Iat sensor SUZUKI SWIFT 2005 2.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 1039 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-1

Restraint

Air Bag System

Precautions

Precautions on Service and Diagnosis of Air

Bag System

S7RS0B8200001

WARNING!

• If the air bag system and another vehicle system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel, dashboard, both front seat or any other on

or around air bag system components.

Modifications can adversely affect air bag

system performance and lead to injury.

• Be sure to follow the procedures described in this section. Failure to follow

procedures could result in possible air bag

system activation, personal injury or

unneeded air bag system repairs.

• WARNING / CAUTION labels are attached on each

part of air bag system components (SDM, air bag

(inflator) modules and seat belt pretensioners). Be

sure to follow the instructions.

• Many of service procedures require disconnection of

“A/BAG” fuse and air bag (inflator) module(s) (driver,

passenger, side of both si des and curtain of both

sides) from initiator circuit to avoid an accidental

deployment.

• Do not apply power to the air bag system unless all components are connected or a diagnostic flow

requests it, as this will set a DTC.

• The “Air Bag Diagnostic S ystem Check” must be the

starting point of any air bag diagnostics. The “Air Bag

Diagnostic System Check” will verify proper “AIR

BAG” warning right operatio n and will lead you to the

correct flow to diagnose any air bag malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements. • Never use air bag component parts from another

vehicle.

• If the vehicle will be exposed to temperatures over 93

° C (200 °F) (for example, during a paint baking

process), remove the air bag system components

beforehand to avoid component damage or

unintended system activation.

• When handling the air bag (inflator) modules (driver, passenger, side of both si des and curtain of both

sides), seat belt pretensio ners (driver and passenger),

SDM, forward-sensor or side-sensor, be careful not to

drop it or apply an impact to it. If an excessive impact

was applied (e.g., SDM, forward-sensor and side-

sensor are dropped, air bag (inflator) module is

dropped from a height of 90 cm (3 ft) or more, seat

belt pretensioner (retractor assembly) is dropped from

a height of 30 cm (1 ft) or more), never attempt

disassembly or repair but replace it with a new one.

• When using electric welding, be sure to disconnect air bag (inflator) module connectors (driver, passenger,

side of both sides and curtain of both sides) and seat

belt pretensioner connectors (driver and passenger)

respectively.

• When applying paint around the air bag system related parts, use care so that the harness or

connector will not be expo sed to the paint mist.

• Never expose air bag system component parts directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING!

When performing service on or around air

bag system components or air bag wiring,

follow the procedures listed in “Disabling Air

Bag System” to temporarily disable the air

bag system.

Failure to follow procedures could result in

possible air bag system activation, personal

injury or unneeded air bag system repairs.

Page 1163 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-125

Specifications

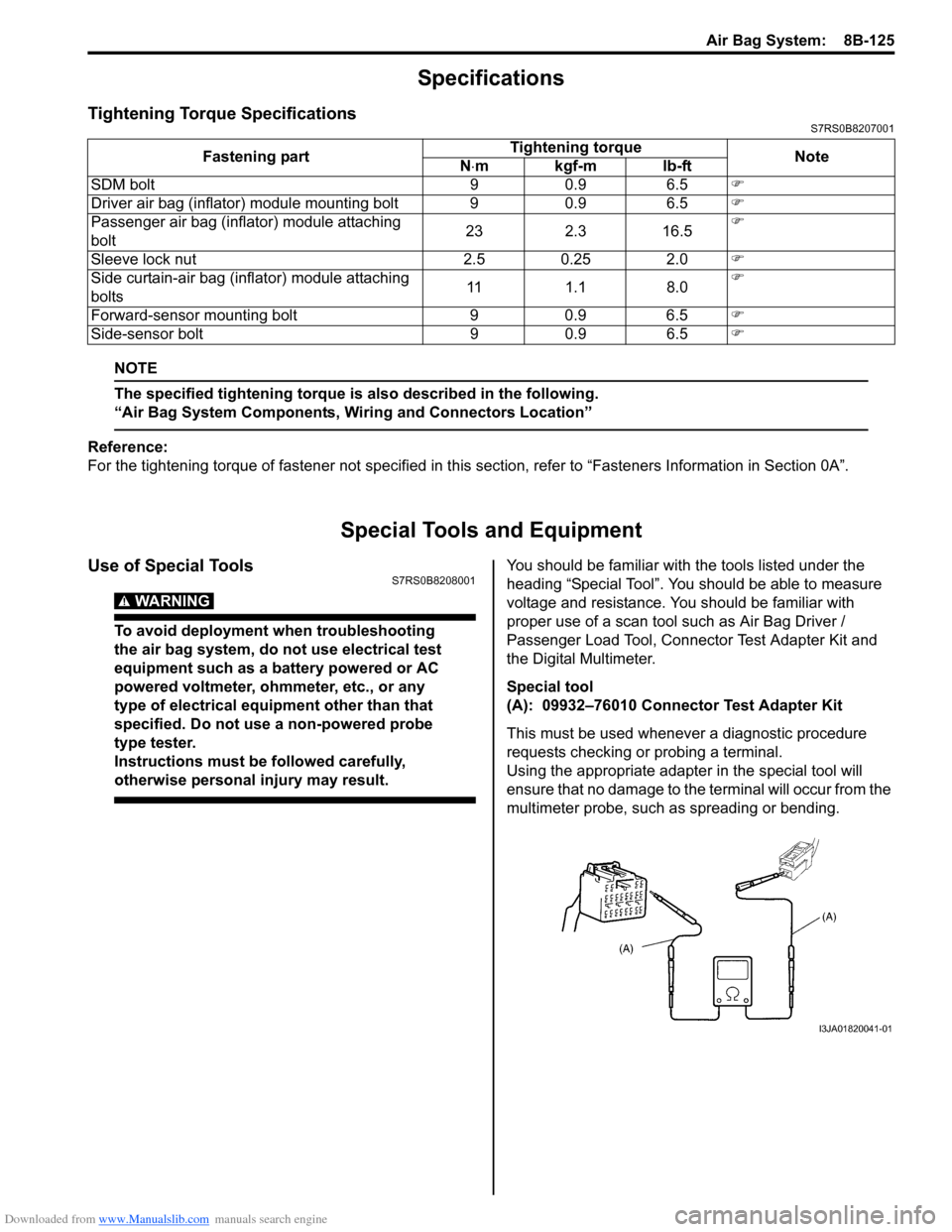

Tightening Torque SpecificationsS7RS0B8207001

NOTE

The specified tightening torque is also described in the following.

“Air Bag System Components, Wiring and Connectors Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Use of Special ToolsS7RS0B8208001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified. Do not use a non-powered probe

type tester.

Instructions must be followed carefully,

otherwise personal injury may result.

You should be familiar with the tools listed under the

heading “Special Tool”. You should be able to measure

voltage and resistance. You should be familiar with

proper use of a scan tool such as Air Bag Driver /

Passenger Load Tool, Connector Test Adapter Kit and

the Digital Multimeter.

Special tool

(A): 09932–76010 Connector Test Adapter Kit

This must be used whenever a diagnostic procedure

requests checking or probing a terminal.

Using the appropriate adapter in the special tool will

ensure that no damage to the terminal will occur from the

multimeter probe, such as spreading or bending.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

SDM bolt 9 0.9 6.5 �)

Driver air bag (inflator) module mounting bolt 9 0.9 6.5 �)

Passenger air bag (inflator) module attaching

bolt 23 2.3 16.5�)

Sleeve lock nut 2.5 0.25 2.0 �)

Side curtain-air bag (inflator) module attaching

bolts 11 1.1 8.0�)

Forward-sensor mounting bolt 9 0.9 6.5 �)

Side-sensor bolt 9 0.9 6.5 �)

I3JA01820041-01

Page 1180 of 1496

![SUZUKI SWIFT 2005 2.G Service Manual Online Downloaded from www.Manualslib.com manuals search engine 9A-9 Wiring Systems:

[D]: Terminals-in-one-connector mark

[E]: Wire color

[F]: Shield wire

[G]: Ground point

[H]: “From” or “To” (With SUZUKI SWIFT 2005 2.G Service Manual Online Downloaded from www.Manualslib.com manuals search engine 9A-9 Wiring Systems:

[D]: Terminals-in-one-connector mark

[E]: Wire color

[F]: Shield wire

[G]: Ground point

[H]: “From” or “To” (With](/img/20/7607/w960_7607-1179.png)

Downloaded from www.Manualslib.com manuals search engine 9A-9 Wiring Systems:

[D]: Terminals-in-one-connector mark

[E]: Wire color

[F]: Shield wire

[G]: Ground point

[H]: “From” or “To” (With ID letter (s))

[I]: Specification variation

The white arrow between A and B means “or”.

[J]: “From” (With ID letter (s))

[K] “To” (With ID letter (s))

[L]: Connector code

[M]: Terminal No.

[N]: Symbol mark

[O]: “SEE” mark

Switch

BLU

BLU

GRN/BLK

GRN/REDGRN/BLK

12

GRN

GRN

C262

1

BLK

5

BLK

2

1

C40

GRN/BLK

"XX"

Solenoid

Fuse

Fuse

3

15A

Main

relay

ON

OFF

1

15A

6

20A

1

Sensor

1

2

8

BRN/RED

E521

2E52 1

BRN/RED

RED

2

BRN/REDBRN/RED

MotorM

M

655

A

B

AB5

6

1

2

56464

4-DOOR

2-DOOR

2

C71

E03

E34

O06

C31

E19

[A]

[B]

[C]

[F]

[G]

[H] [D] [I]

[K] [L]

E3375E341

21

43E08

ORNWHTYEL

RED

YELYEL/REDGRN/RED

4

3

YEL

BLK/RED

ORN

GRN

GRN

BA

GRN

GRN

2

XX

Cont.M

[J]

[E]

[N] [O]

[M]

GBGR

Y

Y

GB

P

3

4

2

3

L50

G20

1

GR

Y

BLK

BLK

GR

I5RW0A910994-02

Page 1185 of 1496

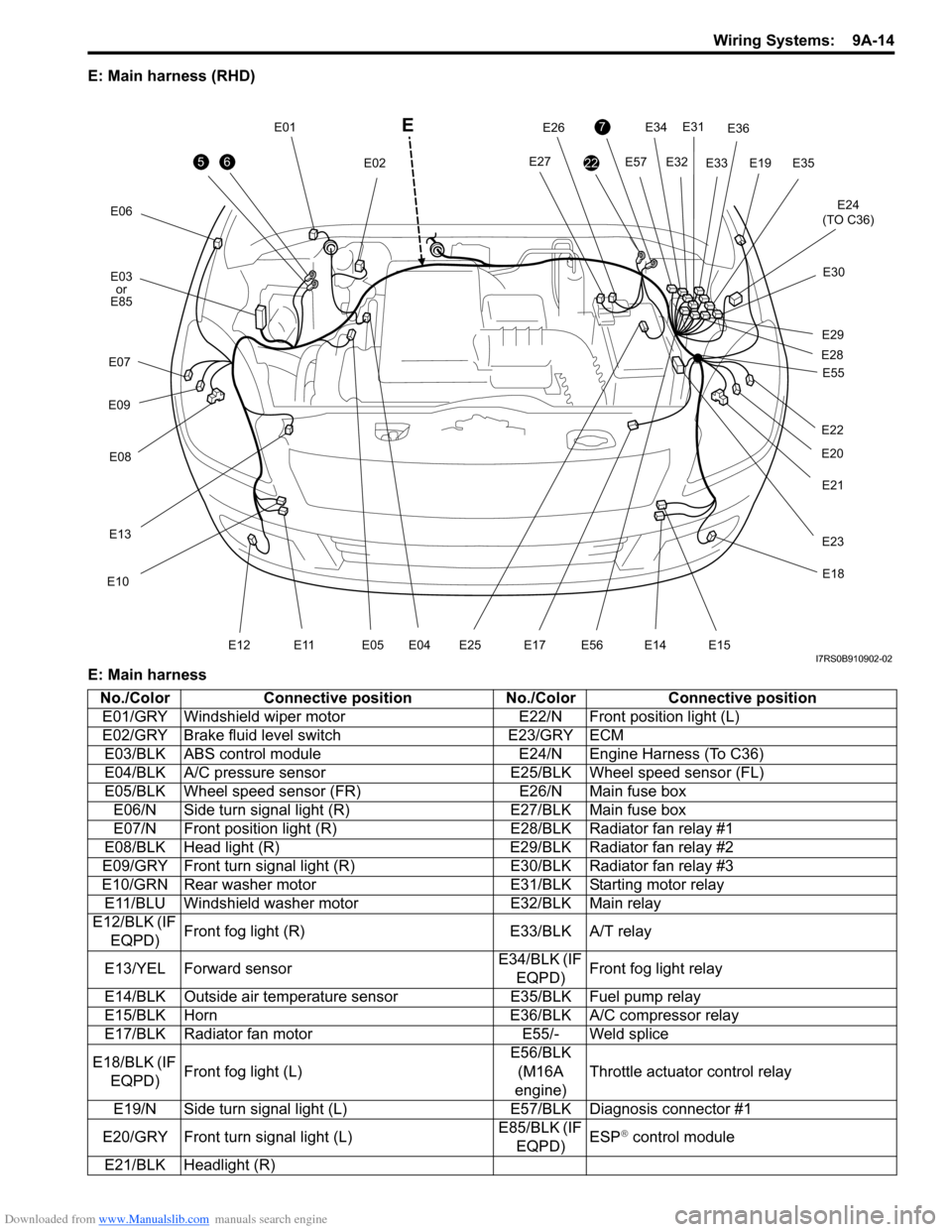

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-14

E: Main harness (RHD)

E: Main harness

56

E06E12

E03or

E85

E07

E09

E08

E13

E10

E11E05 E04

E01 E02

E19

7

22

E34E31

E32

E57

E24

(TO C36)

E33

E36

E35

E30

E29

E28

E20

E21

E22

E27

E26

E23

E25E17E56

E18

E14 E15

E55

E

I7RS0B910902-02

No./Color

Connective position No./ColorConnective position

E01/GRY Windshield wiper motor E22/N Front position light (L)

E02/GRY Brake fluid level switch E23/GRY ECM

E03/BLK ABS control module E24/N Engine Harness (To C36)

E04/BLK A/C pressure sensor E25/BLK Wheel speed sensor (FL)

E05/BLK Wheel speed sensor (FR) E26/N Main fuse box

E06/N Side turn signal light (R) E27/BLK Main fuse box

E07/N Front position light (R) E28/BLK Radiator fan relay #1

E08/BLK Head light (R) E29/BLK Radiator fan relay #2

E09/GRY Front turn signal light (R) E30/BLK Radiator fan relay #3

E10/GRN Rear washer motor E31/BLK Starting motor relay

E11/BLU Windshield washer motor E32/BLK Main relay

E12/BLK (IF EQPD) Front fog light (R)

E33/BLK A/T relay

E13/YEL Forward sensor E34/BLK (IF

EQPD) Front fog light relay

E14/BLK Outside air temperature sensor E35/BLK Fuel pump relay

E15/BLK Horn E36/BLK A/C compressor relay

E17/BLK Radiator fan motor E55/- Weld splice

E18/BLK (IF EQPD) Front fog light (L) E56/BLK

(M16A

engine) Throttle actuator control relay

E19/N Side turn signal light (L) E57/BLK Diagnosis connector #1

E20/GRY Front turn signal light (L) E85/BLK (IF

EQPD) ESP

® control module

E21/BLK Headlight (R)

Page 1186 of 1496

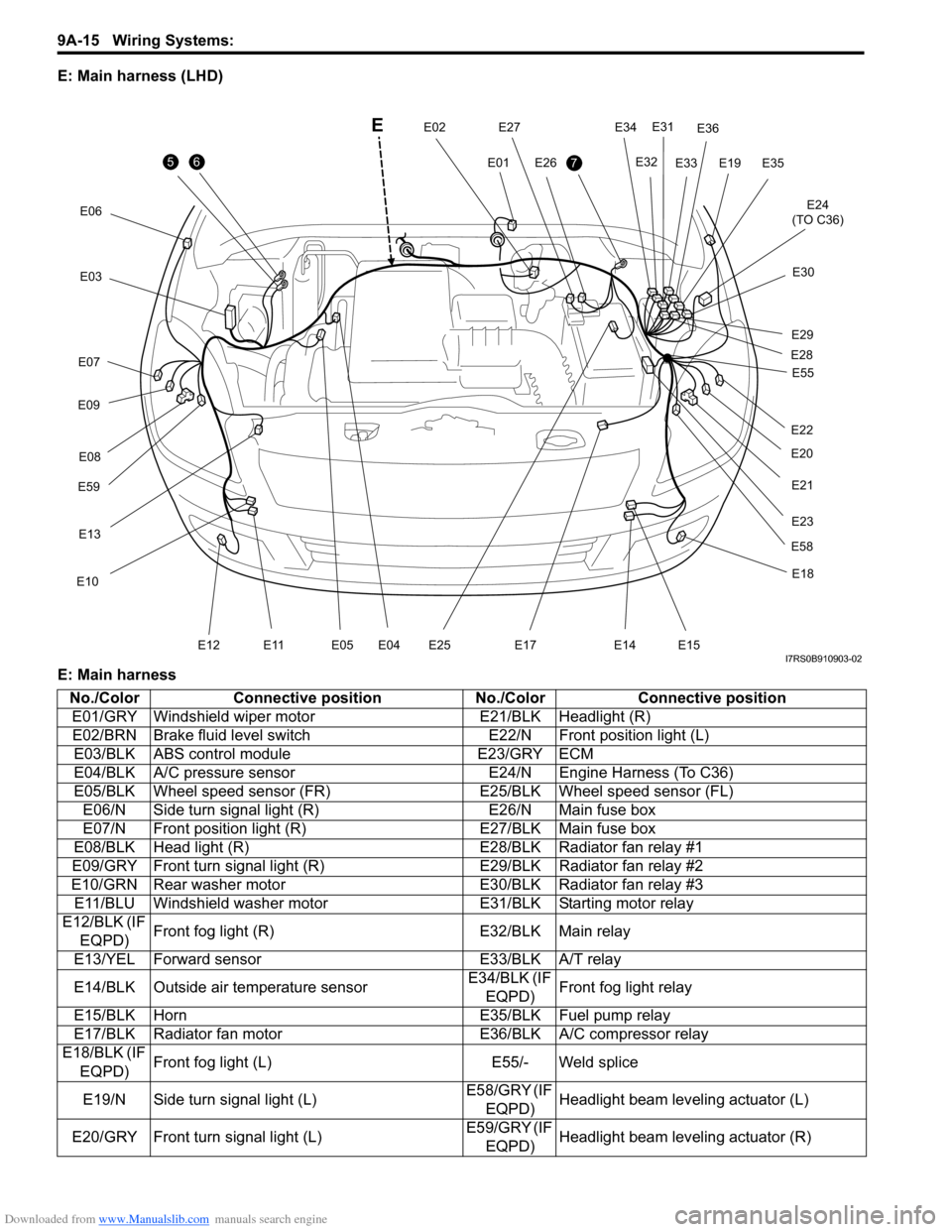

Downloaded from www.Manualslib.com manuals search engine 9A-15 Wiring Systems:

E: Main harness (LHD)

E: Main harness

56

E06E12

E

E03

E07

E09

E59E08

E13

E10

E11E05 E04

E01

E02E197

E34

E31

E32

E24

(TO C36)

E33

E36

E35

E30

E29

E28

E20

E21

E22

E58

E27

E26

E23

E25E17

E18

E14 E15

E55

I7RS0B910903-02

No./Color

Connective position No./ColorConnective position

E01/GRY Windshield wiper motor E21/BLK Headlight (R)

E02/BRN Brake fluid level switch E22/N Front position light (L)

E03/BLK ABS control module E23/GRY ECM

E04/BLK A/C pressure sensor E24/N Engine Harness (To C36)

E05/BLK Wheel speed sensor (FR) E25/BLK Wheel speed sensor (FL)

E06/N Side turn signal light (R) E26/N Main fuse box

E07/N Front position light (R) E27/BLK Main fuse box

E08/BLK Head light (R) E28/BLK Radiator fan relay #1

E09/GRY Front turn signal light (R) E29/BLK Radiator fan relay #2

E10/GRN Rear washer motor E30/BLK Radiator fan relay #3

E11/BLU Windshield washer motor E31/BLK Starting motor relay

E12/BLK (IF EQPD) Front fog light (R)

E32/BLK Main relay

E13/YEL Forward sensor E33/BLK A/T relay

E14/BLK Outside air temperature sensor E34/BLK (IF

EQPD) Front fog light relay

E15/BLK Horn E35/BLK Fuel pump relay

E17/BLK Radiator fan motor E36/BLK A/C compressor relay

E18/BLK (IF

EQPD) Front fog light (L)

E55/- Weld splice

E19/N Side turn signal light (L) E58/GRY (IF

EQPD) Headlight beam leveling actuator (L)

E20/GRY Front turn signal light (L) E59/GRY (IF

EQPD) Headlight beam leveling actuator (R)