ig 2 sig SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1012 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-64 Air Conditioning System: Automatic Type

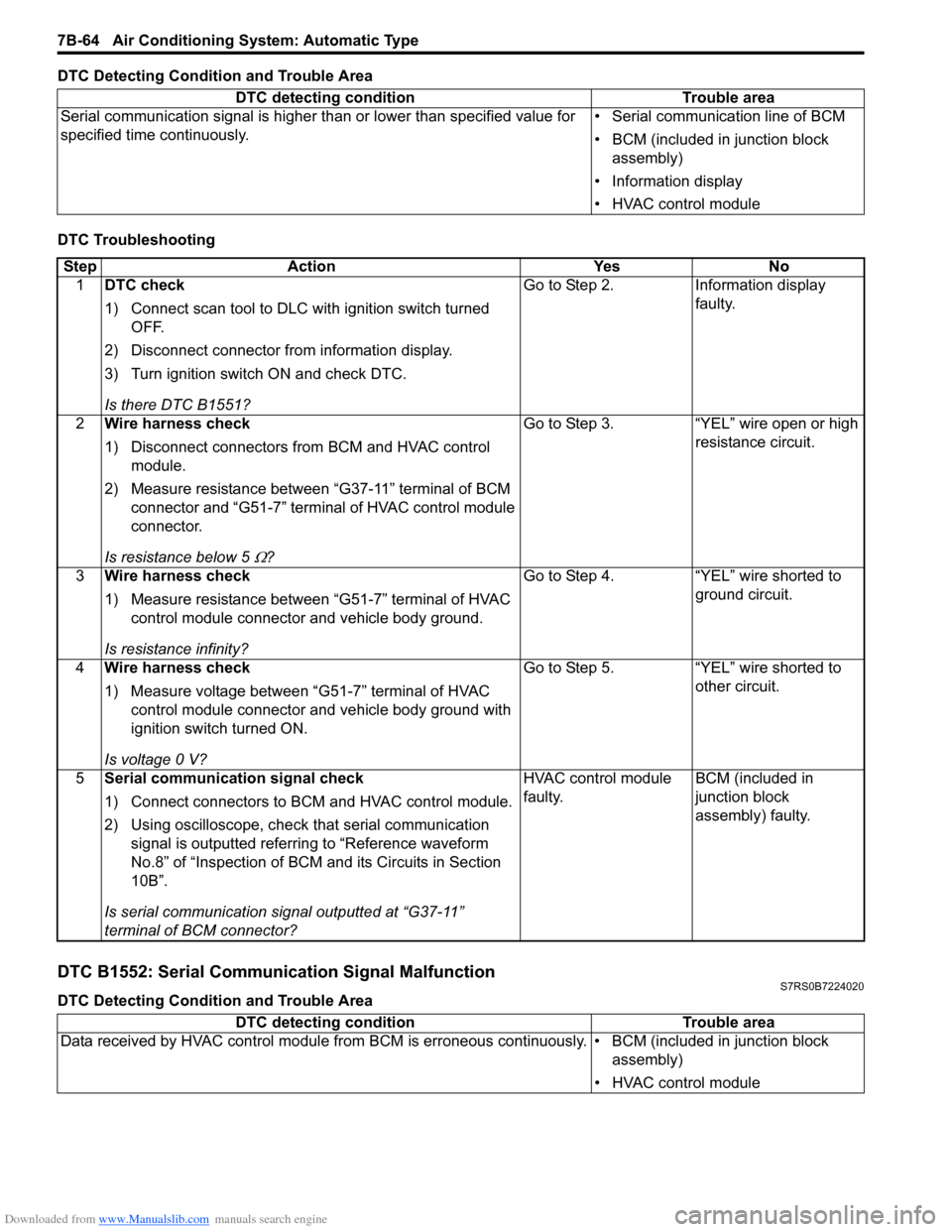

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1552: Serial Communication Signal MalfunctionS7RS0B7224020

DTC Detecting Condition and Trouble AreaDTC detecting condition Trouble area

Serial communication signal is higher than or lower than specified value for

specified time continuously. • Serial communication line of BCM

• BCM (included in junction block

assembly)

• Information display

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Disconnect connector from information display.

3) Turn ignition switch ON and check DTC.

Is there DTC B1551? Go to Step 2.

Information display

faulty.

2 Wire harness check

1) Disconnect connectors from BCM and HVAC control

module.

2) Measure resistance between “G37-11” terminal of BCM connector and “G51-7” terminal of HVAC control module

connector.

Is resistance below 5

Ω? Go to Step 3. “YEL” wire open or high

resistance circuit.

3 Wire harness check

1) Measure resistance between “G51-7” terminal of HVAC

control module connector and vehicle body ground.

Is resistance infinity? Go to Step 4. “YEL” wire shorted to

ground circuit.

4 Wire harness check

1) Measure voltage between “G51-7” terminal of HVAC

control module connector and vehicle body ground with

ignition switch turned ON.

Is voltage 0 V? Go to Step 5. “YEL” wire shorted to

other circuit.

5 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

Data received by HVAC control module from BCM is erroneous continuously. • BCM (included in junction block assembly)

• HVAC control module

Page 1013 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-65

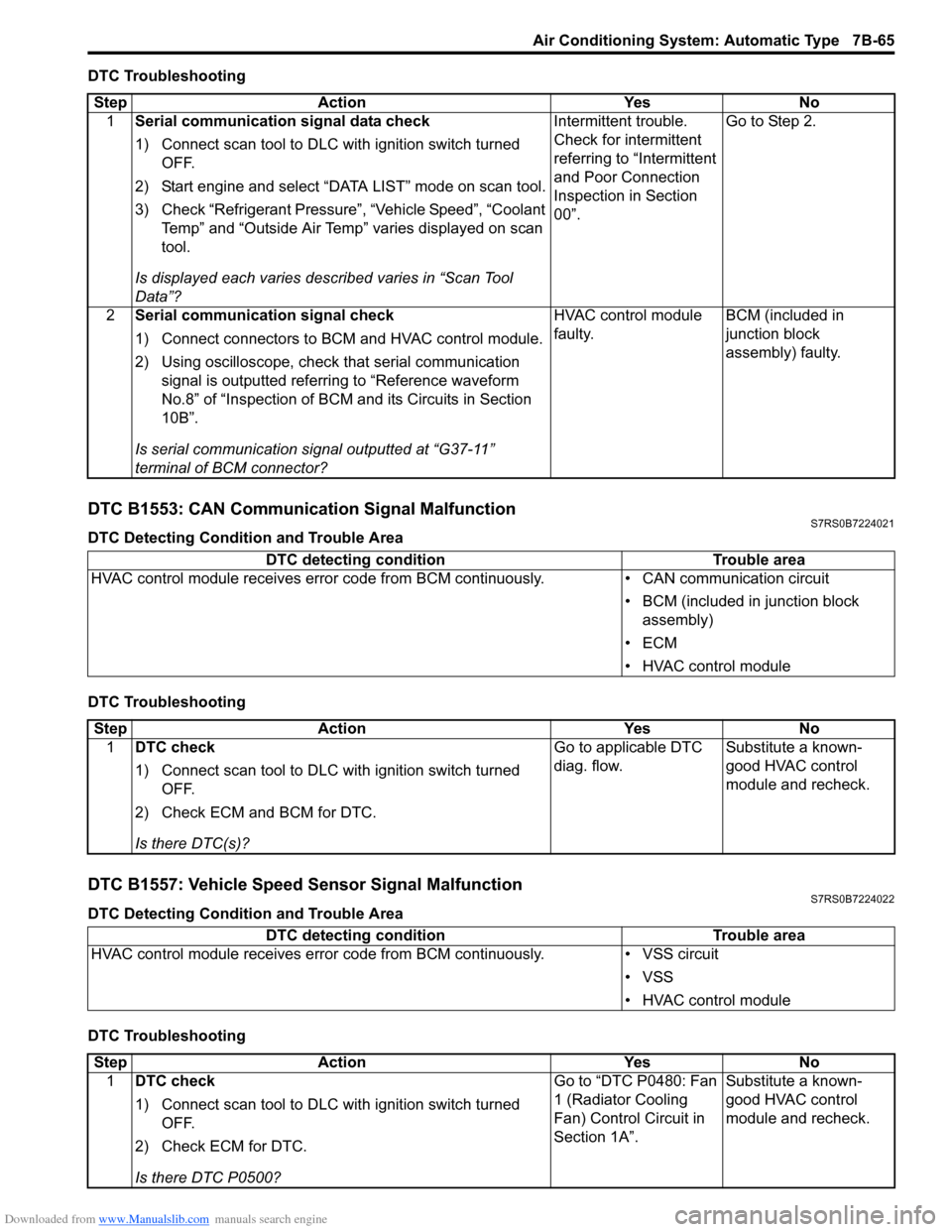

DTC Troubleshooting

DTC B1553: CAN Communication Signal MalfunctionS7RS0B7224021

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1557: Vehicle Speed Sensor Signal MalfunctionS7RS0B7224022

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Serial communication signal data check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure”, “Vehicle Speed”, “Coolant Temp” and “Outside Air Temp” varies displayed on scan

tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 2.

2 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

HVAC control module receives error code fr om BCM continuously.• CAN communication circuit

• BCM (included in junction block assembly)

•ECM

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM and BCM for DTC.

Is there DTC(s)? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives error code from BCM continuously. • VSS circuit

• VSS

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Is there DTC P0500? Go to “DTC P0480: Fan

1 (Radiator Cooling

Fan) Control Circuit in

Section 1A”.

Substitute a known-

good HVAC control

module and recheck.

Page 1014 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-66 Air Conditioning System: Automatic Type

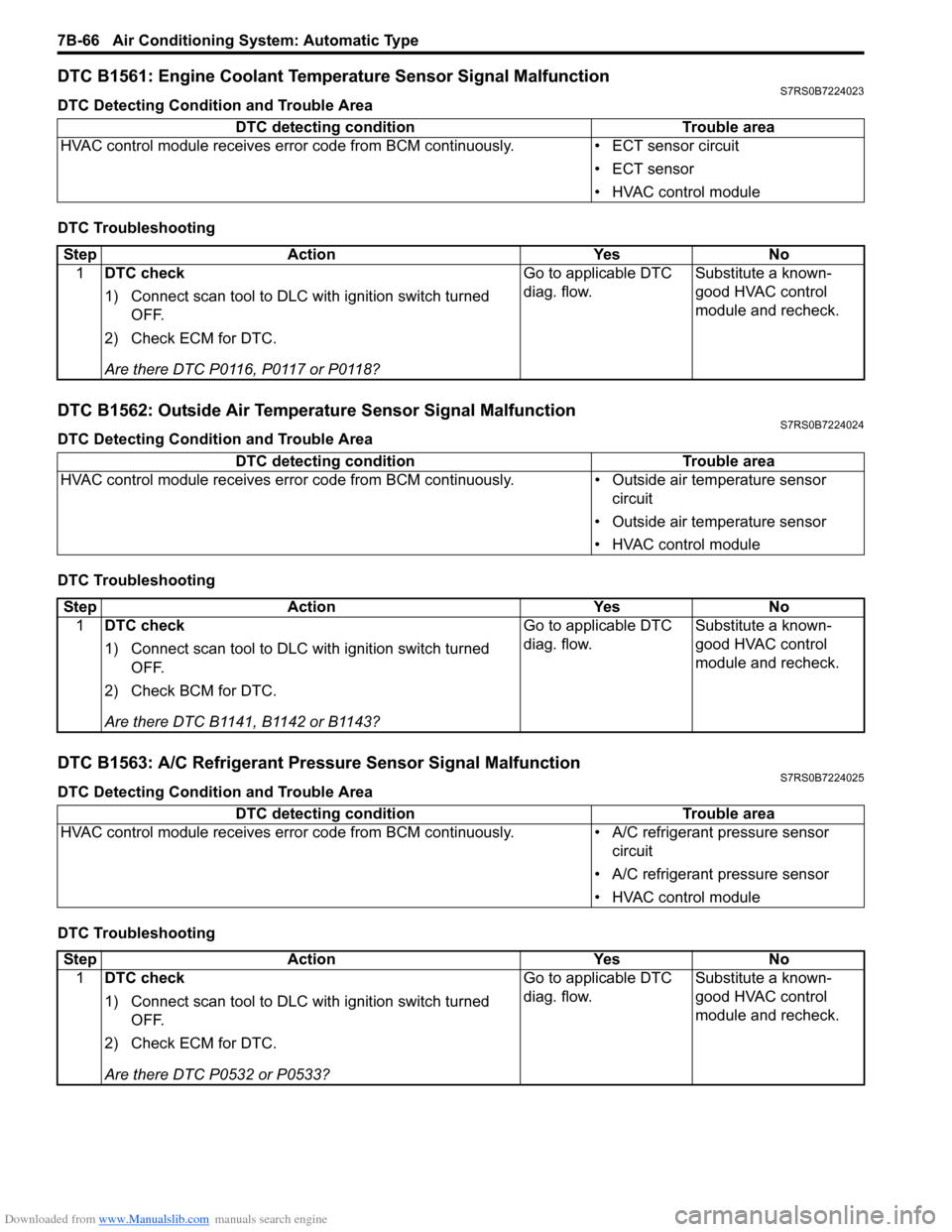

DTC B1561: Engine Coolant Temperature Sensor Signal MalfunctionS7RS0B7224023

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1562: Outside Air Temperature Sensor Signal MalfunctionS7RS0B7224024

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1563: A/C Refrigerant Pressure Sensor Signal MalfunctionS7RS0B7224025

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

HVAC control module receives error code from BCM continuously. • ECT sensor circuit

• ECT sensor

• HVAC control module

StepAction YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Are there DTC P0116, P0117 or P0118? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives er ror code from BCM continuously. • Outside air temperature sensor

circuit

• Outside air temperature sensor

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check BCM for DTC.

Are there DTC B1141, B1142 or B1143? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives er ror code from BCM continuously. • A/C refrigerant pressure sensor

circuit

• A/C refrigerant pressure sensor

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Are there DTC P0532 or P0533? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

Page 1016 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-68 Air Conditioning System: Automatic Type

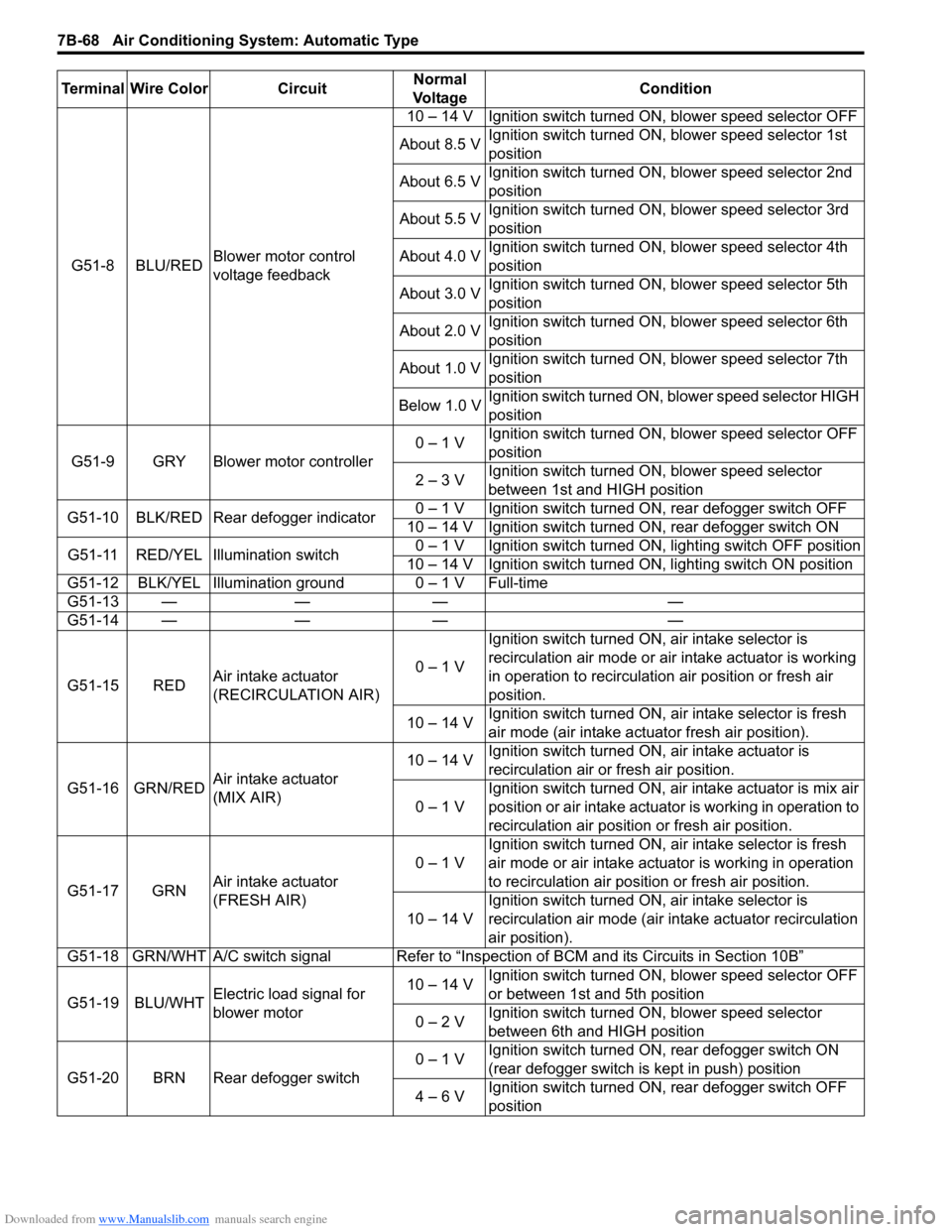

G51-8 BLU/REDBlower motor control

voltage feedback 10 – 14 V Ignition switch turned ON, blower speed selector OFF

About 8.5 V Ignition switch turned ON, blower speed selector 1st

position

About 6.5 V Ignition switch turned ON, blower speed selector 2nd

position

About 5.5 V Ignition switch turned ON, blower speed selector 3rd

position

About 4.0 V Ignition switch turned ON, blower speed selector 4th

position

About 3.0 V Ignition switch turned ON, blower speed selector 5th

position

About 2.0 V Ignition switch turned ON, blower speed selector 6th

position

About 1.0 V Ignition switch turned ON, blower speed selector 7th

position

Below 1.0 V Ignition switch turned ON, blower speed selector HIGH

position

G51-9 GRY Blower motor controller 0 – 1 V

Ignition switch turned ON, blower speed selector OFF

position

2 – 3 V Ignition switch turned ON, blower speed selector

between 1st and HIGH position

G51-10 BLK/RED Rear defogger indicator 0 – 1 V Ignition switch turned ON, rear defogger switch OFF

10 – 14 V Ignition switch turned ON, rear defogger switch ON

G51-11 RED/YEL Illumination switch 0 – 1 V Ignition switch turned ON, lighting switch OFF position

10 – 14 V Ignition switch turned ON, lighting switch ON position

G51-12 BLK/YEL Illumination ground 0 – 1 V Full-time

G51-13 — — — —

G51-14 — — — —

G51-15 RED Air intake actuator

(RECIRCULATION AIR) 0 – 1 VIgnition switch turned ON, air intake selector is

recirculation air mode or air intake actuator is working

in operation to recirculation air position or fresh air

position.

10 – 14 V Ignition switch turned ON, ai

r intake selector is fresh

air mode (air intake actuator fresh air position).

G51-16 GRN/RED Air intake actuator

(MIX AIR) 10 – 14 V

Ignition switch turned ON, air intake actuator is

recirculation air or fresh air position.

0 – 1 V Ignition switch turned ON, air intake actuator is mix air

position or air intake actuator is working in operation to

recirculation air position or fresh air position.

G51-17 GRN Air intake actuator

(FRESH AIR) 0 – 1 V

Ignition switch turned ON, ai

r intake selector is fresh

air mode or air intake actuator is working in operation

to recirculation air position or fresh air position.

10 – 14 V Ignition switch turned ON, air intake selector is

recirculation air mode (air intake actuator recirculation

air position).

G51-18 GRN/WHT A/C switch signal Refer to “Inspe ction of BCM and its Circuits in Section 10B”

G51-19 BLU/WHT Electric load signal for

blower motor 10 – 14 V

Ignition switch turned ON, blower speed selector OFF

or between 1st and 5th position

0 – 2 V Ignition switch turned ON, blower speed selector

between 6th and HIGH position

G51-20 BRN Rear defogger switch 0 – 1 V

Ignition switch turned ON, rear defogger switch ON

(rear defogger switch is kept in push) position

4 – 6 V Ignition switch turned ON, rear defogger switch OFF

position

Terminal Wire Color Circuit

Normal

Vo l ta g e Condition

Page 1017 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-69

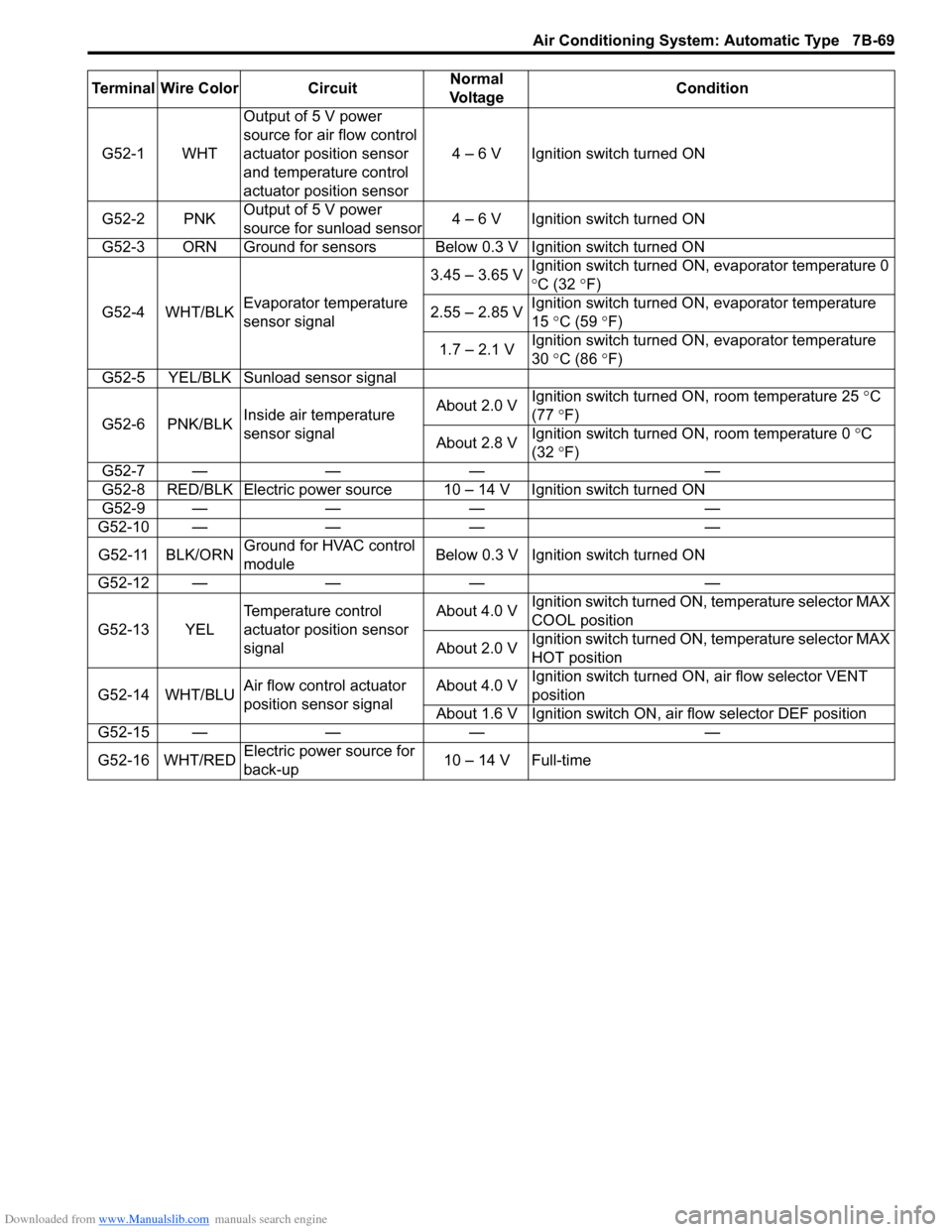

Terminal Wire Color CircuitNormal

Vo l ta g e Condition

G52-1 WHT Output of 5 V power

source for air flow control

actuator position sensor

and temperature control

actuator position sensor 4 – 6 V Ignition switch turned ON

G52-2 PNK Output of 5 V power

source for sunload sensor 4 – 6 V Ignition switch turned ON

G52-3 ORN Ground for sensors Below 0.3 V Ignition switch turned ON

G52-4 WHT/BLK Evaporator temperature

sensor signal 3.45 – 3.65 V

Ignition switch turned ON, evaporator temperature 0

°

C (32 °F)

2.55 – 2.85 V Ignition switch turned ON, evaporator temperature

15

°C (59 ° F)

1.7 – 2.1 V Ignition switch turned ON, evaporator temperature

30

°C (86 ° F)

G52-5 YEL/BLK Sunload sensor signal

G52-6 PNK/BLK Inside air temperature

sensor signal About 2.0 V

Ignition switch turned ON, room temperature 25

°C

(77 °F)

About 2.8 V Ignition switch turned ON, room temperature 0

°C

(32 °F)

G52-7 — — — —

G52-8 RED/BLK Electric power source 10 – 14 V Ignition switch turned ON

G52-9 — — — —

G52-10 — — — —

G52-11 BLK/ORN Ground for HVAC control

module Below 0.3 V Ignition

switch turned ON

G52-12 — — — —

G52-13 YEL Temperature control

actuator position sensor

signal About 4.0 V

Ignition switch turned ON, temperature selector MAX

COOL position

About 2.0 V Ignition switch turned ON, temperature selector MAX

HOT position

G52-14 WHT/BLU Air flow control actuator

position sensor signal About 4.0 V

Ignition switch turned ON

, air flow selector VENT

position

About 1.6 V Ignition switch ON, air flow selector DEF position

G52-15 — — — —

G52-16 WHT/RED Electric power source for

back-up 10 – 14 V Full-time

Page 1019 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-71

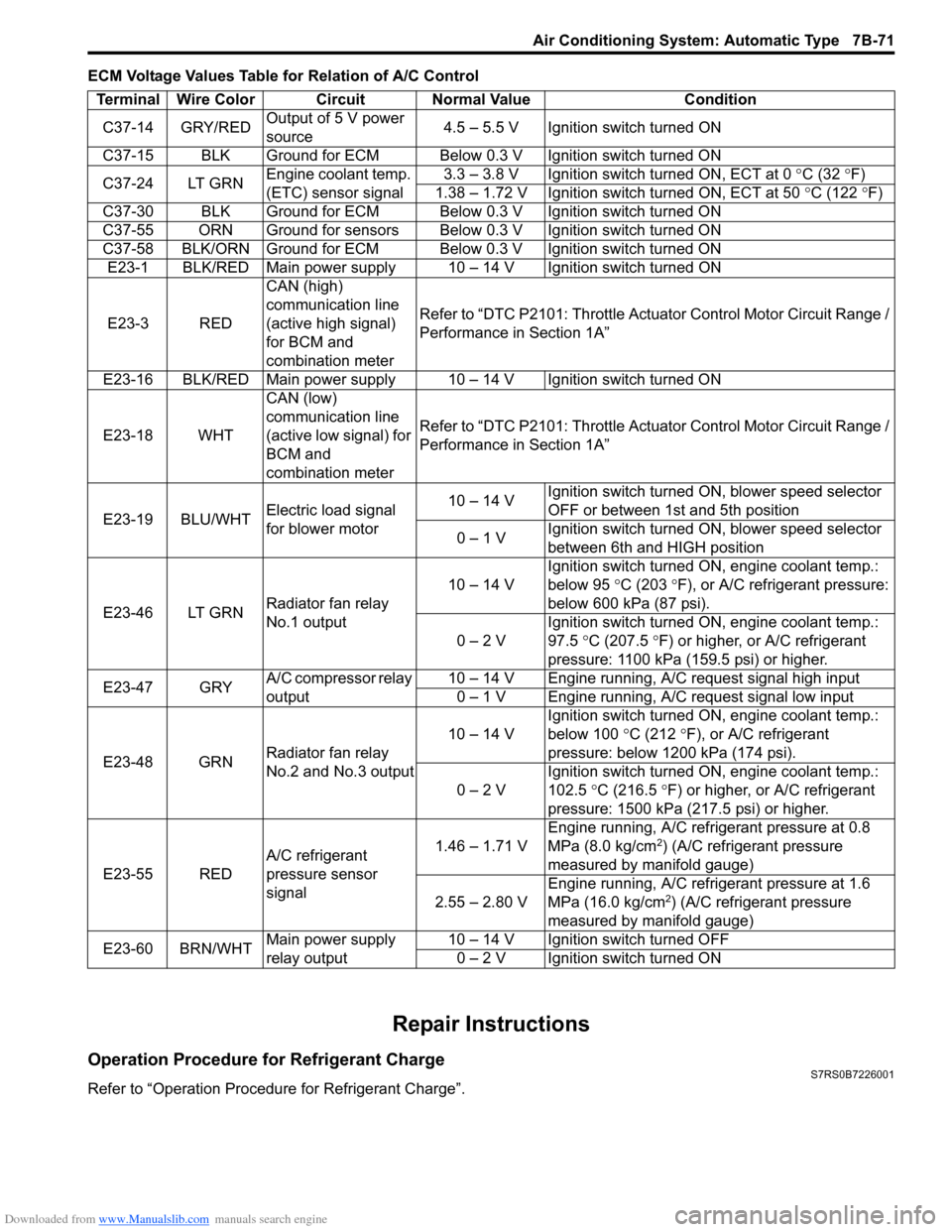

ECM Voltage Values Table for Relation of A/C Control

Repair Instructions

Operation Procedure for Refrigerant ChargeS7RS0B7226001

Refer to “Operation Procedure for Refrigerant Charge”.Terminal Wire Color Circuit Normal Value Condition

C37-14 GRY/RED Output of 5 V power

source 4.5 – 5.5 V Ignition switch turned ON

C37-15 BLK Ground for ECM Below 0.3 V Ignition switch turned ON

C37-24 LT GRN Engine coolant temp.

(ETC) sensor signal 3.3 – 3.8 V Ignition switch turned ON, ECT at 0

°C (32 ° F)

1.38 – 1.72 V Ignition switch turned ON, ECT at 50 °C (122 °F)

C37-30 BLK Ground for ECM Below 0.3 V Ignition switch turned ON

C37-55 ORN Ground for sensors Below 0.3 V Ignition switch turned ON

C37-58 BLK/ORN Ground for ECM Below 0.3 V Ignition switch turned ON E23-1 BLK/RED Main power supply 10 – 14 V Ignition switch turned ON

E23-3 RED CAN (high)

communication line

(active high signal)

for BCM and

combination meterRefer to “DTC P2101: Throttle Actu

ator Control Motor Circuit Range /

Performance in Section 1A”

E23-16 BLK/RED Main power supply 10 – 14 V Ignition switch turned ON

E23-18 WHT CAN (low)

communication line

(active low signal) for

BCM and

combination meterRefer to “DTC P2101: Throttle Actu

ator Control Motor Circuit Range /

Performance in Section 1A”

E23-19 BLU/WHT Electric load signal

for blower motor 10 – 14 V

Ignition switch turned ON, blower speed selector

OFF or between 1st and 5th position

0 – 1 V Ignition switch turned ON, blower speed selector

between 6th and HIGH position

E23-46 LT GRN Radiator fan relay

No.1 output 10 – 14 V

Ignition switch turned ON, engine coolant temp.:

below 95

°C (203 ° F), or A/C refrigerant pressure:

below 600 kPa (87 psi).

0 – 2 V Ignition switch turned ON, engine coolant temp.:

97.5

°C (207.5 °F) or higher, or A/C refrigerant

pressure: 1100 kPa (159.5 psi) or higher.

E23-47 GRY A/C compressor relay

output 10 – 14 V Engine running, A/C request signal high input

0 – 1 V Engine running, A/C request signal low input

E23-48 GRN Radiator fan relay

No.2 and No.3 output 10 – 14 V

Ignition switch turned ON, engine coolant temp.:

below 100

°C (212 °F), or A/C refrigerant

pressure: below 1200 kPa (174 psi).

0 – 2 V Ignition switch turned ON, engine coolant temp.:

102.5

°C (216.5 ° F) or higher, or A/C refrigerant

pressure: 1500 kPa (217.5 psi) or higher.

E23-55 RED A/C refrigerant

pressure sensor

signal 1.46 – 1.71 V

Engine running, A/C refrigerant pressure at 0.8

MPa (8.0 kg/cm

2) (A/C refrigerant pressure

measured by manifold gauge)

2.55 – 2.80 V Engine running, A/C refrigerant pressure at 1.6

MPa (16.0 kg/cm

2) (A/C refrigerant pressure

measured by manifold gauge)

E23-60 BRN/WHT Main power supply

relay output 10 – 14 V Ignition switch turned OFF

0 – 2 V Ignition switch turned ON

Page 1033 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-2

Seat Belt with ELR

The seat belt with emergency locking retractor (ELR) is

designed so that it locks immediately (to prevent the

webbing from being pulled out of the retractor any

further) when any of the following items is detected as

exceeding each set value;

• Speed at which the webbing is pulled out of the retractor.

• Acceleration or deceleration of the vehicle speed.

• Inclination.

Seat Belt with A-ELR

The automatic and emergency locking retractor (A-ELR)

works as an Emergency Locking Retractor (ELR) till its

webbing is pulled all the way out and then on as an

Automatic Locking Retractor (ALR ) till it is retracted fully.

ALR: Automatically locks when the webbing is pulled out

from the retractor and allowed to retract even a little.

Then the webbing can not be pulled out any further,

unless it is wound all the way back into the retractor,

which releases the lock and allows the webbing to be

pulled out.

Seat Belt with ELR and Pretensioner

The seat belt with ELR and a pretensioner has a

pretensioner mechanism whic h operates in linkage with

the air bag in addition to the described ELR.

The pretensioner is incorporated in retractor assembly

and controlled by SDM as one of air bag system

components. It will be activated at the same time as the

driver and passenger air bag module when an impact at

the front of vehicle exceeds the specified value.

When servicing seat belt (retractor assembly) with

pretensioner, be sure to observe all WARNINGS and

CAUTIONS and “Precautions on Service and Diagnosis

of Air Bag System in Section 8B”. CAUTION!

Do not reuse the seat belt pretensioner

(retractor assembly) that has activated.

Replace it with a new seat belt assembly and

buckle together as a set. For checking

procedure of its activation, refer to “Repair

and Inspection Required after Accident in

Section 8B”.

Seat Belt Remainder

When driver’s seat belt is unfastened (under the

following conditions), seat belt reminder light and

warning buzzer inform that driver’s seat belt is

unfastened. Seat belt reminder light located in

combination meter and warning buzzer located inside

BCM operate as follows:

• Seat belt reminder light comes on when driver’s seat belt is unfastened while igni tion key switch is at ON

position.

• If vehicle speed exceeds 15 km/h with seat belt unfastened, warning buzzer operates for

approximately 95 seconds and seat belt reminder light

flashes synchronously with buzzer. When warning

buzzer stops operating, seat belt reminder light is

turned on.

• If driver’s seat belt state is changed from “fastened” to “unfastened” while vehicle speed is above 15 km/h,

warning buzzer operates for approximately 95

seconds and seat belt reminder light flashes

synchronously with buzzer. When warning buzzer

stops operating, seat belt reminder light is turned on.

Diagnostic Information and Procedures

Repair and Inspection Required after AccidentS7RS0B8104001

After an accident, whether the seat belt pretensioner has been activated or not, be sure to perform checks and repairs

described on “Repair and Inspection Required after Accident in Section 8B”.

Page 1044 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-6 Air Bag System:

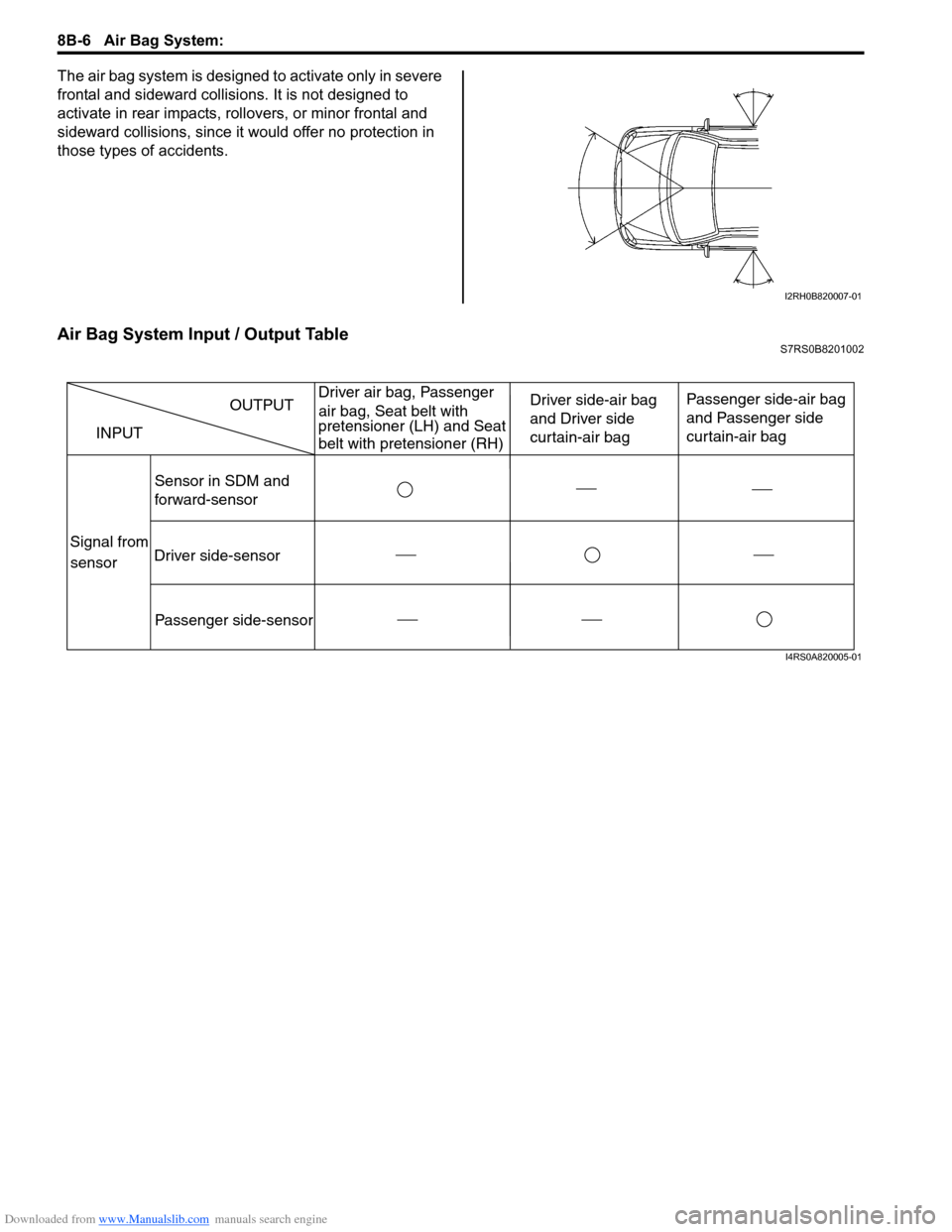

The air bag system is designed to activate only in severe

frontal and sideward collisions. It is not designed to

activate in rear impacts, rollovers, or minor frontal and

sideward collisions, since it would offer no protection in

those types of accidents.

Air Bag System Input / Output TableS7RS0B8201002

I2RH0B820007-01

INPUT

Sensor in SDM and

forward-sensor Driver side-air bag

and Driver side

curtain-air bag

Passenger side-air bag

and Passenger side

curtain-air bag

Driver side-sensor Passenger side-sensor OUTPUT

Signal from

sensor Driver air bag, Passenger

air bag, Seat belt with

pretensioner (LH) and Seat

belt with pretensioner (RH)

I4RS0A820005-01

Page 1046 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-8 Air Bag System:

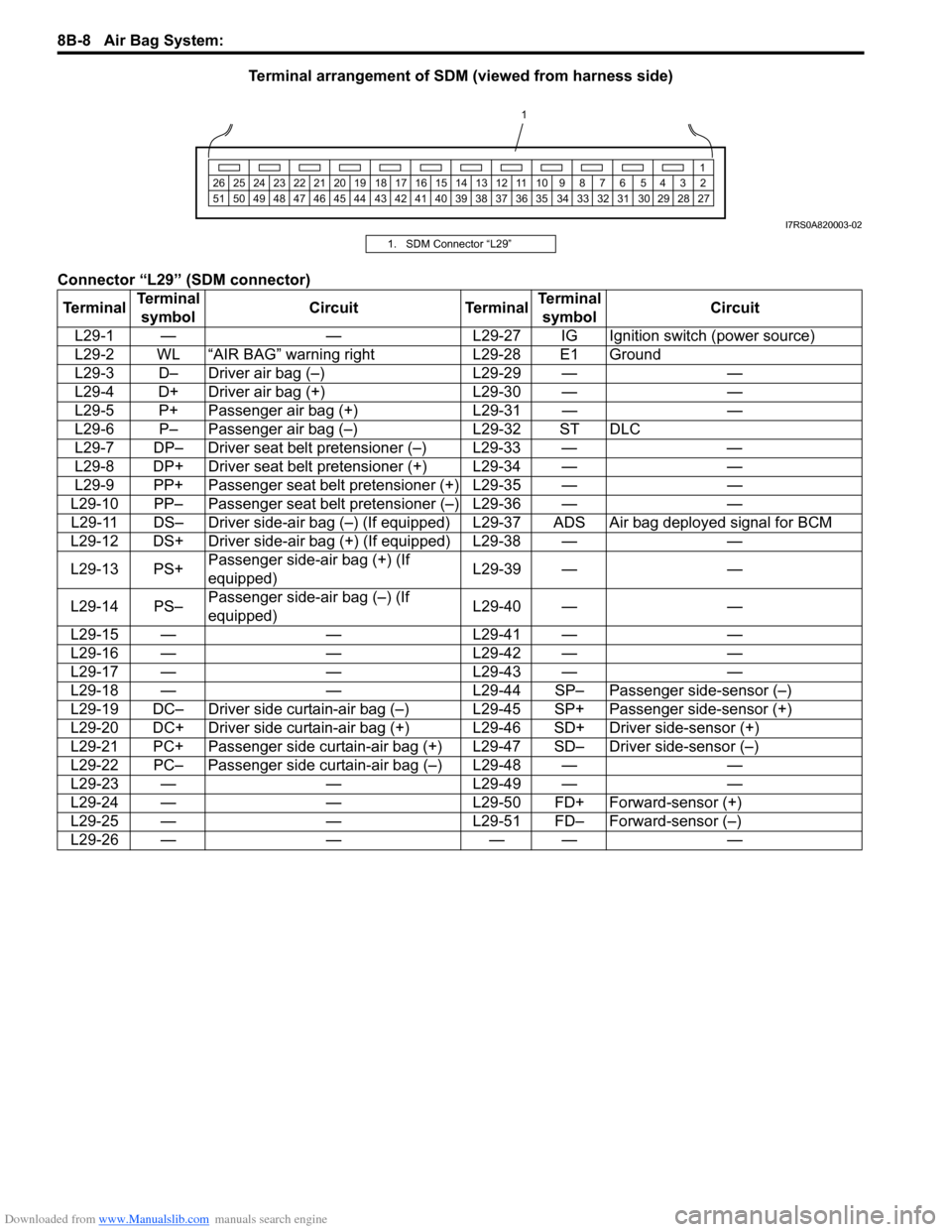

Terminal arrangement of SDM (viewed from harness side)

Connector “L29” (SDM connector)

1 2345678910

11

1213141516171819202122232425

272829303132333435363738394041424344454647484950

1

26

51

I7RS0A820003-02

1. SDM Connector “L29”

Terminal Terminal

symbol Circuit Terminal Terminal

symbol Circuit

L29-1 — — L29-27 IG Ignition switch (power source)

L29-2 WL “AIR BAG” warning right L29-28 E1 Ground

L29-3 D– Driver air bag (–) L29-29 — —

L29-4 D+ Driver air bag (+) L29-30 — —

L29-5 P+ Passenger air bag (+) L29-31 — —

L29-6 P– Passenger air bag (–) L29-32 ST DLC

L29-7 DP– Driver seat belt pretensioner (–) L29-33 — —

L29-8 DP+ Driver seat belt pretensioner (+) L29-34 — —

L29-9 PP+ Passenger seat belt pretensioner (+) L29-35 — —

L29-10 PP– Passenger seat belt pretensioner (–) L29-36 — — L29-11 DS– Driver side-air bag (–) (If equipped ) L29-37 ADS Air bag deployed signal for BCM

L29-12 DS+ Driver side-air bag (+) (If equipped) L29-38 — —

L29-13 PS+ Passenger side-air bag (+) (If

equipped) L29-39 — —

L29-14 PS– Passenger side-air bag (–) (If

equipped) L29-40 — —

L29-15 — — L29-41 — —

L29-16 — — L29-42 — —

L29-17 — — L29-43 — —

L29-18 — — L29-44 SP– Passenger side-sensor (–)

L29-19 DC– Driver side curtain-air bag (–) L29-45 SP+ Passenger side-sensor (+)

L29-20 DC+ Driver side curtain-air bag (+) L29-46 SD+ Driver side-sensor (+)

L29-21 PC+ Passenger side curtain-air bag (+) L29-47 SD– Driver side-sensor (–)

L29-22 PC– Passenger side curtain-air bag (–) L29-48 — —

L29-23 — — L29-49 — —

L29-24 — — L29-50 FD+ Forward-sensor (+)

L29-25 — — L29-51 FD– Forward-sensor (–)

L29-26 — — — — —

Page 1048 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-10 Air Bag System:

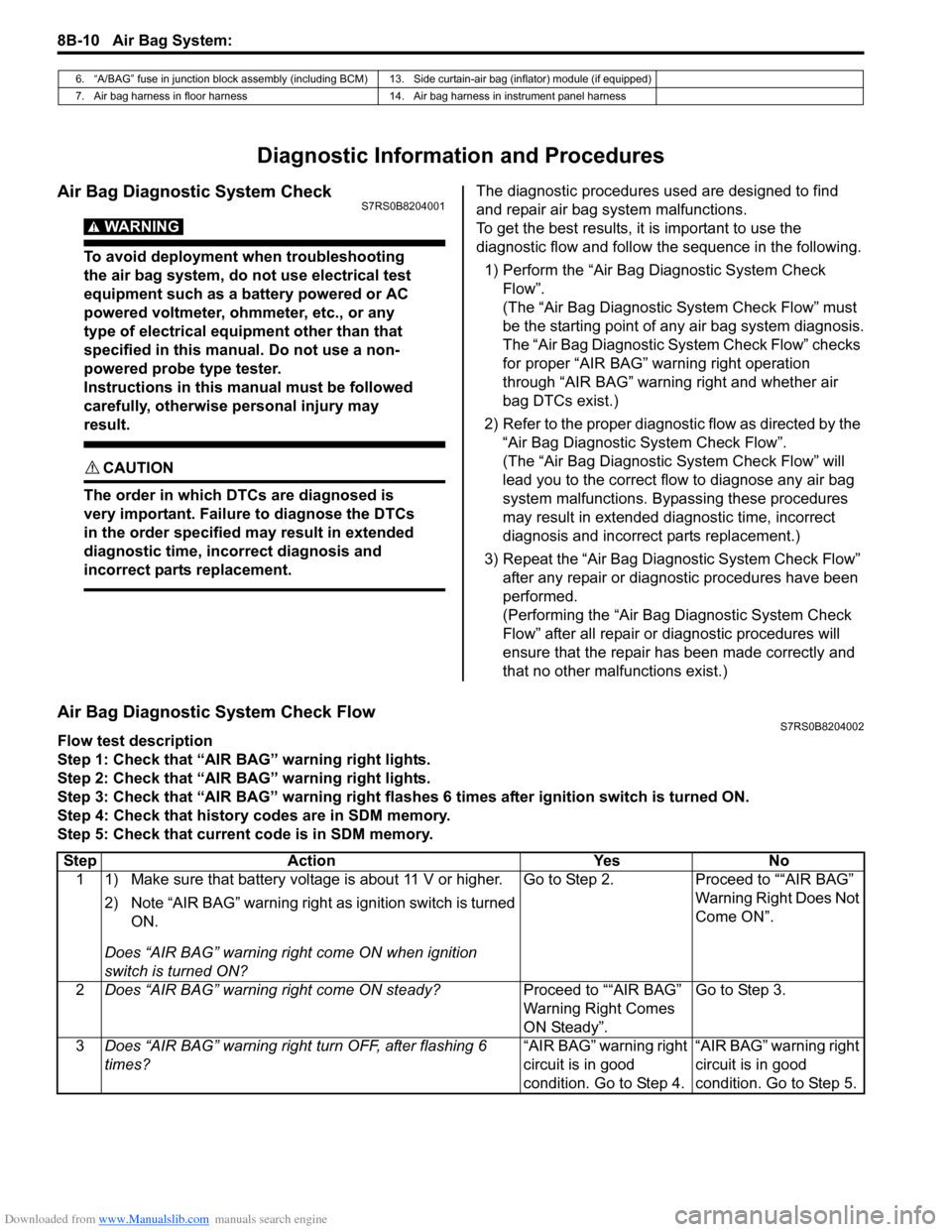

Diagnostic Information and Procedures

Air Bag Diagnostic System CheckS7RS0B8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

The order in which DTCs are diagnosed is

very important. Failure to diagnose the DTCs

in the order specified may result in extended

diagnostic time, incorrect diagnosis and

incorrect parts replacement.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.1) Perform the “Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning right operation

through “AIR BAG” warning right and whether air

bag DTCs exist.)

2) Refer to the proper diagnost ic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow” after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

Air Bag Diagnostic System Check FlowS7RS0B8204002

Flow test description

Step 1: Check that “AIR BAG” warning right lights.

Step 2: Check that “AIR BAG” warning right lights.

Step 3: Check that “AIR BAG” warning right flas hes 6 times after ignition switch is turned ON.

Step 4: Check that history codes are in SDM memory.

Step 5: Check that current code is in SDM memory.

6. “A/BAG” fuse in junction block assembly (including BCM) 13. Side curtain-air bag (inflator) module (if equipped)

7. Air bag harness in floor harness 14. Air bag harness in instrument panel harness

Step Action YesNo

1 1) Make sure that battery voltage is about 11 V or higher.

2) Note “AIR BAG” warning right as ignition switch is turned

ON.

Does “AIR BAG” warning ri ght come ON when ignition

switch is turned ON? Go to Step 2.

Proceed to ““AIR BAG”

Warning Right Does Not

Come ON”.

2 Does “AIR BAG” warning right come ON steady? Proceed to ““AIR BAG”

Warning Right Comes

ON Steady”.Go to Step 3.

3 Does “AIR BAG” warning right turn OFF, after flashing 6

times? “AIR BAG” warning right

circuit is in good

condition. Go to Step 4.“AIR BAG” warning right

circuit is in good

condition. Go to Step 5.