Power lock SUZUKI SWIFT 2006 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 731 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-87

Troubleshooting

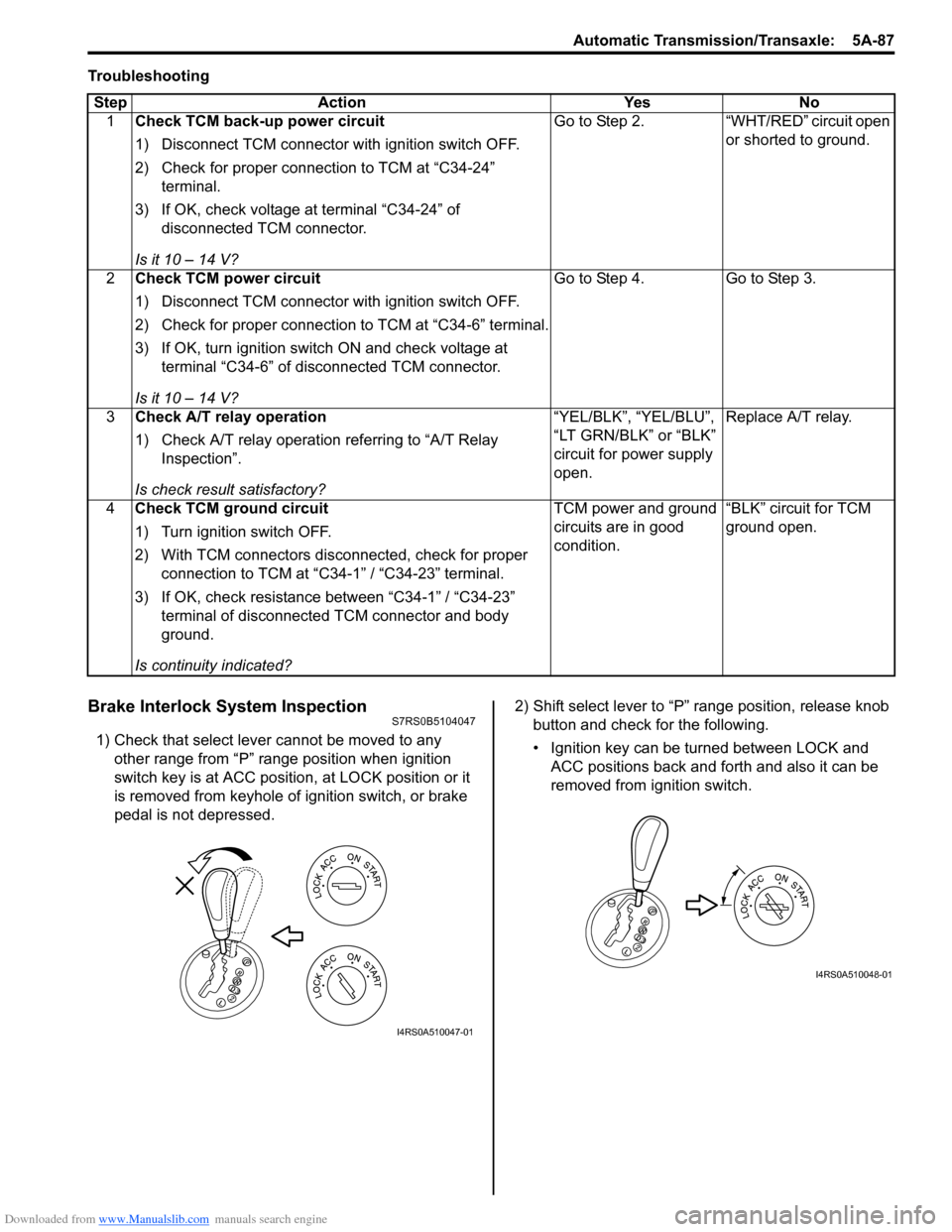

Brake Interlock System InspectionS7RS0B5104047

1) Check that select lever cannot be moved to any other range from “P” range position when ignition

switch key is at ACC position, at LOCK position or it

is removed from keyhole of ignition switch, or brake

pedal is not depressed. 2) Shift select lever to “P” range position, release knob

button and check for the following.

• Ignition key can be turned between LOCK and ACC positions back and forth and also it can be

removed from ignition switch.

Step Action Yes No

1 Check TCM back-up power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C34-24”

terminal.

3) If OK, check voltage at terminal “C34-24” of disconnected TCM connector.

Is it 10 – 14 V? Go to Step 2. “WHT/RED” circuit open

or shorted to ground.

2 Check TCM power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C34-6” terminal.

3) If OK, turn ignition switch ON and check voltage at

terminal “C34-6” of disconnected TCM connector.

Is it 10 – 14 V? Go to Step 4. Go to Step 3.

3 Check A/T relay operation

1) Check A/T relay operation referring to “A/T Relay

Inspection”.

Is check result satisfactory? “YEL/BLK”, “YEL/BLU”,

“LT GRN/BLK” or “BLK”

circuit for power supply

open.

Replace A/T relay.

4 Check TCM ground circuit

1) Turn ignition switch OFF.

2) With TCM connectors disconnected, check for proper

connection to TCM at “C34-1” / “C34-23” terminal.

3) If OK, check resistance between “C34-1” / “C34-23” terminal of disconnected TCM connector and body

ground.

Is continuity indicated? TCM power and ground

circuits are in good

condition.

“BLK” circuit for TCM

ground open.

I4RS0A510047-01

I4RS0A510048-01

Page 867 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 6- i

6

Section 6

CONTENTS

Steering

Precautions ................................................. 6-1

Precautions............................................................. 6-1

Precautions on Steering........................................ 6-1

Steering General Diagnosi s.................... 6A-1

Precautions........................................................... 6A-1

Precautions for Steering Diagnosis ..................... 6A-1

Diagnostic Information and Procedures ............ 6A-2 Steering Symptom Diagnosis .............................. 6A-2

Steering Wheel and Column ................... 6B-1

Precautions........................................................... 6B-1

Service Precautions of Steering Wheel and Column.............................................................. 6B-1

General Description ............................................. 6B-1 Steering Wheel and Column Construction .......... 6B-1

Diagnostic Information and Procedures ............ 6B-2 Checking Steering Column for Accident Damage ............................................................ 6B-2

Repair Instructions .............................................. 6B-3 Steering Wheel and Column Construction .......... 6B-3

Steering Wheel Removal and Installation ........... 6B-4

Contact Coil Cable Assembly Removal and Installation ......................................................... 6B-5

Centering Contact Coil Cable Assembly ............. 6B-6

Contact Coil Cable Assembly Inspection ............ 6B-6

Steering Angle Sensor Removal and Installation ......................................................... 6B-6

Steering Angle Sensor Inspection ....................... 6B-6

Steering Column Removal and Installation ......... 6B-7

Steering Column Inspecti on ................................ 6B-8

Ignition Switch Cylinder Assembly Removal and Installation (Non- Keyless Start Model)...... 6B-9

Steering Lock Assembly (Ignition Switch) Removal and Installation................................... 6B-9

Steering Lower Shaft Removal and Installation ....................................................... 6B-10

Specifications ..................................................... 6B-11

Tightening Torque Specifications ...................... 6B-11

Special Tools and Equipmen t ........................... 6B-11

Special Tool ...................................................... 6B-11

Power Assisted Steering System........... 6C-1

Precautions........................................................... 6C-1 Steering System Note .........................................6C-1

Precautions in Diagnosing Troubles ...................6C-1

General Description .............................................6C-2 P/S System Description ......................................6C-2

EPS Diagnosis General Descr iption ...................6C-3

On-Board Diagnostic System Description ...........6C-3

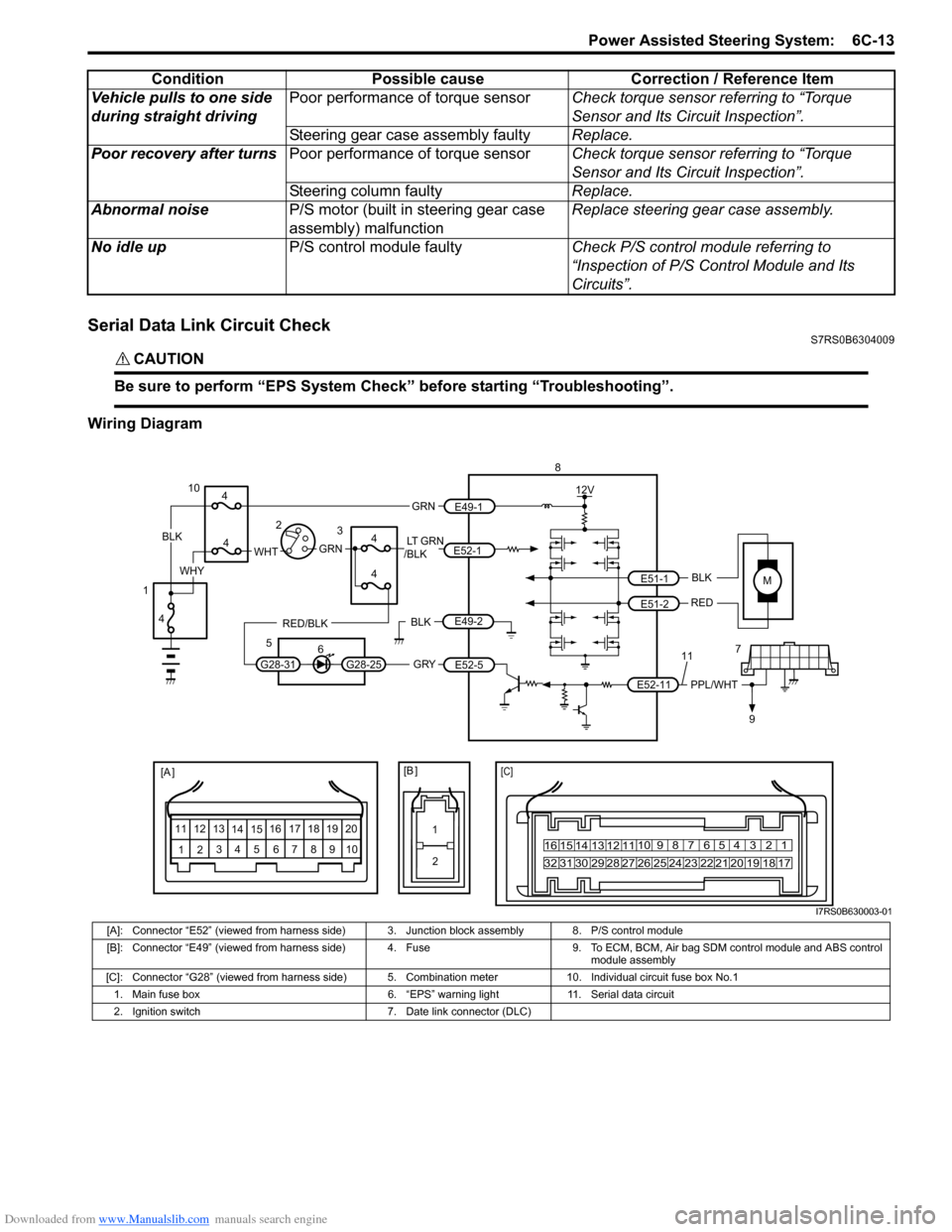

Schematic and Routing Diagram ........................6C-4 EPS System Wiring Circuit Diagram ...................6C-4

Diagnostic Information and Procedures ............6C-5 EPS System Check .............. ...............................6C-5

“EPS” Warning Light Check . ...............................6C-8

DTC Check..........................................................6C-8

DTC Clearance ...................................................6C-9

DTC Table ...........................................................6C-9

Scan Tool Data .................................................6C-11

Visual Inspection ...............................................6C-12

P/S System Symptom Diagnosis ......................6C-12

Serial Data Link Circuit Check ..........................6C-13

“EPS” Warning Light Do es Not Come ON with

Ignition Switch Turn ed ON before Engine

Starts ...............................................................6C-15

“EPS” Warning Light Remains ON Steady after Engine Starts ..........................................6C-16

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit Correlation ............................6C-17

DTC C1114: Steering Torque Sensor Reference Power Supply Circuit .....................6C-19

DTC C1117: Steering Torque Sensor Failure Signal Circuit Low ...........................................6C-21

DTC C1118: Steering Torque Sensor Failure Signal Circuit High...........................................6C-22

DTC C1119: Steering Torque Sensor Power Supply Circuit ..................................................6C-24

DTC C1121 / C1123 / C1124: VSS Circuit

Failure .............................................................6C-26

DTC C1122: Engine Speed Signal....................6C-28

DTC C1141 / C1142 / C1143 / C1145: P/S Motor Circuit Failure ........................................6C-30

DTC C1153: P/S Control Module Power Supply Circuit Voltage Low .............................6C-32

DTC C1155: P/S Control Module Failure ..........6C-33

P/S Control Module Power Supply and Ground Circuit Check ......................................6C-34

Inspection of P/S Control Module and Its Circuits ............................................................6C-35

Page 886 of 1496

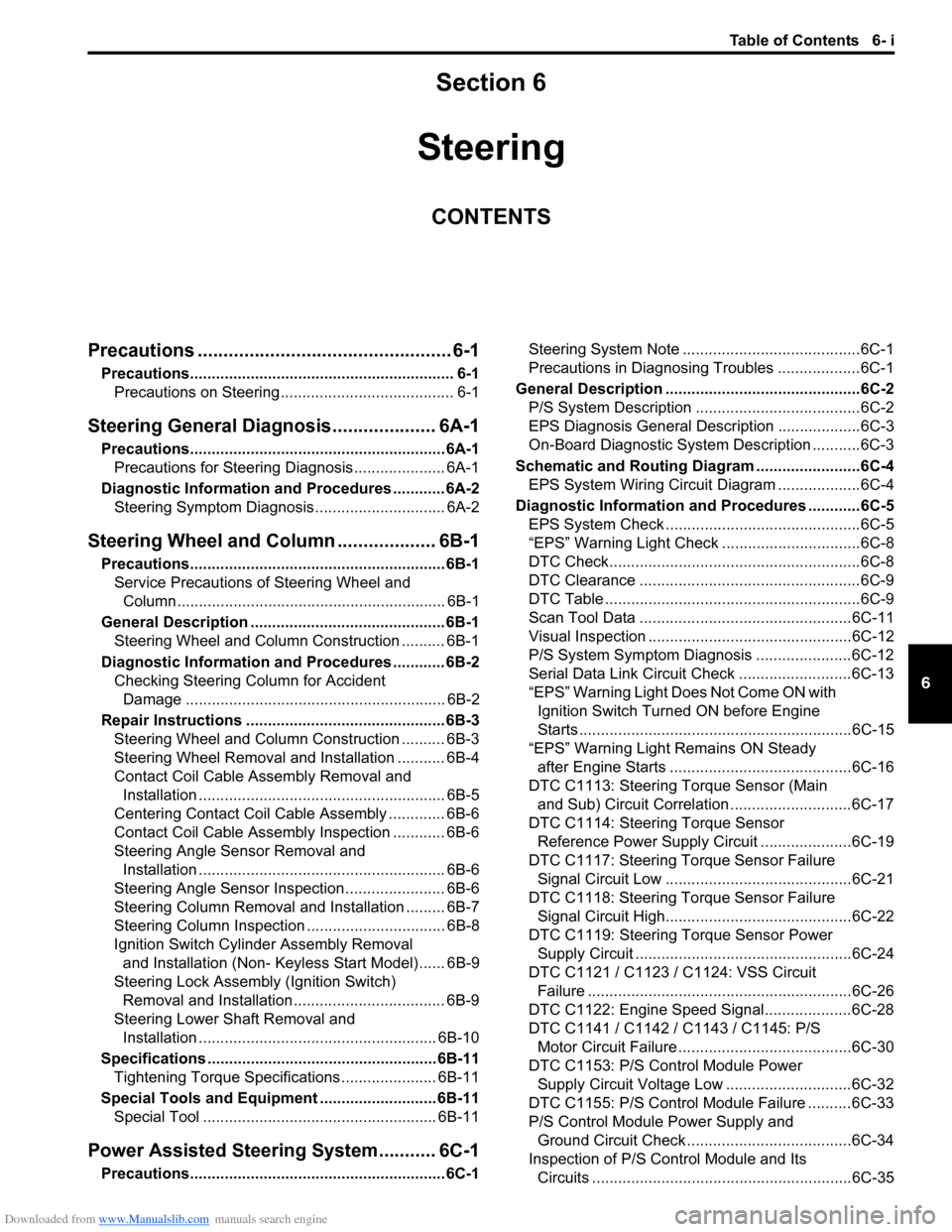

Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS7RS0B6302001

M

5V

BRNRED/

BLU

BLK

RED

WHT

BLU

GRN

BRN YEL

E52-11

E52-14E52-12

E23-4

E23-26

E23-25 E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

PPL/WHT

[A ]

[E ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

1

2

[B ][C ]

1210 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[D]

5V

PPL

E52-4

11

12

13 14

15

10

9

16

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

7654321

5

REDRED/

BLKWHT

6WHTWHT/BLKWHTBLK

12V

12V

17BLK

GRY

LT GRN

/BLK

E52-1

E52-5

E49-1

GRNGRNWHTBLK

WHY

G28-25G28-31

RED/BLK

18

3

4

4

7 8

4

4

1 2

4

E49-2BLK

I7RS0B630002-01

[A]: Connector “E52” (viewed from harness side) 4. Fuse 12. P/S motor

[B]: Connector “E49” (viewed from harness side ) 5. Left-front wheel speed sensor 13. Shield

[C]: Connector “E51” (viewed from harness side) 6 . Right-front wheel speed sensor 14. Torque sensor

[D]: Connector “G28” (viewed from harness side) 7. Combination meter 15. Torque sensor amplifier

[E]: Connector “E53” (viewed from harness side) 8. “EPS” warning light16. To ECM, BCM, Air bag SDM and ABS control module assembly

1. Main fuse box 9. Date link connector (DLC) 17. ABS/ESP ® control module

2. Ignition switch 10. ECM18. Individual circuit fuse box No.1

3. Junction block assembly 11. P/S control module

Page 895 of 1496

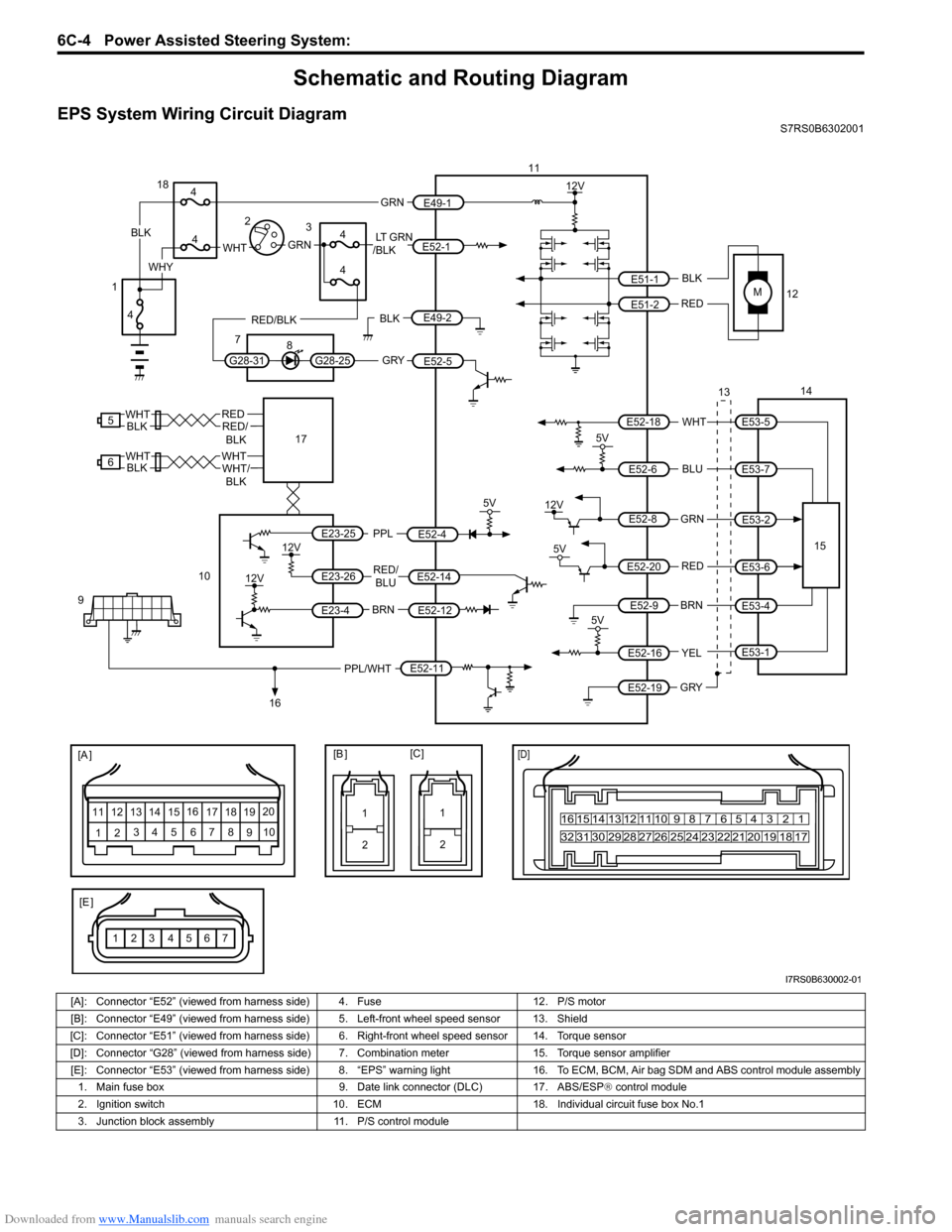

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-13

Serial Data Link Circuit CheckS7RS0B6304009

CAUTION!

Be sure to perform “EPS System Check” before starting “Troubleshooting”.

Wiring DiagramVehicle pulls to one side

during straight driving

Poor performance of torque sensor

Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Steering gear case assembly faulty Replace.

Poor recovery after turns Poor performance of torque sensor Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Steering column faulty Replace.

Abnormal noise P/S motor (built in steering gear case

assembly) malfunction Replace steering gear case assembly.

No idle up P/S control module faulty Check P/S control module referring to

“Inspection of P/S Control Module and Its

Circuits”.

Condition Possible cause Correction / Reference Item

MBLK

RED

E52-11 E51-1

E51-2PPL/WHT

[A ]

12

3

4 5 67

89

11

10

12 13

141516

17 18 19 2010 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

8

79

12V

[B ]

11

12

GRY

LT GRN

/BLK

E52-1

E52-5

E49-1

GRNGRNWHTBLK

WHY

G28-25G28-31

RED/BLK

10

3

4

4

5 6

4

4

1 2

4

E49-2BLK

I7RS0B630003-01

[A]: Connector “E52” (viewed from harness side) 3. Junction block assembly 8. P/S control module

[B]: Connector “E49” (viewed from harness side) 4. Fuse 9. T o ECM, BCM, Air bag SDM control module and ABS control

module assembly

[C]: Connector “G28” (viewed from harness side) 5. Comb ination meter 10. Individual circuit fuse box No.1

1. Main fuse box 6. “EPS” warning light 11. Serial data circuit

2. Ignition switch 7. Date link connector (DLC)

Page 897 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-15

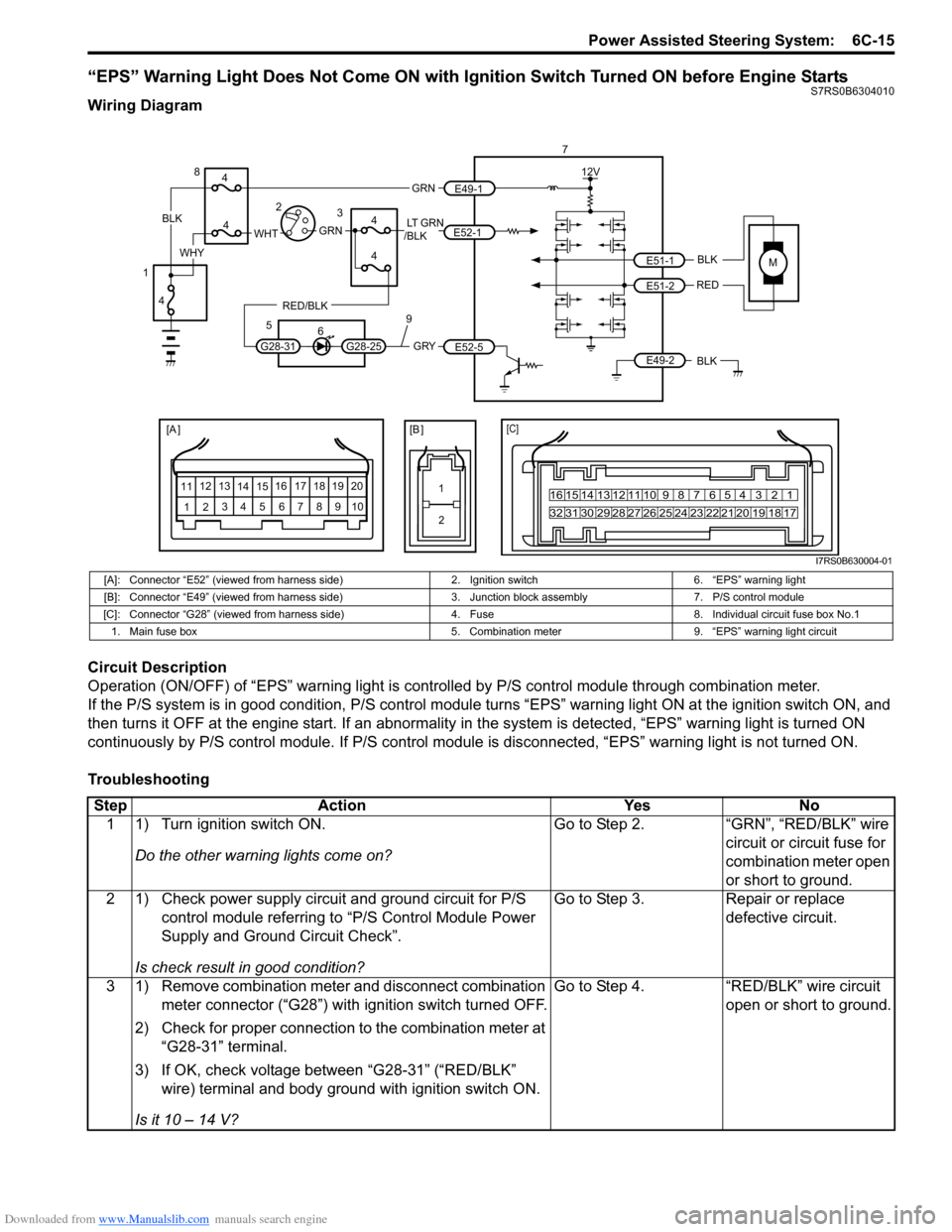

“EPS” Warning Light Does Not Come ON with Ignition Switch Turned ON before Engine StartsS7RS0B6304010

Wiring Diagram

Circuit Description

Operation (ON/OFF) of “EPS” warning light is controlled by P/S control module through combination meter.

If the P/S system is in good condition, P/S control module turns “ EPS” warning light ON at the ignition switch ON, and

then turns it OFF at the engine start. If an abnormality in the system is detected, “EPS” warning light is turned ON

continuously by P/S control module. If P/S control module is disconnected, “EPS” warning light is not turned ON.

Troubleshooting

MBLK

REDE51-1

E51-2

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 2010 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

7

12V

E49-2BLK

[B ]

1 2

GRY

LT GRN

/BLK

E52-1

E52-5

E49-1

GRNGRNWHTBLK

WHY

G28-25G28-31

RED/BLK

8

3

4

4

5 6

4

4

1 2

4

9

I7RS0B630004-01

[A]: Connector “E52” (viewed from harness side) 2. Ignition switch6. “EPS” warning light

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly7. P/S control module

[C]: Connector “G28” (viewed from harness si de)4. Fuse 8. Individual circuit fuse box No.1

1. Main fuse box 5. Combination meter9. “EPS” warning light circuit

StepAction YesNo

1 1) Turn ignition switch ON.

Do the other warning lights come on? Go to Step 2.

“GRN”, “RED/BLK” wire

circuit or circuit fuse for

combination meter open

or short to ground.

2 1) Check power supply circuit and ground circuit for P/S control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition? Go to Step 3.

Repair or replace

defective circuit.

3 1) Remove combination meter and disconnect combination meter connector (“G28”) with ignition switch turned OFF.

2) Check for proper connection to the combination meter at “G28-31” terminal.

3) If OK, check voltage between “G28-31” (“RED/BLK” wire) terminal and body ground with ignition switch ON.

Is it 10 – 14 V? Go to Step 4.

“RED/BLK” wire circuit

open or short to ground.

Page 899 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-17

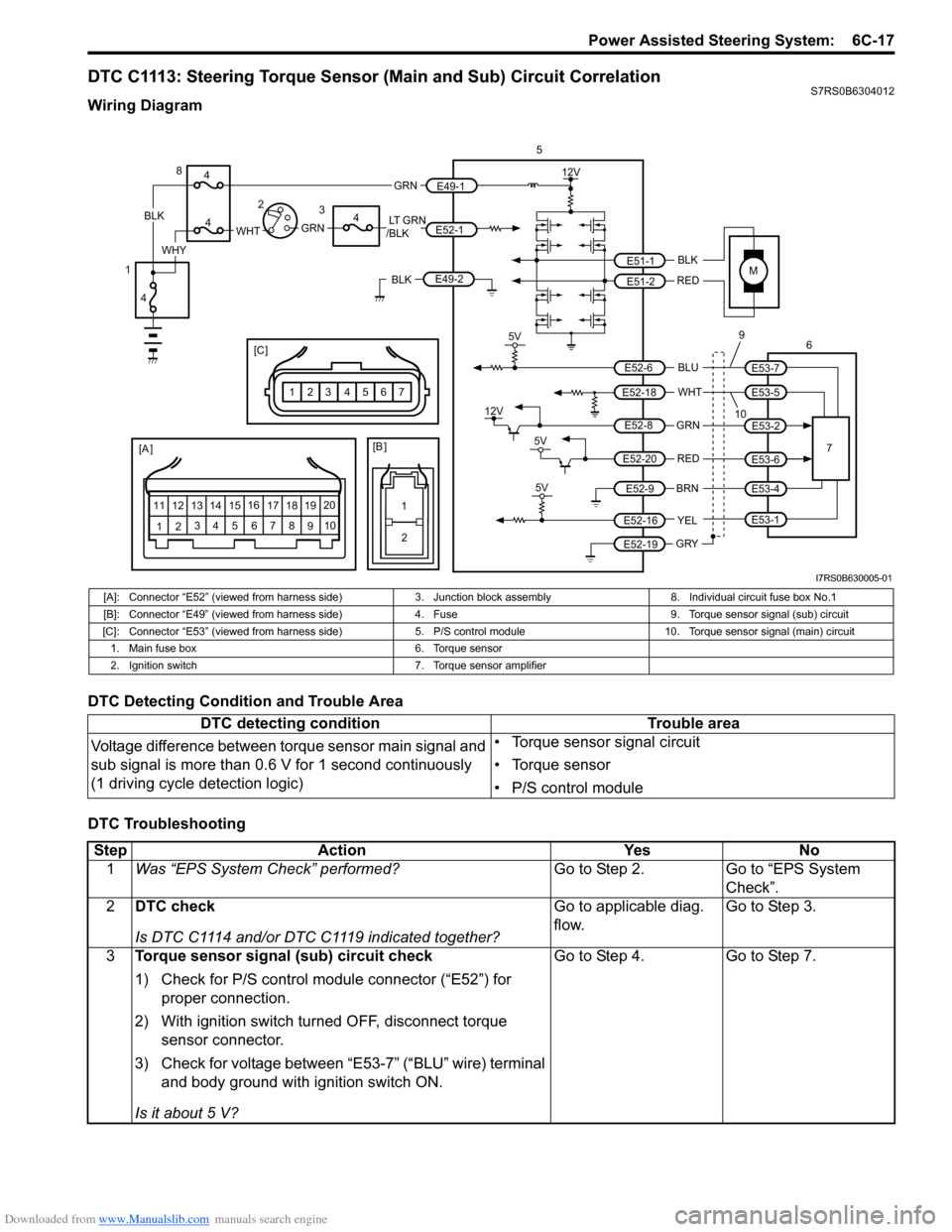

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit CorrelationS7RS0B6304012

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

M

5V

BLK

RED

WHT BLU

GRN

BRN YEL

E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

5

67

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

109

1

2

[B ]

[C ]

7654321

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

8

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630005-01

[A]: Connector “E52” (viewed from harness side)

3. Junction block assembly 8. Individual circuit fuse box No.1

[B]: Connector “E49” (viewed from harness side )4. Fuse 9. Torque sensor signal (sub) circuit

[C]: Connector “E53” (viewed from harness side) 5. P/S control module 10. Torque sensor signal (main) circuit

1. Main fuse box 6. Torque sensor

2. Ignition switch 7. Torque sensor amplifier

DTC detecting condition Trouble area

Voltage difference between torque sensor main signal and

sub signal is more than 0.6 V for 1 second continuously

(1 driving cycle detection logic) • Torque sensor signal circuit

• Torque sensor

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 DTC check

Is DTC C1114 and/or DTC C1119 indicated together? Go to applicable diag.

flow.

Go to Step 3.

3 Torque sensor signal (sub) circuit check

1) Check for P/S control module connector (“E52”) for

proper connection.

2) With ignition switch turned OFF, disconnect torque sensor connector.

3) Check for voltage between “E53-7” (“BLU” wire) terminal and body ground with ignition switch ON.

Is it about 5 V? Go to Step 4.

Go to Step 7.

Page 901 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-19

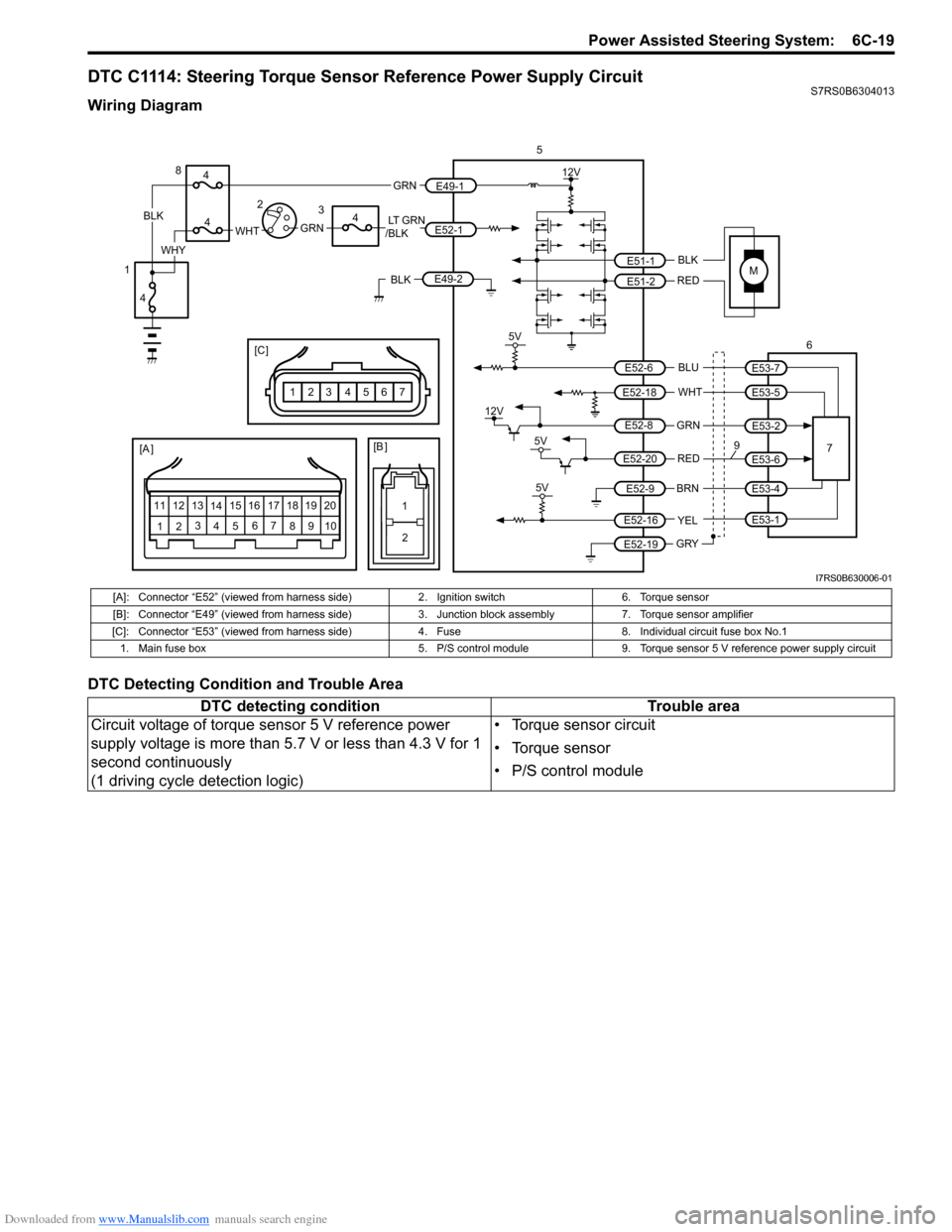

DTC C1114: Steering Torque Sensor Reference Power Supply CircuitS7RS0B6304013

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

5V

BLK

RED

WHT BLU

GRN

BRN YEL

E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

5

67

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

9[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

1

2

[B ]

[C ]

7654321

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

8

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630006-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch6. Torque sensor

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly 7. Torque sensor amplifier

[C]: Connector “E53” (viewed from harness si de)4. Fuse 8. Individual circuit fuse box No.1

1. Main fuse box 5. P/S control module9. Torque sensor 5 V reference power supply circuit

DTC detecting condition Trouble area

Circuit voltage of torque sensor 5 V reference power

supply voltage is more than 5.7 V or less than 4.3 V for 1

second continuously

(1 driving cycle detection logic) • Torque sensor circuit

• Torque sensor

• P/S control module

Page 903 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-21

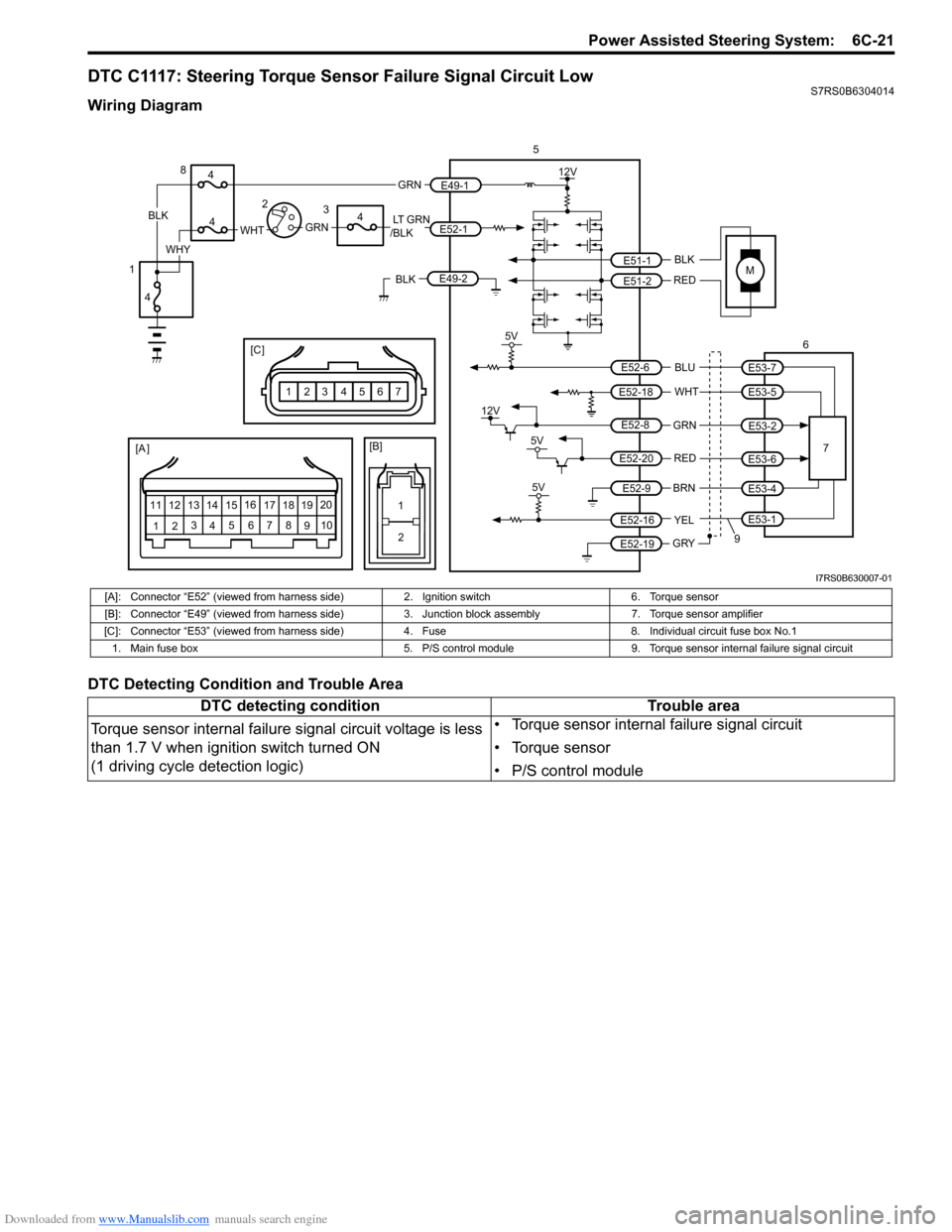

DTC C1117: Steering Torque Sensor Failure Signal Circuit LowS7RS0B6304014

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

5V

BLK

RED

WHT BLU

GRN

BRN YEL

E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

5

67

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

9

12

[B]

[C ]

7654321

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

8

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630007-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch6. Torque sensor

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly7. Torque sensor amplifier

[C]: Connector “E53” (viewed from harness side) 4. Fuse8. Individual circuit fuse box No.1

1. Main fuse box 5. P/S control module9. Torque sensor internal failure signal circuit

DTC detecting condition Trouble area

Torque sensor internal failure signal circuit voltage is less

than 1.7 V when ignition switch turned ON

(1 driving cycle detection logic) • Torque sensor internal failure signal circuit

• Torque sensor

• P/S control module

Page 906 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-24 Power Assisted Steering System:

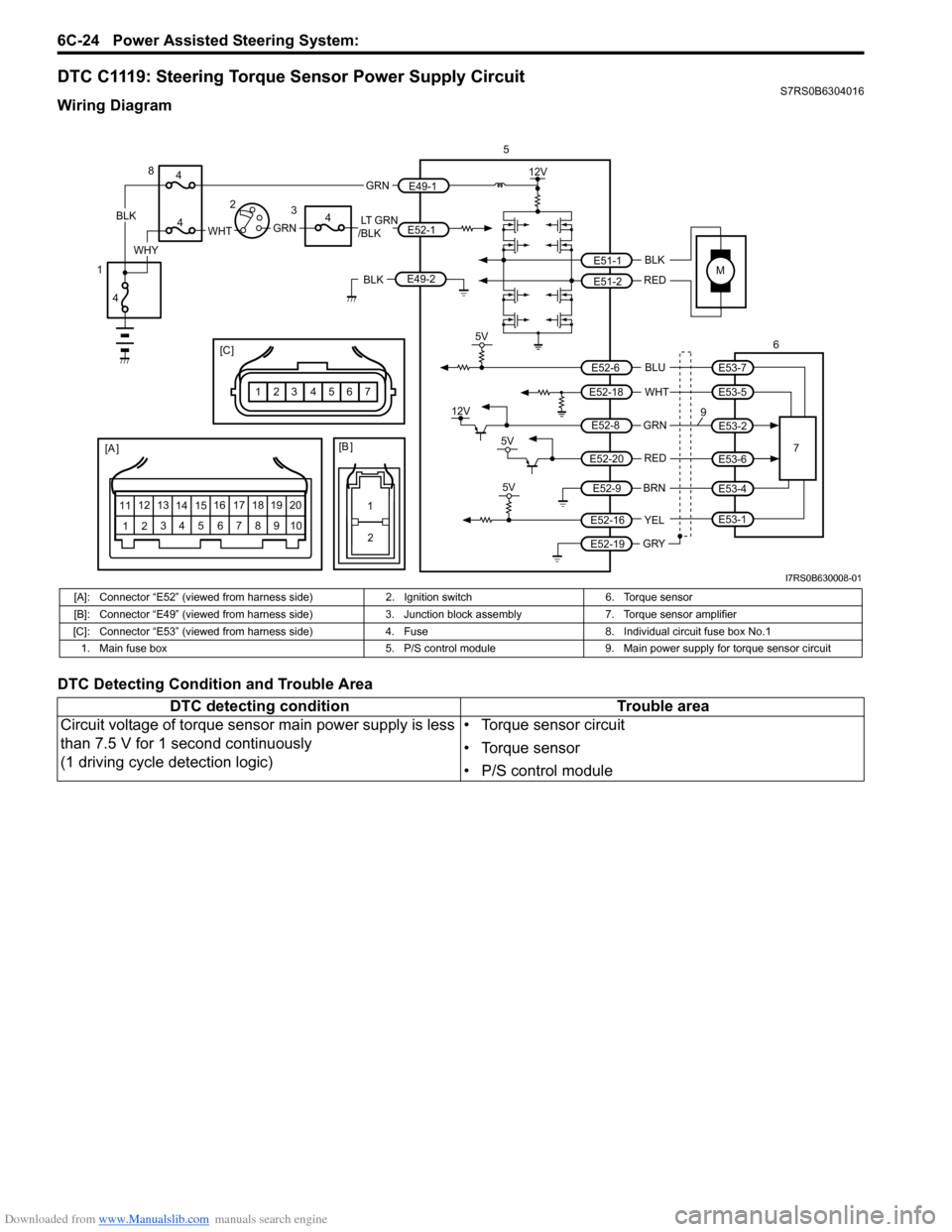

DTC C1119: Steering Torque Sensor Power Supply CircuitS7RS0B6304016

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

5V

BLK

RED

WHT BLU

GRN

BRN YEL

E51-1

E51-2

E52-18

E53-5

E53-7

E52-6

E52-8

E53-2

E52-9

E52-16

E52-19

GRY

5

67

12V

5V

5V

12V

REDE52-20E53-6

E53-4

E53-1

9

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

1

2

[B ]

[C ]

7654321

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

8

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630008-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch6. Torque sensor

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly7. Torque sensor amplifier

[C]: Connector “E53” (viewed from harness si de)4. Fuse 8. Individual circuit fuse box No.1

1. Main fuse box 5. P/S control module9. Main power supply for torque sensor circuit

DTC detecting condition Trouble area

Circuit voltage of torque sensor main power supply is less

than 7.5 V for 1 second continuously

(1 driving cycle detection logic) • Torque sensor circuit

• Torque sensor

• P/S control module

Page 908 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-26 Power Assisted Steering System:

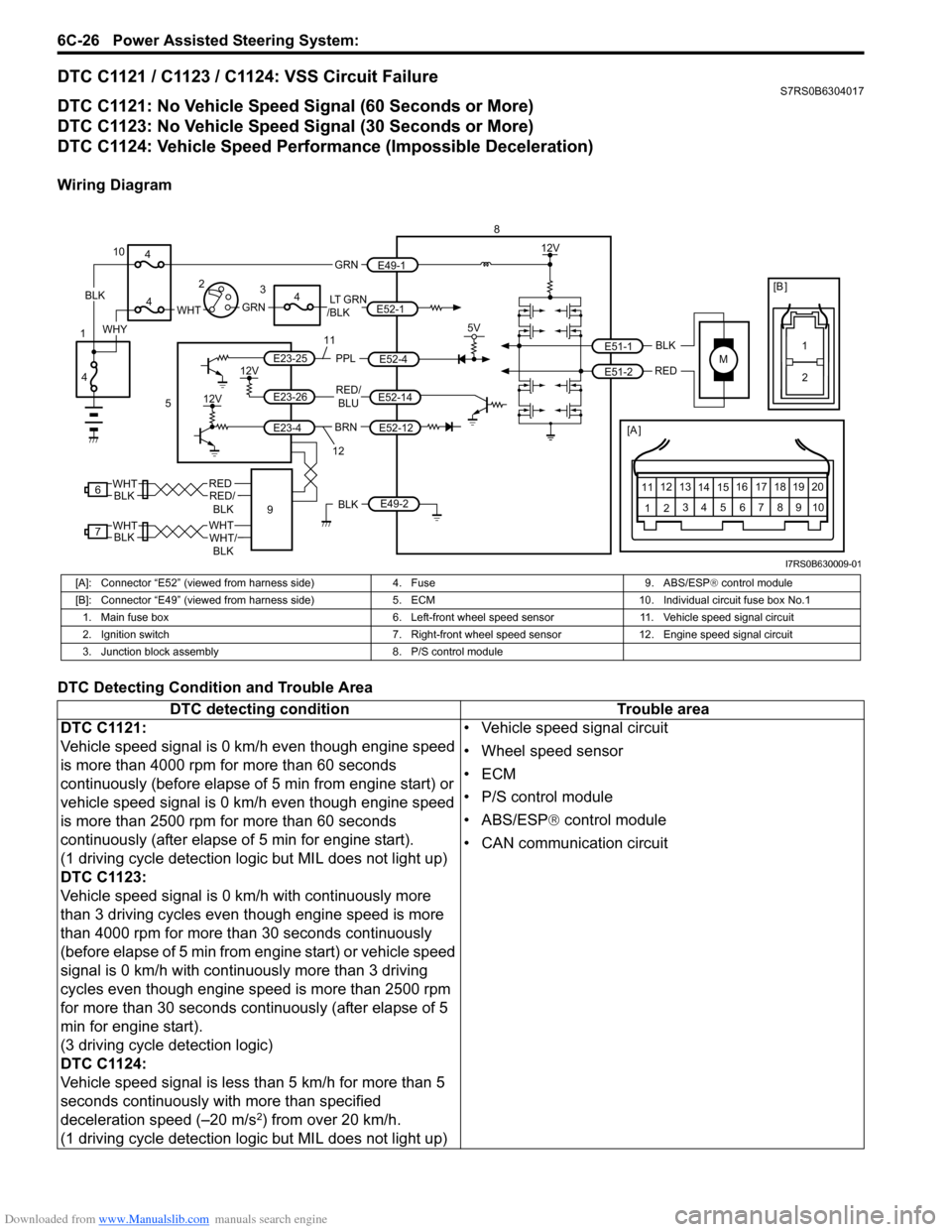

DTC C1121 / C1123 / C1124: VSS Circuit FailureS7RS0B6304017

DTC C1121: No Vehicle Speed Signal (60 Seconds or More)

DTC C1123: No Vehicle Speed Signal (30 Seconds or More)

DTC C1124: Vehicle Speed Performance (Impossible Deceleration)

Wiring Diagram

DTC Detecting Condition and Trouble Area

M

BRNRED/

BLU

BLK

RED

E52-14

E52-12

E23-4

E23-26

E23-25 E51-1

E51-2

[A ]

12

3

4 5 67

89

11

10

12 13

141516

17 18 19 20

5V

PPL

E52-4

8

5

12V

E49-2BLK

12V

12V

6REDRED/ BLKWHT

7WHTWHT/BLKWHTBLK BLK

111

2

[B ]

9

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

10

3

4

4

4

4

1 2

12

I7RS0B630009-01

[A]: Connector “E52” (viewed from harness side)

4. Fuse9. ABS/ESP® control module

[B]: Connector “E49” (viewed from harness si de)5. ECM 10. Individual circuit fuse box No.1

1. Main fuse box 6. Left-front wheel speed sensor11. Vehicle speed signal circuit

2. Ignition switch 7. Right-front wheel speed sensor 12. Engine speed signal circuit

3. Junction block assembly 8. P/S control module

DTC detecting condition Trouble area

DTC C1121:

Vehicle speed signal is 0 km/h even though engine speed

is more than 4000 rpm for more than 60 seconds

continuously (before elapse of 5 min from engine start) or

vehicle speed signal is 0 km/h even though engine speed

is more than 2500 rpm for more than 60 seconds

continuously (after elapse of 5 min for engine start).

(1 driving cycle detection logic but MIL does not light up)

DTC C1123:

Vehicle speed signal is 0 km/h with continuously more

than 3 driving cycles even though engine speed is more

than 4000 rpm for more than 30 seconds continuously

(before elapse of 5 min from engine start) or vehicle speed

signal is 0 km/h with continuously more than 3 driving

cycles even though engine speed is more than 2500 rpm

for more than 30 seconds continuously (after elapse of 5

min for engine start).

(3 driving cycle detection logic)

DTC C1124:

Vehicle speed signal is less than 5 km/h for more than 5

seconds continuously with more than specified

deceleration speed (–20 m/s

2) from over 20 km/h.

(1 driving cycle detection logic but MIL does not light up) • Vehicle speed signal circuit

• Wheel speed sensor

•ECM

• P/S control module

• ABS/ESP®

control module

• CAN communication circuit