Oxygen SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 227 of 1496

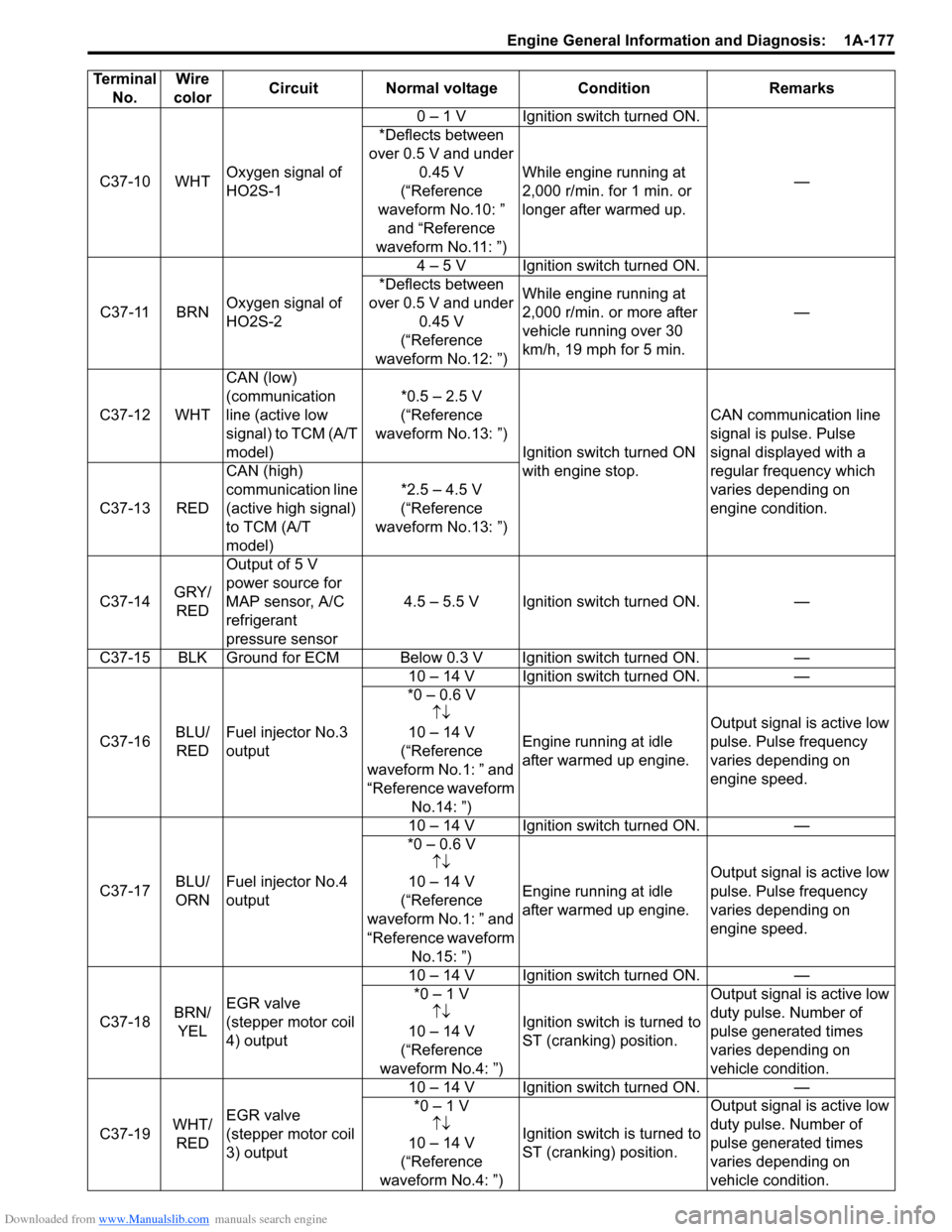

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-177

C37-10 WHTOxygen signal of

HO2S-1 0 – 1 V Ignition switch turned ON.

—

*Deflects between

over 0.5 V and under 0.45 V

(“Reference

waveform No.10: ” and “Reference

waveform No.11: ”) While engine running at

2,000 r/min. for 1 min. or

longer after warmed up.

C37-11 BRN Oxygen signal of

HO2S-2 4 – 5 V Ignition switch turned ON.

—

*Deflects between

over 0.5 V and under 0.45 V

(“Reference

waveform No.12: ”) While engine running at

2,000 r/min. or more after

vehicle running over 30

km/h, 19 mph for 5 min.

C37-12 WHT CAN (low)

(communication

line (active low

signal) to TCM (A/T

model) *0.5 – 2.5 V

(“Reference

waveform No.13: ”) Ignition switch turned ON

with engine stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition.

C37-13 RED CAN (high)

communication line

(active high signal)

to TCM (A/T

model) *2.5 – 4.5 V

(“Reference

waveform No.13: ”)

C37-14 GRY/

RED Output of 5 V

power source for

MAP sensor, A/C

refrigerant

pressure sensor

4.5 – 5.5 V Ignition switch turned ON. —

C37-15 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. —

C37-16 BLU/

RED Fuel injector No.3

output 10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V ↑↓

10 – 14 V

(“Reference

waveform No.1: ” and

“Reference waveform No.14: ”) Engine running at idle

after warmed up engine.

Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C37-17 BLU/

ORNFuel injector No.4

output 10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V ↑↓

10 – 14 V

(“Reference

waveform No.1: ” and

“Reference waveform No.15: ”) Engine running at idle

after warmed up engine.

Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C37-18 BRN/

YEL EGR valve

(stepper motor coil

4) output 10 – 14 V Ignition switch turned ON. —

*0 – 1 V ↑↓

10 – 14 V

(“Reference

waveform No.4: ”) Ignition switch is turned to

ST (cranking) position. Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

C37-19 WHT/

RED EGR valve

(stepper motor coil

3) output 10 – 14 V Ignition switch turned ON. —

*0 – 1 V ↑↓

1

0 – 14 V

(“Reference

waveform No.4: ”) Ignition switch is turned to

ST (cranking) position. Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

Terminal

No. Wire

color Circuit Normal voltage

ConditionRemarks

Page 279 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-7

Installation

Reverse removal procedure noting the following.

• Clean mating surfaces of ECT sensor and thermostat case.

• Check O-ring for damage and replace, if necessary.

• Tighten ECT sensor (1) to specified torque.

Tightening torque

ECT sensor (a): 15 N·m (1.5 kgf-m, 11.0 lb-ft)

• Connect connector to ECT sensor securely.

• Refill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

ECT Sensor InspectionS7RS0B1306009

Immerse temperature sensing part of ECT sensor (1) in

water (or ice) and measure resistance between sensor

terminals while heating water gradually.

If measured resistance doesn’t show such characteristic

as shown, replace ECT sensor.

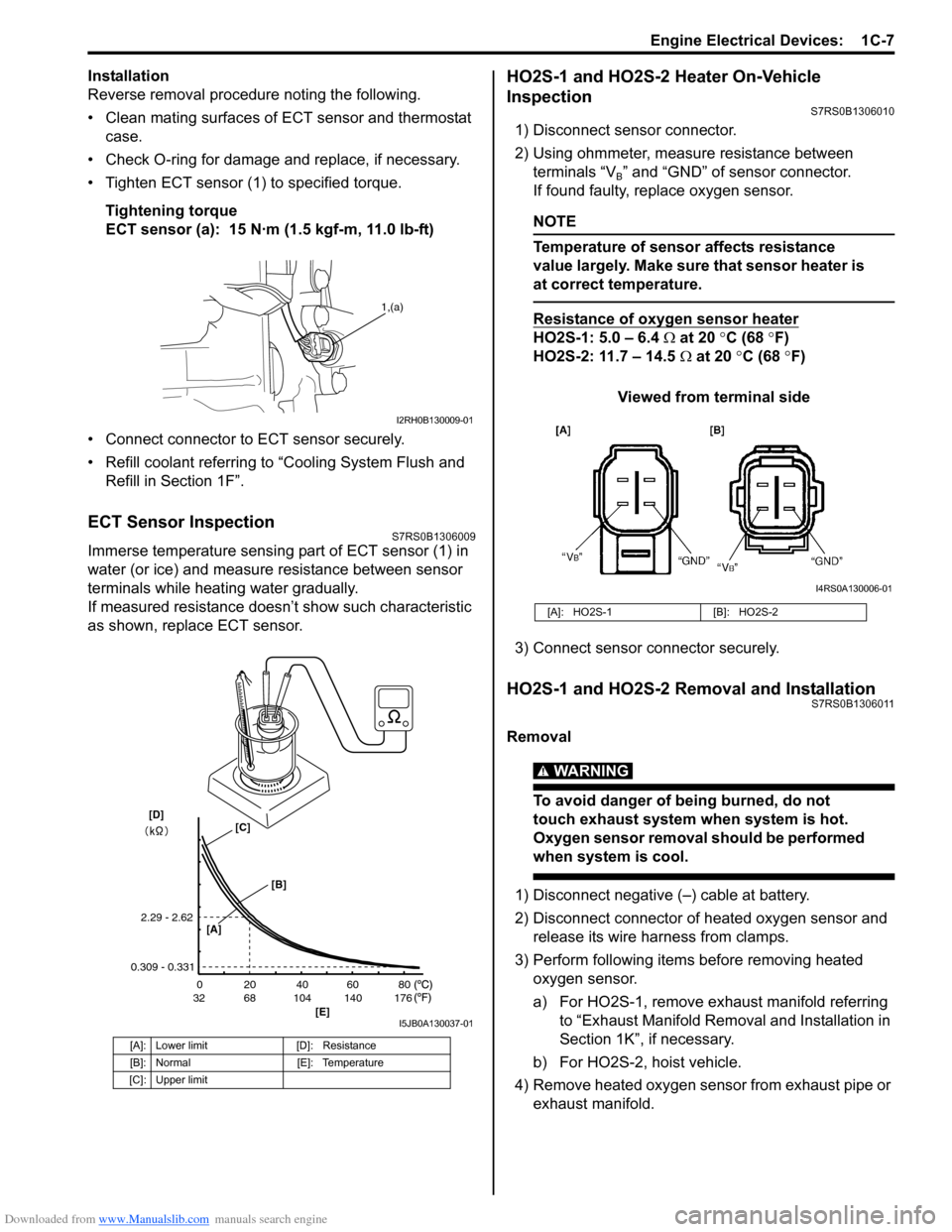

HO2S-1 and HO2S-2 Heater On-Vehicle

Inspection

S7RS0B1306010

1) Disconnect sensor connector.

2) Using ohmmeter, measure resistance between terminals “V

B” and “GND” of sensor connector.

If found faulty, replace oxygen sensor.

NOTE

Temperature of sensor affects resistance

value largely. Make sure that sensor heater is

at correct temperature.

Resistance of oxygen sensor heater

HO2S-1: 5.0 – 6.4 Ω at 20 °C (68 °F)

HO2S-2: 11.7 – 14.5 Ω at 20 °C (68 °F)

Viewed from terminal side

3) Connect sensor co nnector securely.

HO2S-1 and HO2S-2 Removal and InstallationS7RS0B1306011

Removal

WARNING!

To avoid danger of being burned, do not

touch exhaust system when system is hot.

Oxygen sensor removal should be performed

when system is cool.

1) Disconnect negative (–) cable at battery.

2) Disconnect connector of heated oxygen sensor and

release its wire harness from clamps.

3) Perform following items before removing heated oxygen sensor.

a) For HO2S-1, remove exhaust manifold referring to “Exhaust Manifold Remo val and Installation in

Section 1K”, if necessary.

b) For HO2S-2, hoist vehicle.

4) Remove heated oxygen sensor from exhaust pipe or exhaust manifold.

[A]: Lower limit [D]: Resistance

[B]: Normal [E]: Temperature

[C]: Upper limit

1,(a)

I2RH0B130009-01

20

0

68

32 104 140 176 40 60 80

[E]

2.29 - 2.62

0.309 - 0.331

[A]

[B]

[C][D]

I5JB0A130037-01

[A]: HO2S-1 [B]: HO2S-2

I4RS0A130006-01

Page 280 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-8 Engine Electrical Devices:

Installation

Reverse removal procedure noting the following.

• Tighten heated oxygen sensor to specified torque.Tightening torque

Heated oxygen sensor (a): 45 N·m (4.5 kgf-m,

32.5 lb-ft)

• Install exhaust manifold referring to “Exhaust Manifold Removal and Installation in Section 1K”, if removed.

• Connect connector of heated oxygen sensor and clamp wire harness securely.

• After installing heated oxygen sensor, start engine and check that no exhaust gas leakage exists.

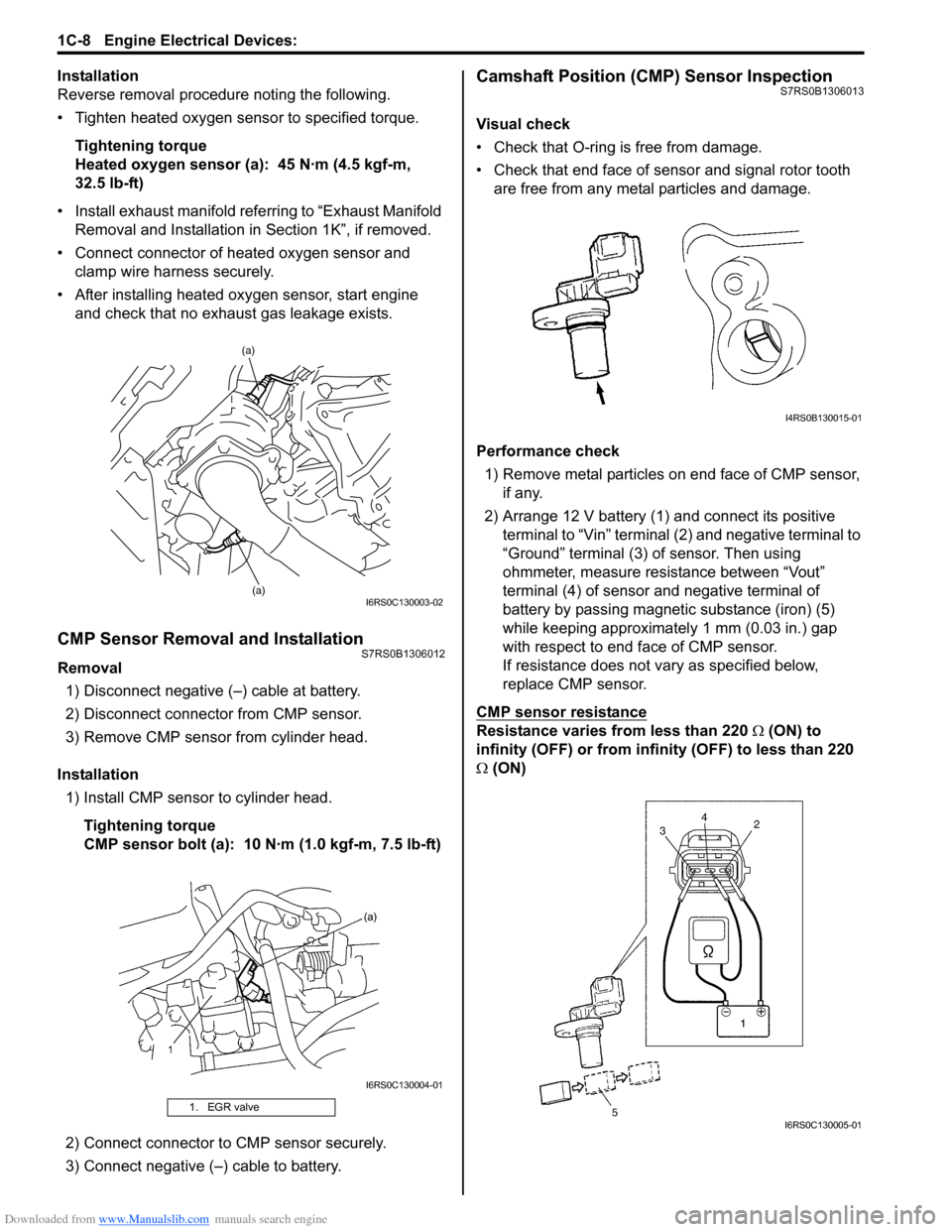

CMP Sensor Removal and InstallationS7RS0B1306012

Removal

1) Disconnect negative (–) cable at battery.

2) Disconnect connector from CMP sensor.

3) Remove CMP sensor from cylinder head.

Installation 1) Install CMP sensor to cylinder head.

Tightening torque

CMP sensor bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

2) Connect connector to CMP sensor securely.

3) Connect negative (–) cable to battery.

Camshaft Position (CMP) Sensor InspectionS7RS0B1306013

Visual check

• Check that O-ring is free from damage.

• Check that end face of sensor and signal rotor tooth are free from any metal particles and damage.

Performance check 1) Remove metal particles on end face of CMP sensor, if any.

2) Arrange 12 V battery (1) and connect its positive terminal to “Vin” terminal (2) and negative terminal to

“Ground” terminal (3) of sensor. Then using

ohmmeter, measure resistance between “Vout”

terminal (4) of sensor and negative terminal of

battery by passing magnetic substance (iron) (5)

while keeping approximately 1 mm (0.03 in.) gap

with respect to end face of CMP sensor.

If resistance does not vary as specified below,

replace CMP sensor.

CMP sensor resistance

Resistance varies from less than 220 Ω (ON) to

infinity (OFF) or from infinity (OFF) to less than 220

Ω (ON)

1. EGR valve

(a)

(a)

I6RS0C130003-02

I6RS0C130004-01

I4RS0B130015-01

I6RS0C130005-01

Page 285 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-13

Without Using SUZUKI Scan Tool1) Measure sensor voltage between “C37-23” terminal of ECM connector and vehicle body ground referring

to “Inspection of ECM and Its Circuits in Section 1A”.

If check result is satisfactory, electric load current

sensor is in good condition.

If check result is not satisfactory, check the following

parts and circuit.

• Electric load current sensor circuit (power, ground and output)

• Following charging system components – Battery (refer to “Battery Inspection in Section

1J”)

– Generator (refer to “Generator Inspection in Section 1J”)

– Generator output control circuit (refer to “Generator Test (Undercharged Battery Check)

in Section 1J”)

– Generator field coil monitor circuit (refer to “Generator Inspection in Section 1J”) If electric load current sensor circuit and charging

system is in good condition,

electric load current sensor

(1) is faulty.

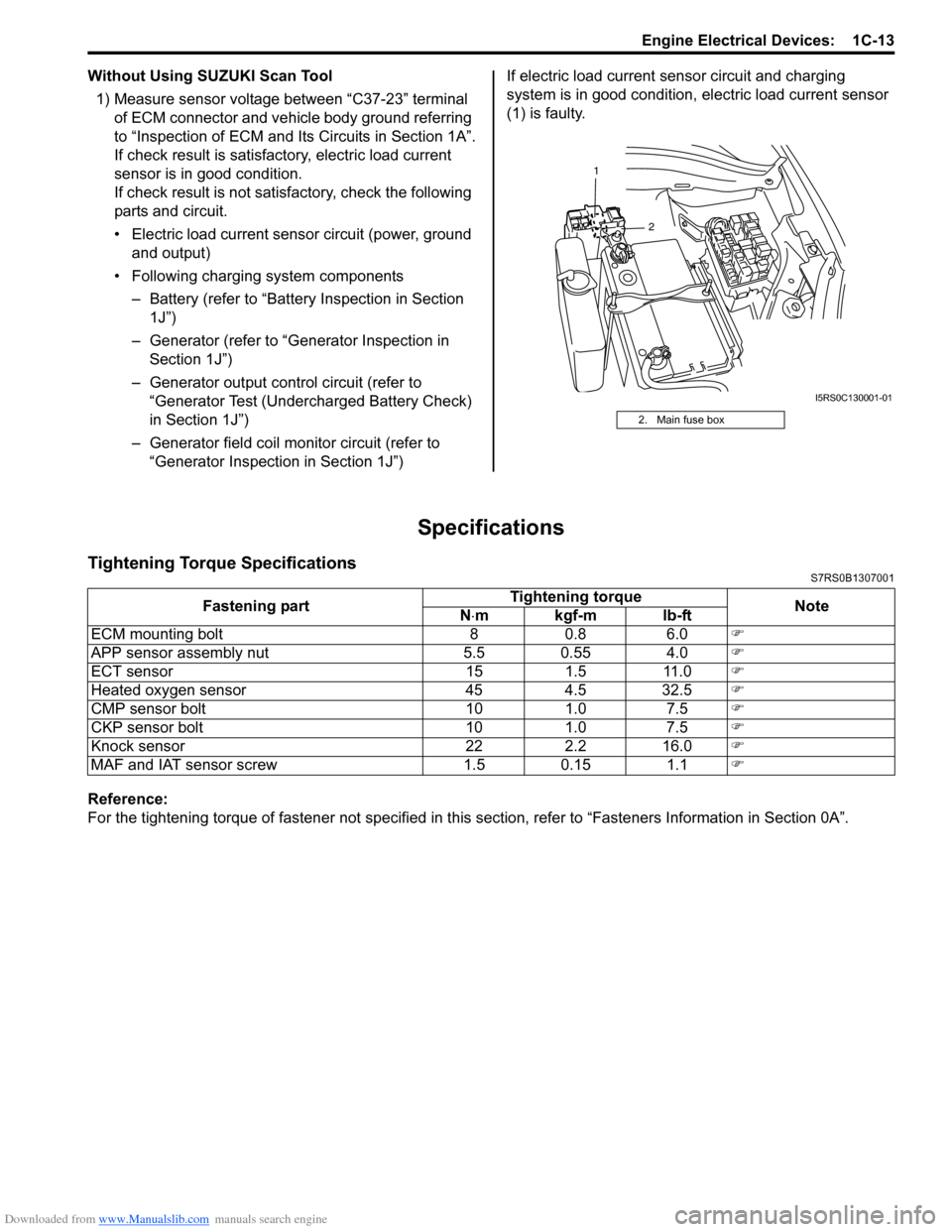

Specifications

Tightening Torque SpecificationsS7RS0B1307001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

2. Main fuse box

2

1

I5RS0C130001-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

ECM mounting bolt 8 0.8 6.0 �)

APP sensor assembly nut 5.5 0.55 4.0 �)

ECT sensor 15 1.5 11.0 �)

Heated oxygen sensor 45 4.5 32.5 �)

CMP sensor bolt 10 1.0 7.5 �)

CKP sensor bolt 10 1.0 7.5 �)

Knock sensor 22 2.2 16.0 �)

MAF and IAT sensor screw 1.5 0.15 1.1 �)

Page 302 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-17 Engine Mechanical:

Engine Assembly Removal and InstallationS7RS0B1406011

NOTE

After replacing electric throttle body

assembly, perform calibration of throttle

valve referring to “Electric Throttle Body

System Calibration in Section 1C”.

Removal1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure in Section 1G”.

2) Disconnect negative and pos itive cable at battery.

3) Remove battery and tray.

4) Remove engine hood after disconnecting windshield washer hose.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to “Compressor Drive Belt Remo val and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil, transaxle oil and coolant.

8) Remove cowl top plate referring to “Cowl Top Components in Section 9K”.

9) Remove air cleaner assembly referring to “Air Cleaner Components”.

10) With hose connected, detach A/C compressor from its bracket (A/C model) referring to “Compressor

Assembly Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

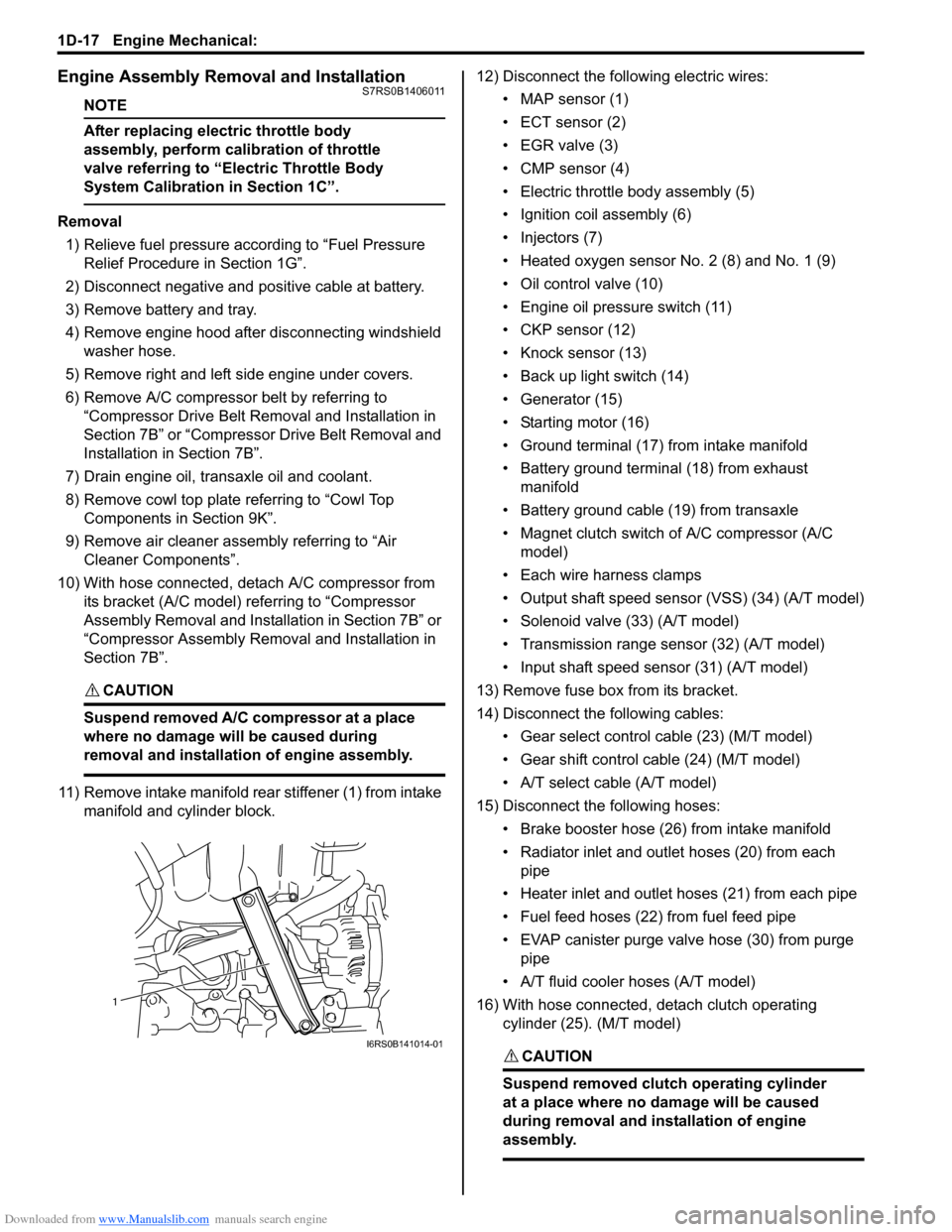

11) Remove intake manifold rear stiffener (1) from intake manifold and cylinder block. 12) Disconnect the following electric wires:

• MAP sensor (1)

• ECT sensor (2)

•EGR valve (3)

• CMP sensor (4)

• Electric throttle body assembly (5)

• Ignition coil assembly (6)

• Injectors (7)

• Heated oxygen sensor No. 2 (8) and No. 1 (9)

• Oil control valve (10)

• Engine oil pressure switch (11)

• CKP sensor (12)

• Knock sensor (13)

• Back up light switch (14)

• Generator (15)

• Starting motor (16)

• Ground terminal (17) from intake manifold

• Battery ground terminal (18) from exhaust manifold

• Battery ground cable (19) from transaxle

• Magnet clutch switch of A/C compressor (A/C model)

• Each wire harness clamps

• Output shaft speed sensor (VSS) (34) (A/T model)

• Solenoid valve (33) (A/T model)

• Transmission range sensor (32) (A/T model)

• Input shaft speed sensor (31) (A/T model)

13) Remove fuse box from its bracket.

14) Disconnect the following cables: • Gear select control cable (23) (M/T model)

• Gear shift control cable (24) (M/T model)

• A/T select cable (A/T model)

15) Disconnect the following hoses: • Brake booster hose (26) from intake manifold

• Radiator inlet and outlet hoses (20) from each pipe

• Heater inlet and outlet hoses (21) from each pipe

• Fuel feed hoses (22) from fuel feed pipe

• EVAP canister purge valve hose (30) from purge pipe

• A/T fluid cooler hoses (A/T model)

16) With hose connected, detach clutch operating cylinder (25). (M/T model)

CAUTION!

Suspend removed clutch operating cylinder

at a place where no damage will be caused

during removal and installation of engine

assembly.

1

I6RS0B141014-01

Page 357 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-5

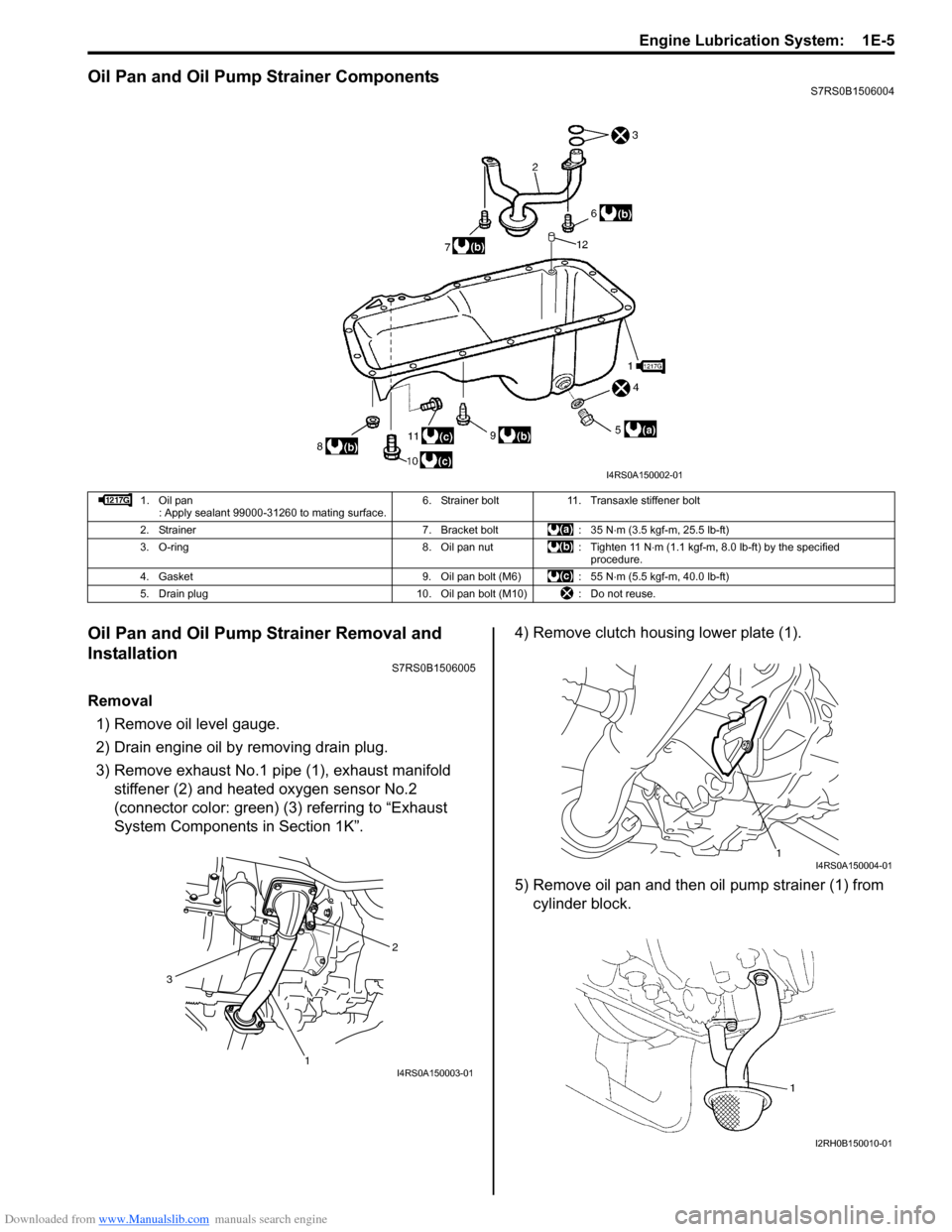

Oil Pan and Oil Pump Strainer ComponentsS7RS0B1506004

Oil Pan and Oil Pump Strainer Removal and

Installation

S7RS0B1506005

Removal1) Remove oil level gauge.

2) Drain engine oil by removing drain plug.

3) Remove exhaust No.1 pipe (1), exhaust manifold stiffener (2) and heated oxygen sensor No.2

(connector color: green) (3) referring to “Exhaust

System Components in Section 1K”. 4) Remove clutch housing lower plate (1).

5) Remove oil pan and then oil pump strainer (1) from

cylinder block.

I4RS0A150002-01

1. Oil pan : Apply sealant 99000-31260 to mating surface. 6. Strainer bolt 11. Transaxle stiffener bolt

2. Strainer 7. Bracket bolt : 35 N ⋅m (3.5 kgf-m, 25.5 lb-ft)

3. O-ring 8. Oil pan nut : Tighten 11 N ⋅m (1.1 kgf-m, 8.0 lb-ft) by the specified

procedure.

4. Gasket 9. Oil pan bolt (M6) : 55 N ⋅m (5.5 kgf-m, 40.0 lb-ft)

5. Drain plug 10. Oil pan bolt (M10) : Do not reuse.

2

1

3

I4RS0A150003-01

1I4RS0A150004-01

I2RH0B150010-01

Page 359 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-7

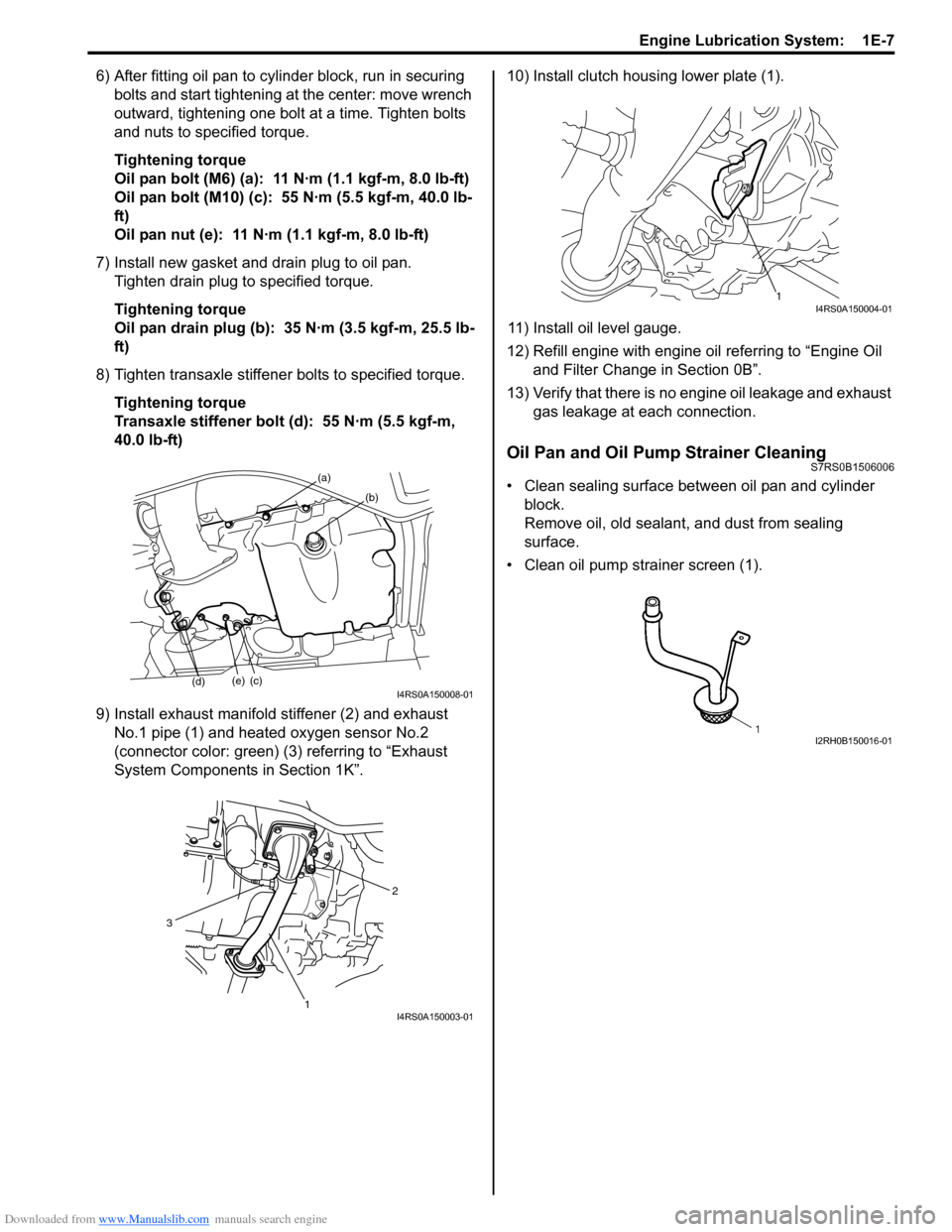

6) After fitting oil pan to cylinder block, run in securing bolts and start tightening at the center: move wrench

outward, tightening one bolt at a time. Tighten bolts

and nuts to specified torque.

Tightening torque

Oil pan bolt (M6) (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

Oil pan bolt (M10) (c): 55 N·m (5.5 kgf-m, 40.0 lb-

ft)

Oil pan nut (e): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

7) Install new gasket and drain plug to oil pan. Tighten drain plug to specified torque.

Tightening torque

Oil pan drain plug (b): 35 N·m (3.5 kgf-m, 25.5 lb-

ft)

8) Tighten transaxle stiffener bolts to specified torque. Tightening torque

Transaxle stiffener bolt (d): 55 N·m (5.5 kgf-m,

40.0 lb-ft)

9) Install exhaust manifold stiffener (2) and exhaust No.1 pipe (1) and heated oxygen sensor No.2

(connector color: green) (3) referring to “Exhaust

System Components in Section 1K”. 10) Install clutch housing lower plate (1).

11) Install oil level gauge.

12) Refill engine with engine oil referring to “Engine Oil

and Filter Change in Section 0B”.

13) Verify that there is no en gine oil leakage and exhaust

gas leakage at each connection.

Oil Pan and Oil Pump Strainer CleaningS7RS0B1506006

• Clean sealing surface between oil pan and cylinder block.

Remove oil, old sealant, and dust from sealing

surface.

• Clean oil pump strainer screen (1).(a)

(b)

(c)(e)

(d)I4RS0A150008-01

2

1

3

I4RS0A150003-01

1I4RS0A150004-01

I2RH0B150016-01

Page 425 of 1496

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-2

Repair Instructions

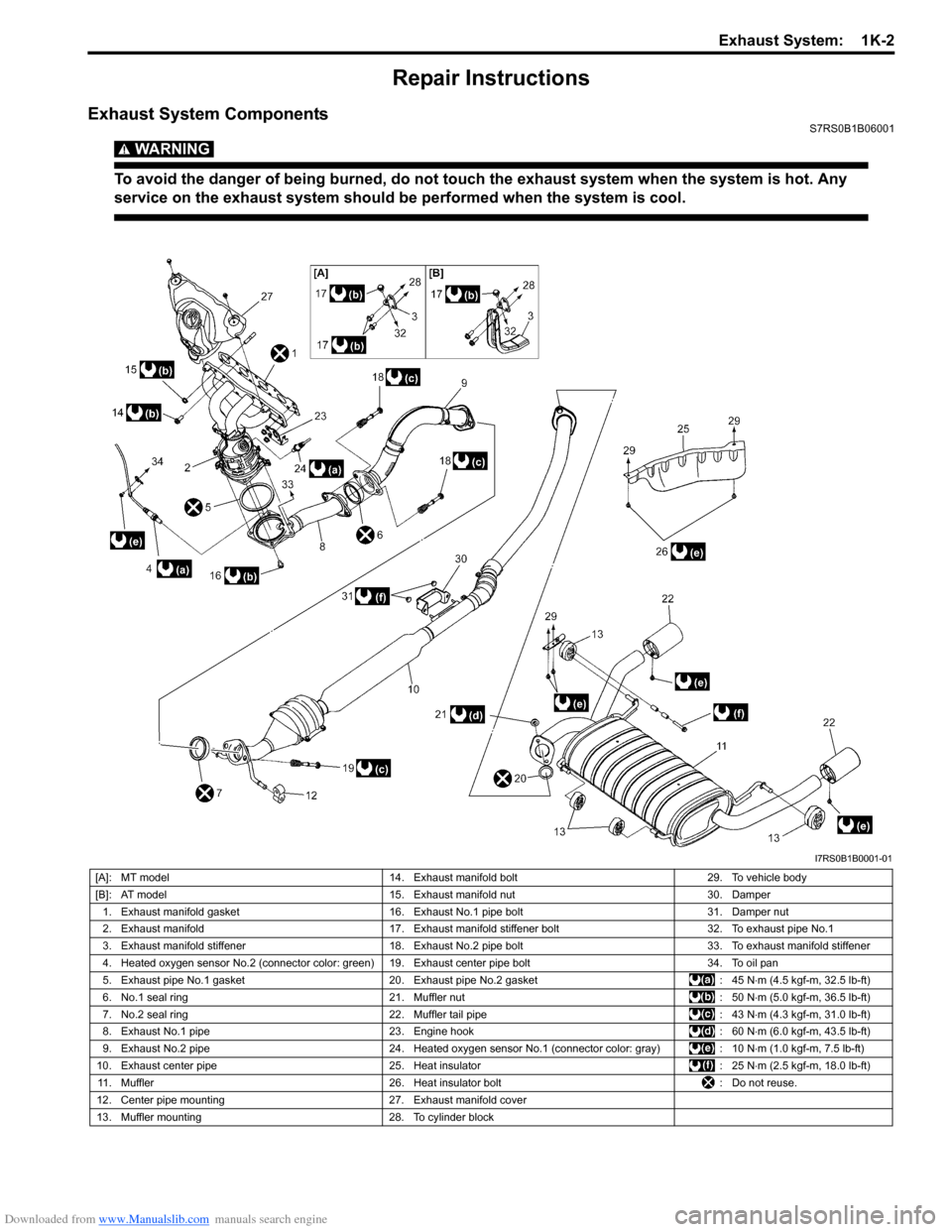

Exhaust System ComponentsS7RS0B1B06001

WARNING!

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

I7RS0B1B0001-01

[A]: MT model14. Exhaust manifold bolt 29. To vehicle body

[B]: AT model 15. Exhaust manifold nut 30. Damper

1. Exhaust manifold gasket 16. Exhaust No.1 pipe bolt 31. Damper nut

2. Exhaust manifold 17. Exhaust manifold stiffener bolt 32. To exhaust pipe No.1

3. Exhaust manifold stiffener 18. Exhaust No.2 pipe bolt 33. To exhaust manifold stiffener

4. Heated oxygen sensor No.2 (connector color: green) 19. Exhaust center pipe bolt 34. To oil pan

5. Exhaust pipe No.1 gasket 20. Exhaust pipe No.2 gasket : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

6. No.1 seal ring 21. Muffler nut : 50 N⋅m (5.0 kgf-m, 36.5 lb-ft)

7. No.2 seal ring 22. Muffler tail pipe : 43 N⋅m (4.3 kgf-m, 31.0 lb-ft)

8. Exhaust No.1 pipe 23. Engine hook : 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

9. Exhaust No.2 pipe 24. Heated oxygen sensor No.1 (connector color: gray) : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

10. Exhaust center pipe 25. Heat insulator : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

11. Muffler 26. Heat insulator bolt : Do not reuse.

12. Center pipe mounting 27. Exhaust manifold cover

13. Muffler mounting 28. To cylinder block

Page 426 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-3 Exhaust System:

Exhaust Manifold Removal and InstallationS7RS0B1B06002

Removal

WARNING!

To avoid danger of being burned, do not

service exhaust system while it is still hot.

Service should be performed after system

cools down.

1) Disconnect negative cable at battery.

2) Remove engine cover.

3) Remove front bumper with front grille referring to

“Front Bumper and Rear Bumper Components in

Section 9K”.

4) Remove radiator referring to “Radiator Removal and Installation in Section 1F ” for equipped with A/C.

5) With hose connected, detach A/C condenser from vehicle body for equipped with A/C.

6) Remove exhaust manifold cover from exhaust manifold.

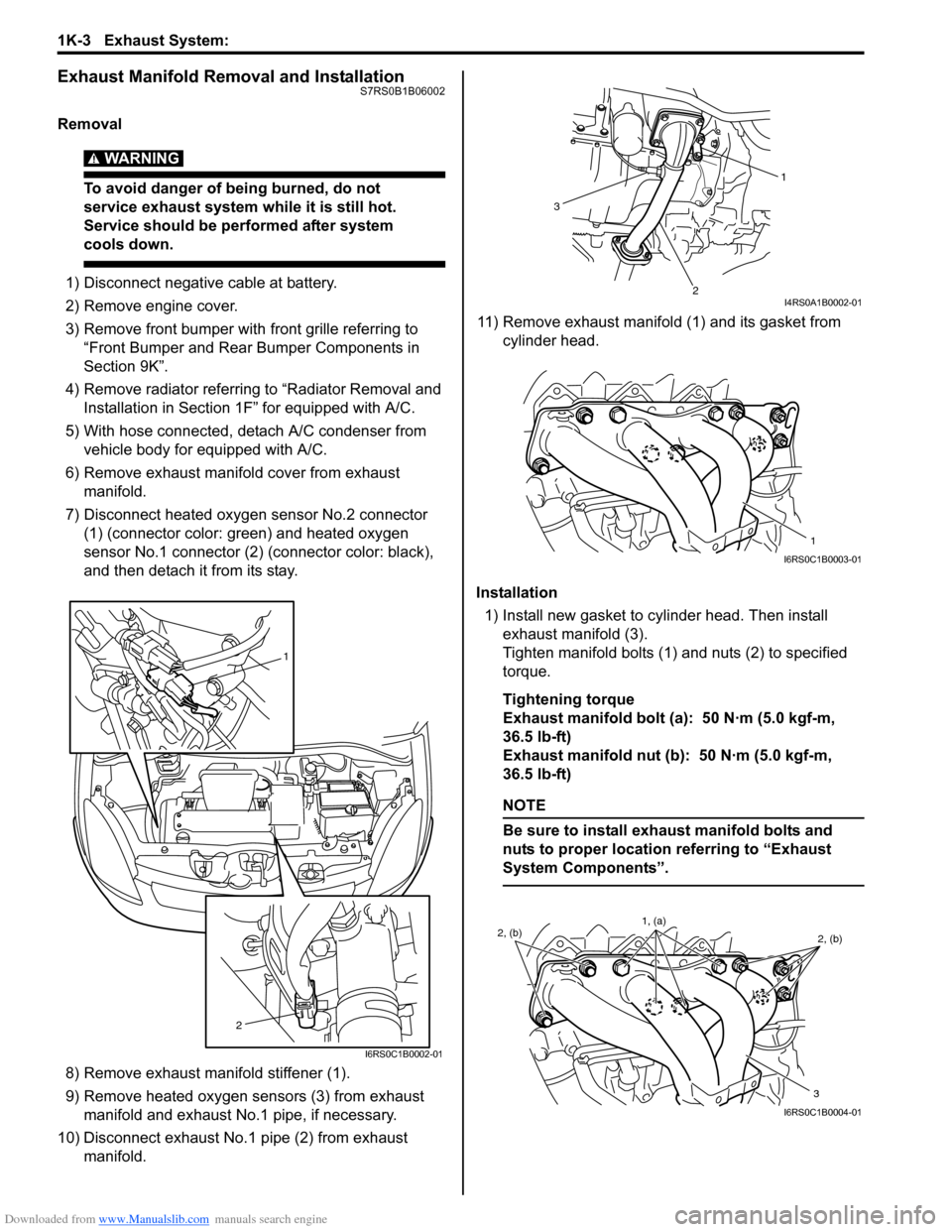

7) Disconnect heated oxygen sensor No.2 connector (1) (connector color: green) and heated oxygen

sensor No.1 connector (2) (connector color: black),

and then detach it from its stay.

8) Remove exhaust manifold stiffener (1).

9) Remove heated oxygen sensors (3) from exhaust manifold and exhaust No.1 pipe, if necessary.

10) Disconnect exhaust No.1 pipe (2) from exhaust manifold. 11) Remove exhaust manifold (1) and its gasket from

cylinder head.

Installation 1) Install new gasket to cylinder head. Then install exhaust manifold (3).

Tighten manifold bolts (1) and nuts (2) to specified

torque.

Tightening torque

Exhaust manifold bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

Exhaust manifold nut (b): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

NOTE

Be sure to install exhaust manifold bolts and

nuts to proper location referring to “Exhaust

System Components”.

1

2

I6RS0C1B0002-01

1

2

3

I4RS0A1B0002-01

1

I6RS0C1B0003-01

2, (b) 2, (b)

3

1, (a)

I6RS0C1B0004-01

Page 427 of 1496

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-4

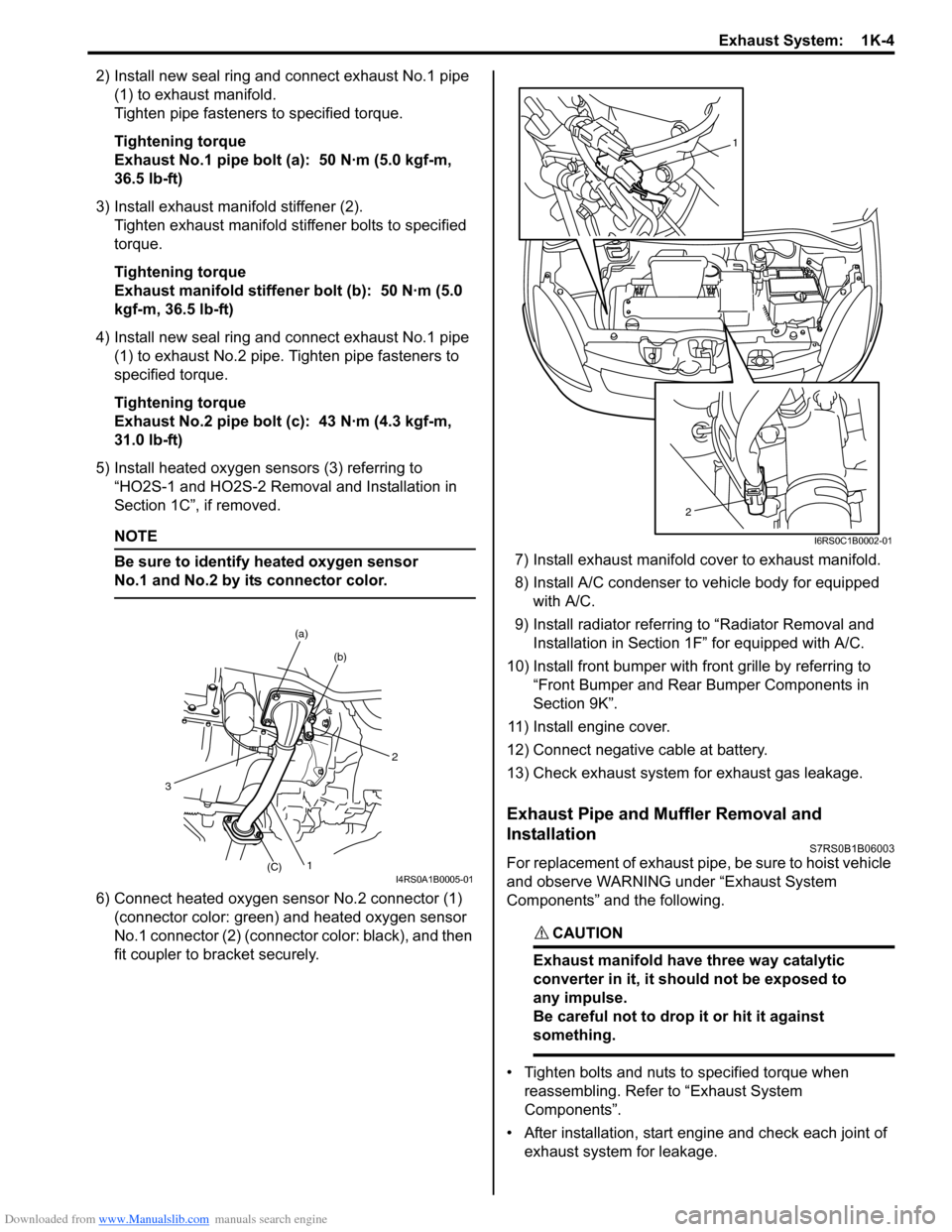

2) Install new seal ring and connect exhaust No.1 pipe (1) to exhaust manifold.

Tighten pipe fasteners to specified torque.

Tightening torque

Exhaust No.1 pipe bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

3) Install exhaust manifold stiffener (2). Tighten exhaust manifold stiffener bolts to specified

torque.

Tightening torque

Exhaust manifold stiffener bolt (b): 50 N·m (5.0

kgf-m, 36.5 lb-ft)

4) Install new seal ring and connect exhaust No.1 pipe (1) to exhaust No.2 pipe. Tighten pipe fasteners to

specified torque.

Tightening torque

Exhaust No.2 pipe bolt (c): 43 N·m (4.3 kgf-m,

31.0 lb-ft)

5) Install heated oxygen sensors (3) referring to “HO2S-1 and HO2S-2 Removal and Installation in

Section 1C”, if removed.

NOTE

Be sure to identify heated oxygen sensor

No.1 and No.2 by its connector color.

6) Connect heated oxygen sensor No.2 connector (1)

(connector color: green) and heated oxygen sensor

No.1 connector (2) (connector color: black), and then

fit coupler to br acket securely. 7) Install exhaust manifold cover to exhaust manifold.

8) Install A/C condenser to vehicle body for equipped

with A/C.

9) Install radiator referrin g to “Radiator Removal and

Installation in Section 1F” for equipped with A/C.

10) Install front bumper with fr ont grille by referring to

“Front Bumper and Rear Bumper Components in

Section 9K”.

11) Install engine cover.

12) Connect negative cable at battery.

13) Check exhaust system for exhaust gas leakage.

Exhaust Pipe and Muffler Removal and

Installation

S7RS0B1B06003

For replacement of exhaust pipe, be sure to hoist vehicle

and observe WARNING under “Exhaust System

Components” and the following.

CAUTION!

Exhaust manifold have three way catalytic

converter in it, it should not be exposed to

any impulse.

Be careful not to drop it or hit it against

something.

• Tighten bolts and nuts to specified torque when reassembling. Refer to “Exhaust System

Components”.

• After installation, start engine and check each joint of exhaust system for leakage.

2

(b)

(a)

1(C)

3

I4RS0A1B0005-01

1

2

I6RS0C1B0002-01