hvac control SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 4 of 1496

Downloaded from www.Manualslib.com manuals search engine 00

0

1

2

3

4

5

6

7

8

9

10

11

Vo l u m e 1

Precautions............................................................... 00-iPrecautions ............................................................ 00-1

General Information ................ ................................... 0-i

General Information ............................................... 0A-1

Maintenance and Lubricatio n ................................. 0B-1

Engine ......................................................................... 1-i Precautions .............................................................. 1-1

Engine General Information and Diagnosis ........... 1A-1

Aux. Emission Control Devices .............................. 1B-1

Engine Electrical Devices....................................... 1C-1

Engine Mechanical ................................................. 1D-1

Engine Lubrication System .................................... 1E-1

Engine Cooling System .......................................... 1F-1

Fuel System ...........................................................1G-1

Ignition System....................................................... 1H-1

Starting System ....................................................... 1I-1

Charging System.....................................................1J-1

Exhaust System ..................................................... 1K-1

Suspension ................................................................. 2-i Precautions .............................................................. 2-1

Suspension General Diagnosis .............................. 2A-1

Front Suspension ................................................... 2B-1

Rear Suspension................ .................................... 2C-1

Wheels and Tires ................................................... 2D-1

Driveline / Axle ........................................................... 3-i Precautions .............................................................. 3-1

Drive Shaft / Axle ................................................... 3A-1

Brakes ......................................................................... 4-i Precautions .............................................................. 4-1

Brake Control System and Diagnosis .................... 4A-1

Front Brakes........................................................... 4B-1

Rear Brakes ........................................................... 4C-1

Parking Brake......................................................... 4D-1

ABS ........................................................................ 4E-1

Electronic Stability Program ................................... 4F-1

Vo l u m e 2

Precautions ............................................................... 00-iPrecautions ............................................................ 00-1

Transmission / Transaxle .... ...................................... 5-i

Precautions .............................................................. 5-1

Automatic Transmission/Transaxle ........................ 5A-1

Manual Transmission/Transaxle ............................ 5B-1

Clutch .....................................................................5C-1

Steering ....................................................................... 6-i Precautions .............................................................. 6-1

Steering General Diagnosis ................................... 6A-1

Steering Wheel and Column .................................. 6B-1

Power Assisted Steering System ...........................6C-1

HVAC ........................................................................... 7-i Precautions .............................................................. 7-1

Heater and Ventilation............................................ 7A-1

Air Conditioning System ......................................... 7B-1

Restraint ...................................................................... 8-i Precautions .............................................................. 8-1

Seat Belts ............................................................... 8A-1

Air Bag System ...................................................... 8B-1

Body, Cab and Accessories .... .................................. 9-i

Precautions .............................................................. 9-1

Wiring Systems ...................................................... 9A-1

Lighting Systems .................................................... 9B-1

Instrumentation / Driver Info. / Horn .......................9C-1

Wipers / Washers ...................................................9D-1

Glass / Windows / Mirrors ...................................... 9E-1

Security and Locks ................................................. 9F-1

Seats ..................................................................... 9G-1

Interior Trim ............................................................9H-1

Hood / Fenders / Doors .......................................... 9J-1

Body Structure ....................................................... 9K-1

Paint / Coatings ...................................................... 9L-1

Exterior Trim .......................................................... 9M-1

Control Systems ....................................................... 10-i Precautions ............................................................ 10-1

Body Electrical Control Sy stem ............................ 10B-1

Immobilizer Control System .................................10C-1

Keyless Start System ........................................... 10E-1

TABLE OF CONTENTS

Page 10 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-5 Precautions:

• When performing service to electrical parts that does not require use of battery power, disconnect the

negative cable of the battery.

• When disconnecting the negative cable from the battery, be careful to the following.

– Check and record DTCs in ECM and HVAC control module if necessary before disconnecting.

– Record displayed contents of the clock and/or audio system, etc. before disconnecting and reset it

as before after connecting.

– For vehicle equipped with electric throttle body system, perform electric throttle body system

calibration referring to “Electric Throttle Body

System Calibration in Section 1C” after

reconnecting the negative cable to the battery.

– For vehicle equipped with ESP ®, calibrate steering

angle sensor referring to “Sensor Calibration in

Section 4F” after reconnecting the negative cable

to the battery.

• When removing the battery, be sure to disconnect the negative cable first and then the positive cable. When

reconnecting the battery, connect the positive cable

first and then the negative cable, and replace the

terminal cover. • When removing parts that are to be reused, be sure to

keep them arranged in an orderly manner so that they

may be reinstalled in the proper order and position.

• Whenever you use oil seals, gaskets, packing, O- rings, locking washers, split pins, self-locking nuts,

and certain other parts as specified, be sure to use

new ones. Also, before installing new gaskets,

packing, etc., be sure to remove any residual material

from the mating surfaces.

• Make sure that all parts used in reassembly are perfectly clean.

When use of a certain type of lubricant, bond or

sealant is specified, be sure to use the specified type.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

I2RH01010026-01

I2RH01010027-01

I2RH01010028-01

I2RH01010029-01

I2RH01010030-01

Page 21 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 0- i

0

Section 0

CONTENTS

General Information

General Information ................................ 0A-1

General Description ............................................. 0A-1

Abbreviations ...................................................... 0A-1

Symbols .............................................................. 0A-2

Wire Color Symbols ............................................ 0A-2

Fasteners Information ......................................... 0A-3

Vehicle Lifting Points ........................................... 0A-5

Engine Supporting Points ................................... 0A-7

Vehicle Identification Number ............................. 0A-7

Engine Identification Number .............................. 0A-7

Transmission Identification Number .................... 0A-7

Component Locatio n ........................................... 0A-8

Warning, Caution and Information Labels Location ............................................................ 0A-8

Maintenance and Lubricat ion ................. 0B-1

Precautions........................................................... 0B-1

Precautions for Maintenance and Lubrication ..... 0B-1

Scheduled Maintenance ...................................... 0B-1 Maintenance Schedule under Normal Driving Conditions ......................................................... 0B-1

Maintenance Recommended under Severe Driving Conditions ............................................. 0B-2

Repair Instructions .............................................. 0B-3 Accessory Drive Belt Inspection.......................... 0B-3

Accessory Drive Belt Repl acement ..................... 0B-4

Valve Lash (Clearance) Inspection ..................... 0B-4

Engine Oil and Filter Change .............................. 0B-4

Engine Coolant Change ...... ................................ 0B-5

Exhaust System Inspection ................................. 0B-6

Spark Plug Replacement .................................... 0B-6

Air Cleaner Filter Inspection ................................ 0B-6

Air Cleaner Filter Replac ement ........................... 0B-6 Fuel Lines and Connections Inspection .............. 0B-6

Fuel Filter Replacement ...................................... 0B-7

Fuel Tank Inspection ........................................... 0B-7

PCV Valve Inspection ......................................... 0B-7

Fuel Evaporative Emission Control System

Inspection .......................................................... 0B-7

Brake Discs and Pads Inspection ....................... 0B-7

Brake Hoses and Pipes Inspection ..................... 0B-7

Brake Fluid Inspection......................................... 0B-8

Brake Fluid Replacement .................................... 0B-8

Brake Lever and Cable Inspection ...................... 0B-8

Clutch Fluid Inspection ........................................ 0B-8

Tires Inspection ................................................... 0B-9

Wheel Discs Inspection ....................................... 0B-9

Wheel Bearing Inspection ................................... 0B-9

Suspension System Inspection ........................... 0B-9

Steering System Inspection .............................. 0B-10

Drive Shaft (Axle) Boots Inspection .................. 0B-10

Manual Transaxle Oil Inspection ....................... 0B-10

Manual Transaxle Oil Replacement .................. 0B-10

Automatic Transaxle Fluid Level Inspection...... 0B-11

Automatic Transaxle Fluid Replacement .......... 0B-11

Automatic Transaxle Fluid Cooler Hose Inspection ........................................................ 0B-11

All Latches, Hinges and Locks Inspection......... 0B-11

HVAC Air Filter (If Equipped) Inspection ........... 0B-12

HVAC Air Filter (If Equipped) Replacement ...... 0B-12

Final Inspection for Maint enance Service ......... 0B-12

Specifications .................... .................................0B-13

Tightening Torque Specifications ...................... 0B-13

Special Tools and Equipmen t ...........................0B-13

Recommended Fluids and Lubricants............... 0B-13

Special Tool ...................................................... 0B-14

Page 22 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-1 General Information:

General Information

General Information

General Description

AbbreviationsS7RS0B0101001

A:

ABDC: After Bottom Dead Center

ABS: Anti-lock Brake System

AC: Alternating Current

A/C: Air Conditioning

A-ELR: Automatic-Emergency Locking Retractor

A/F: Air Fuel Mixture Ratio

ALR: Automatic Locking Retractor

API: American Petroleum Institute

APP sensor: Accelerator Pedal Position Sensor

A/T: Automatic Transmission , Automatic Transaxle

AT D C : After Top Dead Center

ATF: Automatic Transmission Fluid, Automatic

Transaxle Fluid

B:

B+: Battery Positive Voltage

BBDC: Before Bottom Dead Center

BCM: Body Electrical Control Module

BDC: Bottom Dead Center

BTDC: Before Top Dead Center

C:

CAN: Controller Area Network

CKT: Circuit

CKP Sensor: Crankshaft Position Sensor

CMP Sensor: Camshaft Position Sensor

CO: Carbon Monoxide

CPP Switch: Clutch Pedal Position Switch (Clutch

Switch, Clutch Start Switch)

CPU: Central Processing Unit

CRS: Child Restraint System

D:

DC: Direct Current

DLC: Data Link Connector (Assembly Line Diag. Link,

ALDL, Serial Data Link, SDL)

DOHC: Double Over Head Camshaft

DOJ: Double Offset Joint

DRL: Daytime Running Light

DTC: Diagnostic Trouble Code (Diagnostic Code)

E:

EBCM: Electronic Brake Cont rol Module, ABS Control

Module

EBD: Electronic Brake Force Distribution

ECM: Engine Control Module

ECT Sensor: Engine Coolant Temperature Sensor (Water Temp. Sensor, WTS)

EFE Heater: Early Fuel Evaporation Heater (Positive

Temperature Coefficient, PTC Heater)

EGR: Exhaust Gas Recirculation

EGRT Sensor: EGR Temperature Sensor (Recirculated

Exhaust Gas Temp. Sensor, REGTS)

ELR: Emergency Locking Retractor

ESP ®: Electronic Stability Program

EPS: Electronic Power Steering

EVAP: Evaporative Emission EVAP Canister:

Evaporative Emission Canister

(Charcoal Canister)

F:

4WD: 4 Wheel

Drive

G:

GEN: Generator

GND: Ground

GPS: Global Positioning System

H:

HVAC: Heating, Ventilating and Air Conditioning

HC: Hydrocarbons

HO2S: Heated Oxygen Sensor

I:

IAC Valve: Idle Air Control Valve (Idle Speed Control

Solenoid Valve, ISC Solenoid Valve)

IAT Sensor: Intake Air Temperature Sensor (Air

temperature Sensor, ATS)

ICM: Immobilizer Control Module

IG: Ignition

ISC Actuator: Idle Speed Control Actuator

L:

LH: Left Hand

LHD: Left Hand Drive Vehicle

LSPV: Load Sensing Proportioning Valve

M:

MAF Sensor: Mass Air Flow Sensor (Air Flow Sensor, AFS, Air Flow Meter, AFM)

MAP Sensor: Manifold Absolute Pressure Sensor

(Pressure Sensor, PS)

Max: Maximum

MFI: Multiport Fuel Injection (Mu ltipoint Fuel Injection)

Min: Minimum

MIL: Malfunction Indicator Lamp (“SERVICE ENGINE

SOON” Light)

M/T: Manual Transmission, Manual Transaxle

N:

NOx: Nitrogen Oxides

O:

OBD: On-Board Diagnostic System (Self-Diagnosis

Function)

O/D: Overdrive

OHC: Over Head Camshaft

O2S: Oxygen Sensor

P:

PCM: Powertrain Control Module

PCV: Positive Crankcase Ventilation

PNP: Park / Neutral Position

P/S: Power Steering

PSP Switch: Power Steering Pressure Switch (P/S

Pressure Switch)

R:

RH: Right Hand

RHD: Right Hand Drive Vehicle

S:

SAE: Society of Automotive Engineers

Page 56 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-6 Engine General Information and Diagnosis:

For information about the following items, refer to “Euro

OBD Model: ”.

• Warm-up cycle

• Driving cycle

• 2 driving cycle detection logic

• Pending DTC

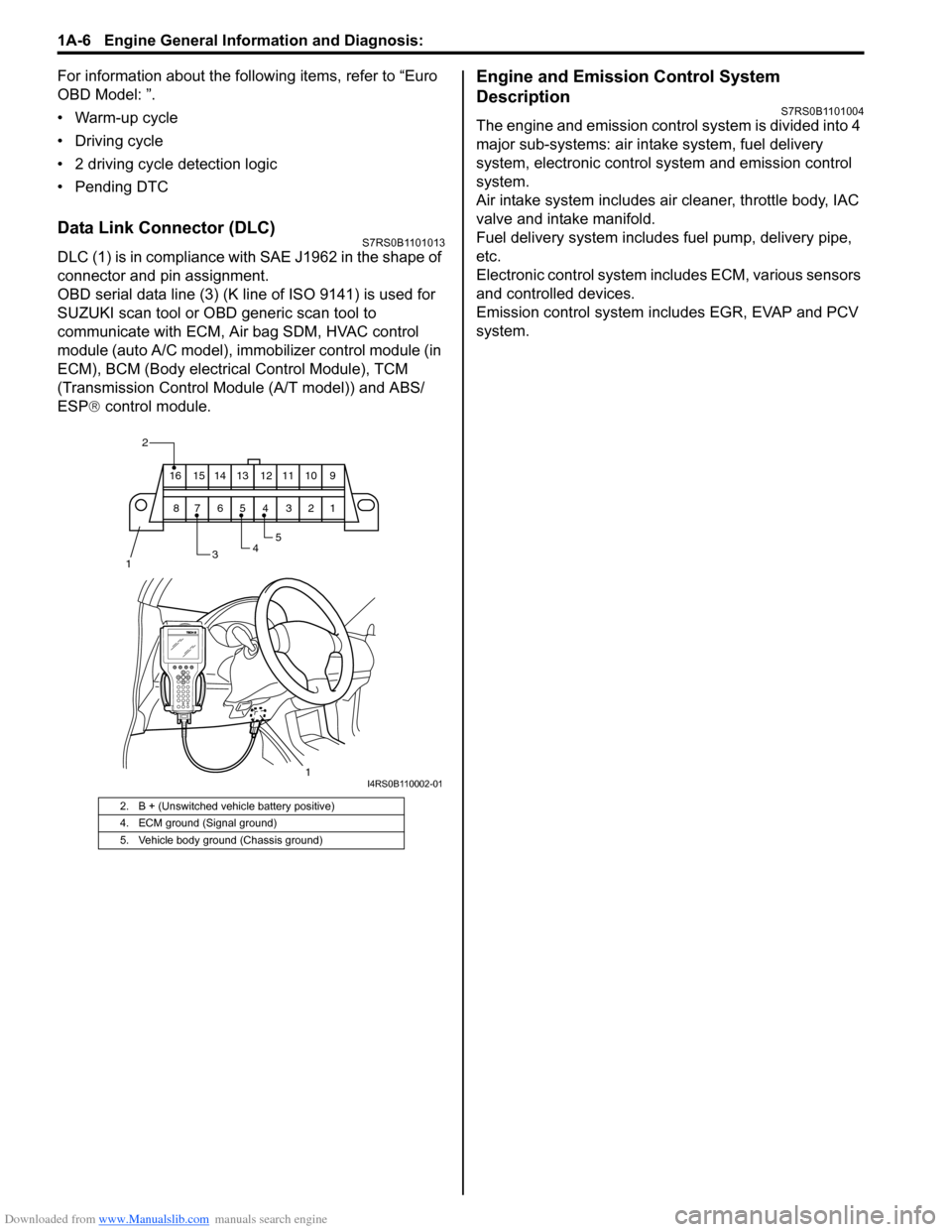

Data Link Connector (DLC)S7RS0B1101013

DLC (1) is in compliance with SAE J1962 in the shape of

connector and pin assignment.

OBD serial data line (3) (K line of ISO 9141) is used for

SUZUKI scan tool or OBD generic scan tool to

communicate with ECM, Air bag SDM, HVAC control

module (auto A/C model), immobilizer control module (in

ECM), BCM (Body electrical Control Module), TCM

(Transmission Cont rol Module (A/T model)) and ABS/

ESP ® control module.

Engine and Emission Control System

Description

S7RS0B1101004

The engine and emission control system is divided into 4

major sub-systems: air in take system, fuel delivery

system, electronic control sy stem and emission control

system.

Air intake system includes air cleaner, throttle body, IAC

valve and intake manifold.

Fuel delivery system includes fuel pump, delivery pipe,

etc.

Electronic control system incl udes ECM, various sensors

and controlled devices.

Emission control system includes EGR, EVAP and PCV

system.

2. B + (Unswitched vehicle battery positive)

4. ECM ground (Signal ground)

5. Vehicle body ground (Chassis ground)

2

345

1

910111213141516

12345678

1I4RS0B110002-01

Page 65 of 1496

![SUZUKI SWIFT 2006 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS / SUZUKI SWIFT 2006 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS /](/img/20/7607/w960_7607-64.png)

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS / ESP® control module 49. Radiator cooling fan motor

[B]: Auto A/C model 25. TCM 50. “RDTR FAN” fuse

1. ECM 26. To other control module connected CAN 51. A/C compressor relay

2. APP sensor assembly 27. Generator 52. Magnet clutch of compressor (A/C model)

3. Shield wire 28. Electric load current sensor (if equipped) 53. “A/C CPRSR” fuse

4. CMP sensor 29. Brake light 54. Ignition coil assembly (for No.1 and No.4 spark

plugs)

5. CKP sensor 30. Brake light switch 55. Ignition coil assembly (for No.2 and No.3 spark

plugs)

6. MAF and IAT sensor 31. Diagnosis connector (Hong Kong model) 56. P/S control module

7. MAP sensor 32. Throttle actuator control relay 57. “RADIO” fuse

8. ECT sensor 33. “THR MOT” fuse 58. Main relay

9. A/C refrigerant pressure sensor 34. Throttle throttle body assembly 59. “IG COIL” fuse

10. A/C evaporator outlet air temp. sensor (Manual A/C model) 35. Throttle actuator

60. Ignition switch

11. HO2S-1 36. TP sensor 61. “IG ACC” fuse

12. HO2S-2 37. Injector No.1 62. “FI” fuse

13. Knock sensor 38. Injector No.2 63. Starting motor control relay

14. Blower motor relay 39. Injector No.3 64. “ST SIG” fuse

15. Blower motor 40. Injector No.4 65. “ST MOT” fuse

16. Blower motor resistor 41. EVAP canister purge valve66. Transmission range switch (A/T model) or CPP

switch (Hong Kong model with M/T)

17. Blower speed selector 42. EGR valve 67. Starting motor

18. A/C switch 43. Oil control valve (Camshaft position

control) (VVT model) 68. Immobilizer coil antenna

19. Blower motor controller 44. Fuel pump relay 69. Main fuse box

20. HVAC control module 45. Fuel pump 70. Battery

21. Data link connector (DLC) 46. Radiator cooling fan motor relay No.1 71. Barometric pressure sensor

22. To other control module connected with DLC 47. Radiator cooling fan motor relay No.2

72. Engine ground

23. BCM 48. Radiator cooling fan motor relay No.3 73. Body ground

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A110008-01

Page 86 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-36 Engine General Information and Diagnosis:

O2S B1 S1 ACT (HEATED OXYGEN SENSOR-1,

ACTIVE / INACTIVE)

This parameter indicates activation condition of HO2S-1.

ACTIVE: Activating

INACTIVE: warming up or at stop

O2S SENSOR B1 S2 (HEATED OXYGEN SENSOR-2,

V)

It indicates output voltage of HO2S-2 installed on

exhaust pipe (post-catalyst). It is used to detect catalyst

deterioration.

O2S B1 S2 ACT (HEATED OXYGEN SENSOR-2,

ACTIVE / INACTIVE)

This parameter indicates acti vation condition of HO2S-2.

ACTIVE: Activating

INACTIVE: warming up or at stop

FUEL SYSTEM (FUEL SYSTEM STATUS)

Air/fuel ratio feedback loop status displayed as one of

the followings.

OPEN: Open-loop has not yet satisfied conditions to go

closed loop.

CLOSED: Closed-loop using oxygen sensor(s) as

feedback for fuel control.

OPEN-DRIVE COND: Open-loop due to driving

conditions (Power enrichment, etc.).

OPEN SYS FAULT: Open-loop due to detected system

fault.

MAP (MANIFOLD ABSOLUTE PRESSURE, in.Hg,

kPa)

This value indicates how much correction is necessary

to keep the air/fuel mixture stoichiometrical.

It is detected by manifold absolute pressure sensor.

BAROMETRIC PRESS (kPa, in.Hg)

This parameter represents a measurement of barometric

air pressure and is used for al titude correction of the fuel

injection quantity and IAC valve control.

STEP EGR FLOW DUTY (%)

This parameter indicates opening rate of EGR valve

which controls the amount of EGR flow.

FUEL CUT (ON/OFF)

ON: Fuel being cut (output signal to injector is stopped)

OFF: Fuel not being cut

A/C PRESSURE (A/C REFRIGERANT ABSOLUTE

PRESSURE, kPa)

This parameter indicates A/C refrigerant absolute

pressure calculated by ECM.

CLOSED THROTTLE PO S (CLOSED THROTTLE

POSITION, ON/OFF)

This parameter reads ON wh en throttle valve is fully

closed, or OFF when it is not fully closed. CANIST PRG DUTY (EVAP CANISTER PURGE FLOW

DUTY, %)

This parameter indicates valve ON (valve open) time

rate within a certain set cycle of EVAP canister purge

valve which controls the amount of EVAP purge.

IGNITION ADVANCE (IGNITION TIMING ADVANCE

FOR NO.1 CYLINDER,

°)

Ignition timing of No.1 cylinder is commanded by ECM.

The actual ignition timing should be checked by using

the timing light.

BATTERY VOLTAGE (V)

This parameter indicates battery positive voltage

inputted from main relay to ECM.

FUEL PUMP (ON/OFF)

ON is displayed when ECM activates the fuel pump via

the fuel pump relay switch.

ELECTRIC LOAD (ON/OFF)

ON: Headlight or small light ON signal inputted.

OFF: Above electric loads all turned OFF.

BRAKE SW (ON/OFF)

This parameter indicates the state of the brake switch.

RADIATOR COOLING FAN (RADIATOR COOLING

FAN CONTROL RELAY, ON/OFF)

ON: Command for radiator cooling fan control relay

operation being output.

OFF: Command for relay operation not being output.

BLOWER FAN (ON/OFF)

This parameter indicates the state of the blower fan

motor switch.

A/C SWITCH (ON/OFF)

ON: Command for A/C operatio n being output from ECM

to HVAC.

OFF: Command for A/C oper ation not being output.

A/C COMP RELAY (A/C COMPRESSOR RELAY, ON/

OFF)

This parameter indicates the state of the A/C switch.

VEHICLE SPEED (km/h, mph)

It is computed based on pulse signals from vehicle

speed sensor.

VVT GAP (TARGET-ACTUAL POSITION, °)

It is calculated using the formula: target valve timing

advance – actual valve timing advance.

TP SENSOR 1 VOLT (THROTTLE POSITION SENSOR

(MAIN) OUTPUT VOLTAGE, V)

The TP sensor (main) reading provides throttle valve

opening information in the form of voltage.

Page 255 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-205

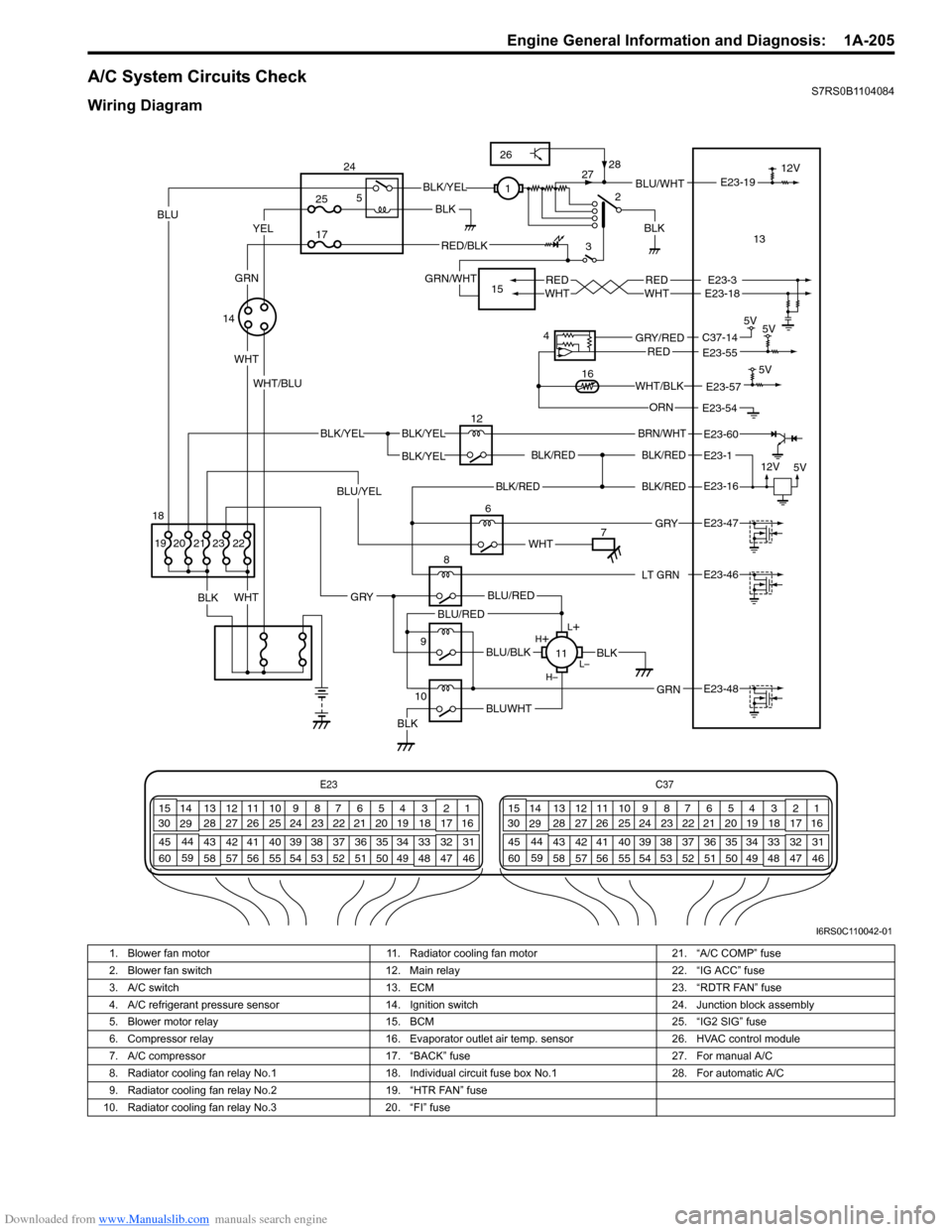

A/C System Circuits CheckS7RS0B1104084

Wiring Diagram

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V

5V

12

E23-1

E23-60

BLK/RED

LT GRN

BLK/REDE23-16

E23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLUWHTBLK

BLU/BLK

BLU/RED

GRN

GRY

E23-48

8

11

2

3BLU/WHT

REDWHTREDWHTE23-3E23-18

E23-19

6

BLK

WHT

BLK 12V

E23-47 GRY

WHT

YELBLU

WHT

BLK/YEL

RED/BLK

GRN/WHT

WHT/BLU1

713

14

5V

5V

4

E23-55C37-14GRY/REDRED

E23-54ORN 5V

E23-57WHT/BLK16

9

10

25

17

5

24

15

22

BLU/YEL

23212019

GRN

BLK

18

26

28

27

I6RS0C110042-01

1. Blower fan motor 11. Radiator cooling fan motor 21. “A/C COMP” fuse

2. Blower fan switch 12. Main relay 22. “IG ACC” fuse

3. A/C switch 13. ECM 23. “RDTR FAN” fuse

4. A/C refrigerant pressure sensor 14. Ignition switch 24. Junction block assembly

5. Blower motor relay 15. BCM 25. “IG2 SIG” fuse

6. Compressor relay 16. Evaporator outlet air temp. sensor 26. HVAC control module

7. A/C compressor 17. “BACK” fuse 27. For manual A/C

8. Radiator cooling fan relay No.1 18. Individual circuit fuse box No.1 28. For automatic A/C

9. Radiator cooling fan relay No.2 19. “HTR FAN” fuse

10. Radiator cooling fan relay No.3 20. “FI” fuse

Page 259 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-209

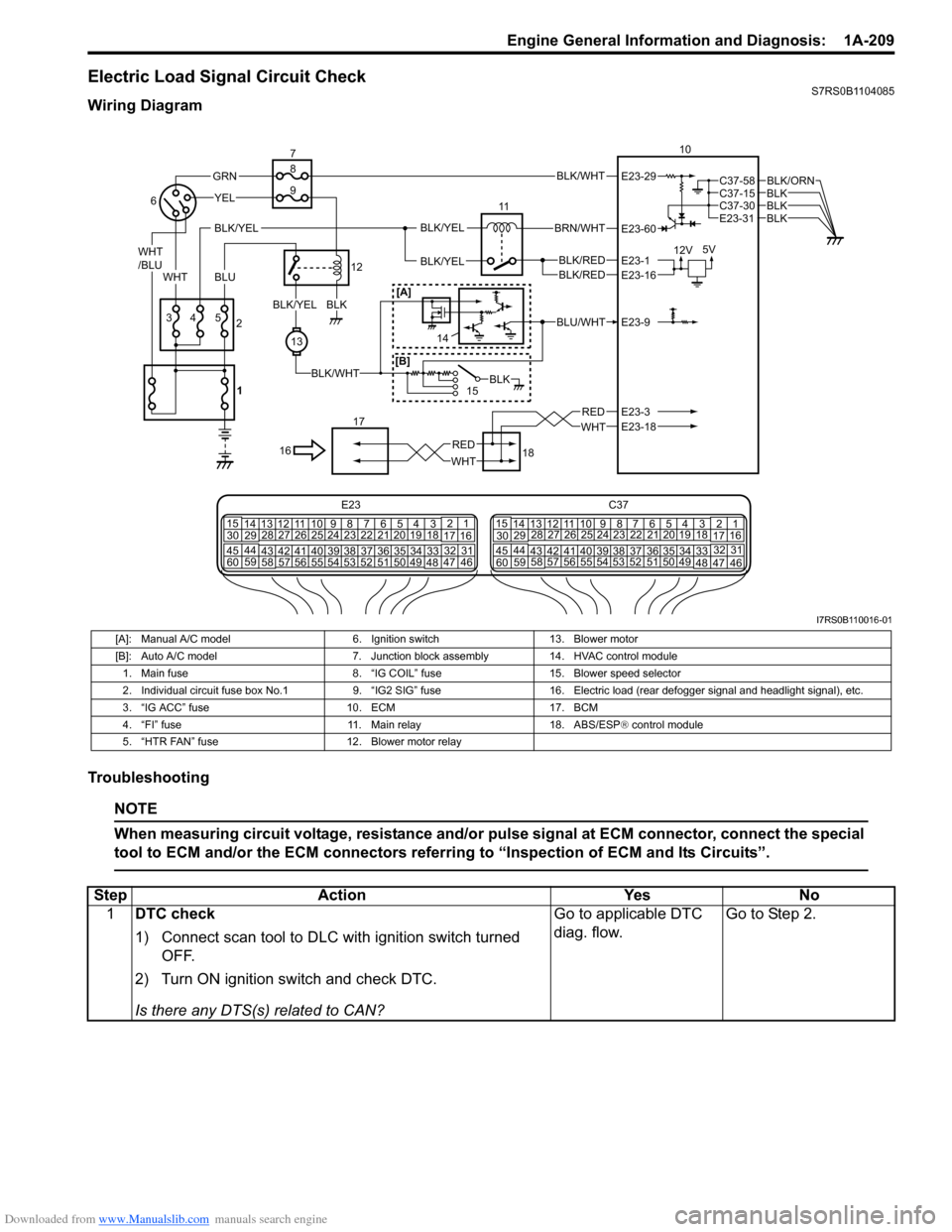

Electric Load Signal Circuit CheckS7RS0B1104085

Wiring Diagram

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

BLK/WHT

BLK/RED

WHT

BRN/WHT

12V5V

11

BLK/YELBLK/YEL

BLK/YEL

BLKBLKBLK

BLK/ORN

10

18

17

BLU/WHT

15

WHTRED

43

YEL

5

13

BLK/WHT

BLKBLK/YEL

GRN

WHT

/BLU

BLU

16

2

6

7

12

8

9

BLK

WHT

RED

E23-29

E23-60

E23-1E23-16

E23-9

E23-3E23-18

C37-58C37-15

E23-31C37-30

BLK/RED

[A]

[B]

E23 C37

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

12

13

238

1

14

I7RS0B110016-01

[A]: Manual A/C model

6. Ignition switch13. Blower motor

[B]: Auto A/C model 7. Junction block assembly14. HVAC control module

1. Main fuse 8. “IG COIL” fuse15. Blower speed selector

2. Individual circuit fuse box No.1 9. “IG2 SIG” fuse16. Electric load (rear defogger signal and headlight signal), etc.

3. “IG ACC” fuse 10. ECM17. BCM

4. “FI” fuse 11. Main relay18. ABS/ESP® control module

5. “HTR FAN” fuse 12. Blower motor relay

StepAction YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there any DTS(s) related to CAN? Go to applicable DTC

diag. flow.

Go to Step 2.

Page 933 of 1496

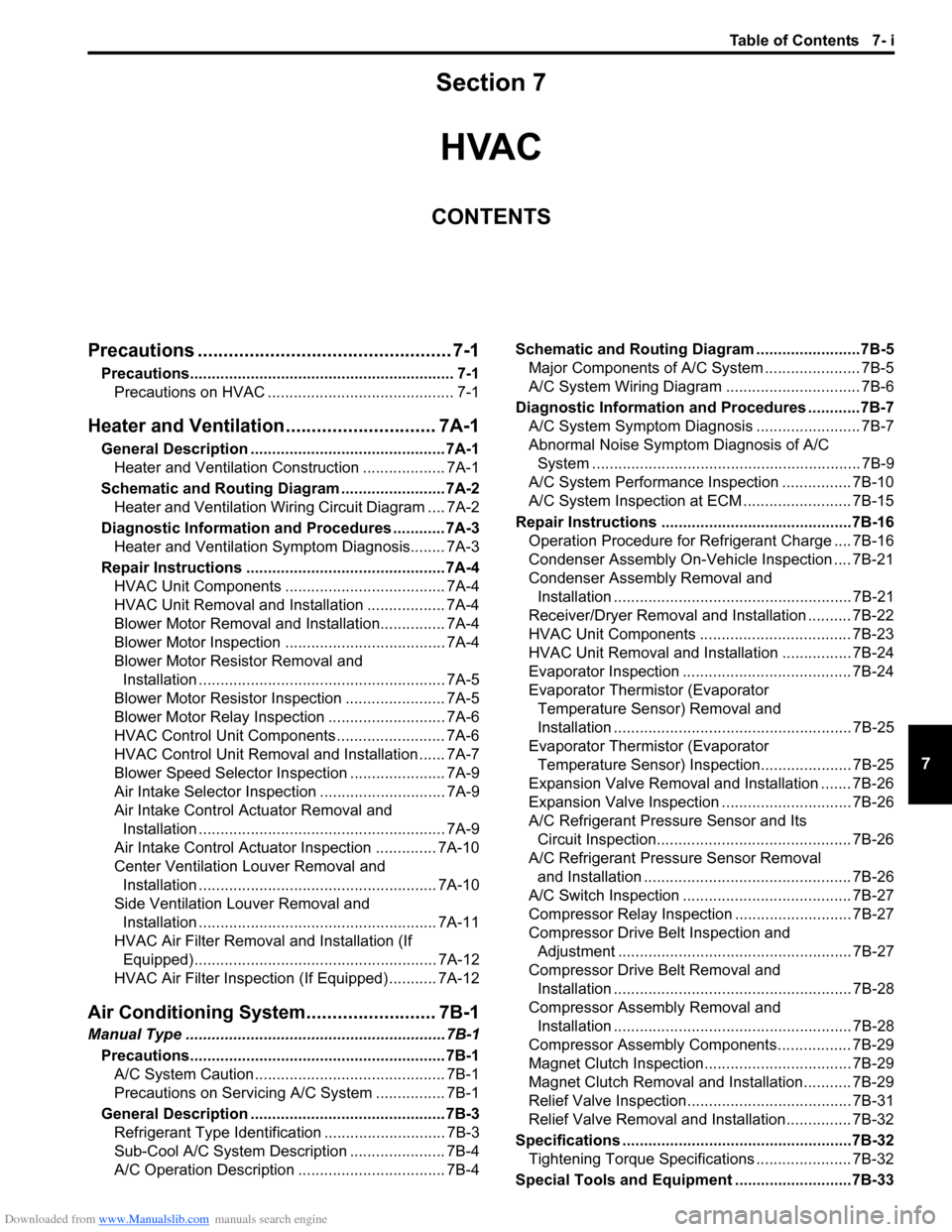

Downloaded from www.Manualslib.com manuals search engine Table of Contents 7- i

7

Section 7

CONTENTS

HVAC

Precautions ................................................. 7-1

Precautions............................................................. 7-1

Precautions on HVAC ........................................... 7-1

Heater and Ventilation.... ......................... 7A-1

General Description ............................................. 7A-1

Heater and Ventilation Construction ................... 7A-1

Schematic and Routing Diagram ........................ 7A-2 Heater and Ventilation Wiring Circuit Diagram .... 7A-2

Diagnostic Information and Procedures ............ 7A-3 Heater and Ventilation Symptom Diagnosis........ 7A-3

Repair Instructions .............................................. 7A-4 HVAC Unit Components ..................................... 7A-4

HVAC Unit Removal and Installation .................. 7A-4

Blower Motor Removal and Installation............... 7A-4

Blower Motor Inspection ..................................... 7A-4

Blower Motor Resistor Removal and Installation ......................................................... 7A-5

Blower Motor Resistor Inspection ....................... 7A-5

Blower Motor Relay Inspection ........................... 7A-6

HVAC Control Unit Components ......................... 7A-6

HVAC Control Unit Remova l and Installation ...... 7A-7

Blower Speed Selector In spection ...................... 7A-9

Air Intake Selector Inspec tion ............................. 7A-9

Air Intake Control Actuator Removal and Installation ......................................................... 7A-9

Air Intake Control Actuator Inspection .............. 7A-10

Center Ventilation Louver Removal and Installation ....................................................... 7A-10

Side Ventilation Louver Removal and Installation ....................................................... 7A-11

HVAC Air Filter Removal and Installation (If Equipped)........................................................ 7A-12

HVAC Air Filter Inspection (If Equipped) ........... 7A-12

Air Conditioning System... ...................... 7B-1

Manual Type ............................................................ 7B-1

Precautions........................................................... 7B-1A/C System Caution ............................................ 7B-1

Precautions on Servicing A/C System ................ 7B-1

General Description ............................................. 7B-3 Refrigerant Type Identifica tion ............................ 7B-3

Sub-Cool A/C System Description ...................... 7B-4

A/C Operation Description .................................. 7B-4 Schematic and Routing Diagram ........................7B-5

Major Components of A/C System ...................... 7B-5

A/C System Wiring Diagram ............................... 7B-6

Diagnostic Information and Procedures ............7B-7 A/C System Symptom Diagnosis ........................ 7B-7

Abnormal Noise Sympto m Diagnosis of A/C

System .............................................................. 7B-9

A/C System Performance Inspection ................ 7B-10

A/C System Inspection at ECM ......................... 7B-15

Repair Instructions ........... .................................7B-16

Operation Procedure for Re frigerant Charge .... 7B-16

Condenser Assembly On-Vehicle Inspection .... 7B-21

Condenser Assembly Removal and Installation ....................................................... 7B-21

Receiver/Dryer Removal and Installation .......... 7B-22

HVAC Unit Components ................................... 7B-23

HVAC Unit Removal and In stallation ................ 7B-24

Evaporator Inspection ....................................... 7B-24

Evaporator Thermistor (Evaporator Temperature Sensor) Removal and

Installation ....................................................... 7B-25

Evaporator Thermistor (Evaporator Temperature Sensor) Inspec tion..................... 7B-25

Expansion Valve Removal and Installation ....... 7B-26

Expansion Valve Inspection .............................. 7B-26

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-26

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-26

A/C Switch Inspection ....................................... 7B-27

Compressor Relay Inspection ........................... 7B-27

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-27

Compressor Drive Belt Removal and Installation ....................................................... 7B-28

Compressor Assembly Removal and Installation ....................................................... 7B-28

Compressor Assembly Components................. 7B-29

Magnet Clutch Inspection.................................. 7B-29

Magnet Clutch Removal and Installation........... 7B-29

Relief Valve Inspection...................................... 7B-31

Relief Valve Removal and Installation............... 7B-32

Specifications .................... .................................7B-32

Tightening Torque Specifications ...................... 7B-32

Special Tools and Equipmen t ...........................7B-33