dryer SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 989 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-41

Cool air does not come

out or insufficient cooling

(A/C system normal

operation)Insufficient or excessive charge of

refrigerant

Check the amount of refrigerant and system

for leaks.

Condenser clogged Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frosted Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Evaporator temperature sensor faulty Check evaporator temperature sensor

referring to “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Desiccant clogged Replace receiver/dryer.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Compressor faulty Check compressor.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air duct Repair as necessary.

Heater and ventilation system faulty Check HVAC unit.

Temperature selector faulty Check temperature selector referring to

“Inspection of HVAC Control Module and Its

Circuit”.

HVAC control module faulty Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Temperature control actuator faulty Check temperature control actuator referring to

“Temperature Control Actuator Inspection”.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C system Drain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittently Wiring connection faulty

Repair as necessary.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faulty Check magnet clutch. Referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerant Check the amount of refrigerant.

Cool air comes out only at

high speed Condenser clogged

Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerant Check the amount of refrigerant and system

for leaks.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Condition Possible cause Correction / Reference Item

Page 1026 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-78 Air Conditioning System: Automatic Type

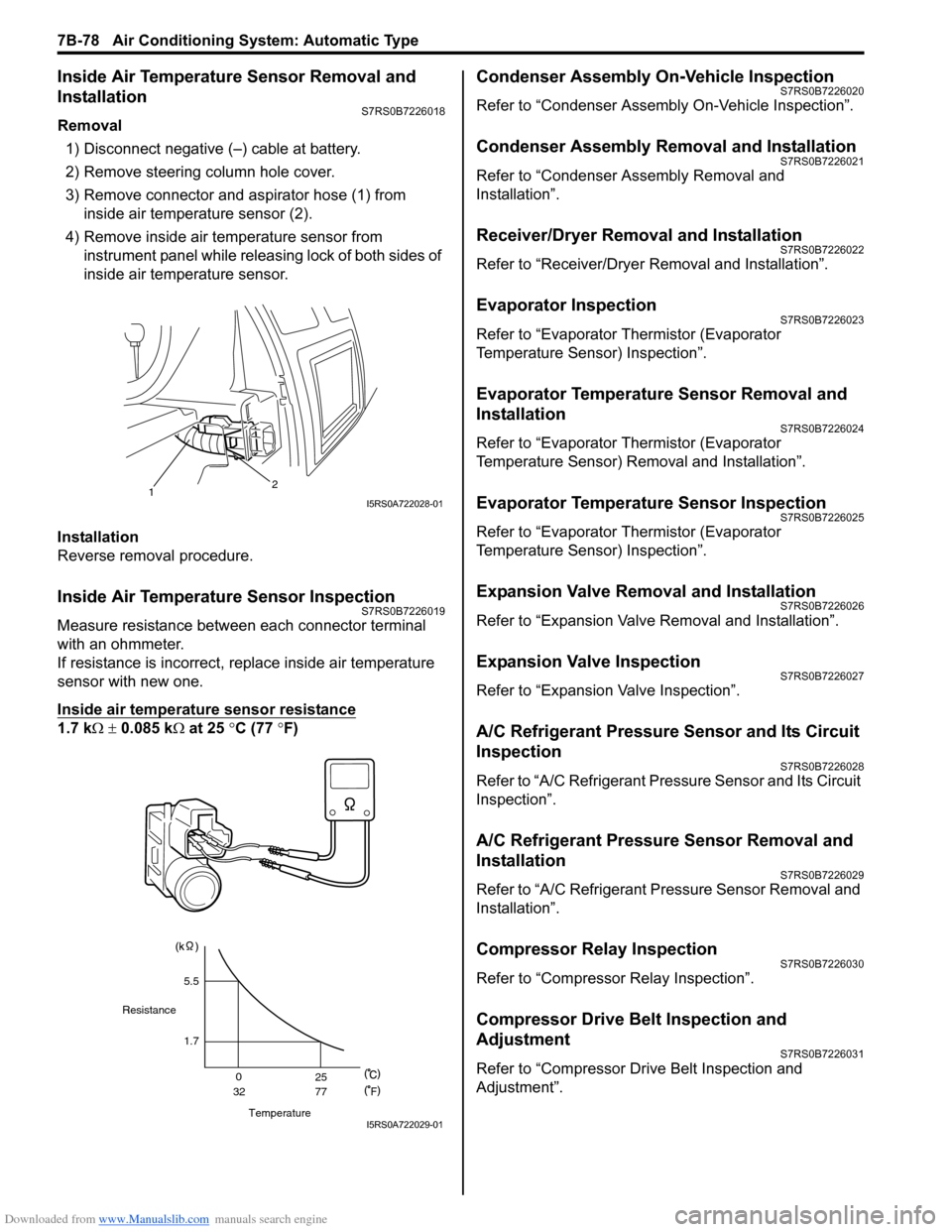

Inside Air Temperature Sensor Removal and

Installation

S7RS0B7226018

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover.

3) Remove connector and aspirator hose (1) from inside air temperature sensor (2).

4) Remove inside air temperature sensor from instrument panel while releas ing lock of both sides of

inside air temperature sensor.

Installation

Reverse removal procedure.

Inside Air Temperature Sensor InspectionS7RS0B7226019

Measure resistance between each connector terminal

with an ohmmeter.

If resistance is incorrect, replace inside air temperature

sensor with new one.

Inside air temperature sensor resistance

1.7 k Ω ± 0.085 k Ω at 25 °C (77 ° F)

Condenser Assembly On-Vehicle InspectionS7RS0B7226020

Refer to “Condenser Assembly On-Vehicle Inspection”.

Condenser Assembly Removal and InstallationS7RS0B7226021

Refer to “Condenser Assembly Removal and

Installation”.

Receiver/Dryer Removal and InstallationS7RS0B7226022

Refer to “Receiver/Dryer Removal and Installation”.

Evaporator InspectionS7RS0B7226023

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator Temperature Sensor Removal and

Installation

S7RS0B7226024

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Removal and Installation”.

Evaporator Temperature Sensor InspectionS7RS0B7226025

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Expansion Valve Removal and InstallationS7RS0B7226026

Refer to “Expansion Valve Removal and Installation”.

Expansion Valve InspectionS7RS0B7226027

Refer to “Expansion Valve Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7226028

Refer to “A/C Refrigerant Pressure Sensor and Its Circuit

Inspection”.

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7226029

Refer to “A/C Refrigerant Pressure Sensor Removal and

Installation”.

Compressor Relay InspectionS7RS0B7226030

Refer to “Compressor Relay Inspection”.

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7226031

Refer to “Compressor Drive Belt Inspection and

Adjustment”.

12I5RS0A722028-01

Temperature

Resistance

1.7

0

32 25

77

F

5.5

I5RS0A722029-01