battery SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1181 of 1496

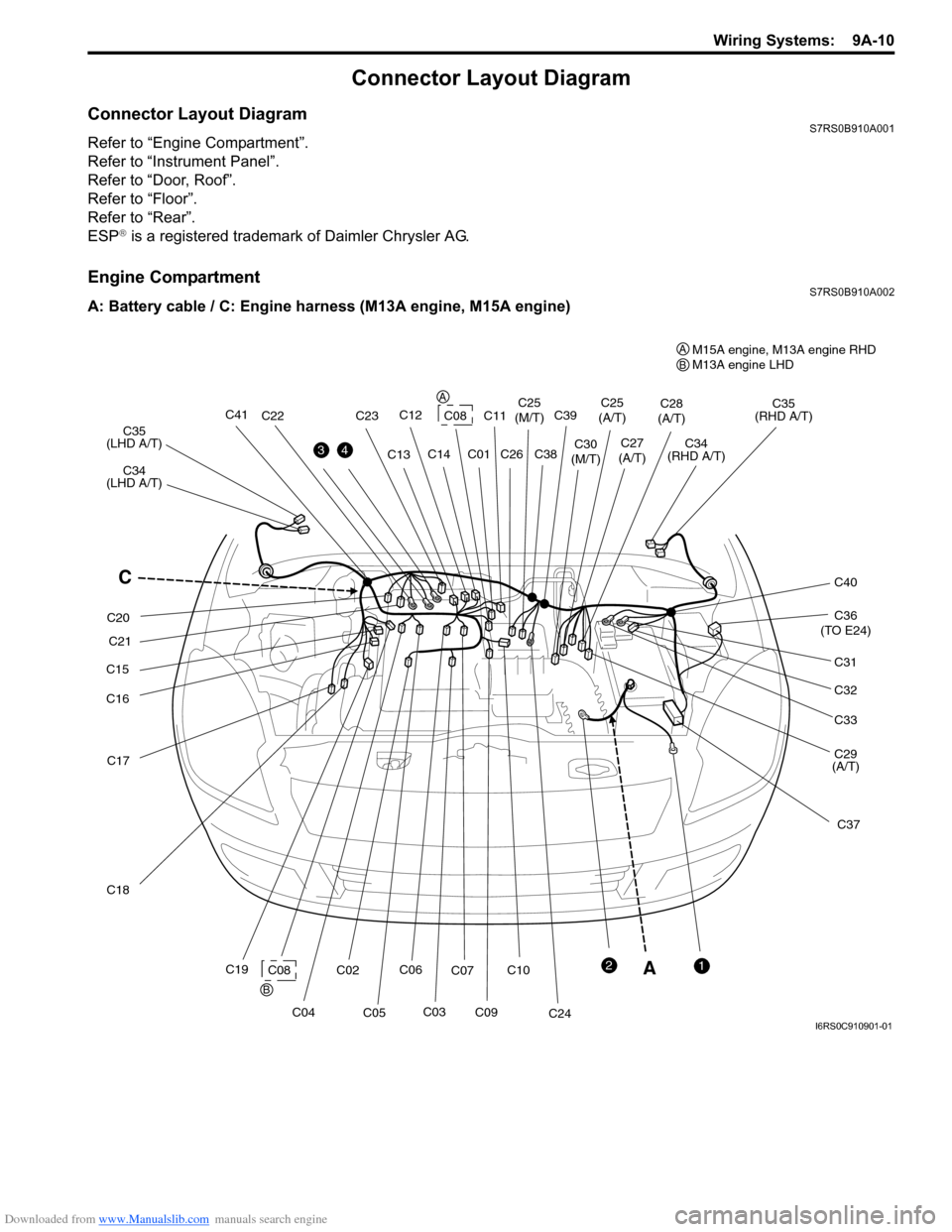

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-10

Connector Layout Diagram

Connector Layout DiagramS7RS0B910A001

Refer to “Engine Compartment”.

Refer to “Instrument Panel”.

Refer to “Door, Roof”.

Refer to “Floor”.

Refer to “Rear”.

ESP

® is a registered trademark of Daimler Chrysler AG.

Engine CompartmentS7RS0B910A002

A: Battery cable / C: Engine harness (M13A engine, M15A engine)

A

C36

(TO E24)

C17

C18

C19 C35

(RHD A/T)

C34

(LHD A/T) C35

(LHD A/T) C34

(RHD A/T)

C37

C15

C16

C02C08

C03

C10

C0912

34

C31

C32

C33

C29

(A/T)

C28

(A/T)

C27

(A/T)C30

(M/T) C25

(A/T)

C24

C25

(M/T)

C26

C07

C06

C05

C04

C22

C21

C20 C23

C13

C12C14

C08

C01

CC40

C41C39

C38C11

A

A

B

BM15A engine, M13A engine RHD

M13A engine LHD

I6RS0C910901-01

Page 1183 of 1496

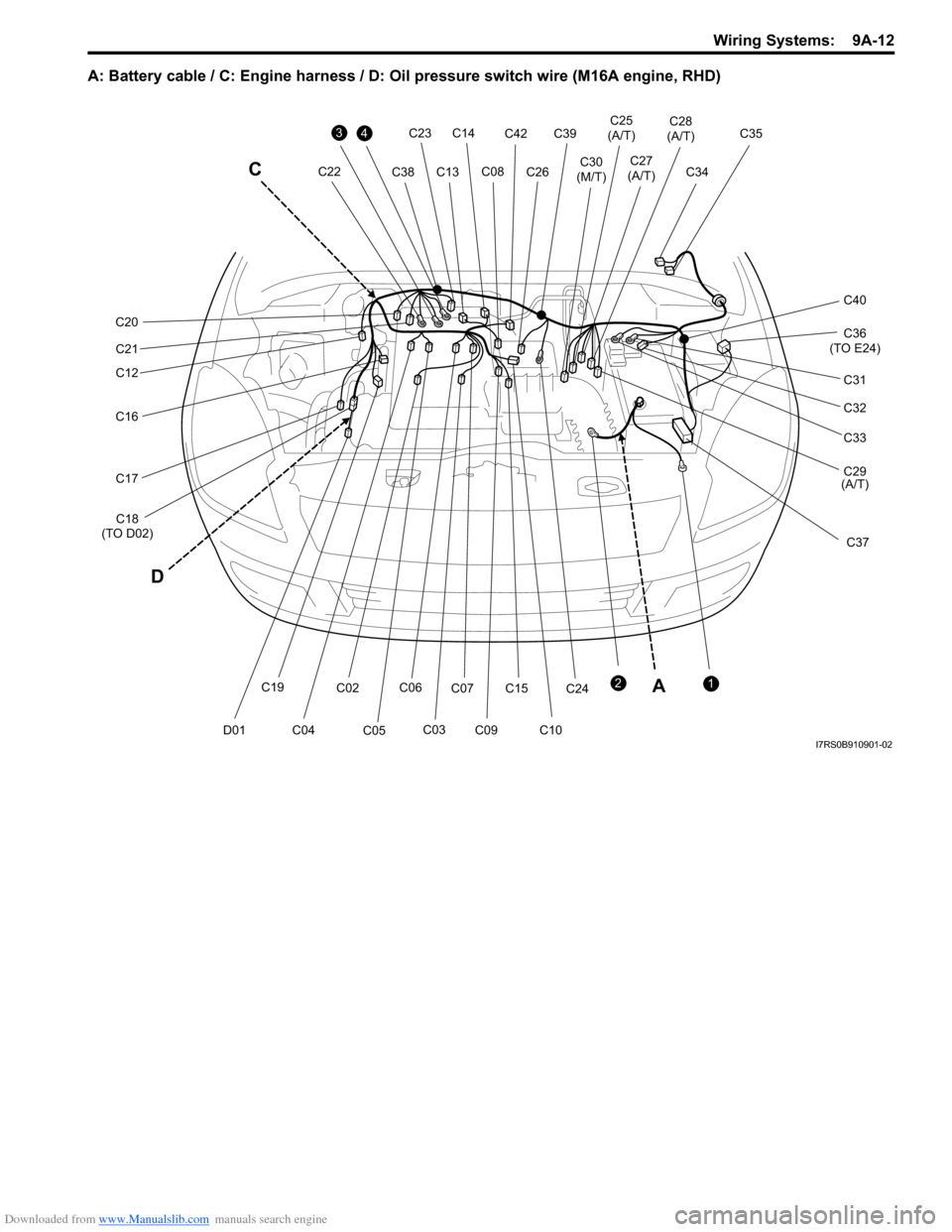

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-12

A: Battery cable / C: Engine harness / D: Oil pressure switch wire (M16A engine, RHD)

C36

(TO E24)

C35

C34

C37

34

C31

C32

C33

C29

(A/T)

C28

(A/T)

C27

(A/T)C30

(M/T) C25

(A/T)C26C22 C23C13C38

C14

C08

C40

C39

C42

A

C17

C18

(TO D02)

C19

C16

C02

C03C10

C09

12C24C07C15

C06

C05

C04D01

C21

C12

C20

C

D

I7RS0B910901-02

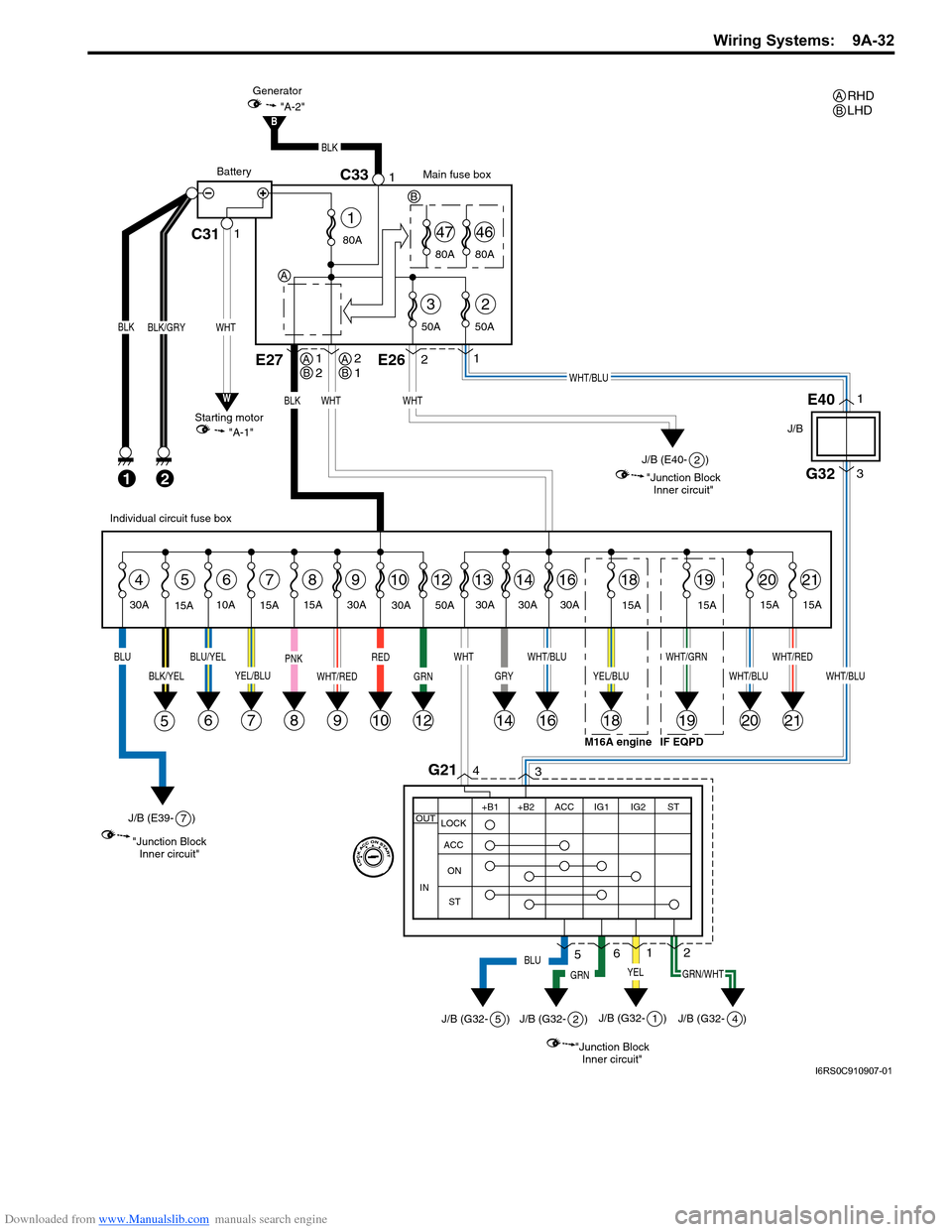

Page 1203 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-32

G32

J/B

3

WHT/BLU

4G213

12

10

BLK

21

BLK/GRY

10A

15A30A

5647891012

E27

WHT

131416192021

BLUBLU/YEL

6

BLK/YEL

5

YEL/BLU

7

PNK

89

WHT/RED

RED

GRN

12

WHT

GRY

14

WHT/GRN

19

WHT/BLU

2021

WHT/REDWHT/BLU

16

15A

15A 30A 50A

30A

30A 30A

30A

15A15A

15A

BLK

2E261

WHT/BLU

C31 C331 1

WHT

BLK

Main fuse box

Starting motor "A-1"

Generator

"A-2"

Battery

80A

50A

50A

3

80A

47

80A

46

2

1

E401WHT

"Junction Block

Inner circuit"

J/B (E40- )

YEL

"Junction BlockInner circuit"

J/B (G32- )

2

1

"Junction BlockInner circuit"

J/B (E39- ) 7

J/B (G32- ) 4

GRN/WHT

Individual circuit fuse box

+B1

LOCK

ACC

ON

ST ACC IG1 IG2

STOUT

IN

+B2

6

GRN

J/B (G32- )

2

5BLU

J/B (G32- )5

IF EQPD

18

YEL/BLU

18

15A

M16A engine

W

B

RHD

LHDAB

A

A

B1 2AB21

B

I6RS0C910907-01

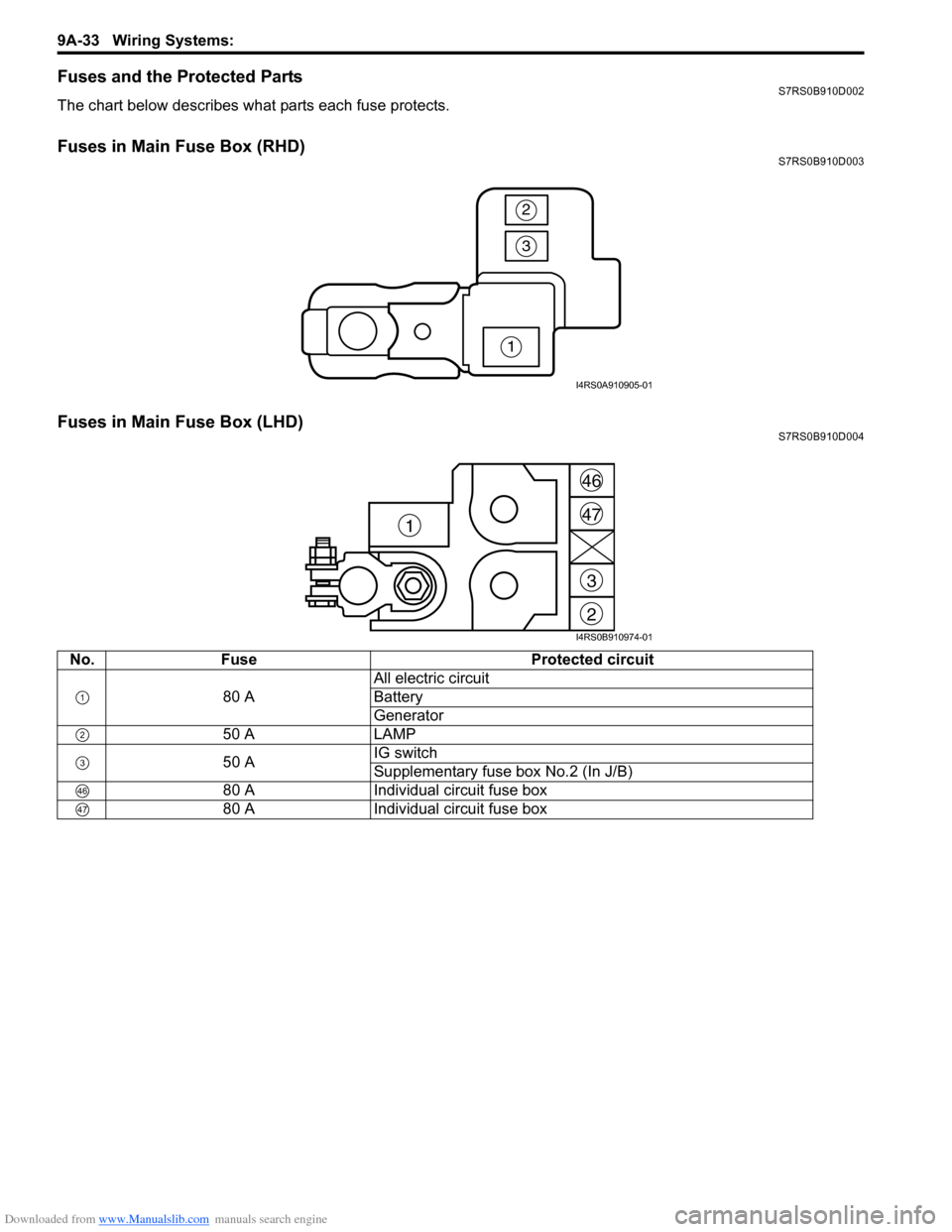

Page 1204 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-33 Wiring Systems:

Fuses and the Protected PartsS7RS0B910D002

The chart below describes what parts each fuse protects.

Fuses in Main Fuse Box (RHD)S7RS0B910D003

Fuses in Main Fuse Box (LHD)S7RS0B910D004

No.Fuse Protected circuit

80 A All electric circuit

Battery

Generator

50 A LAMP

50 A IG switch

Supplementary fuse box No.2 (In J/B)

80 A Individual circuit fuse box

80 A Individual circuit fuse box

1

3

2

I4RS0A910905-01

2

3

47

46

1

I4RS0B910974-01

Page 1217 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-46

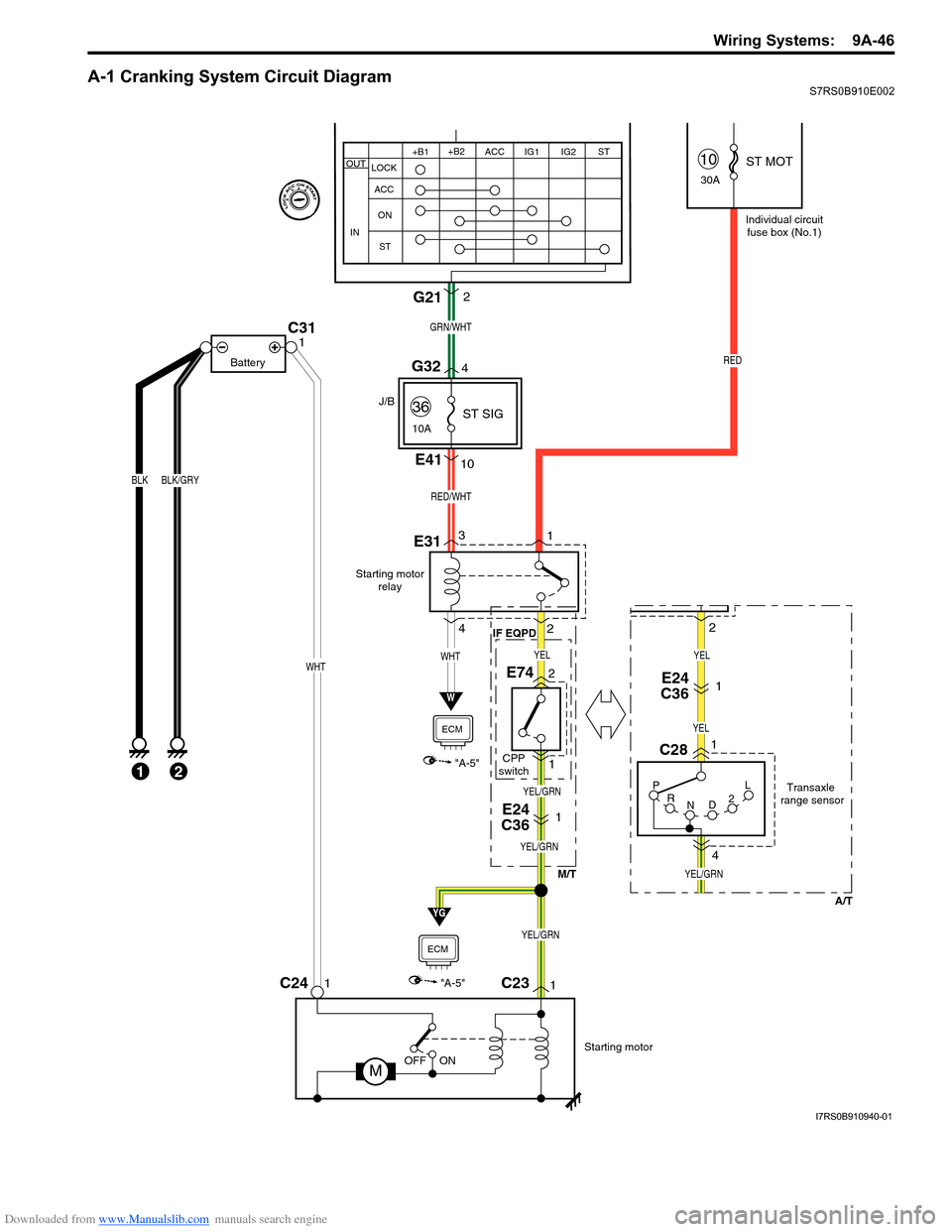

A-1 Cranking System Circuit DiagramS7RS0B910E002

Starting motorrelay

W

"A-5"

ECM

P

R N D2LTransaxle

range sensor

C28

E741

4

E31

C231C241

Starting motor

MOFF ON

BLK

1

BLK/GRY

C311

Battery

E24

C361

RED

Individual circuit

fuse box (No.1)

10

30A

36

10A

WHTWHT

M/T

IF EQPD

E24

C361

J/B

A/T

E4110

13

2

4

RED/WHT

2 ST MOT

ST SIG

YEL/GRN

YG

"A-5"

ECM

GRN/WHT

G212

YEL/GRN

YEL/GRN

YEL

YEL/GRN

YEL

YEL

G324

+B1

LOCK

ACC

ON

ST ACC IG1 IG2

STOUT

IN

+B2

21CPP

switch

2

I7RS0B910940-01

Page 1284 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-2 Lighting Systems:

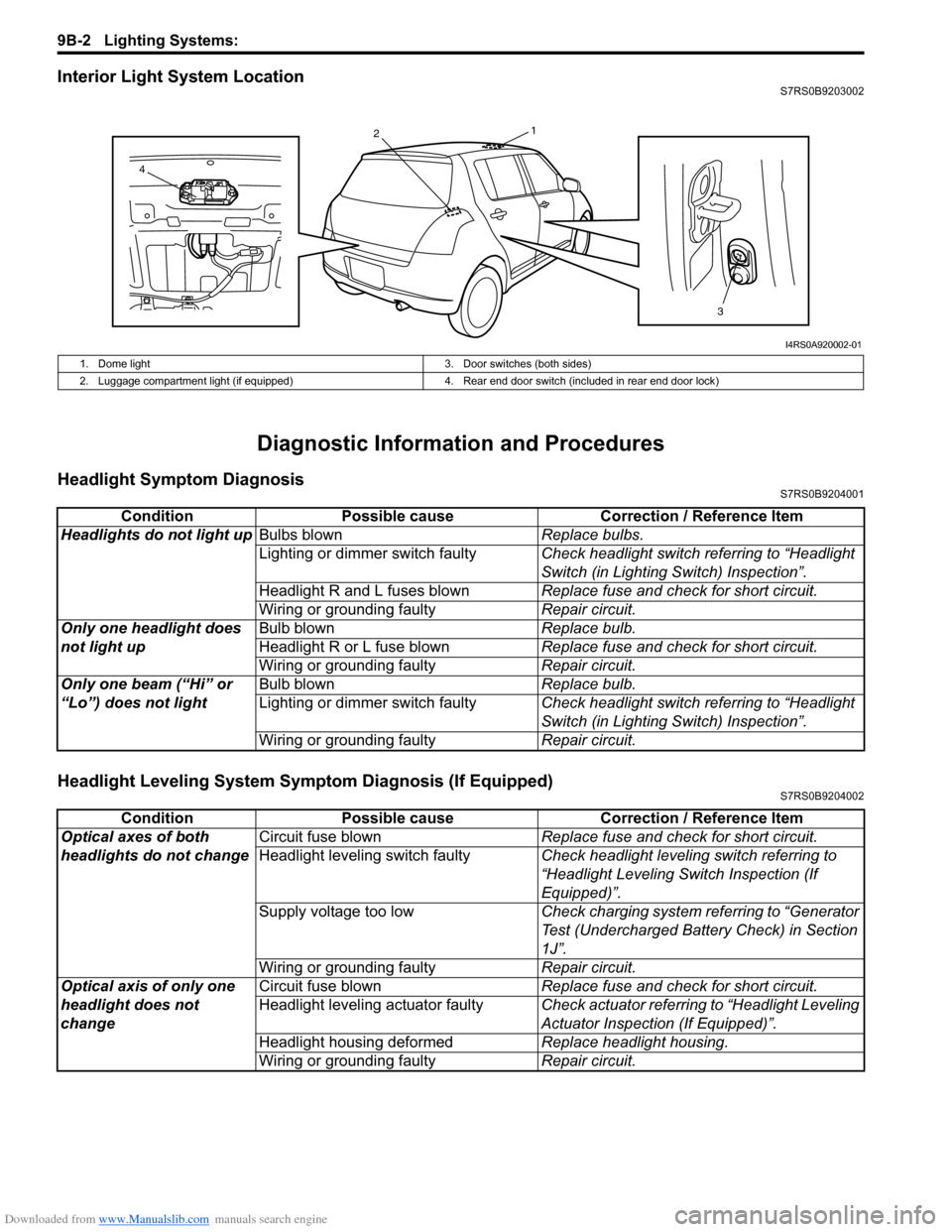

Interior Light System LocationS7RS0B9203002

Diagnostic Information and Procedures

Headlight Symptom DiagnosisS7RS0B9204001

Headlight Leveling System Symptom Diagnosis (If Equipped)S7RS0B9204002

13

2

4

I4RS0A920002-01

1. Dome light 3. Door switches (both sides)

2. Luggage compartment light (if equipped) 4. Rear end door switch (included in rear end door lock)

ConditionPossible cause Correction / Reference Item

Headlights do not light up Bulbs blown Replace bulbs.

Lighting or dimmer switch faulty Check headlight switch referring to “Headlight

Switch (in Lighting Switch) Inspection”.

Headlight R and L fuses blown Replace fuse and check for short circuit.

Wiring or grounding faulty Repair circuit.

Only one headlight does

not light up Bulb blown

Replace bulb.

Headlight R or L fuse blown Replace fuse and check for short circuit.

Wiring or grounding faulty Repair circuit.

Only one beam (“Hi” or

“Lo”) does not light Bulb blown

Replace bulb.

Lighting or dimmer switch faulty Check headlight switch referring to “Headlight

Switch (in Lighting Switch) Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

Optical axes of both

headlights do not change Circuit fuse blown

Replace fuse and check for short circuit.

Headlight leveling switch faulty Check headlight leveling switch referring to

“Headlight Leveling Switch Inspection (If

Equipped)”.

Supply voltage too low Check charging system referring to “Generator

Test (Undercharged Battery Check) in Section

1J”.

Wiring or grounding faulty Repair circuit.

Optical axis of only one

headlight does not

change Circuit fuse blown

Replace fuse and check for short circuit.

Headlight leveling actuator faulty Check actuator referring to “Headlight Leveling

Actuator Inspection (If Equipped)”.

Headlight housing deformed Replace headlight housing.

Wiring or grounding faulty Repair circuit.

Page 1285 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-3

Turn Signal and Hazard Warning Light Symptom DiagnosisS7RS0B9204003

Clearance, Tail and License Plate Light Symptom DiagnosisS7RS0B9204004

ConditionPossible cause Correction / Reference Item

Flash rate high or one

side only flashes Bulb blown on “flash rate high”-side

Replace bulb.

Incorrect bulb Replace bulb.

Turn signal / hazard warning relay faulty Check turn signal / hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection”.

Open circuit or high resistance existing

either; between turn signal switch and

non lighting bulb, or between hazard

warning switch and non lighting bulb Repair circuit.

Wiring or grounding faulty Repair circuit.

No flashing

NOTE

• Use of SUZUKI scan tool makes it easy to

check whether a faulty

condition is on the

input side or output

side of BCM. For

checking procedure,

refer to “Diagnosis

Using Output Test

Function of SUZUKI

Scan Tool” under

“Scan Tool Data in

Section 10B”.

• Check each part in the order from the top of

the following list.

Circuit fuse(s) blown Replace fuse(s) and check for short circuit.

Turn signal / hazard warning relay faulty Check turn signal / hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection”.

Turn signal light switch faulty Check turn signal light switch referring to “Turn

Signal Light Switch (in Lighting Switch)

Inspection”.

Hazard warning switch faulty Check hazard warning switch referring to

“Hazard Warning Switch Inspection”.

Open circuit or high resistance existing

between battery and switch Repair circuit.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Flash rate low Supply voltage low Check charging system.

Turn signal / hazard warning relay faulty Check turn signal / hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection”.

ConditionPossible cause Correction / Reference Item

All lights do not light up Circuit fuse blown Replace fuse and check for short circuit.

Lighting and dimmer switch of

combination switch faulty Check lighting and dimmer switch referring to

“Headlight Switch (in Lighting Switch)

Inspection”.

Wiring or grounding faulty Repair circuit.

Some lights do not light

up Bulb(s) blown

Replace bulb(s).

Wiring or grounding faulty Repair circuit.

Page 1287 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-5

Interior Light Symptom DiagnosisS7RS0B9204008

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Repair Instructions

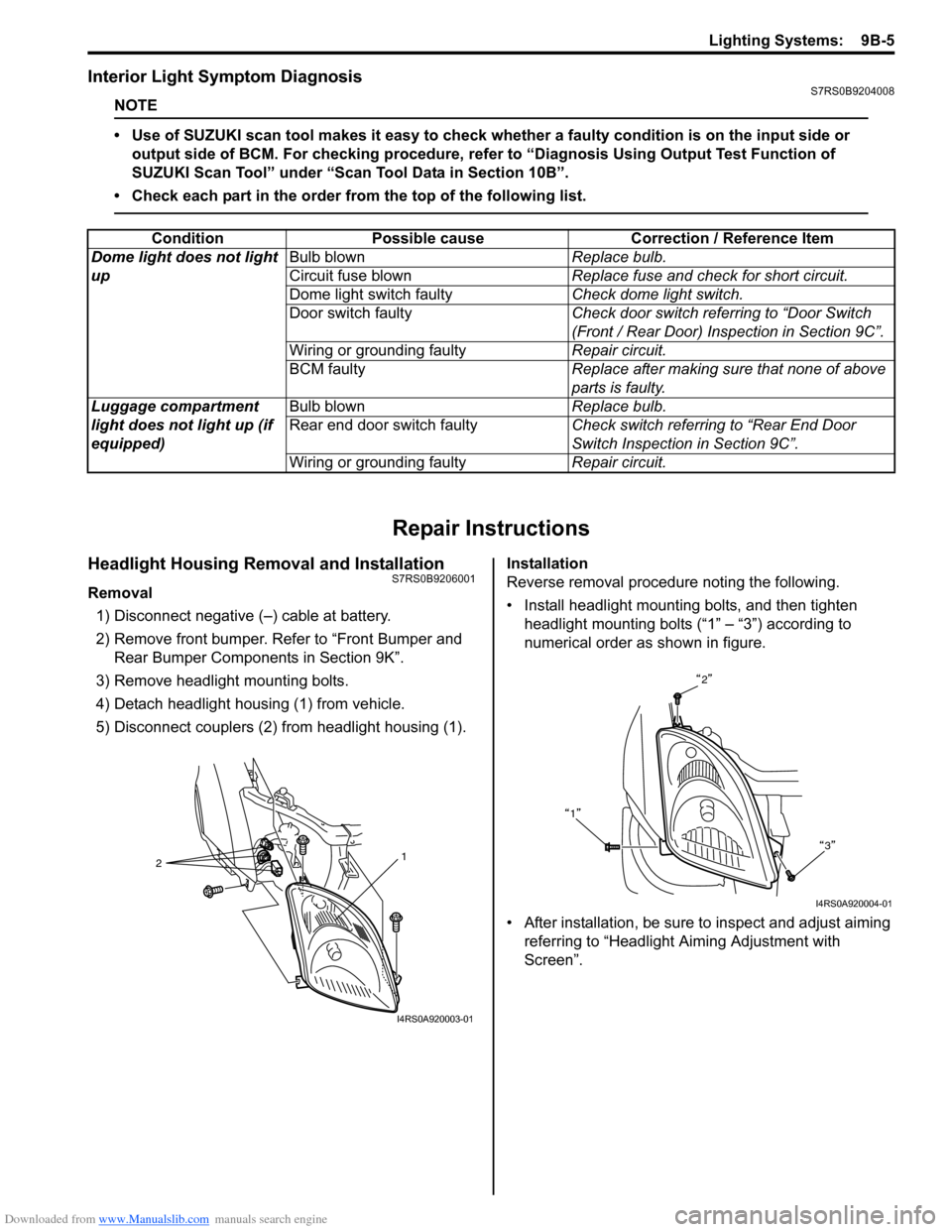

Headlight Housing Removal and InstallationS7RS0B9206001

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper. Refer to “Front Bumper and Rear Bumper Componen ts in Section 9K”.

3) Remove headlight mounting bolts.

4) Detach headlight housing (1) from vehicle.

5) Disconnect couplers (2) from headlight housing (1). Installation

Reverse removal procedure noting the following.

• Install headlight mounting bolts, and then tighten

headlight mounting bolts (“1” – “3”) according to

numerical order as shown in figure.

• After installation, be sure to inspect and adjust aiming referring to “Headlight Aiming Adjustment with

Screen”.

Condition Possible cause Correction / Reference Item

Dome light does not light

up Bulb blown

Replace bulb.

Circuit fuse blown Replace fuse and check for short circuit.

Dome light switch faulty Check dome light switch.

Door switch faulty Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Luggage compartment

light does not light up (if

equipped) Bulb blown

Replace bulb.

Rear end door switch faulty Check switch referring to “Rear End Door

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

2 1

I4RS0A920003-01

2

1 3

I4RS0A920004-01

Page 1288 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-6 Lighting Systems:

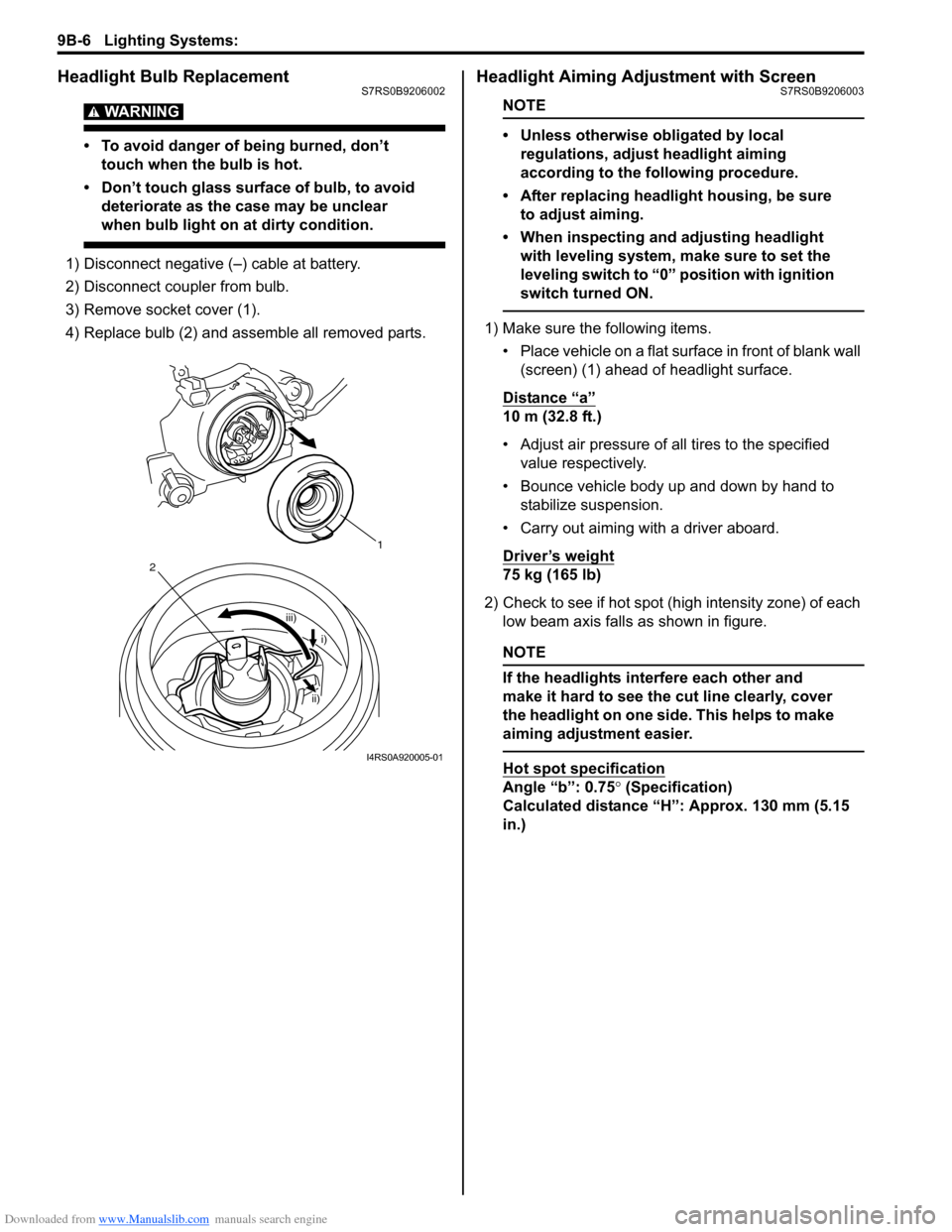

Headlight Bulb ReplacementS7RS0B9206002

WARNING!

• To avoid danger of being burned, don’t touch when the bulb is hot.

• Don’t touch glass surface of bulb, to avoid deteriorate as the case may be unclear

when bulb light on at dirty condition.

1) Disconnect negative (–) cable at battery.

2) Disconnect coupler from bulb.

3) Remove socket cover (1).

4) Replace bulb (2) and assemble all removed parts.

Headlight Aiming Adjustment with ScreenS7RS0B9206003

NOTE

• Unless otherwise obligated by local regulations, adjust headlight aiming

according to the following procedure.

• After replacing headlight housing, be sure to adjust aiming.

• When inspecting and adjusting headlight with leveling system, make sure to set the

leveling switch to “0 ” position with ignition

switch turned ON.

1) Make sure the following items.

• Place vehicle on a flat surface in front of blank wall (screen) (1) ahead of headlight surface.

Distance “a”

10 m (32.8 ft.)

• Adjust air pressure of all tires to the specified value respectively.

• Bounce vehicle body up and down by hand to stabilize suspension.

• Carry out aiming with a driver aboard.

Driver’s weight

75 kg (165 lb)

2) Check to see if hot spot (high intensity zone) of each low beam axis falls as shown in figure.

NOTE

If the headlights interfere each other and

make it hard to see the cut line clearly, cover

the headlight on one side. This helps to make

aiming adjustment easier.

Hot spot specification

Angle “b”: 0.75 ° (Specification)

Calculated distance “H”: Approx. 130 mm (5.15

in.)

1

iii)

2

i)

ii)

I4RS0A920005-01

Page 1290 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-8 Lighting Systems:

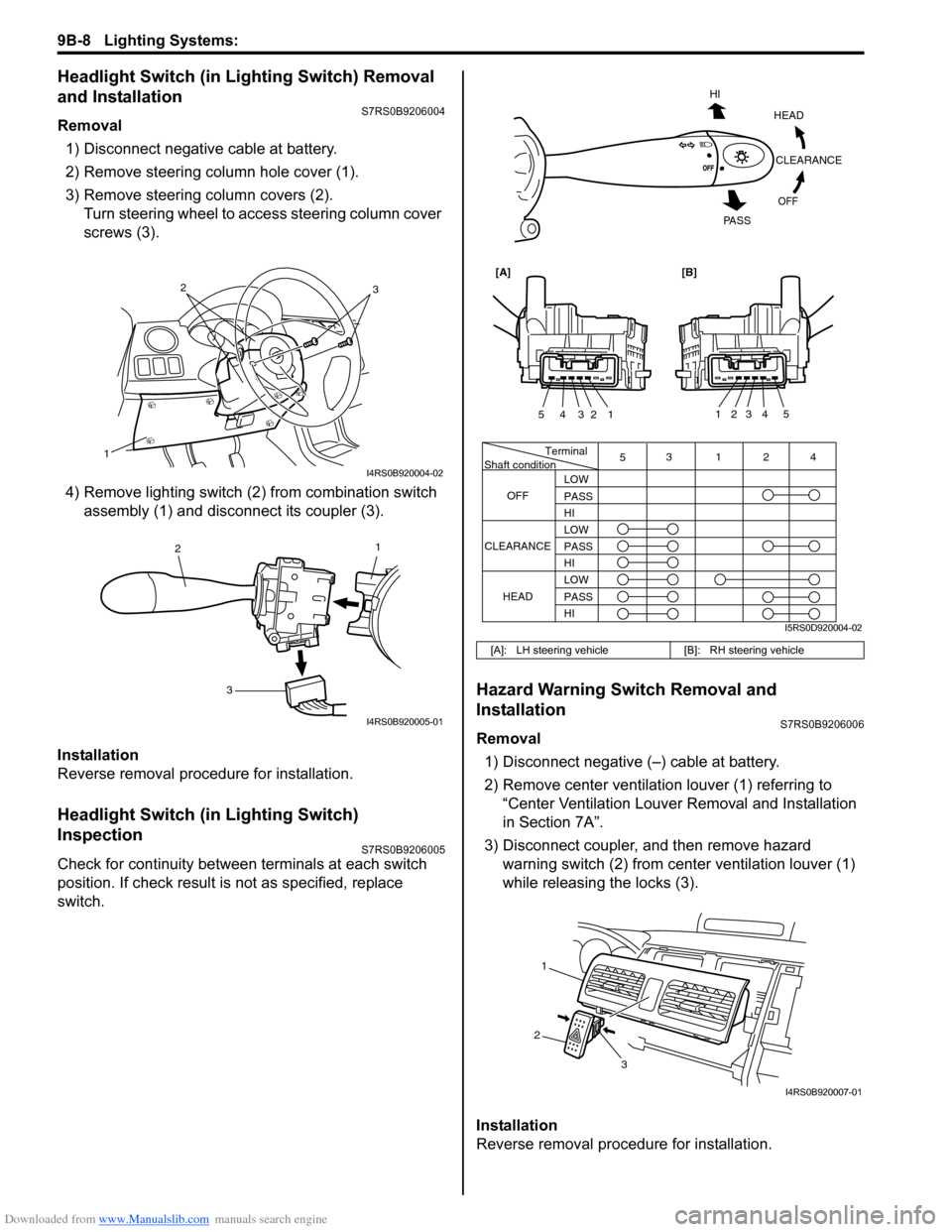

Headlight Switch (in Lighting Switch) Removal

and Installation

S7RS0B9206004

Removal1) Disconnect negative cable at battery.

2) Remove steering column hole cover (1).

3) Remove steering column covers (2). Turn steering wheel to acce ss steering column cover

screws (3).

4) Remove lighting switch (2 ) from combination switch

assembly (1) and disconnect its coupler (3).

Installation

Reverse removal procedure for installation.

Headlight Switch (in Lighting Switch)

Inspection

S7RS0B9206005

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Hazard Warning Switch Removal and

Installation

S7RS0B9206006

Removal 1) Disconnect negative (–) cable at battery.

2) Remove center ventilation louver (1) referring to

“Center Ventilation Louver Removal and Installation

in Section 7A”.

3) Disconnect coupler, and then remove hazard warning switch (2) from center ventilation louver (1)

while releasing the locks (3).

Installation

Reverse removal procedure for installation.

1

32

I4RS0B920004-02

1

2

3

I4RS0B920005-01

[A]: LH steering vehicle [B]: RH steering vehicle

Terminal

Shaft condition

OFF 5

3124

LOW

PASS

HI

LOW

PASS

HI LOW

PASS

HI

CLEARANCE

HEAD

HEADCLEARANCE

OFF

HI

PA S S

54321

54321

[A][B]

I5RS0D920004-02

1

2 3

I4RS0B920007-01