wipe SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 511 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-13

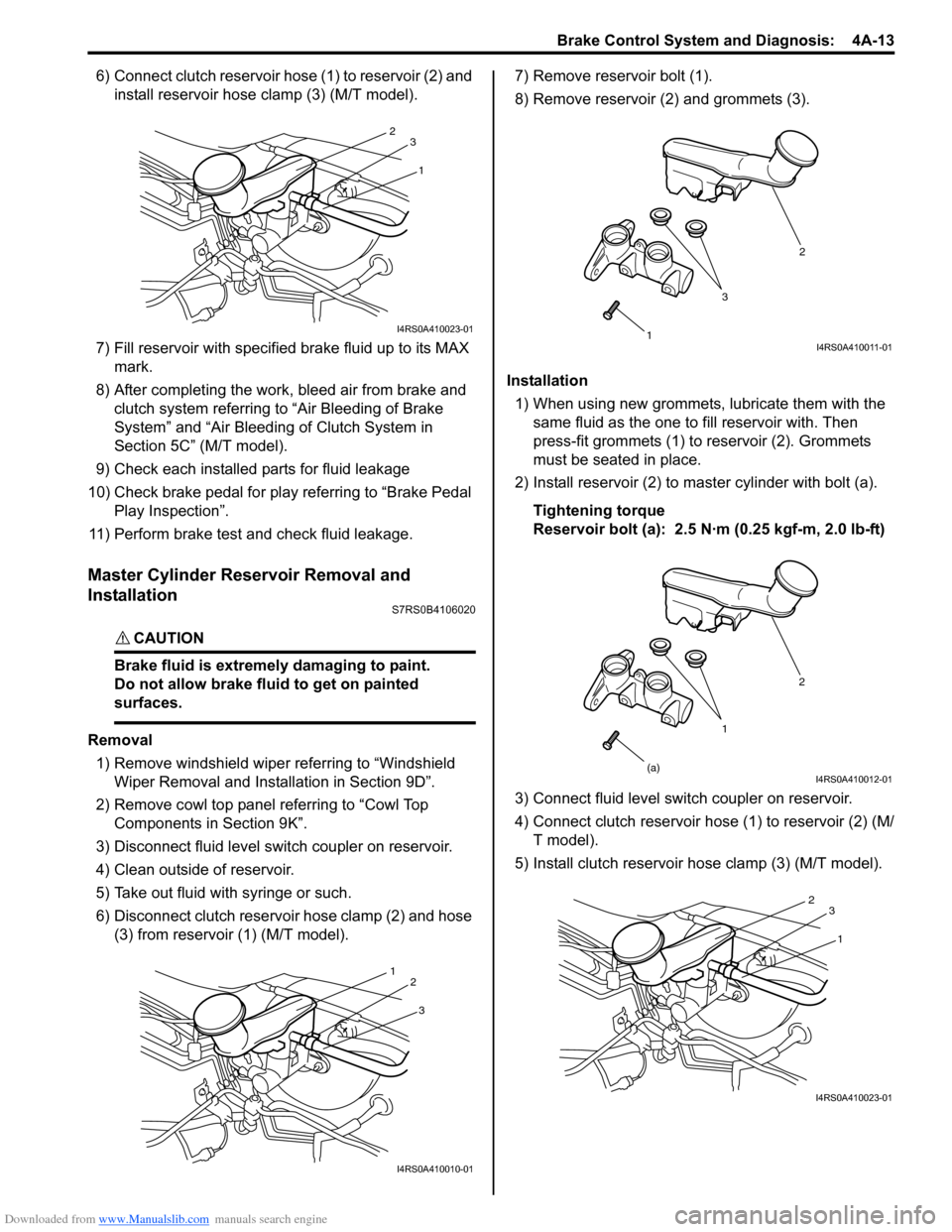

6) Connect clutch reservoir hose (1) to reservoir (2) and install reservoir hose clamp (3) (M/T model).

7) Fill reservoir with specified brake fluid up to its MAX

mark.

8) After completing the work, bleed air from brake and clutch system referring to “Air Bleeding of Brake

System” and “Air Bleeding of Clutch System in

Section 5C” (M/T model).

9) Check each installed parts for fluid leakage

10) Check brake pedal for play referring to “Brake Pedal Play Inspection”.

11) Perform brake test and check fluid leakage.

Master Cylinder Reservoir Removal and

Installation

S7RS0B4106020

CAUTION!

Brake fluid is extremely damaging to paint.

Do not allow brake fluid to get on painted

surfaces.

Removal 1) Remove windshield wiper referring to “Windshield Wiper Removal and Insta llation in Section 9D”.

2) Remove cowl top panel referring to “Cowl Top Components in Section 9K”.

3) Disconnect fluid level s witch coupler on reservoir.

4) Clean outside of reservoir.

5) Take out fluid with syringe or such.

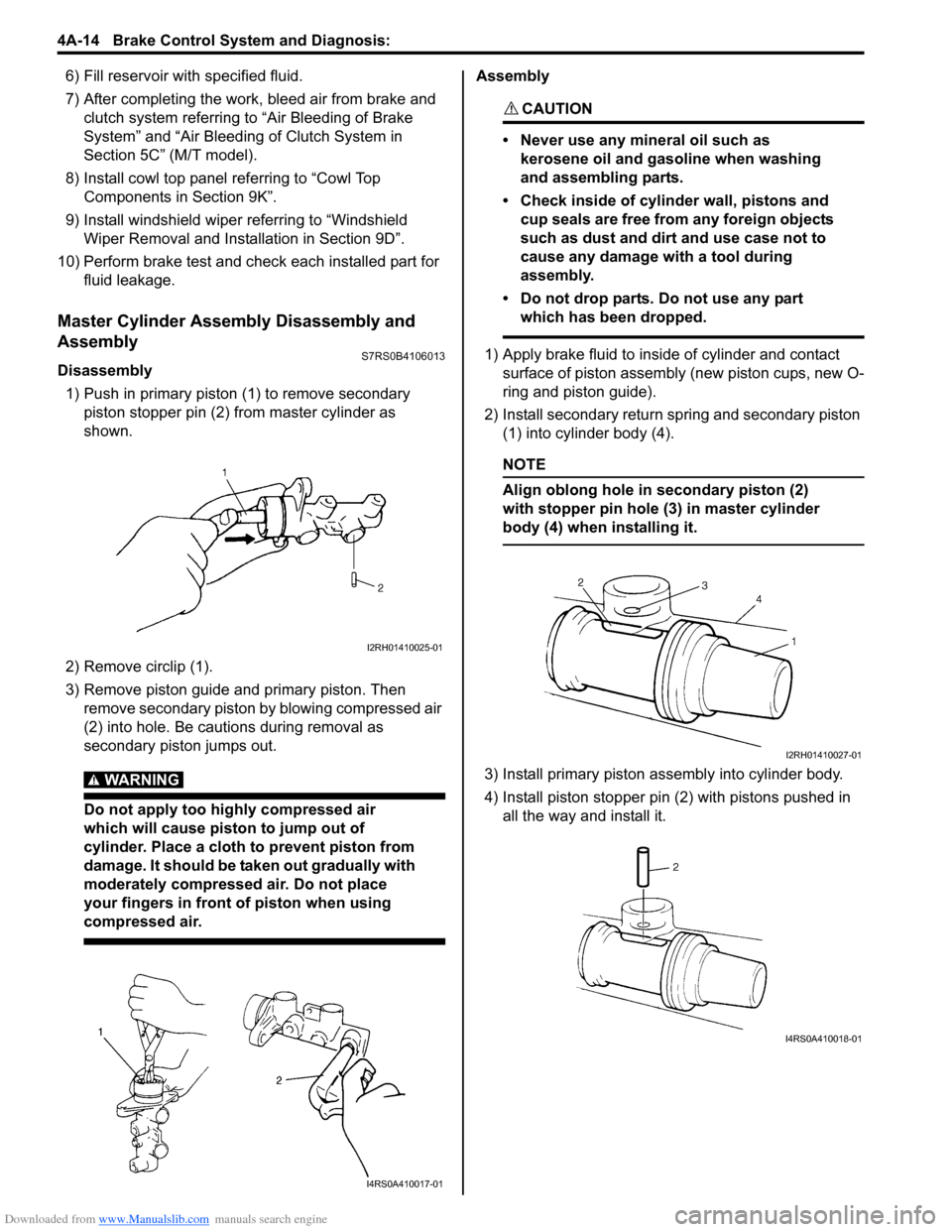

6) Disconnect clutch reservoir hose clamp (2) and hose (3) from reservoir (1) (M/T model). 7) Remove reservoir bolt (1).

8) Remove reservoir (2) and grommets (3).

Installation 1) When using new grommets, lubricate them with the same fluid as the one to fill reservoir with. Then

press-fit grommets (1) to reservoir (2). Grommets

must be seated in place.

2) Install reservoir (2) to master cylinder with bolt (a).

Tightening torque

Reservoir bolt (a): 2.5 N·m (0.25 kgf-m, 2.0 lb-ft)

3) Connect fluid level switch coupler on reservoir.

4) Connect clutch reservoir hose (1) to reservoir (2) (M/ T model).

5) Install clutch reservoir hose clamp (3) (M/T model).

1

2

3

I4RS0A410023-01

3

1

2

I4RS0A410010-01

1 2

3I4RS0A410011-01

1 2

(a)

I4RS0A410012-01

1

2

3

I4RS0A410023-01

Page 512 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-14 Brake Control System and Diagnosis:

6) Fill reservoir with specified fluid.

7) After completing the work, bleed air from brake and clutch system referring to “Air Bleeding of Brake

System” and “Air Bleeding of Clutch System in

Section 5C” (M/T model).

8) Install cowl top panel referring to “Cowl Top Components in Section 9K”.

9) Install windshield wiper referring to “Windshield

Wiper Removal and Insta llation in Section 9D”.

10) Perform brake test and check each installed part for fluid leakage.

Master Cylinder Assembly Disassembly and

Assembly

S7RS0B4106013

Disassembly

1) Push in primary piston (1) to remove secondary

piston stopper pin (2) from master cylinder as

shown.

2) Remove circlip (1).

3) Remove piston guide and primary piston. Then remove secondary piston by blowing compressed air

(2) into hole. Be cautions during removal as

secondary piston jumps out.

WARNING!

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. Place a cloth to prevent piston from

damage. It should be taken out gradually with

moderately compressed air. Do not place

your fingers in front of piston when using

compressed air.

Assembly

CAUTION!

• Never use any mineral oil such as kerosene oil and gasoline when washing

and assembling parts.

• Check inside of cylinder wall, pistons and cup seals are free from any foreign objects

such as dust and dirt and use case not to

cause any damage with a tool during

assembly.

• Do not drop parts. Do not use any part which has been dropped.

1) Apply brake fluid to inside of cylinder and contact surface of piston assembly (new piston cups, new O-

ring and piston guide).

2) Install secondary return spring and secondary piston (1) into cylinder body (4).

NOTE

Align oblong hole in secondary piston (2)

with stopper pin hole (3) in master cylinder

body (4) when installing it.

3) Install primary piston assembly into cylinder body.

4) Install piston stopper pin (2) with pistons pushed in all the way and install it.

I2RH01410025-01

I4RS0A410017-01

I2RH01410027-01

I4RS0A410018-01

Page 733 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-89

A/T Fluid Level CheckS7RS0B5106002

CAUTION!

Do not use any fluid other than the specified

ATF. Use of any fluid other than the specified

ATF may cause juddering or some other

faulty condition to occur.

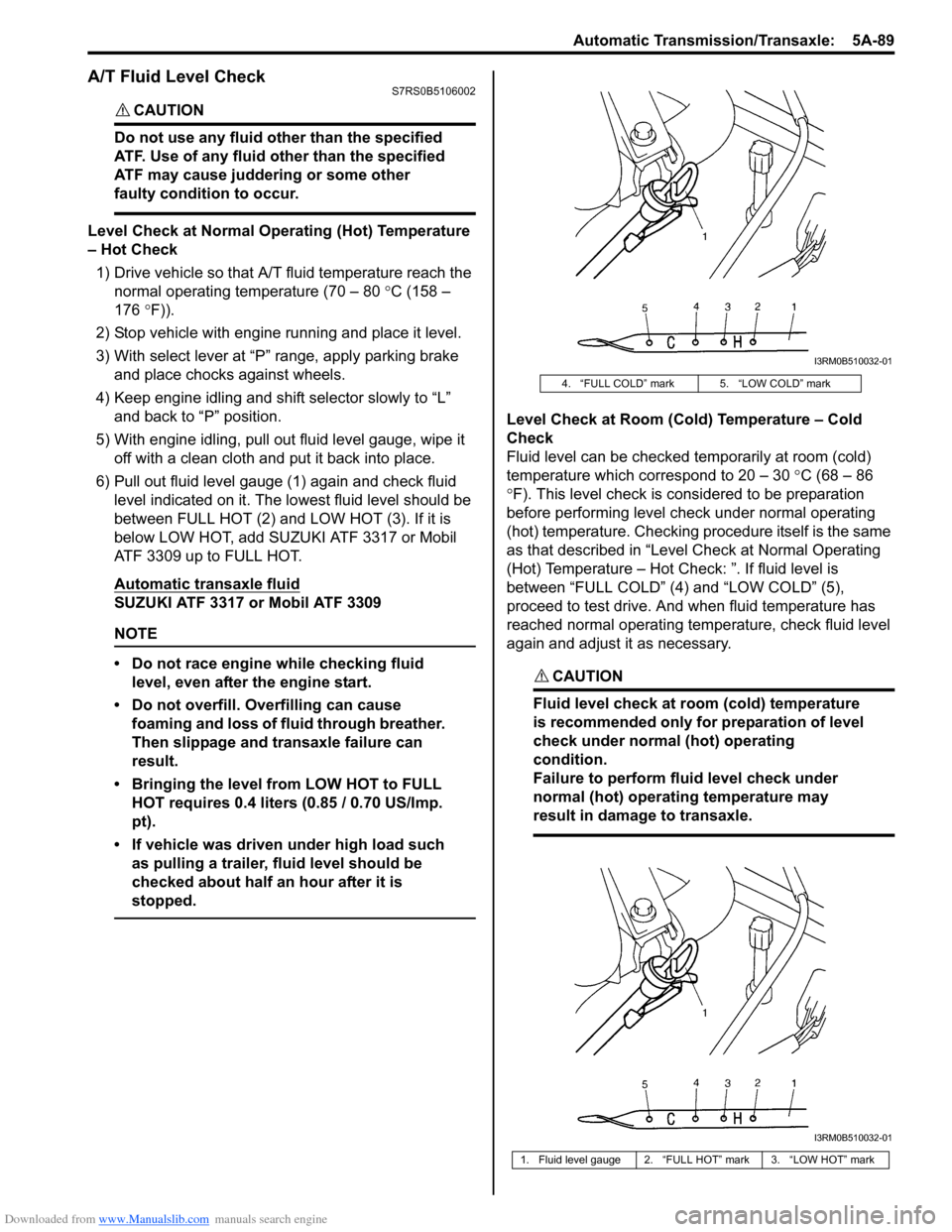

Level Check at Normal Operating (Hot) Temperature

– Hot Check1) Drive vehicle so that A/T fluid temperature reach the

normal operating temperature (70 – 80 °C (158 –

176 °F)).

2) Stop vehicle with engine running and place it level.

3) With select lever at “P” range, apply parking brake and place chocks against wheels.

4) Keep engine idling and shift selector slowly to “L” and back to “P” position.

5) With engine idling, pull out fluid level gauge, wipe it off with a clean cloth and put it back into place.

6) Pull out fluid level gauge (1) again and check fluid level indicated on it. The lo west fluid level should be

between FULL HOT (2) and LOW HOT (3). If it is

below LOW HOT, add SUZUKI ATF 3317 or Mobil

ATF 3309 up to FULL HOT.

Automatic transaxle fluid

SUZUKI ATF 3317 or Mobil ATF 3309

NOTE

• Do not race engine while checking fluid level, even after the engine start.

• Do not overfill. Overfilling can cause foaming and loss of fluid through breather.

Then slippage and transaxle failure can

result.

• Bringing the level from LOW HOT to FULL HOT requires 0.4 liters (0.85 / 0.70 US/Imp.

pt).

• If vehicle was driven under high load such as pulling a trailer, fluid level should be

checked about half an hour after it is

stopped.

Level Check at Room (Cold) Temperature – Cold

Check

Fluid level can be checked temporarily at room (cold)

temperature which correspond to 20 – 30 °C (68 – 86

° F). This level check is considered to be preparation

before performing level check under normal operating

(hot) temperature. Checking procedure itself is the same

as that described in “Level Check at Normal Operating

(Hot) Temperature – Hot Check: ”. If fluid level is

between “FULL COLD” (4) and “LOW COLD” (5),

proceed to test drive. And when fluid temperature has

reached normal operating temp erature, check fluid level

again and adjust it as necessary.

CAUTION!

Fluid level check at room (cold) temperature

is recommended only for preparation of level

check under normal (hot) operating

condition.

Failure to perform fluid level check under

normal (hot) operating temperature may

result in damage to transaxle.

4. “FULL COLD” mark 5. “LOW COLD” mark

1. Fluid level gauge 2. “FULL HOT” mark 3. “LOW HOT” mark

I3RM0B510032-01

I3RM0B510032-01

Page 805 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-161

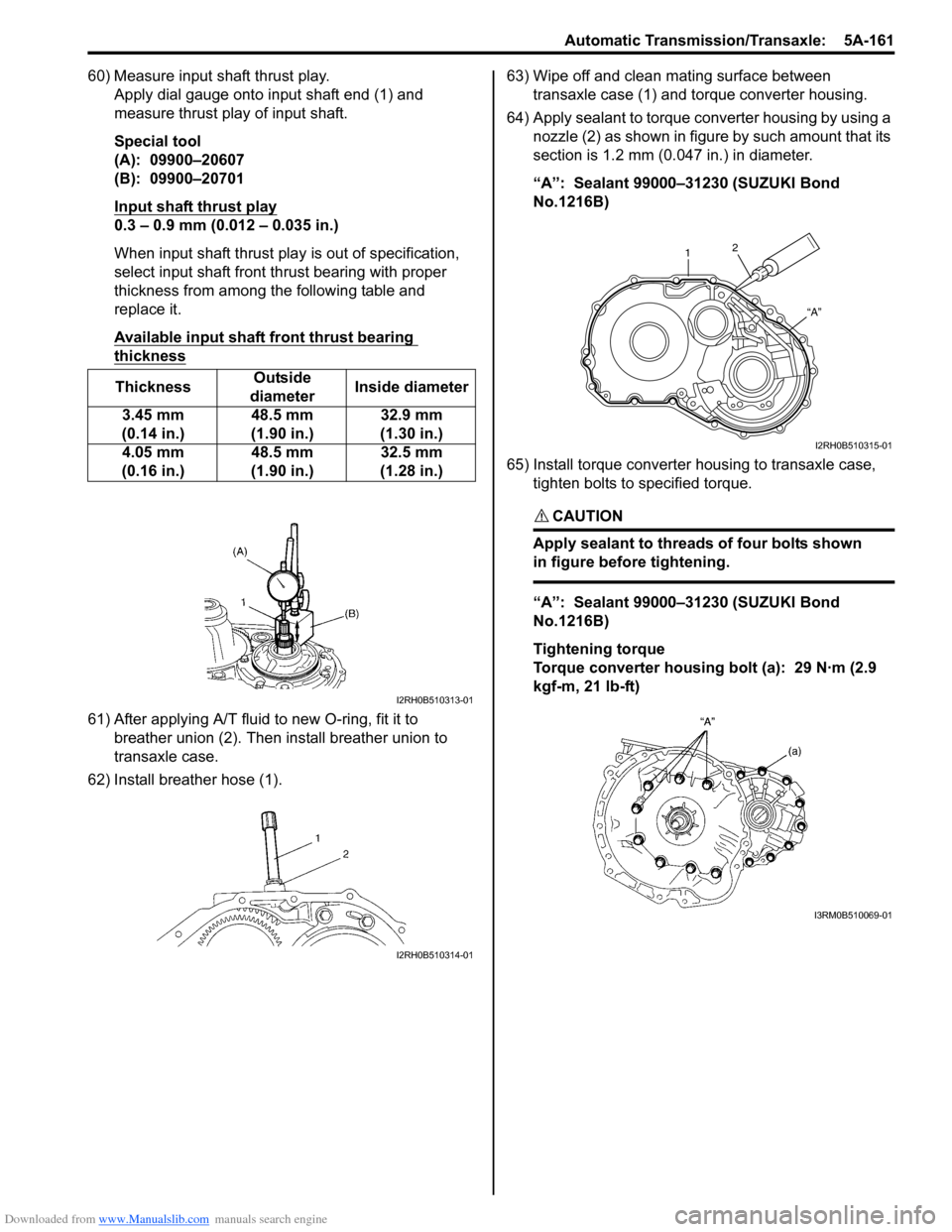

60) Measure input shaft thrust play.Apply dial gauge onto input shaft end (1) and

measure thrust play of input shaft.

Special tool

(A): 09900–20607

(B): 09900–20701

Input shaft thrust play

0.3 – 0.9 mm (0.012 – 0.035 in.)

When input shaft thrust play is out of specification,

select input shaft front th rust bearing with proper

thickness from among the following table and

replace it.

Available input shaft front thrust bearing

thickness

61) After applying A/T fluid to new O-ring, fit it to breather union (2). Then install breather union to

transaxle case.

62) Install breather hose (1). 63) Wipe off and clean mating surface between

transaxle case (1) and torque converter housing.

64) Apply sealant to torque converter housing by using a nozzle (2) as shown in figure by such amount that its

section is 1.2 mm (0.047 in.) in diameter.

“A”: Sealant 99000–31230 (SUZUKI Bond

No.1216B)

65) Install torque converter housing to transaxle case, tighten bolts to specified torque.

CAUTION!

Apply sealant to threads of four bolts shown

in figure before tightening.

“A”: Sealant 99000–31230 (SUZUKI Bond

No.1216B)

Tightening torque

Torque converter housing bolt (a): 29 N·m (2.9

kgf-m, 21 lb-ft)

Thickness

Outside

diameter Inside diameter

3.45 mm

(0.14 in.) 48.5 mm

(1.90 in.) 32.9 mm

(1.30 in.)

4.05 mm

(0.16 in.) 48.5 mm

(1.90 in.) 32.5 mm

(1.28 in.)

I2RH0B510313-01

I2RH0B510314-01

1 2

“A”

I2RH0B510315-01

I3RM0B510069-01

Page 855 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-3

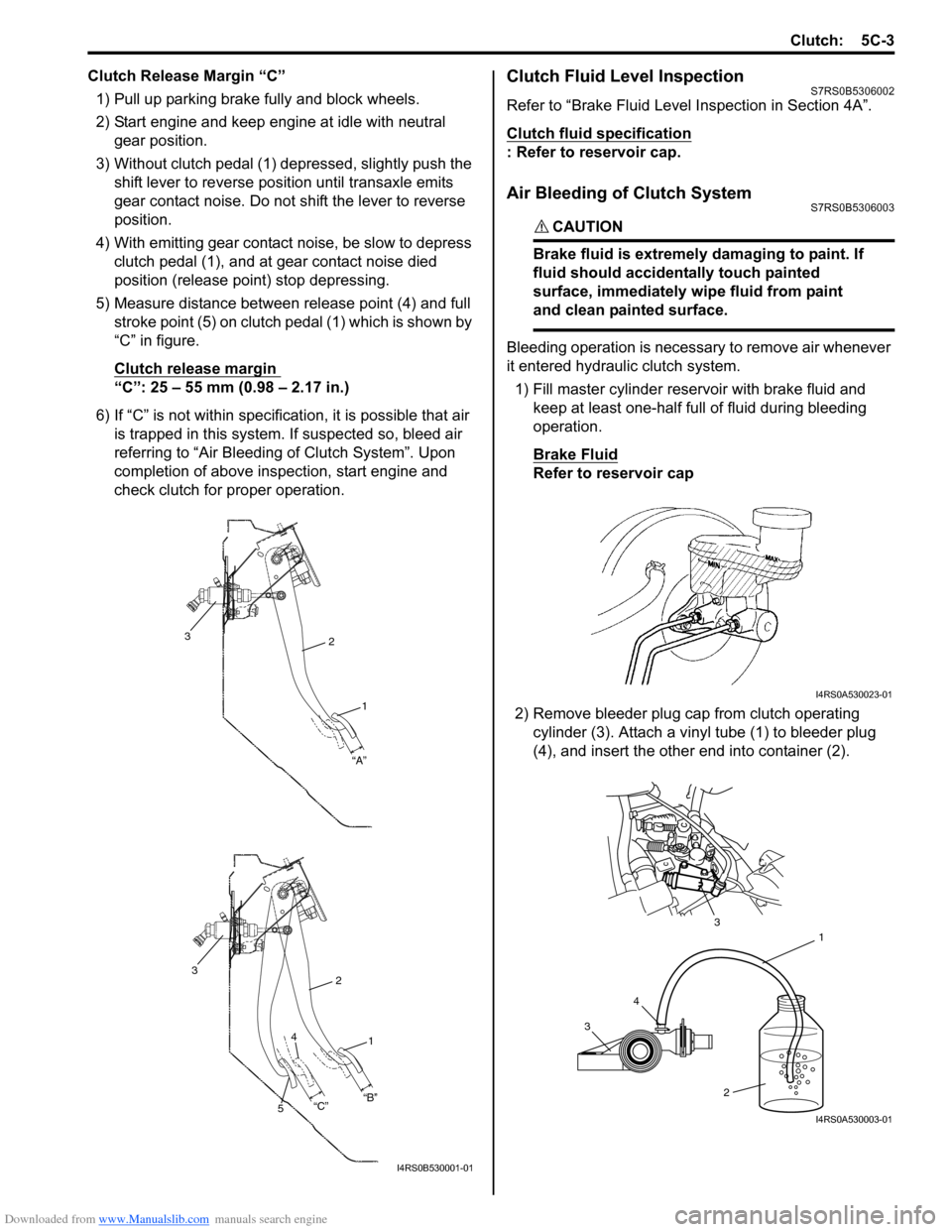

Clutch Release Margin “C”1) Pull up parking brake fully and block wheels.

2) Start engine and keep engine at idle with neutral gear position.

3) Without clutch pedal (1) dep ressed, slightly push the

shift lever to re verse position until transaxle emits

gear contact noise. Do not shift the lever to reverse

position.

4) With emitting gear contact noise, be slow to depress clutch pedal (1), and at gear contact noise died

position (release point) stop depressing.

5) Measure distance between release point (4) and full stroke point (5) on clutch pedal (1) which is shown by

“C” in figure.

Clutch release margin

“C”: 25 – 55 mm (0.98 – 2.17 in.)

6) If “C” is not within specificat ion, it is possible that air

is trapped in this system. If suspected so, bleed air

referring to “Air Bleeding of Clutch System”. Upon

completion of above inspection, start engine and

check clutch for proper operation.

Clutch Fluid Level InspectionS7RS0B5306002

Refer to “Brake Fluid Level Inspection in Section 4A”.

Clutch fluid specification

: Refer to reservoir cap.

Air Bleeding of Clutch SystemS7RS0B5306003

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic clutch system.

1) Fill master cylinder reservoir with brake fluid and keep at least one-half full of fluid during bleeding

operation.

Brake Fluid

Refer to reservoir cap

2) Remove bleeder plug cap from clutch operating cylinder (3). Attach a vinyl tube (1) to bleeder plug

(4), and insert the other end into container (2).

2

1

“A”

3

2

1

3

“B”

“C”

4

5

I4RS0B530001-01

I4RS0A530023-01

3 4 1

2

3

I4RS0A530003-01

Page 874 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-3 Steering Wheel and Column:

Repair Instructions

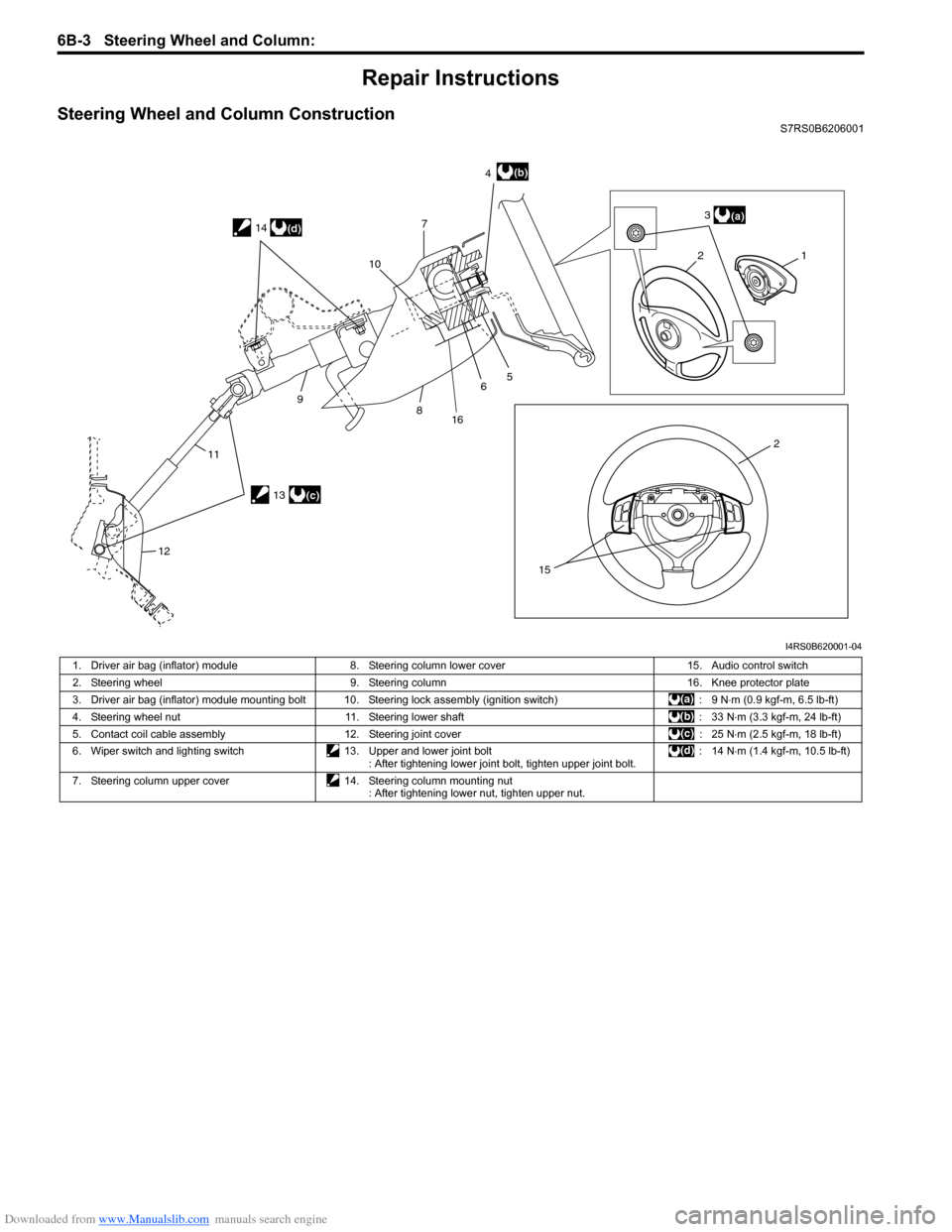

Steering Wheel and Column ConstructionS7RS0B6206001

21

2 3

4

7

5

6

8

9

11

12 10

15

(a)

(b)

13(c)

14

(d)

16

I4RS0B620001-04

1. Driver air bag (inflator) module

8. Steering column lower cover 15. Audio control switch

2. Steering wheel 9. Steering column 16. Knee protector plate

3. Driver air bag (inflator) module mounting bolt 10. Steering lock assembly (ignition switch) : 9 N⋅m (0.9 kgf-m, 6.5 lb-ft)

4. Steering wheel nut 11. Steering lower shaft : 33 N⋅m (3.3 kgf-m, 24 lb-ft)

5. Contact coil cable assembly 12. Steering joint cover : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

6. Wiper switch and lighting switch 13. Upper and lower joint bolt

: After tightening lower joint bolt, tighten upper joint bolt. : 14 N

⋅m (1.4 kgf-m, 10.5 lb-ft)

7. Steering column upper cover 14. Steering column mounting nut

: After tightening lower nut, tighten upper nut.

Page 878 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-7 Steering Wheel and Column:

Steering Column Removal and InstallationS7RS0B6206006

CAUTION!

Once the steering column is removed from

the vehicle, the column is extremely

susceptible to damage.

• Dropping the column assembly on its end could collapse the steering shaft or loosen

the plastic shear pins which maintain

column length.

• Leaning on the column assembly could cause it to bend or deform.

Any of the damage could impair the column’s

collapsible design.

Steering column mounting nuts should not

be loosened with steering shaft joint upper

side bolt tightened as this could cause

damage to shaft joint bearing.

NOTE

When servicing steering column or any

column-mounted component, remove

steering wheel. But when removing steering

column simply to gain access to instrument

panel components, leave steering wheel

installed on steering column.

Removal

WARNING!

Never rest a steering column assembly on

the steering wheel with the air bag (inflator)

module face down and column vertical.

Otherwise, personal injury may result.

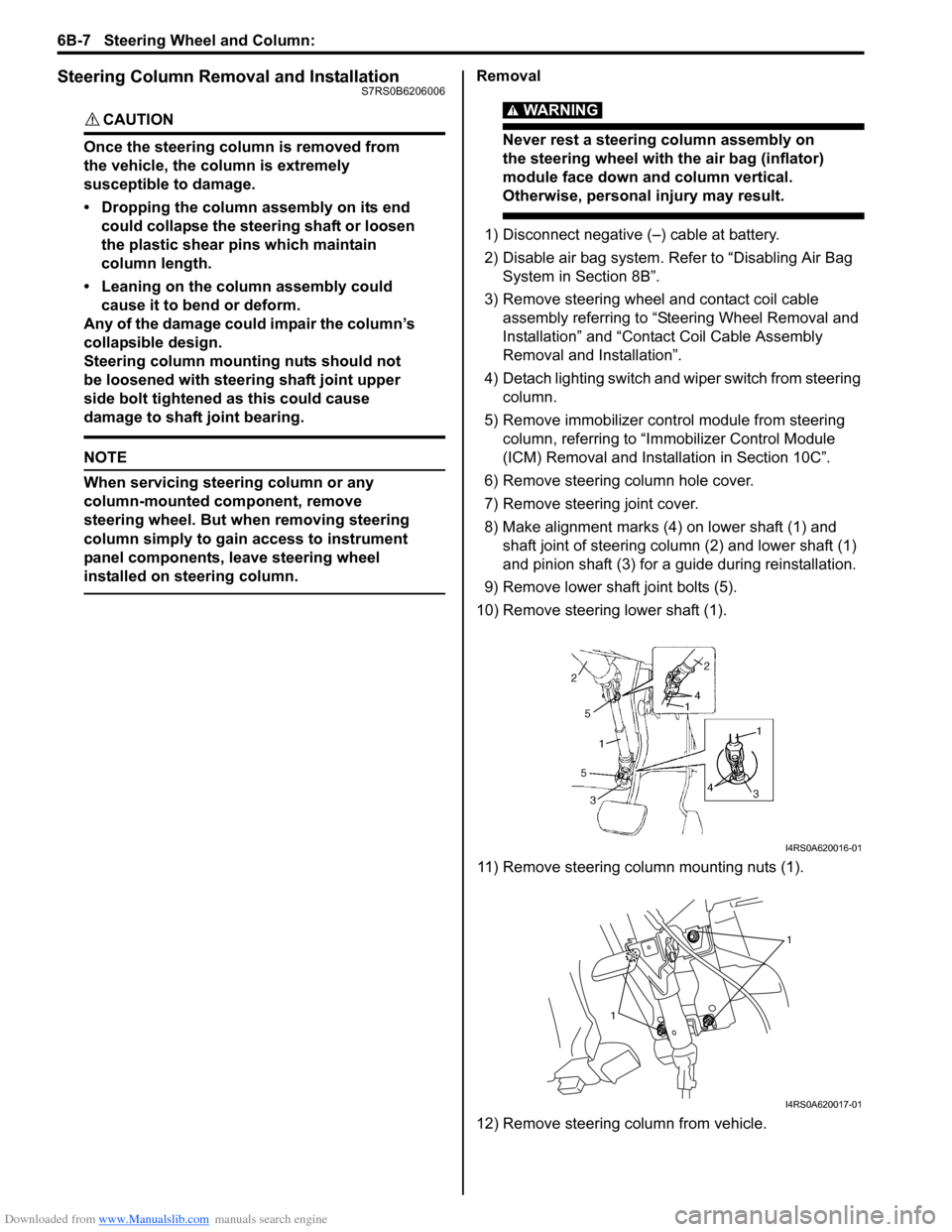

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System in Section 8B”.

3) Remove steering wheel and contact coil cable assembly referring to “S teering Wheel Removal and

Installation” and “Contact Coil Cable Assembly

Removal and Installation”.

4) Detach lighting switch and wiper switch from steering column.

5) Remove immobilizer cont rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

6) Remove steering column hole cover.

7) Remove steering joint cover.

8) Make alignment marks (4) on lower shaft (1) and shaft joint of steering column (2) and lower shaft (1)

and pinion shaft (3) for a guide during reinstallation.

9) Remove lower shaf t joint bolts (5).

10) Remove steering lower shaft (1).

11) Remove steering column mounting nuts (1).

12) Remove steering column from vehicle.

I4RS0A620016-01

1

1

I4RS0A620017-01

Page 879 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-8

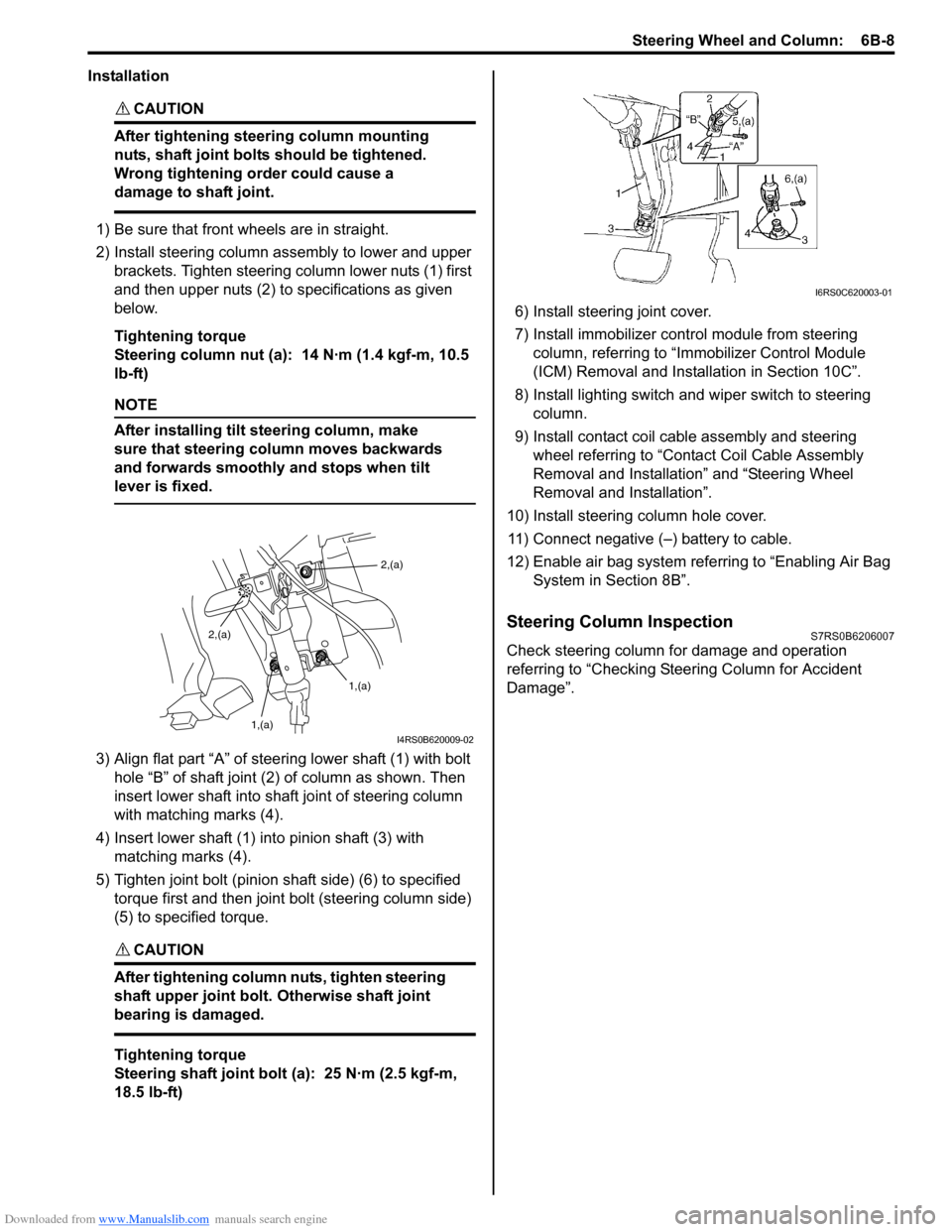

Installation

CAUTION!

After tightening steering column mounting

nuts, shaft joint bolts should be tightened.

Wrong tightening order could cause a

damage to shaft joint.

1) Be sure that front wheels are in straight.

2) Install steering column assembly to lower and upper brackets. Tighten steering column lower nuts (1) first

and then upper nuts (2) to specifications as given

below.

Tightening torque

Steering column nut (a): 14 N·m (1.4 kgf-m, 10.5

lb-ft)

NOTE

After installing tilt steering column, make

sure that steering column moves backwards

and forwards smoothly and stops when tilt

lever is fixed.

3) Align flat part “A” of stee ring lower shaft (1) with bolt

hole “B” of shaft joint (2) of column as shown. Then

insert lower shaft into shaf t joint of steering column

with matching marks (4).

4) Insert lower shaft (1) into pinion shaft (3) with matching marks (4).

5) Tighten joint bolt (pinion shaft side) (6) to specified torque first and then joint bolt (steering column side)

(5) to specified torque.

CAUTION!

After tightening column nuts, tighten steering

shaft upper joint bolt. Otherwise shaft joint

bearing is damaged.

Tightening torque

Steering shaft joint bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft) 6) Install steering joint cover.

7) Install immobilizer cont

rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

8) Install lighting switch and wiper switch to steering column.

9) Install contact coil cable assembly and steering wheel referring to “Conta ct Coil Cable Assembly

Removal and Installation” and “Steering Wheel

Removal and Installation”.

10) Install steering column hole cover. 11) Connect negative (–) battery to cable.

12) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

Steering Column InspectionS7RS0B6206007

Check steering column for damage and operation

referring to “Checking Steering Column for Accident

Damage”.

2,(a)

1,(a)

1,(a)

2,(a)

I4RS0B620009-02

I6RS0C620003-01

Page 949 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-1

HVAC

Air Conditioning System

Manual Type

Precautions

A/C System CautionS7RS0B7210001

CAUTION!

• The air conditioning system of this vehicle uses refrigerant HFC-134a (R-134a).

None of refrigerant, compressor oil and component parts is interchangeable between two types of

A/C: one using refrigerant HFC-134a (R-134a) and the other using refrigerant CFC-12 (R-12).

Be sure to check which refrigerant is used be fore any service work including inspection and

maintenance. For identification between these two types, refer to “Refrigerant Type Identification”.

When replenishing or changing refrigerant and comp ressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being

serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

• When servicing the compressor, keep dirt or foreign material away from getting on or into the compressor parts and system. Clean tools and a clean work area are important for proper service.

The compressor connection and the outside of the compressor should be cleaned before any “On

vehicle” repair or before removal of the compressor. The parts must be kept clean at all times and

any parts to be reassembled should be cleaned with trichloromethane, naphtha, kerosene or

equivalent solvent and dried with dry air. Use only lint free cloths to wipe parts.

• When compressor is removed from the vehicle for servicing, the oil remaining in the compressor

should be discarded and new refrigerant oil added to the compressor.

Minor repair procedures may be done on the vehicle without discharging the system. Major repair

procedures require that the system be discharged of refrigerant.

Precautions on Servicing A/C SystemS7RS0B7210002

WARNING!

Should refrigerant HFC-134a (R-134a) is exposed to your eye(s), consult a doctor immediately.

• Do not use your hand to rub affected eye(s). Instead, use fresh cold water to splash it over affected area to thus gradually raise its temperature above the freezing point.

• Obtain proper treatment as soon as possible from a doctor or eye specialist. Should liquid refrigerant HFC-134a (R-134a) is exposed to your skin, such affected part should be treated in the

same manner as when skin is frostbitten or frozen.

Handling Refrigerant HFC-134a (R-134a)

• Always wear goggles to protect your eyes.

• Avoid direct contact to liquid refrigerant.

• Do not heat refrigerant container higher than 40 °C (104 ° F).

• Do not discharge refrigerant into atmosphere.

• Do not expose bright metals to liquid refrigerant. Refrig erant combined with moisture is corrosive and tarnishes

surfaces of bright metals including chrome.

Page 1041 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-3

• Never attempt disassembly of the air bag (inflator) modules.

• If any abnormality is found, be sure to replace it with

new one as an assembly.

• When an abnormality is noted as existing in the live (undeployed) air bag (inflator) module, be sure to

deploy it before discarding it.

• When grease, cleaning agent, oil, water, etc., got on the air bag (inflator) modules (driver, passenger, side

of both sides and curtain of both sides), wipe it off

immediately with a dry cloth.

• If air bag (inflator) module was dropped from a height of 90 cm (3 ft) or more, it should be replaced with a

new one as an assembly.

WARNING!

• For handling and storage of a live air bag (inflator) module, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you. In case of an

accidental deployment, the bag will then

deploy with minimal chance of injury.

Never carry the air bag (inflator) module by

the wires or connector on the underside of

the module.

Otherwise, personal injury may result.

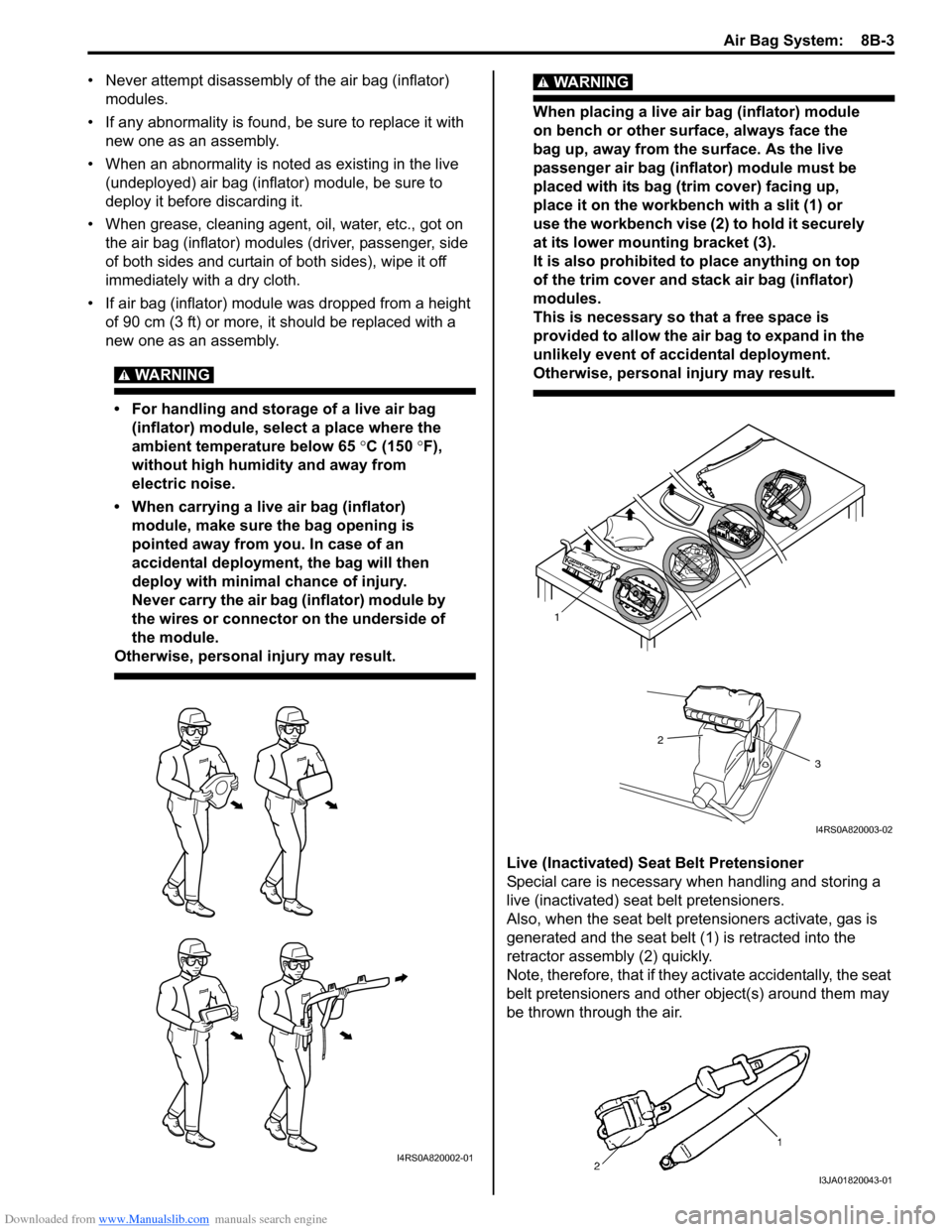

WARNING!

When placing a live air bag (inflator) module

on bench or other surface, always face the

bag up, away from the surface. As the live

passenger air bag (inflator) module must be

placed with its bag (trim cover) facing up,

place it on the workbench with a slit (1) or

use the workbench vise (2) to hold it securely

at its lower mounting bracket (3).

It is also prohibited to place anything on top

of the trim cover and stack air bag (inflator)

modules.

This is necessary so that a free space is

provided to allow the air bag to expand in the

unlikely event of accidental deployment.

Otherwise, personal injury may result.

Live (Inactivated) Seat Belt Pretensioner

Special care is necessary when handling and storing a

live (inactivated) seat belt pretensioners.

Also, when the seat belt pretensioners activate, gas is

generated and the seat belt (1) is retracted into the

retractor assembly (2) quickly.

Note, therefore, that if they activate accidentally, the seat

belt pretensioners and other object(s) around them may

be thrown through the air.

I4RS0A820002-01

1

2

3

I4RS0A820003-02

I3JA01820043-01