Panel SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 511 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-13

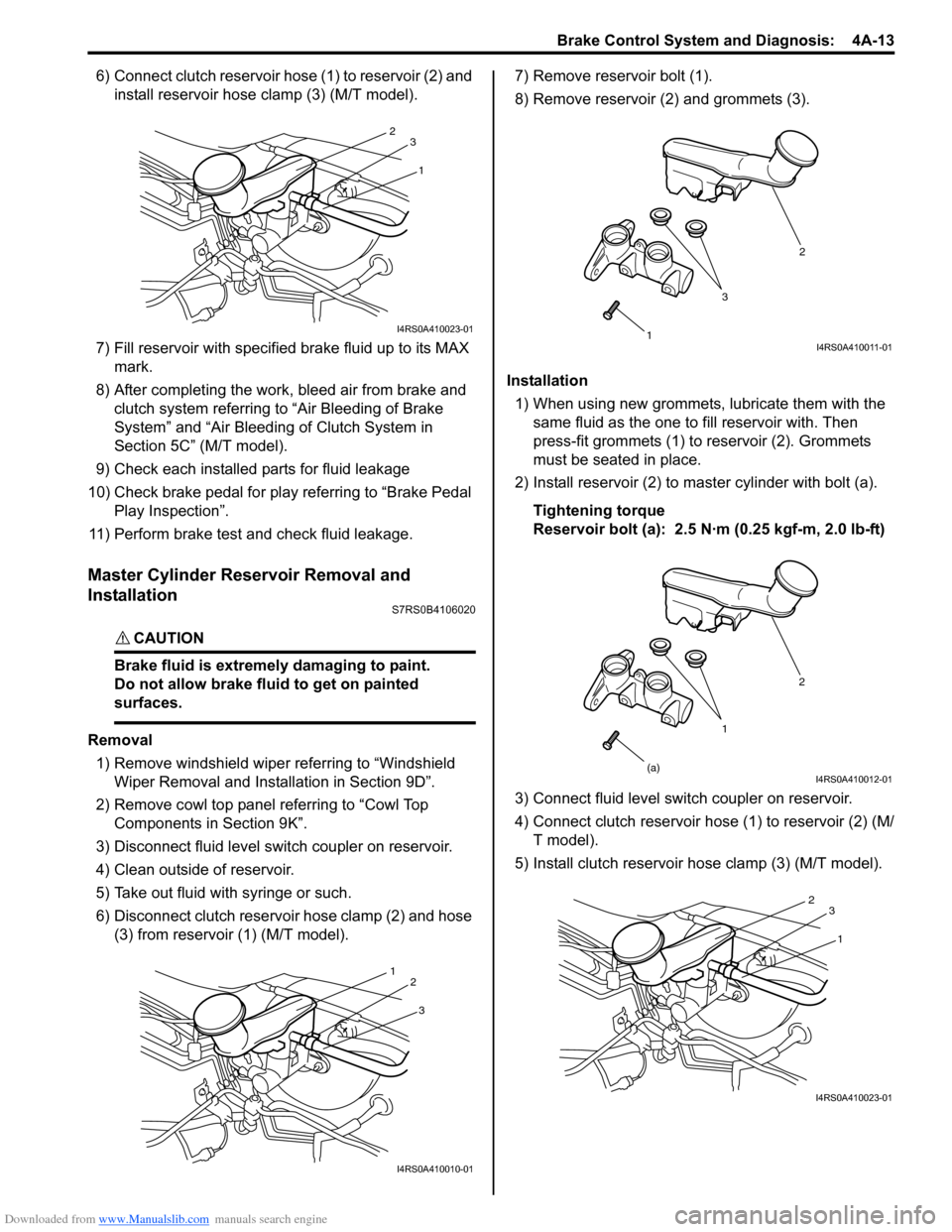

6) Connect clutch reservoir hose (1) to reservoir (2) and install reservoir hose clamp (3) (M/T model).

7) Fill reservoir with specified brake fluid up to its MAX

mark.

8) After completing the work, bleed air from brake and clutch system referring to “Air Bleeding of Brake

System” and “Air Bleeding of Clutch System in

Section 5C” (M/T model).

9) Check each installed parts for fluid leakage

10) Check brake pedal for play referring to “Brake Pedal Play Inspection”.

11) Perform brake test and check fluid leakage.

Master Cylinder Reservoir Removal and

Installation

S7RS0B4106020

CAUTION!

Brake fluid is extremely damaging to paint.

Do not allow brake fluid to get on painted

surfaces.

Removal 1) Remove windshield wiper referring to “Windshield Wiper Removal and Insta llation in Section 9D”.

2) Remove cowl top panel referring to “Cowl Top Components in Section 9K”.

3) Disconnect fluid level s witch coupler on reservoir.

4) Clean outside of reservoir.

5) Take out fluid with syringe or such.

6) Disconnect clutch reservoir hose clamp (2) and hose (3) from reservoir (1) (M/T model). 7) Remove reservoir bolt (1).

8) Remove reservoir (2) and grommets (3).

Installation 1) When using new grommets, lubricate them with the same fluid as the one to fill reservoir with. Then

press-fit grommets (1) to reservoir (2). Grommets

must be seated in place.

2) Install reservoir (2) to master cylinder with bolt (a).

Tightening torque

Reservoir bolt (a): 2.5 N·m (0.25 kgf-m, 2.0 lb-ft)

3) Connect fluid level switch coupler on reservoir.

4) Connect clutch reservoir hose (1) to reservoir (2) (M/ T model).

5) Install clutch reservoir hose clamp (3) (M/T model).

1

2

3

I4RS0A410023-01

3

1

2

I4RS0A410010-01

1 2

3I4RS0A410011-01

1 2

(a)

I4RS0A410012-01

1

2

3

I4RS0A410023-01

Page 512 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-14 Brake Control System and Diagnosis:

6) Fill reservoir with specified fluid.

7) After completing the work, bleed air from brake and clutch system referring to “Air Bleeding of Brake

System” and “Air Bleeding of Clutch System in

Section 5C” (M/T model).

8) Install cowl top panel referring to “Cowl Top Components in Section 9K”.

9) Install windshield wiper referring to “Windshield

Wiper Removal and Insta llation in Section 9D”.

10) Perform brake test and check each installed part for fluid leakage.

Master Cylinder Assembly Disassembly and

Assembly

S7RS0B4106013

Disassembly

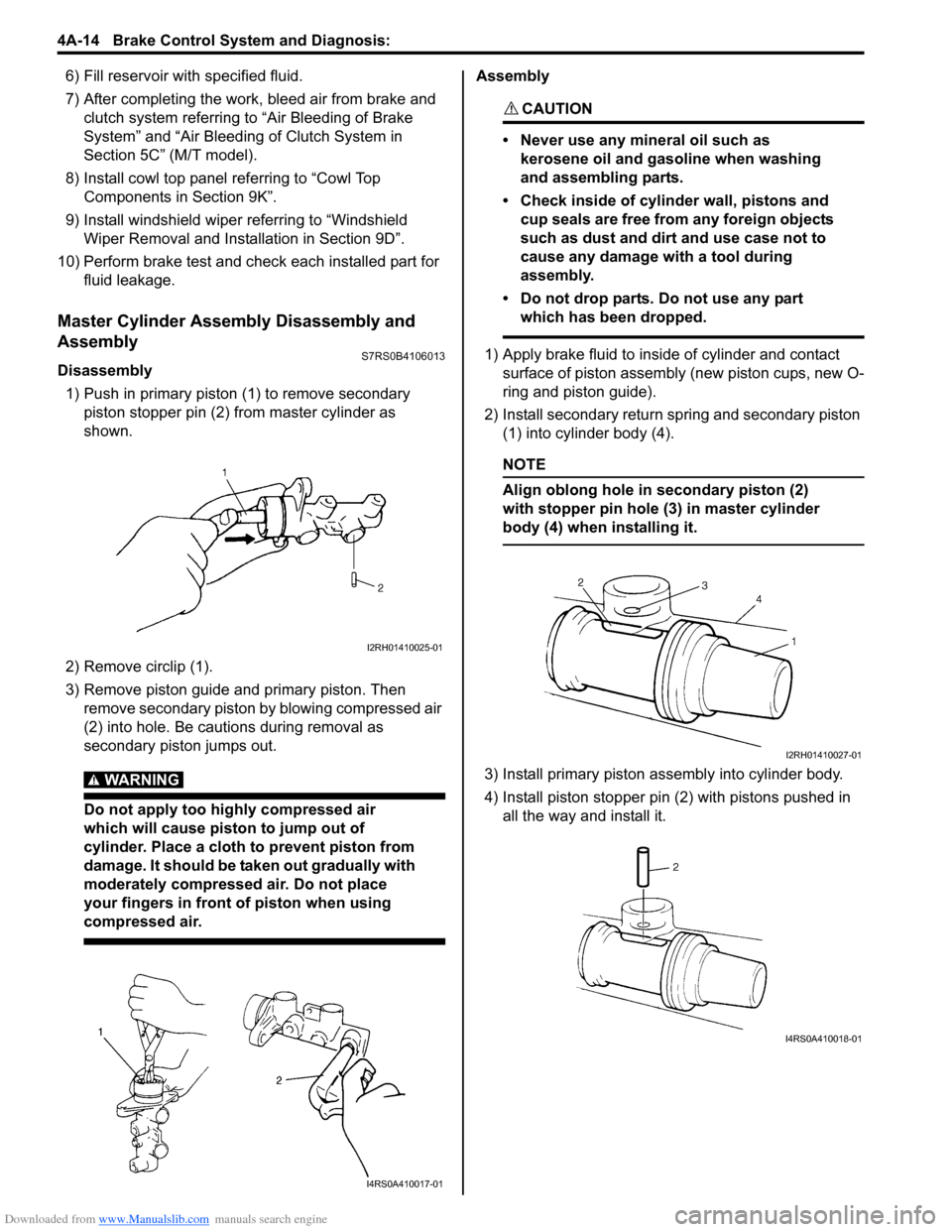

1) Push in primary piston (1) to remove secondary

piston stopper pin (2) from master cylinder as

shown.

2) Remove circlip (1).

3) Remove piston guide and primary piston. Then remove secondary piston by blowing compressed air

(2) into hole. Be cautions during removal as

secondary piston jumps out.

WARNING!

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. Place a cloth to prevent piston from

damage. It should be taken out gradually with

moderately compressed air. Do not place

your fingers in front of piston when using

compressed air.

Assembly

CAUTION!

• Never use any mineral oil such as kerosene oil and gasoline when washing

and assembling parts.

• Check inside of cylinder wall, pistons and cup seals are free from any foreign objects

such as dust and dirt and use case not to

cause any damage with a tool during

assembly.

• Do not drop parts. Do not use any part which has been dropped.

1) Apply brake fluid to inside of cylinder and contact surface of piston assembly (new piston cups, new O-

ring and piston guide).

2) Install secondary return spring and secondary piston (1) into cylinder body (4).

NOTE

Align oblong hole in secondary piston (2)

with stopper pin hole (3) in master cylinder

body (4) when installing it.

3) Install primary piston assembly into cylinder body.

4) Install piston stopper pin (2) with pistons pushed in all the way and install it.

I2RH01410025-01

I4RS0A410017-01

I2RH01410027-01

I4RS0A410018-01

Page 515 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-17

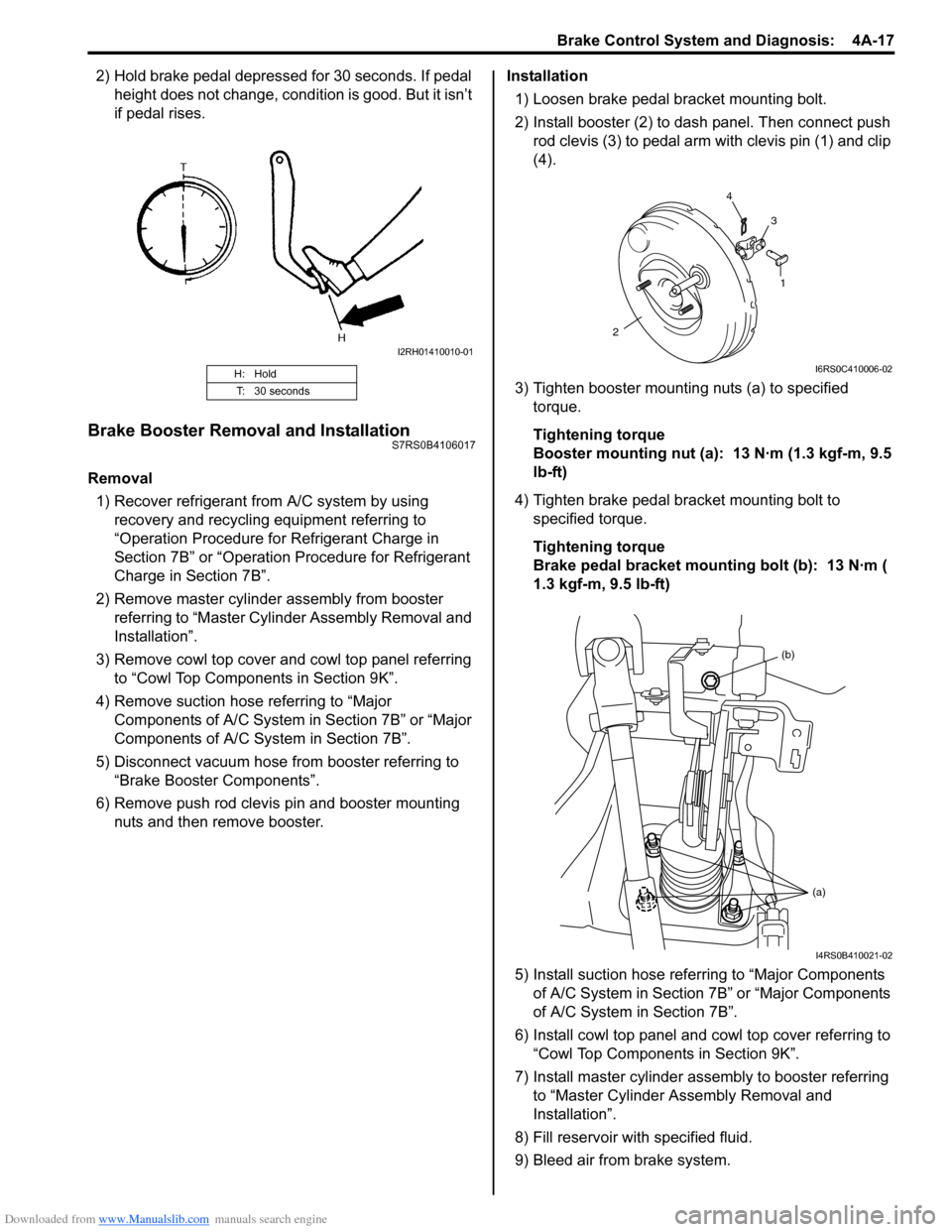

2) Hold brake pedal depressed for 30 seconds. If pedal height does not change, condition is good. But it isn’t

if pedal rises.

Brake Booster Removal and InstallationS7RS0B4106017

Removal

1) Recover refrigerant from A/C system by using recovery and recycling equipment referring to

“Operation Procedure for Refrigerant Charge in

Section 7B” or “Operation Procedure for Refrigerant

Charge in Section 7B”.

2) Remove master cylinder assembly from booster referring to “Master Cylin der Assembly Removal and

Installation”.

3) Remove cowl top cover and cowl top panel referring to “Cowl Top Components in Section 9K”.

4) Remove suction hose referring to “Major Components of A/C System in Section 7B” or “Major

Components of A/C System in Section 7B”.

5) Disconnect vacuum hose from booster referring to “Brake Booster Components”.

6) Remove push rod clevis pin and booster mounting nuts and then remove booster. Installation

1) Loosen brake pedal bracket mounting bolt.

2) Install booster (2) to dash panel. Then connect push rod clevis (3) to pedal arm with clevis pin (1) and clip

(4).

3) Tighten booster mounting nuts (a) to specified torque.

Tightening torque

Booster mounting nut (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft)

4) Tighten brake pedal bracket mounting bolt to specified torque.

Tightening torque

Brake pedal bracket mounting bolt (b): 13 N·m (

1.3 kgf-m, 9.5 lb-ft)

5) Install suction hose referring to “Major Components of A/C System in Section 7B” or “Major Components

of A/C System in Section 7B”.

6) Install cowl top panel and cowl top cover referring to

“Cowl Top Components in Section 9K”.

7) Install master cylinder assembly to booster referring to “Master Cylinder Assembly Removal and

Installation”.

8) Fill reservoir with specified fluid.

9) Bleed air from brake system.

H: Hold

T: 30 seconds

I2RH01410010-01

1

2 4

3

I6RS0C410006-02

(b)

(a)

I4RS0B410021-02

Page 638 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-64 Electronic Stability Program:

Removal1) Disconnect negative (–) cable at battery.

2) Remove front console box referring to “Console Box Components in Section 9H”.

3) Disconnect connector from yaw rate / G sensor

assembly.

4) Remove yaw rate / G sens or assembly from sensor

bracket.

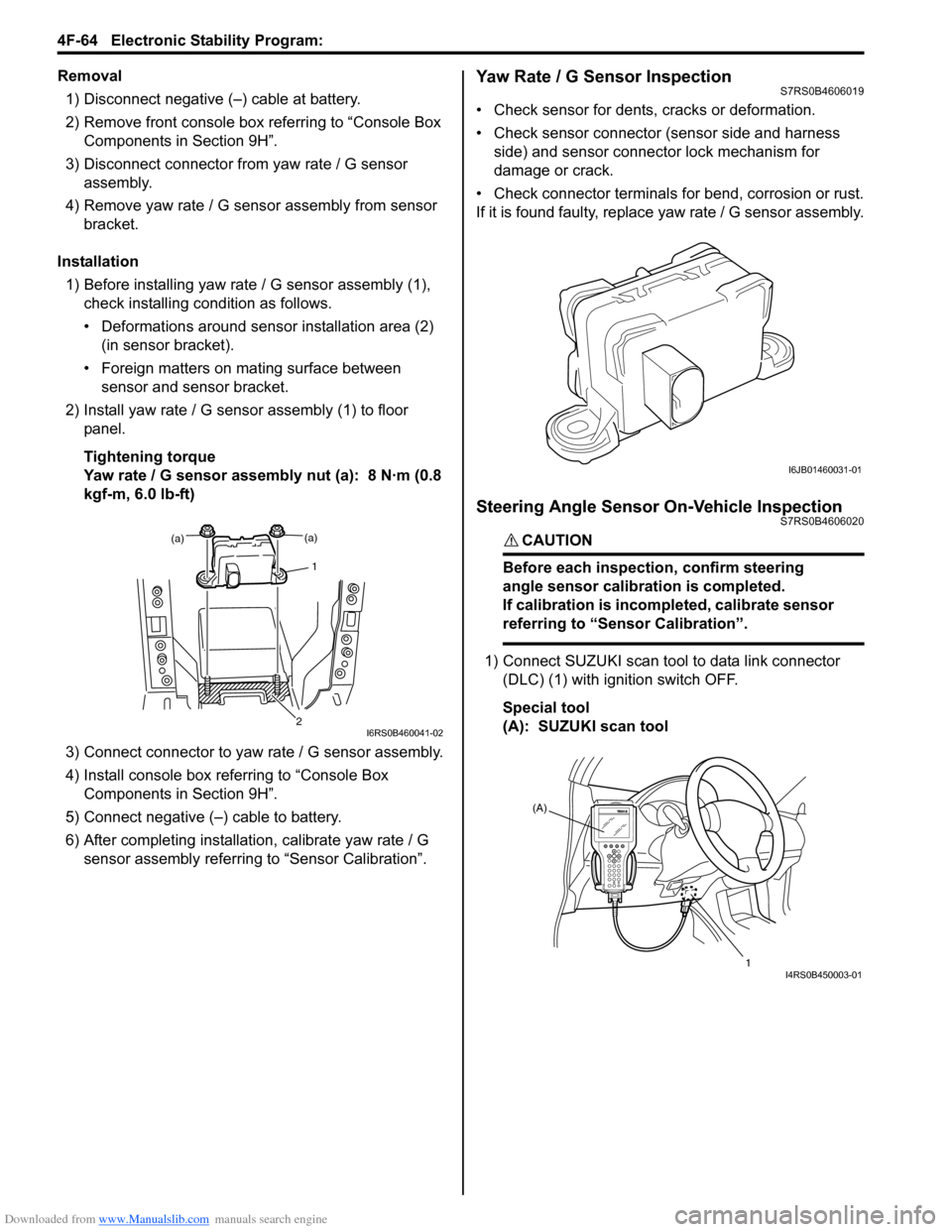

Installation 1) Before installing yaw rate / G sensor assembly (1),

check installing condition as follows.

• Deformations around sensor installation area (2) (in sensor bracket).

• Foreign matters on mating surface between sensor and sensor bracket.

2) Install yaw rate / G sensor assembly (1) to floor panel.

Tightening torque

Yaw rate / G sensor assembly nut (a): 8 N·m (0.8

kgf-m, 6.0 lb-ft)

3) Connect connector to yaw rate / G sensor assembly.

4) Install console box referring to “Console Box Components in Section 9H”.

5) Connect negative (–) cable to battery.

6) After completing installation, calibrate yaw rate / G

sensor assembly referring to “Sensor Calibration”.Yaw Rate / G Sensor InspectionS7RS0B4606019

• Check sensor for dents, cracks or deformation.

• Check sensor connector (sensor side and harness

side) and sensor connector lock mechanism for

damage or crack.

• Check connector terminals for bend, corrosion or rust.

If it is found faulty, replace yaw rate / G sensor assembly.

Steering Angle Sensor On-Vehicle InspectionS7RS0B4606020

CAUTION!

Before each inspection, confirm steering

angle sensor calibration is completed.

If calibration is incompleted, calibrate sensor

referring to “Sensor Calibration”.

1) Connect SUZUKI scan tool to data link connector

(DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

(a)

1

(a)

2I6RS0B460041-02

I6JB01460031-01

(A)

1

I4RS0B450003-01

Page 736 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-92 Automatic Transmission/Transaxle:

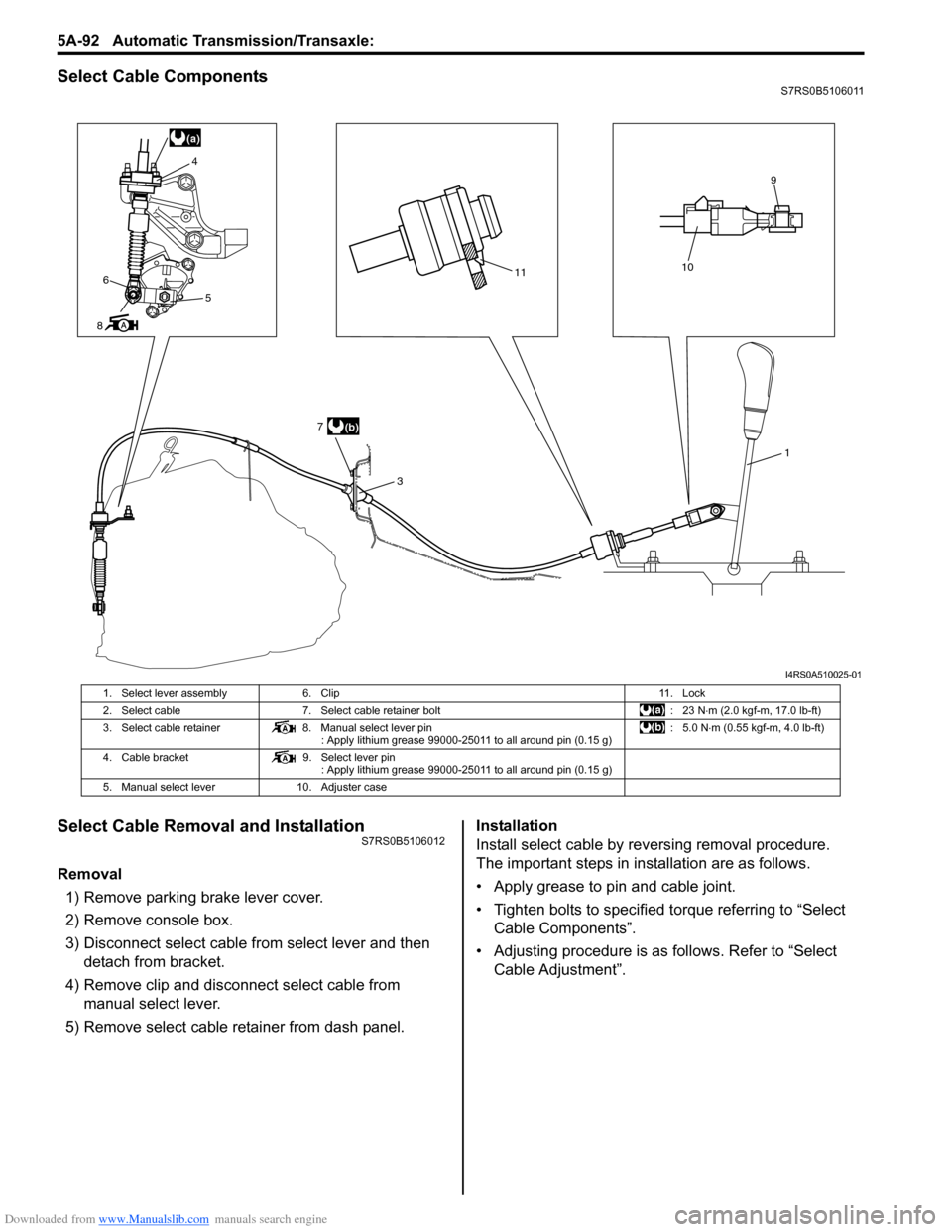

Select Cable ComponentsS7RS0B5106011

Select Cable Removal and InstallationS7RS0B5106012

Removal

1) Remove parking brake lever cover.

2) Remove console box.

3) Disconnect select cable from select lever and then detach from bracket.

4) Remove clip and disconnect select cable from manual select lever.

5) Remove select cable retainer from dash panel. Installation

Install select cable by reversing removal procedure.

The important steps in inst

allation are as follows.

• Apply grease to pin and cable joint.

• Tighten bolts to specified torque referring to “Select Cable Components”.

• Adjusting procedure is as follows. Refer to “Select Cable Adjustment”.

(a)

11

3

10

9

6

8 4

5

(b)

7

1

I4RS0A510025-01

1. Select lever assembly

6. Clip 11. Lock

2. Select cable 7. Select cable retainer bolt : 23 N⋅m (2.0 kgf-m, 17.0 lb-ft)

3. Select cable retainer 8. Manual select lever pin

: Apply lithium grease 99000-25011 to all around pin (0.15 g) :5.0 N

⋅m (0.55 kgf-m, 4.0 lb-ft)

4. Cable bracket 9. Select lever pin

: Apply lithium grease 99000-25011 to all around pin (0.15 g)

5. Manual select lever 10. Adjuster case

Page 820 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-6 Manual Transmission/Transaxle:

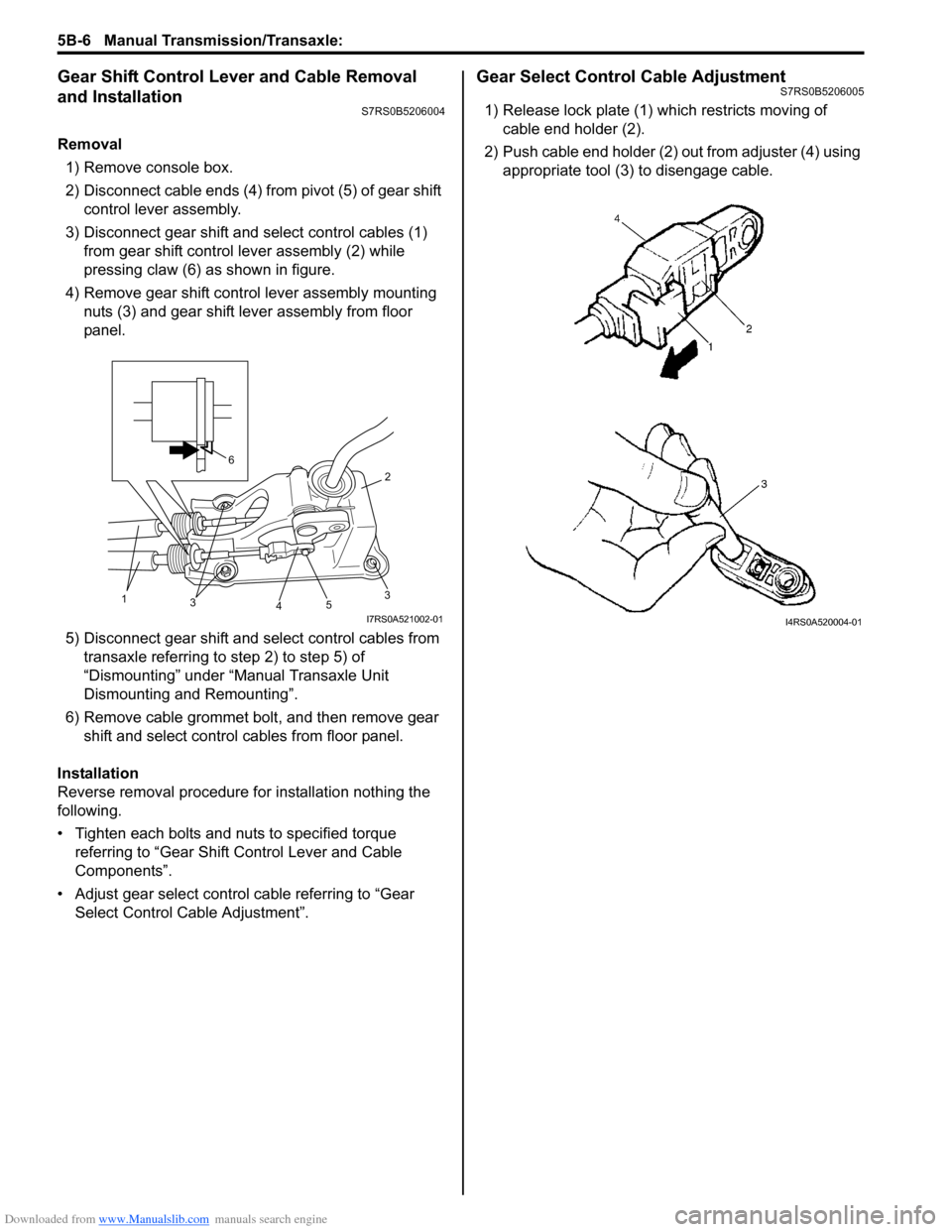

Gear Shift Control Lever and Cable Removal

and Installation

S7RS0B5206004

Removal1) Remove console box.

2) Disconnect cable ends (4) from pivot (5) of gear shift control lever assembly.

3) Disconnect gear shift and select control cables (1) from gear shift control lever assembly (2) while

pressing claw (6) as shown in figure.

4) Remove gear shift control lever assembly mounting nuts (3) and gear shift lever assembly from floor

panel.

5) Disconnect gear shift and select control cables from transaxle referring to step 2) to step 5) of

“Dismounting” under “Manual Transaxle Unit

Dismounting and Remounting”.

6) Remove cable grommet bolt, and then remove gear shift and select control cables from floor panel.

Installation

Reverse removal procedure for installation nothing the

following.

• Tighten each bolts and nuts to specified torque referring to “Gear Shift Control Lever and Cable

Components”.

• Adjust gear select control cable referring to “Gear Select Control Cable Adjustment”.

Gear Select Control Cable AdjustmentS7RS0B5206005

1) Release lock plate (1) which restricts moving of cable end holder (2).

2) Push cable end holder (2) out from adjuster (4) using appropriate tool (3) to disengage cable.

35

4

2

31

6

I7RS0A521002-01I4RS0A520004-01

Page 878 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-7 Steering Wheel and Column:

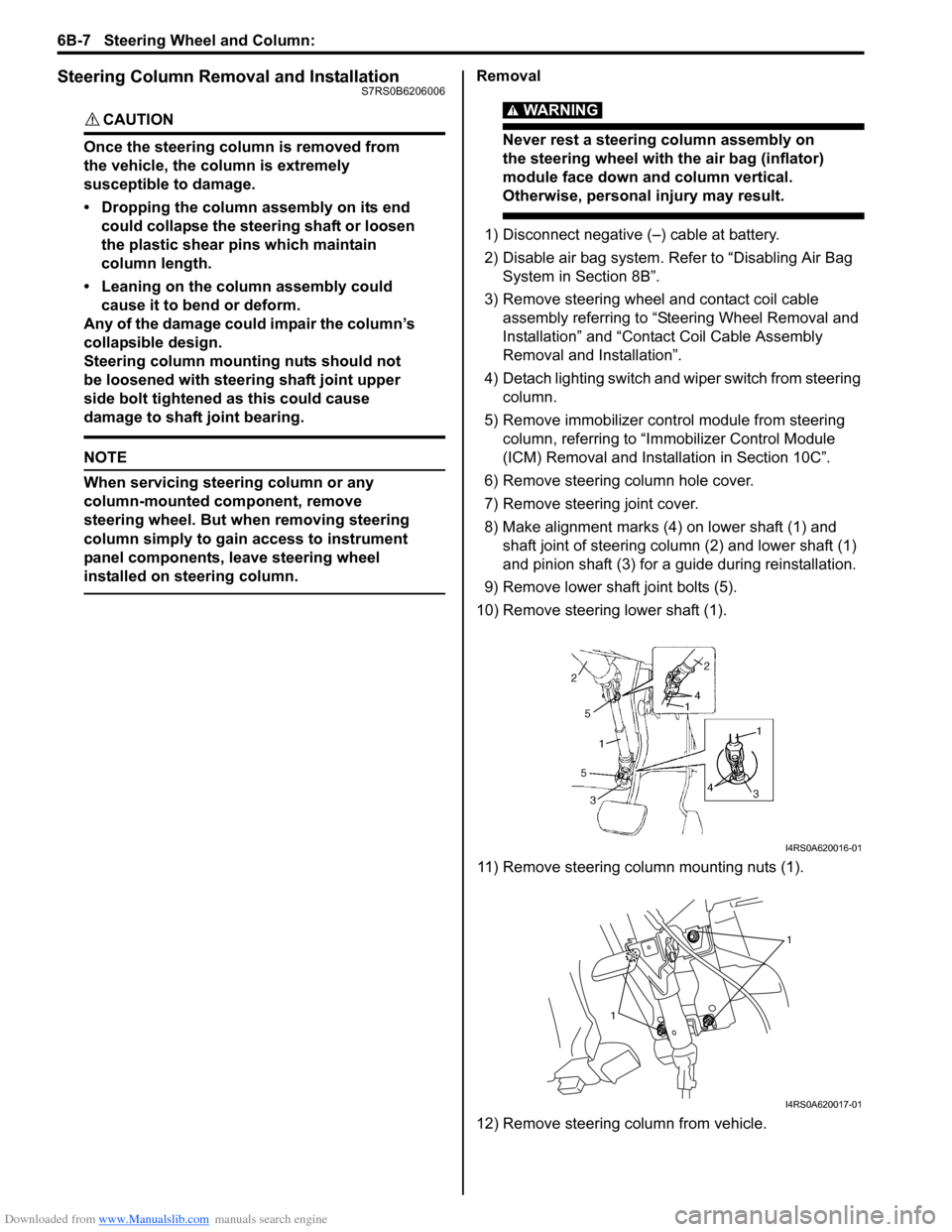

Steering Column Removal and InstallationS7RS0B6206006

CAUTION!

Once the steering column is removed from

the vehicle, the column is extremely

susceptible to damage.

• Dropping the column assembly on its end could collapse the steering shaft or loosen

the plastic shear pins which maintain

column length.

• Leaning on the column assembly could cause it to bend or deform.

Any of the damage could impair the column’s

collapsible design.

Steering column mounting nuts should not

be loosened with steering shaft joint upper

side bolt tightened as this could cause

damage to shaft joint bearing.

NOTE

When servicing steering column or any

column-mounted component, remove

steering wheel. But when removing steering

column simply to gain access to instrument

panel components, leave steering wheel

installed on steering column.

Removal

WARNING!

Never rest a steering column assembly on

the steering wheel with the air bag (inflator)

module face down and column vertical.

Otherwise, personal injury may result.

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System in Section 8B”.

3) Remove steering wheel and contact coil cable assembly referring to “S teering Wheel Removal and

Installation” and “Contact Coil Cable Assembly

Removal and Installation”.

4) Detach lighting switch and wiper switch from steering column.

5) Remove immobilizer cont rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

6) Remove steering column hole cover.

7) Remove steering joint cover.

8) Make alignment marks (4) on lower shaft (1) and shaft joint of steering column (2) and lower shaft (1)

and pinion shaft (3) for a guide during reinstallation.

9) Remove lower shaf t joint bolts (5).

10) Remove steering lower shaft (1).

11) Remove steering column mounting nuts (1).

12) Remove steering column from vehicle.

I4RS0A620016-01

1

1

I4RS0A620017-01

Page 890 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-8 Power Assisted Steering System:

Step 2: DTC Check, Record and Clearance

First, check DTC, referring to “DTC Check”. If DTC is

indicated, print it or write them down and then clear them

by referring to “DTC Clearance”. DTC indicates

malfunction that occurred in the system but does not

indicate whether it exists now or it occurred in the past

and the normal condition has been restored now. To

check which case applies, check the symptom in

question according to Step 5 and recheck DTC

according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the P/S system

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “S tep 2: DTC Check, Record

and Clearance: ”, confirm trouble symptoms. Also,

reconfirm trouble symptom by performing test drive and

turning steering wheel fully to right and left at stopped

vehicle.

Step 6 and 7: Rechecking and Record of DTC

Refer to “DTC Check” for checking procedure.

Step 8: Steering Symptom Diagnosis and P/S

System Symptom Diagnosis

Perform basic steering system check according to

“Steering Symptom Diagnosis in Section 6A” first. When

the end of the flow has been reached, check the parts of

the system suspected as a possible cause referring to

“P/S System Symptom Diagnosis” and based on

symptoms appearing on the vehicle (symptoms obtained

through steps of customer complaint analysis, trouble

symptom confirmation and/or basic P/S system check)

and repair or replace faulty parts, if any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, P/S control module or other part and

repair or replace faulty parts.

Step 10: Intermittent Problems Check

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2. Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the P/

S system is free from any abnormal conditions. If what

has been repaired is related to the DTC, clear the DTC

once, perform DTC confirmation procedure and confirm

that no DTC is indicated.

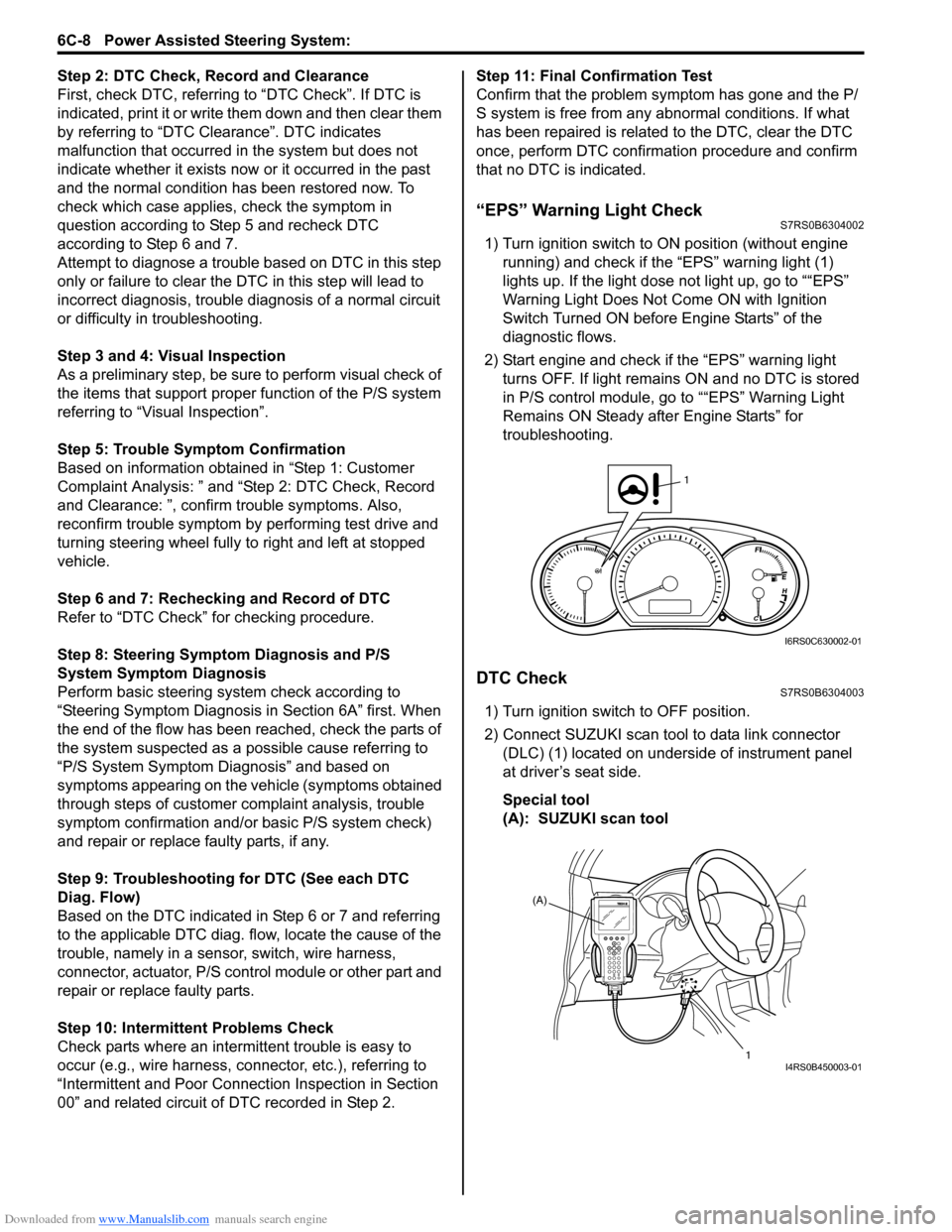

“EPS” Warning Light CheckS7RS0B6304002

1) Turn ignition switch to ON position (without engine

running) and chec k if the “EPS” warning light (1)

lights up. If the light dose not light up, go to ““EPS”

Warning Light Does Not Come ON with Ignition

Switch Turned ON before Engine Starts” of the

diagnostic flows.

2) Start engine and check if the “EPS” warning light turns OFF. If light remains ON and no DTC is stored

in P/S control module, go to ““EPS” Warning Light

Remains ON Steady after Engine Starts” for

troubleshooting.

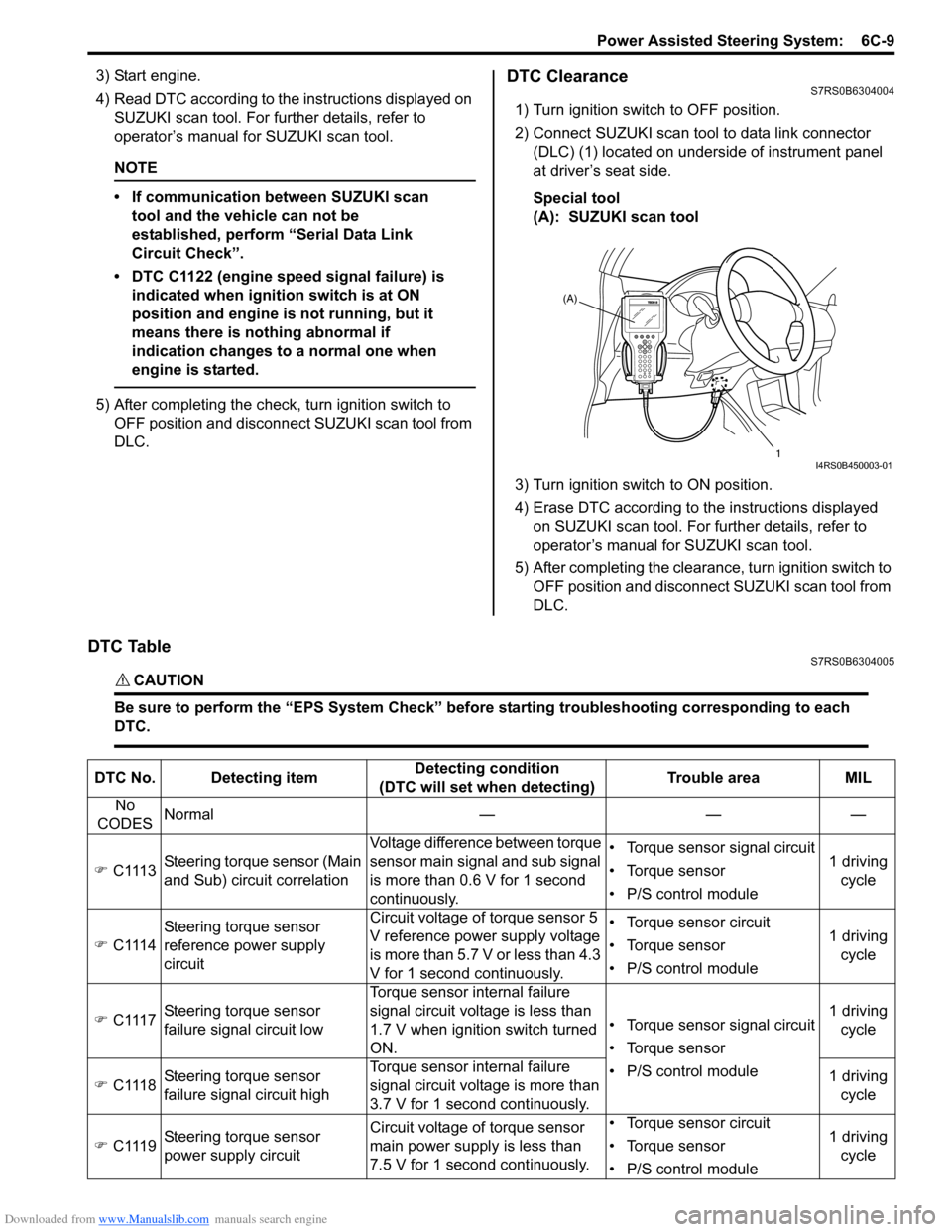

DTC CheckS7RS0B6304003

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

1

I6RS0C630002-01

(A)

1

I4RS0B450003-01

Page 891 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-9

3) Start engine.

4) Read DTC according to the instructions displayed on

SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

NOTE

• If communication between SUZUKI scan tool and the vehicle can not be

established, perform “Serial Data Link

Circuit Check”.

• DTC C1122 (engine speed signal failure) is indicated when ignition switch is at ON

position and engine is not running, but it

means there is nothing abnormal if

indication changes to a normal one when

engine is started.

5) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

DTC ClearanceS7RS0B6304004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Erase DTC according to the instructions displayed on SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

5) After completing the clearance, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

DTC TableS7RS0B6304005

CAUTION!

Be sure to perform the “EPS Syst em Check” before starting troubleshooting corresponding to each

DTC.

(A)

1

I4RS0B450003-01

DTC No. Detecting item Detecting condition

(DTC will set when detecting) Trouble area MIL

No

CODES Normal — — —

�) C1113 Steering torque sensor (Main

and Sub) circuit correlation Voltage difference between torque

sensor main signal and sub signal

is more than 0.6 V for 1 second

continuously. • Torque sensor signal circuit

• Torque sensor

• P/S control module

1 driving

cycle

�) C1114 Steering torque sensor

reference power supply

circuit Circuit voltage of torque sensor 5

V reference power supply voltage

is more than 5.7 V or less than 4.3

V for 1 second continuously. • Torque sensor circuit

• Torque sensor

• P/S control module

1 driving

cycle

�) C1117 Steering torque sensor

failure signal circuit low Torque sensor internal failure

signal circuit voltage is less than

1.7 V when ignition switch turned

ON.

• Torque sensor signal circuit

• Torque sensor

• P/S control module1 driving

cycle

�) C1118 Steering torque sensor

failure signal circuit high Torque sensor internal failure

signal circuit voltage is more than

3.7 V for 1 second continuously. 1 driving

cycle

�) C1119 Steering torque sensor

power supply circuit Circuit voltage of torque sensor

main power supply

is less than

7.5 V for 1 second continuously. • Torque sensor circuit

• Torque sensor

• P/S control module

1 driving

cycle

Page 928 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-46 Power Assisted Steering System:

P/S Control Module Removal and InstallationS7RS0B6306011

Removal1) Disconnect negative cable at battery.

2) Remove console box.

3) Disconnect connectors (1) from P/S control module (2).

4) Disconnect connector from yaw rate / G sensor

(ESP ® model).

5) Remove P/S control module (2) with bracket (3) from floor panel.

6) Separate P/S control module and bracket.

Installation

Reverse removal procedure for installation noting the

following.

• Tighten each screw to the specified torque. Tightening torque

P/S control module bracket screw (ABS model)

(a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

P/S control module bracket screw (ESP ® model)

(a): 7 N·m (0.7 kgf-m, 5.0 lb-ft)

P/S control module mounting screw (b): 5 N·m (

0.5 kgf-m, 3.7 lb-ft)

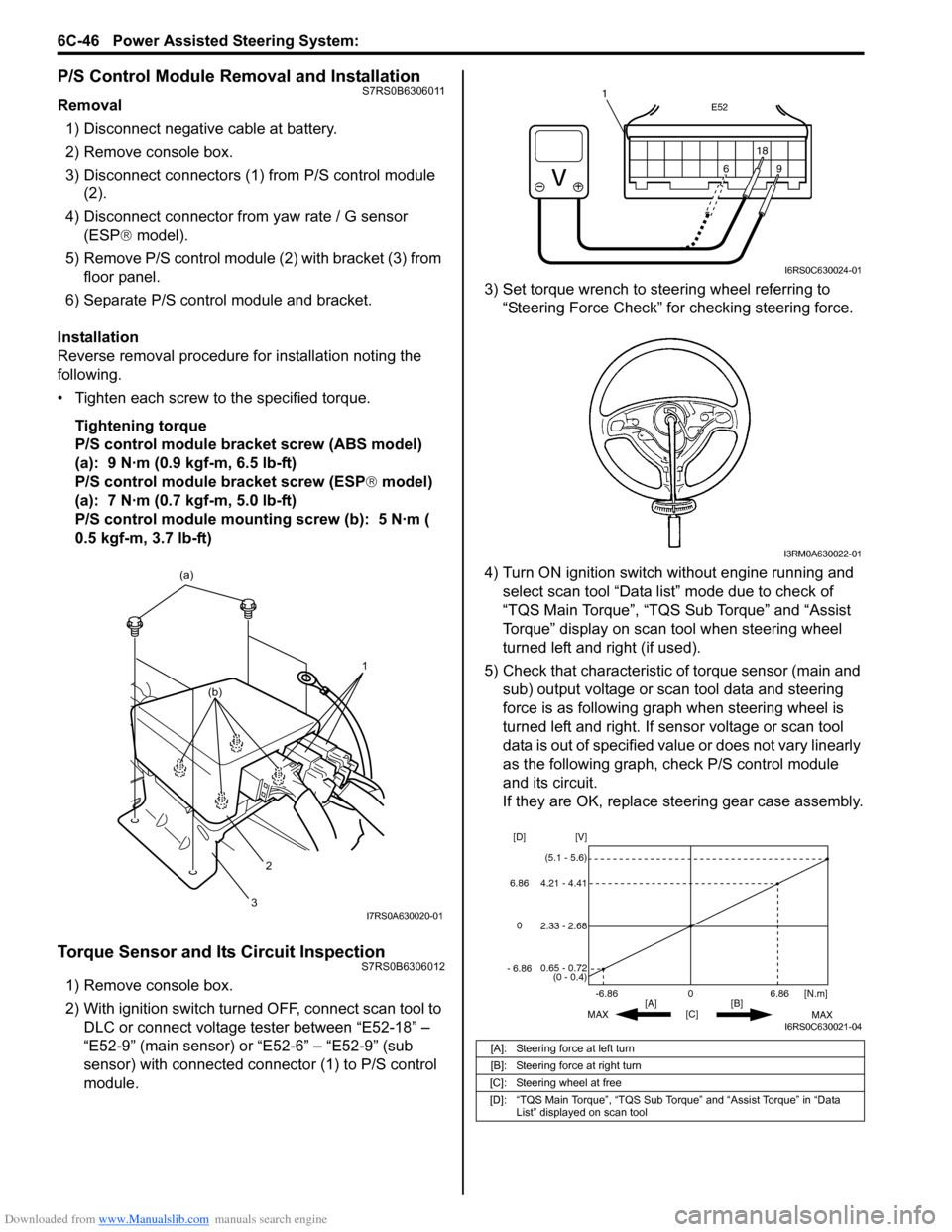

Torque Sensor and Its Circuit InspectionS7RS0B6306012

1) Remove console box.

2) With ignition switch turned OFF, connect scan tool to DLC or connect voltage tester between “E52-18” –

“E52-9” (main sensor) or “E52-6” – “E52-9” (sub

sensor) with connected connector (1) to P/S control

module. 3) Set torque wrench to stee

ring wheel referring to

“Steering Force Check” for checking steering force.

4) Turn ON ignition switch without engine running and select scan tool “Data list” mode due to check of

“TQS Main Torque”, “TQS Sub Torque” and “Assist

Torque” display on scan tool when steering wheel

turned left and right (if used).

5) Check that characteristic of torque sensor (main and sub) output voltage or scan tool data and steering

force is as following graph when steering wheel is

turned left and right. If sensor voltage or scan tool

data is out of specified value or does not vary linearly

as the following graph, check P/S control module

and its circuit.

If they are OK, replace steering gear case assembly.

1

(a)

2

3

(b)

I7RS0A630020-01

[A]: Steering force at left turn

[B]: Steering force at right turn

[C]: Steering wheel at free

[D]: “TQS Main Torque”, “TQS Sub Torque” and “Assist Torque” in “Data List” displayed on scan tool

E52

18

9

6

9

6 18

1

I6RS0C630024-01

I3RM0A630022-01

0

[C] [N.m]

MAX MAX

[B]

[A]

2.33 - 2.68 [V]

[D]

0.65 - 0.72

(0 - 0.4)

4.21 - 4.41

(5.1 - 5.6)

6.86

-6.86

0

6.86

- 6.86

I6RS0C630021-04