Rear end solenoid SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 302 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-17 Engine Mechanical:

Engine Assembly Removal and InstallationS7RS0B1406011

NOTE

After replacing electric throttle body

assembly, perform calibration of throttle

valve referring to “Electric Throttle Body

System Calibration in Section 1C”.

Removal1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure in Section 1G”.

2) Disconnect negative and pos itive cable at battery.

3) Remove battery and tray.

4) Remove engine hood after disconnecting windshield washer hose.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to “Compressor Drive Belt Remo val and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil, transaxle oil and coolant.

8) Remove cowl top plate referring to “Cowl Top Components in Section 9K”.

9) Remove air cleaner assembly referring to “Air Cleaner Components”.

10) With hose connected, detach A/C compressor from its bracket (A/C model) referring to “Compressor

Assembly Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

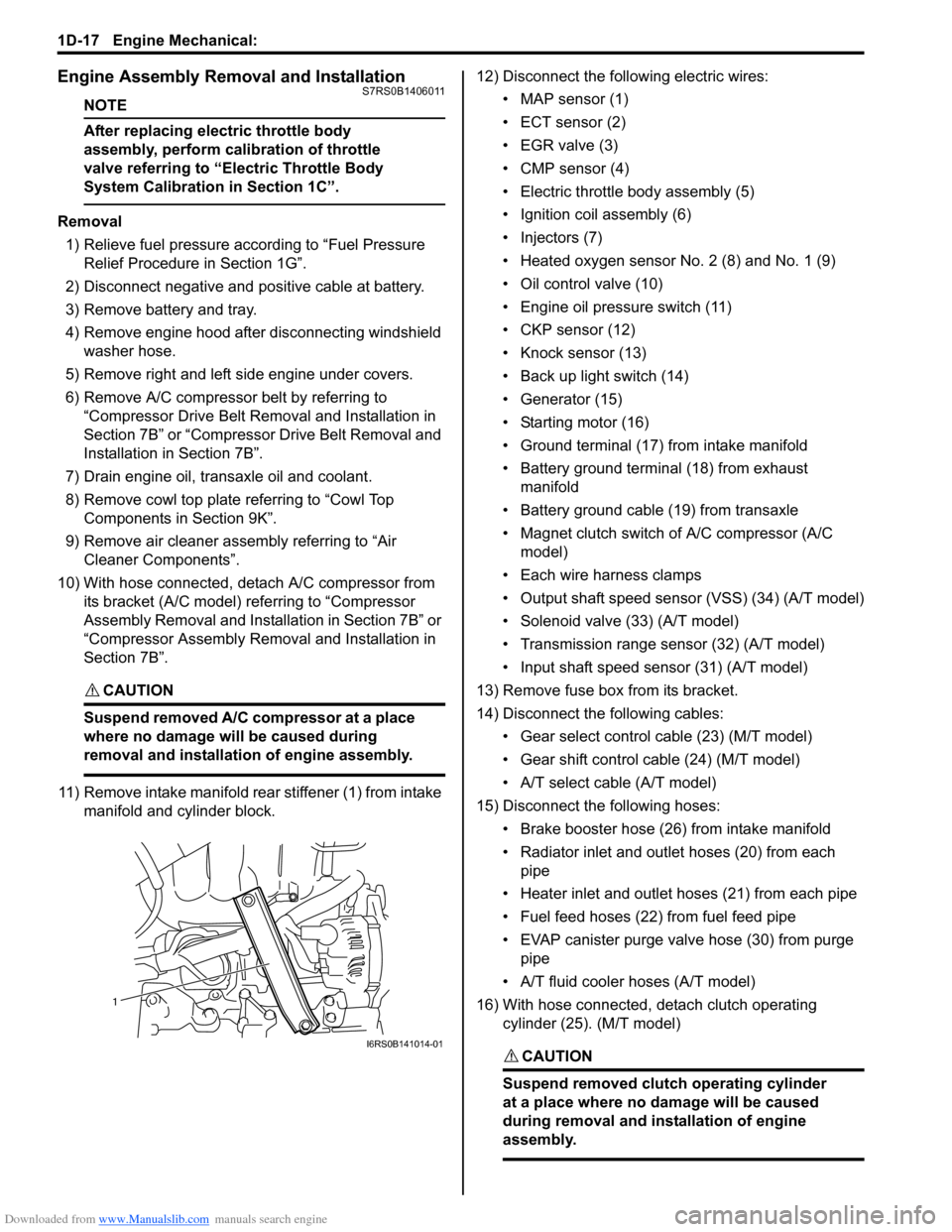

11) Remove intake manifold rear stiffener (1) from intake manifold and cylinder block. 12) Disconnect the following electric wires:

• MAP sensor (1)

• ECT sensor (2)

•EGR valve (3)

• CMP sensor (4)

• Electric throttle body assembly (5)

• Ignition coil assembly (6)

• Injectors (7)

• Heated oxygen sensor No. 2 (8) and No. 1 (9)

• Oil control valve (10)

• Engine oil pressure switch (11)

• CKP sensor (12)

• Knock sensor (13)

• Back up light switch (14)

• Generator (15)

• Starting motor (16)

• Ground terminal (17) from intake manifold

• Battery ground terminal (18) from exhaust manifold

• Battery ground cable (19) from transaxle

• Magnet clutch switch of A/C compressor (A/C model)

• Each wire harness clamps

• Output shaft speed sensor (VSS) (34) (A/T model)

• Solenoid valve (33) (A/T model)

• Transmission range sensor (32) (A/T model)

• Input shaft speed sensor (31) (A/T model)

13) Remove fuse box from its bracket.

14) Disconnect the following cables: • Gear select control cable (23) (M/T model)

• Gear shift control cable (24) (M/T model)

• A/T select cable (A/T model)

15) Disconnect the following hoses: • Brake booster hose (26) from intake manifold

• Radiator inlet and outlet hoses (20) from each pipe

• Heater inlet and outlet hoses (21) from each pipe

• Fuel feed hoses (22) from fuel feed pipe

• EVAP canister purge valve hose (30) from purge pipe

• A/T fluid cooler hoses (A/T model)

16) With hose connected, detach clutch operating cylinder (25). (M/T model)

CAUTION!

Suspend removed clutch operating cylinder

at a place where no damage will be caused

during removal and installation of engine

assembly.

1

I6RS0B141014-01

Page 541 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-2

General Description

ABS DescriptionS7RS0B4501001

The ABS (Antilock Brake System) controls the fluid

pressure applied to the wheel cylinder of each brake

from the master cylinder so that each wheel is not locked

even when hard braking is applied.

This ABS has also the following function.

While braking is applied, but before ABS control

becomes effective, braking force is distributed between

the front and rear so as to prevent the rear wheels from

being locked too early for better stability of the vehicle.

The main component parts of this ABS include the

following parts in addition to those of the conventional

brake system.

• Wheel speed sensor which senses revolution speed of each wheel and outputs its signal.

• ABS warning light which light s to inform abnormality

when system fails to operate properly.

• ABS hydraulic unit / cont rol module assembly is

incorporated ABS co ntrol module, ABS hydraulic unit

(actuator assembly), solenoid valve power supply

driver (transistor), solenoid valve driver (transistor),

pump motor driver (transistor).

– ABS control module which sends operation signal to ABS hydraulic unit to control fluid pressure

applied to each wheel cylinder based on signal

from each wheel speed sensor so as to prevent

wheel from locking.

– ABS hydraulic unit which operates according to signal from ABS control module to control fluid

pressure applied to wheel cylinder of each 4

wheels.

– Solenoid valve power supp ly driver (transistor)

which supplies power to solenoid valve in ABS

hydraulic unit.

– Solenoid valve driver (transistor) which controls each solenoid valves in ABS hydraulic unit.

– Pump motor driver (transistor) which supplies power to pump motor in ABS hydraulic unit.

This ABS is equipped with Electronic Brake force

Distribution (EBD) system that controls a fluid pressure

of rear wheels to best condition, which is the same

function as that of proportion ing valve, by the signal from

wheel sensor independently of change of load due to

load capacity and so on. An d if the EBD system fails to

operate properly, the brake warning light lights to inform

abnormality.

ABS Hydraulic Unit / Control Module Assembly

Description

S7RS0B4501002

ABS control module is a component of ABS hydraulic

unit / control module asse mbly and has the following

functions.

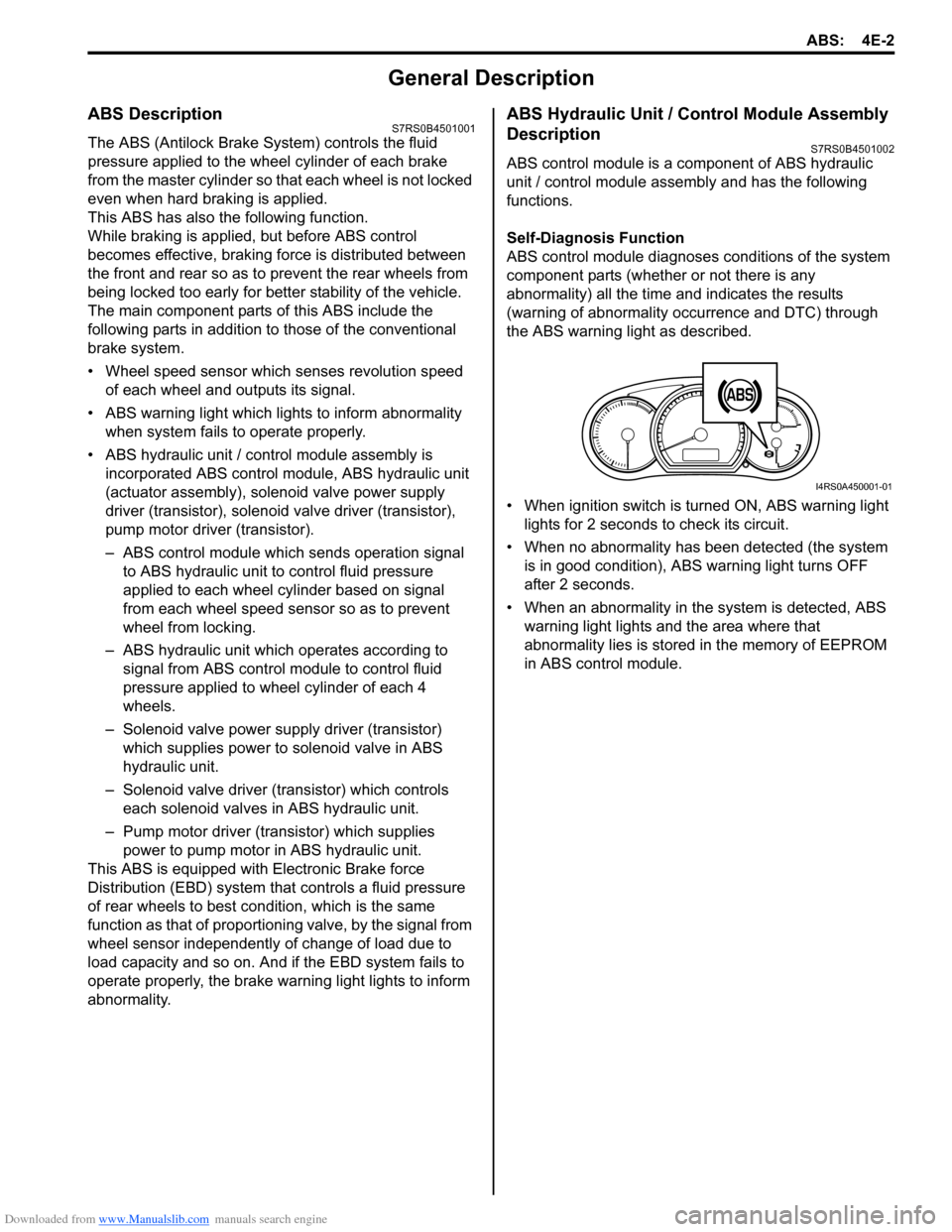

Self-Diagnosis Function

ABS control module diagnose s conditions of the system

component parts (whether or not there is any

abnormality) all the time and indicates the results

(warning of abnormality occurrence and DTC) through

the ABS warning light as described.

• When ignition switch is turned ON, ABS warning light lights for 2 seconds to check its circuit.

• When no abnormality has been detected (the system is in good condition), ABS warning light turns OFF

after 2 seconds.

• When an abnormality in th e system is detected, ABS

warning light lights and the area where that

abnormality lies is stored in the memory of EEPROM

in ABS control module.

1

I4RS0A450001-01

Page 578 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-4 Electronic Stability Program:

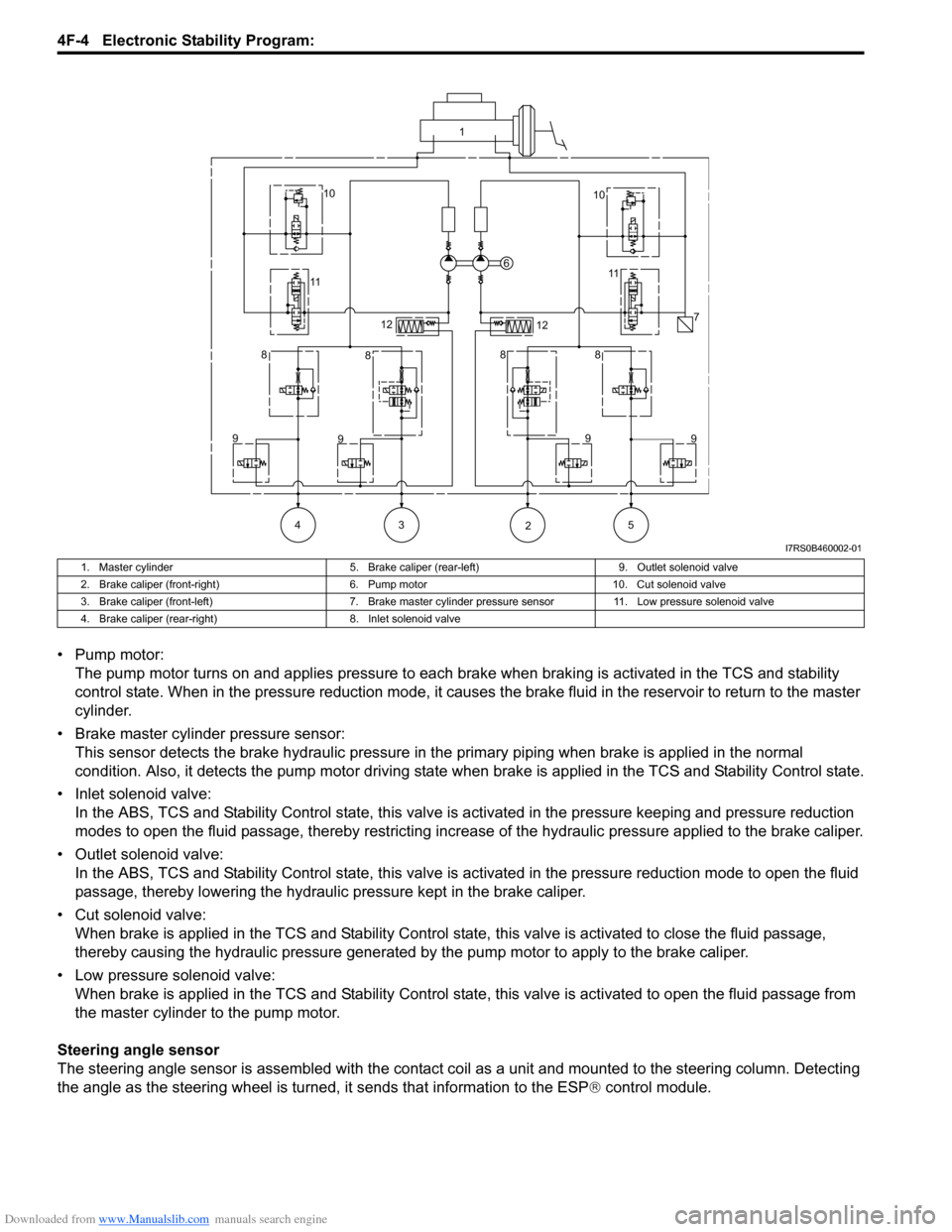

• Pump motor:The pump motor turns on and applies pressure to each brake when braking is activated in the TCS and stability

control state. When in the pressure reduction mode, it causes the brake fluid in the reservoir to return to the master

cylinder.

• Brake master cylinder pressure sensor: This sensor detects the brake hydraulic pressure in th e primary piping when brake is applied in the normal

condition. Also, it detects the pump motor driving state wh en brake is applied in the TCS and Stability Control state.

• Inlet solenoid valve: In the ABS, TCS and Stability Control stat e, this valve is activated in the pressure keeping and pressure reduction

modes to open the fluid passage, thereby restricting increase of the hydraulic pressure applied to the brake caliper.

• Outlet solenoid valve: In the ABS, TCS and Stability Control state, this valve is activated in the pressure reduction mode to open the fluid

passage, thereby lowering the hydraulic pressure kept in the brake caliper.

• Cut solenoid valve: When brake is applied in the TCS and Stability Control state, this valve is activated to close the fluid passage,

thereby causing the hydraulic pressure generated by the pump motor to apply to the brake caliper.

• Low pressure solenoid valve: When brake is applied in the TCS and Stab ility Control state, this valve is activated to open the fluid passage from

the master cylinder to the pump motor.

Steering angle sensor

The steering angle sensor is assembled with the contact co il as a unit and mounted to the steering column. Detecting

the angle as the steering wheel is turned, it sends that information to the ESP ® control module.

1

10 10

11 11

6

7

12 12

8 8 88

9 9 9

9

43 5 2

I7RS0B460002-01

1. Master cylinder 5. Brake caliper (rear-left)9. Outlet solenoid valve

2. Brake caliper (front-right) 6. Pump motor10. Cut solenoid valve

3. Brake caliper (front-left) 7. Brake master cylinder pressure sensor 11. Low pressure solenoid valve

4. Brake caliper (rear-right) 8. Inlet solenoid valve

Page 642 of 1496

Downloaded from www.Manualslib.com manuals search engine 5-ii Table of Contents

DTC P1878: Torque Converter Clutch Shudder .......................................................... 5A-75

DTC P2762: Torque Converter Clutch (TCC) Pressure Control Sole noid Control Circuit

Range /Performance ....................................... 5A-76

DTC P2763: Torque Converter Clutch Pressure Control Sole noid Control Circuit

High ................................................................. 5A-78

DTC P2764: Torque Converter Clutch Circuit Pressure Control Sole noid Control Circuit

Low ................................................................. 5A-80

Inspection of TCM and Its Circuits .................... 5A-82

TCM Power and Ground Circuit Check ............. 5A-86

Brake Interlock System Inspection .................... 5A-87

Repair Instructions ........... .................................5A-88

Learning Control Initializat ion ............................ 5A-88

A/T Fluid Level Check ....................................... 5A-89

A/T Fluid Change .............................................. 5A-90

Select Lever Components ... .............................. 5A-90

Select Lever Assembly Removal and Installation ....................................................... 5A-90

Select Lever Knob Installa tion........................... 5A-90

Select Lever Inspection .... ................................. 5A-91

“3” Position Switch Inspec tion ........................... 5A-91

Shift Lock Solenoid Inspec tion .......................... 5A-91

Shift Lock Solenoid Replacement ..................... 5A-91

Select Cable Components ................................ 5A-92

Select Cable Removal and Installation ............. 5A-92

Select Cable Adjustment ................................... 5A-93

Key Interlock Cable Removal and Installation... 5A-93

Transmission Range Sensor (Shift Switch) Inspection and Adjustment .............................. 5A-95

Output Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Output Shaft Speed Sensor Inspection ............. 5A-96

Input Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Input Shaft Speed Sensor Inspection................ 5A-97

Transmission Fluid Temperature Sensor Removal and Installation ................................. 5A-97

Transmission Fluid Temperature Sensor Inspection ........................................................ 5A-98

Solenoid Valves (Shift Solenoid Valves and Timing Solenoid Valve) Removal and

Installation ....................................................... 5A-98

Solenoid Valves (Shift Solenoid Valves, and Timing Solenoid Valve) Inspection .................. 5A-99

Pressure Control Soleno id Valves (Pressure

Control Solenoid and TCC Pressure Control

Solenoid) Removal and Inst allation .............. 5A-101

Pressure Control Solenoid Valve Inspection ... 5A-101

Transmission Control Module (TCM) Removal and Installation ............................... 5A-102

A/T Relay Inspection ....................................... 5A-103

Differential Side Oil Seal Replacement ........... 5A-103

A/T Fluid Cooler Hoses Replacement ............. 5A-104

Automatic Transaxle Unit Components........... 5A-105

Automatic Transaxle Unit Dismounting and Remounting ................................................... 5A-106

Automatic Transaxle Asse mbly Components . 5A-108 Automatic Transaxle Unit

Disassembly........... 5A-110

Oil Pump Assembly Components ................... 5A-121

Oil Pump Assembly Disassembly and Reassembly .................................................. 5A-122

Oil Pump Assembly Inspection ....................... 5A-122

Direct Clutch Assembly Components.............. 5A-124

Direct Clutch Assembly Preliminary Check ..... 5A-124

Direct Clutch Assembly Disassembly and Reassembly .................................................. 5A-125

Direct Clutch Assembly Inspection.................. 5A-127

Forward and Reverse Clutch Assembly Components .................................................. 5A-128

Forward and Reverse Clutch Assembly Preliminary Check ......................................... 5A-129

Forward and Reverse Clutch Assembly Disassembly and Reassembly ...................... 5A-129

Forward and Reverse Clutch Assembly Inspection ...................................................... 5A-133

2nd Brake Piston Assembly Components ....... 5A-134

2nd Brake Piston Assembly Disassembly and Reassembly .................................................. 5A-134

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Components........... 5A-135

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Disassembly and

Reassembly .................................................. 5A-136

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Inspection............... 5A-137

Countershaft Assembly Co mponents.............. 5A-138

Countershaft Assembly Disassembly and Reassembly .................................................. 5A-138

Valve Body Assembly Components ................ 5A-139

Valve Body Assembly Disassembly and Reassembly .................................................. 5A-140

Differential Assembly Components ................. 5A-141

Differential Assembly Disassembly and Reassembly .................................................. 5A-142

Differential Assembly Inspection ..................... 5A-143

Torque Converter Housing Disassembly and Reassembly .................................................. 5A-144

Transaxle Case Disassembly and Reassembly .................................................. 5A-146

Automatic Transaxle Unit Inspection and Adjus

tment .................................................... 5A-147

Automatic Transaxle Unit Assembly ............... 5A-150

Specifications .................. .................................5A-167

Tightening Torque Specifications .................... 5A-167

Special Tools and Equipmen t .........................5A-168

Recommended Service Material ..................... 5A-168

Special Tool .................................................... 5A-168

Manual Transmission/Tr ansaxle ............ 5B-1

General Description .............................................5B-1

Manual Transaxle Construction and Servicing .... 5B-1

Diagnostic Information and Procedures ............5B-3 Manual Transaxle Symptom Diagnosis............... 5B-3

Repair Instructions ............ ..................................5B-3

Manual Transaxle Oil Change............................. 5B-3

Differential Side Oil Seal Replacement ............... 5B-4

Page 1200 of 1496

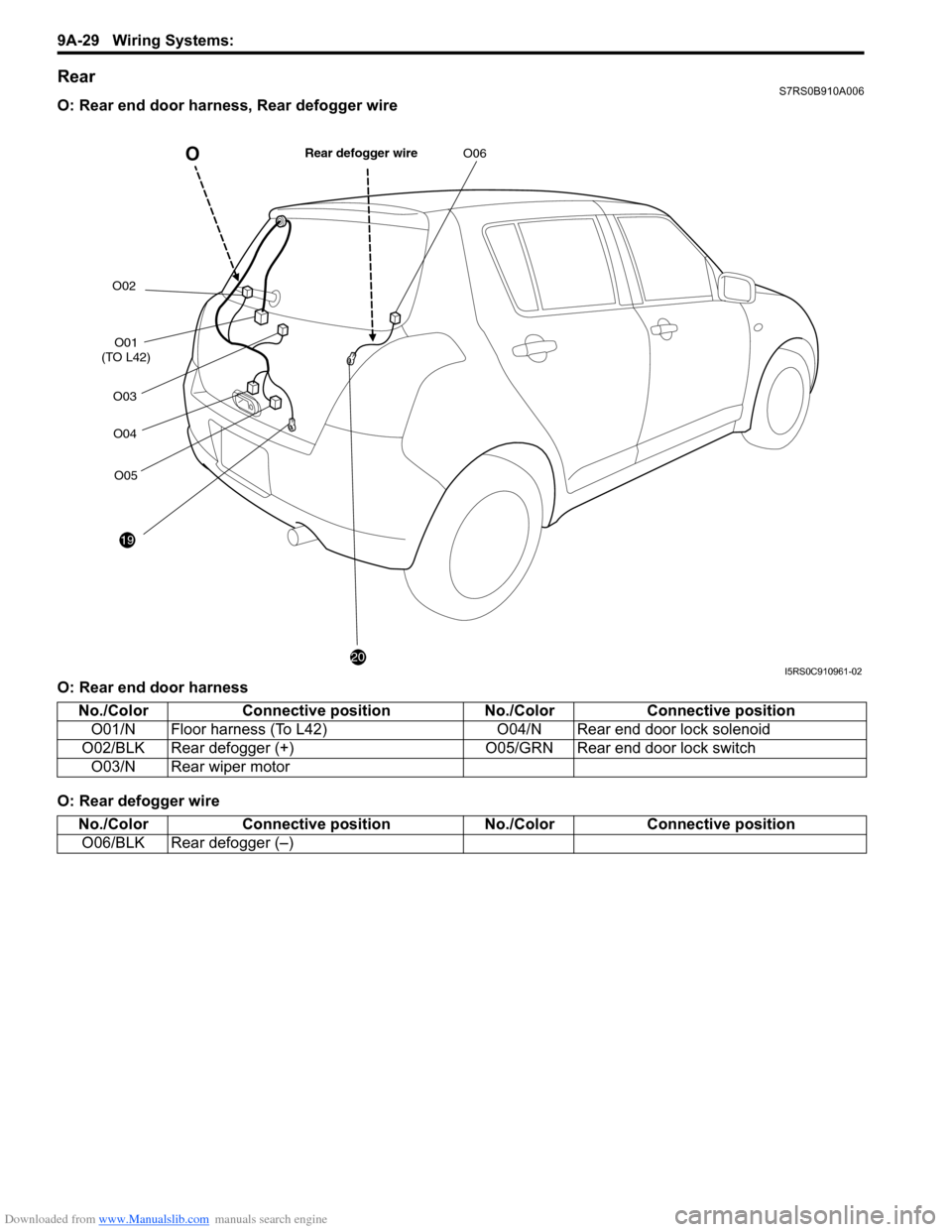

Downloaded from www.Manualslib.com manuals search engine 9A-29 Wiring Systems:

RearS7RS0B910A006

O: Rear end door harness, Rear defogger wire

O: Rear end door harness

O: Rear defogger wire

ORear defogger wire

O01

(TO L42) O02

O03

19

O04

O05

O06

20I5RS0C910961-02

No./Color Connective position No./ColorConnective position

O01/N Floor harness (To L42) O04/N Rear end door lock solenoid

O02/BLK Rear defogger (+) O05/GRN Rear end door lock switch

O03/N Rear wiper motor

No./Color Connective position No./ColorConnective position

O06/BLK Rear defogger (–)

Page 1231 of 1496

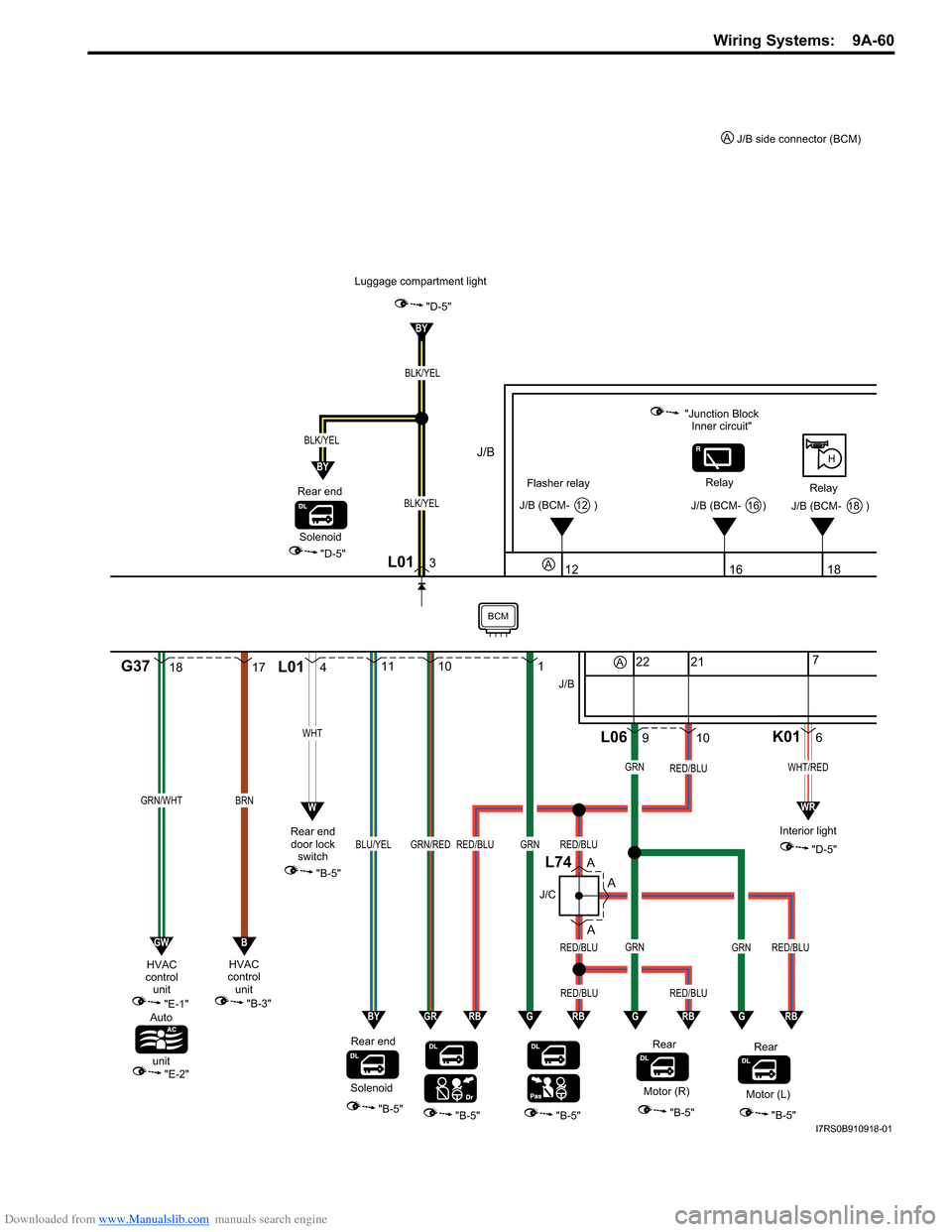

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-60

1817

GRN/WHTBRN

"E-1"

"E-2"

HVAC

control unit

Auto

unit

G37

Flasher relay Relay

Relay

H

12

"Junction Block

Inner circuit"

J/B (BCM- 12 )J/B (BCM- 18 )

1618

J/B (BCM- 16 )

J/B

"B-5""B-5""B-5""B-5"

11

9

L06

22

10

21

Rear

J/B

GRN

GRN

RED/BLU

RED/BLURED/BLU

RED/BLUGRNRED/BLU

GRN

110

GRN/REDRED/BLURED/BLUBLU/YEL

Rear end

L014

WHT

Rear end

door lock switch

3

"D-5"

BLK/YEL

L01

Luggage compartment light

7

6K01

Interior light

"D-5"

WHT/RED

WR

J/B side connector (BCM)

A

A

A

BY

GWB

W

BYGRRBGGRBGRBGRB

"B-5"

SolenoidMotor (R)

"B-5"

Rear

Motor (L)

"B-3"

HVAC

control unit

BCM

BLK/YEL

BY

BLK/YEL

"D-5"

Solenoid

Rear end

A

A

A

J/C

L74

I7RS0B910918-01

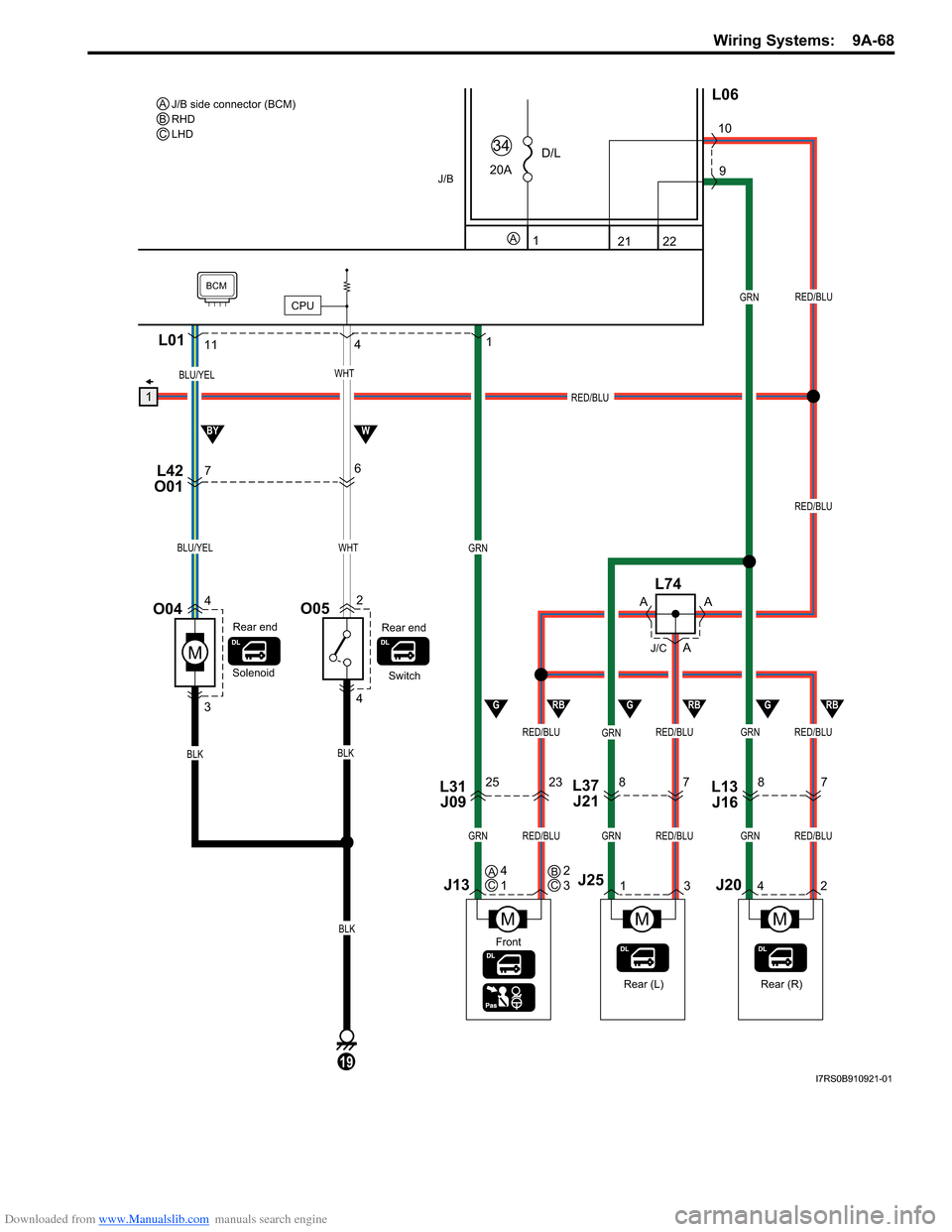

Page 1239 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-68

114

10

L06

21 9

221

8

42L13 J1678L37J217

7L42

O01

O04

Rear (R)

J/B

GRN

GRN

RED/BLU

J20

RED/BLUGRNRED/BLU

GRN

RED/BLU

D/L

20A34

3

M

1

J13

L01

M

13

Rear (L)

J25

M

25L31 J0923

M

GRNRED/BLUGRNRED/BLUGRNRED/BLU

BLU/YEL

BLU/YEL

BCM

1

Switch

6

4

O05

BLK

19

WHT

WHT

BLKBLK

RED/BLU

RED/BLU

CPU

2

4

Solenoid

A

Rear end

BY

GRBGRBGRB

Rear end

W

Front

J/B side connector (BCM)

RHD

LHD

A

BC

C

A4

1CB2

3

A

A

A

J/C

L74

I7RS0B910921-01

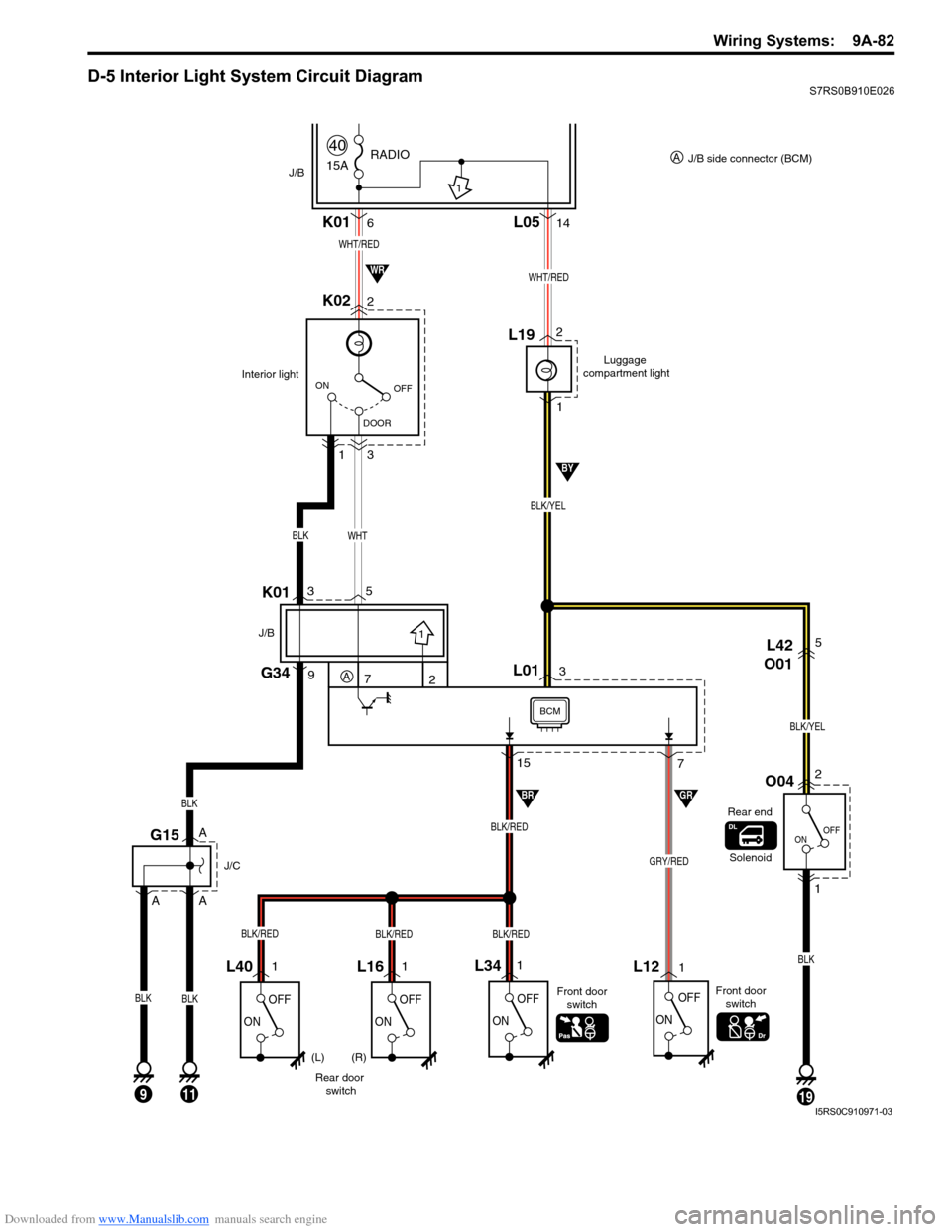

Page 1253 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-82

D-5 Interior Light System Circuit DiagramS7RS0B910E026

15A

40RADIO

J/B

OFF

DOOR

ON

K02 K012 6

3

1

Interior light

15

7

OFF

ON

OFF

ON

L121

1

GRY/RED

BLK

OFF

ONOFF

ON

L16 L341L401

Rear door

switch Front door

switch

BLK/RED

BLK

BLK

BLK

L0514

WHT/RED

G15

J/C

A

A

5

7G34

K01

J/B

L01

Luggage

compartment light

2

1

3L19

WHT/RED

BLK/YEL

WHT

1119

OFF

ON

O042

L42

O015

1

BLK/YEL

3

Solenoid

2

1

1

J/B side connector (BCM)

A

(L) (R) Front door

switch

A

BLK/REDBLK/REDBLK/RED

Rear end

9

BRGR

9

BLK

A

BY

WR

BCM

I5RS0C910971-03

Page 1469 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-7

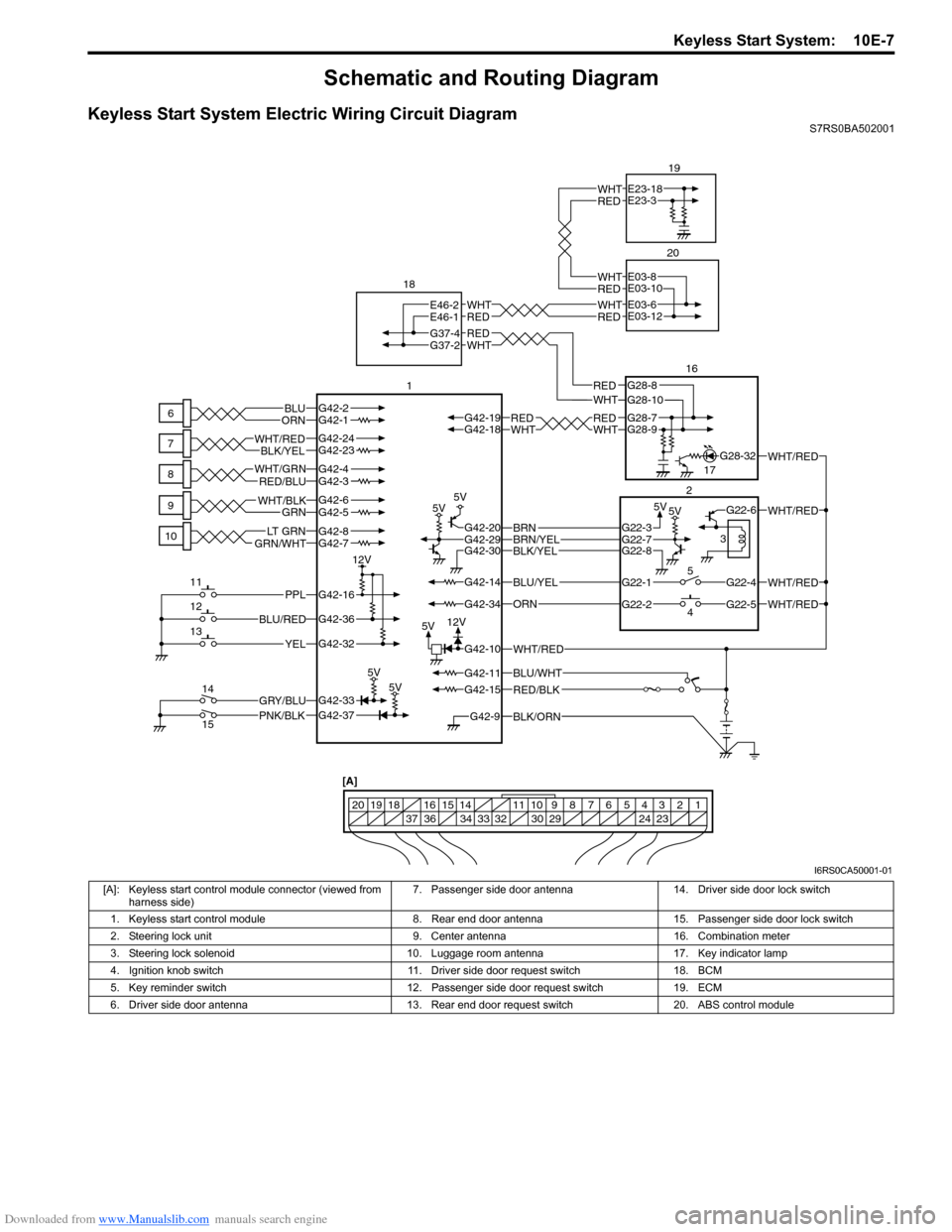

Schematic and Routing Diagram

Keyless Start System Electric Wiring Circuit DiagramS7RS0BA502001

BLK/ORNG42-9

G42-15

G42-14

G42-37G42-33

G42-16

G42-20G42-29G42-30

G42-36

G42-32G42-10

G42-34

G42-11BLU/WHT

WHT/RED

WHT/RED

WHT/RED

PNK/BLKGRY/BLU

BLU/RED

YEL

PPL

RED/BLK

5V5V

5V5V

5V5V

5V

12V

12V

G42-2G42-1BLUORNWHTREDWHTREDG42-18G42-19G28-9G28-7

BLU/YEL

ORN

G42-24G42-23BLK/YELWHT/RED

G42-7GRN/WHTLT G R NG42-8

G42-5G42-6GRNWHT/BLK

G42-4G42-3WHT/GRNRED/BLU

BLK/YELBRN/YELBRNG22-3

G22-1

G22-2G22-5

G22-4

G22-6

G22-7G22-8

WHT/RED

WHT/RED

G37-4

REDWHTREDWHT

G28-10G28-8WHTRED

RED

WHT

G37-2

E46-2

E46-1E03-6

E03-12

G28-32

6

7

8

9

10

11

12

13

14

15 1

18

20

1617

2

4 5 3

1234567891011

141516

36 34 33 32 30 29 24 23

37

181920

[A]

REDWHTE23-18

E23-3

19

REDWHTE03-8

E03-10

I6RS0CA50001-01

[A]: Keyless start control module connector (viewed from

harness side) 7. Passenger side door antenna 14. Driver side door lock switch

1. Keyless start control module 8. Rear end door antenna 15. Passenger side door lock switch

2. Steering lock unit 9. Center antenna 16. Combination meter

3. Steering lock solenoid 10. Luggage room antenna 17. Key indicator lamp

4. Ignition knob switch 11. Driver side door request switch 18. BCM

5. Key reminder switch 12. Passenger side door request switch 19. ECM

6. Driver side door antenna 13. Rear end door request switch 20. ABS control module