Information SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 431 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 2-1

Suspension

Precautions

Precautions

Precautions on SuspensionS7RS0B2000001

Emergency Flat Tire Repair Kit handle Warning

Refer to “Warning for Handling Emergency Flat Tire Repair Kit in Section 00”.

Suspension Caution

Refer to “Suspension Caution in Section 00”.

Wheels and Tires Caution

Refer to “Wheels and Tires Caution in Section 00”.

General Precautions

Refer to “General Precautions in Section 00”.

Vehicle Lifting Points

Refer to “Vehicle Lifting Points in Section 0A”.

Fastener Caution

Refer to “Fastener Caution in Section 00”.

Fastener Information

Refer to “Fasteners Information in Section 0A”.

Brake Caution

Refer to “Brake Caution in Section 00”.

Page 432 of 1496

Downloaded from www.Manualslib.com manuals search engine 2A-1 Suspension General Diagnosis:

Suspension

Suspension General Diagnosis

Diagnostic Information and Procedures

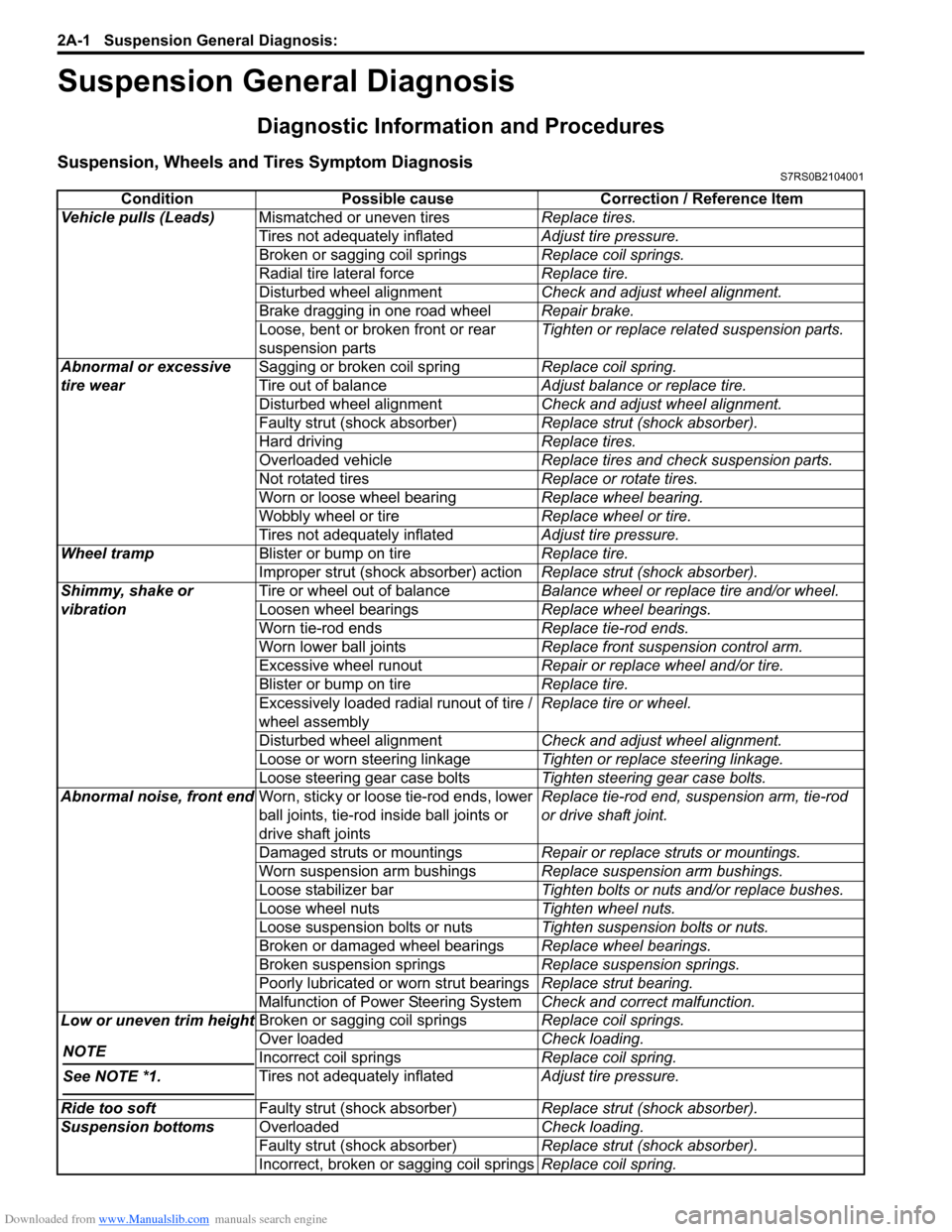

Suspension, Wheels and Tires Symptom DiagnosisS7RS0B2104001

ConditionPossible cause Correction / Reference Item

Vehicle pulls (Leads) Mismatched or uneven tires Replace tires.

Tires not adequately inflated Adjust tire pressure.

Broken or sagging coil springs Replace coil springs.

Radial tire lateral force Replace tire.

Disturbed wheel alignment Check and adjust wheel alignment.

Brake dragging in one road wheel Repair brake.

Loose, bent or broken front or rear

suspension parts Tighten or replace related suspension parts.

Abnormal or excessive

tire wear Sagging or broken coil spring

Replace coil spring.

Tire out of balance Adjust balance or replace tire.

Disturbed wheel alignment Check and adjust wheel alignment.

Faulty strut (shock absorber) Replace strut (shock absorber).

Hard driving Replace tires.

Overloaded vehicle Replace tires and check suspension parts.

Not rotated tires Replace or rotate tires.

Worn or loose wheel bearing Replace wheel bearing.

Wobbly wheel or tire Replace wheel or tire.

Tires not adequately inflated Adjust tire pressure.

Wheel tramp Blister or bump on tire Replace tire.

Improper strut (shock absorber) action Replace strut (shock absorber).

Shimmy, shake or

vibration Tire or wheel out of balance

Balance wheel or replace tire and/or wheel.

Loosen wheel bearings Replace wheel bearings.

Worn tie-rod ends Replace tie-rod ends.

Worn lower ball joints Replace front suspension control arm.

Excessive wheel runout Repair or replace wheel and/or tire.

Blister or bump on tire Replace tire.

Excessively loaded radial runout of tire /

wheel assembly Replace tire or wheel.

Disturbed wheel alignment Check and adjust wheel alignment.

Loose or worn steering linkage Tighten or replace steering linkage.

Loose steering gear case bolts Tighten steering gear case bolts.

Abnormal noise, front end Worn, sticky or loose tie-rod ends, lower

ball joints, tie-rod in side ball joints or

drive shaft joints Replace tie-rod end, su

spension arm, tie-rod

or drive shaft joint.

Damaged struts or mountings Repair or replace struts or mountings.

Worn suspension arm bushings Replace suspension arm bushings.

Loose stabilizer bar Tighten bolts or nuts and/or replace bushes.

Loose wheel nuts Tighten wheel nuts.

Loose suspension bolts or nuts Tighten suspension bolts or nuts.

Broken or damaged wheel bearings Replace wheel bearings.

Broken suspension springs Replace suspension springs.

Poorly lubricated or worn strut bearings Replace strut bearing.

Malfunction of Power Steering System Check and correct malfunction.

Low or uneven trim height

NOTE

See NOTE *1.

Broken or sagging coil springs Replace coil springs.

Over loaded Check loading.

Incorrect coil springs Replace coil spring.

Tires not adequately inflated Adjust tire pressure.

Ride too soft Faulty strut (shock absorber) Replace strut (shock absorber).

Suspension bottoms Overloaded Check loading.

Faulty strut (shock absorber) Replace strut (shock absorber).

Incorrect, broken or sagging coil springs Replace coil spring.

Page 437 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-4

Reference Information

Side slip

When checked with side slip tester, side slip should

satisfy following specification.Side slip

0 to IN 3.0 mm/m (0 to IN 0.118 in/3.3 ft)

If side slip is greatly di

fferent, toe or front wheel

alignment may not be correct.

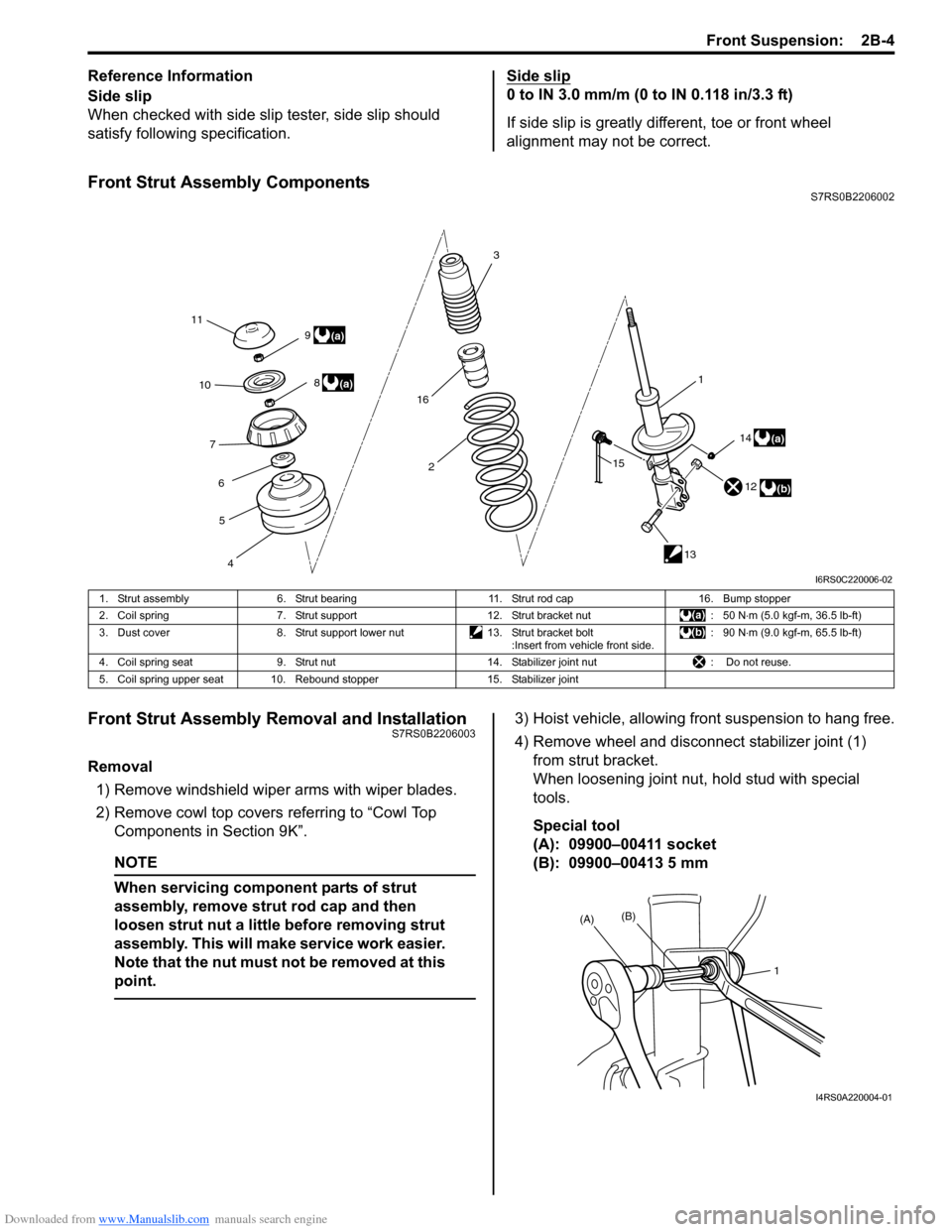

Front Strut Assembly ComponentsS7RS0B2206002

Front Strut Assembly Removal and InstallationS7RS0B2206003

Removal

1) Remove windshield wipe r arms with wiper blades.

2) Remove cowl top covers referring to “Cowl Top

Components in Section 9K”.

NOTE

When servicing component parts of strut

assembly, remove stru t rod cap and then

loosen strut nut a little before removing strut

assembly. This will make service work easier.

Note that the nut must not be removed at this

point.

3) Hoist vehicle, allowing front suspension to hang free.

4) Remove wheel and disconn ect stabilizer joint (1)

from strut bracket.

When loosening joint nu t, hold stud with special

tools.

Special tool

(A): 09900–00411 socket

(B): 09900–00413 5 mm

11 3

2 1

12

13

4

5

6

7

10

8(a)

(b)

9

(a)

14

15(a)

16

I6RS0C220006-02

1. Strut assembly

6. Strut bearing 11. Strut rod cap16. Bump stopper

2. Coil spring 7. Strut support 12. Strut bracket nut : 50 N⋅m (5.0 kgf-m, 36.5 lb-ft)

3. Dust cover 8. Strut support lower nut 13. Strut bracket bolt

:Insert from vehicle front side. : 90 N

⋅m (9.0 kgf-m, 65.5 lb-ft)

4. Coil spring seat 9. Strut nut 14. Stabilizer joint nut : Do not reuse.

5. Coil spring upper seat 10. Rebound stopper 15. Stabilizer joint

1

(A)

(B)

I4RS0A220004-01

Page 453 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-20

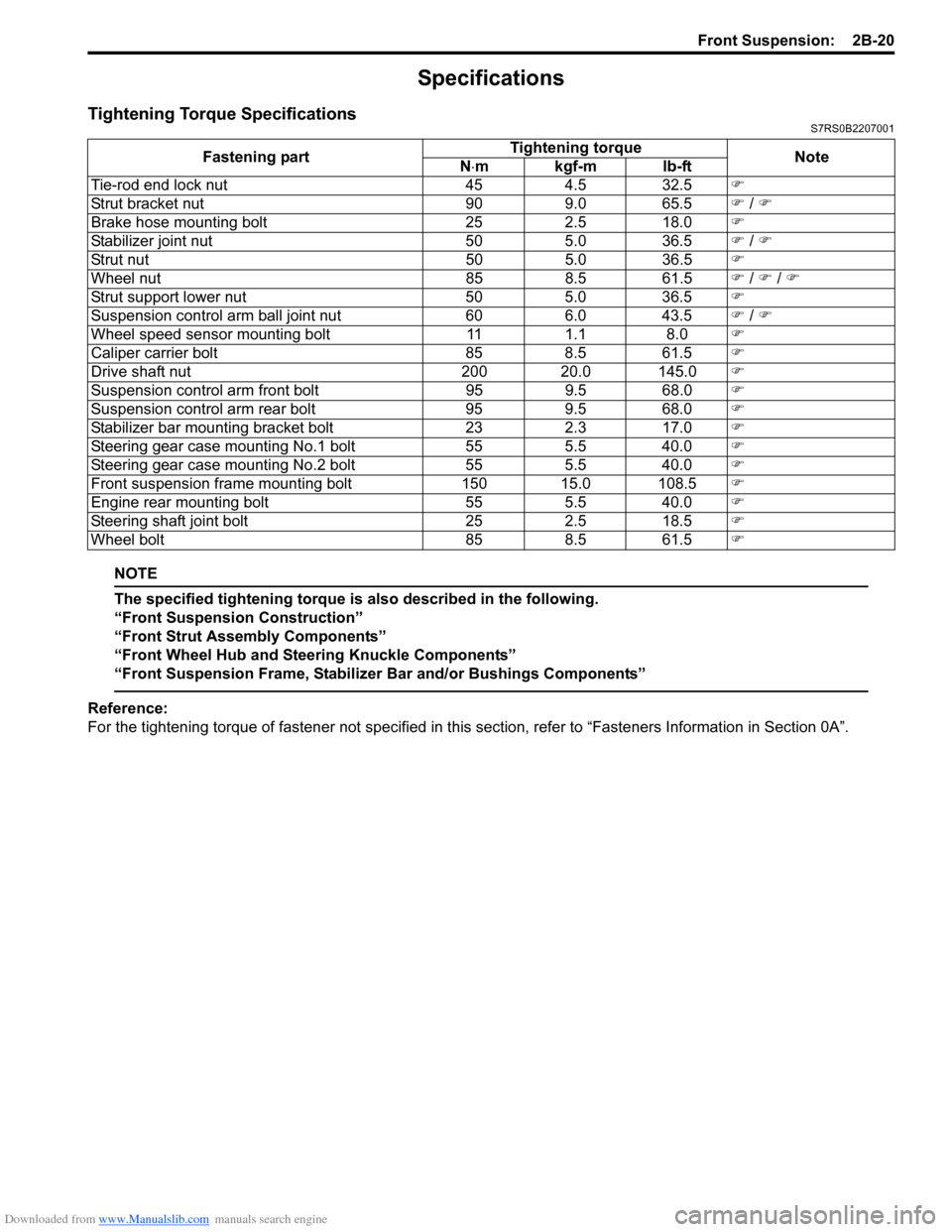

Specifications

Tightening Torque SpecificationsS7RS0B2207001

NOTE

The specified tightening torque is also described in the following.

“Front Suspension Construction”

“Front Strut Assembly Components”

“Front Wheel Hub and Steering Knuckle Components”

“Front Suspension Frame, Stabilizer Bar and/or Bushings Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Tie-rod end lock nut 454.5 32.5 �)

Strut bracket nut 909.0 65.5 �) / �)

Brake hose mounting bolt 252.5 18.0 �)

Stabilizer joint nut 505.0 36.5 �) / �)

Strut nut 505.0 36.5 �)

Wheel nut 858.5 61.5 �) / �) / �)

Strut support lower nut 505.0 36.5 �)

Suspension control arm ball joint nut 606.0 43.5 �) / �)

Wheel speed sensor mounting bolt 111.1 8.0 �)

Caliper carrier bolt 858.5 61.5 �)

Drive shaft nut 200 20.0 145.0�)

Suspension control arm front bolt 959.5 68.0 �)

Suspension control arm rear bolt 959.5 68.0 �)

Stabilizer bar mounting bracket bolt 232.3 17.0 �)

Steering gear case mounting No.1 bolt 555.5 40.0 �)

Steering gear case mounting No.2 bolt 555.5 40.0 �)

Front suspension frame mounting bolt 150 15.0 108.5�)

Engine rear mounting bolt 555.5 40.0 �)

Steering shaft joint bolt 252.5 18.5 �)

Wheel bolt 858.5 61.5 �)

Page 467 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-13

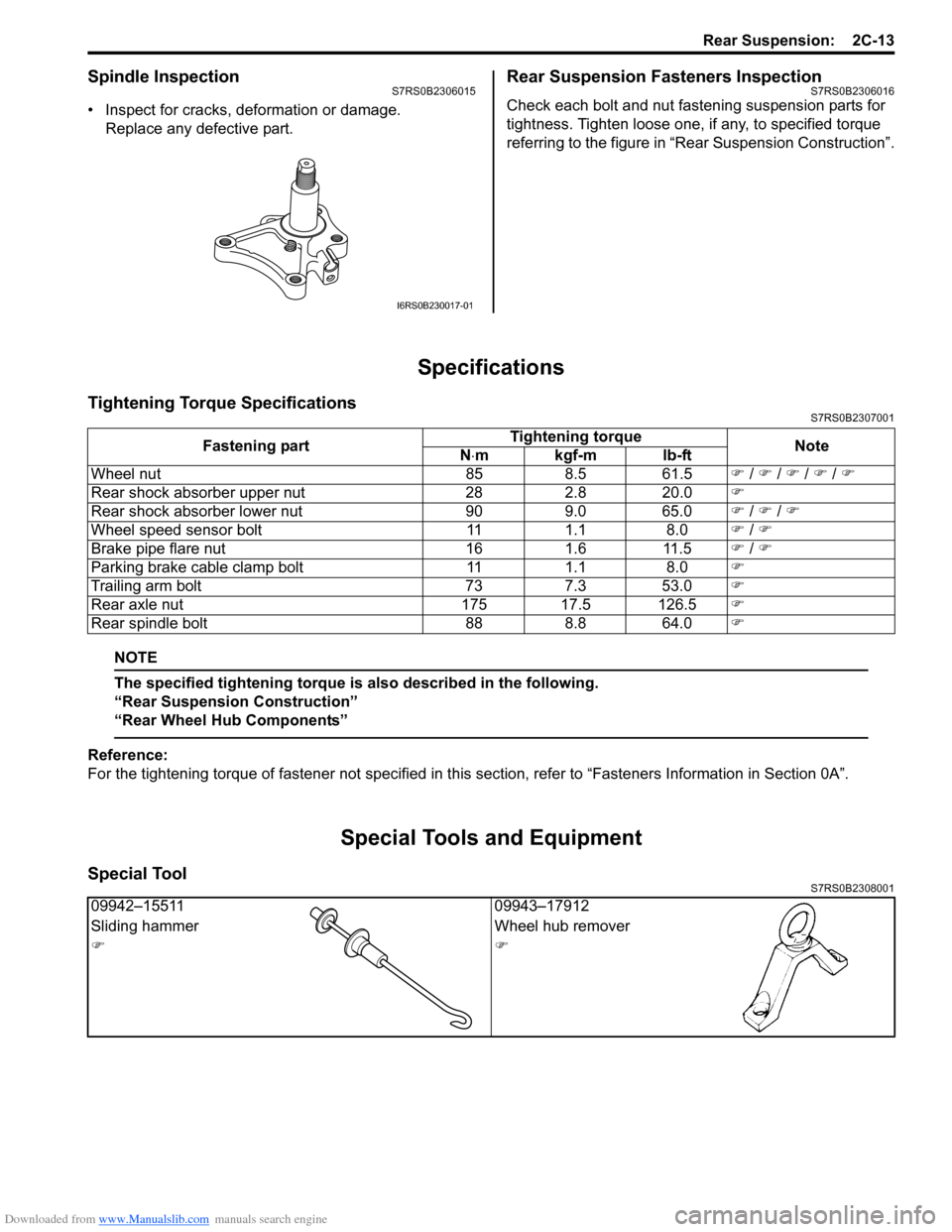

Spindle InspectionS7RS0B2306015

• Inspect for cracks, deformation or damage.Replace any defective part.

Rear Suspension Fasteners InspectionS7RS0B2306016

Check each bolt and nut fastening suspension parts for

tightness. Tighten loose one, if any, to specified torque

referring to the figure in “Rear Suspension Construction”.

Specifications

Tightening Torque SpecificationsS7RS0B2307001

NOTE

The specified tightening torque is also described in the following.

“Rear Suspension Construction”

“Rear Wheel Hub Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B2308001

I6RS0B230017-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Wheel nut 85 8.5 61.5 �) / �) / �) / �) / �)

Rear shock absorber upper nut 28 2.8 20.0 �)

Rear shock absorber lower nut 90 9.0 65.0 �) / �) / �)

Wheel speed sensor bolt 11 1.1 8.0 �) / �)

Brake pipe flare nut 16 1.6 11.5 �) / �)

Parking brake cable clamp bolt 11 1.1 8.0 �)

Trailing arm bolt 73 7.3 53.0 �)

Rear axle nut 175 17.5 126.5 �)

Rear spindle bolt 88 8.8 64.0 �)

09942–1551109943–17912

Sliding hammer Wheel hub remover

�)�)

Page 468 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-1 Wheels and Tires:

Suspension

Wheels and Tires

Precautions

Precaution for Emergency Flat Tire Repair KitS7RS0B2400001

WARNING!

Flat tire repair sealant including in kit is

harmful. Be sure to observe the following.

Otherwise, your health may be ruined.

• If swallowed, get medical attention immediately.

• Keep out of reach of children.

• Select place where there is good ventilation for this work.

• If it enters eye or contacts skin, wash thoroughly with water. If anything

abnormal still rema ins, get medical

attention immediately.

• Do not discard tire containing sealant as it is. Make sure to remove sealant from tire,

referring to “Tire Repair for Emergency

Repaired-Tire with Sealant”.

• Dispose of sealant as waste oil.

CAUTION!

• When tire repaired with Emergency Flat Tire Repair Kit is brought in, remove flat

tire repair sealant from tire and repair flat

tire referring to “Tire Repair for Emergency

Repaired-Tire with Sealant”.

• Sealant expiration date is printed on bottle label. if it expires, sealant should be

replaced with a new one to ensure

emergency flat tire repair.

General Description

Tires DescriptionS7RS0B2401001

The tire is of tubeless type. The tire is designed to

operate satisfactorily with loads up to the full rated load

capacity when inflated to the recommended inflation

pressures.

Correct tire pressures and driving habits have an

important influence on tire life. Heavy cornering,

excessively rapid acceleration, and unnecessary sharp

braking increase tire wear.

Tire Placard

The “Tire Placard” is located on the left or right door lock

pillar and should be referred to tire information.

The placard lists the maximum load, tire size and cold

tire pressure where applicable.

NOTE

Whether rim size and/or maximum load are

listed or not depends on regulations of each

country.

Inflation of Tires

The pressure recommended for any model is carefully

calculated to give a satisfacto ry ride, stability, steering,

tread wear, tire life and resistance to bruises.

Tire pressure, with tires cold, (after vehicle has set for 3

hours or more, or driven less than one mile) should be

checked monthly or before any extended trip. Set to the

specifications on the “Tire Placard” located on the left

door lock pillar.

It is normal for tire pressure to increase when the tires

become hot during driving.

Do not bleed or reduce tire pressure after driving.

Bleeding reduces the “Cold Inflation Pressure”.

Higher than recommended pressure can cause:

• Hard ride

• Tire bruising or carcass damage

• Rapid tread wear at center of tire

Unequal pressure on same axle can cause:

• Uneven braking

• Steering lead

• Reduced handling

• Swerve on acceleration

Page 476 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-9 Wheels and Tires:

2) Check tire if it can be repaired, referring to “Tire

Repair”. If it cannot be repaired, replace it with new

one.

3) Replace valve core of flat tire with new one if tire is reused after repairing.CAUTION!

Be sure to use new valve core. Otherwise, air

leak may occur due to sealant attached to

valve core.

4) Install tire to ri m of wheel, check that there is no air

leakage and adjust it to specified pressure shown on

tire placard.

Specifications

Wheels and Tires SpecificationsS7RS0B2407001

Tire size (Standard)

: 195/50R16 87V

Wheel size (Standard)

: 16x 6 J

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

NOTE

• Tire inflation pressure should be checked when tires are cool.

• Specified tire inflation pressure should be found on tire placard or in owner’s manual which came

with the vehicle.

Tightening Torque SpecificationsS7RS0B2407002

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Wheel nut 858.5 61.5 �) / �)

Page 477 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 3- i

3

Section 3

CONTENTS

Driveline / Axle

Precautions ................................................. 3-1

Precautions............................................................. 3-1

Precautions for Driveline / Axle ............................. 3-1

Drive Shaft / Axle .......... ........................... 3A-1

General Description ............................................. 3A-1

Front Drive Shaft Construction ............................ 3A-1

Component Locatio n ........................................... 3A-1

Front Drive Shaft Assembly Components Location ............................................................ 3A-1

Diagnostic Information and Procedures ............ 3A-2 Front Drive Shaft Symptom Diagnosis ................ 3A-2

Repair Instructions .............................................. 3A-3 Front Drive Shaft Components ........................... 3A-3 Front Drive Shaft Assembly On-Vehicle

Inspection .......................................................... 3A-4

Front Drive Shaft Assembly Removal and Installation ......................................................... 3A-4

Front Drive Shaft Disassembly and Reassembly ...................................................... 3A-6

Center Shaft and Center Bearing Support Disassembly and Reassembly ........................ 3A-14

Specifications .................... .................................3A-15

Tightening Torque Specifications ...................... 3A-15

Special Tools and Equipmen t ...........................3A-15

Recommended Service Material ....................... 3A-15

Special Tool ...................................................... 3A-15

Page 480 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-2 Drive Shaft / Axle:

Diagnostic Information and Procedures

Front Drive Shaft Symptom DiagnosisS7RS0B3104001

ConditionPossible cause Correction / Reference Item

Abnormal noise Worn or breakage of the drive shaft joint Replace.

Worn or breakage of the center bearing Replace.

Page 493 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-15

Specifications

Tightening Torque SpecificationsS7RS0B3107001

NOTE

The specified tightening torque is also described in the following.

“Front Drive Shaft Assembly Components Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B3108001

NOTE

Required service material is also described in the following.

“Front Drive Shaft Components”

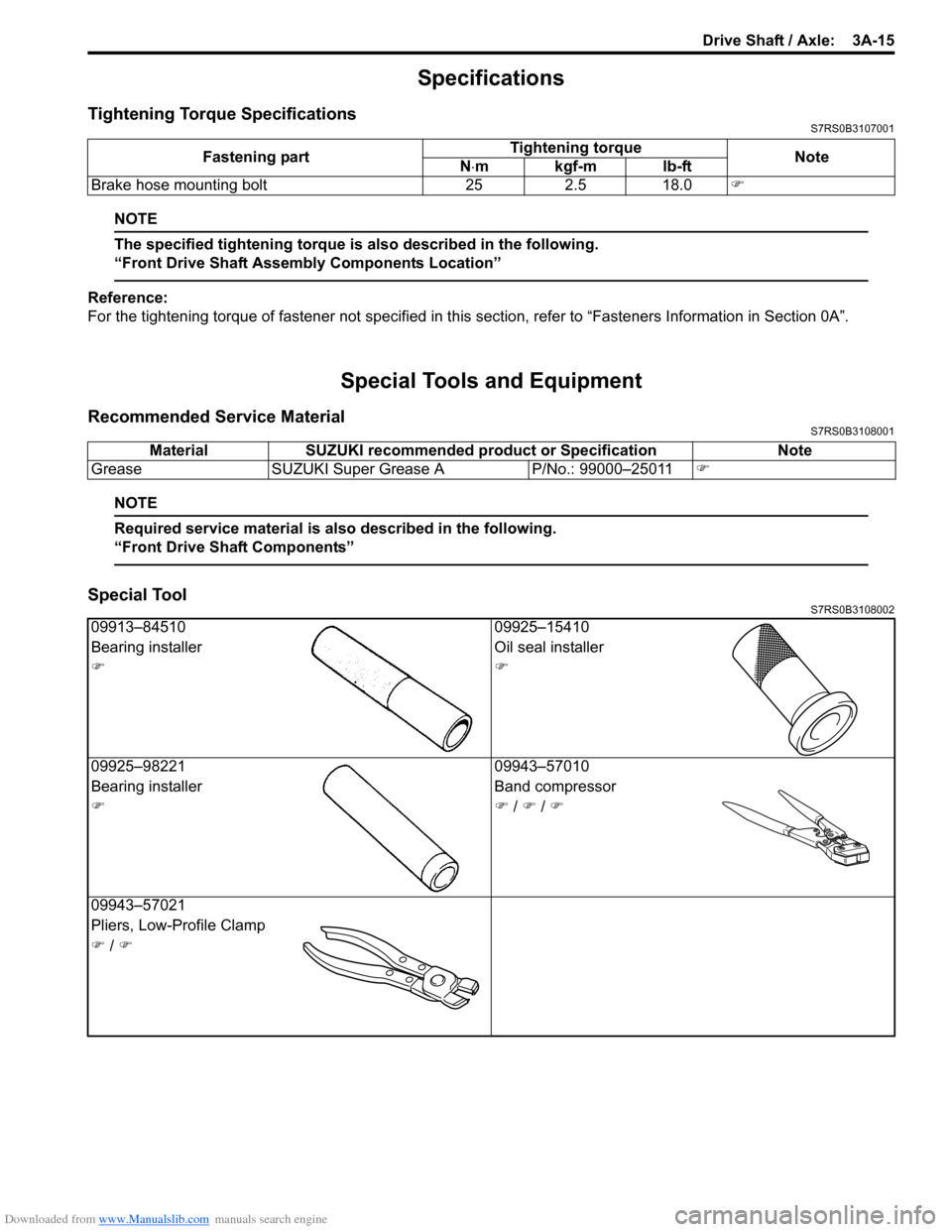

Special ToolS7RS0B3108002

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Brake hose mounting bolt 25 2.5 18.0 �)

MaterialSUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25011�)

09913–84510 09925–15410

Bearing installer Oil seal installer

�)�)

09925–98221 09943–57010

Bearing installer Band compressor

�)�) / �) / �)

09943–57021

Pliers, Low-Profile Clamp

�) / �)