch outer race retainer

22. Direct clutch hub 58. 1st and reverse brake disc : Do not reuse.

23. Lubrication tube clamp 59. 1st and reverse brake separator plate : Apply automatic transaxle fluid.

24. Fluid reservoir LH plate 60. 1st and reverse brake retaining plate : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

25. Governor apply No.2 gasket 61. 1st and reverse brake snap ring : 23 N⋅m (2.3 kgf-m, 17 lb-ft)

26. Automatic transaxle case 62. Planetary gear assembly : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

27. Accumulator piston O-ring 63. Planetary carrier thrust washer

: Apply grease 99000-25030 to slide

contact face. : 7.5 N

⋅m (0.75 kgf-m, 5.5 lb-ft)

28. Accumulator spring 64. One-way clutch No.2 assembly : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

29. C2 accumulator piston 65. 2nd brake retaining plate : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

30. C1 accumulator piston 66. 2nd brake disc : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

31. B1 accumulator piston 67. 2nd brake separator plate : 22 N⋅m (2.2 kgf-m, 16 lb-ft)

32. Oil pan gasket 68. 2nd brake return spring subassembly : 7 N⋅m (0.7 kgf-m, 5.0 lb-ft)

33. Oil pan 69. Front sun gear thrust bearing race : 17 N⋅m (1.7 kgf-m,12.5 lb-ft)

34. A/T fluid drain plug 70. Front planetary sun gear : 29 N⋅m (2.9 kgf-m, 21 lb-ft)

35. Manual select lever 71. Planetary gear thrust bearing

36. Lock washer 72. One-way clutch No.1 assembly

Page 760 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-116 Automatic Transmission/Transaxle:

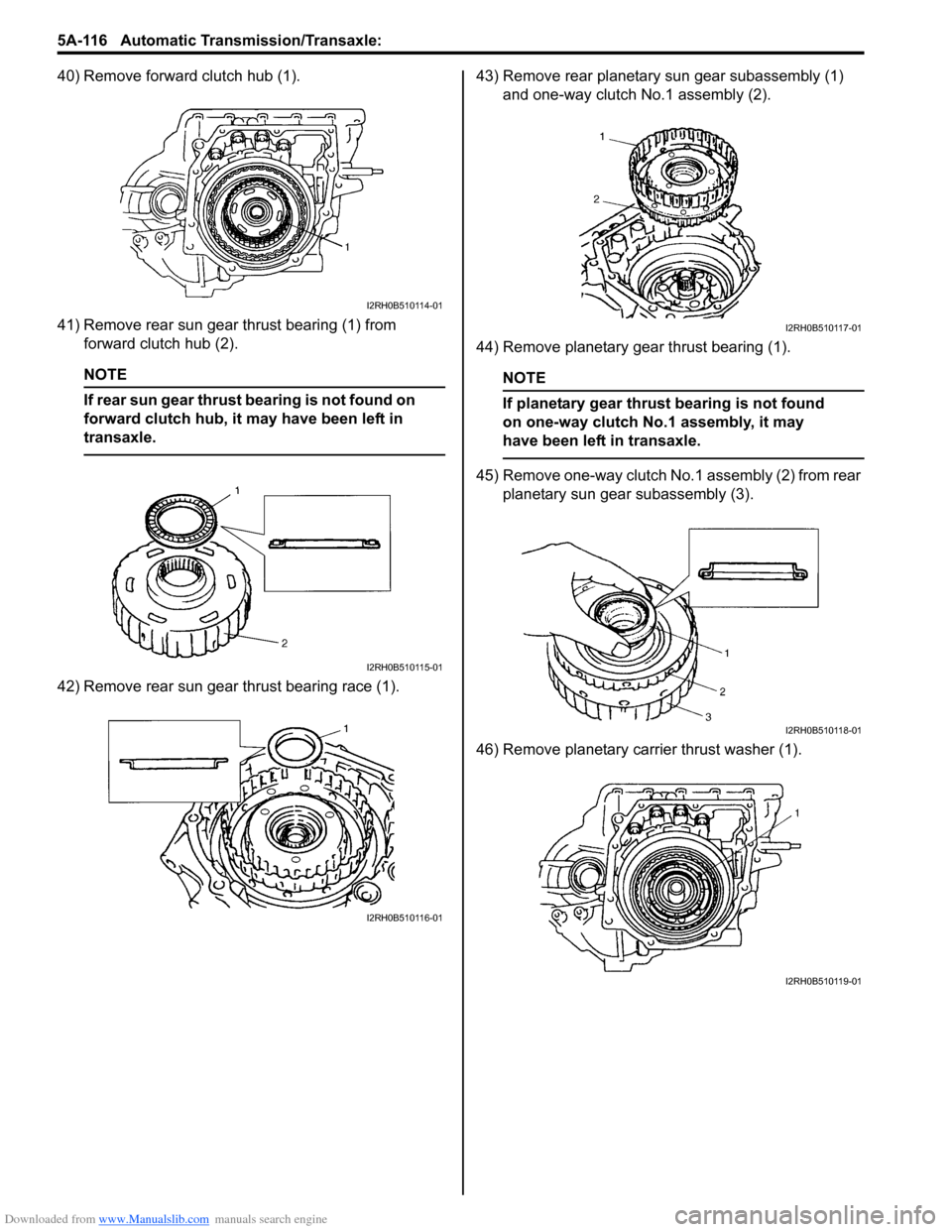

40) Remove forward clutch hub (1).

41) Remove rear sun gear thrust bearing (1) from forward clutch hub (2).

NOTE

If rear sun gear thrust bearing is not found on

forward clutch hub, it may have been left in

transaxle.

42) Remove rear sun gear thrust bearing race (1). 43) Remove rear planetary sun gear subassembly (1)

and one-way clutch No.1 assembly (2).

44) Remove planetary gear thrust bearing (1).

NOTE

If planetary gear thrust bearing is not found

on one-way clutch No.1 assembly, it may

have been left in transaxle.

45) Remove one-way clutch No.1 assembly (2) from rear planetary sun gear subassembly (3).

46) Remove planetary carrier thrust washer (1).

I2RH0B510114-01

I2RH0B510115-01

I2RH0B510116-01

I2RH0B510117-01

I2RH0B510118-01

I2RH0B510119-01

Page 761 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-117

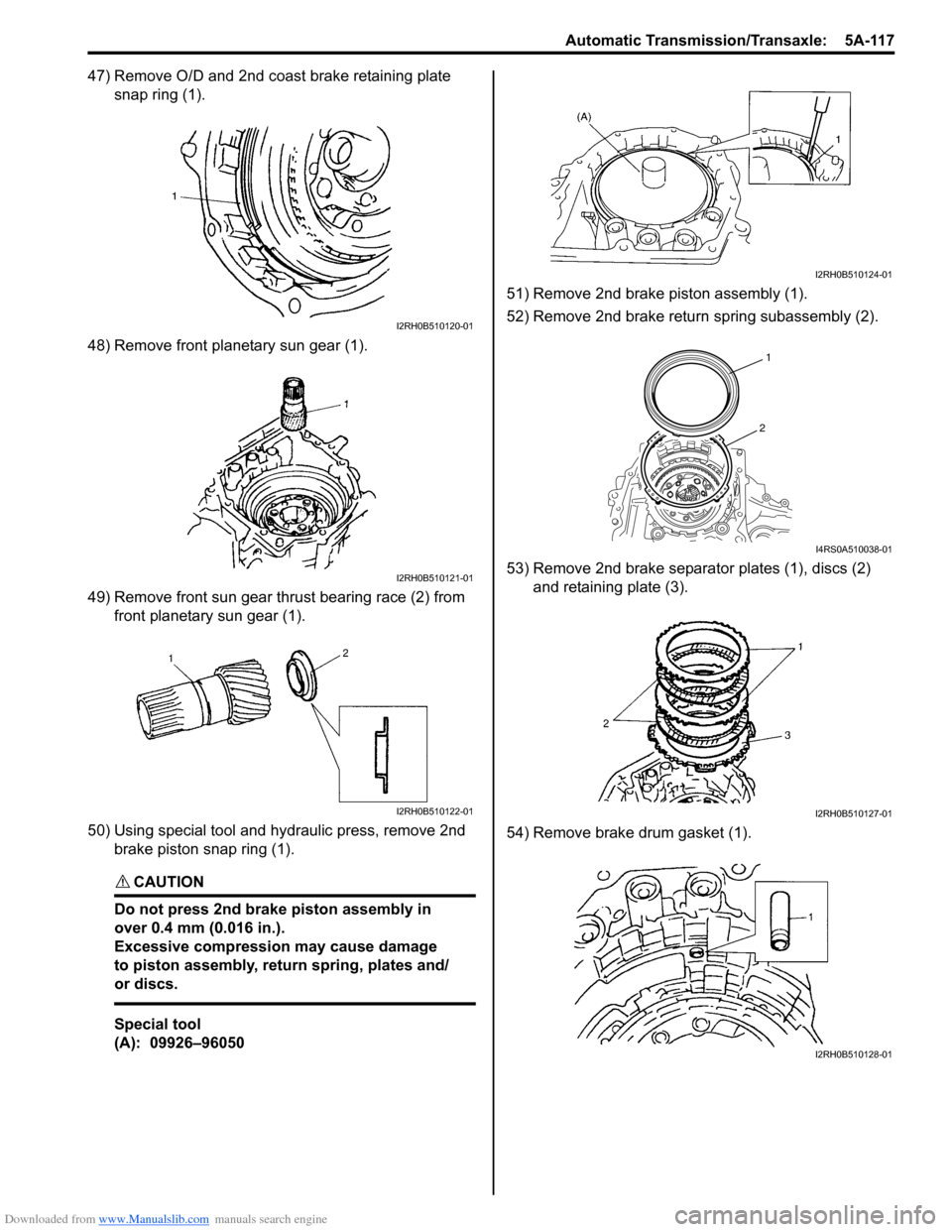

47) Remove O/D and 2nd coast brake retaining plate snap ring (1).

48) Remove front planetary sun gear (1).

49) Remove front sun gear thrust bearing race (2) from front planetary sun gear (1).

50) Using special tool and hydraulic press, remove 2nd brake piston snap ring (1).

CAUTION!

Do not press 2nd brake piston assembly in

over 0.4 mm (0.016 in.).

Excessive compression may cause damage

to piston assembly, return spring, plates and/

or discs.

Special tool

(A): 09926–96050 51) Remove 2nd brake piston assembly (1).

52) Remove 2nd brake return spring subassembly (2).

53) Remove 2nd brake separator plates (1), discs (2)

and retaining plate (3).

54) Remove brake drum gasket (1).

I2RH0B510120-01

I2RH0B510121-01

I2RH0B510122-01

I2RH0B510124-01

1

2

I4RS0A510038-01

I2RH0B510127-01

I2RH0B510128-01

Page 762 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-118 Automatic Transmission/Transaxle:

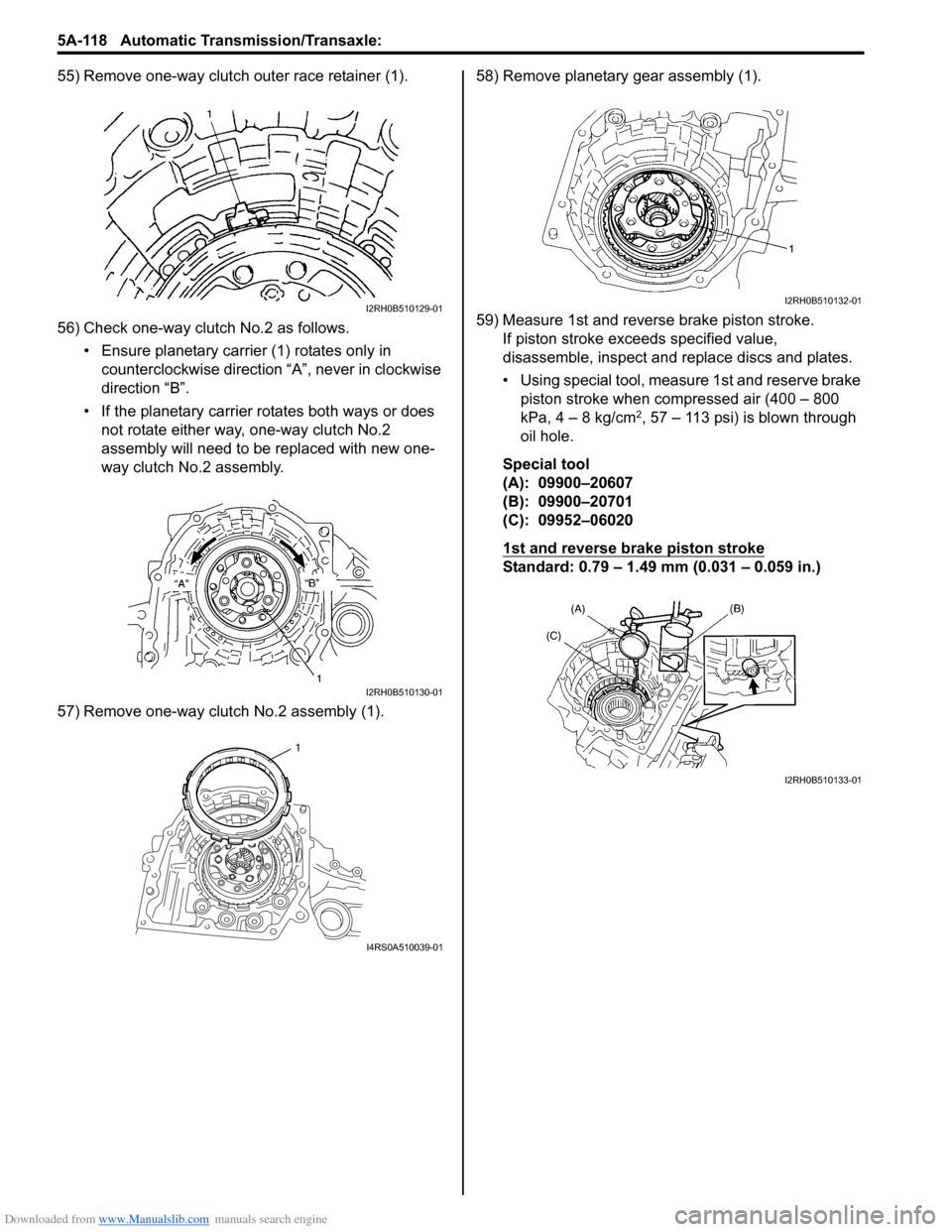

55) Remove one-way clutch outer race retainer (1).

56) Check one-way clutch No.2 as follows.• Ensure planetary carrier (1) rotates only in counterclockwise direction “A”, never in clockwise

direction “B”.

• If the planetary carrier rotates both ways or does not rotate either way, one-way clutch No.2

assembly will need to be replaced with new one-

way clutch No.2 assembly.

57) Remove one-way clutch No.2 assembly (1). 58) Remove planetary gear assembly (1).

59) Measure 1st and reverse brake piston stroke.

If piston stroke exce eds specified value,

disassemble, inspect and replace discs and plates.

• Using special tool, measure 1st and reserve brake piston stroke when compressed air (400 – 800

kPa, 4 – 8 kg/cm

2, 57 – 113 psi) is blown through

oil hole.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06020

1st and reverse brake piston stroke

Standard: 0.79 – 1.49 mm (0.031 – 0.059 in.)

I2RH0B510129-01

I2RH0B510130-01

1

I4RS0A510039-01

I2RH0B510132-01

I2RH0B510133-01

Page 763 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-119

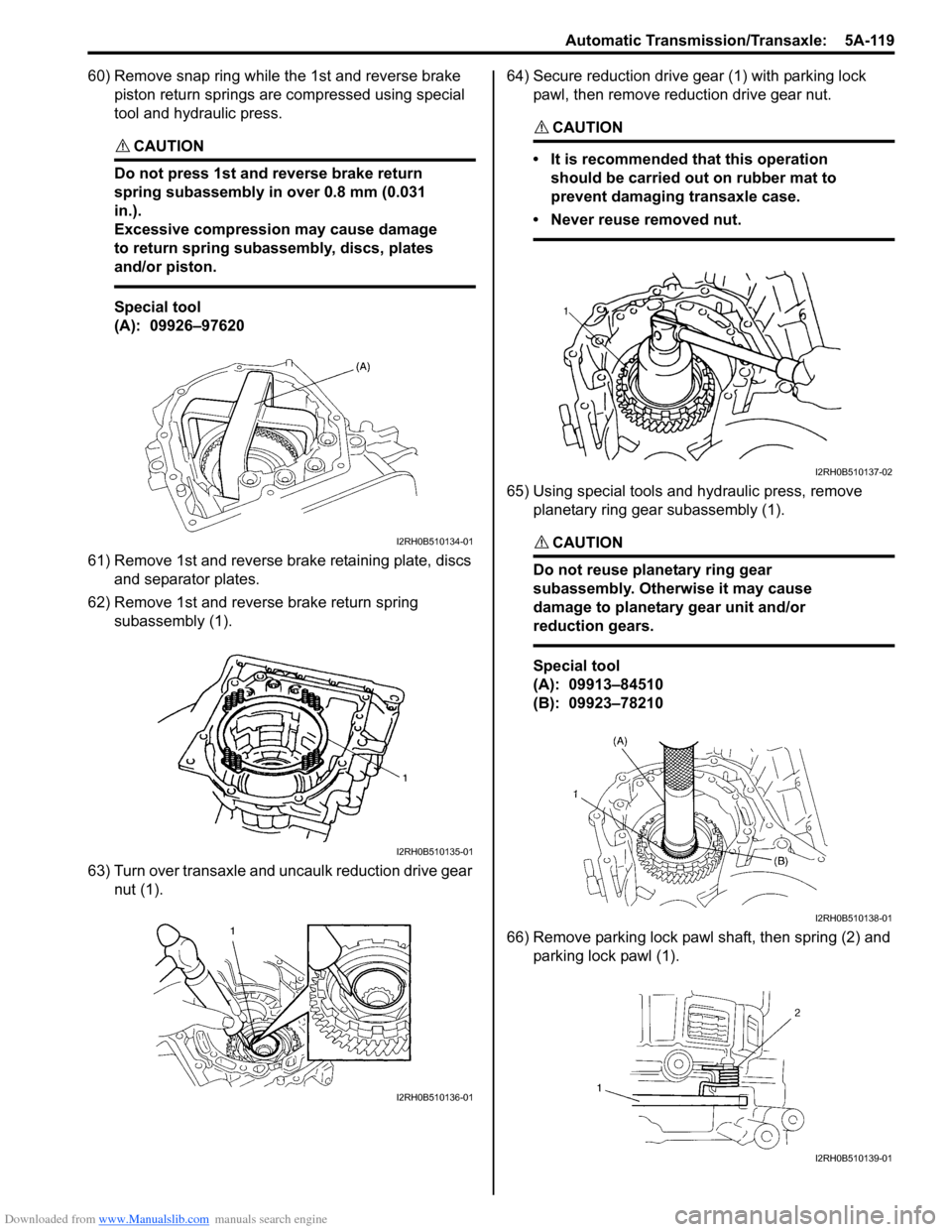

60) Remove snap ring while the 1st and reverse brake piston return springs are compressed using special

tool and hydraulic press.

CAUTION!

Do not press 1st and reverse brake return

spring subassembly in over 0.8 mm (0.031

in.).

Excessive compression may cause damage

to return spring subassembly, discs, plates

and/or piston.

Special tool

(A): 09926–97620

61) Remove 1st and reverse brake retaining plate, discs and separator plates.

62) Remove 1st and reverse brake return spring subassembly (1).

63) Turn over transaxle and uncaulk reduction drive gear nut (1). 64) Secure reduction drive gear (1) with parking lock

pawl, then remove reduction drive gear nut.

CAUTION!

• It is recommended that this operation should be carried out on rubber mat to

prevent damaging transaxle case.

• Never reuse removed nut.

65) Using special tools and hydraulic press, remove planetary ring gear subassembly (1).

CAUTION!

Do not reuse planetary ring gear

subassembly. Otherwise it may cause

damage to planetary gear unit and/or

reduction gears.

Special tool

(A): 09913–84510

(B): 09923–78210

66) Remove parking lock pawl shaft, then spring (2) and parking lock pawl (1).

I2RH0B510134-01

I2RH0B510135-01

I2RH0B510136-01

I2RH0B510137-02

I2RH0B510138-01

I2RH0B510139-01

Page 764 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-120 Automatic Transmission/Transaxle:

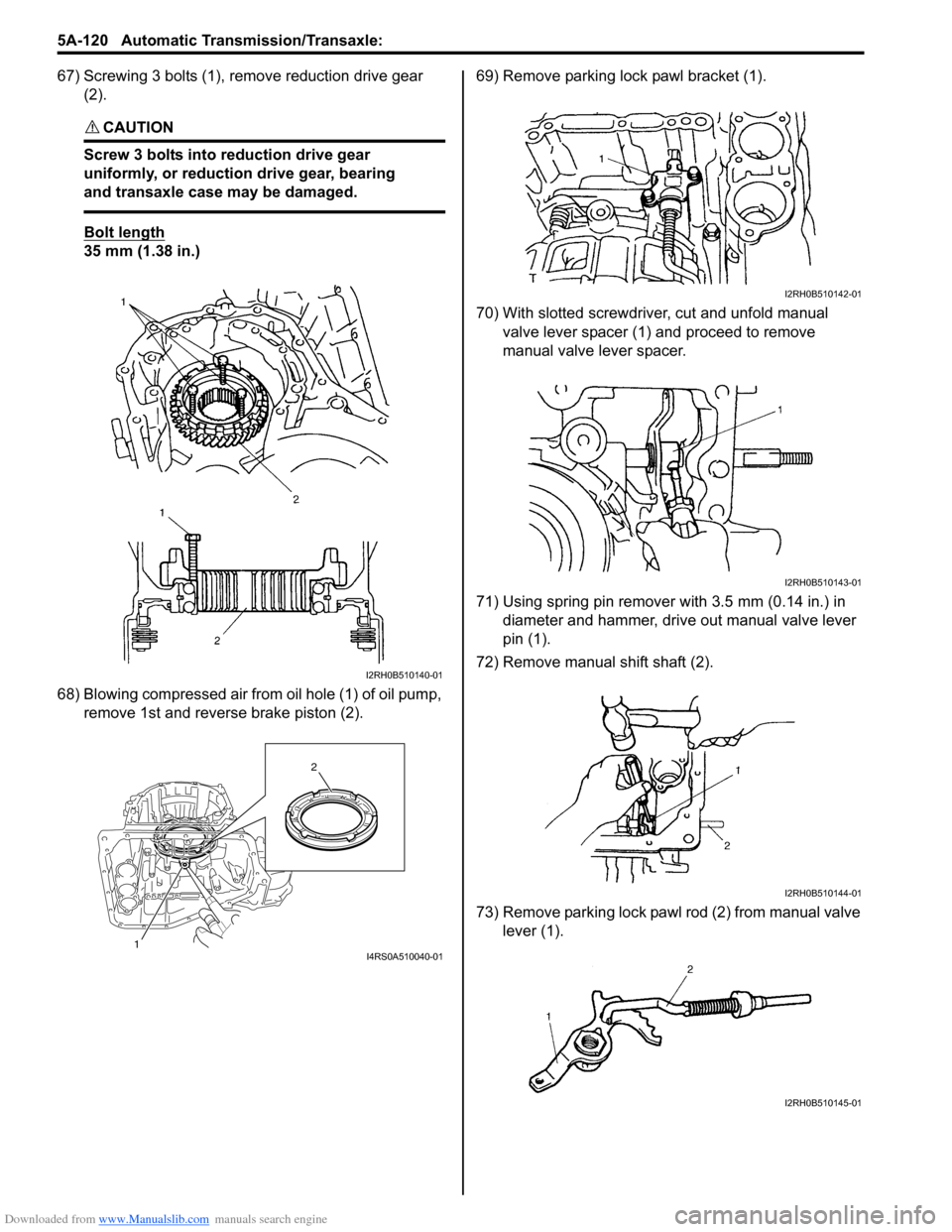

67) Screwing 3 bolts (1), remove reduction drive gear (2).

CAUTION!

Screw 3 bolts into reduction drive gear

uniformly, or reduction drive gear, bearing

and transaxle case may be damaged.

Bolt length

35 mm (1.38 in.)

68) Blowing compressed air from oil hole (1) of oil pump,

remove 1st and reverse brake piston (2). 69) Remove parking lock pawl bracket (1).

70) With slotted screwdriver, cut and unfold manual

valve lever spacer (1) and proceed to remove

manual valve lever spacer.

71) Using spring pin remover with 3.5 mm (0.14 in.) in diameter and hammer, drive out manual valve lever

pin (1).

72) Remove manual shift shaft (2).

73) Remove parking lock pawl rod (2) from manual valve lever (1).

I2RH0B510140-01

1 2I4RS0A510040-01

I2RH0B510142-01

I2RH0B510143-01

I2RH0B510144-01

I2RH0B510145-01

Page 765 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-121

74) Remove manual detent spring (1).75) Remove manual shift shaft oil seal (1).

Oil Pump Assembly ComponentsS7RS0B5106034

I2RH0B510146-01I2RH0B510147-01

I2RH0B510148-01

1. Oil seal

: Apply grease 99000-25030 to oil seal lip. 5. Oil pump drive gear : Apply automatic transaxle fluid.

2. O-ring 6. Stator shaft assembly : Tightening torque

3. Oil pump body 7. Oil pump subassembly bolts : Do not reuse.

4. Oil pump driven gear

Page 766 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-122 Automatic Transmission/Transaxle:

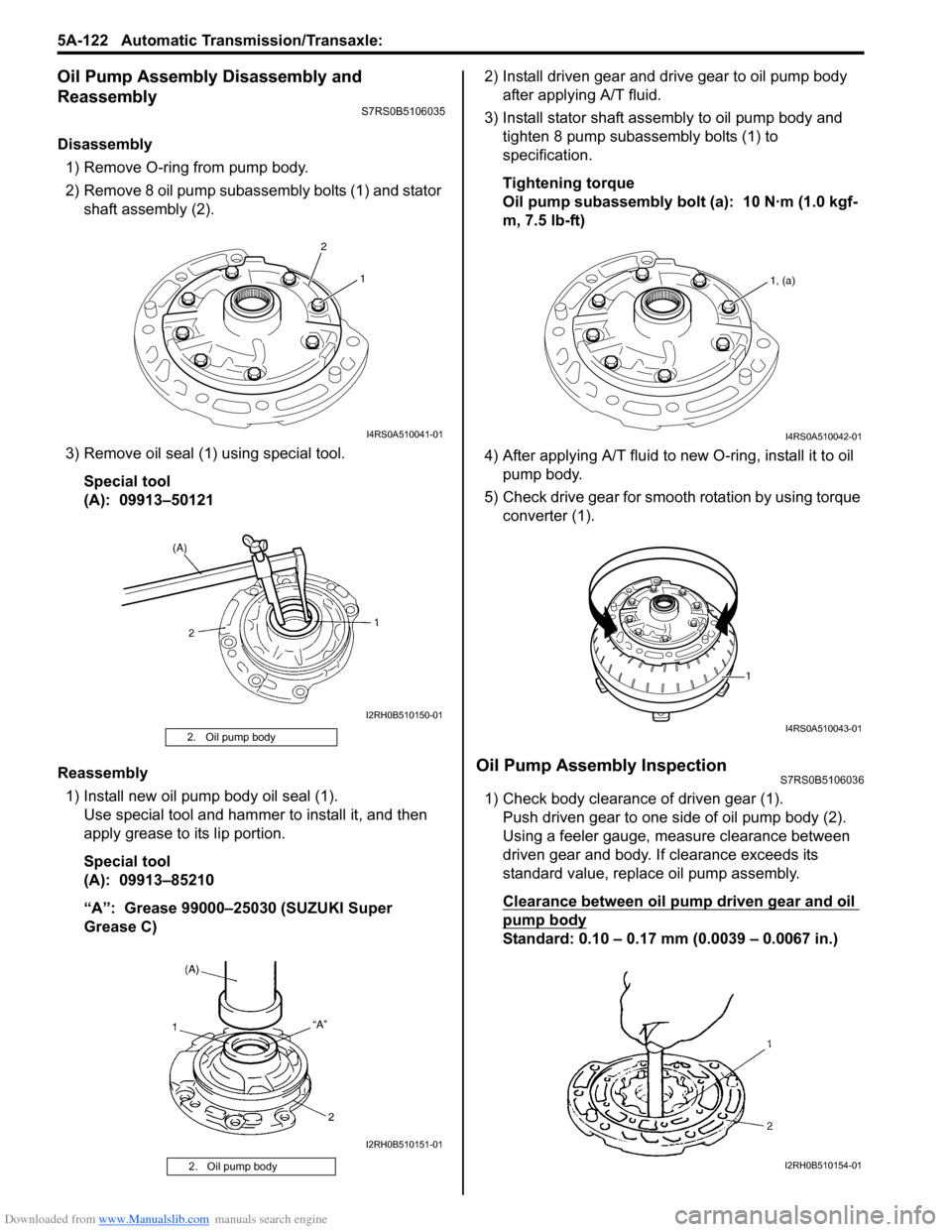

Oil Pump Assembly Disassembly and

Reassembly

S7RS0B5106035

Disassembly1) Remove O-ring from pump body.

2) Remove 8 oil pump subassembly bolts (1) and stator shaft assembly (2).

3) Remove oil seal (1) using special tool. Special tool

(A): 09913–50121

Reassembly 1) Install new oil pump body oil seal (1). Use special tool and hammer to install it, and then

apply grease to its lip portion.

Special tool

(A): 09913–85210

“A”: Grease 99000–25030 (SUZUKI Super

Grease C) 2) Install driven gear and drive gear to oil pump body

after applying A/T fluid.

3) Install stator shaft assembly to oil pump body and tighten 8 pump subassembly bolts (1) to

specification.

Tightening torque

Oil pump subassembly bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

4) After applying A/T fluid to new O-ring, install it to oil pump body.

5) Check drive gear for smooth rotation by using torque converter (1).

Oil Pump Assembly InspectionS7RS0B5106036

1) Check body clearance of driven gear (1).Push driven gear to one side of oil pump body (2).

Using a feeler gauge, m easure clearance between

driven gear and body. If clearance exceeds its

standard value, replace oil pump assembly.

Clearance between oil pump driven gear and oil

pump body

Standard: 0.10 – 0.17 mm (0.0039 – 0.0067 in.)

2. Oil pump body

2. Oil pump body

2 1

I4RS0A510041-01

I2RH0B510150-01

I2RH0B510151-01

1, (a)

I4RS0A510042-01

1

I4RS0A510043-01

I2RH0B510154-01