Harness SUZUKI SWIFT 2005 2.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 645 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-1

Transmission / Transaxle

Automatic Transmission/Transaxle

Precautions

Precautions in Diagnosing TroubleS7RS0B5100001

• Do not disconnect couplers from TCM, battery cable from battery, TCM ground wire harness from engine or

main fuse before checking the diagnostic information

(DTC, freeze frame data, etc.) stored in TCM memory.

Such disconnection will clea r memorized information

in TCM memory.

• Diagnostic information stored in TCM memory can be cleared as well as checked by using SUZUKI scan

tool or generic scan tool. Before using scan tool, read

its Operator’s (Instruction) Manual carefully to have

good understanding as to what functions are available

and how to use it.

It is indistinguishable wh ich module turns on MIL

because not only ECM but also TCM turns on MIL.

Therefore, check both ECM and TCM for DTC when

MIL lights on.

When checking TCM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by TCM.

– Generic scan tool displays DTC detected by each of ECM and TCM simultaneously.

• Using SUZUKI scan tool the diagnostic information stored in TCM memory can be checked and cleared

as well. Before its use, be sure to read Operator’s

Manual supplied with it carefully to have good

understanding of its functions and usage.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• TCM replacement

– When substituting a known-good TCM, check that all relays and actuators have resistance of

specified value.

Neglecting this check may result in damage to good

TCM.

• Communication of ECUs , ECM, TCM, ABS control

module, keyless start control module and BCM is

established by CAN (Controller Area Network).

Therefore, handle CAN communication line with care

referring to “Precaution for CAN Communication

System in Section 00”.

Precautions for Disassembly and ReassemblyS7RS0B5100002

When repairing automatic transaxle, it is necessary to

conduct the on-vehicle test to investigate where the

cause of the trouble lies first.

Then whether overhaul should be done or not is

determined. If the transaxle is disassembled without

such preliminary procedure, not only the cause of the

trouble would be unknown, but also a secondary trouble

may occur and often time would be wasted.

As the automatic transaxle consists of high precision

component, the following cautions should be strictly

observed when handling its parts in disassembly and

reassembly.

• Disassembling valve body assembly is prohibited

essentially. However, a few parts can be

disassembled. When disassembling valve body

component parts, confirm whether their parts are

allowed to disassemble or not referring to “Valve Body

Assembly Disassembly and Reassembly”.

• When component part of forward clutch, direct clutch, 2nd brake and/or O/D and 2nd coast brake, namely

clutch disc, brake disc, retaining plate and/or

separator plate, have been replaced, all learned

contents, which have been stored in TCM memory by

executing learning control, should be initialized

referring to “Learning Control Initialization”.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

dismounting and remounting.

• Select a clean place free from dust and dirt for overhauling.

• Place a rubber mat on the work bench to protect parts from damage.

• Work gloves or shop cloth should not be used. (Use a nylon cloth or a paper towel.)

• When separating the case joint, do not pry with a screwdriver or such but tap with a plastic hammer

lightly.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

disassembly and reassembly.

• Wash the disassembled parts in ATF (Automatic Transaxle Fluid) or kerosene (using care not to allow

ATF or kerosene to get on your face, etc.) and confirm

that each fluid passage is not clogged by blowing air

into it. But use kerosene to wash the discs, resin

washers and rubber parts.

• Replace each gasket, oil seal and O-ring with a new one.

• Apply ATF to sliding or rotating parts before

reassembly.

Page 654 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-10 Automatic Transmission/Transaxle:

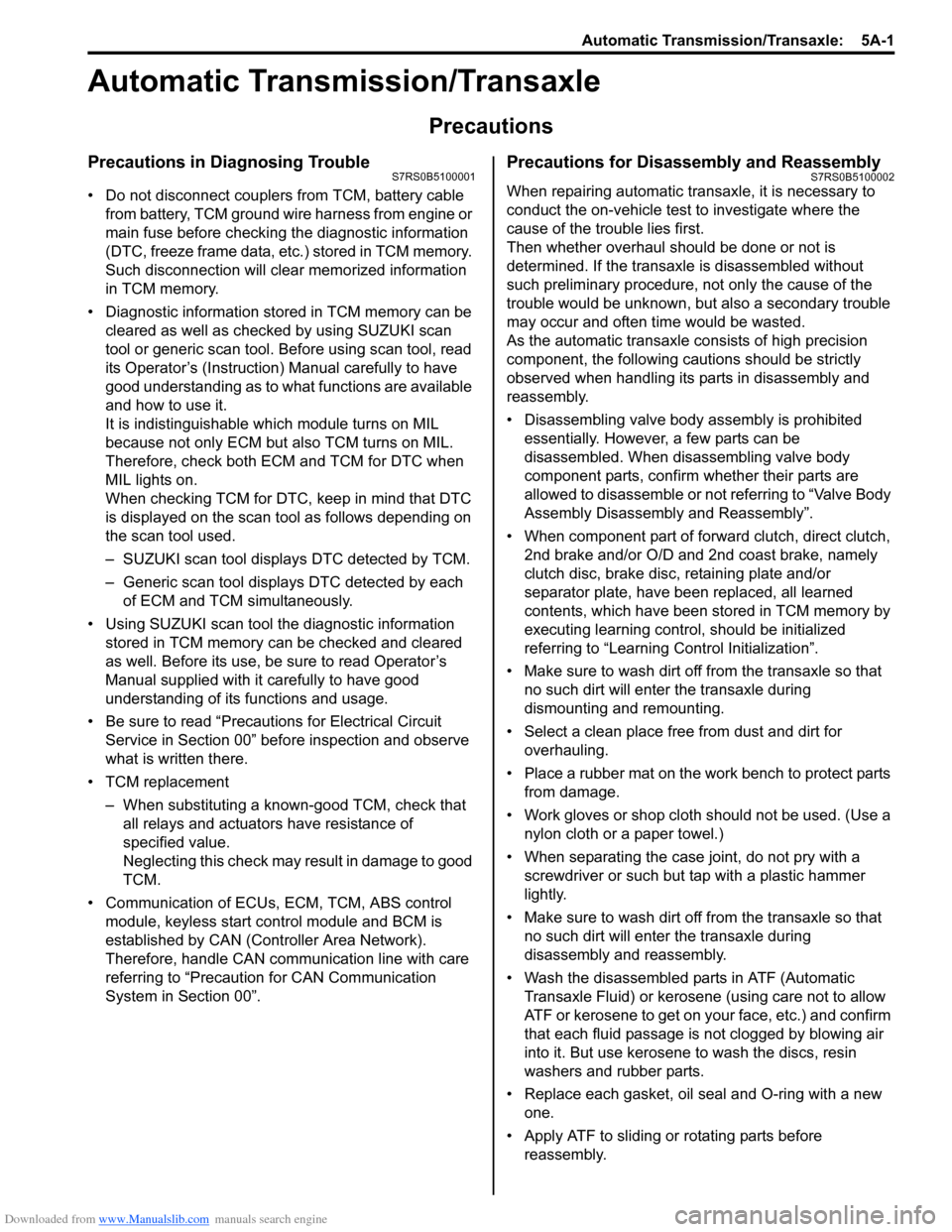

Schematic and Routing Diagram

Transmission Control Module (TCM) Wiring DiagramS7RS0B5102001

IG1

115

5

5

8

9

10 7

P

R

N

D

2

L

12

12V 2.5V

5V

12V

5V

12V

12V

12V

12V

WHT

BLK

BLK

BLK

BLK

PPLBLK/RED

BLK/ORN

IG11

RED/BLK

YEL/BLKYEL/BLU

LT GRN/BLK

+BB

WHT/RED

14

20

15

16

17

19

12V18

1

2

3

4

6

13 21

26

24

27

28 29

30

WHT

WHT

RED

RED

WHT

RED

65

16 15 14 13 12 11 43

24 23 2122 10 9 8 721

1920 18 17

C34

17 16

26 25

15 14

65 3

42

13 12

23 2224 11 10 9

21 20 19 87

18

1

C35

[A]

22

25

YELYEL/GRN

WHT

P

N

BRN

LT GRN

ORN

BLK/YEL

BLU/BLK

GRY

LT GRN/BLK WHT/BLU

WHT/BLK

C34-11

C34-12

C34-16

C34-15

C34-14

C34-4

C34-2

C34-1

C34-23 C34-6

C34-24 C34-5

C34-3

RED

GRN

GRN/ORN PNK/BLK

GRN/YEL

LT GRN/BLKC35-6

C35-16

C35-23 C35-25

C35-20

C35-1

C35-8

C35-7

C35-19

C35-18 C34-17 C34-7

4IG11

12V

23

PPL/WHT

LT GRN

I6RS0C510005-01

1. TCM 12. Backup lamp 23. Starter motor relay

2. Input shaft speed sensor 13. Data link connector DLC 24. Ignition switch

3. Output shaft speed sensor 14. Transmission fluid temperature sensor 25. Starter motor

4. ECM 15. Shift solenoid valve-A (No.1) 26. “DOME” fuse

5. CAN driver 16. Shift solenoid valve-B (No.2) 27. “AT ETM” fuse

6. BCM 17. Timing solenoid valve 28. “IG SIG” fuse

7. Meter driver 18. TCC lock-up pressure control solenoid valve 29. “ST SIG” fuse

8. “3” position switch 19. Pressure control solenoid valve 30. “ST MOT” fuse

9. Shift lock solenoid 20. A/T [A]: Terminal arrangement of TCM connector

(viewed from harness side)

10. Brake light switch 21. A/T relay

11. Transmission range sensor 22. Inhibitor switch (including transmission range sensor)

Page 661 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-17

Step 2. DTC / Freeze Frame Data Check, Record and Clearance

First, referring to “DTC Check”, check DTC and pending DTC. If DTC exists, print or write down DTC and freeze frame

data and then clear malfunction DTC(s) by referring to “DTC Clearance”. Malfunction DTC indicates malfunction in the

system but it is not possible to know from it whether the malfunction is occurring now or it occurred in the past and

normal condition has been restored. In order to know that, check symptom in question according to Step 5 and then

recheck DTC according to Step 6.

Diagnosing a trouble based on the DTC in this step only or fa ilure to clear the DTC in this step may result in an faulty

diagnosis, trouble diagnosis of a normal circuit or difficulty in troubleshooting which is otherwise unnecessary.

Step 3 and 4. Visual Inspection

As a preliminary step, be sure to perform visual check of the items that support proper function of the engine and

automatic transaxle referring to “Visual Inspection”.

Step 5. Trouble Symptom Confirmation

Check trouble symptoms based on information obtained in “Step 1. Customer Complaint Analysis: ” and “Step 2. DTC

/ Freeze Frame Data Check, Record and Clearance: ”.

Also, reconfirm DTC according to “DTC Confirmation Procedure” described in each DTC flow.

Step 6 and 7. Rechecking and Record of DTC and Freeze Frame Data

Refer to “DTC Check” for checking procedure.

Step 8. A/T Basic Check and A/T Symptom Diagnosis

Perform basic check of A/T according to “A/T Basic Check” first. When the end of the flow has been reached, check

the parts of the system suspected as a possible cause referring to “A/T Symptom Diagnosis” and based on symptoms

appearing on the vehicle (symptoms obtained through step s of customer complaint analysis, trouble symptom

confirmation and/or A/T basic check) and re pair or replace faulty parts, if any.

Step 9. Troubleshooting for DTC

Based on the DTC indicated in Step 6 / 7 and referring to “a pplicable DTC flow”, locate the cause of the trouble,

namely in a sensor, switch, wire harness, connector, actuator, TCM or other part and repair or replace faulty parts.

Step 10. Check for Intermittent Problem

Check parts where an intermittent trouble is easy to occur (e.g . wire harness, connector, etc.), referring to “Intermittent

and Poor Connection Inspection in Section 00” and related circuit of DTC recorded in Step 2.

Step 11. Final Confirmation Test

Confirm that the problem symptom has gone and the vehicl e is free from any abnormal conditions. If what has been

repaired is related to the malfunction DTC, clear the DTC once and check to ensure that no malfunction DTC is

indicated.

Page 662 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

Visual InspectionS7RS0B5104002

Visually check the following parts and systems.

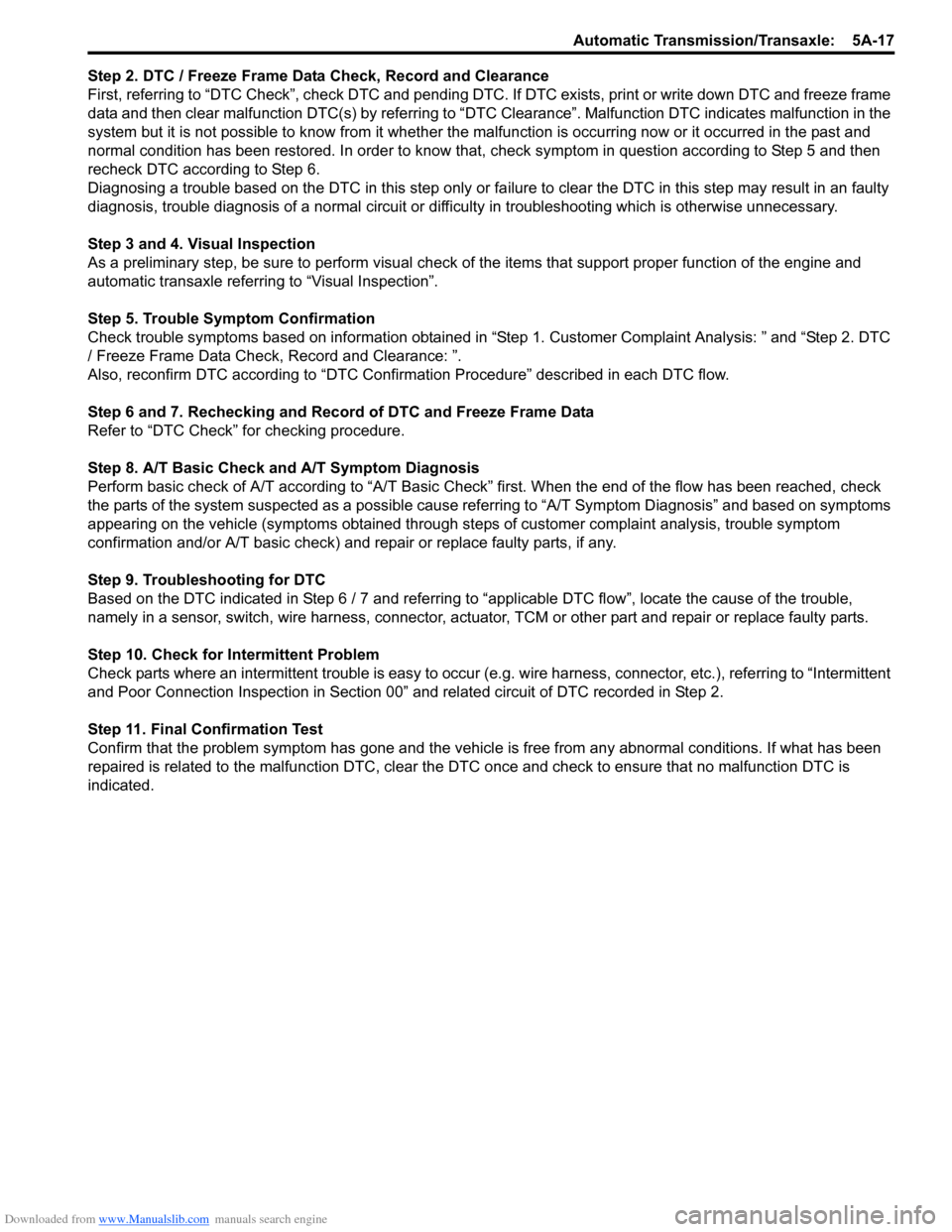

Malfunction Indicator Lamp (MIL) CheckS7RS0B5104003

Refer to the same item in “Malfunction Indicator Lam p (MIL) Check in Section 1A” for checking procedure.

Transmission Warning Light CheckS7RS0B5104004

1) Turn ignition switch ON.

2) Check that transmission warning light lights for about 2 – 4 sec. and then goes OFF.

If anything faulty is found, advance “Transmission Warn ing Light Circuit Check – Light Does Not Come “ON” at

Ignition Switch ON” or “Transmission Warning Light Circu it Check – Light Remains “ON” at Ignition Switch ON”.

Inspection item Referring

• A/T fluid ----- level, leakage, color “Automatic Transaxle Fluid Level Inspection in Section 0B”

• A/T fluid hoses ----- disconnection, looseness, deterioration “A/T Fluid Cooler Hoses Replacement”

• A/T select cable ----- installation “S elect Cable Removal and Installation”

• Engine oil ----- level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant ----- level, leakage “Engine Coolant Change in Section 0B”

• Engine mountings ----- play, looseness, damage “Engine Assembly Removal and Installation in Section 1D”

• Suspension ----- play, looseness “Suspension, Wheels and Tires Symptom Diagnosis in Section 2A”

• Drive shafts ----- damage “Front Drive Shaft Assembly On-Vehicle Inspection in Section 3A”

• Battery ----- indicator condition, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ----- disconnection, friction “Electronic Shift Control System Components

Location”

• Fuses ----- burning

• Parts ----- installation, damage

• Bolts ----- looseness

• Other parts that can be checked visually

Also check the following items at engine start, if possible.

• Transmission warning light (if equipped) ----- Operation “Transmission Warning Light Check”

• Malfunction indicator lamp ----- Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp ----- Operation “Generator Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp ----- Operation “Oil Pressure Warning Ligh t Symptom Diagnosis in

Section 9C”

• Engine coolant temp. meter ----- Operation “Engine Coolant Temperature (ECT) Meter

Symptom Diagnosis in Section 9C”

• Other parts that can be checked visually

I4RS0A510008-01

Page 673 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-29

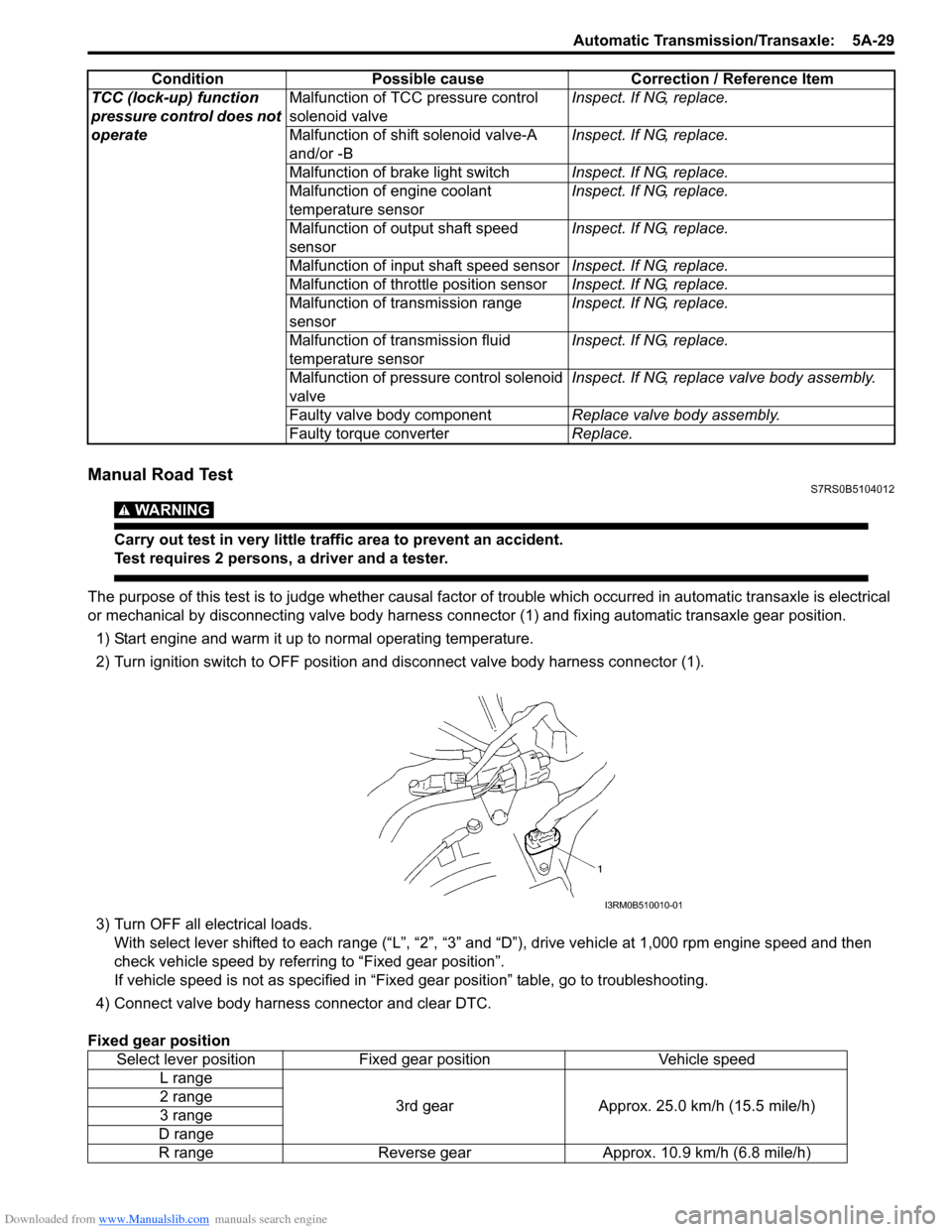

Manual Road TestS7RS0B5104012

WARNING!

Carry out test in very little traffic area to prevent an accident.

Test requires 2 persons, a driver and a tester.

The purpose of this test is to judge whether causal factor of trouble which occurred in automatic transaxle is electrical

or mechanical by disconnecting valve body harness co nnector (1) and fixing automatic transaxle gear position.

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch to OFF position and disconnect valve body harness connector (1).

3) Turn OFF all electrical loads. With select lever shifted to each ra nge (“L”, “2”, “3” and “D”), drive vehi cle at 1,000 rpm engine speed and then

check vehicle speed by referring to “Fixed gear position”.

If vehicle speed is not as specified in “Fix ed gear position” table, go to troubleshooting.

4) Connect valve body harness connector and clear DTC.

Fixed gear position TCC (lock-up) function

pressure control does not

operate

Malfunction of TCC pressure control

solenoid valve

Inspect. If NG, replace.

Malfunction of shif t solenoid valve-A

and/or -B Inspect. If NG, replace.

Malfunction of brake light switch Inspect. If NG, replace.

Malfunction of engine coolant

temperature sensor Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Faulty torque converter Replace.

Condition

Possible cause Correction / Reference Item

Select lever positionFixed gear position Vehicle speed

L range

3rd gearApprox. 25.0 km/h (15.5 mile/h)

2 range

3 range

D range

R range Reverse gear Approx. 10.9 km/h (6.8 mile/h)

I3RM0B510010-01

Page 688 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-44 Automatic Transmission/Transaxle:

DTC P0602: Control Module Programming ErrorS7RS0B5104048

System Description

Internal control module is installed in ECM.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Clear DTC, pending DTC and freeze frame data by using scan tool.

3) Start engine and run it at idle if possible.

4) Check DTC.

DTC Troubleshooting

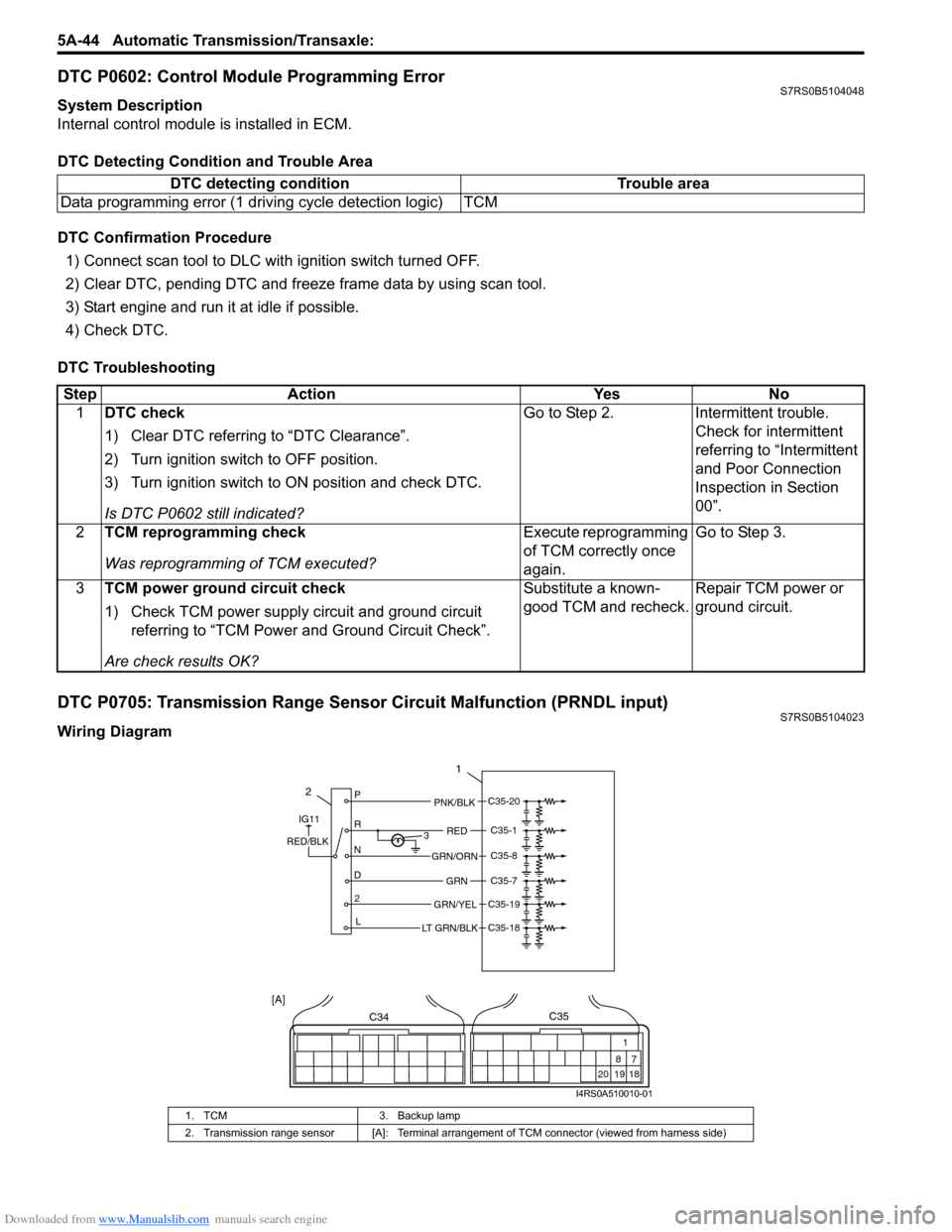

DTC P0705: Transmission Range Sensor Circuit Malfunction (PRNDL input)S7RS0B5104023

Wiring DiagramDTC detecting condition Trouble area

Data programming error (1 driving cycle detection logic) TCM

Step Action YesNo

1 DTC check

1) Clear DTC referring to “DTC Clearance”.

2) Turn ignition switch to OFF position.

3) Turn ignition switch to ON position and check DTC.

Is DTC P0602 still indicated? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 TCM reprogramming check

Was reprogramming of TCM executed? Execute reprogramming

of TCM correctly once

again.Go to Step 3.

3 TCM power ground circuit check

1) Check TCM power supply circuit and ground circuit

referring to “TCM Power and Ground Circuit Check”.

Are check results OK? Substitute a known-

good TCM and recheck.

Repair TCM power or

ground circuit.

1. TCM

3. Backup lamp

2. Transmission range sensor [A]: Terminal arrangem ent of TCM connector (viewed from harness side)

2P

R

N

D 2 L 3

1

PNK/BLK

RED

GRN

GRN/ORN

GRN/YEL

IG11

RED/BLK

LT GRN/BLK

C35-20

C35-1

C35-8

C35-7

C35-19

C35-18

C34

20 19

87

18

1

C35

[A]

I4RS0A510010-01

Page 690 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-46 Automatic Transmission/Transaxle:

Table for Step 4

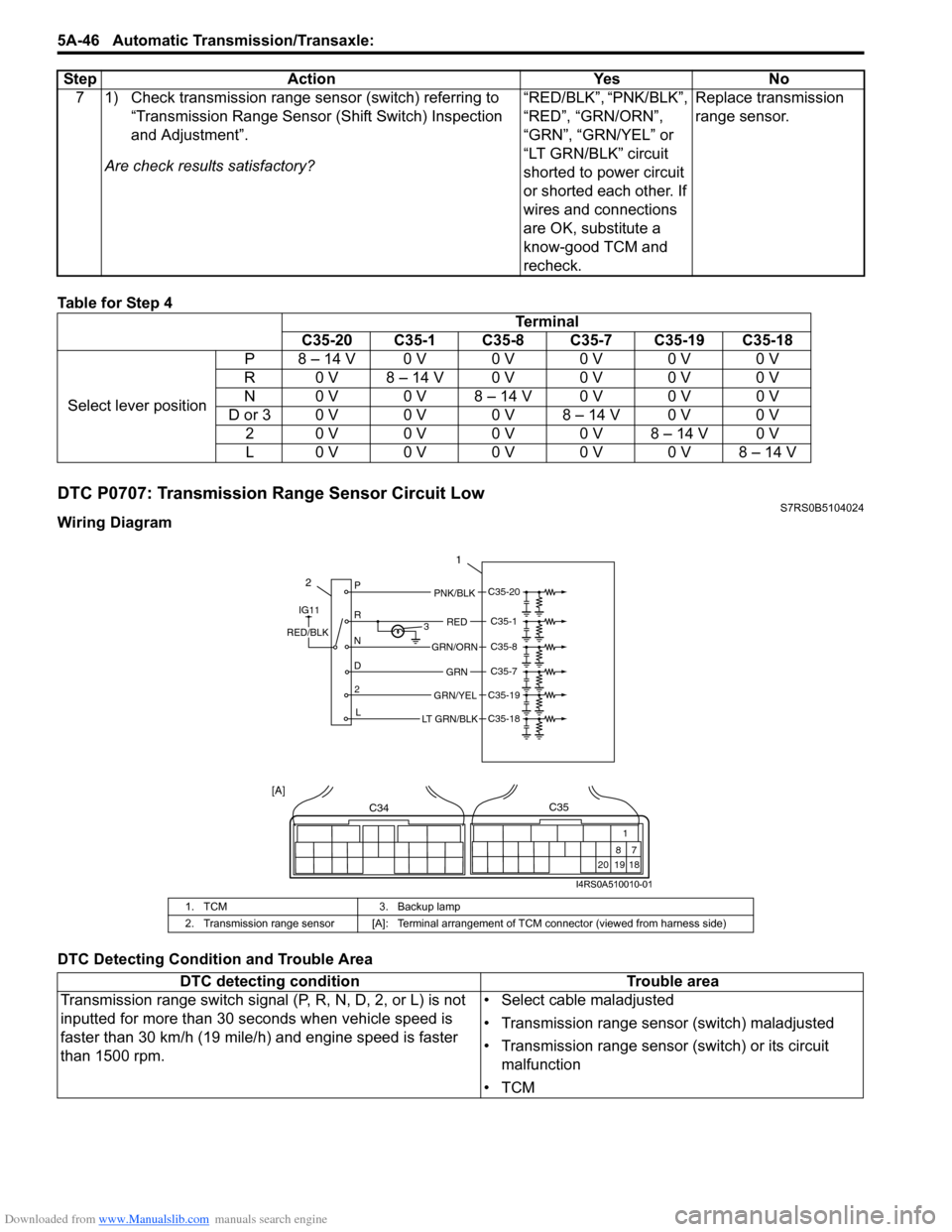

DTC P0707: Transmission Range Sensor Circuit LowS7RS0B5104024

Wiring Diagram

DTC Detecting Condition and Trouble Area7 1) Check transmission range sensor (switch) referring to

“Transmission Range Sensor (Shift Switch) Inspection

and Adjustment”.

Are check results satisfactory? “RED/BLK”, “PNK/BLK”,

“RED”, “GRN/ORN”,

“GRN”, “GRN/YEL” or

“LT GRN/BLK” circuit

shorted to power circuit

or shorted each other. If

wires and connections

are OK, substitute a

know-good TCM and

recheck.Replace transmission

range sensor.

Step Action Yes No

Terminal

C35-20 C35-1 C35-8 C35-7 C35-19 C35-18

Select lever position P 8 – 14 V 0 V 0 V 0 V 0 V 0 V

R 0 V 8 – 14 V 0 V 0 V 0 V 0 V

N 0 V 0 V 8 – 14 V 0 V 0 V 0 V

D or 3 0 V 0 V 0 V 8 – 14 V 0 V 0 V 2 0 V 0 V 0 V 0 V 8 – 14 V 0 V

L0 V0 V0 V0 V0 V8 – 14 V

1. TCM 3. Backup lamp

2. Transmission range sensor [A]: Terminal arrangem ent of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission range switch signal (P, R, N, D, 2, or L) is not

inputted for more than 30 seconds when vehicle speed is

faster than 30 km/h (19 mile/h) and engine speed is faster

than 1500 rpm. • Select cable maladjusted

• Transmission range sensor (switch) maladjusted

• Transmission range sensor (switch) or its circuit

malfunction

•TCM

2P

R

N

D 2 L 3

1

PNK/BLK

RED

GRN

GRN/ORN

GRN/YEL

IG11

RED/BLK

LT GRN/BLK

C35-20

C35-1

C35-8

C35-7

C35-19

C35-18

C34

20 19

87

18

1

C35

[A]

I4RS0A510010-01

Page 692 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-48 Automatic Transmission/Transaxle:

Table for Step 4

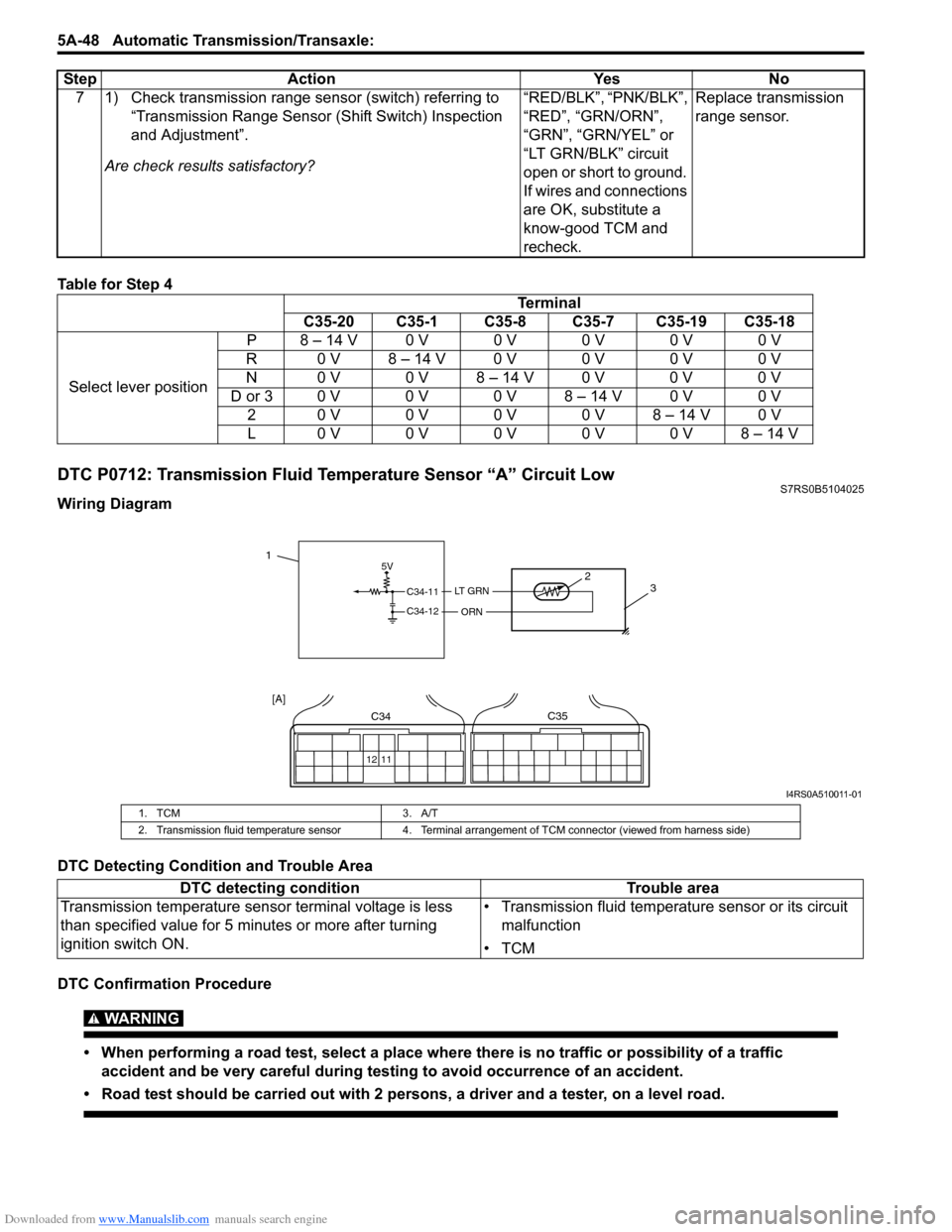

DTC P0712: Transmission Fluid Temperature Sensor “A” Circuit LowS7RS0B5104025

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

7 1) Check transmission range sensor (switch) referring to “Transmission Range Sensor (Shift Switch) Inspection

and Adjustment”.

Are check results satisfactory? “RED/BLK”, “PNK/BLK”,

“RED”, “GRN/ORN”,

“GRN”, “GRN/YEL” or

“LT GRN/BLK” circuit

open or short to ground.

If wires and connections

are OK, substitute a

know-good TCM and

recheck.Replace transmission

range sensor.

Step Action Yes No

Terminal

C35-20 C35-1 C35-8 C35-7 C35-19 C35-18

Select lever position P8 – 14 V0 V0 V0 V0 V0 V

R 0 V 8 – 14 V 0 V 0 V 0 V 0 V

N 0 V 0 V 8 – 14 V 0 V 0 V 0 V

D or 3 0 V 0 V 0 V 8 – 14 V 0 V 0 V 20 V0 V0 V0 V8 – 14 V0 V

L0 V0 V0 V0 V0 V8 – 14 V

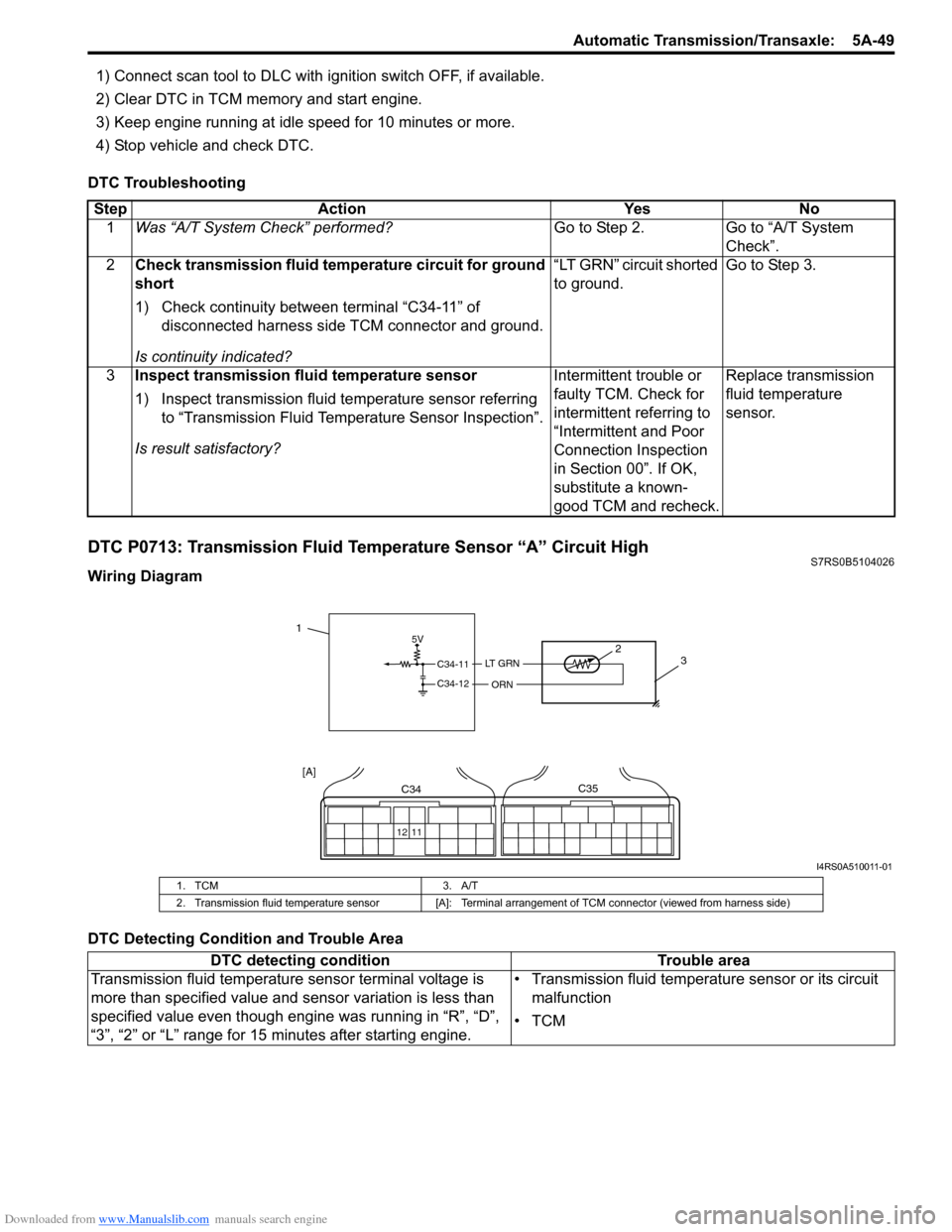

5V

C34-11

C34-12

LT GRN

ORN

2 3

12 11

C34C35

[A]

1

I4RS0A510011-01

1. TCM 3. A/T

2. Transmission fluid temperature sensor 4. Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission temperature sensor terminal voltage is less

than specified value for 5 minutes or more after turning

ignition switch ON. • Transmission fluid temperature sensor or its circuit

malfunction

•TCM

Page 693 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-49

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Keep engine running at idle speed for 10 minutes or more.

4) Stop vehicle and check DTC.

DTC Troubleshooting

DTC P0713: Transmission Fluid Temperature Sensor “A” Circuit HighS7RS0B5104026

Wiring Diagram

DTC Detecting Condition and Trouble Area Step Action Yes No

1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check transmission fluid temperature circuit for ground

short

1) Check continuity between terminal “C34-11” of

disconnected harness side TCM connector and ground.

Is continuity indicated? “LT GRN” circuit shorted

to ground.

Go to Step 3.

3 Inspect transmission fluid temperature sensor

1) Inspect transmission fluid temperature sensor referring

to “Transmission Fluid Temperature Sensor Inspection”.

Is result satisfactory? Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00”. If OK,

substitute a known-

good TCM and recheck.Replace transmission

fluid temperature

sensor.

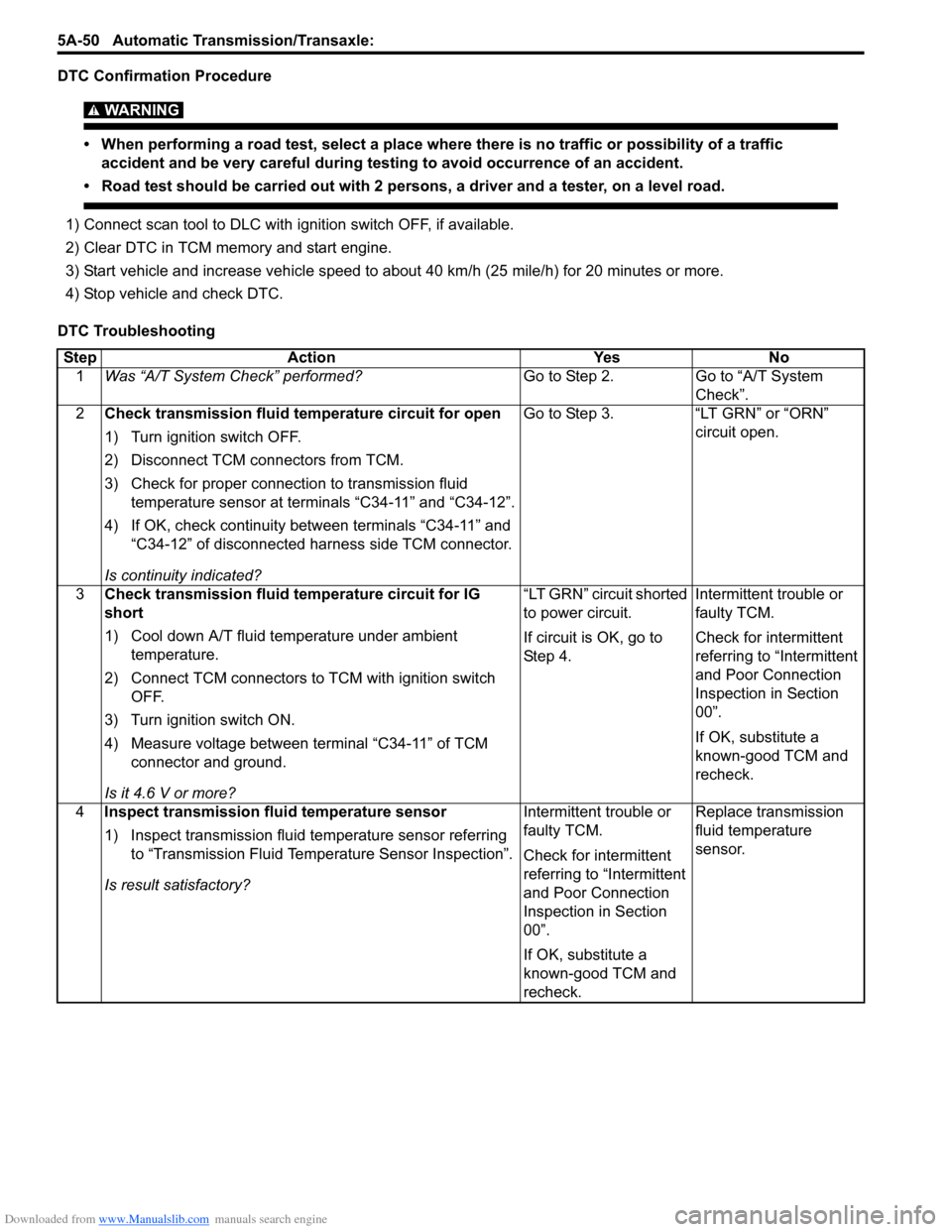

5V

C34-11

C34-12

LT G R N

ORN

2

3

12 11

C34C35

[A]

1

I4RS0A510011-01

1. TCM 3. A/T

2. Transmission fluid temperature sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission fluid temperature sensor terminal voltage is

more than specified value and sensor variation is less than

specified value even though engine was running in “R”, “D”,

“3”, “2” or “L” range for 15 minutes after starting engine. • Transmission fluid temperature sensor or its circuit

malfunction

•TCM

Page 694 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-50 Automatic Transmission/Transaxle:

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Start vehicle and increase vehicle speed to about 40 km/h (25 mile/h) for 20 minutes or more.

4) Stop vehicle and check DTC.

DTC Troubleshooting Step Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check transmission fluid temperature circuit for open

1) Turn ignition switch OFF.

2) Disconnect TCM connectors from TCM.

3) Check for proper connection to transmission fluid

temperature sensor at terminals “C34-11” and “C34-12”.

4) If OK, check continuity between terminals “C34-11” and “C34-12” of disconnected harness side TCM connector.

Is continuity indicated? Go to Step 3. “LT GRN” or “ORN”

circuit open.

3 Check transmission fluid temperature circuit for IG

short

1) Cool down A/T fluid te mperature under ambient

temperature.

2) Connect TCM connectors to TCM with ignition switch OFF.

3) Turn ignition switch ON.

4) Measure voltage between terminal “C34-11” of TCM connector and ground.

Is it 4.6 V or more? “LT GRN” circuit shorted

to power circuit.

If circuit is OK, go to

St ep 4 .

Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.

4 Inspect transmission fluid temperature sensor

1) Inspect transmission fluid temperature sensor referring

to “Transmission Fluid Temperature Sensor Inspection”.

Is result satisfactory? Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.Replace transmission

fluid temperature

sensor.