Control SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 172 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-122 Engine General Information and Diagnosis:

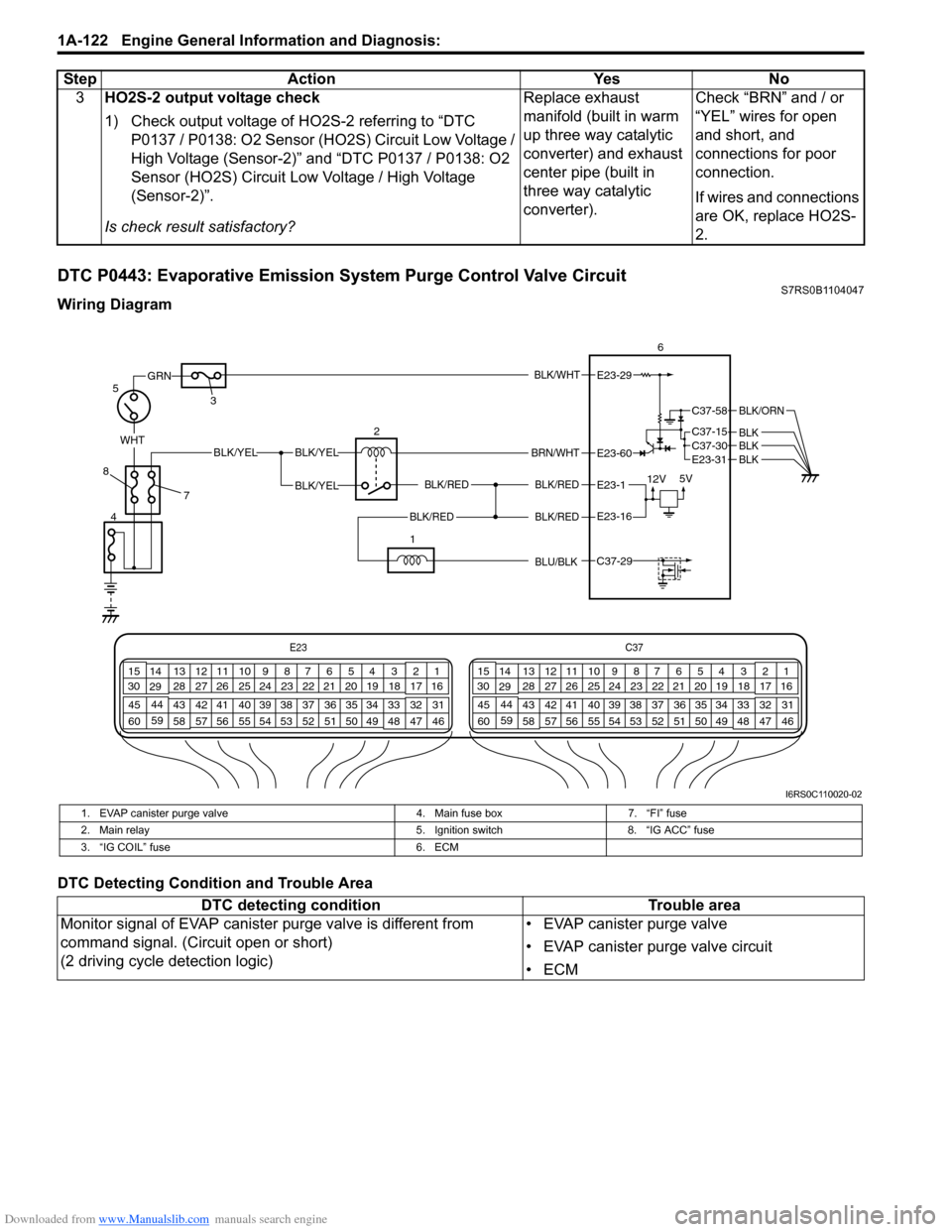

DTC P0443: Evaporative Emission System Purge Control Valve CircuitS7RS0B1104047

Wiring Diagram

DTC Detecting Condition and Trouble Area3

HO2S-2 output voltage check

1) Check output voltage of HO2S-2 referring to “DTC

P0137 / P0138: O2 Sensor (HO2S) Circuit Low Voltage /

High Voltage (Sensor-2)” and “DTC P0137 / P0138: O2

Sensor (HO2S) Circuit Low Voltage / High Voltage

(Sensor-2)”.

Is check result satisfactory? Replace exhaust

manifold (built in warm

up three way catalytic

converter) and exhaust

center pipe (built in

three way catalytic

converter).

Check “BRN” and / or

“YEL” wires for open

and short, and

connections for poor

connection.

If wires and connections

are OK, replace HO2S-

2.

Step Action Yes No

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 33 1

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 48 32 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/WHT

BLK/RED

BLK/RED

WHTBLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V 5V

5

4 2

3 6E23-29

E23-1

E23-60

C37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

7

8

BLK/REDBLK/REDE23-16

1

C37-29 BLU/BLK

I6RS0C110020-02

1. EVAP canister purge valve

4. Main fuse box7. “FI” fuse

2. Main relay 5. Ignition switch8. “IG ACC” fuse

3. “IG COIL” fuse 6. ECM

DTC detecting conditionTrouble area

Monitor signal of EVAP canister purge valve is different from

command signal. (Circuit open or short)

(2 driving cycle detection logic) • EVAP canister purge valve

• EVAP canister purge valve circuit

•ECM

Page 173 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-123

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

1) With ignition switch OFF, connect scan tool to DLC.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up normal operating temperature.

4) Drive vehicle at more than 40 km/h, 25 mph for 5 min. or more.

5) Check DTC and pending DTC.

DTC Troubleshooting

WARNING!

In order to reduce risk of fire and personal injury, this work must be performed in a well ventilated area

and away from any open flames such as gas water heater.

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 EVAP canister purge power supply circuit check

1) Turn OFF ignition switch and disconnect connector from

EVAP canister purge valve.

2) Measure voltage between engine ground and “BLK/ RED” wire terminal of EVAP canister purge valve

connector with ignition switch turned ON.

Is it voltage 10 – 14 V? Go to Step 3.

“BLK/RED” wire is open

circuit.

3 Wire circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “C37-29” terminal of ECM connector and vehicle body ground.

Is resistance infinity? Go to Step 4.

“BLU/BLK” wire is

shorted to ground

circuit.

4 Wire circuit check

1) Measure voltage between “C37-29” terminal of ECM

connector and vehicle body ground with ignition switch

turned ON.

Is voltage 0 V? Go to Step 5.

“BLU/BLK” wire is

shorted to other circuit.

Page 174 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-124 Engine General Information and Diagnosis:

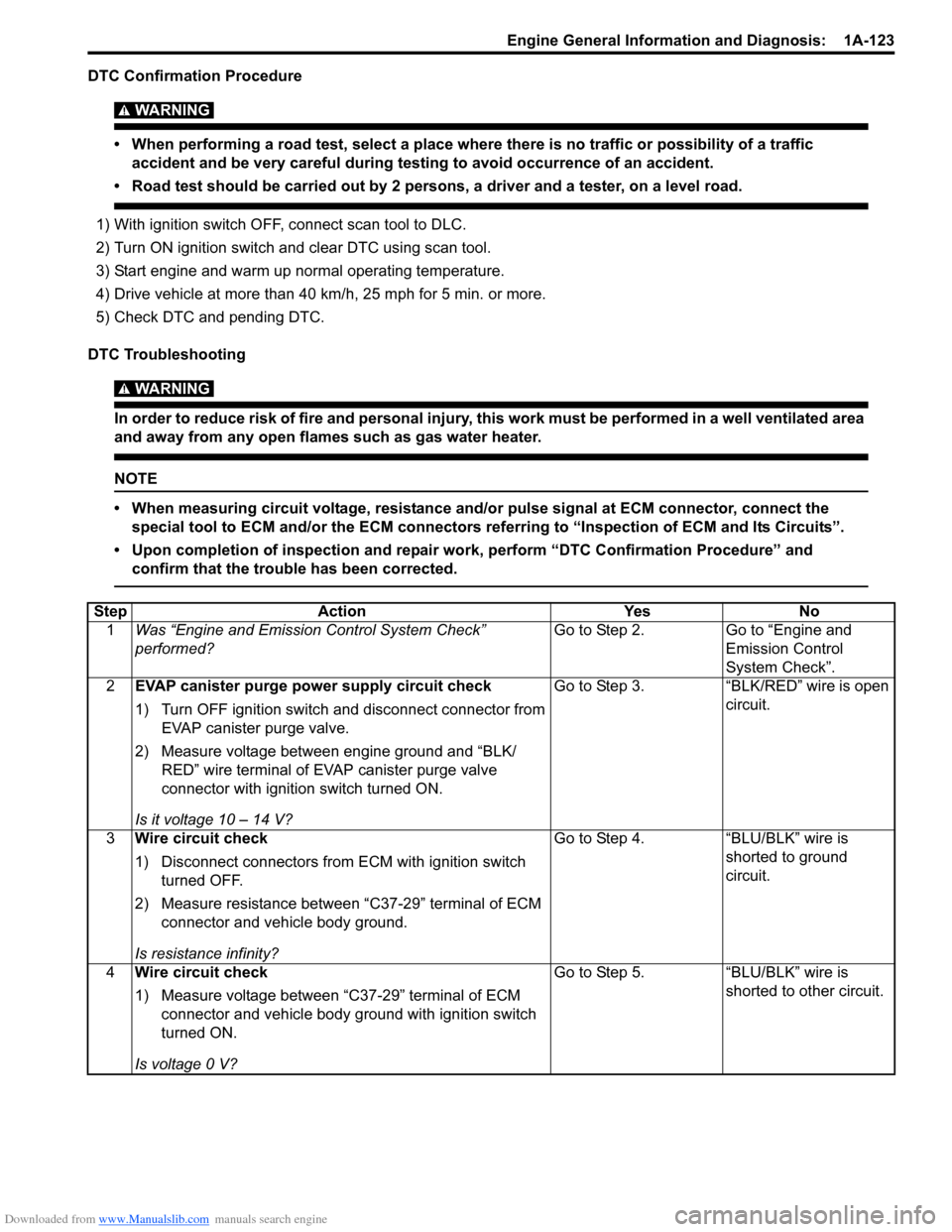

DTC P0480: Fan 1 (Radiator Cooling Fan) Control CircuitS7RS0B1104050

Wiring Diagram5

Wire circuit check

1) Connect connector to purge control valve with ignition

switch turned OFF.

2) Turn ON ignition switch and measure voltage between “C37-29” terminal of ECM connector and vehicle body

ground.

Is it voltage 10 – 14 V? Go to Step 6. “BLU/BLK” wire is open

circuit.

6 EVAP canister purge control valve check

1) Check EVAP canister purge control valve referring to

“EVAP Canister Purge Valve Inspection in Section 1B”.

Is it in good condition? Go to Step 7. Faulty EVAP canister

purge control valve.

7 EVAP canister purge control circuit check

1) With ignition switch turn OFF, measure resistance

between “E23-1/16” terminal and “C37-29” terminal of

ECM connector.

Is resistance below 40

Ω at 20 °C, 68 °F? Faulty ECM. Substitute

a known-good ECM and

recheck.

“BLK/RED” and/or

“BLU/BLK” wire are high

resistance circuit.

Step Action Yes No

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V

5V5V

2

8

E23-1

E23-60

C37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31BLK

BLK/RED

LT GRN

BLK/REDE23-16

E23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLUWHTBLK

BLU/BLK

BLU/RED

4

GRN

GRY

E23-48

LT GRN

ORN

C37-24

C37-55

35

6

7

10

9

1

I6RS0C110022-02

1. Individual circuit fuse box No.1

5. Radiator cooling fan relay No. 3 9. “FI” fuse

2. Main relay 6. Radiator cooling fan motor10. “RDTR FAN” fuse

3. Radiator cooling fan relay No. 1 7. ECT sensor

4. Radiator cooling fan relay No. 2 8. ECM

Page 175 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-125

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Turn OFF ignition switch.

2) Clear DTC with ignition switch turned ON.

3) Run engine at idle speed.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Monitor signal of radiator cooling fan relay is different from

command signal.

(1 driving cycle detection logic) • Radiator cooling fan relay circuit malfunction

• Radiator cooling fa

n relay malfunction

• ECM malfunction

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

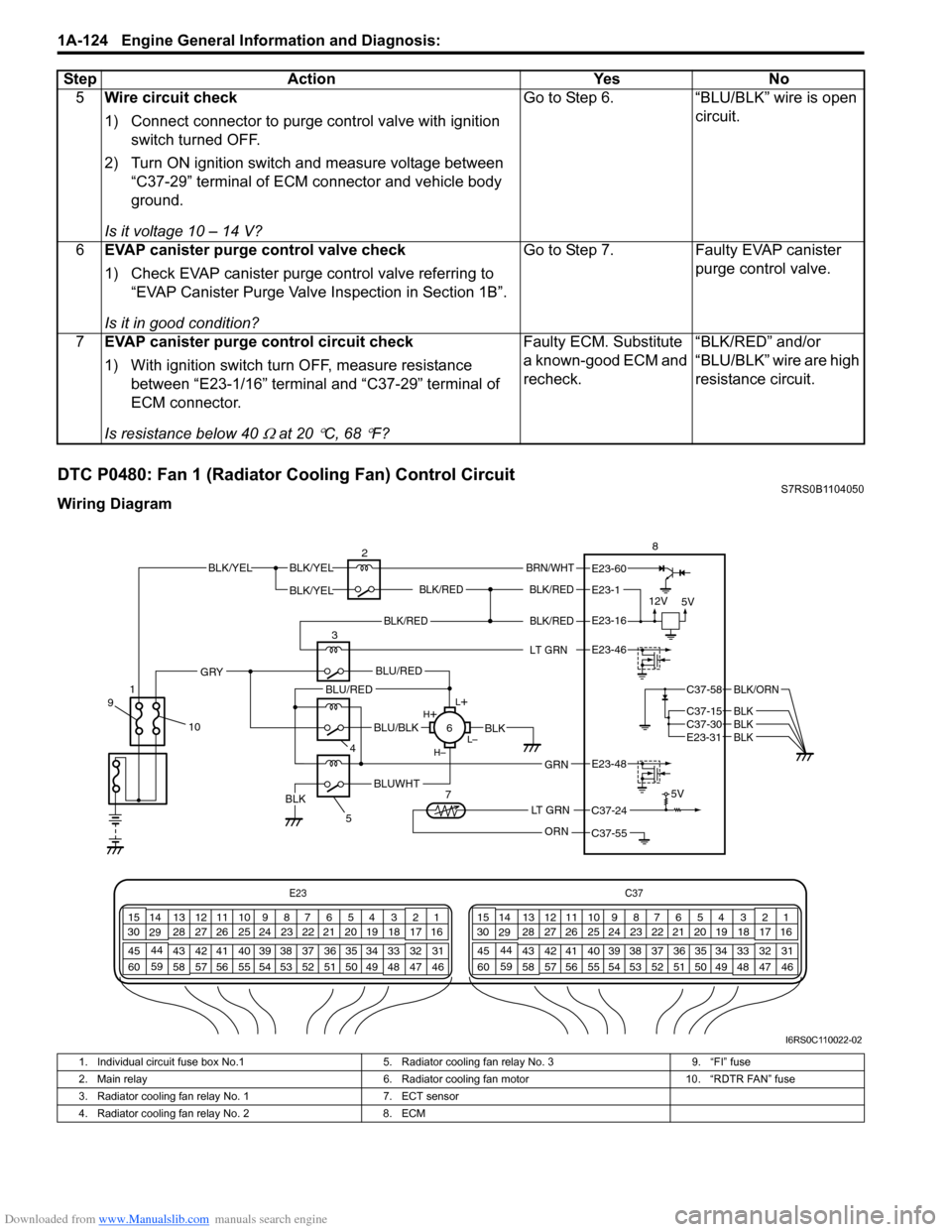

2 Circuit fuse check

1) Check “RDTR FAN” fuse (1) in individual circuit fuse box

No.1 with ignition switch turned OFF.

Is “RDTR FAN” fuse in good condition? Go to Step 3.

Check for short in

circuits connected to

this fuse.

1

I4RS0A110022-01

Page 177 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-127

8Radiator cooling fan control No. 1 check

1) Run engine until ECT is over 97.5 °C, 207.5 °F.

2) Measure voltage between vehicle body ground and “E23-46” terminal of ECM connector.

Is voltage lower than 1.5 V? Go to Step 9. Faulty ECM.

Substitute a known-

good ECM and recheck.

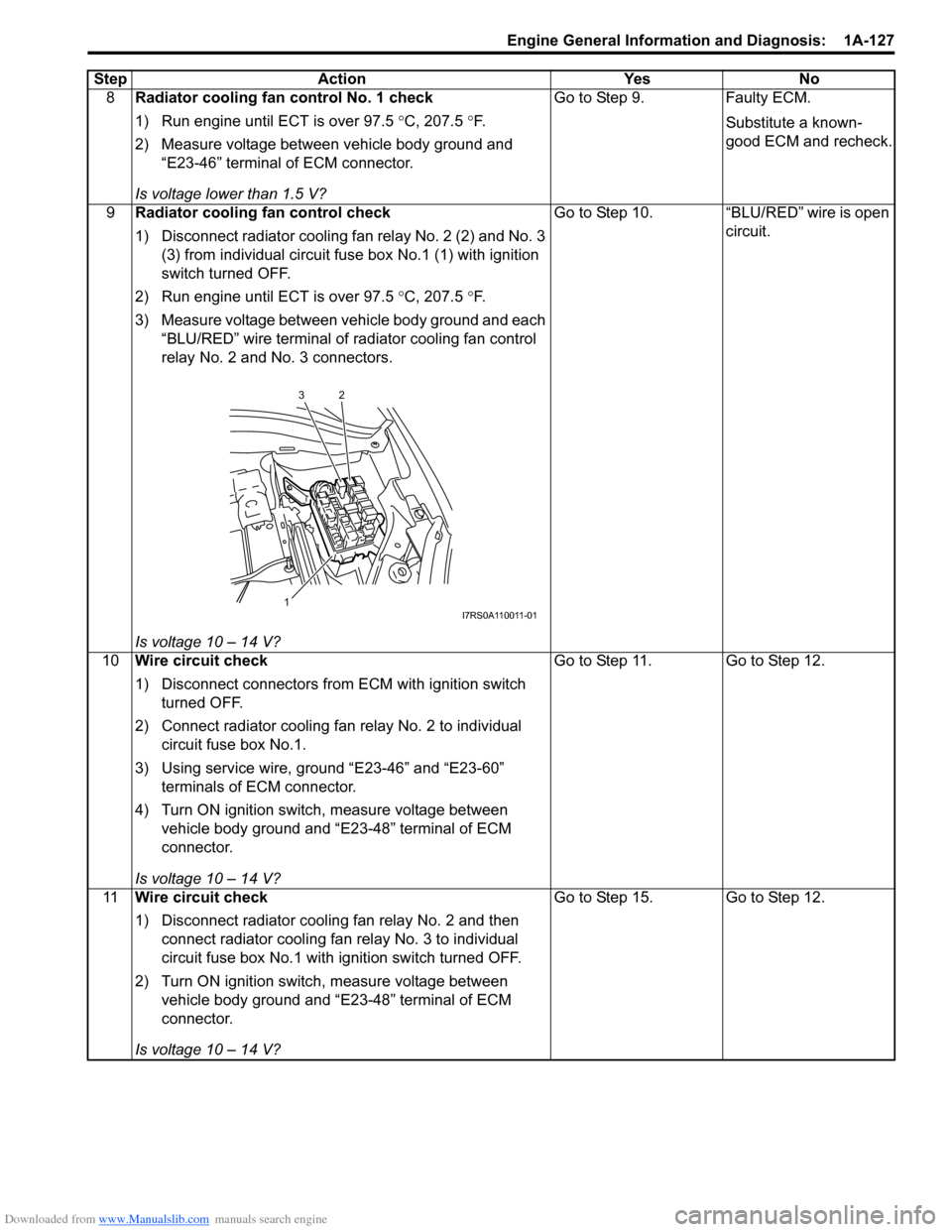

9 Radiator cooling fan control check

1) Disconnect radiator cooling fan relay No. 2 (2) and No. 3

(3) from individual circuit fuse box No.1 (1) with ignition

switch turned OFF.

2) Run engine until ECT is over 97.5 °C, 207.5 °F.

3) Measure voltage between vehicle body ground and each “BLU/RED” wire terminal of radiator cooling fan control

relay No. 2 and No. 3 connectors.

Is voltage 10 – 14 V? Go to Step 10. “BLU/RED” wire is open

circuit.

10 Wire circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Connect radiator cooling fan relay No. 2 to individual circuit fuse box No.1.

3) Using service wire, ground “E23-46” and “E23-60” terminals of ECM connector.

4) Turn ON ignition switch, measure voltage between vehicle body ground and “E23-48” terminal of ECM

connector.

Is voltage 10 – 14 V? Go to Step 11. Go to Step 12.

11 Wire circuit check

1) Disconnect radiator cooling fan relay No. 2 and then

connect radiator cooling fan relay No. 3 to individual

circuit fuse box No.1 with ignition switch turned OFF.

2) Turn ON ignition switch, measure voltage between vehicle body ground and “E23-48” terminal of ECM

connector.

Is voltage 10 – 14 V? Go to Step 15. Go to Step 12.

Step Action Yes No

23

1

I7RS0A110011-01

Page 178 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-128 Engine General Information and Diagnosis:

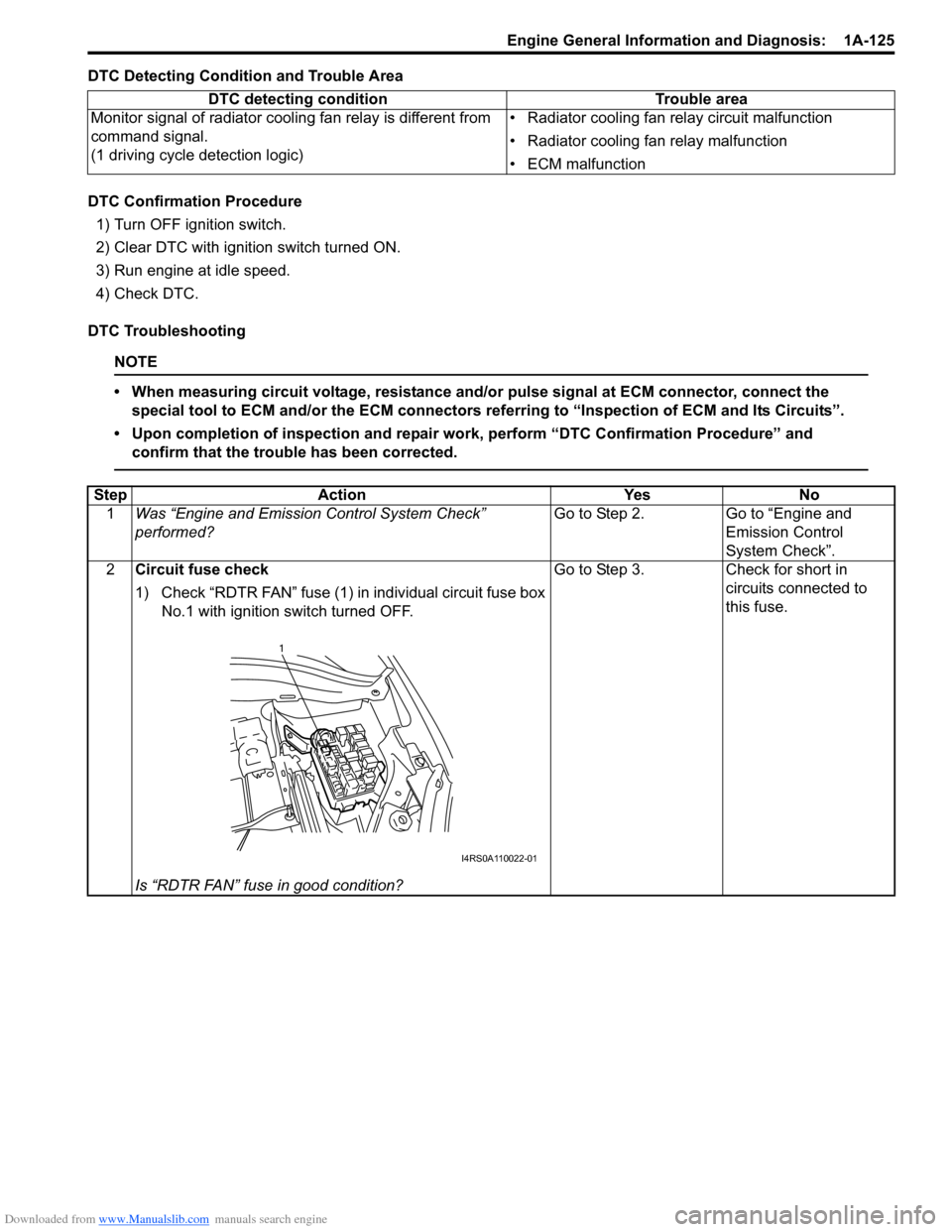

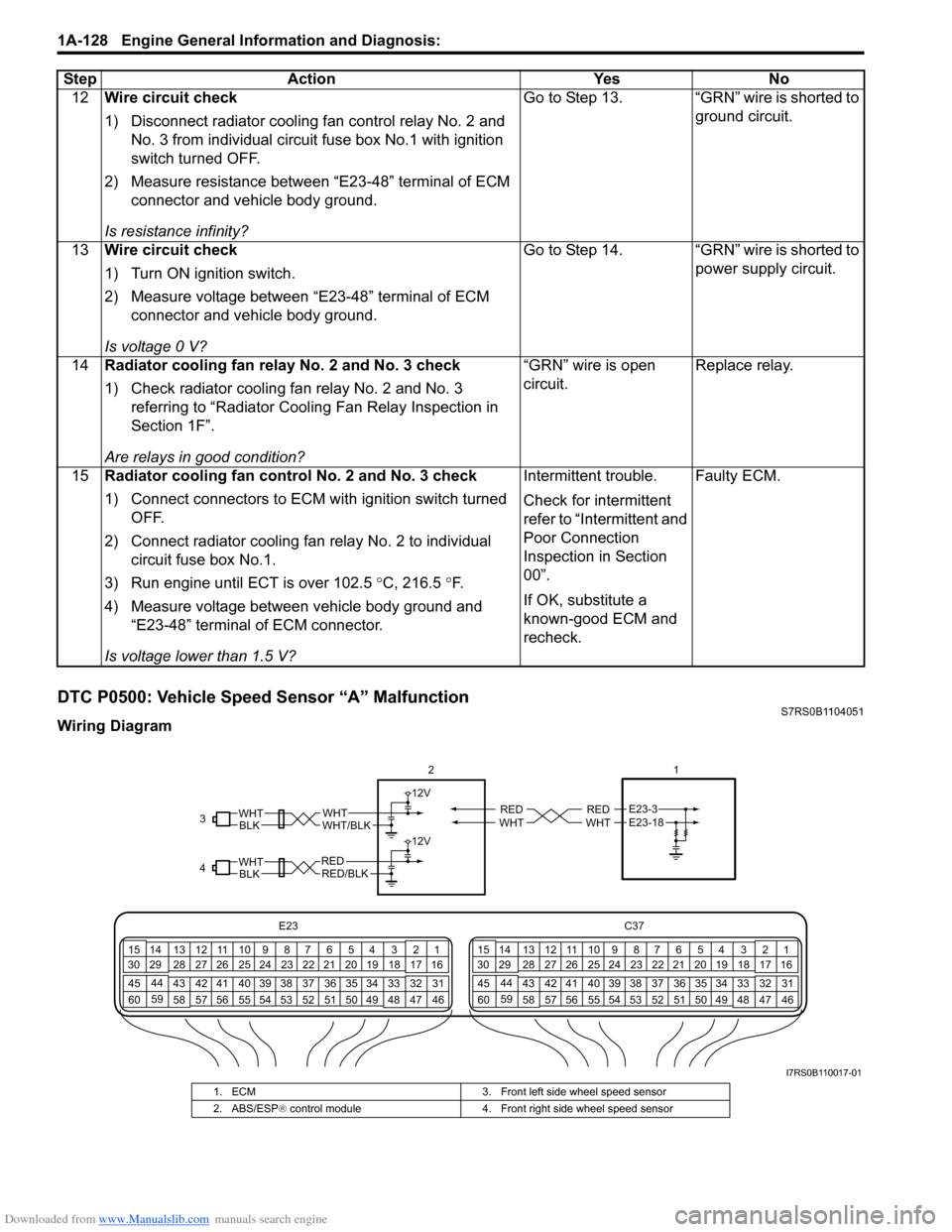

DTC P0500: Vehicle Speed Sensor “A” MalfunctionS7RS0B1104051

Wiring Diagram12

Wire circuit check

1) Disconnect radiator cooling fan control relay No. 2 and

No. 3 from individual circuit fuse box No.1 with ignition

switch turned OFF.

2) Measure resistance between “E23-48” terminal of ECM connector and vehicle body ground.

Is resistance infinity? Go to Step 13. “GRN” wire is shorted to

ground circuit.

13 Wire circuit check

1) Turn ON ignition switch.

2) Measure voltage between “E23-48” terminal of ECM

connector and vehicle body ground.

Is voltage 0 V? Go to Step 14. “GRN” wire is shorted to

power supply circuit.

14 Radiator cooling fan relay No. 2 and No. 3 check

1) Check radiator cooling fan relay No. 2 and No. 3

referring to “Radiator Coolin g Fan Relay Inspection in

Section 1F”.

Are relays in good condition? “GRN” wire is open

circuit.

Replace relay.

15 Radiator cooling fan control No. 2 and No. 3 check

1) Connect connectors to ECM with ignition switch turned

OFF.

2) Connect radiator cooling fan relay No. 2 to individual circuit fuse box No.1.

3) Run engine until ECT is over 102.5 °C, 216.5 °F.

4) Measure voltage between vehicle body ground and “E23-48” terminal of ECM connector.

Is voltage lower than 1.5 V? Intermittent trouble.

Check for intermittent

refer to “Intermittent and

Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good ECM and

recheck.

Faulty ECM.

Step Action Yes No

E23

C37

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

E23-3E23-18REDWHTREDWHTWHT/BLKWHTBLKWHT

BLKWHTREDRED/BLK

12V

12V

3

4 21

I7RS0B110017-01

1. ECM

3. Front left side wheel speed sensor

2. ABS/ESP® control module 4. Front right side wheel speed sensor

Page 179 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-129

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester.

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Warm up engine to normal operating temperature.

4) M/T model

a) Drive vehicle at 4000 rpm (e ngine speed) with 3rd gear.

b) Release accelerator pedal and with engine brake applied, keep vehicle coasting for 6 sec. or more (fuel cut condition for 5 sec. or more) and stop vehicle.

A/T model

a) Drive vehicle at more than 3000 rpm for 10 sec.

5) Check pending DTC and DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

• Vehicle speed signal is not input while fuel is cut at deceleration for 4 seconds continuously at 3600 rpm or

less.

• Vehicle speed signal is not input even if engine is running with more than 3000 rpm at D-Range for 4 sec. (A/T model).

(2 driving cycle detection logic) • Wheel speed sensor and/or its circuit

• ABS/ESP®

control module

•ECM

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Vehicle speed signal check

Is vehicle speed displayed on scan tool in Step 4) and 5) of

“DTC Confirmation Procedure”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 3.

3 DTC check in ABS/ESP ® control module

1) Check ABS/ESP ® control module for DTC.

Is there any DTC of wheel speed sensor or CAN

communication system? Go to applicable DTC

diag. flow.

Substitute a know-good

ECM and recheck.

Page 181 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-131

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 A/C refrigerant pressure sensor power supply circuit

check

1) Disconnect connector from A/C refrigerant pressure

sensor with ignition switch turned OFF.

2) Check for proper connection of A/C refrigerant pressure sensor at “GRY/RED”, “RED ” and “ORN” wire terminals.

3) Turn ON ignition switch, measure voltage between engine ground and “GRY/RED” wire terminal of A/C

refrigerant pressure sensor connector.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 3.

3 A/C refrigerant pressure sensor power supply circuit

check

1) Disconnect connectors from MAP sensor with ignition

switch turned OFF.

2) Turn ON ignition switch, measure voltage between engine ground and “GRY/RED” wire terminal of A/C

refrigerant pressure sensor connector.

Is voltage 4 – 6 V? Faulty MAP sensor. Go to Step 4.

4 A/C refrigerant pressure sensor power supply circuit

check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between engine ground and “C37- 14” terminal of ECM connector.

Is resistance infinity? Go to Step 6.

“GRY/RED” wire is

shorted to ground

circuit.

5 A/C refrigerant pressure sensor signal circuit check

1) Connect connectors to ECM.

2) Turn ON ignition switch, measure voltage between

engine ground and “RED” wire terminal of A/C

refrigerant pressure sensor connector.

Is voltage 4 – 6 V? Go to Step 7.

Go to Step 6.

6 A/C refrigerant pressure sensor signal circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between engine ground and “E23- 55” terminal of ECM connector.

Is resistance infinity? Go to Step 7.

“RED” wire is shorted to

ground circuit.

Page 182 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-132 Engine General Information and Diagnosis:

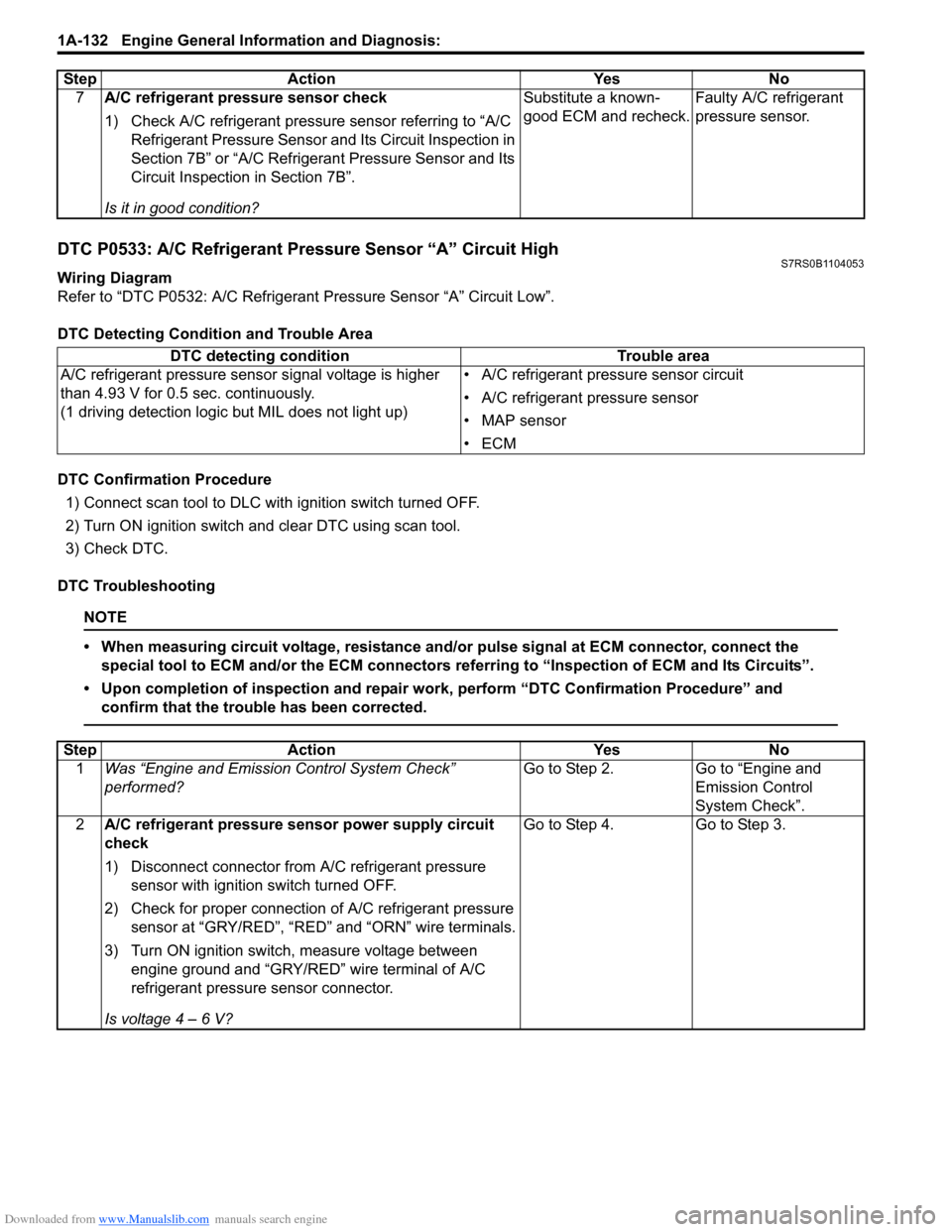

DTC P0533: A/C Refrigerant Pressure Sensor “A” Circuit HighS7RS0B1104053

Wiring Diagram

Refer to “DTC P0532: A/C Refrigerant Pressure Sensor “A” Circuit Low”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

7 A/C refrigerant pressure sensor check

1) Check A/C refrigerant pressure sensor referring to “A/C

Refrigerant Pressure Sensor and Its Circuit Inspection in

Section 7B” or “A/C Refrigerant Pressure Sensor and Its

Circuit Inspection in Section 7B”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Faulty A/C refrigerant

pressure sensor.

Step Action Yes No

DTC detecting condition

Trouble area

A/C refrigerant pressure sensor signal voltage is higher

than 4.93 V for 0.5 sec. continuously.

(1 driving detection logic but MIL does not light up) • A/C refrigerant pressure sensor circuit

• A/C refrigerant pressure sensor

• MAP sensor

•ECM

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 A/C refrigerant pressure sensor power supply circuit

check

1) Disconnect connector from A/C refrigerant pressure

sensor with ignition switch turned OFF.

2) Check for proper connection of A/C refrigerant pressure sensor at “GRY/RED”, “RED ” and “ORN” wire terminals.

3) Turn ON ignition switch, measure voltage between engine ground and “GRY/RED” wire terminal of A/C

refrigerant pressure sensor connector.

Is voltage 4 – 6 V? Go to Step 4.

Go to Step 3.

Page 184 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-134 Engine General Information and Diagnosis:

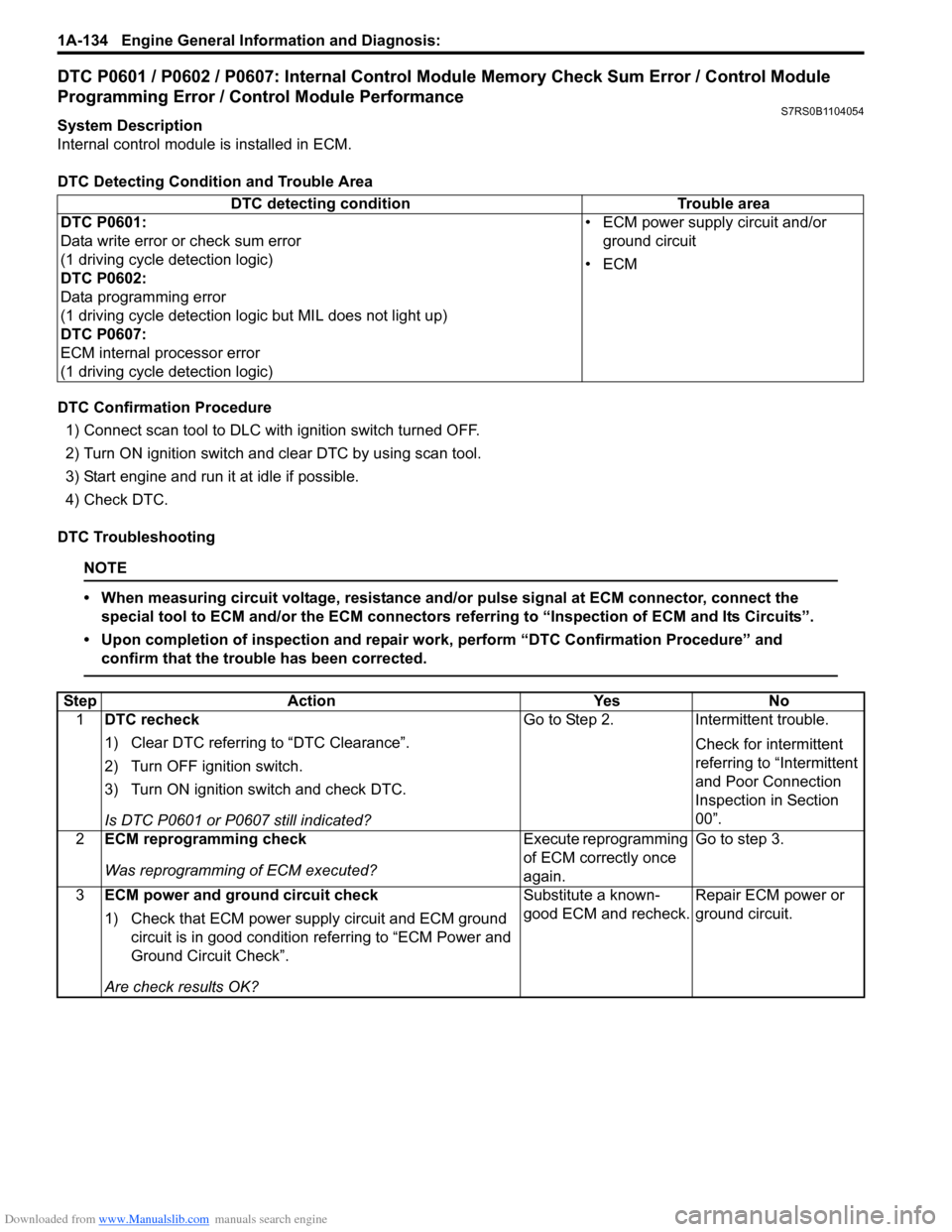

DTC P0601 / P0602 / P0607: Internal Control Module Memory Check Sum Error / Control Module

Programming Error / Control Module Performance

S7RS0B1104054

System Description

Internal control module is installed in ECM.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it at idle if possible.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

DTC P0601:

Data write error or check sum error

(1 driving cycle detection logic)

DTC P0602:

Data programming error

(1 driving cycle detection logic but MIL does not light up)

DTC P0607:

ECM internal processor error

(1 driving cycle detection logic) • ECM power supply circuit and/or

ground circuit

•ECM

Step Action YesNo

1 DTC recheck

1) Clear DTC referring to “DTC Clearance”.

2) Turn OFF ignition switch.

3) Turn ON ignition switch and check DTC.

Is DTC P0601 or P0 607 still indicated? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 ECM reprogramming check

Was reprogramming of ECM executed? Execute reprogramming

of ECM correctly once

again.Go to step 3.

3 ECM power and ground circuit check

1) Check that ECM power supply circuit and ECM ground

circuit is in good condition referring to “ECM Power and

Ground Circuit Check”.

Are check results OK? Substitute a known-

good ECM and recheck.

Repair ECM power or

ground circuit.