gear SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 820 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-6 Manual Transmission/Transaxle:

Gear Shift Control Lever and Cable Removal

and Installation

S7RS0B5206004

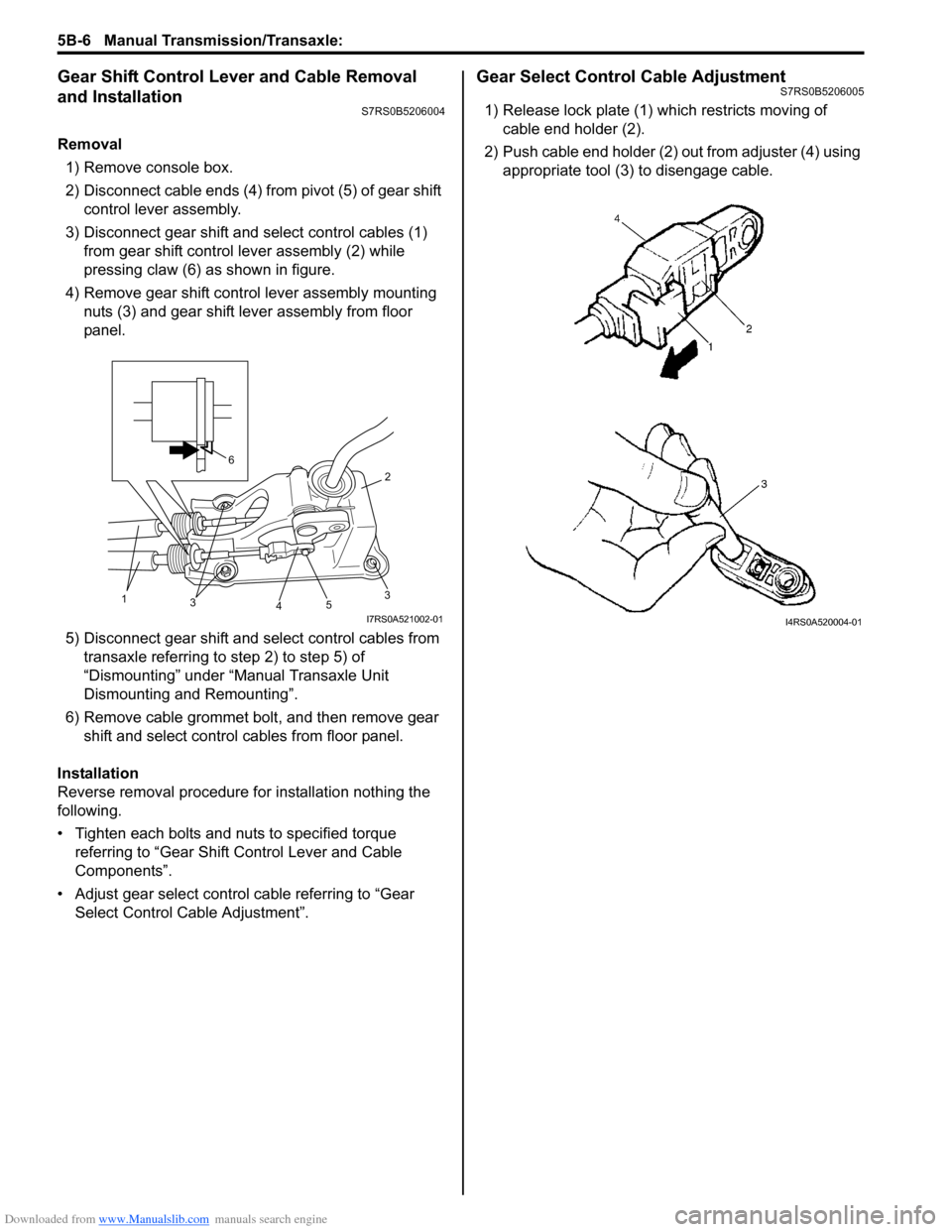

Removal1) Remove console box.

2) Disconnect cable ends (4) from pivot (5) of gear shift control lever assembly.

3) Disconnect gear shift and select control cables (1) from gear shift control lever assembly (2) while

pressing claw (6) as shown in figure.

4) Remove gear shift control lever assembly mounting nuts (3) and gear shift lever assembly from floor

panel.

5) Disconnect gear shift and select control cables from transaxle referring to step 2) to step 5) of

“Dismounting” under “Manual Transaxle Unit

Dismounting and Remounting”.

6) Remove cable grommet bolt, and then remove gear shift and select control cables from floor panel.

Installation

Reverse removal procedure for installation nothing the

following.

• Tighten each bolts and nuts to specified torque referring to “Gear Shift Control Lever and Cable

Components”.

• Adjust gear select control cable referring to “Gear Select Control Cable Adjustment”.

Gear Select Control Cable AdjustmentS7RS0B5206005

1) Release lock plate (1) which restricts moving of cable end holder (2).

2) Push cable end holder (2) out from adjuster (4) using appropriate tool (3) to disengage cable.

35

4

2

31

6

I7RS0A521002-01I4RS0A520004-01

Page 821 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-7

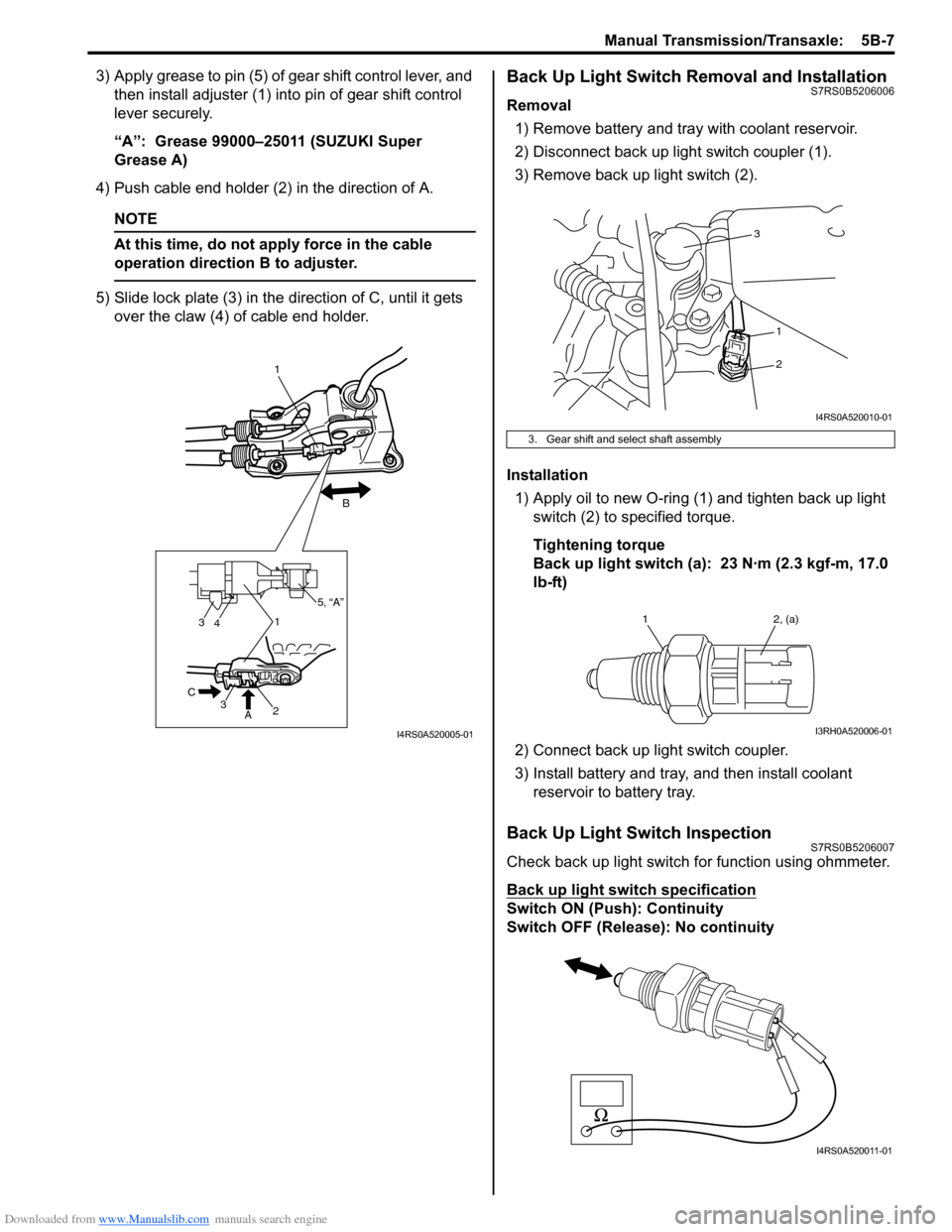

3) Apply grease to pin (5) of gear shift control lever, and then install adjuster (1) into pin of gear shift control

lever securely.

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

4) Push cable end holder (2) in the direction of A.

NOTE

At this time, do not a pply force in the cable

operation direction B to adjuster.

5) Slide lock plate (3) in the direction of C, until it gets over the claw (4) of cable end holder.

Back Up Light Switch Removal and InstallationS7RS0B5206006

Removal

1) Remove battery and tray with coolant reservoir.

2) Disconnect back up light switch coupler (1).

3) Remove back up light switch (2).

Installation 1) Apply oil to new O-ring (1) and tighten back up light switch (2) to specified torque.

Tightening torque

Back up light switch (a): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

2) Connect back up light switch coupler.

3) Install battery and tray, and then install coolant reservoir to battery tray.

Back Up Light Switch InspectionS7RS0B5206007

Check back up light switch for function using ohmmeter.

Back up light switch specification

Switch ON (Push): Continuity

Switch OFF (Release ): No continuity

3

3

41

2

A

C

1

B

5, “A”

I4RS0A520005-01

3. Gear shift and select shaft assembly

3

1

2

I4RS0A520010-01

1 2, (a)

I3RH0A520006-01

I4RS0A520011-01

Page 822 of 1496

![SUZUKI SWIFT 2005 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 5B-8 Manual Transmission/Transaxle:

Manual Transaxle Unit ComponentsS7RS0B5206008

13

6(a)

5

14(c)

114 7

(b)

12

7(b)

8

2

5 [A]

1

10

6

(a)

(a)

( SUZUKI SWIFT 2005 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 5B-8 Manual Transmission/Transaxle:

Manual Transaxle Unit ComponentsS7RS0B5206008

13

6(a)

5

14(c)

114 7

(b)

12

7(b)

8

2

5 [A]

1

10

6

(a)

(a)

(](/img/20/7607/w960_7607-821.png)

Downloaded from www.Manualslib.com manuals search engine 5B-8 Manual Transmission/Transaxle:

Manual Transaxle Unit ComponentsS7RS0B5206008

13

6(a)

5

14(c)

114 7

(b)

12

7(b)

8

2

5 [A]

1

10

6

(a)

(a)

(b)3

9

9

(b)

(d)

I6RS0C520004-03

[A]: Forward

7. Engine left mounting bracket bolt and nuts 14. Clutch operating cylinder bolt

1. Engine 8. Clutch housing lower plate : 85 N⋅m (8.5 kgf-m, 61.5 lb-ft)

2. Transaxle 9. Engine rear mounting bracket bolts : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)

3. Engine rear mounting and bracket 10. Transaxle to engine nut : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

4. Back up light switch connector 11. Ground cable : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

5. Clutch operating cylinder 12. Engine left mounting bracket

6. Transaxle to engine bolt 13. Gear shift & select control cables

Page 823 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-9

Manual Transaxle Unit Dismounting and

Remounting

S7RS0B5206009

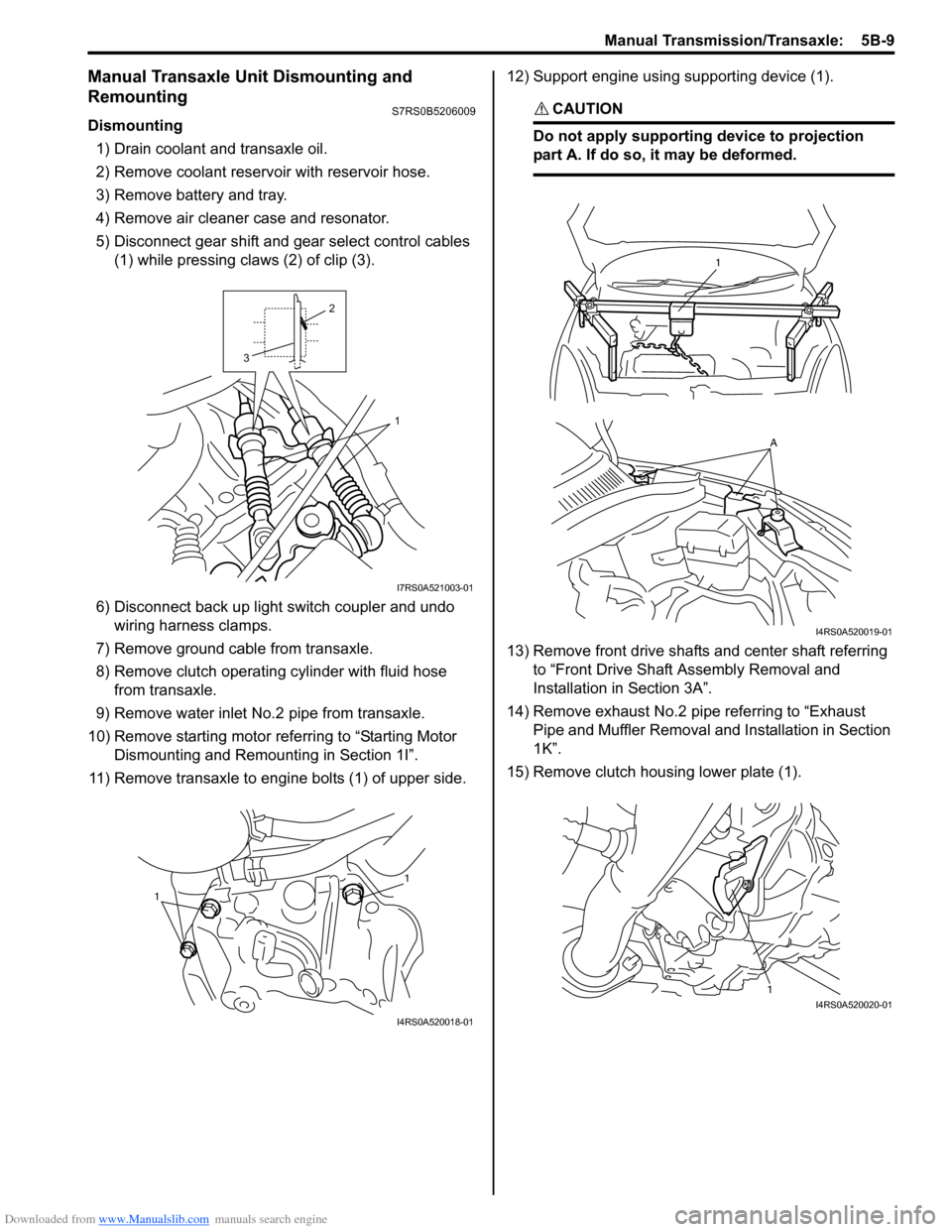

Dismounting1) Drain coolant and transaxle oil.

2) Remove coolant reservoir with reservoir hose.

3) Remove battery and tray.

4) Remove air cleaner case and resonator.

5) Disconnect gear shift and gear select control cables (1) while pressing claws (2) of clip (3).

6) Disconnect back up light switch coupler and undo wiring harness clamps.

7) Remove ground cable from transaxle.

8) Remove clutch operating cylinder with fluid hose from transaxle.

9) Remove water inlet No.2 pipe from transaxle.

10) Remove starting motor re ferring to “Starting Motor

Dismounting and Remounting in Section 1I”.

11) Remove transaxle to engine bolts (1) of upper side. 12) Support engine using supporting device (1).

CAUTION!

Do not apply supporting device to projection

part A. If do so, it may be deformed.

13) Remove front drive shafts and center shaft referring

to “Front Drive Shaft Assembly Removal and

Installation in Section 3A”.

14) Remove exhaust No.2 pipe referring to “Exhaust Pipe and Muffler Removal a nd Installation in Section

1K”.

15) Remove clutch housing lower plate (1).

1

2

3

I7RS0A521003-01

1

1

I4RS0A520018-01

1

A

I4RS0A520019-01

1I4RS0A520020-01

Page 824 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-10 Manual Transmission/Transaxle:

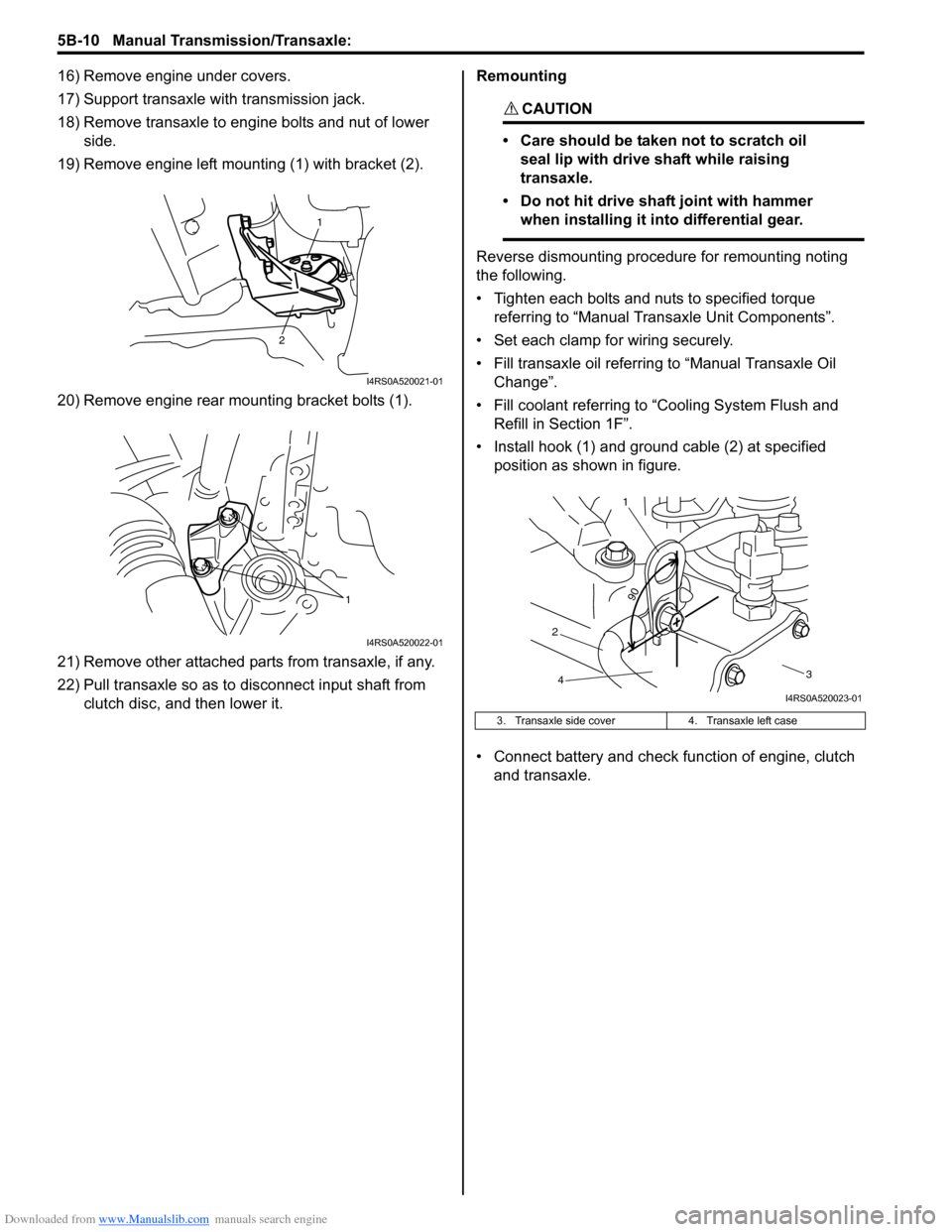

16) Remove engine under covers.

17) Support transaxle with transmission jack.

18) Remove transaxle to engine bolts and nut of lower side.

19) Remove engine left mounting (1) with bracket (2).

20) Remove engine rear mounting bracket bolts (1).

21) Remove other attached parts from transaxle, if any.

22) Pull transaxle so as to disconnect input shaft from clutch disc, and then lower it. Remounting

CAUTION!

• Care should be taken not to scratch oil

seal lip with drive shaft while raising

transaxle.

• Do not hit drive shaft joint with hammer when installing it into differential gear.

Reverse dismounting procedure for remounting noting

the following.

• Tighten each bolts and nuts to specified torque referring to “Manual Transaxle Unit Components”.

• Set each clamp for wiring securely.

• Fill transaxle oil referring to “Manual Transaxle Oil

Change”.

• Fill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

• Install hook (1) and ground cable (2) at specified position as shown in figure.

• Connect battery and check function of engine, clutch

and transaxle.

1

2

I4RS0A520021-01

1

I4RS0A520022-01

3. Transaxle side cover 4. Transaxle left case

90

1

2 3

4

I4RS0A520023-01

Page 825 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-11

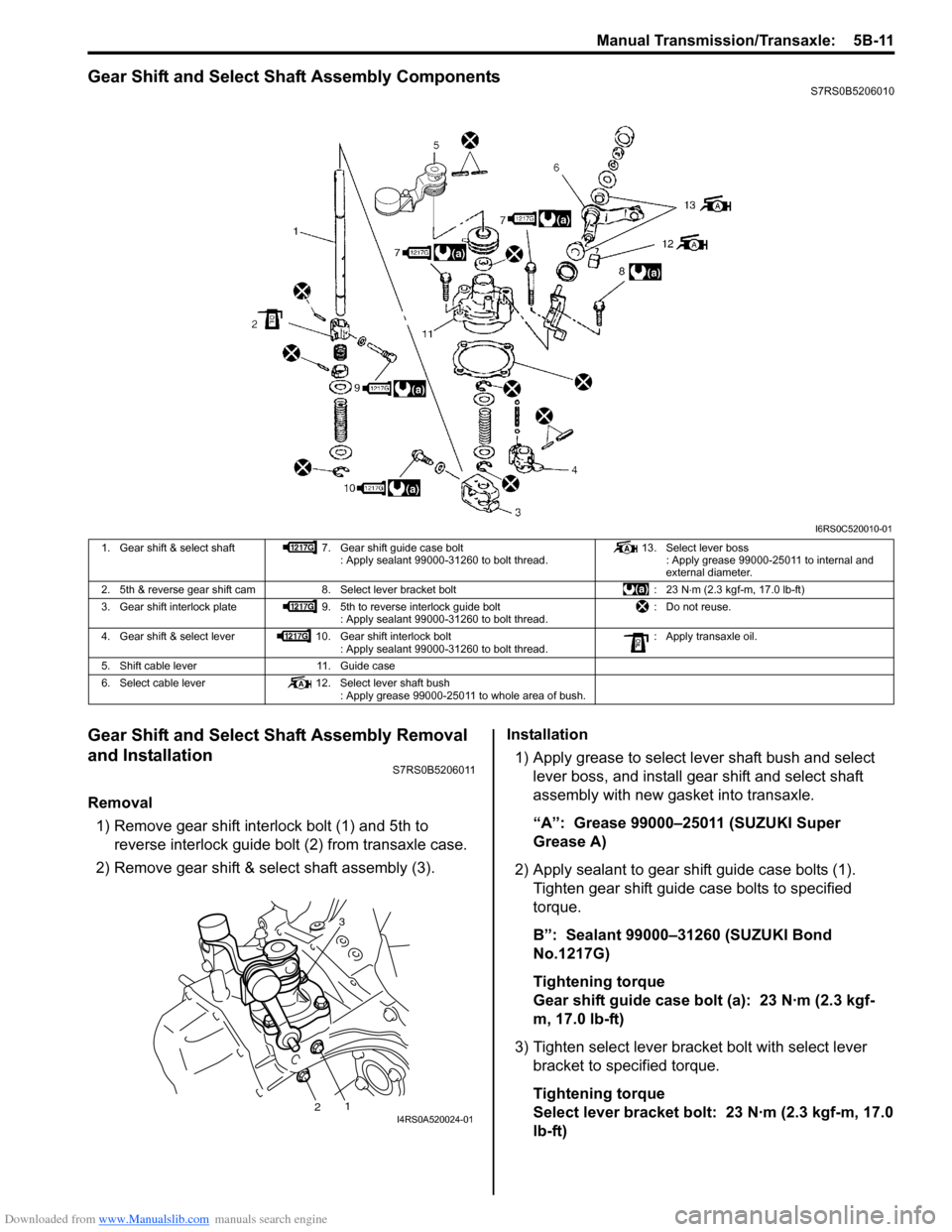

Gear Shift and Select Shaft Assembly ComponentsS7RS0B5206010

Gear Shift and Select Shaft Assembly Removal

and Installation

S7RS0B5206011

Removal1) Remove gear shift interlock bolt (1) and 5th to reverse interlock guide bolt (2) from transaxle case.

2) Remove gear shift & select shaft assembly (3). Installation

1) Apply grease to select lever shaft bush and select lever boss, and install gear shift and select shaft

assembly with new gasket into transaxle.

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

2) Apply sealant to gear shift guide case bolts (1). Tighten gear shift guide case bolts to specified

torque.

B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Gear shift guide case bolt (a): 23 N·m (2.3 kgf-

m, 17.0 lb-ft)

3) Tighten select lever brac ket bolt with select lever

bracket to specified torque.

Tightening torque

Select lever bracket bolt: 23 N·m (2.3 kgf-m, 17.0

lb-ft)

I6RS0C520010-01

1. Gear shift & select shaft 7. Gear shift guide case bolt

: Apply sealant 99000-31260 to bolt thread. 13. Select lever boss

: Apply grease 99000-25011 to internal and

external diameter.

2. 5th & reverse gear shift cam 8. Select lever bracket bolt : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Gear shift interlock plate 9. 5th to reverse interlock guide bolt

: Apply sealant 99000-31260 to bolt thread. : Do not reuse.

4. Gear shift & select lever 10. Gear shift interlock bolt

: Apply sealant 99000-31260 to bolt thread. : Apply transaxle oil.

5. Shift cable lever 11. Guide case

6. Select cable lever 12. Select lever shaft bush

: Apply grease 99000-25011 to whole area of bush.

3

12I4RS0A520024-01

Page 826 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-12 Manual Transmission/Transaxle:

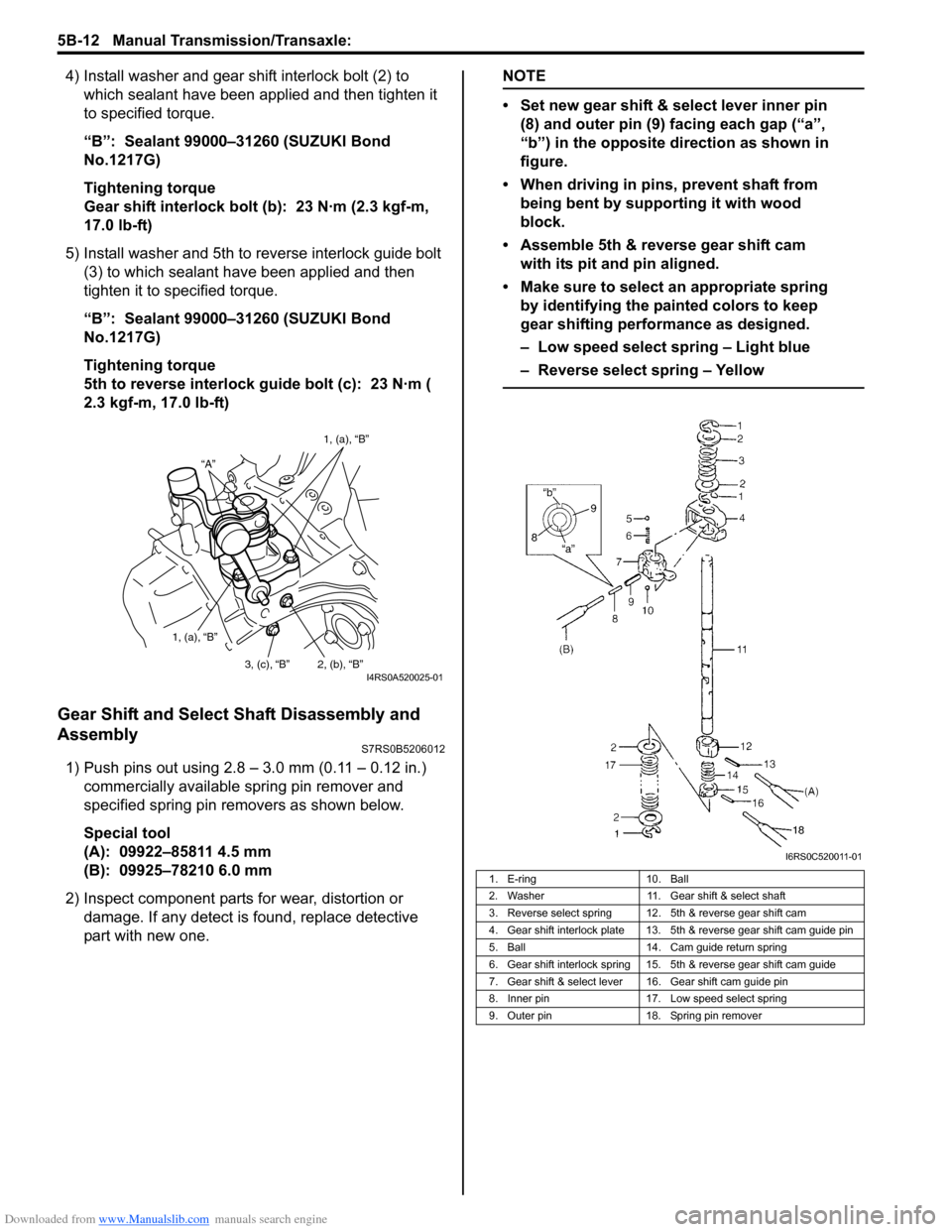

4) Install washer and gear shift interlock bolt (2) to which sealant have been app lied and then tighten it

to specified torque.

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Gear shift interlock bolt (b): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

5) Install washer and 5th to reverse interlock guide bolt (3) to which sealant have been applied and then

tighten it to specified torque.

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

5th to reverse interlock guide bolt (c): 23 N·m (

2.3 kgf-m, 17.0 lb-ft)

Gear Shift and Select Shaft Disassembly and

Assembly

S7RS0B5206012

1) Push pins out using 2.8 – 3.0 mm (0.11 – 0.12 in.) commercially available spring pin remover and

specified spring pin removers as shown below.

Special tool

(A): 09922–85811 4.5 mm

(B): 09925–78210 6.0 mm

2) Inspect component parts for wear, distortion or

damage. If any detect is found, replace detective

part with new one.

NOTE

• Set new gear shift & select lever inner pin (8) and outer pin (9) facing each gap (“a”,

“b”) in the opposite direction as shown in

figure.

• When driving in pins, prevent shaft from being bent by supporting it with wood

block.

• Assemble 5th & reverse gear shift cam with its pit and pin aligned.

• Make sure to select an appropriate spring by identifying the painted colors to keep

gear shifting performance as designed.

– Low speed select spring – Light blue

– Reverse select spring – Yellow

“A” 1, (a), “B”

1, (a), “B” 2, (b), “B”

3, (c), “B”

I4RS0A520025-01

1. E-ring 10. Ball

2. Washer 11. Gear shift & select shaft

3. Reverse select spring 12. 5th & reverse gear shift cam

4. Gear shift interlock plate 13. 5th & reverse gear shift cam guide pin

5. Ball 14. Cam guide return spring

6. Gear shift interlock spring 15. 5th & reverse gear shift cam guide

7. Gear shift & select lever 16. Gear shift cam guide pin

8. Inner pin 17. Low speed select spring

9. Outer pin 18. Spring pin remover

I6RS0C520011-01

Page 827 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-13

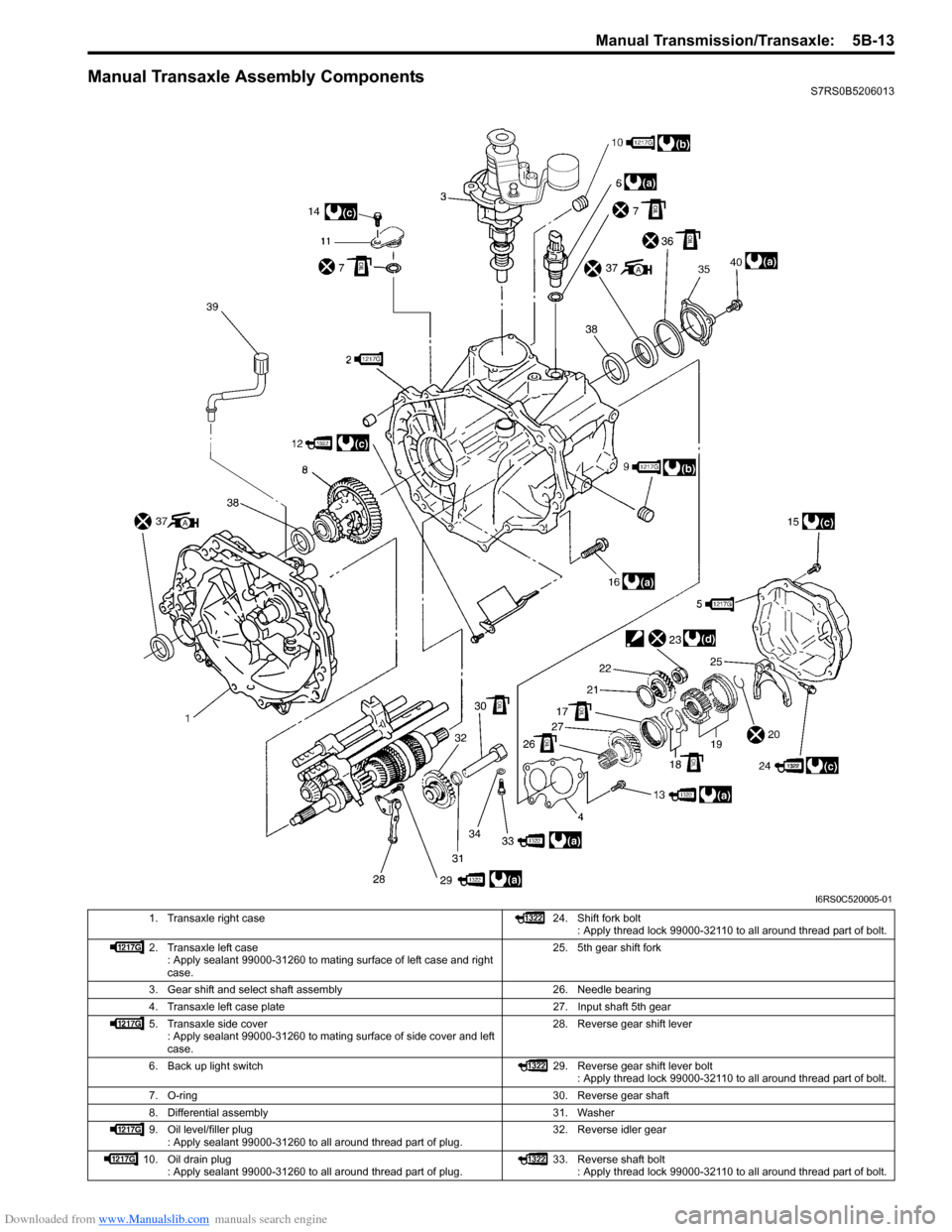

Manual Transaxle Assembly ComponentsS7RS0B5206013

I6RS0C520005-01

1. Transaxle right case 24. Shift fork bolt

: Apply thread lock 99000-32110 to all around thread part of bolt.

2. Transaxle left case : Apply sealant 99000-31260 to mating surface of left case and right

case. 25. 5th gear shift fork

3. Gear shift and select shaft assembly 26. Needle bearing

4. Transaxle left case plate 27. Input shaft 5th gear

5. Transaxle side cover : Apply sealant 99000-31260 to mating surface of side cover and left

case. 28. Reverse gear shift lever

6. Back up light switch 29. Reverse gear shift lever bolt

: Apply thread lock 99000-32110 to all around thread part of bolt.

7. O-ring 30. Reverse gear shaft

8. Differential assembly 31. Washer

9. Oil level/filler plug : Apply sealant 99000-31260 to all around thread part of plug. 32. Reverse idler gear

10. Oil drain plug : Apply sealant 99000-31260 to all around thread part of plug. 33. Reverse shaft bolt

: Apply thread lock 99000-32110 to all around thread part of bolt.

Page 828 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-14 Manual Transmission/Transaxle:

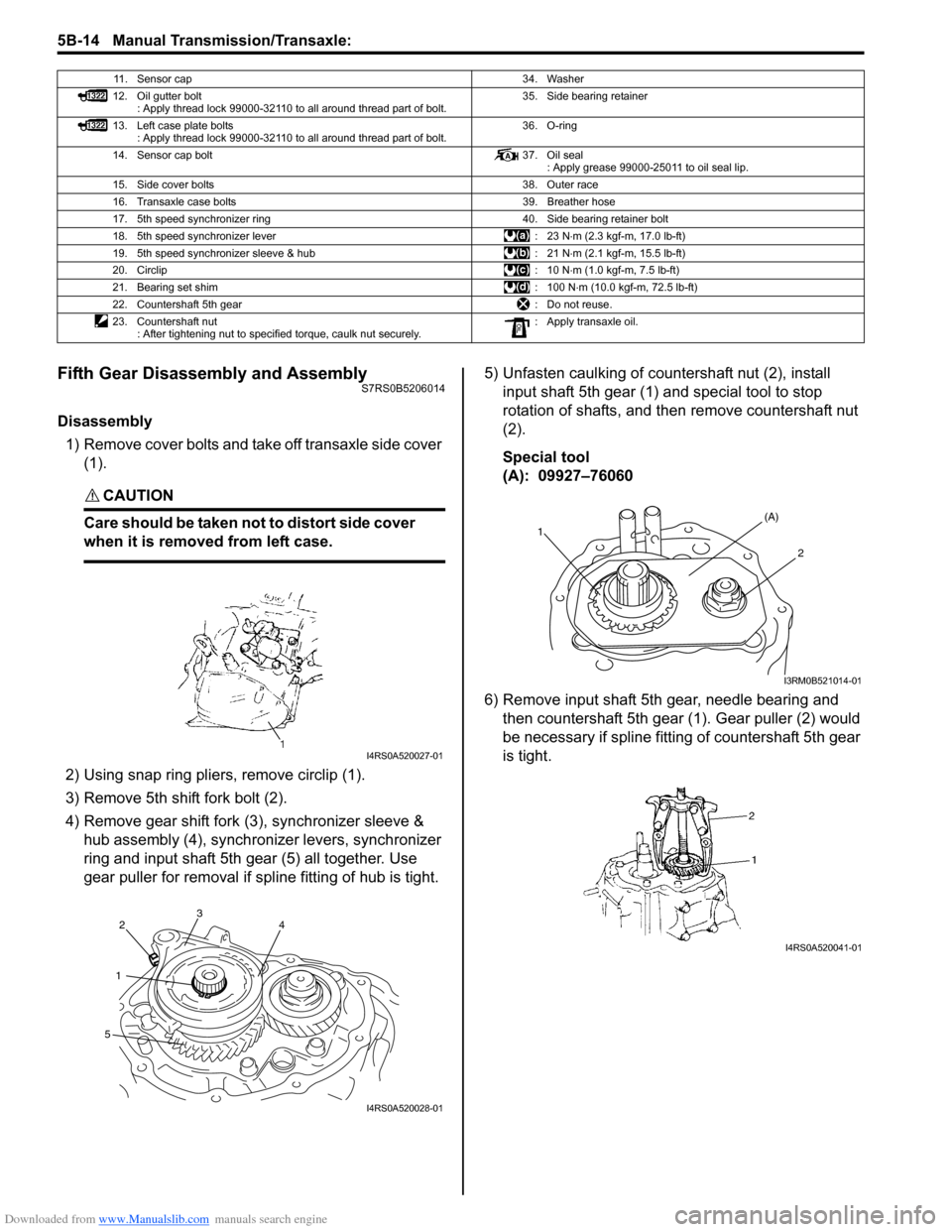

Fifth Gear Disassembly and AssemblyS7RS0B5206014

Disassembly1) Remove cover bolts and take off transaxle side cover (1).

CAUTION!

Care should be taken not to distort side cover

when it is removed from left case.

2) Using snap ring pliers, remove circlip (1).

3) Remove 5th shift fork bolt (2).

4) Remove gear shift fork (3), synchronizer sleeve &

hub assembly (4), synchron izer levers, synchronizer

ring and input shaft 5th gear (5) all together. Use

gear puller for removal if spline fitting of hub is tight. 5) Unfasten caulking of countershaft nut (2), install

input shaft 5th gear (1) and special tool to stop

rotation of shafts, and then remove countershaft nut

(2).

Special tool

(A): 09927–76060

6) Remove input shaft 5th gear, needle bearing and then countershaft 5th gear (1). Gear puller (2) would

be necessary if spline fitting of countershaft 5th gear

is tight.

11. Sensor cap 34. Washer

12. Oil gutter bolt : Apply thread lock 99000-32110 to all around thread part of bolt. 35. Side bearing retainer

13. Left case plate bolts : Apply thread lock 99000-32110 to all around thread part of bolt. 36. O-ring

14. Sensor cap bolt 37. Oil seal

: Apply grease 99000-25011 to oil seal lip.

15. Side cover bolts 38. Outer race

16. Transaxle case bolts 39. Breather hose

17. 5th speed synchronizer ring 40. Side bearing retainer bolt

18. 5th speed synchronizer lever : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

19. 5th speed synchronizer sleeve & hub : 21 N⋅m (2.1 kgf-m, 15.5 lb-ft)

20. Circlip :10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

21. Bearing set shim : 100 N⋅m (10.0 kgf-m, 72.5 lb-ft)

22. Countershaft 5th gear : Do not reuse.

23. Countershaft nut : After tightening nut to specified torque, caulk nut securely. : Apply transaxle oil.

I4RS0A520027-01

342

1

5

I4RS0A520028-01

1(A)

2

I3RM0B521014-01

I4RS0A520041-01

Page 829 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-15

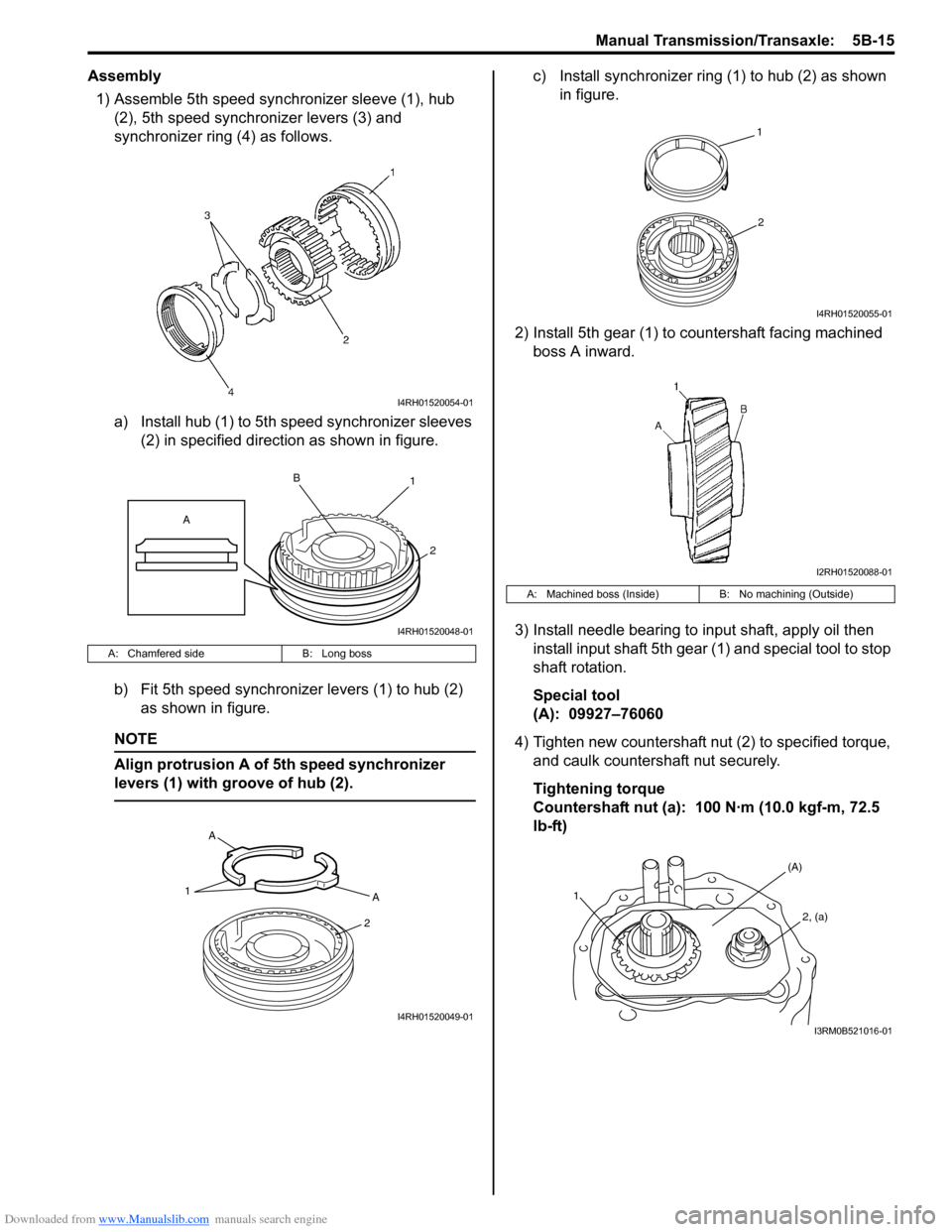

Assembly1) Assemble 5th speed synchronizer sleeve (1), hub (2), 5th speed synchronizer levers (3) and

synchronizer ring (4) as follows.

a) Install hub (1) to 5th speed synchronizer sleeves (2) in specified direction as shown in figure.

b) Fit 5th speed synchronizer levers (1) to hub (2) as shown in figure.

NOTE

Align protrusion A of 5th speed synchronizer

levers (1) with groove of hub (2).

c) Install synchronizer ring (1) to hub (2) as shown in figure.

2) Install 5th gear (1) to countershaft facing machined boss A inward.

3) Install needle bearing to input shaft, apply oil then install input shaft 5th gear (1) and special tool to stop

shaft rotation.

Special tool

(A): 09927–76060

4) Tighten new countershaft nut (2) to specified torque, and caulk countershaft nut securely.

Tightening torque

Countershaft nut (a): 100 N·m (10.0 kgf-m, 72.5

lb-ft)

A: Chamfered side B: Long boss

I4RH01520054-01

1

2

B

A

I4RH01520048-01

1A

2

A

I4RH01520049-01

A: Machined boss (Inside)

B: No machining (Outside)

1

2

I4RH01520055-01

I2RH01520088-01

1

(A)

2, (a)

I3RM0B521016-01