Cord inspection SUZUKI SWIFT 2005 2.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1127 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-89

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side curtain-air bag (driver or passenger) initiator circuit is below a specified value for

specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

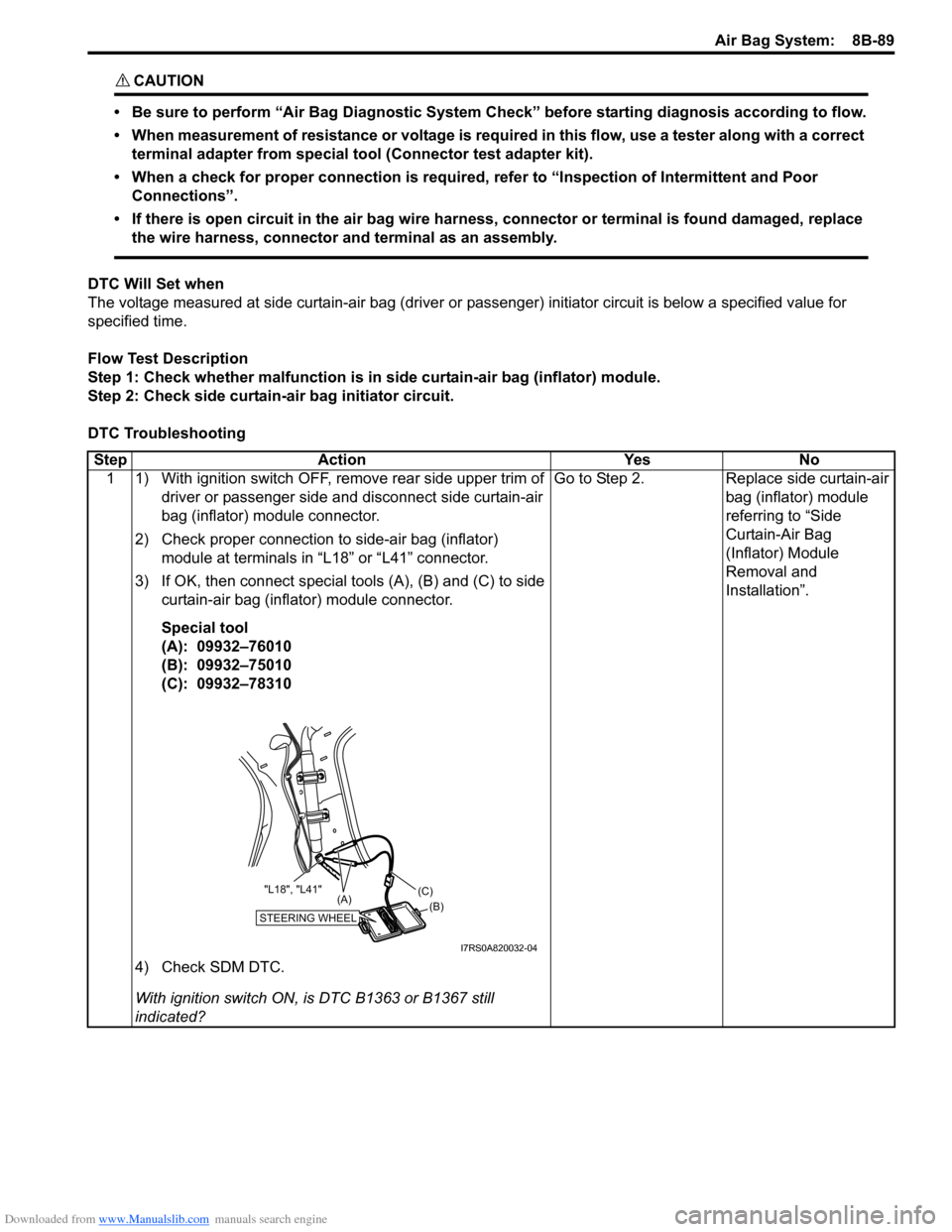

Step Action YesNo

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1363 or B1367 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1129 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-91

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side curtain-air bag (driver or passenger) initiator circuit is above a specified value for

specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

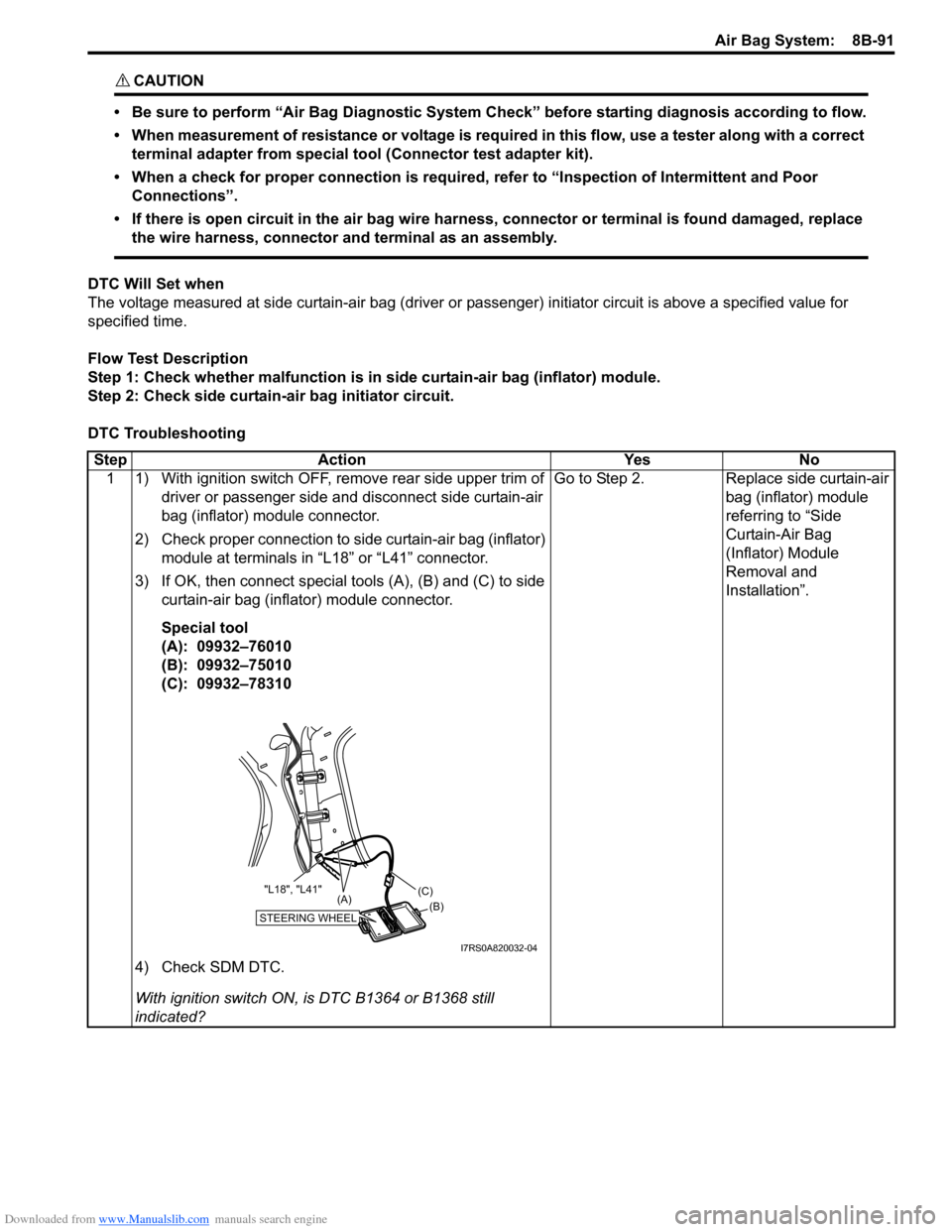

Step Action YesNo

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side curtain-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1364 or B1368 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1134 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-96 Air Bag System:

Repair and Inspection Required after AccidentS7RS0B8204049

CAUTION!

• All air bag system components, including the electrical harness (component

mounting points), must be inspected after

an accident. If any components are

damaged or bent, they must be replaced

even if air bag system activation did not

occur.

• Never use air bag system parts from another vehicle.

• Do not attempt to service the parts below. Service of these parts is by replacement

only.

– Driver / Passenger air bag (inflator) modules

– Driver / Passenger side-air bag (inflator) modules

– Driver / Passenger side curtain-air bag (inflator) modules

– Driver / Passenger seat belt pretensioners

–Forward-sensor

– Driver / Passenger side-sensors

–SDM

– Contact coil and combination switch assembly

– Air bag wire harness in main harness, instrument panel harness and floor

harness.

• Proper operation of the sensors and air bag system requires that any repairs to the

vehicle structure return it to its original

production configuration.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, the SDM

must not be used.

Refer to “Air Bag Diagnostic System Check”

when checking the SDM.

Accident with Deployment / Activation – Component

Replacement

When driver and passenger air bags are deployed, the

following components must be replaced.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• SDM after detecting such collision as to meet

deployment conditions

• Forward-sensor

• Instrument panel When side-air bag and side curtain-air bag are deployed,

the following components must be replaced.

• Deployed side-air bag (inflator) module

• Deployed side curtain-air bag (inflator) module

• Side-sensor

•SDM

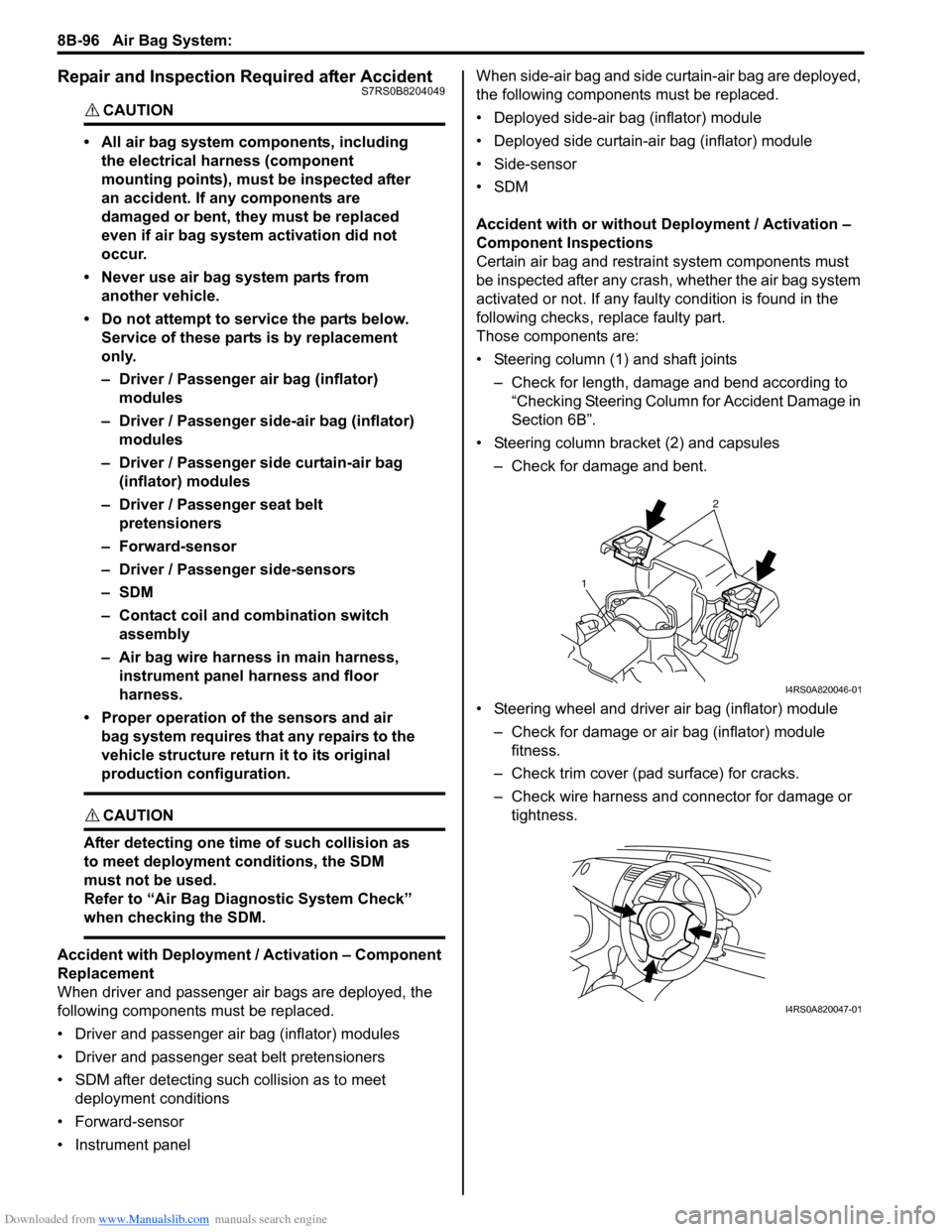

Accident with or without Deployment / Activation –

Component Inspections

Certain air bag and restraint system components must

be inspected after any crash, whether the air bag system

activated or not. If any faul

ty condition is found in the

following checks, replace faulty part.

Those components are:

• Steering column (1) and shaft joints

– Check for length, damage and bend according to “Checking Steering Column for Accident Damage in

Section 6B”.

• Steering column bracket (2) and capsules – Check for damage and bent.

• Steering wheel and driver air bag (inflator) module – Check for damage or air bag (inflator) module fitness.

– Check trim cover (pad surface) for cracks.

– Check wire harness and connector for damage or tightness.

2

1

I4RS0A820046-01

I4RS0A820047-01

Page 1135 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-97

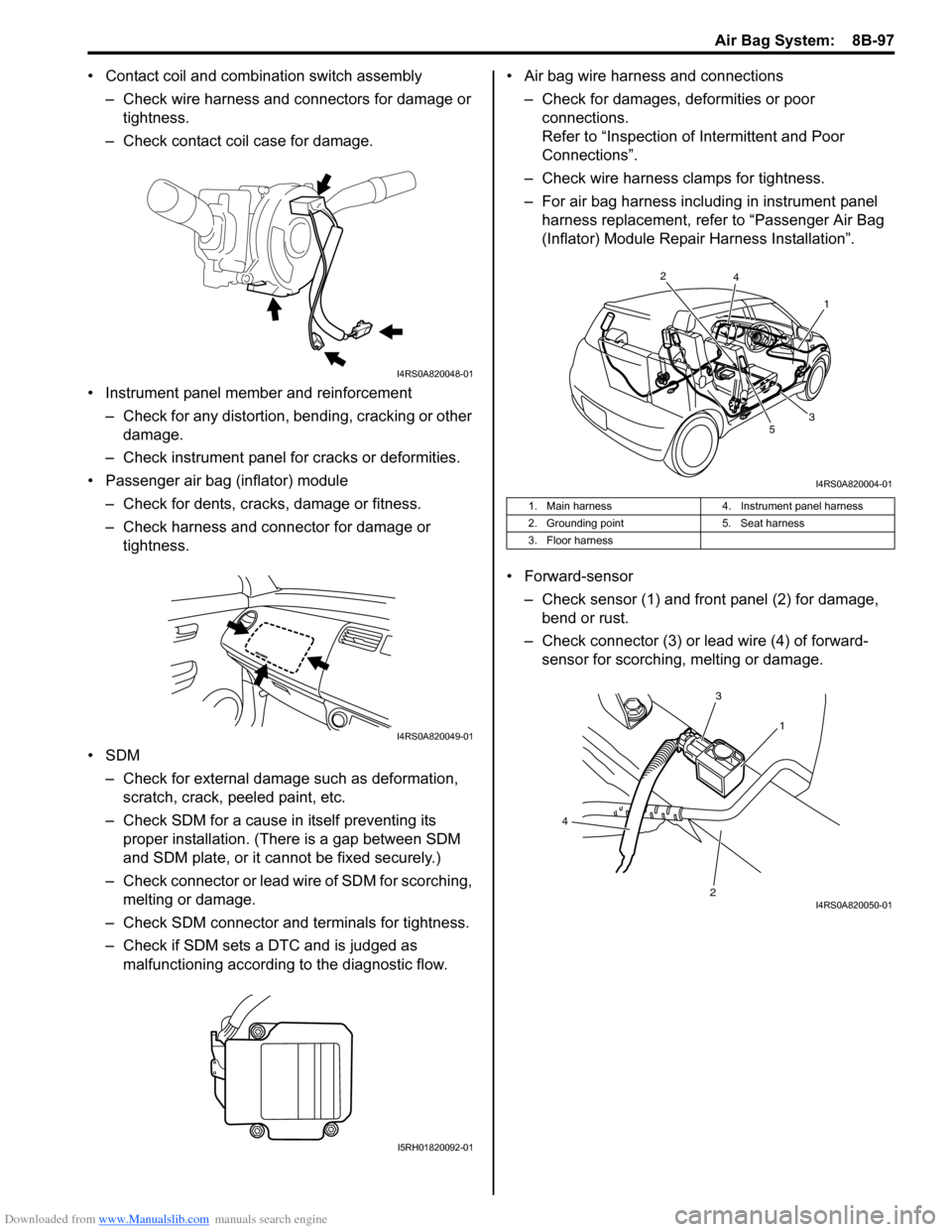

• Contact coil and combination switch assembly

– Check wire harness and connectors for damage or tightness.

– Check contact coil case for damage.

• Instrument panel member and reinforcement – Check for any distortion, bending, cracking or other damage.

– Check instrument panel fo r cracks or deformities.

• Passenger air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness and connector for damage or tightness.

•SDM – Check for external damage such as deformation, scratch, crack, peeled paint, etc.

– Check SDM for a cause in itself preventing its proper installation. (There is a gap between SDM

and SDM plate, or it cannot be fixed securely.)

– Check connector or lead wire of SDM for scorching, melting or damage.

– Check SDM connector and terminals for tightness.

– Check if SDM sets a DTC and is judged as malfunctioning according to the diagnostic flow. • Air bag wire harness and connections

– Check for damages, deformities or poor connections.

Refer to “Inspection of Intermittent and Poor

Connections”.

– Check wire harness clamps for tightness.

– For air bag harness including in instrument panel harness replacement, refer to “Passenger Air Bag

(Inflator) Module Repair Harness Installation”.

• Forward-sensor – Check sensor (1) and front panel (2) for damage, bend or rust.

– Check connector (3) or lead wire (4) of forward- sensor for scorching, melting or damage.

I4RS0A820048-01

I4RS0A820049-01

I5RH01820092-01

1. Main harness 4. Instrument panel harness

2. Grounding point 5. Seat harness

3. Floor harness

1

2

3

4

5

I4RS0A820004-01

1

3

2

4

I4RS0A820050-01

Page 1287 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-5

Interior Light Symptom DiagnosisS7RS0B9204008

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Repair Instructions

Headlight Housing Removal and InstallationS7RS0B9206001

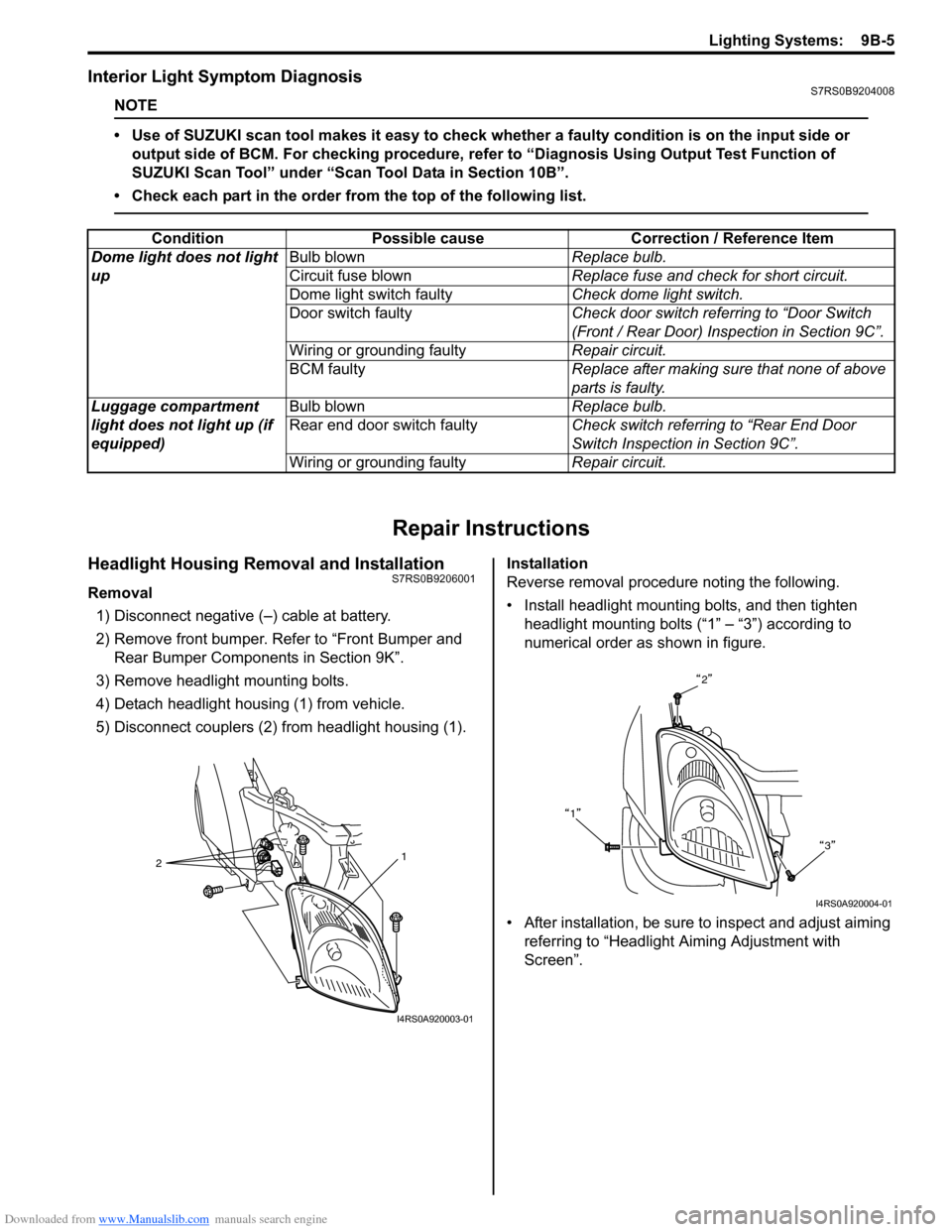

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper. Refer to “Front Bumper and Rear Bumper Componen ts in Section 9K”.

3) Remove headlight mounting bolts.

4) Detach headlight housing (1) from vehicle.

5) Disconnect couplers (2) from headlight housing (1). Installation

Reverse removal procedure noting the following.

• Install headlight mounting bolts, and then tighten

headlight mounting bolts (“1” – “3”) according to

numerical order as shown in figure.

• After installation, be sure to inspect and adjust aiming referring to “Headlight Aiming Adjustment with

Screen”.

Condition Possible cause Correction / Reference Item

Dome light does not light

up Bulb blown

Replace bulb.

Circuit fuse blown Replace fuse and check for short circuit.

Dome light switch faulty Check dome light switch.

Door switch faulty Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Luggage compartment

light does not light up (if

equipped) Bulb blown

Replace bulb.

Rear end door switch faulty Check switch referring to “Rear End Door

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

2 1

I4RS0A920003-01

2

1 3

I4RS0A920004-01

Page 1308 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-13 Instrumentation / Driver Info. / Horn:

CD Player

Auto Volume Control System

Remote Audio Control Switch Symptom Diagnosis (If Equipped)S7RS0B9304018

ConditionPossible cause Correction / Reference Item

CD-ROM does not insert Another CD-ROM already inserted Eject CD-ROM.

Circuit fuse blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Extraneous material come to be mixed

CD player Clear extraneous material from CD player or

replace radio assembly.

Radio assembly faulty Replace radio assembly.

CD-ROM does not eject Circuit fuse blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Extraneous material come to be mixed

in CD player Clear extraneous material from CD player or

replace radio assembly.

Radio assembly faulty Replace radio assembly.

CD player does not load

CD-ROM CD-ROM faulty

—

CD-ROM inserted wit h incorrect side upInsert correctly.

Temperature in cabin is too hot —

Water droplets form on internal lens Dry about 1 hour with power on.

Radio assembly faulty Replace radio assembly.

Sound skips or is noisy CD-ROM faulty —

Driving vibration —

Water droplets form on internal lens Dry about 1 hour with power on.

Radio assembly installed incorrectly Install correctly.

Radio assembly faulty Replace radio assembly.

CD player is operative,

but all speakers does not

sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Individual speaker is

noisy or inoperative Wiring and/or grounding faulty

Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Sound quality or volume

is poor CD-ROM faulty

—

Wiring and/or grounding faulty Repair as necessary.

Speaker installed incorrectly Install correctly.

Speaker faulty Replace speaker.

ConditionPossible cause Correction / Reference Item

Sound volume does not

vary according to

changes of vehicle speed Auto volume control system is “OFF”

mode

Select auto volume control.

Vehicle speed signal faulty Check vehicle speed signal referring to

“Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)”.

Wiring and/or grounding faulty Repair as necessary.

ECM faulty Check input and output signal of ECM referring

to “Inspection of ECM and Its Circuits in

Section 1A”

Radio assembly faulty Replace radio assembly.

ConditionPossible cause Correction / Reference Item

Audio system is

operative, but remote

control switch does not

control audio system Remote audio control switch faulty

Check remote audio control switch referring to

“Remote Audio Control Switch Inspection (If

Equipped)”.

Contact coil faulty Replace contact coil.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Page 1342 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-15 Glass / Windows / Mirrors:

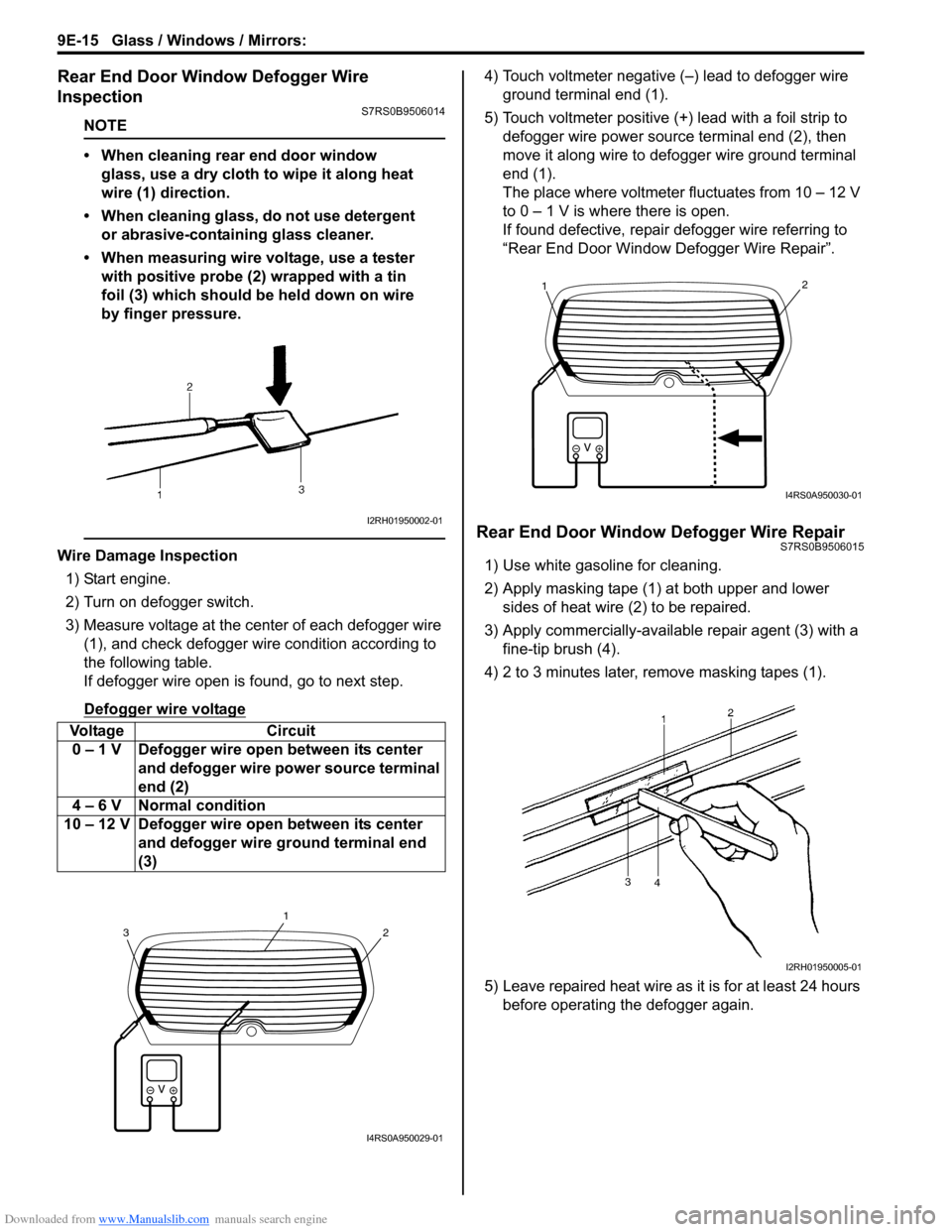

Rear End Door Window Defogger Wire

Inspection

S7RS0B9506014

NOTE

• When cleaning rear end door window glass, use a dry cloth to wipe it along heat

wire (1) direction.

• When cleaning glass, do not use detergent or abrasive-containing glass cleaner.

• When measuring wire voltage, use a tester with positive probe (2) wrapped with a tin

foil (3) which should be held down on wire

by finger pressure.

Wire Damage Inspection

1) Start engine.

2) Turn on defogger switch.

3) Measure voltage at the center of each defogger wire (1), and check defogger wire condition according to

the following table.

If defogger wire open is found, go to next step.

Defogger wire voltage

4) Touch voltmeter negative (–) lead to defogger wire ground terminal end (1).

5) Touch voltmeter positive (+) lead with a foil strip to defogger wire power source terminal end (2), then

move it along wire to defogger wire ground terminal

end (1).

The place where voltmeter fluctuates from 10 – 12 V

to 0 – 1 V is where there is open.

If found defective, repair defogger wire referring to

“Rear End Door Window Defogger Wire Repair”.

Rear End Door Window Defogger Wire RepairS7RS0B9506015

1) Use white gasoline for cleaning.

2) Apply masking tape (1) at both upper and lower sides of heat wire (2) to be repaired.

3) Apply commercially-available repair agent (3) with a fine-tip brush (4).

4) 2 to 3 minutes later, remove masking tapes (1).

5) Leave repaired heat wire as it is for at least 24 hours before operating the defogger again.

Voltage Circuit

0 – 1 V Defogger wire open between its center and defogger wire power source terminal

end (2)

4 – 6 V Normal condition

10 – 12 V Defogger wire open between its center and defogger wire ground terminal end

(3)

I2RH01950002-01

2

1

3

I4RS0A950029-01

21

I4RS0A950030-01

I2RH01950005-01

Page 1361 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-15

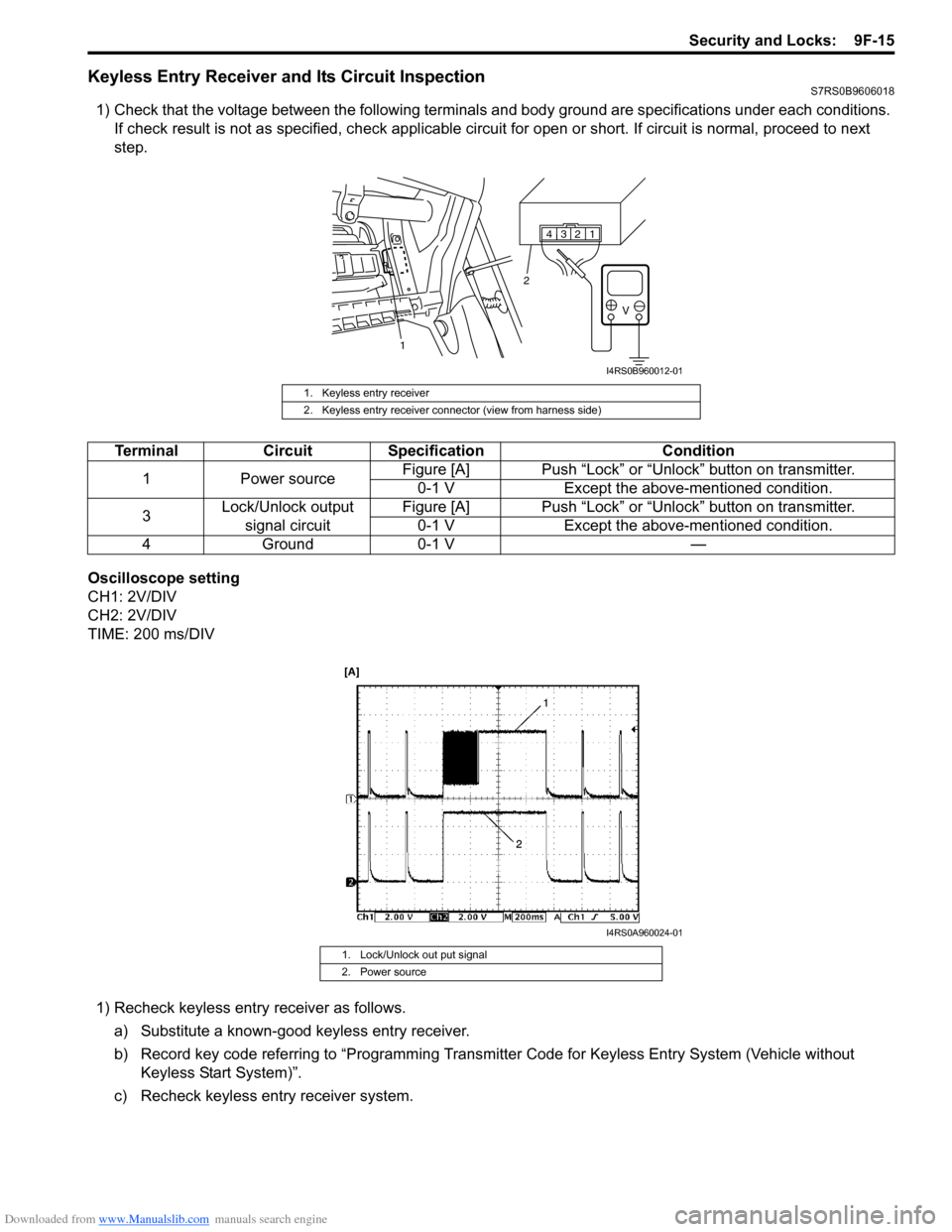

Keyless Entry Receiver and Its Circuit InspectionS7RS0B9606018

1) Check that the voltage between the following terminals and body ground are specifications under each conditions.

If check result is not as specified, ch eck applicable circuit for open or short. If circuit is normal, proceed to next

step.

Oscilloscope setting

CH1: 2V/DIV

CH2: 2V/DIV

TIME: 200 ms/DIV 1) Recheck keyless entry receiver as follows.

a) Substitute a known-good keyless entry receiver.

b) Record key code referring to “Programming Transmit ter Code for Keyless Entry System (Vehicle without

Keyless Start System)”.

c) Recheck keyless entry receiver system.

1. Keyless entry receiver

2. Keyless entry receiver connector (view from harness side)

1234

V

1 2

I4RS0B960012-01

Terminal

Circuit Specification Condition

1 Power source Figure [A] Push “Lock” or “Unlock” button on transmitter.

0-1 V Except the above-mentioned condition.

3 Lock/Unlock output

signal circuit Figure [A] Push “Lock” or “Unlock” button on transmitter.

0-1 V Except the above-mentioned condition.

4G ro un d0 -1 V —

1. Lock/Unlock out put signal

2. Power source

I4RS0A960024-01

Page 1414 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-11 Body Electrical Control System:

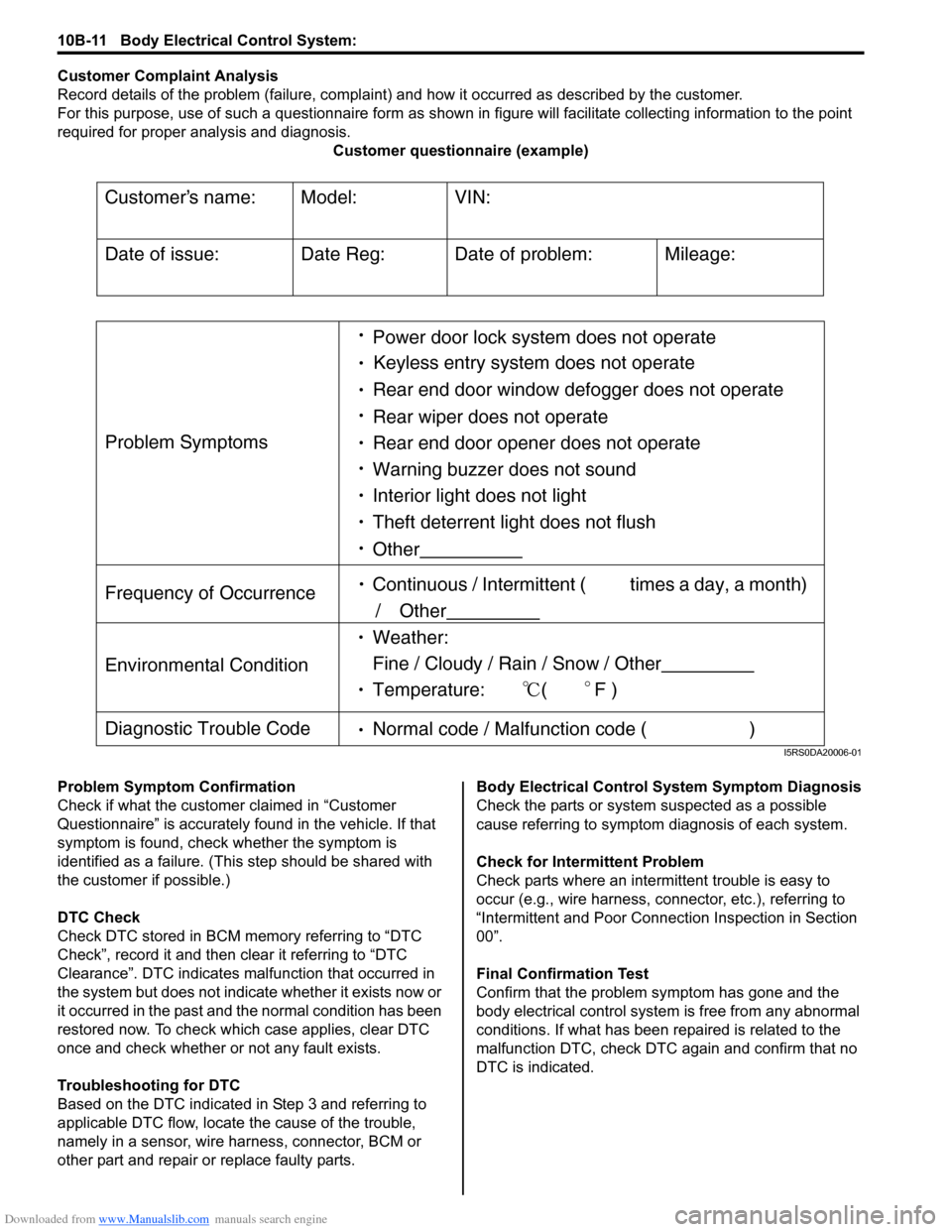

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in figure will facilitate collectin g information to the point

required for proper analysis and diagnosis. Customer questionnaire (example)

Problem Symptom Confirmation

Check if what the custom er claimed in “Customer

Questionnaire” is accurately f ound in the vehicle. If that

symptom is found, check whether the symptom is

identified as a failure. (This step should be shared with

the customer if possible.)

DTC Check

Check DTC stored in BCM me mory referring to “DTC

Check”, record it and then clear it referring to “DTC

Clearance”. DTC indicates malfunction that occurred in

the system but does not indicate whether it exists now or

it occurred in the past and the normal condition has been

restored now. To check which case applies, clear DTC

once and check whether or not any fault exists.

Troubleshooting for DTC

Based on the DTC indicated in Step 3 and referring to

applicable DTC flow, locate the cause of the trouble,

namely in a sensor, wire harness, connector, BCM or

other part and repair or replace faulty parts. Body Electrical Control System Symptom Diagnosis

Check the parts or system

suspected as a possible

cause referring to symptom diagnosis of each system.

Check for Intermi ttent Problem

Check parts where an intermit tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00”.

Final Confirmation Test

Confirm that the problem symptom has gone and the

body electrical control system is free from any abnormal

conditions. If what has been repaired is related to the

malfunction DTC, check DTC again and confirm that no

DTC is indicated.

Customers name:

Model:

VIN:

Date of issue:

Date Reg:

Date of problem:

Mileage:

Problem Symptoms

Power door lock system does not operate

Keyless entry system does not operate

Rear end door window defogger does not operate

Rear wiper does not operate

Rear end door opener does not operate

Other

Frequency of Occurrence

Continuous / Intermittent ( times a day, a month)

/ Other

Environmental Condition

Weather:

Fine / Cloudy / Rain / Snow / Other

Temperature: (F )

Diagnostic Trouble Code Normal code / Malfunction code ( )

Warning buzzer does not sound

Interior light does not light

Theft deterrent light does not flush

I5RS0DA20006-01

Page 1470 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-8 Keyless Start System:

Diagnostic Information and Procedures

Precautions in Diagnosing TroublesS7RS0BA504001

• The keyless start system executes data transmission/reception by means of th e radio wave. Therefore,

proper operation may not be obtained if use of the

door lock function and engine start function of the

keyless start system is attempted near the place

where strong radio wave is emitted (TV and radio

broadcasting stations, etc.).

• Diagnostic information stored in keyless start control

module memory can be checked only by key indicator

lamp.

• Be sure to use the trouble diagnosis procedure as described in “Keyless Start System Check”. Failure to

follow it may result in incorrect diagnosis. (Some other

DTC may be stored by mistake in the memory of

keyless start control module during inspection.)

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• Communication of ECM, BCM, TCM (A/T model), ABS control module, keyless start control module and

combination meter is estab lished by CAN (Controller

Area Network). (For detail of CAN communication for

keyless start control module, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”. • Replacement of the keyless start control module

When keyless start control module is replaced with

new one, make sure that r egister remote controller ID

code to keyless start co ntrol module correctly

according to “Registration Procedure for Remote

Controller ID Code”.

• Keyless start control module substitution When the keyless start control module used in

another vehicle was installed in the vehicle, register

the ID code of the remote controller in the keyless

start control module as well as the ignition key

transponder code fo r the immobilizer control system in

ECM. For the registration procedure of the ignition key

transponder code, refer to “Registration of the Ignition

Key in Section 10C”.

Self-Diagnosis FunctionS7RS0BA504002

The keyless start control module has self-diagnosis

function to monitor the system components and circuits

while the keyless start system is at work. When the

keyless start control module detects an abnormality in

the system, it saves the ar ea where such abnormality

has occurred as a DTC in its memory. The DTC stored in

memory of the keyless start control module is indicated

by the key indicator lamp in the combination meter

flashing in a specific pattern. For DTC indication, refer to

“DTC Check” and for the clearing procedure, to “DTC

Clearance”.

Keyless Start System Diagnosis IntroductionS7RS0BA504003

To ensure that the trouble diagnosis is done accurately

and smoothly, observe “Precautions in Diagnosing

Troubles” and follow “Keyless Start System Check”.

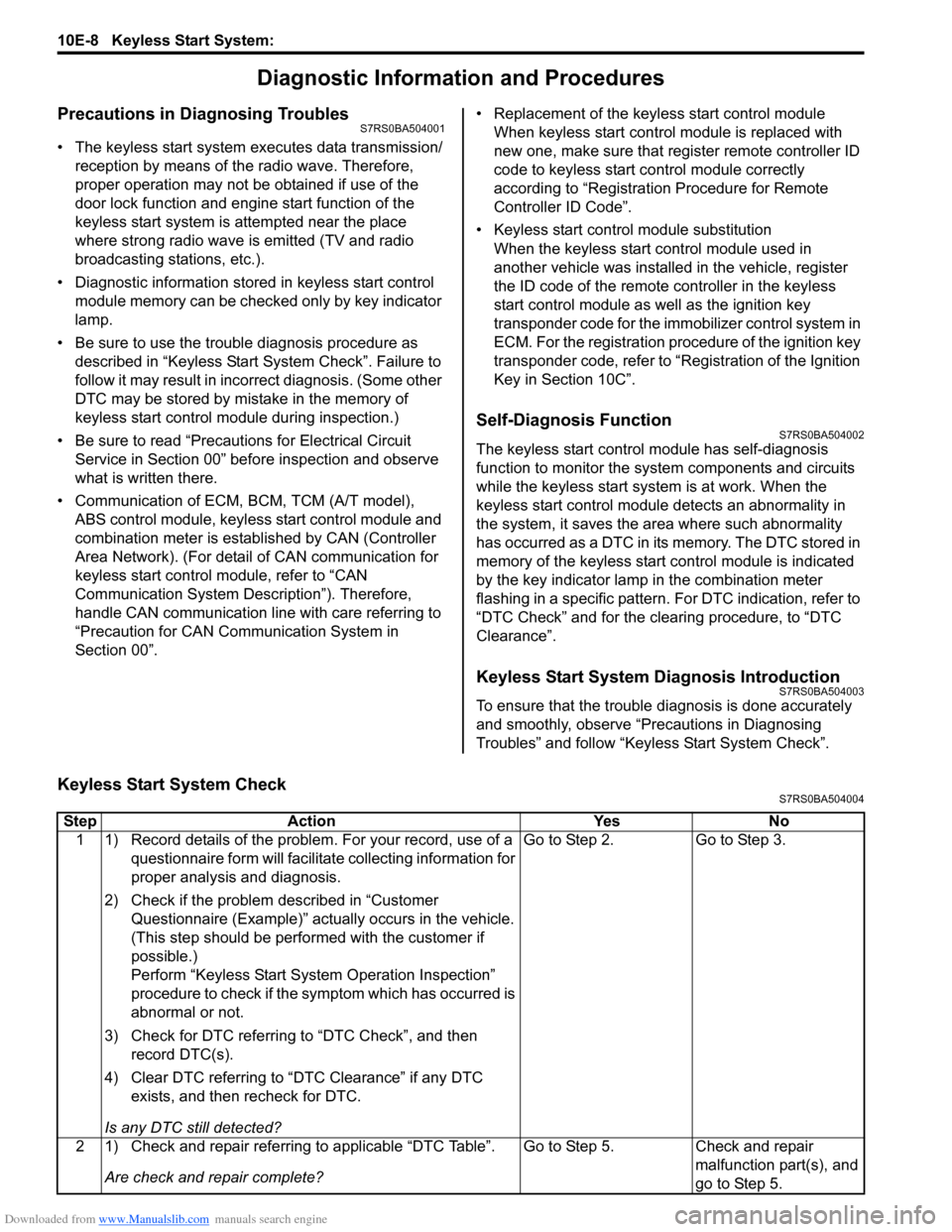

Keyless Start System CheckS7RS0BA504004

Step Action YesNo

1 1) Record details of the problem. For your record, use of a questionnaire form will facilit ate collecting information for

proper analysis and diagnosis.

2) Check if the problem described in “Customer Questionnaire (Example)” actually occurs in the vehicle.

(This step should be performed with the customer if

possible.)

Perform “Keyless Start System Operation Inspection”

procedure to check if the symptom which has occurred is

abnormal or not.

3) Check for DTC referring to “DTC Check”, and then record DTC(s).

4) Clear DTC referring to “DTC Clearance” if any DTC exists, and then recheck for DTC.

Is any DTC still detected? Go to Step 2.

Go to Step 3.

2 1) Check and repair referring to applicable “DTC Table”. Are check and repair complete? Go to Step 5.

Check and repair

malfunction part(s), and

go to Step 5.