Test driving SUZUKI SWIFT 2006 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 606 of 1496

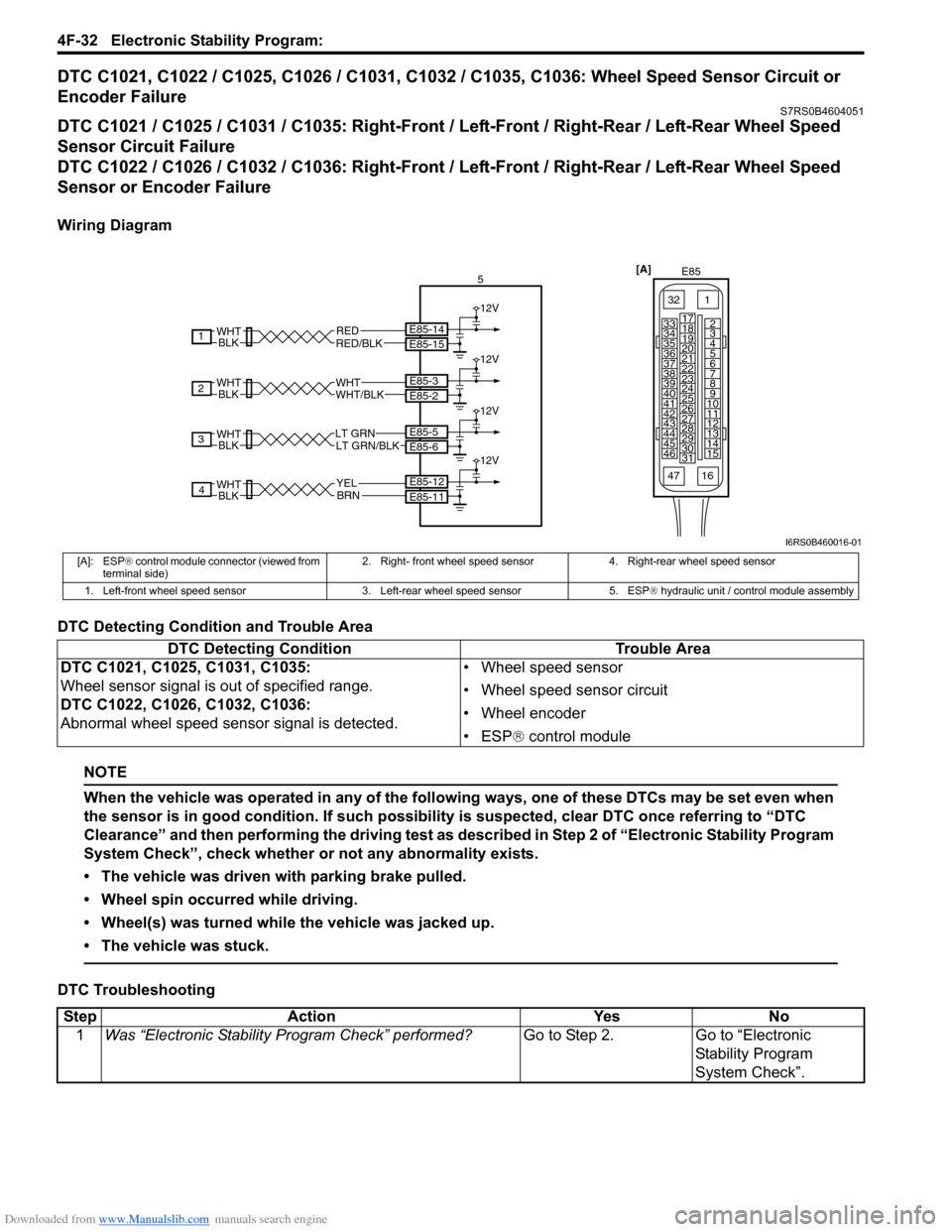

Downloaded from www.Manualslib.com manuals search engine 4F-32 Electronic Stability Program:

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Wheel Speed Sensor Circuit or

Encoder Failure

S7RS0B4604051

DTC C1021 / C1025 / C1031 / C1035: Right-Front / Left-Front / Right-Rear / Left-Rear Wheel Speed

Sensor Circuit Failure

DTC C1022 / C1026 / C1032 / C1036: Right-Front / Left-Front / Right-Rear / Left-Rear Wheel Speed

Sensor or Encoder Failure

Wiring Diagram

DTC Detecting Condition and Trouble Area

NOTE

When the vehicle was operated in any of the following ways, one of these DTCs may be set even when

the sensor is in good condition. If such possibility is suspected, clear DTC once referring to “DTC

Clearance” and then performing the driving test as described in Step 2 of “Electronic Stability Program

System Check”, check whether or not any abnormality exists.

• The vehicle was driven with parking brake pulled.

• Wheel spin occurred while driving.

• Wheel(s) was turned while the vehicle was jacked up.

• The vehicle was stuck.

DTC Troubleshooting

[A]E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

RED/BLKRED E85-15 E85-14

12V

BLKWHT

1

WHT/BLKWHTE85-2 E85-3

12V

BLKWHT

2

BLKWHTLT GRN/BLKLT GRNE85-6 E85-5

12V

3

BLKWHTBRNE85-11 E85-12

12V

4YEL 5

I6RS0B460016-01

[A]: ESP

® control module connector (viewed from

terminal side) 2. Right- front wheel speed sensor 4. Right-rear wheel speed sensor

1. Left-front wheel speed sensor 3. Left-rear wheel speed sensor 5. ESP ® hydraulic unit / control module assembly

DTC Detecting Condition Trouble Area

DTC C1021, C1025, C1031, C1035:

Wheel sensor signal is out of specified range.

DTC C1022, C1026, C1032, C1036:

Abnormal wheel speed sensor signal is detected. • Wheel speed sensor

• Wheel speed sensor circuit

• Wheel encoder

• ESP

® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

Page 671 of 1496

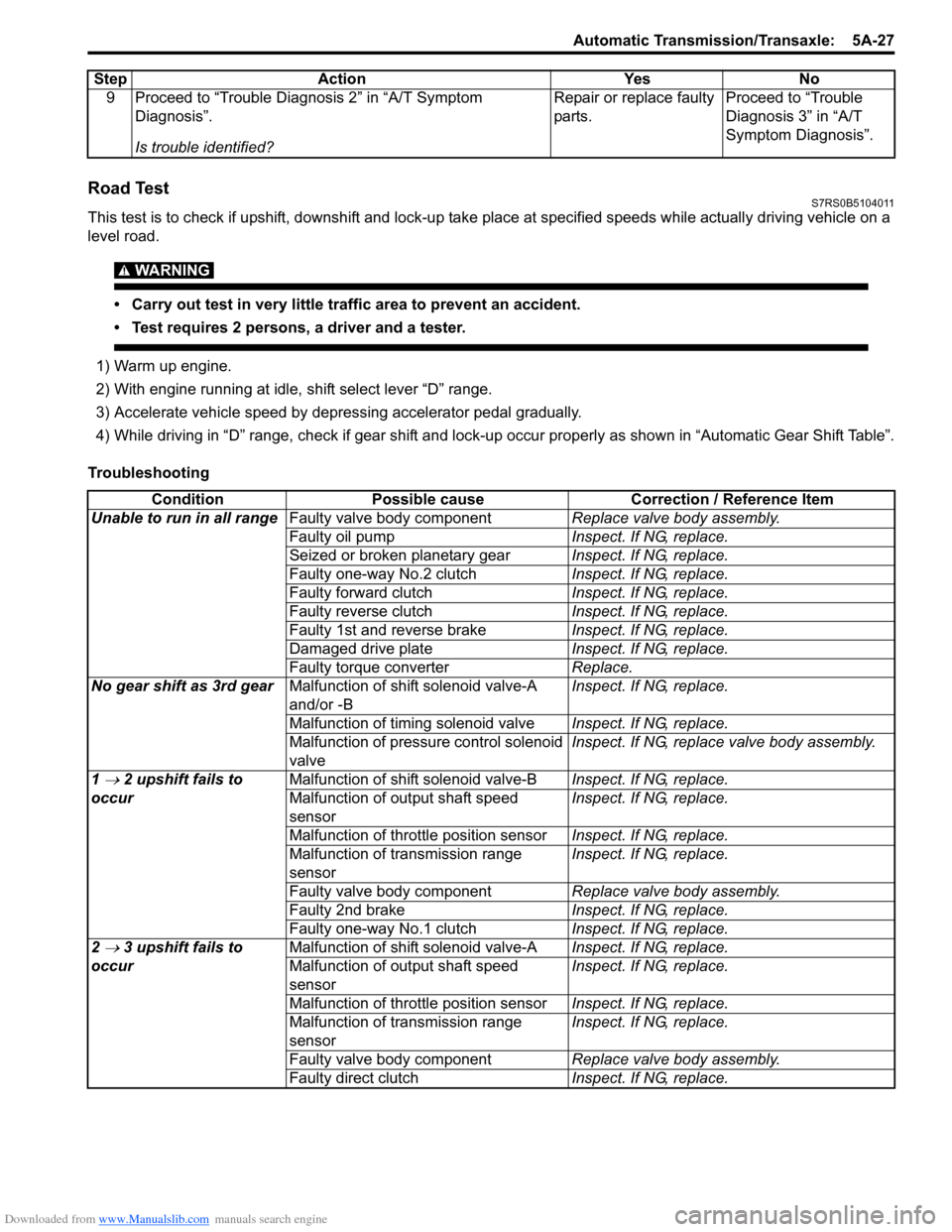

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-27

Road TestS7RS0B5104011

This test is to check if upshift, downshift and lock-up take place at specified speeds while actually driving vehicle on a

level road.

WARNING!

• Carry out test in very little traffic area to prevent an accident.

• Test requires 2 persons, a driver and a tester.

1) Warm up engine.

2) With engine running at idle, shift select lever “D” range.

3) Accelerate vehicle speed by depressing accelerator pedal gradually.

4) While driving in “D” range, check if gear shift and lock-up occur properly as shown in “Automatic Gear Shift Table”.

Troubleshooting 9 Proceed to “Trouble Diag

nosis 2” in “A/T Symptom

Diagnosis”.

Is trouble identified? Repair or replace faulty

parts.

Proceed to “Trouble

Diagnosis 3” in “A/T

Symptom Diagnosis”.

Step Action Yes No

Condition

Possible cause Correction / Reference Item

Unable to run in all range Faulty valve body component Replace valve body assembly.

Faulty oil pump Inspect. If NG, replace.

Seized or broken planetary gear Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Faulty forward clutch Inspect. If NG, replace.

Faulty reverse clutch Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Damaged drive plate Inspect. If NG, replace.

Faulty torque converter Replace.

No gear shift as 3rd gear Malfunction of shift solenoid valve-A

and/or -B Inspect. If NG, replace.

Malfunction of timing solenoid valve Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

1

→ 2 upshift fails to

occur Malfunction of shif

t solenoid valve-B Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty 2nd brake Inspect. If NG, replace.

Faulty one-way No.1 clutch Inspect. If NG, replace.

2

→ 3 upshift fails to

occur Malfunction of shif

t solenoid valve-A Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty direct clutch Inspect. If NG, replace.

Page 674 of 1496

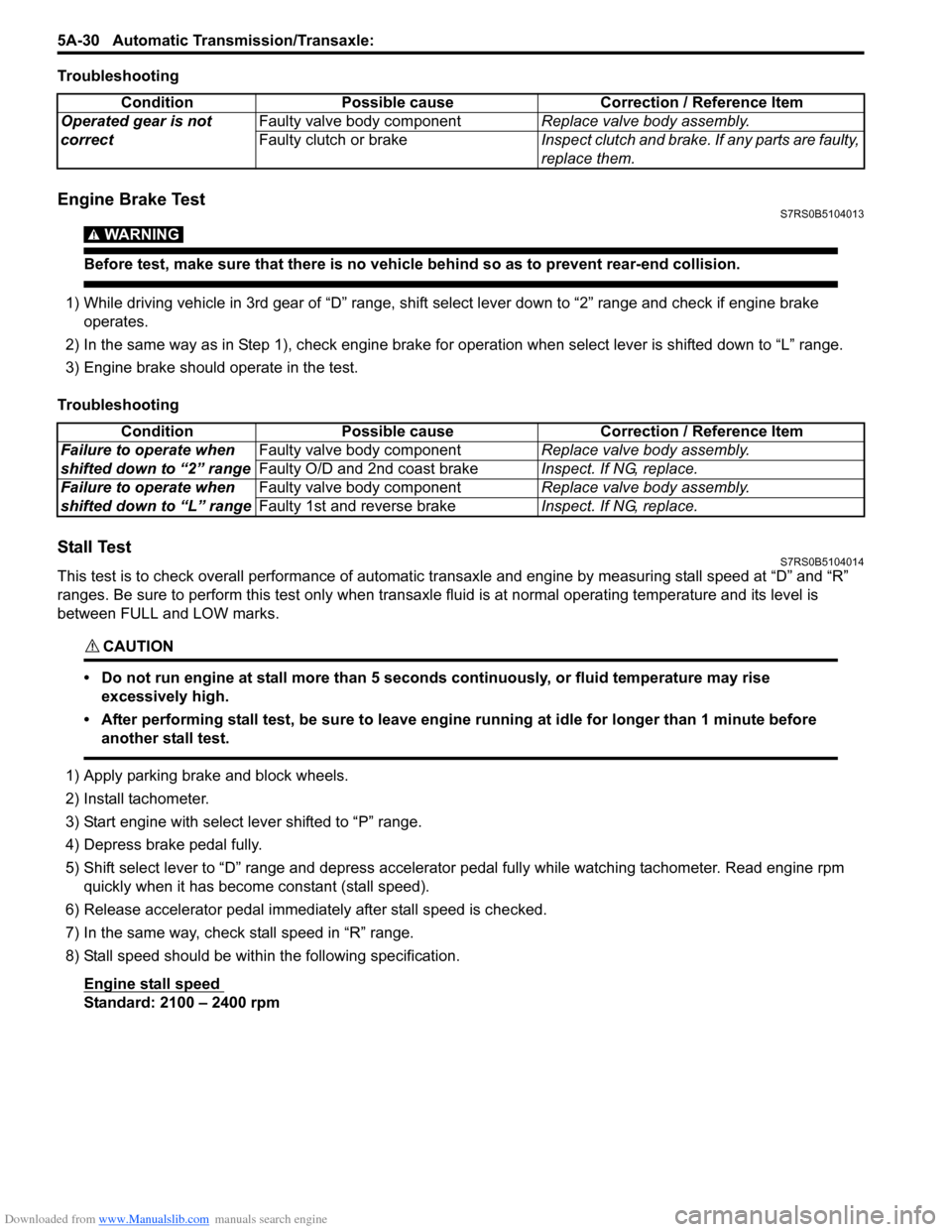

Downloaded from www.Manualslib.com manuals search engine 5A-30 Automatic Transmission/Transaxle:

Troubleshooting

Engine Brake TestS7RS0B5104013

WARNING!

Before test, make sure that there is no vehicle behind so as to prevent rear-end collision.

1) While driving vehicle in 3rd gear of “D” range, shift select lever down to “2” range and check if engine brake

operates.

2) In the same way as in Step 1), check engine brake for operation when select lever is shifted down to “L” range.

3) Engine brake should operate in the test.

Troubleshooting

Stall TestS7RS0B5104014

This test is to check overall performance of automatic tr ansaxle and engine by measuring stall speed at “D” and “R”

ranges. Be sure to perform this test only when transaxle fluid is at normal operating temperature and its level is

between FULL and LOW marks.

CAUTION!

• Do not run engine at stall more than 5 seconds continuously, or fluid temperature may rise excessively high.

• After performing stall test, be su re to leave engine running at idle for longer than 1 minute before

another stall test.

1) Apply parking brake and block wheels.

2) Install tachometer.

3) Start engine with select lever shifted to “P” range.

4) Depress brake pedal fully.

5) Shift select lever to “D” range and depress accelerator pedal fully while watching tachometer. Read engine rpm quickly when it has become constant (stall speed).

6) Release accelerator pedal immediately after stall speed is checked.

7) In the same way, check stall speed in “R” range.

8) Stall speed should be withi n the following specification.

Engine stall speed

Standard: 2100 – 2400 rpm Condition Possible cause Correction / Reference Item

Operated gear is not

correct Faulty valve body component

Replace valve body assembly.

Faulty clutch or brake Inspect clutch and brake. If any parts are faulty,

replace them.

Condition Possible cause Correction / Reference Item

Failure to operate when

shifted down to “2” range Faulty valve body component

Replace valve body assembly.

Faulty O/D and 2nd coast brake Inspect. If NG, replace.

Failure to operate when

shifted down to “L” range Faulty valve body component

Replace valve body assembly.

Faulty 1st and reverse brake Inspect. If NG, replace.

Page 914 of 1496

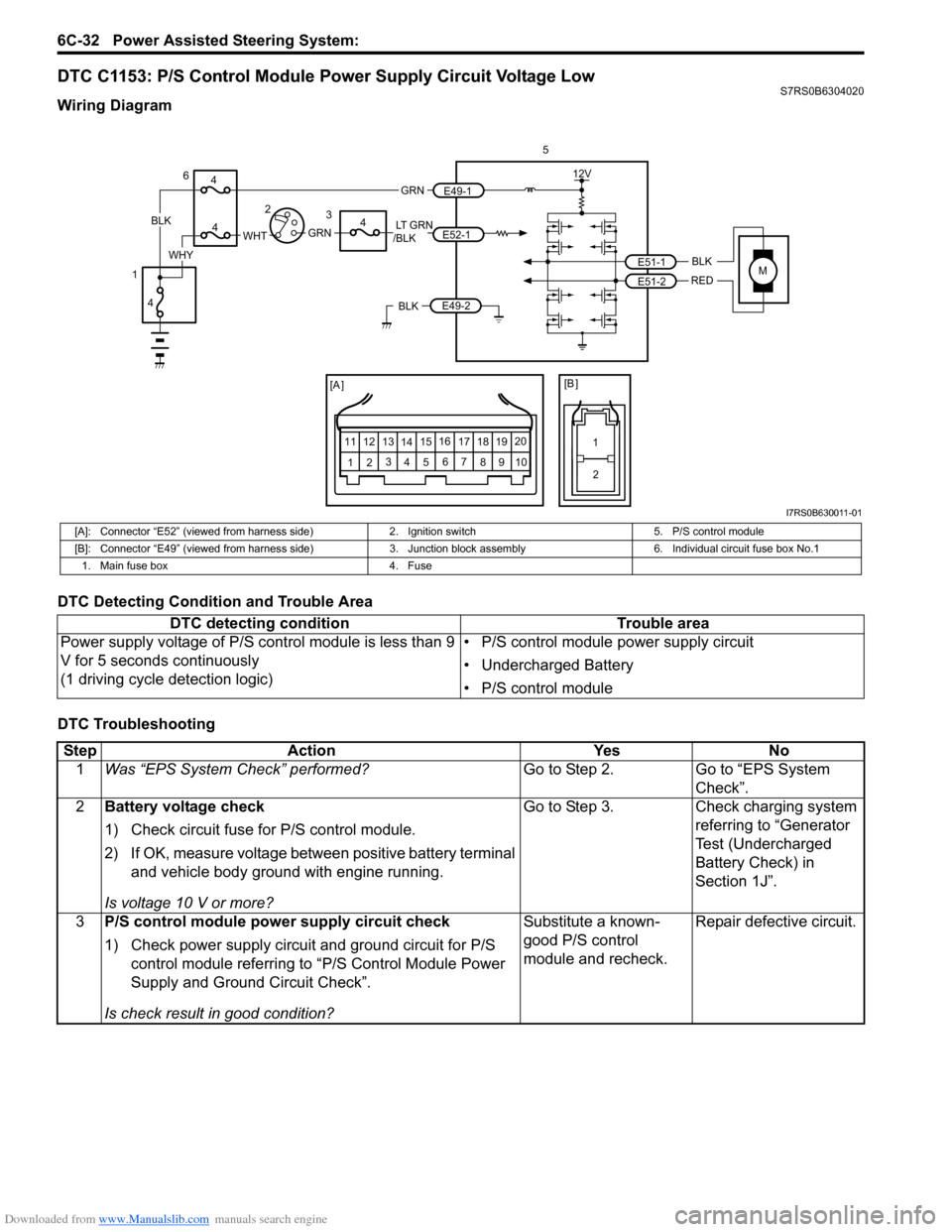

Downloaded from www.Manualslib.com manuals search engine 6C-32 Power Assisted Steering System:

DTC C1153: P/S Control Module Power Supply Circuit Voltage LowS7RS0B6304020

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

MBLK

REDE51-1

E51-2

12V

5

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

[B ]

1

2

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

6

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630011-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch5. P/S control module

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly 6. Individual circuit fuse box No.1

1. Main fuse box 4. Fuse

DTC detecting condition Trouble area

Power supply voltage of P/S control module is less than 9

V for 5 seconds continuously

(1 driving cycle detection logic) • P/S control module power supply circuit

• Undercharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 Battery voltage check

1) Check circuit fuse for P/S control module.

2) If OK, measure voltage between positive battery terminal

and vehicle body ground with engine running.

Is voltage 10 V or more? Go to Step 3.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

3 P/S control module power supply circuit check

1) Check power supply circuit and ground circuit for P/S

control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition? Substitute a known-

good P/S control

module and recheck.

Repair defective circuit.

Page 915 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-33

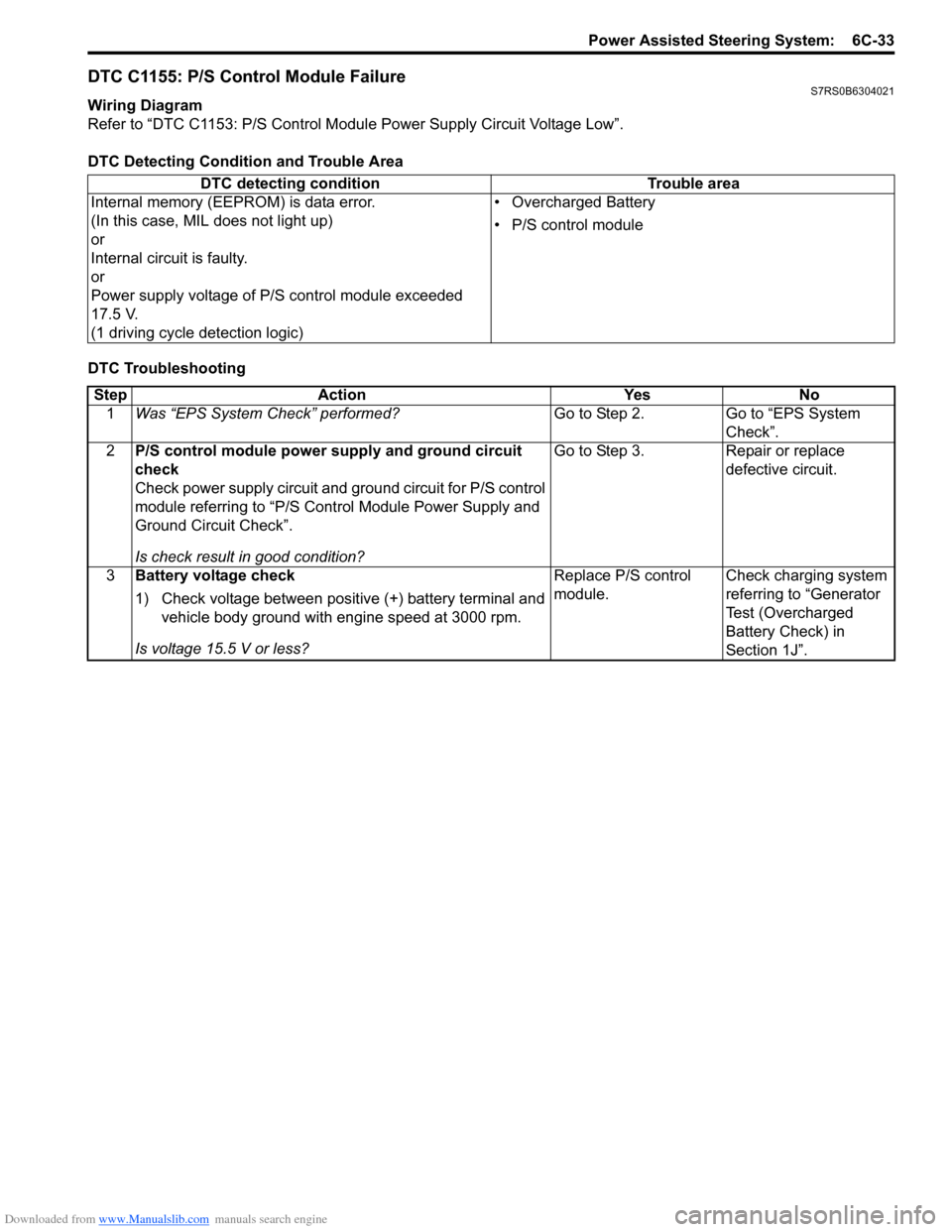

DTC C1155: P/S Control Module FailureS7RS0B6304021

Wiring Diagram

Refer to “DTC C1153: P/S Control Module Power Supply Circuit Voltage Low”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting DTC detecting condition Trouble area

Internal memory (EEPROM) is data error.

(In this case, MIL does not light up)

or

Internal circuit is faulty.

or

Power supply voltage of P/S control module exceeded

17.5 V.

(1 driving cycle detection logic) • Overcharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 P/S control module power supply and ground circuit

check

Check power supply circuit and ground circuit for P/S control

module referring to “P/S Control Module Power Supply and

Ground Circuit Check”.

Is check result in good condition? Go to Step 3.

Repair or replace

defective circuit.

3 Battery voltage check

1) Check voltage between positive (+) battery terminal and

vehicle body ground with engine speed at 3000 rpm.

Is voltage 15.5 V or less? Replace P/S control

module.

Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.