G37 SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 611 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-37

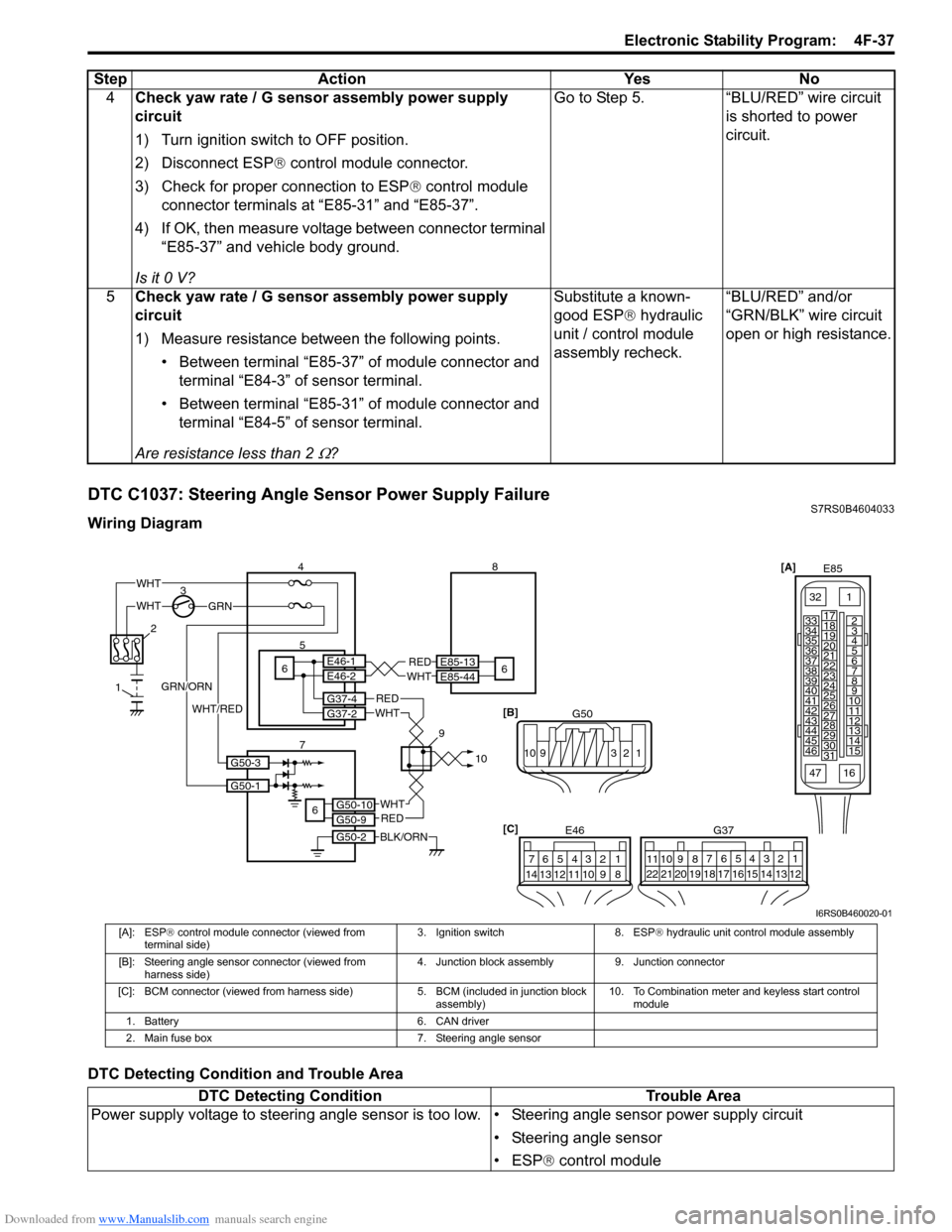

DTC C1037: Steering Angle Sensor Power Supply FailureS7RS0B4604033

Wiring Diagram

DTC Detecting Condition and Trouble Area4

Check yaw rate / G sensor assembly power supply

circuit

1) Turn ignition switch to OFF position.

2) Disconnect ESP ® control module connector.

3) Check for proper connection to ESP ® control module

connector terminals at “E85-31” and “E85-37”.

4) If OK, then measure voltage between connector terminal “E85-37” and vehicle body ground.

Is it 0 V? Go to Step 5. “BLU/RED” wire circuit

is shorted to power

circuit.

5 Check yaw rate / G sensor assembly power supply

circuit

1) Measure resistance between the following points.

• Between terminal “E85-37” of module connector and terminal “E84-3” of sensor terminal.

• Between terminal “E85-31” of module connector and terminal “E84-5” of sensor terminal.

Are resistance less than 2

Ω? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly recheck. “BLU/RED” and/or

“GRN/BLK” wire circuit

open or high resistance.

Step

Action YesNo

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

[C] G37

E46

124

53

67

891011121314124

53

67

891011

1213141516171819202122

WHTGRN

3

E85-13

E85-44REDWHT65E46-1E46-2

4 8

6

BLK/ORN

REDWHT

REDWHT

G37-4G37-2

G50-10G50-9

G50-2

6

2

1

7 910

G50-1

G50-3

GRN/ORN

WHT/RED

WHT

[B]

G50

109 321

I6RS0B460020-01

[A]: ESP® control module connector (viewed from

terminal side) 3. Ignition switch 8. ESP

® hydraulic unit control module assembly

[B]: Steering angle sensor connector (viewed from harness side) 4. Junction block assembly 9. Junction connector

[C]: BCM connector (viewed from harnes s side) 5. BCM (included in junction block

assembly) 10. To Combination meter and keyless start control

module

1. Battery 6. CAN driver

2. Main fuse box 7. Steering angle sensor

DTC Detecting Condition Trouble Area

Power supply voltage to steering angle sensor is to o low. • Steering angle sensor power supply circuit

• Steering angle sensor

• ESP® control module

Page 623 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-49

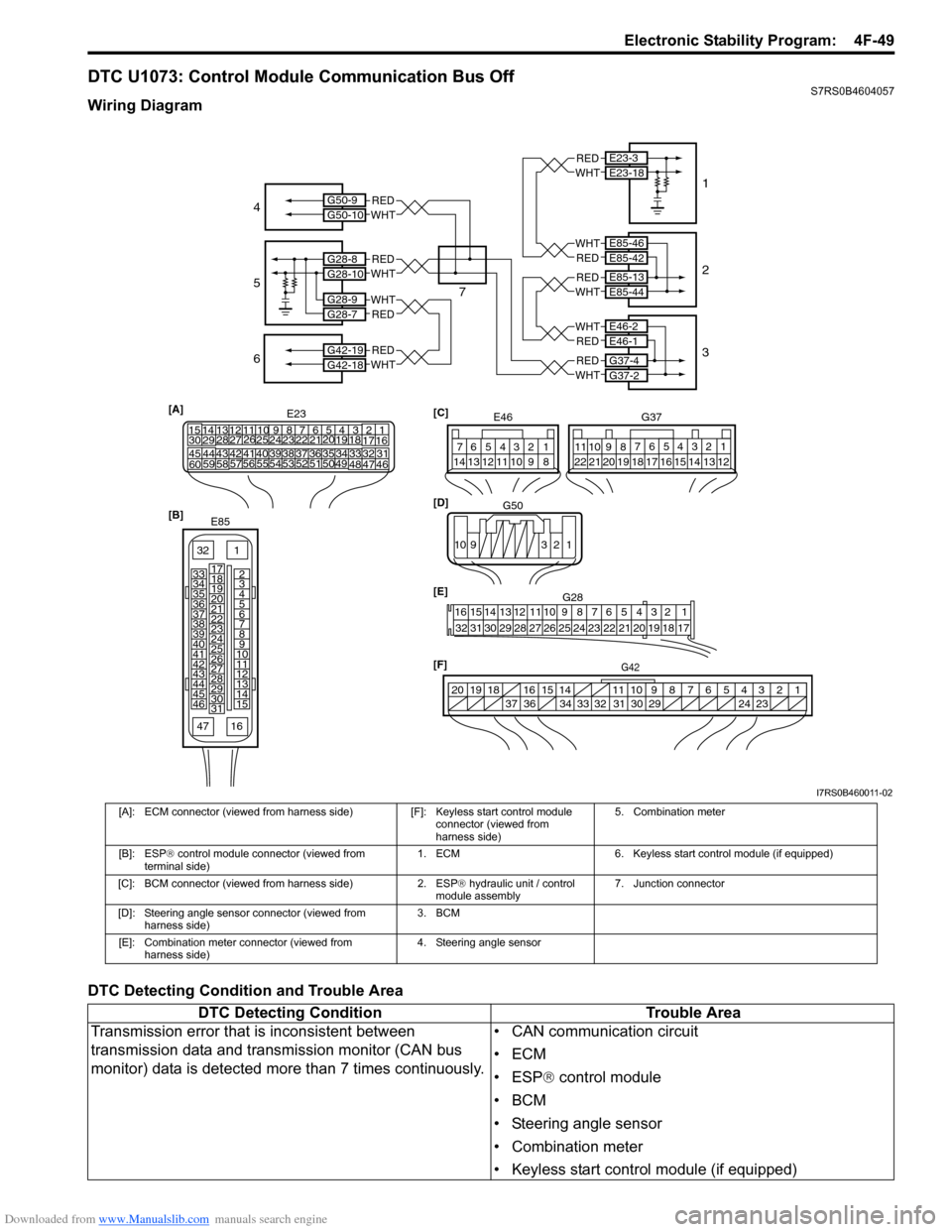

DTC U1073: Control Module Communication Bus OffS7RS0B4604057

Wiring Diagram

DTC Detecting Condition and Trouble Area

E85-13E85-44

E46-2E46-1

G37-4G37-2

E85-46E85-42

E23-3E23-18

G50-9G50-10

G28-8G28-10

G28-9G28-7

G42-19G42-18

REDWHT

WHTRED

WHTRED

REDWHT

REDWHT

WHTRED

REDWHT

REDWHT

REDWHT

[A]

21

E2334

1819

5671011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 5826

27

28

15

30

56 4832 31343536374042 39 38

44

45 43 41 33

1213

238

G42[F]

1234567891011

141516

36 34 33 32 31 30 29 24 23

37

181920

[B]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47 [C]

G37

E46

124

53

67

891011121314124

53

67

891011

1213141516171819202122

[E] G28

12345678910111213141516

17181920212223242526272829303132

[D] G50

109 321

4

5

7 1

2

3

6

I7RS0B460011-02

[A]: ECM connector (viewed from harness side) [F]: Keyless start control module

connector (viewed from

harness side) 5. Combination meter

[B]: ESP ® control module connector (viewed from

terminal side) 1. ECM

6. Keyless start control module (if equipped)

[C]: BCM connector (viewed from harness side) 2. ESP® hydraulic unit / control

module assembly 7. Junction connector

[D]: Steering angle sensor connector (viewed from harness side) 3. BCM

[E]: Combination meter connector (viewed from harness side) 4. Steering angle sensor

DTC Detecting Condition

Trouble Area

Transmission error that is inconsistent between

transmission data and transmission monitor (CAN bus

monitor) data is detected more than 7 times continuously. • CAN communication circuit

•ECM

• ESP

® control module

•BCM

• Steering angle sensor

• Combination meter

• Keyless start control module (if equipped)

Page 715 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-71

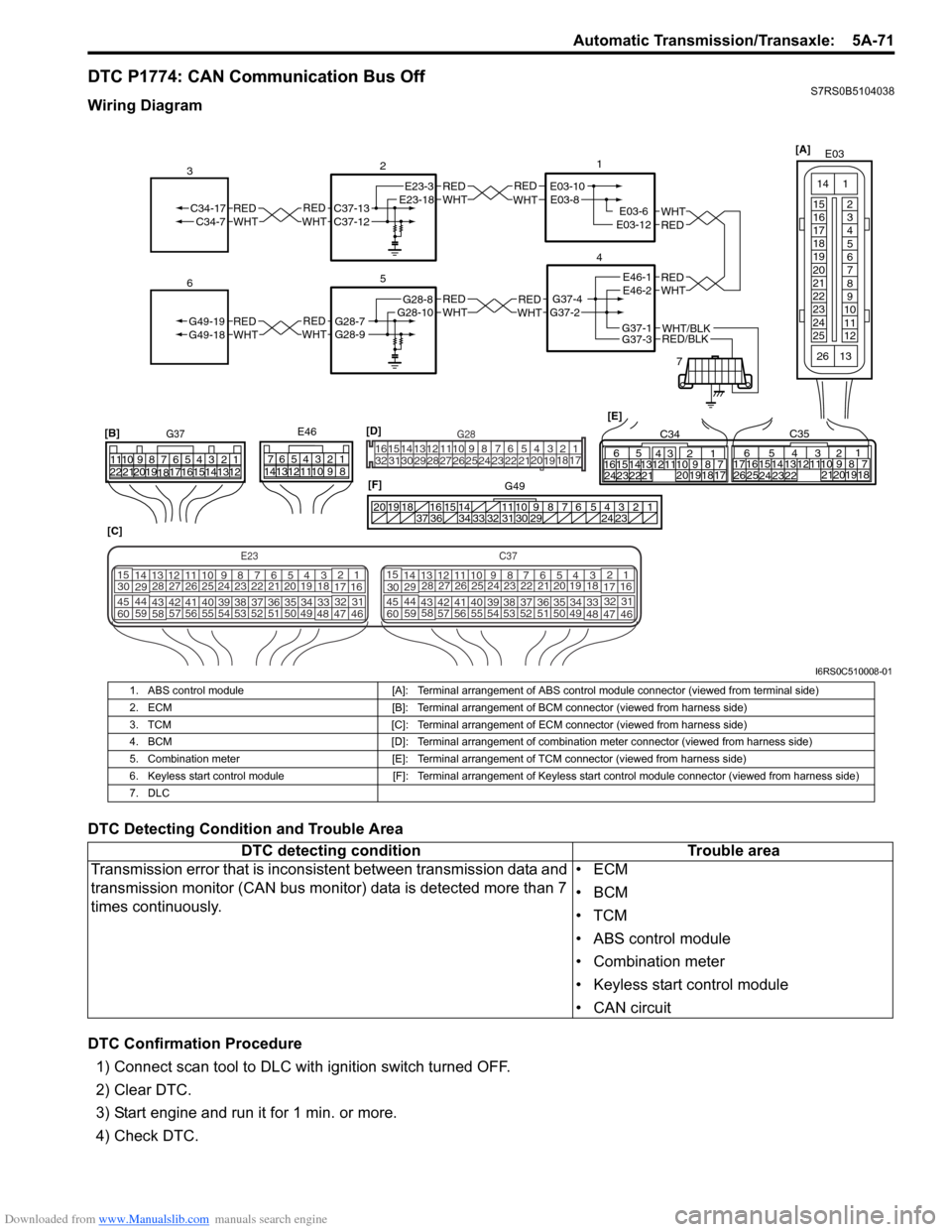

DTC P1774: CAN Communication Bus OffS7RS0B5104038

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch turned OFF.

2) Clear DTC.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

REDWHTE03-6E03-12

1

4

7

REDWHT

2

[C]

[B]

G37E46

1234567

1234567

891011

891011

121314 121314

151617

18

19202122 [E]65

1615 14131211 43

2423 2122 10 9 8 7

21

1920 1817

C3417 16

26 2515 14

65 3

42

13 12

23 2224 1110 9

212019 87

18

1

C35

[F]

REDWHTC37-13C37-12REDWHTC34-17C34-7

3

1234567891011

141516

36 34 33 32 31 30 29 24 23

37

181920

[D] [A]

G49

E23-3E23-18

5

REDWHTG28-7G28-9REDWHTG49-19G49-18

6

REDWHTE03-10E03-8

G37-4G37-2

REDWHTE46-1E46-2REDWHTREDWHTG28-8G28-10

RED/BLKWHT/BLKG37-3G37-1

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 33 1

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

G281234567

8

910111213141516

1718

19

20

212223242526272829303132

I6RS0C510008-01

1. ABS control module [A]: Terminal arrangement of ABS control module connector (viewed from terminal side)

2. ECM [B]: Terminal arrangement of BCM connector (viewed from harness side)

3. TCM [C]: Terminal arrangement of ECM connector (viewed from harness side)

4. BCM [D]: Terminal arrangement of combination meter connector (viewed from harness side)

5. Combination meter [E]: Terminal arrangement of TCM connector (viewed from harness side)

6. Keyless start control module [F]: Terminal arrangement of Keyless start control module connector (viewed from harness side)

7. DLC

DTC detecting condition Trouble area

Transmission error that is incons istent between transmission data and

transmission monitor (CAN bus monitor) data is detected more than 7

times continuously. •ECM

•BCM

•TCM

• ABS control module

• Combination meter

• Keyless start control module

• CAN circuit

Page 1011 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-63

DTC B1546: A/C Refrigerant Pressure MalfunctionS7RS0B7224018

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

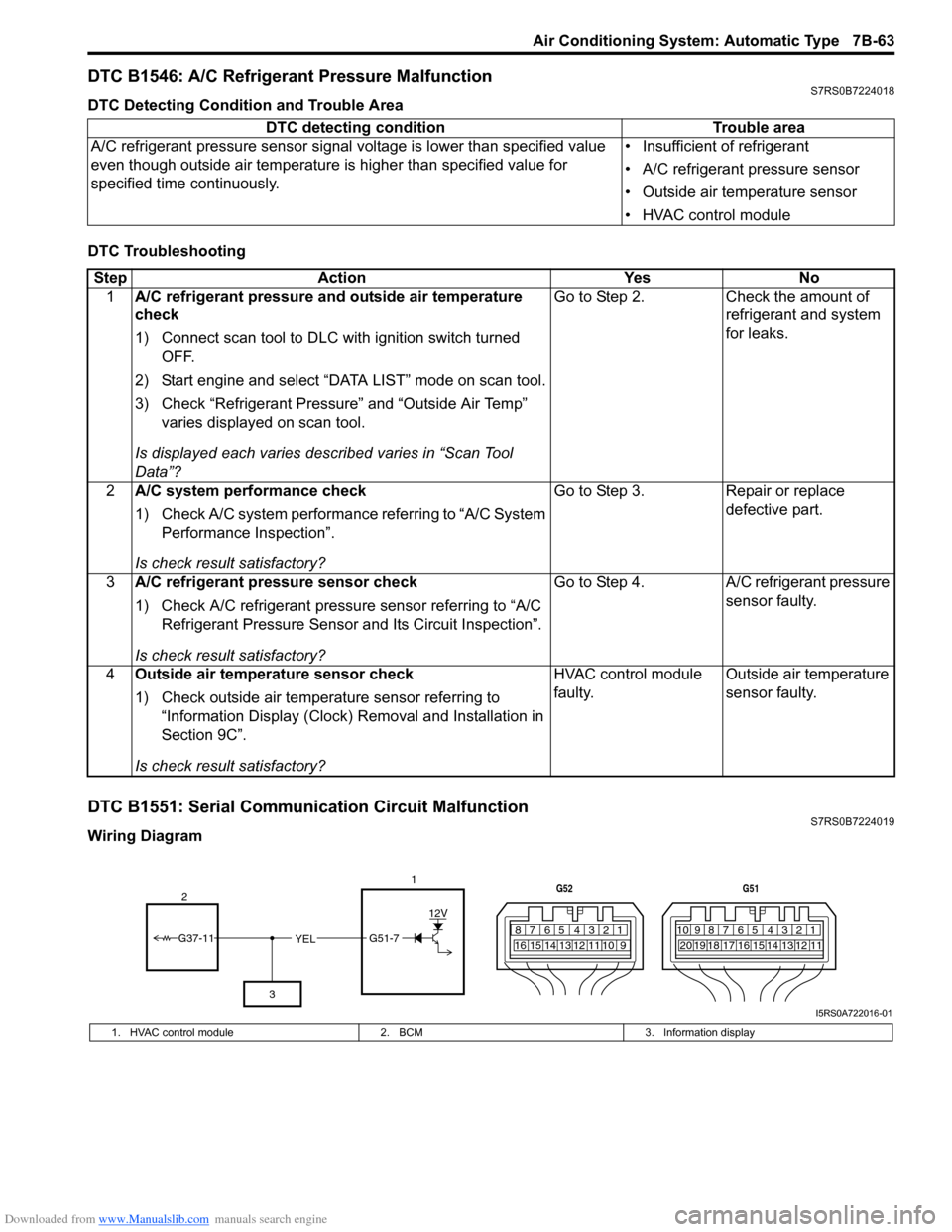

DTC B1551: Serial Communication Circuit MalfunctionS7RS0B7224019

Wiring DiagramDTC detecting condition Trouble area

A/C refrigerant pressure sensor signal voltage is lower t han specified value

even though outside air temperature is higher than specified value for

specified time continuously. • Insufficient of refrigerant

• A/C refrigerant pressure sensor

• Outside air temperature sensor

• HVAC control module

Step

Action YesNo

1 A/C refrigerant pressure and outside air temperature

check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure” and “Outside Air Temp” varies displayed on scan tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Go to Step 2.

Check the amount of

refrigerant and system

for leaks.

2 A/C system performance check

1) Check A/C system performance referring to “A/C System

Performance Inspection”.

Is check result satisfactory? Go to Step 3.

Repair or replace

defective part.

3 A/C refrigerant pressure sensor check

1) Check A/C refrigerant pressure sensor referring to “A/C

Refrigerant Pressure Sensor and Its Circuit Inspection”.

Is check result satisfactory? Go to Step 4.

A/C refrigerant pressure

sensor faulty.

4 Outside air temperature sensor check

1) Check outside air temperature sensor referring to

“Information Display (Clock) Removal and Installation in

Section 9C”.

Is check result satisfactory? HVAC control module

faulty.

Outside air temperature

sensor faulty.

YEL17812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

G51-7

12V

2

3

G37-11

I5RS0A722016-01

1. HVAC control module 2. BCM3. Information display

Page 1012 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-64 Air Conditioning System: Automatic Type

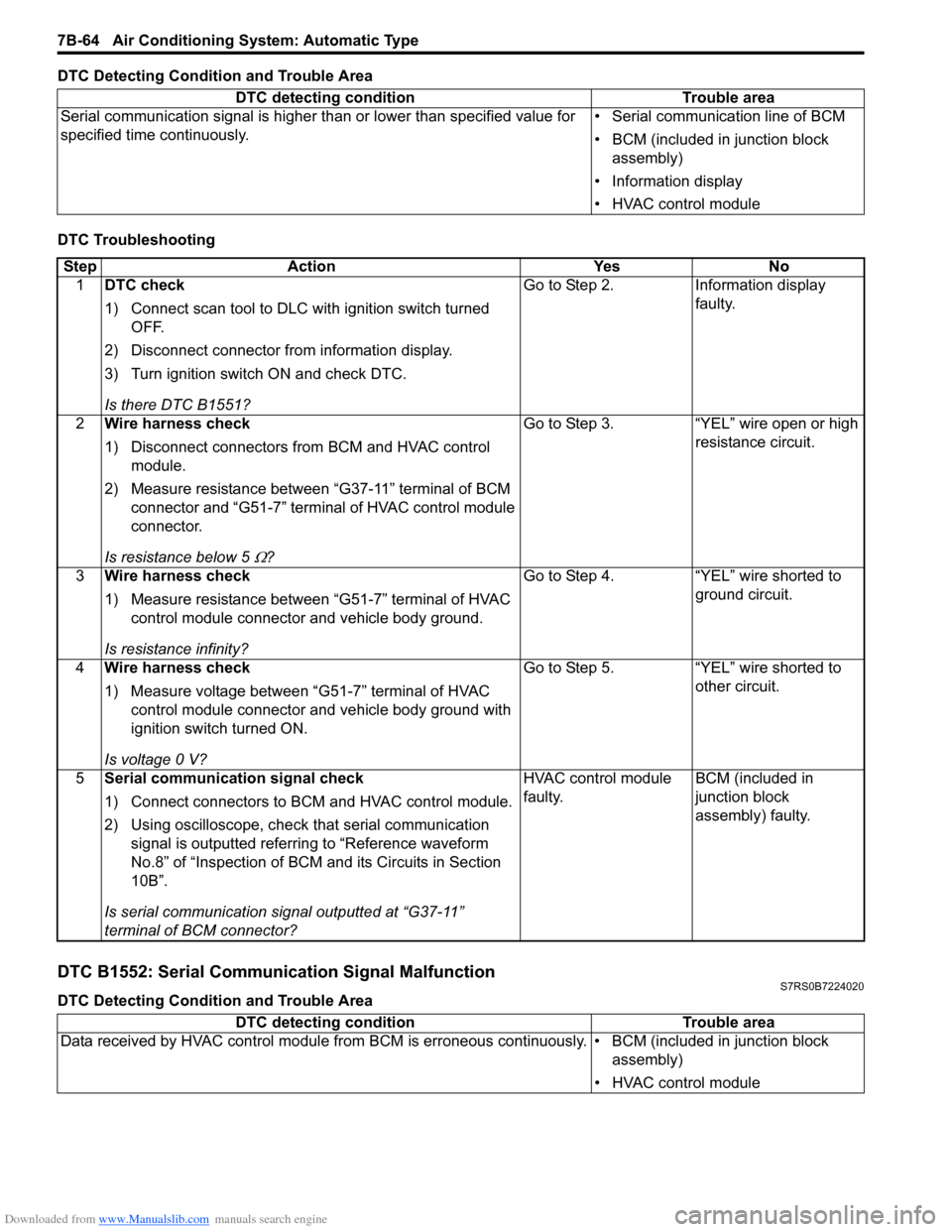

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1552: Serial Communication Signal MalfunctionS7RS0B7224020

DTC Detecting Condition and Trouble AreaDTC detecting condition Trouble area

Serial communication signal is higher than or lower than specified value for

specified time continuously. • Serial communication line of BCM

• BCM (included in junction block

assembly)

• Information display

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Disconnect connector from information display.

3) Turn ignition switch ON and check DTC.

Is there DTC B1551? Go to Step 2.

Information display

faulty.

2 Wire harness check

1) Disconnect connectors from BCM and HVAC control

module.

2) Measure resistance between “G37-11” terminal of BCM connector and “G51-7” terminal of HVAC control module

connector.

Is resistance below 5

Ω? Go to Step 3. “YEL” wire open or high

resistance circuit.

3 Wire harness check

1) Measure resistance between “G51-7” terminal of HVAC

control module connector and vehicle body ground.

Is resistance infinity? Go to Step 4. “YEL” wire shorted to

ground circuit.

4 Wire harness check

1) Measure voltage between “G51-7” terminal of HVAC

control module connector and vehicle body ground with

ignition switch turned ON.

Is voltage 0 V? Go to Step 5. “YEL” wire shorted to

other circuit.

5 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

Data received by HVAC control module from BCM is erroneous continuously. • BCM (included in junction block assembly)

• HVAC control module

Page 1013 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-65

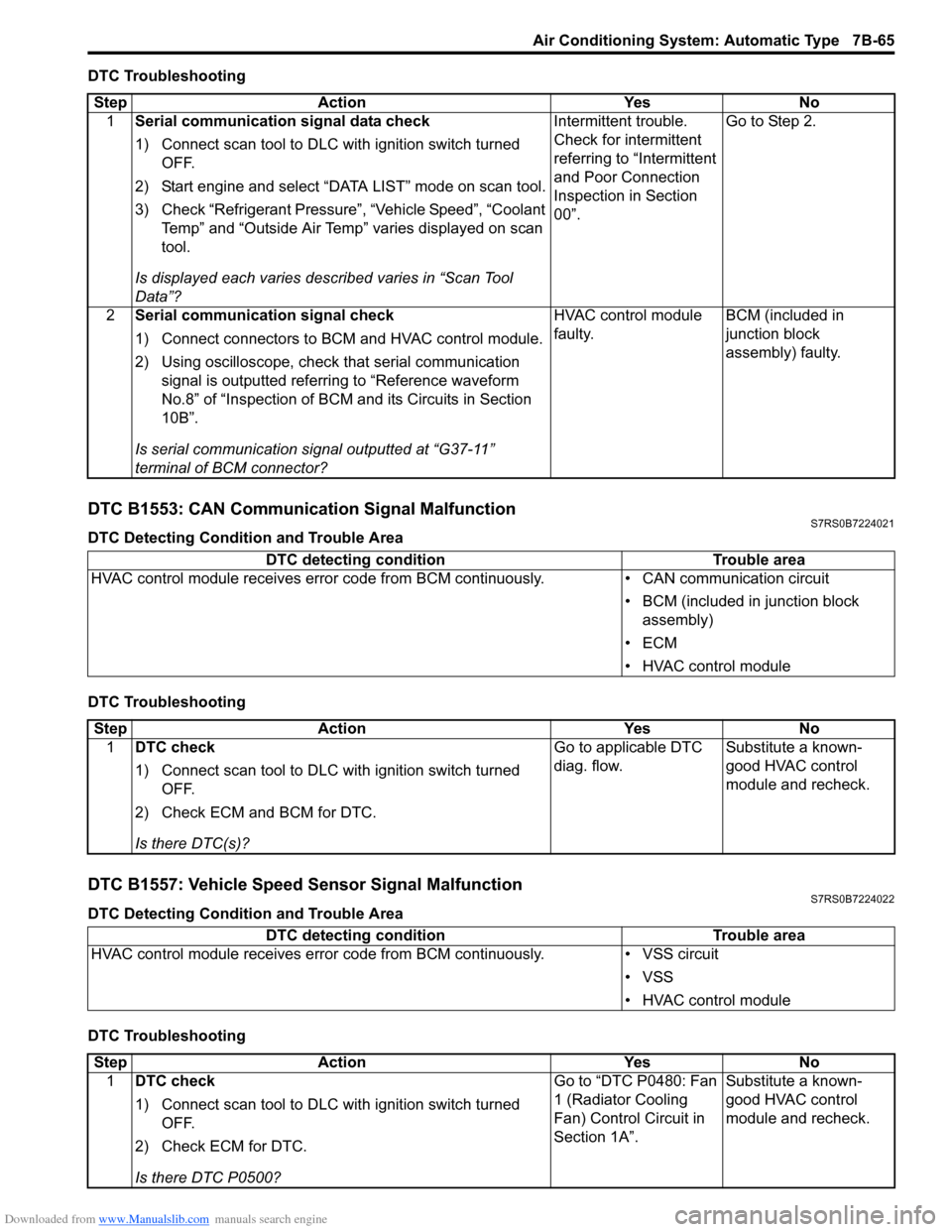

DTC Troubleshooting

DTC B1553: CAN Communication Signal MalfunctionS7RS0B7224021

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1557: Vehicle Speed Sensor Signal MalfunctionS7RS0B7224022

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Serial communication signal data check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure”, “Vehicle Speed”, “Coolant Temp” and “Outside Air Temp” varies displayed on scan

tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 2.

2 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

HVAC control module receives error code fr om BCM continuously.• CAN communication circuit

• BCM (included in junction block assembly)

•ECM

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM and BCM for DTC.

Is there DTC(s)? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives error code from BCM continuously. • VSS circuit

• VSS

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Is there DTC P0500? Go to “DTC P0480: Fan

1 (Radiator Cooling

Fan) Control Circuit in

Section 1A”.

Substitute a known-

good HVAC control

module and recheck.

Page 1189 of 1496

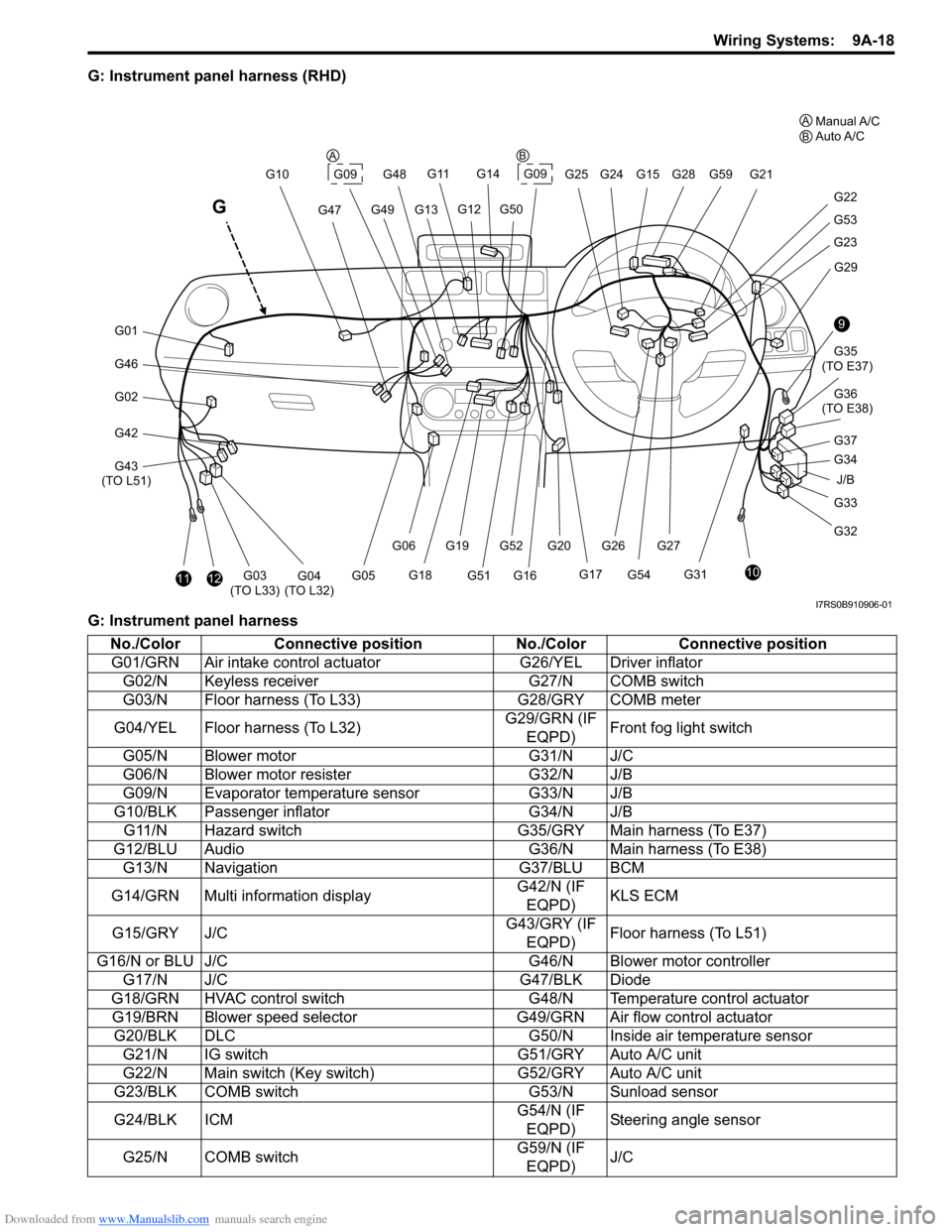

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-18

G: Instrument panel harness (RHD)

G: Instrument panel harness

J/B

9

10

G33

G32 G34 G35

(TO E37)

G36

(TO E38)

G31 G29

G23

G53

G22

G21

G28G59

G20G52G27

G54

G261112G03

(TO L33)G04

(TO L32)

G46

G01

G02

G42

G43

(TO L51) G10

G47

G11

G13G49

G14

G09G25 G24G15

G12G50

G48

G17

G16G51

G19

G18

G06

G05

G

G09

G37

A

BManual A/C

Auto A/C

AB

I7RS0B910906-01

No./Color Connective position No./ColorConnective position

G01/GRN Air intake control ac tuatorG26/YEL Driver inflator

G02/N Keyless receiver G27/N COMB switch

G03/N Floor harness (To L33) G28/GRY COMB meter

G04/YEL Floor harness (To L32) G29/GRN (IF

EQPD) Front fog light switch

G05/N Blower motor G31/N J/C

G06/N Blower motor resister G32/N J/B

G09/N Evaporator temperature sensor G33/N J/B

G10/BLK Passenger inflator G34/N J/B

G11/N Hazard switch G35/GRY Main harness (To E37)

G12/BLU Audio G36/N Main harness (To E38)

G13/N Navigation G37/BLU BCM

G14/GRN Multi information display G42/N (IF

EQPD) KLS ECM

G15/GRY J/C G43/GRY (IF

EQPD) Floor harness (To L51)

G16/N or BLU J/C G46/N Blower motor controller

G17/N J/C G47/BLK Diode

G18/GRN HVAC control switch G48/N Temperature control actuator

G19/BRN Blower speed selector G49/GRN Air flow control actuator

G20/BLK DLC G50/N Inside air temperature sensor

G21/N IG switch G51/GRY Auto A/C unit

G22/N Main switch (Key switch) G52/GRY Auto A/C unit

G23/BLK COMB switch G53/N Sunload sensor

G24/BLK ICM G54/N (IF

EQPD) Steering angle sensor

G25/N COMB switch G59/N (IF

EQPD) J/C

Page 1190 of 1496

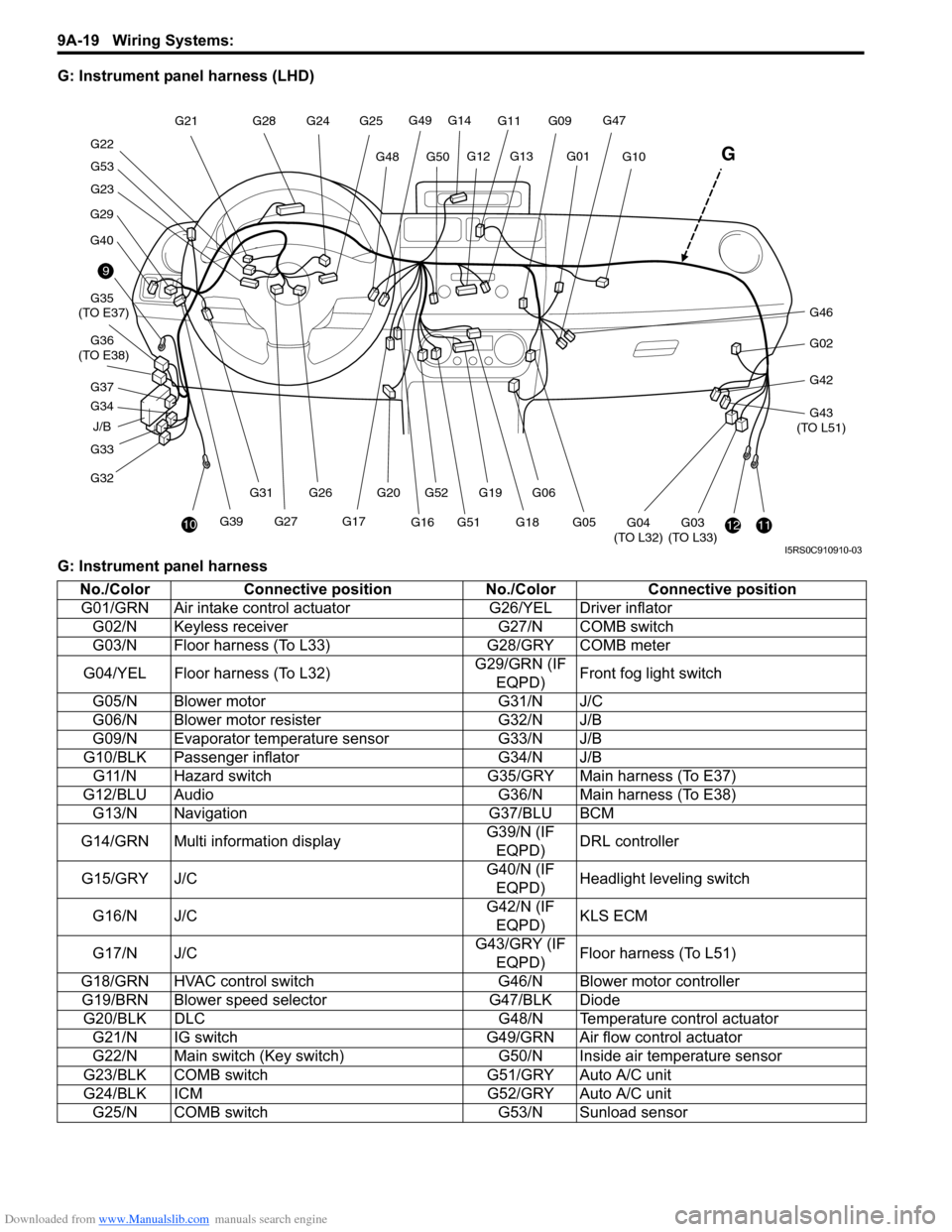

Downloaded from www.Manualslib.com manuals search engine 9A-19 Wiring Systems:

G: Instrument panel harness (LHD)

G: Instrument panel harness

J/B

9

10

G33

G32 G34 G35

(TO E37)

G36

(TO E38)

G29

G40

G23

G53

G22 G21

G28

G20G52

G27G39 G26

G31

1112G03

(TO L33)G04

(TO L32)

G46

G02

G42

G43

(TO L51)

G10

G47G11

G13G01

G14

G49

G50G48

G25

G24

G12

G17

G16G51G19

G18

G06

G05

G

G09

G37

I5RS0C910910-03

No./Color Connective position No./ColorConnective position

G01/GRN Air intake control ac tuatorG26/YEL Driver inflator

G02/N Keyless receiver G27/N COMB switch

G03/N Floor harness (To L33) G28/GRY COMB meter

G04/YEL Floor harness (To L32) G29/GRN (IF

EQPD) Front fog light switch

G05/N Blower motor G31/N J/C

G06/N Blower motor resister G32/N J/B

G09/N Evaporator temperature sensor G33/N J/B

G10/BLK Passenger inflator G34/N J/B

G11/N Hazard switch G35/GRY Main harness (To E37)

G12/BLU Audio G36/N Main harness (To E38)

G13/N Navigation G37/BLU BCM

G14/GRN Multi information display G39/N (IF

EQPD) DRL controller

G15/GRY J/C G40/N (IF

EQPD) Headlight leveling switch

G16/N J/C G42/N (IF

EQPD) KLS ECM

G17/N J/C G43/GRY (IF

EQPD) Floor harness (To L51)

G18/GRN HVAC control switch G46/N Blower motor controller

G19/BRN Blower speed selector G47/BLK Diode

G20/BLK DLC G48/N Temperature control actuator

G21/N IG switch G49/GRN Air flow control actuator

G22/N Main switch (Key switch) G50/N Inside air temperature sensor

G23/BLK COMB switch G51/GRY Auto A/C unit

G24/BLK ICM G52/GRY Auto A/C unit

G25/N COMB switch G53/N Sunload sensor

Page 1224 of 1496

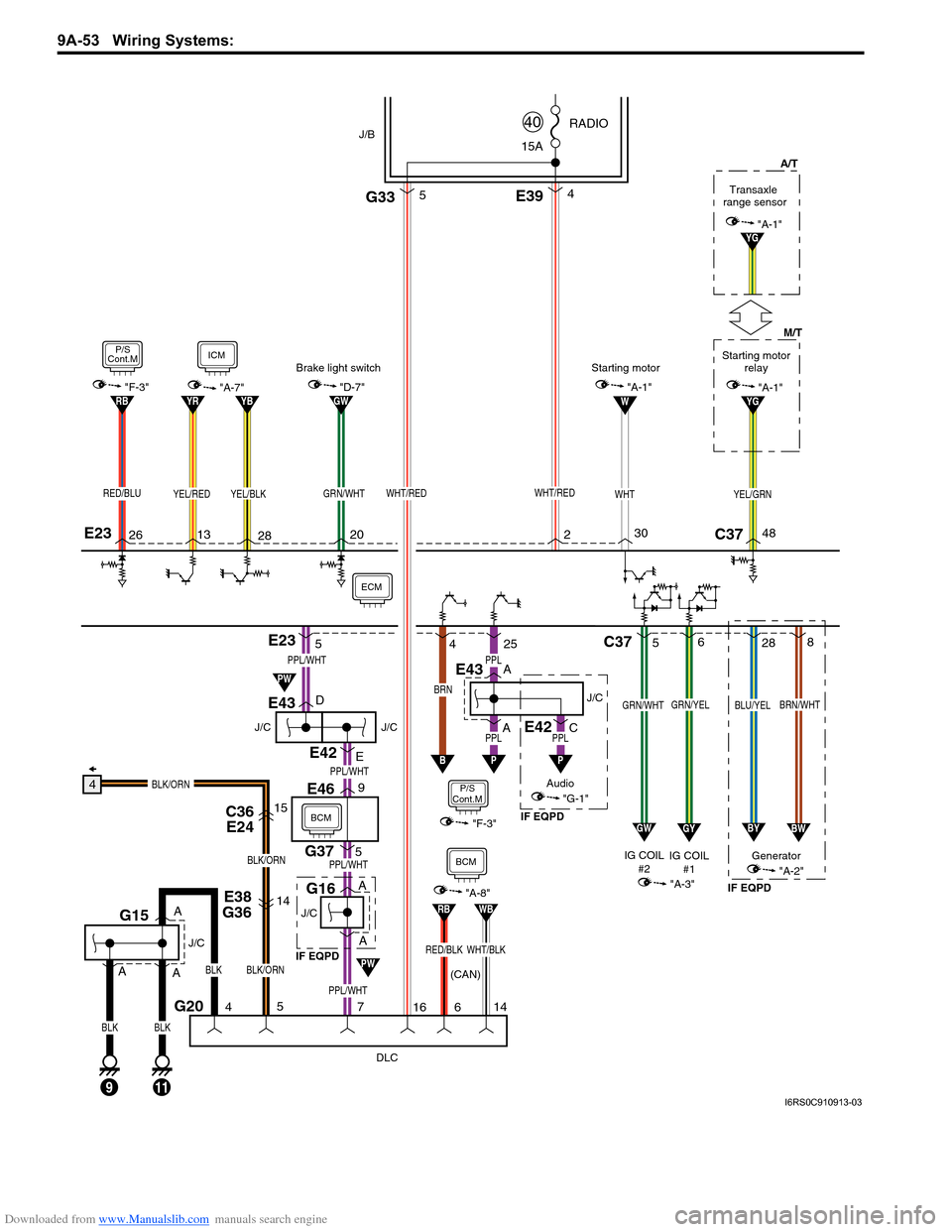

Downloaded from www.Manualslib.com manuals search engine 9A-53 Wiring Systems:

J/C

E43

J/C

G16

DLC

G20

G375

E469

E38

G3614

C36 E2415

BLK/ORN

BLK/ORN

BLK/ORN

4

BLK

11

J/C

G15

5

4

516

WHT/RED

C37

GRN/YELGRN/WHT

5 6

YG

BRN

B

P/S

Cont.M

4

"F-3"

25

A

A D

E

AA

PPL/WHT

PPL/WHT

PPL/WHT

PPL/WHT

YEL/GRNWHT/RED

BLK

9

A

PPL

E42

PPLJ/C

ECM

E394

J/B15A RADIO

40

E23

E23

YEL/BLKYEL/REDRED/BLU

13

282620

BLK

2C37

M/T

A/T

48

W

WHT

30

GYGW

BRN/WHTBLU/YEL

28

8

BWBY

IG COIL

#1 Generator

IG COIL

#2

(CAN) "A-3""A-2"

Audio

"G-1"

GRN/WHT

P

7

BCM

Starting motor relay

"A-1"

Transaxle

range sensor

YG"A-1"

ICM

"A-7"

P/S

Cont.M

"F-3"YBYRRBGW"D-7"

Brake light switch

"A-1"Starting motor

PW

PW

G335

WHT/BLKRED/BLK

RBWB

"A-8"

14

6

BCM

A

J/C

E43

APPL

P

E42C

IF EQPD IF EQPD

IF EQPD

I6RS0C910913-03

Page 1226 of 1496

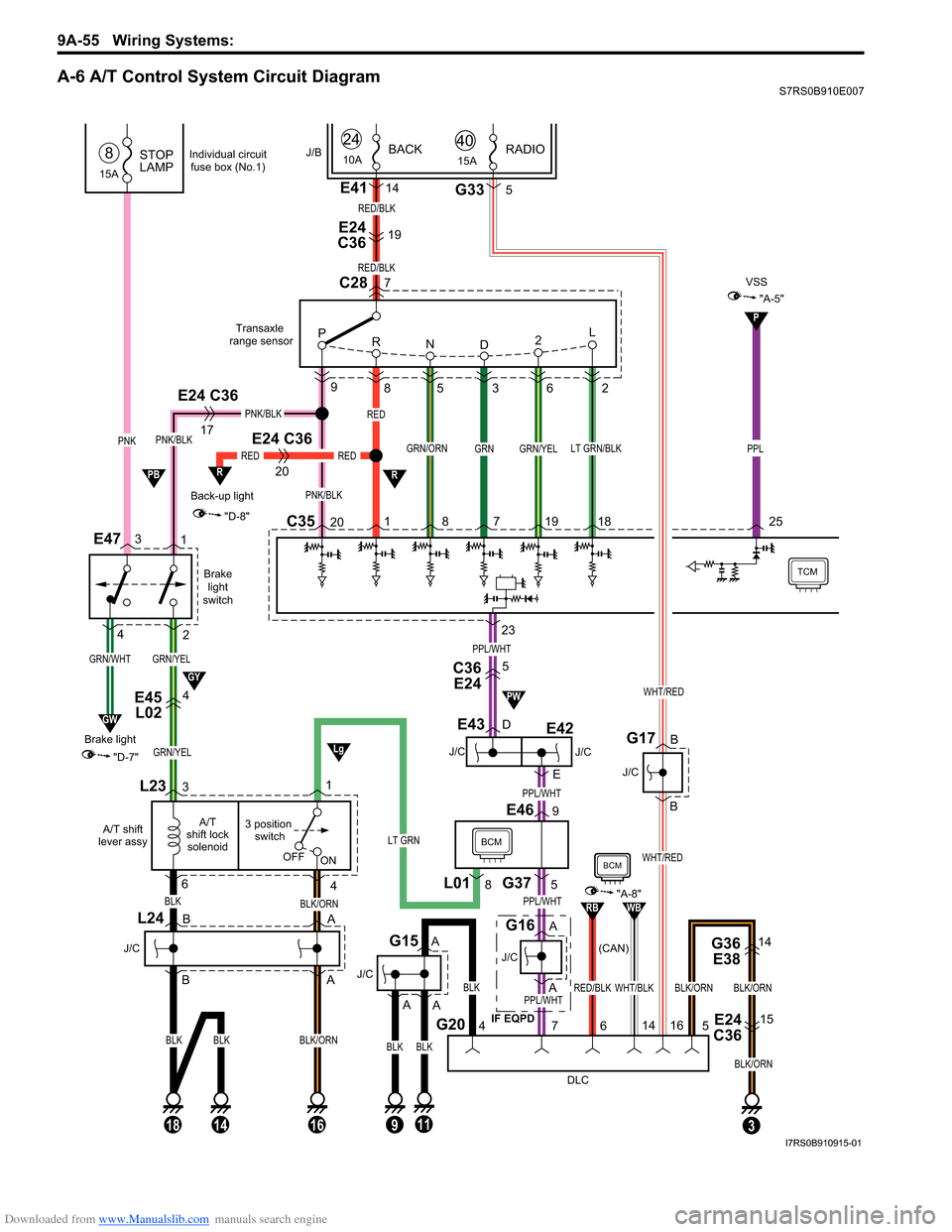

Downloaded from www.Manualslib.com manuals search engine 9A-55 Wiring Systems:

A-6 A/T Control System Circuit DiagramS7RS0B910E007

GRN/YEL

Brakelight

switch

E47

GRN/YEL

C3520 8 7 19 18

9

85 3 6 2

GRN/YEL

Back-up light

20

RED

"D-8"

R

Transaxle

range sensor

TCM

L23

4

3 position switch

A/T

shift lock solenoid

A/T shift

lever assy

BLK/ORN

16

OFF ON

RED

1

RED

BLK

PNK/BLK

GRN/ORNLT GRN/BLK

C28

P

R ND 2L

PNK/BLK

1

2

E24 C36

17

PNK/BLK

BLK

63

BLK/ORN

18

BLK

14

L24

J/C

E45

L024

J/C

E43

J/C (CAN)

G16

BCM

DLC

G207

G375

E469

4

BLK

BLKBLK

11

J/C

G15

3

G36

E3814

E24

C3615

BLK/ORNBLK/ORN

5

23

GRN

RED/BLK

7

E24

C3619

E4114

RED/BLK

PNK

15A

STOP

LAMP8

GRN/WHT

GW

"D-7"

Brake light

3

4

J/B

L018

1

24

10ABACK

A

A

B

B A

A

PPL/WHT

PPL/WHT

PPL/WHT

PPL/WHT

A

A

D

E

LT GRN

P

"A-5"

VSS

PPL

25

R

C36E245

Lg

GY

PB

PW

9

A

Individual circuit

fuse box (No.1)

WHT/BLKRED/BLK

RBWB

BCM

"A-8"

14

6

BLK/ORN

15ARADIO40

G335

WHT/RED

B

B

J/C

G17

WHT/RED

16

J/C

E42

IF EQPD

E24 C36

I7RS0B910915-01