200 SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1159 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-121

Deployment / Activation Inside of Vehicle

When the vehicle will be destroyed, or salvaged for

component parts, deploy the air bag modules and/or

activate seat belt pretensioners installed on vehicle.

NOTE

If equipped with the seat belt pretensioners,

activate both side of seat belt pretensioners

at the same time when using special tool (C).

1) Turn ignition switch to LOCK position, remove key

and put on safety glasses.

2) Remove all loose objects from front seats and instrument panel.

3) Disconnect air bag (inflator) module or seat belt pretensioner connector as follows.

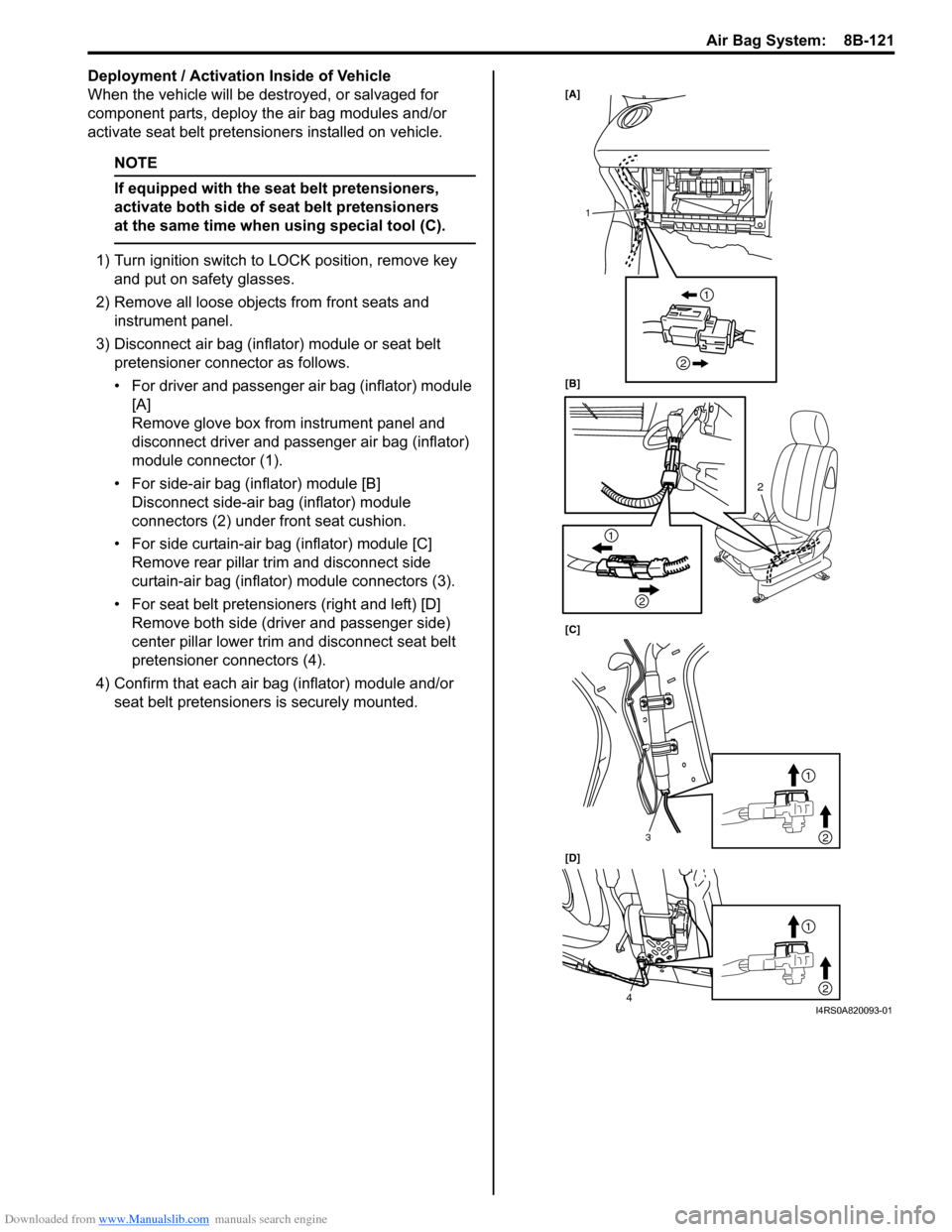

• For driver and passenger air bag (inflator) module [A]

Remove glove box from instrument panel and

disconnect driver and passenger air bag (inflator)

module connector (1).

• For side-air bag (inflator) module [B] Disconnect side-air bag (inflator) module

connectors (2) under front seat cushion.

• For side curtain-air bag (inflator) module [C] Remove rear pillar trim and disconnect side

curtain-air bag (inflator) module connectors (3).

• For seat belt pretensioners (right and left) [D] Remove both side (driver and passenger side)

center pillar lower trim an d disconnect seat belt

pretensioner connectors (4).

4) Confirm that each air bag (inflator) module and/or seat belt pretensioners is securely mounted.

[A]

[B]

[C]

[D]

2

1

3

4

1

2

1

2

1

2

1

2

I4RS0A820093-01

Page 1160 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-122 Air Bag System:

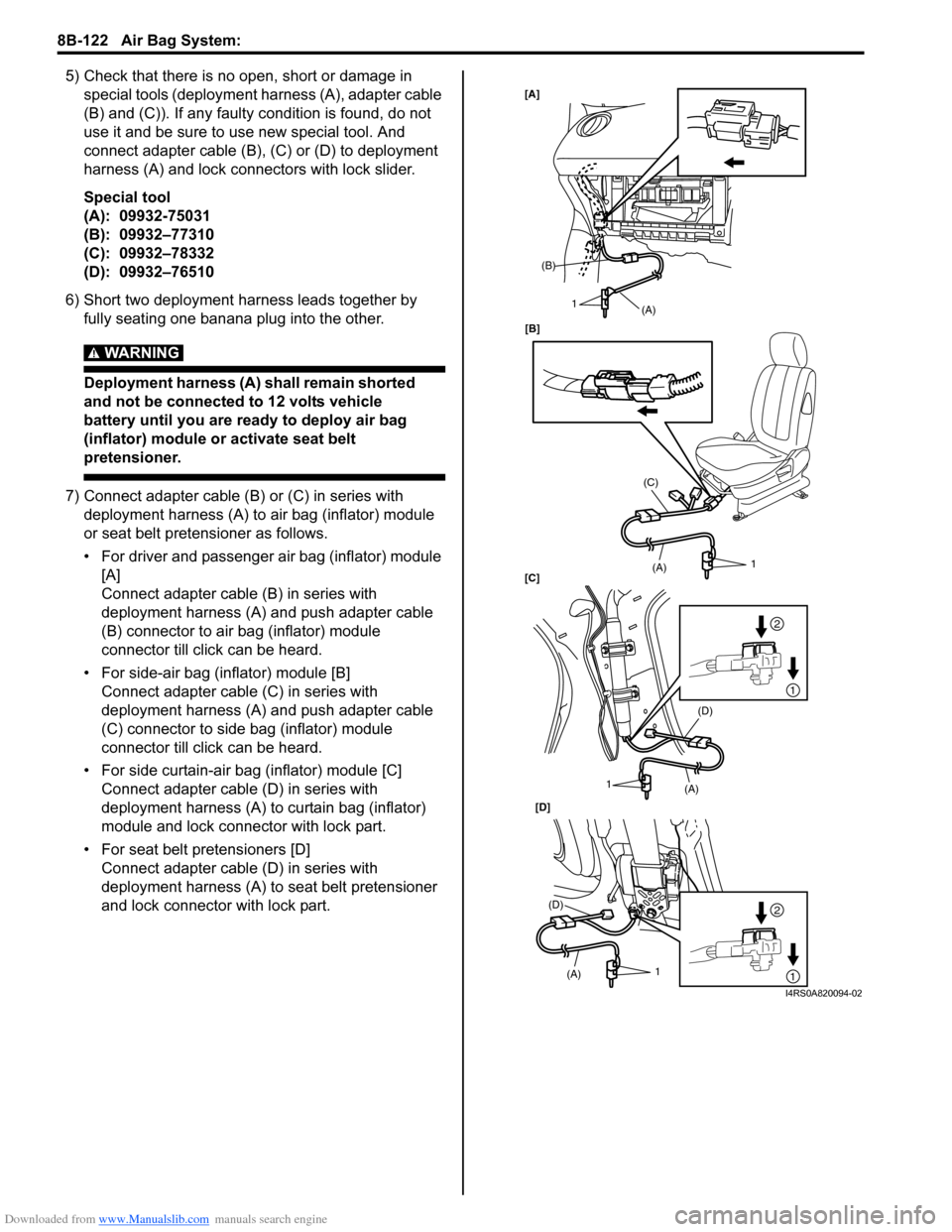

5) Check that there is no open, short or damage in special tools (deployment harness (A), adapter cable

(B) and (C)). If any faulty condition is found, do not

use it and be sure to use new special tool. And

connect adapter cable (B), (C) or (D) to deployment

harness (A) and lock connectors with lock slider.

Special tool

(A): 09932-75031

(B): 09932–77310

(C): 09932–78332

(D): 09932–76510

6) Short two deployment harness leads together by fully seating one banana plug into the other.

WARNING!

Deployment harness (A) shall remain shorted

and not be connected to 12 volts vehicle

battery until you are ready to deploy air bag

(inflator) module or activate seat belt

pretensioner.

7) Connect adapter cable (B) or (C) in series with deployment harness (A) to air bag (inflator) module

or seat belt pretensioner as follows.

• For driver and passenger air bag (inflator) module [A]

Connect adapter cable (B) in series with

deployment harness (A) and push adapter cable

(B) connector to air bag (inflator) module

connector till click can be heard.

• For side-air bag (inflator) module [B] Connect adapter cable (C) in series with

deployment harness (A) and push adapter cable

(C) connector to side bag (inflator) module

connector till click can be heard.

• For side curtain-air bag (inflator) module [C] Connect adapter cable (D) in series with

deployment harness (A) to curtain bag (inflator)

module and lock connector with lock part.

• For seat belt pretensioners [D] Connect adapter cable (D) in series with

deployment harness (A) to seat belt pretensioner

and lock connector with lock part.

[A]

[C]

[D]

1

2

1

2

1

(B) (A)

[B]

1

(C)

(A)

1

(D)

(A)

(A)

(D)

1

I4RS0A820094-02

Page 1161 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-123

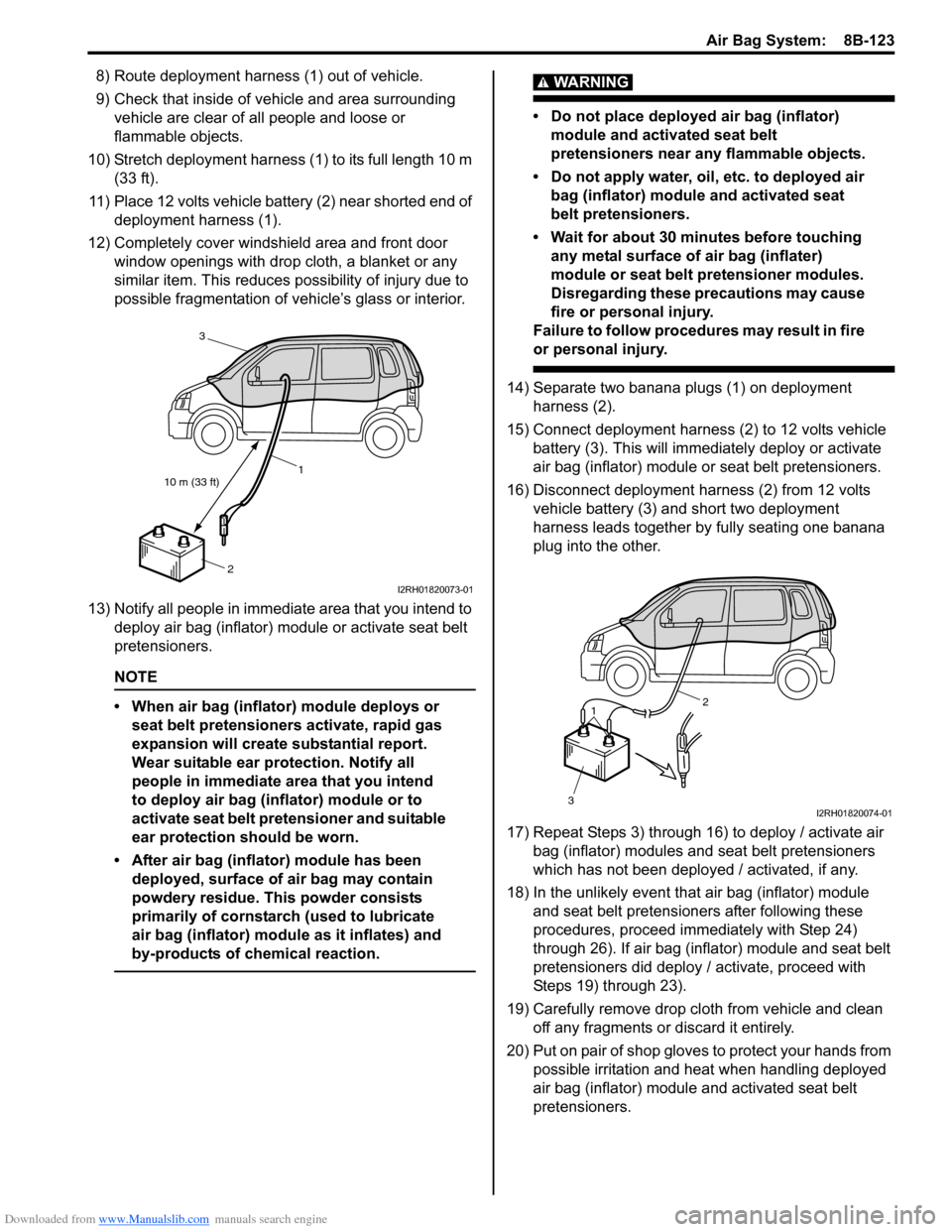

8) Route deployment harness (1) out of vehicle.

9) Check that inside of vehicle and area surrounding vehicle are clear of all people and loose or

flammable objects.

10) Stretch deployment harness (1) to its full length 10 m (33 ft).

11) Place 12 volts vehicle battery (2) near shorted end of deployment harness (1).

12) Completely cover windshield area and front door window openings with drop cloth, a blanket or any

similar item. This reduces possibility of injury due to

possible fragmentation of vehicle’s glass or interior.

13) Notify all people in immediate area that you intend to deploy air bag (inflator) module or activate seat belt

pretensioners.

NOTE

• When air bag (inflator) module deploys or seat belt pretensioners activate, rapid gas

expansion will create substantial report.

Wear suitable ear protection. Notify all

people in immediate area that you intend

to deploy air bag (inflator) module or to

activate seat belt pretensioner and suitable

ear protection should be worn.

• After air bag (inflator) module has been deployed, surface of air bag may contain

powdery residue. This powder consists

primarily of cornstarch (used to lubricate

air bag (inflator) module as it inflates) and

by-products of chemical reaction.

WARNING!

• Do not place deployed air bag (inflator) module and activated seat belt

pretensioners near any flammable objects.

• Do not apply water, oil, etc. to deployed air bag (inflator) module and activated seat

belt pretensioners.

• Wait for about 30 minutes before touching any metal surface of air bag (inflater)

module or seat belt pretensioner modules.

Disregarding these precautions may cause

fire or personal injury.

Failure to follow procedures may result in fire

or personal injury.

14) Separate two banana plugs (1) on deployment harness (2).

15) Connect deployment harness (2) to 12 volts vehicle battery (3). This will immedi ately deploy or activate

air bag (inflator) module or seat belt pretensioners.

16) Disconnect deployment harness (2) from 12 volts vehicle battery (3) and short two deployment

harness leads together by fully seating one banana

plug into the other.

17) Repeat Steps 3) through 16) to deploy / activate air bag (inflator) modules and seat belt pretensioners

which has not been deployed / activated, if any.

18) In the unlikely event that air bag (inflator) module and seat belt pretensioners after following these

procedures, proceed immediately with Step 24)

through 26). If air bag (inflator) module and seat belt

pretensioners did deploy / activate, proceed with

Steps 19) through 23).

19) Carefully remove drop cloth from vehicle and clean off any fragments or discard it entirely.

20) Put on pair of shop gloves to protect your hands from

possible irritation and heat when handling deployed

air bag (inflator) module and activated seat belt

pretensioners.

10 m (33 ft) 1

2

3

I2RH01820073-01

1

3 2

I2RH01820074-01

Page 1162 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-124 Air Bag System:

21) Disconnect adapter cable (special tool) from air bag (inflator) module or seat belt pretensioner as soon as

possible. This will preven t adapter cable (special

tool) from damage due to possible contact with hot

air bag (inflator) module or hot seat belt

pretensioner.

22) Check adapter cable connector as follows. Adapter cable connector (special tool) is designed to

be reused. However it should be inspected for

damage after deployment and replaced if necessary.

23) With air bag (inflator) modules deployed and seat belt pretensioners acti vated, vehicle may be

scrapped in the same manner as non-air bag system

/ seat belt pretensioner equipped vehicle.

NOTE

Remaining steps are to be followed in the

unlikely event that air bag (inflator) module

did not deploy or seat belt pretensioner did

not activate.

24) Remove undeployed air bag (inflator) module(s) and/ or inactivated seat belt pretensioner(s) from vehicle.

For driver air bag (inflator) module, refer to “Driver

Air Bag (Inflator) Module Removal and Installation”.

For passenger air bag (inflator) module, refer to

“Passenger Air Bag (Inflator) Module Removal and

Installation”. For seat belt pretensioner, refer to

“Front Seat Belt Removal an d Installation in Section

8A”.

25) Temporarily store undeployed air bag (inflator) module referring to “Precautions on Service and

Diagnosis of Air Bag System” for details.

26) Contact your local distribu tor for further assistance.

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal

S7RS0B8206019

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which may cause

personal injury. The undeployed air bag

(inflator) module and the inactivated seat belt

pretensioner must not be disposed of

through normal refuse channels.

The undeployed air bag (inflator) module and

the inactivated seat belt pretensioner

contains substances that can cause severe

illness or personal injury if the sealed

container is damaged during disposal.

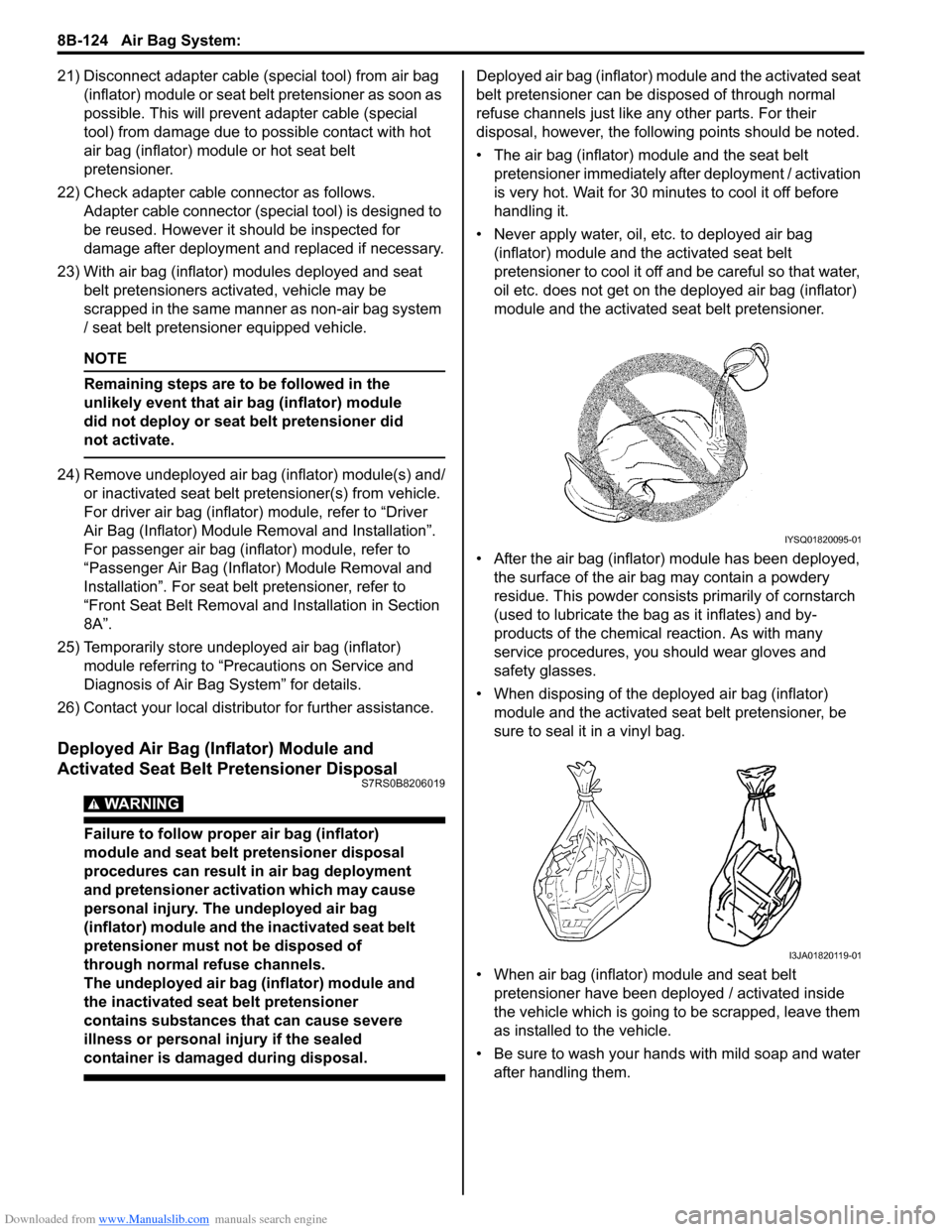

Deployed air bag (inflator) module and the activated seat

belt pretensioner can be disposed of through normal

refuse channels just like any other parts. For their

disposal, however, the following points should be noted.

• The air bag (inflator) module and the seat belt

pretensioner immediately after deployment / activation

is very hot. Wait for 30 minu tes to cool it off before

handling it.

• Never apply water, oil, etc. to deployed air bag (inflator) module and the activated seat belt

pretensioner to cool it off and be careful so that water,

oil etc. does not get on the deployed air bag (inflator)

module and the activated seat belt pretensioner.

• After the air bag (inflator) module has been deployed, the surface of the air bag may contain a powdery

residue. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-

products of the chemical reaction. As with many

service procedures, you should wear gloves and

safety glasses.

• When disposing of the deployed air bag (inflator) module and the activated seat belt pretensioner, be

sure to seal it in a vinyl bag.

• When air bag (inflator) module and seat belt pretensioner have been deployed / activated inside

the vehicle which is going to be scrapped, leave them

as installed to the vehicle.

• Be sure to wash your hand s with mild soap and water

after handling them.

IYSQ01820095-01

I3JA01820119-01

Page 1163 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-125

Specifications

Tightening Torque SpecificationsS7RS0B8207001

NOTE

The specified tightening torque is also described in the following.

“Air Bag System Components, Wiring and Connectors Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Use of Special ToolsS7RS0B8208001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified. Do not use a non-powered probe

type tester.

Instructions must be followed carefully,

otherwise personal injury may result.

You should be familiar with the tools listed under the

heading “Special Tool”. You should be able to measure

voltage and resistance. You should be familiar with

proper use of a scan tool such as Air Bag Driver /

Passenger Load Tool, Connector Test Adapter Kit and

the Digital Multimeter.

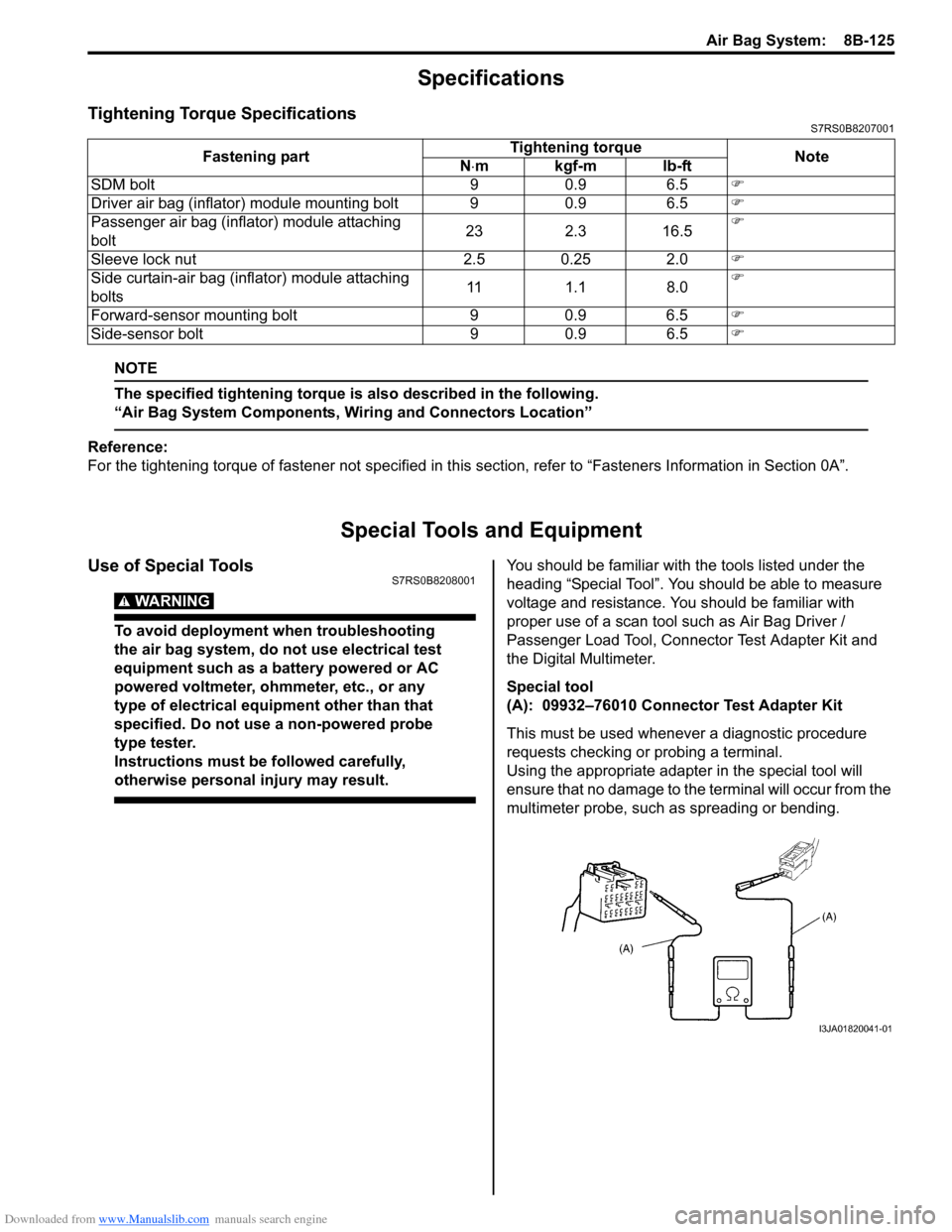

Special tool

(A): 09932–76010 Connector Test Adapter Kit

This must be used whenever a diagnostic procedure

requests checking or probing a terminal.

Using the appropriate adapter in the special tool will

ensure that no damage to the terminal will occur from the

multimeter probe, such as spreading or bending.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

SDM bolt 9 0.9 6.5 �)

Driver air bag (inflator) module mounting bolt 9 0.9 6.5 �)

Passenger air bag (inflator) module attaching

bolt 23 2.3 16.5�)

Sleeve lock nut 2.5 0.25 2.0 �)

Side curtain-air bag (inflator) module attaching

bolts 11 1.1 8.0�)

Forward-sensor mounting bolt 9 0.9 6.5 �)

Side-sensor bolt 9 0.9 6.5 �)

I3JA01820041-01

Page 1164 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-126 Air Bag System:

The adapter (1) will also give an idea of whether or not

contact tension is sufficient, helping to find an open or

intermittent open due to poor terminal contact. An SDM

short bar release tool (2) is included in the connector test

adapter kit. Inserting it in to the SDM connector (3) will

releases the shorting bar.

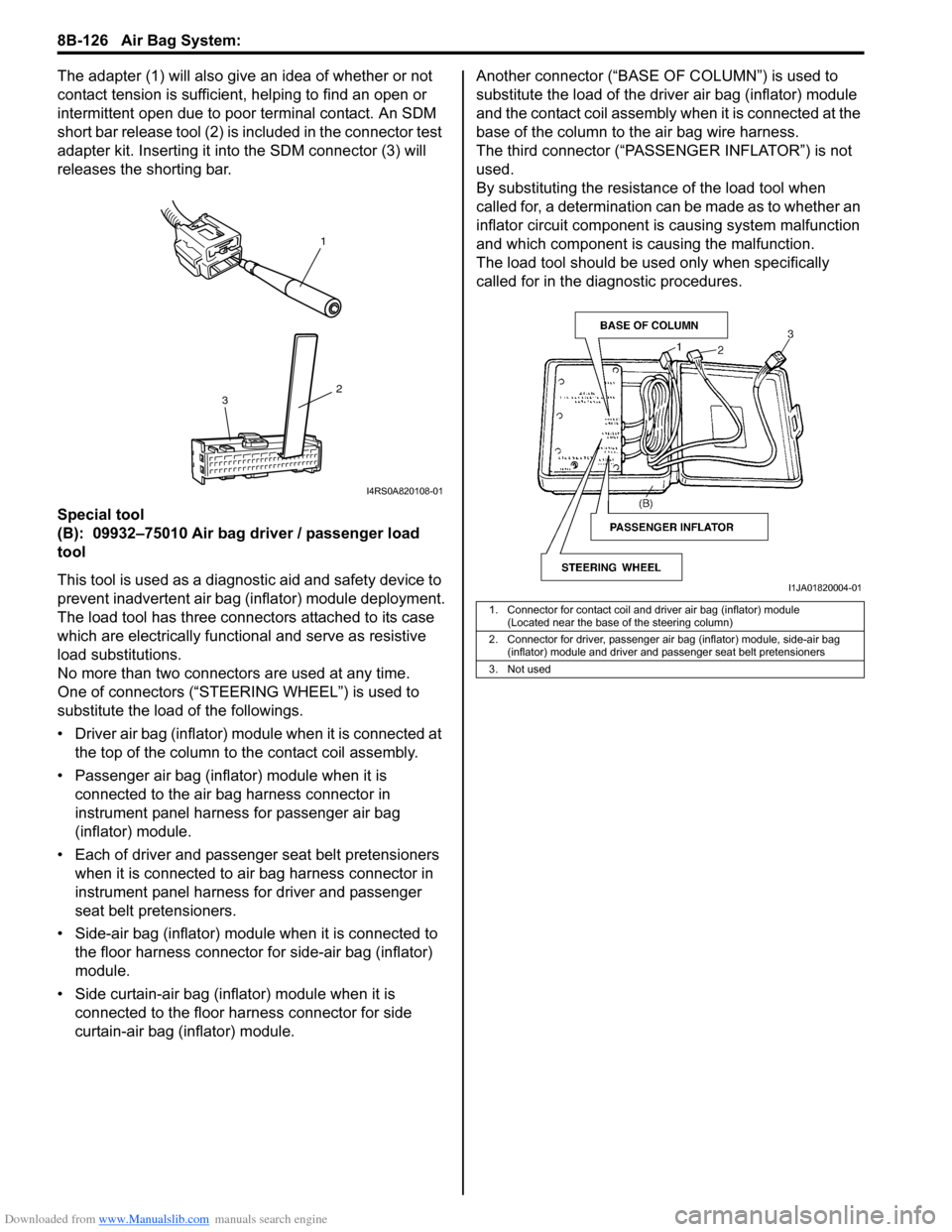

Special tool

(B): 09932–75010 Air bag driver / passenger load

tool

This tool is used as a diagno stic aid and safety device to

prevent inadvertent air bag (inflator) module deployment.

The load tool has three connectors attached to its case

which are electrically functional and serve as resistive

load substitutions.

No more than two connectors are used at any time.

One of connectors (“STEER ING WHEEL”) is used to

substitute the load of the followings.

• Driver air bag (inflator) module when it is connected at the top of the column to the contact coil assembly.

• Passenger air bag (inflator) module when it is connected to the air bag harness connector in

instrument panel harness for passenger air bag

(inflator) module.

• Each of driver and passen ger seat belt pretensioners

when it is connected to air bag harness connector in

instrument panel harness for driver and passenger

seat belt pretensioners.

• Side-air bag (inflator) module when it is connected to the floor harness connector for side-air bag (inflator)

module.

• Side curtain-air bag (inflator) module when it is connected to the floor harness connector for side

curtain-air bag (inflator) module. Another connec

tor (“BASE OF COLUMN ”) is used to

substitute the load of the driver air bag (inflator) module

and the contact coil assembly when it is connected at the

base of the column to the air bag wire harness.

The third connector (“PASSENGER INFLATOR”) is not

used.

By substituting the resistan ce of the load tool when

called for, a determination can be made as to whether an

inflator circuit component is causing system malfunction

and which component is causing the malfunction.

The load tool should be used only when specifically

called for in the diagnostic procedures.

1

2

3

I4RS0A820108-01

1. Connector for contact coil and driver air bag (inflator) module

(Located near the base of the steering column)

2. Connector for driver, passenger air bag (inflator) module, side-air bag (inflator) module and driver and passenger seat belt pretensioners

3. Not used

I1JA01820004-01

Page 1274 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-103 Wiring Systems:

List of Connector

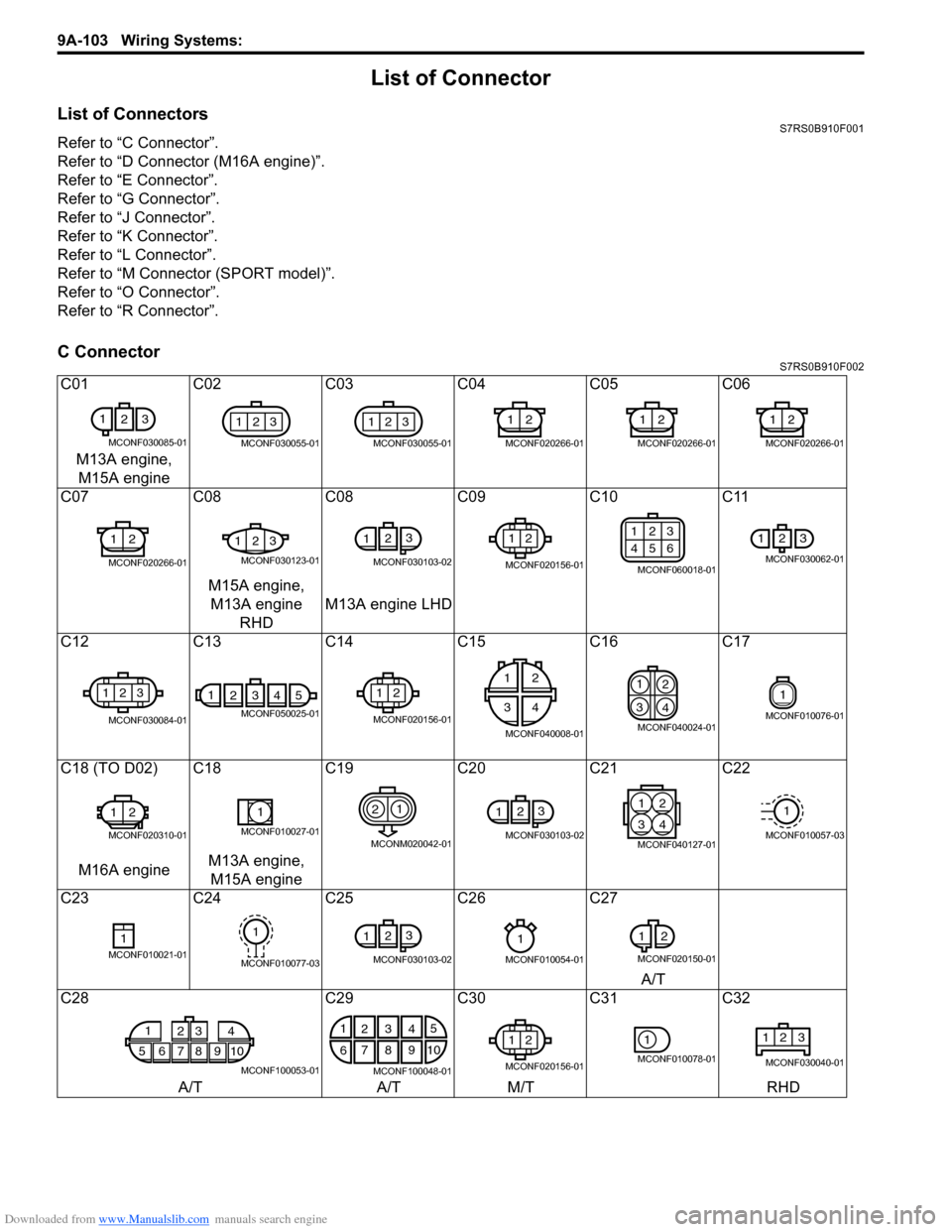

List of ConnectorsS7RS0B910F001

Refer to “C Connector”.

Refer to “D Connector (M16A engine)”.

Refer to “E Connector”.

Refer to “G Connector”.

Refer to “J Connector”.

Refer to “K Connector”.

Refer to “L Connector”.

Refer to “M Connector (SPORT model)”.

Refer to “O Connector”.

Refer to “R Connector”.

C ConnectorS7RS0B910F002

C01C02C03 C04 C05 C06

M13A engine, M15A engine

C07 C08C08 C09 C10 C11

M15A engine, M13A engine RHD M13A engine LHD

C12 C13C14 C15 C16 C17

C18 (TO D02) C18 C19C20C21C22

M16A engine M13A engine,

M15A engine

C23 C24C25 C26 C27

A/T

C28 C29C30C31C32

A/T A/TM/T RHD

1

23

MCONF030085-01

123

MCONF030055-01

123

MCONF030055-01

12

MCONF020266-01

12

MCONF020266-01

12

MCONF020266-01

12

MCONF020266-01

123

MCONF030123-01

123

MCONF030103-02

12

MCONF020156-01

123

456

MCONF060018-01

123

MCONF030062-01

123

MCONF030084-01

14325

MCONF050025-01

12

MCONF020156-01

12

34

MCONF040008-01

1

2

3 4

MCONF040024-01

1

MCONF010076-01

12

MCONF020310-01

1

MCONF010027-01

21

MCONM020042-01

12

3

MCONF030103-02

21

43

MCONF040127-01

1

MCONF010057-03

1MCONF010021-01

1

MCONF010077-03

123

MCONF030103-02

1

MCONF010054-01

1

2

MCONF020150-01

1

5678910 23 4

MCONF100053-01

1

2 5

6 7

103

84

9

MCONF100048-01

12

MCONF020156-01

1

MCONF010078-01

123

MCONF030040-01

Page 1275 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-104

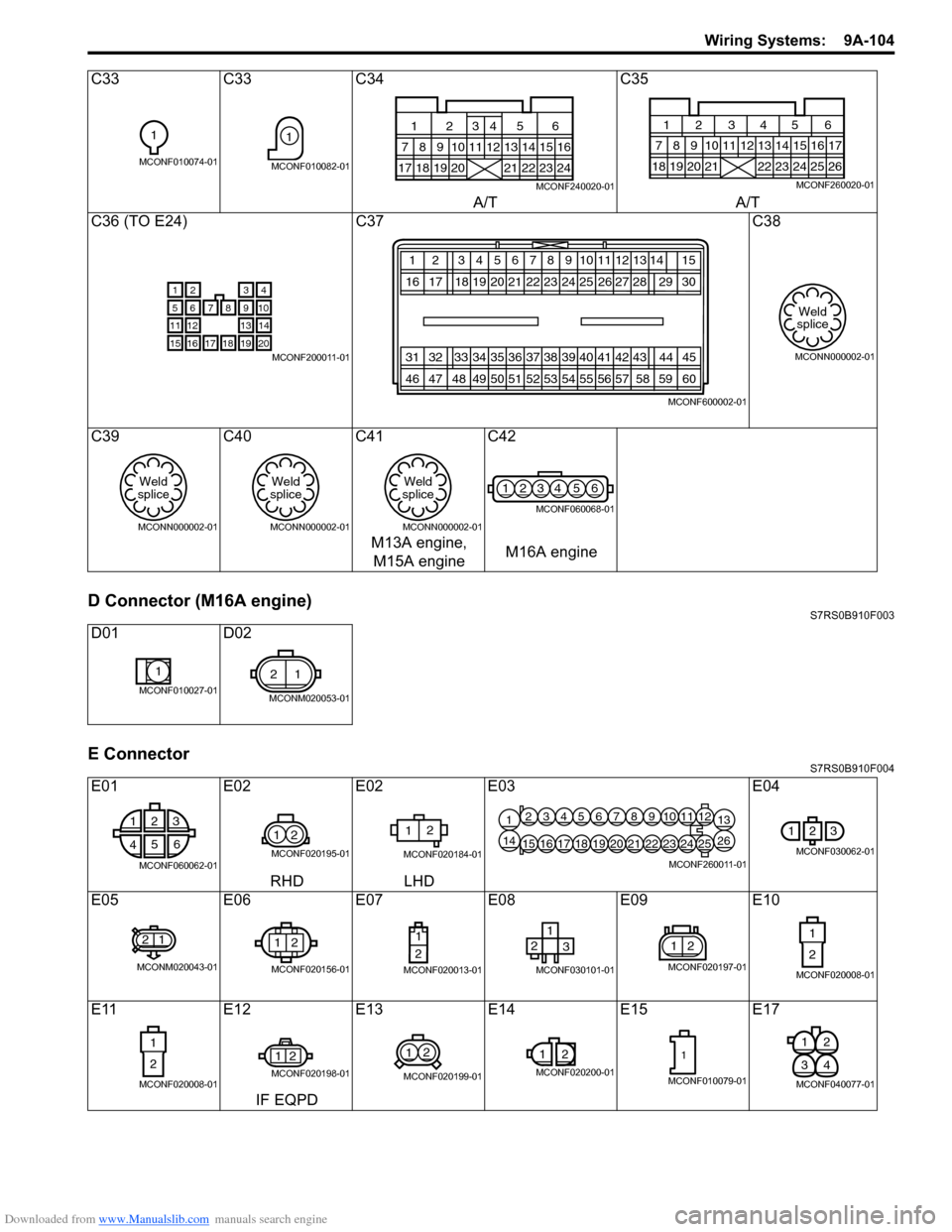

D Connector (M16A engine)S7RS0B910F003

E ConnectorS7RS0B910F004

C33C33C34 C35

A/T A/T

C36 (TO E24) C37 C38

C39 C40C41 C42

M13A engine, M15A engine M16A engine

D01 D02

E01 E02E02E03 E04

RHD LHD

E05 E06E07E08 E09E10

E11 E12E13 E14 E15 E17

IF EQPD

1

MCONF010074-01

1

MCONF010082-0117181920

7

1256

89101113141516

21222324

12

34

MCONF240020-01

181920 21

7 12345 68910

22232425

13141516

26

171112

MCONF260020-01

21

8

3

9765

131211

1819

4

10

14

20171615MCONF200011-01

12 3456

20 21

16 17 18 1978910

22 23 24 25 12

272613

28

31 32 33 34 35 36 50 51

46 47 48 49 37 38 39 40

52 53 54 5511

41

56

42

5743

5814 15 29 30

44 60 45

59

MCONF600002-01

Weld

splice

MCONN000002-01

Weld

splice

MCONN000002-01

Weld

splice

MCONN000002-01

Weld

splice

MCONN000002-01

1234 56

MCONF060068-01

1

MCONF010027-01

21

MCONM020053-01

1 2 3

4 5

6

MCONF060062-01

12

MCONF020195-01

12

MCONF020184-01

12345678910111213

14151617181920212223242526

MCONF260011-01

123

MCONF030062-01

21

MCONM020043-01

12

MCONF020156-01

1

2

MCONF020013-01

12 3

MCONF030101-01

21

MCONF020197-01

1

2

MCONF020008-01

1

2

MCONF020008-01

21

MCONF020198-01

12

MCONF020199-01

1

2

MCONF020200-01

1

MCONF010079-01

21

43

MCONF040077-01

Page 1276 of 1496

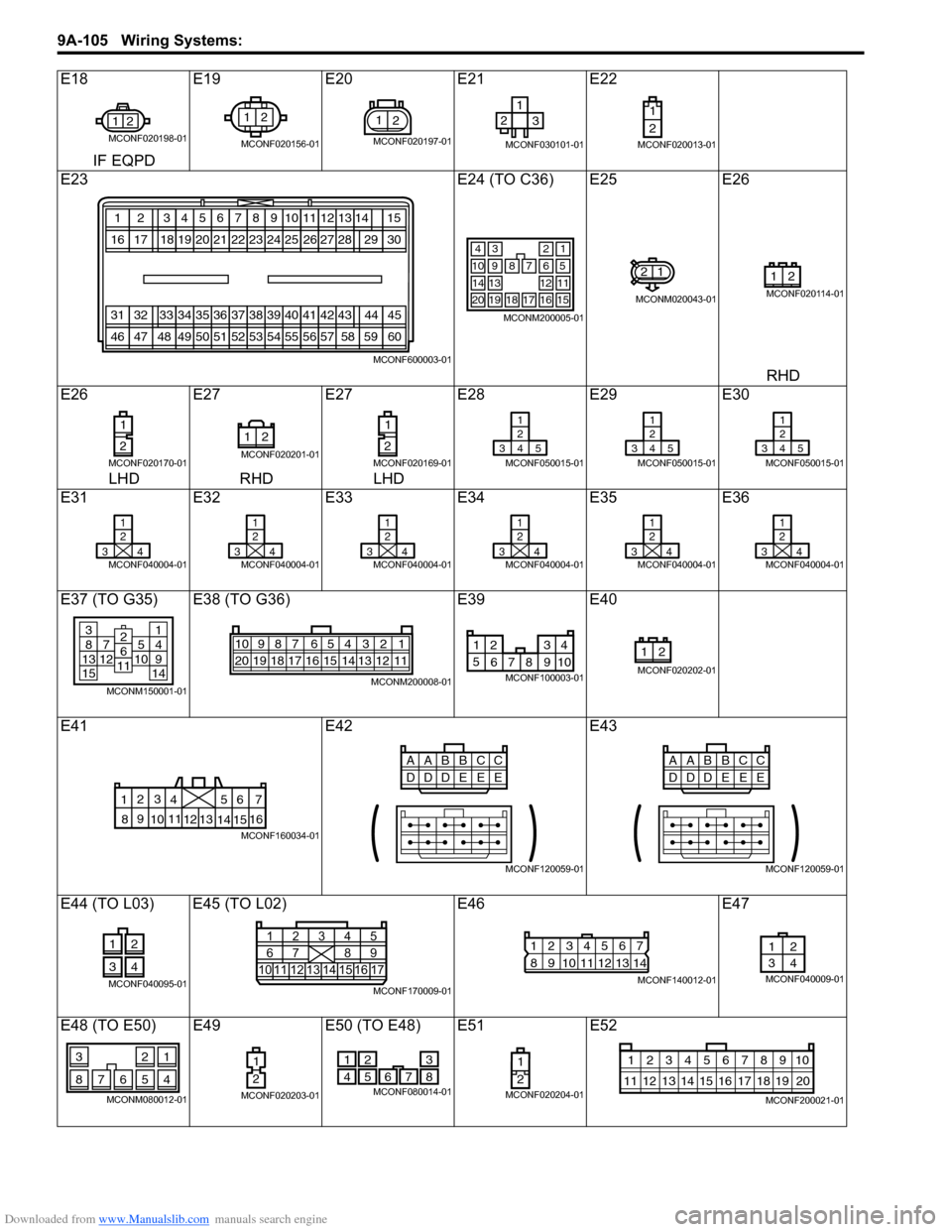

Downloaded from www.Manualslib.com manuals search engine 9A-105 Wiring Systems:

E18E19E20E21 E22

IF EQPD

E23 E24 (TO C36) E25E26

RHD

E26 E27E27E28 E29E30

LHD RHD LHD

E31 E32E33E34 E35E36

E37 (TO G35) E38 (TO G36) E39E40

E41 E42E43

E44 (TO L03) E45 (TO L02) E46E47

E48 (TO E50) E49 E50 (TO E48) E51E52

21

MCONF020198-01

12

MCONF020156-01

21

MCONF020197-01

12

3

MCONF030101-01

1

2

MCONF020013-01

123456

202116171819

78910

22232425

12

2726

13

28

313233343536

505146474849

37383940

52535455

11

41

56

42

57

43

58

1415

2930

44

60

45

59

MCONF600003-01

34

7

2

68910

121314

1716

1

5

11

15181920

MCONM200005-01

21

MCONM020043-01

21

MCONF020114-01

1

2

MCONF020170-01

21

MCONF020201-01

1

2

MCONF020169-01

1

2

345

MCONF050015-01

1

2

345

MCONF050015-01

1

2

345

MCONF050015-01

1

2

34

MCONF040004-01

1

2

34

MCONF040004-01

1

2

34

MCONF040004-01

1

2

34

MCONF040004-01

1

2

34

MCONF040004-01

1

2

34

MCONF040004-01

381371251015

14914

2611

MCONM150001-01

54 32 167910

20 19 18 17 16 15 14 13 12 118

MCONM200008-01

1 234

5 678 910

MCONF100003-01

21

MCONF020202-01

6

5

4

3

2

17

11

10

9

8 15

14

13

12 16

MCONF160034-01

CC

AABB

DE

DD

EE

MCONF120059-01

CC

AABB

DE

DD

EE

MCONF120059-01

12

34

MCONF040095-0110 1

6111415 16 171213

2

734

85

9

MCONF170009-01

12567

8

9 1011121314

34

MCONF140012-01

12

34

MCONF040009-01

21

7654

3

8

MCONM080012-01

1

2

MCONF020203-01

2

51

47 6

8

3

MCONF080014-01

1

2

MCONF020204-01

10

11 12 13 14 15 16 17 18 19 123456789

20

MCONF200021-01

Page 1277 of 1496

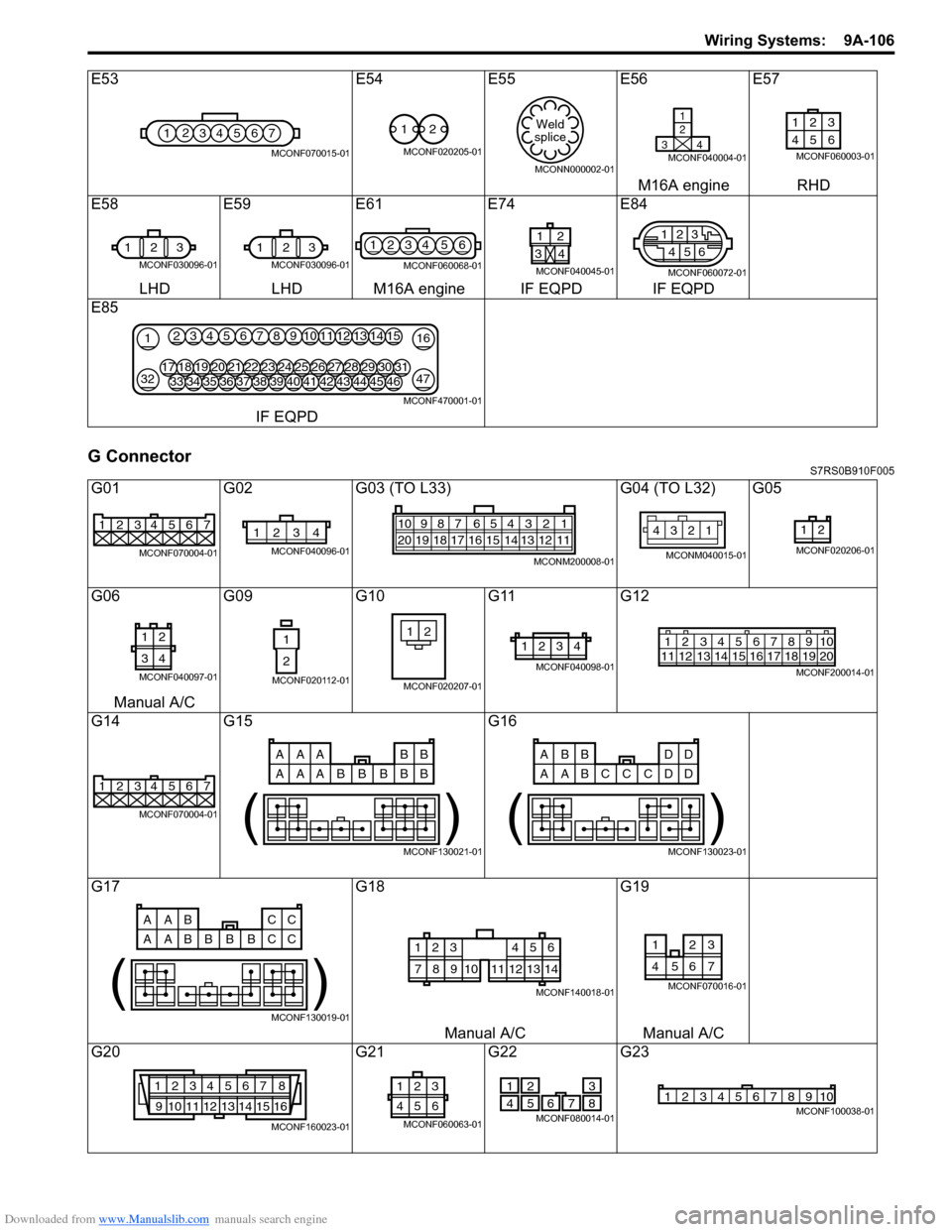

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-106

G ConnectorS7RS0B910F005

E53E54E55 E56E57

M16A engine RHD

E58 E59E61E74 E84

LHD LHD M16A engine IF EQPD IF EQPD

E85

IF EQPD

G01 G02G03 (TO L33) G04 (TO L32) G05

G06 G09G10G11G12

Manual A/C

G14 G15 G16

G17 G18G19

Manual A/C Manual A/C

G20 G21G22G23

1234567

MCONF070015-01

12

MCONF020205-01

Weld

splice

MCONN000002-01

1

2

34

MCONF040004-01

123

46 5

MCONF060003-01

1 23

MCONF030096-01

123

MCONF030096-01

1234 56

MCONF060068-01

1

34

2

MCONF040045-01

2

5

46

13

MCONF060072-01

21

3247

163451213141567891011

3334353643444546373839404142181719202128293031222324252627

MCONF470001-01

1234567

MCONF070004-01

1234

MCONF040096-01

54 32 167910

20 19 18 17 16 15 14 13 12 118

MCONM200008-01

12

34

MCONM040015-01

12

MCONF020206-01

12

34

MCONF040097-01

1

2

MCONF020112-01

21

MCONF020207-01

1234

MCONF040098-01

125678911 12 13 14 15 16 17 18 1910

2034

MCONF200014-01

1234567

MCONF070004-01

AAA BB

AAA B

BB

BB

( )

MCONF130021-01

ABB DD

AAB D

CC

CD

( )

MCONF130023-01

AAB CC

AAB C

BB

BC

( )

MCONF130019-01

123

78910

456

11121314

MCONF140018-01

3

7654

21

MCONF070016-01

1234567 8

9 10111213141516

MCONF160023-01

3

21

654

MCONF060063-01

2

51

47 6

8

3

MCONF080014-01

12345678910MCONF100038-01