key SUZUKI SWIFT 2006 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 731 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-87

Troubleshooting

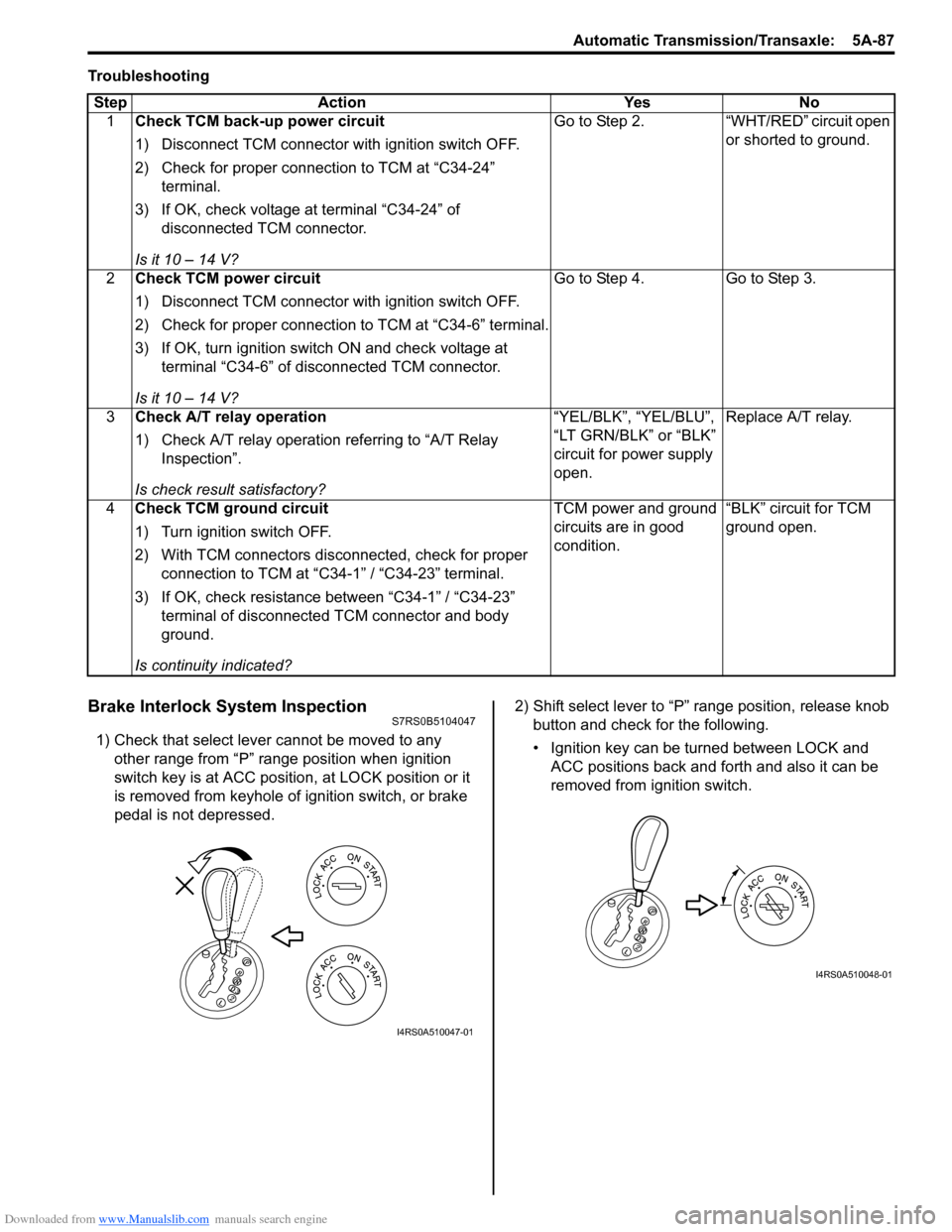

Brake Interlock System InspectionS7RS0B5104047

1) Check that select lever cannot be moved to any other range from “P” range position when ignition

switch key is at ACC position, at LOCK position or it

is removed from keyhole of ignition switch, or brake

pedal is not depressed. 2) Shift select lever to “P” range position, release knob

button and check for the following.

• Ignition key can be turned between LOCK and ACC positions back and forth and also it can be

removed from ignition switch.

Step Action Yes No

1 Check TCM back-up power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C34-24”

terminal.

3) If OK, check voltage at terminal “C34-24” of disconnected TCM connector.

Is it 10 – 14 V? Go to Step 2. “WHT/RED” circuit open

or shorted to ground.

2 Check TCM power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C34-6” terminal.

3) If OK, turn ignition switch ON and check voltage at

terminal “C34-6” of disconnected TCM connector.

Is it 10 – 14 V? Go to Step 4. Go to Step 3.

3 Check A/T relay operation

1) Check A/T relay operation referring to “A/T Relay

Inspection”.

Is check result satisfactory? “YEL/BLK”, “YEL/BLU”,

“LT GRN/BLK” or “BLK”

circuit for power supply

open.

Replace A/T relay.

4 Check TCM ground circuit

1) Turn ignition switch OFF.

2) With TCM connectors disconnected, check for proper

connection to TCM at “C34-1” / “C34-23” terminal.

3) If OK, check resistance between “C34-1” / “C34-23” terminal of disconnected TCM connector and body

ground.

Is continuity indicated? TCM power and ground

circuits are in good

condition.

“BLK” circuit for TCM

ground open.

I4RS0A510047-01

I4RS0A510048-01

Page 732 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-88 Automatic Transmission/Transaxle:

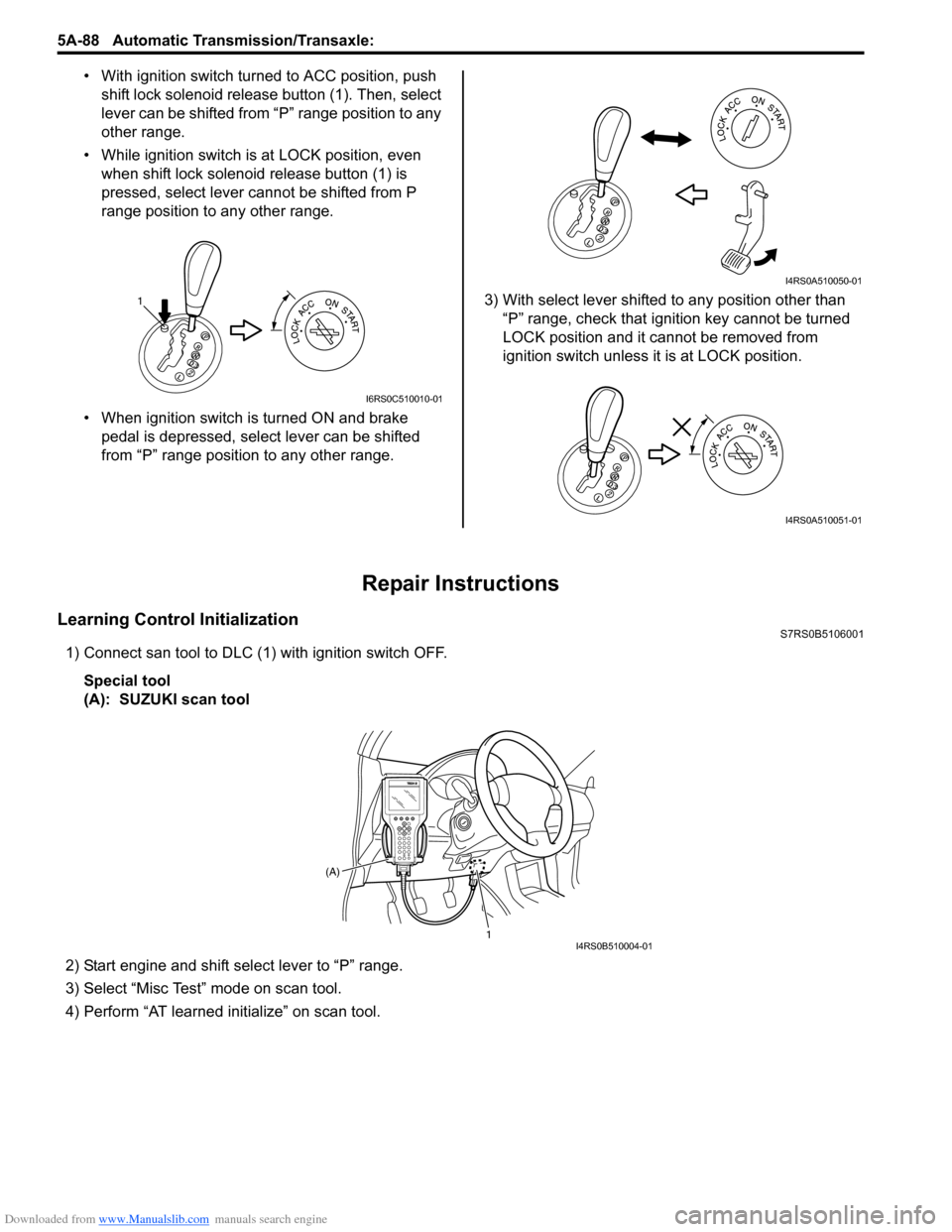

• With ignition switch turned to ACC position, push

shift lock solenoid release button (1). Then, select

lever can be shifted from “P” range position to any

other range.

• While ignition switch is at LOCK position, even when shift lock solenoid release button (1) is

pressed, select lever cannot be shifted from P

range position to any other range.

• When ignition switch is turned ON and brake pedal is depressed, select lever can be shifted

from “P” range position to any other range. 3) With select lever shifted to any position other than

“P” range, check that ignition key cannot be turned

LOCK position and it cannot be removed from

ignition switch unless it is at LOCK position.

Repair Instructions

Learning Control InitializationS7RS0B5106001

1) Connect san tool to DLC (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

2) Start engine and shift select lever to “P” range.

3) Select “Misc Test” mode on scan tool.

4) Perform “AT learned initialize” on scan tool.

1

I6RS0C510010-01

I4RS0A510050-01

I4RS0A510051-01

1

(A)I4RS0B510004-01

Page 737 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-93

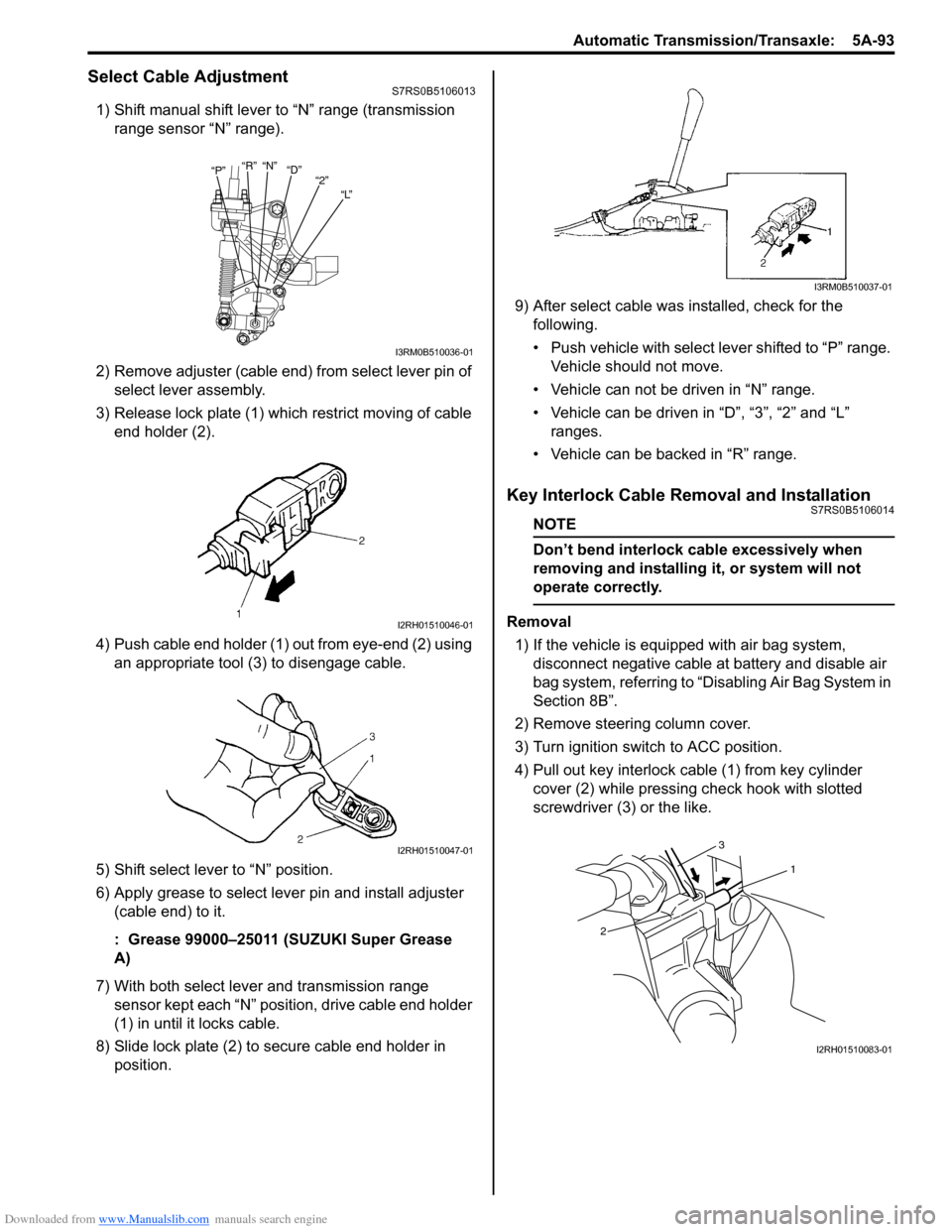

Select Cable AdjustmentS7RS0B5106013

1) Shift manual shift lever to “N” range (transmission range sensor “N” range).

2) Remove adjuster (cable end) from select lever pin of select lever assembly.

3) Release lock plate (1) which restrict moving of cable end holder (2).

4) Push cable end holder (1) out from eye-end (2) using an appropriate tool (3) to disengage cable.

5) Shift select lever to “N” position.

6) Apply grease to select lever pin and install adjuster (cable end) to it.

: Grease 99000–25011 (SUZUKI Super Grease

A)

7) With both select lever and transmission range sensor kept each “N” position, drive cable end holder

(1) in until it locks cable.

8) Slide lock plate (2) to secure cable end holder in position. 9) After select cable was

installed, check for the

following.

• Push vehicle with select lever shifted to “P” range. Vehicle should not move.

• Vehicle can not be driven in “N” range.

• Vehicle can be driven in “D”, “3”, “2” and “L” ranges.

• Vehicle can be backed in “R” range.

Key Interlock Cable Removal and InstallationS7RS0B5106014

NOTE

Don’t bend interlock cable excessively when

removing and installing it, or system will not

operate correctly.

Removal

1) If the vehicle is equipped with air bag system, disconnect negative cable at battery and disable air

bag system, referring to “Disabling Air Bag System in

Section 8B”.

2) Remove steering column cover.

3) Turn ignition switch to ACC position.

4) Pull out key interlock cable (1) from key cylinder cover (2) while pressing check hook with slotted

screwdriver (3) or the like.

“P” “R”

“N”

“D”

“2”

“L”

I3RM0B510036-01

I2RH01510046-01

I2RH01510047-01

I3RM0B510037-01

1

2 3

I2RH01510083-01

Page 738 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-94 Automatic Transmission/Transaxle:

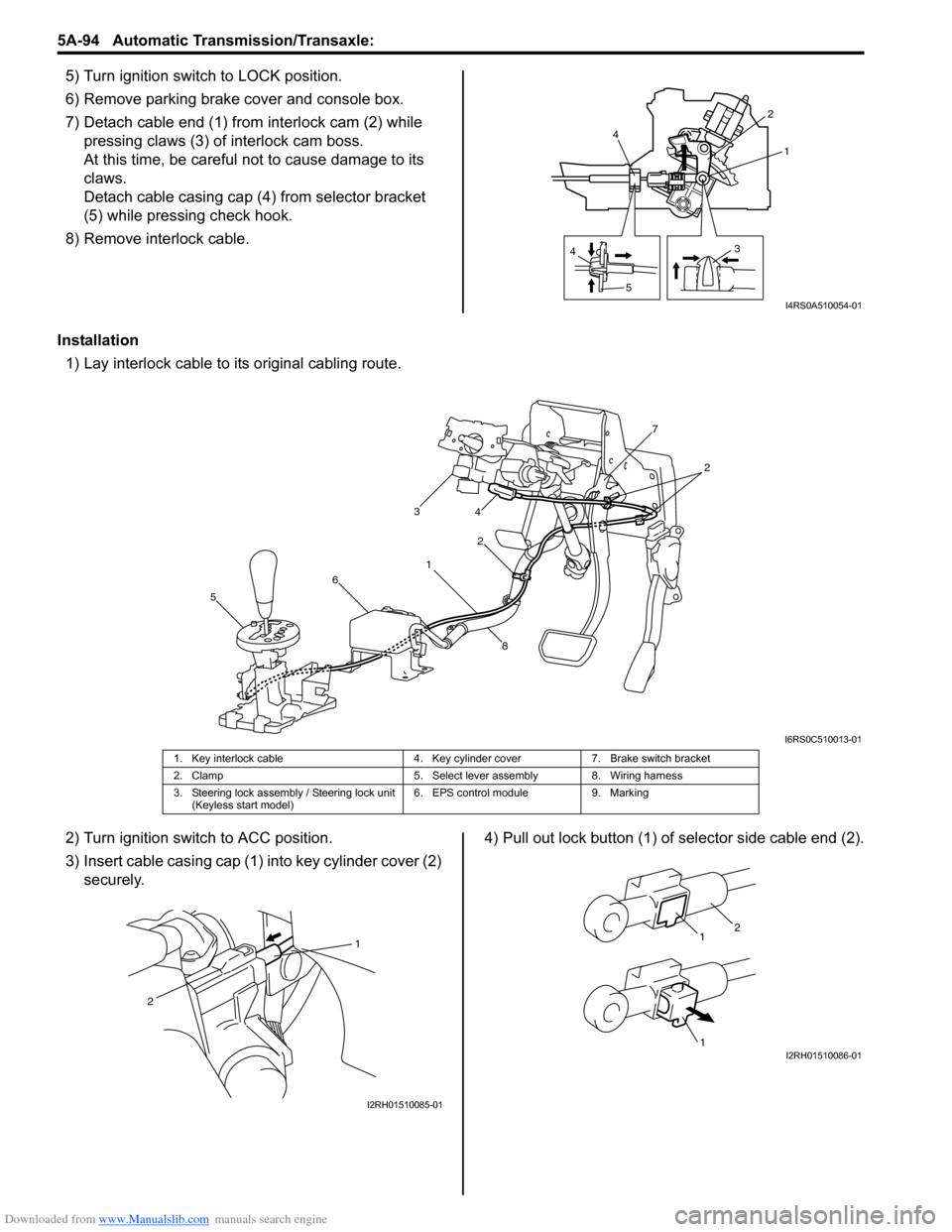

5) Turn ignition switch to LOCK position.

6) Remove parking brake cover and console box.

7) Detach cable end (1) from interlock cam (2) while

pressing claws (3) of interlock cam boss.

At this time, be careful no t to cause damage to its

claws.

Detach cable casing cap (4 ) from selector bracket

(5) while pressing check hook.

8) Remove interlock cable.

Installation 1) Lay interlock cable to its original cabling route.

2) Turn ignition switch to ACC position.

3) Insert cable casing cap (1) into key cylinder cover (2) securely. 4) Pull out lock button (1) of selector side cable end (2).

4

5 31

2

4

I4RS0A510054-01

1 2

3

4

5 6 7

8

2

I6RS0C510013-01

1. Key interlock cable 4. Key cylinder cover7. Brake switch bracket

2. Clamp 5. Select lever assembly 8. Wiring harness

3. Steering lock assembly / Steering lock unit (Keyless start model) 6. EPS control module

9. Marking

1

2

I2RH01510085-01

1

1

2

I2RH01510086-01

Page 739 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-95

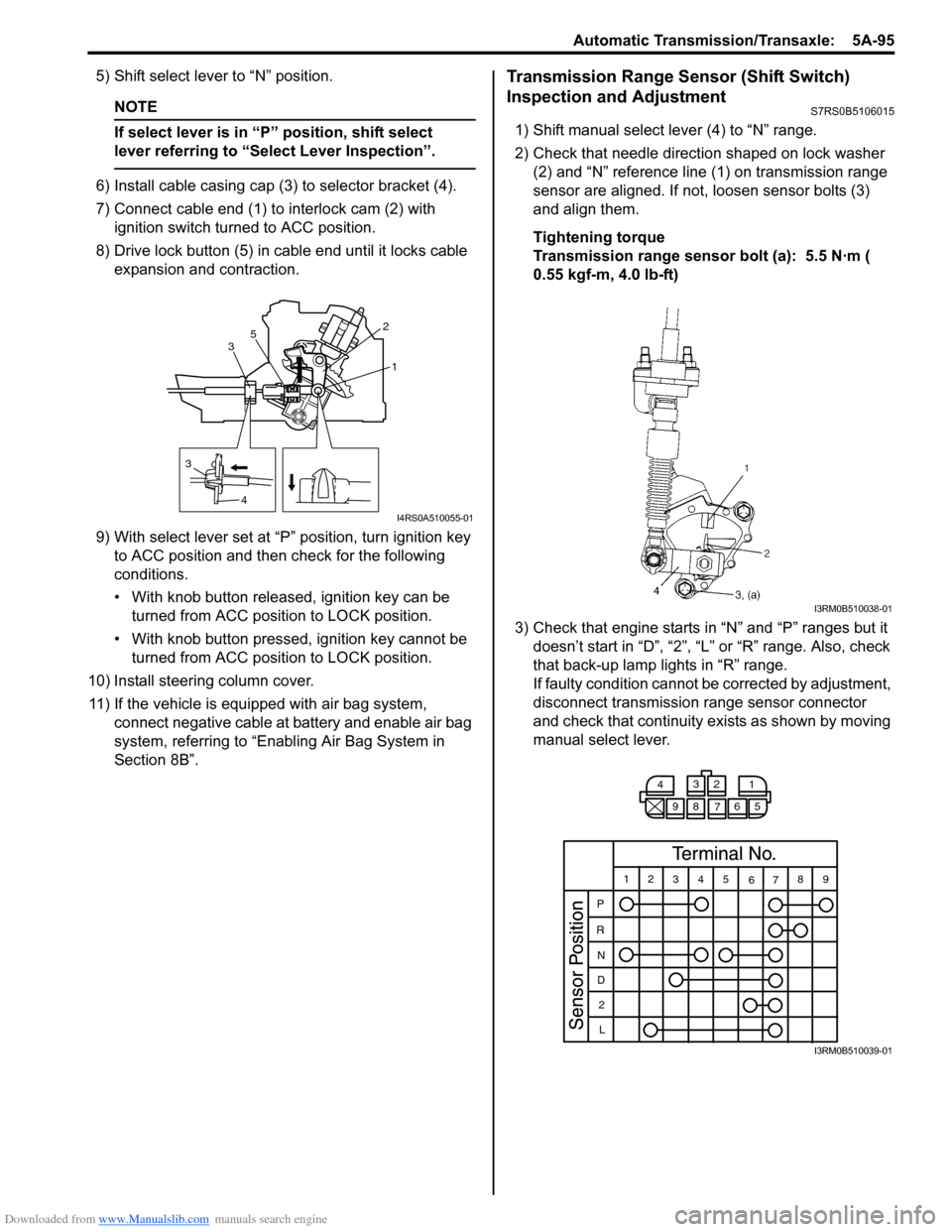

5) Shift select lever to “N” position.

NOTE

If select lever is in “P” position, shift select

lever referring to “Select Lever Inspection”.

6) Install cable casing cap (3) to selector bracket (4).

7) Connect cable end (1) to interlock cam (2) with ignition switch turned to ACC position.

8) Drive lock button (5) in cable end until it locks cable expansion and contraction.

9) With select lever set at “P ” position, turn ignition key

to ACC position and then check for the following

conditions.

• With knob button released, ignition key can be turned from ACC position to LOCK position.

• With knob button pressed, ignition key cannot be

turned from ACC position to LOCK position.

10) Install steering column cover. 11) If the vehicle is equipped with air bag system, connect negative cable at battery and enable air bag

system, referring to “Enabling Air Bag System in

Section 8B”.

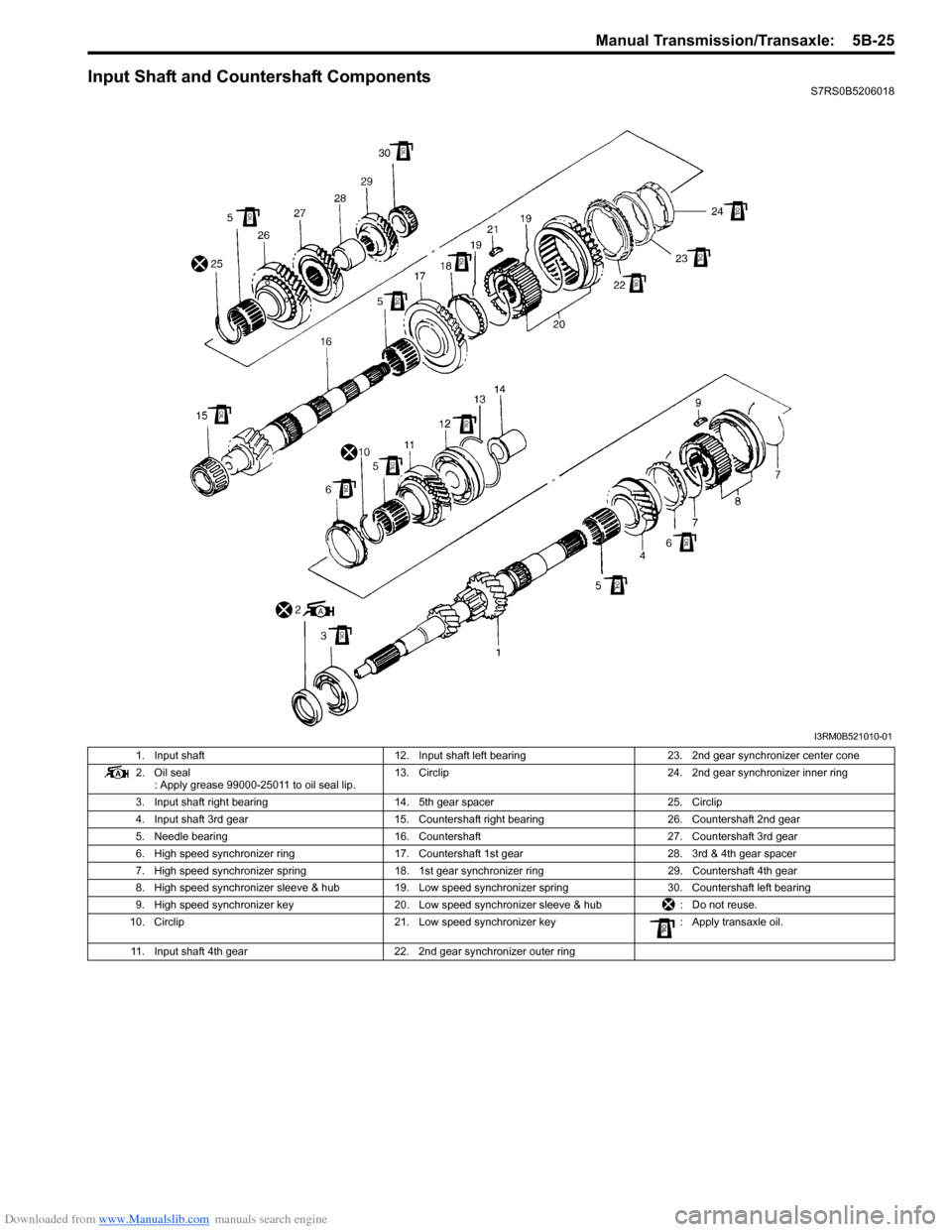

Transmission Range Sensor (Shift Switch)

Inspection and Adjustment

S7RS0B5106015

1) Shift manual select lever (4) to “N” range.

2) Check that needle direction shaped on lock washer (2) and “N” reference line (1) on transmission range

sensor are aligned. If not, loosen sensor bolts (3)

and align them.

Tightening torque

Transmission range sensor bolt (a): 5.5 N·m (

0.55 kgf-m, 4.0 lb-ft)

3) Check that engine starts in “N” and “P” ranges but it doesn’t start in “D”, “2”, “L” or “R” range. Also, check

that back-up lamp lights in “R” range.

If faulty condition cannot be corrected by adjustment,

disconnect transmission range sensor connector

and check that continuity ex ists as shown by moving

manual select lever.

3

4 1

2

3 5

I4RS0A510055-01

I3RM0B510038-01

4

3

2

1

98 76 5

12 345

6789

P

R N

D 2

L

I3RM0B510039-01

Page 839 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-25

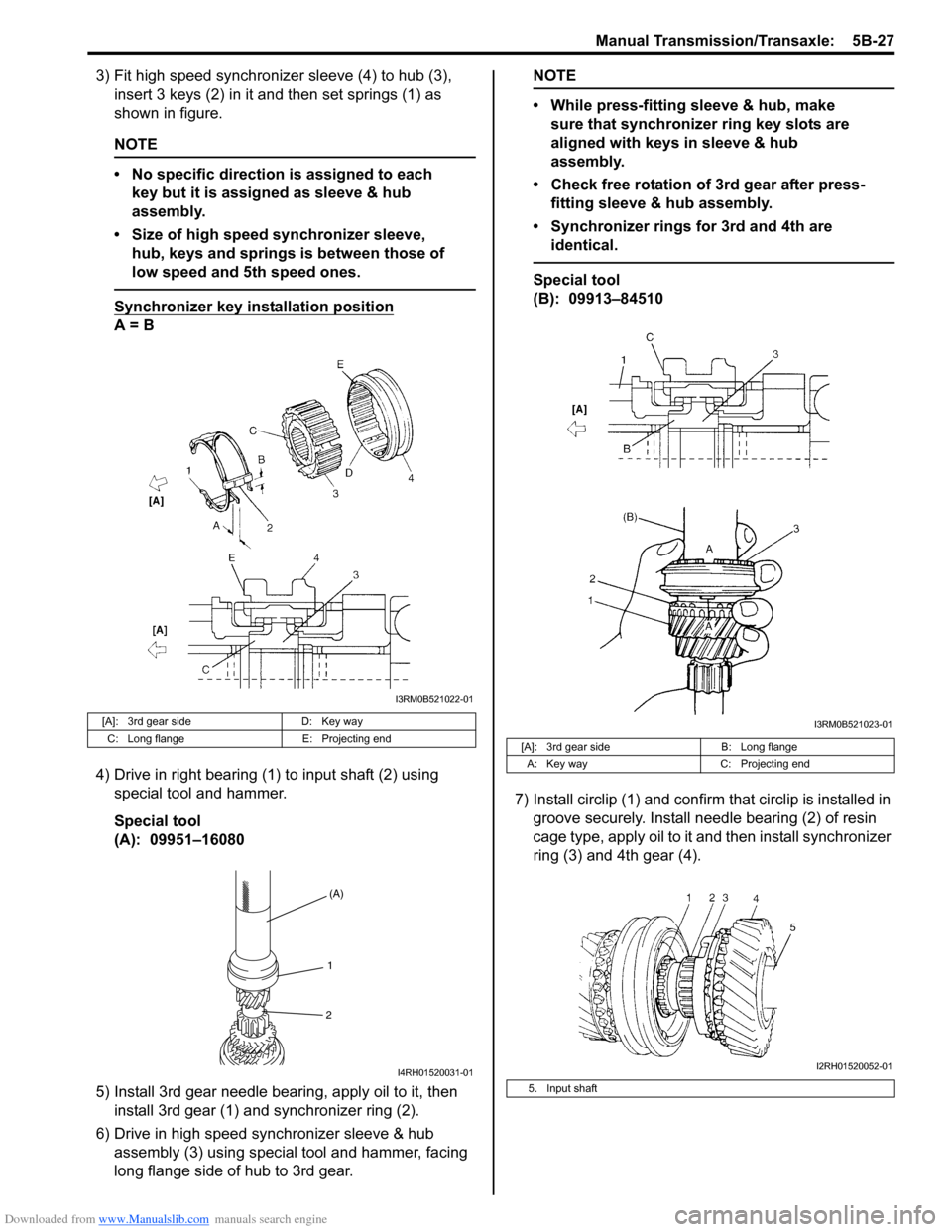

Input Shaft and Countershaft ComponentsS7RS0B5206018

I3RM0B521010-01

1. Input shaft12. Input shaft left bearing 23. 2nd gear synchronizer center cone

2. Oil seal : Apply grease 99000-25011 to oil seal lip. 13. Circlip

24. 2nd gear synchronizer inner ring

3. Input shaft right bearing 14. 5th gear spacer 25. Circlip

4. Input shaft 3rd gear 15. Countershaft right bearing 26. Countershaft 2nd gear

5. Needle bearing 16. Countershaft 27. Countershaft 3rd gear

6. High speed synchronizer ring 17. Countershaft 1st gear 28. 3rd & 4th gear spacer

7. High speed synchronizer spring 18. 1st gear synchronizer ring 29. Countershaft 4th gear

8. High speed synchronizer sleeve & hub 19. Low speed synchronizer spring 30. Countershaft left bearing

9. High speed synchronizer key 20. Low speed synchronizer sleeve & hub : Do not reuse.

10. Circlip 21. Low speed synchronizer key : Apply transaxle oil.

11. Input shaft 4th gear 22. 2nd gear synchronizer outer ring

Page 841 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-27

3) Fit high speed synchronizer sleeve (4) to hub (3), insert 3 keys (2) in it and then set springs (1) as

shown in figure.

NOTE

• No specific direction is assigned to each key but it is assigned as sleeve & hub

assembly.

• Size of high speed synchronizer sleeve, hub, keys and springs is between those of

low speed and 5th speed ones.

Synchronizer key in stallation position

A = B

4) Drive in right bearing (1) to input shaft (2) using special tool and hammer.

Special tool

(A): 09951–16080

5) Install 3rd gear needle bearing, apply oil to it, then install 3rd gear (1) and synchronizer ring (2).

6) Drive in high speed synchronizer sleeve & hub assembly (3) using special tool and hammer, facing

long flange side of hub to 3rd gear.

NOTE

• While press-fitting sleeve & hub, make sure that synchronizer ring key slots are

aligned with keys in sleeve & hub

assembly.

• Check free rotation of 3rd gear after press- fitting sleeve & hub assembly.

• Synchronizer rings for 3rd and 4th are identical.

Special tool

(B): 09913–84510

7) Install circlip (1) and confirm that circlip is installed in

groove securely. Install needle bearing (2) of resin

cage type, apply oil to it and then install synchronizer

ring (3) and 4th gear (4).

[A]: 3rd gear side D: Key way

C: Long flange E: Projecting end

I3RM0B521022-01

(A)

1

2

I4RH01520031-01

[A]: 3rd gear side B: Long flange

A: Key way C: Projecting end

5. Input shaft

I3RM0B521023-01

I2RH01520052-01

Page 843 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-29

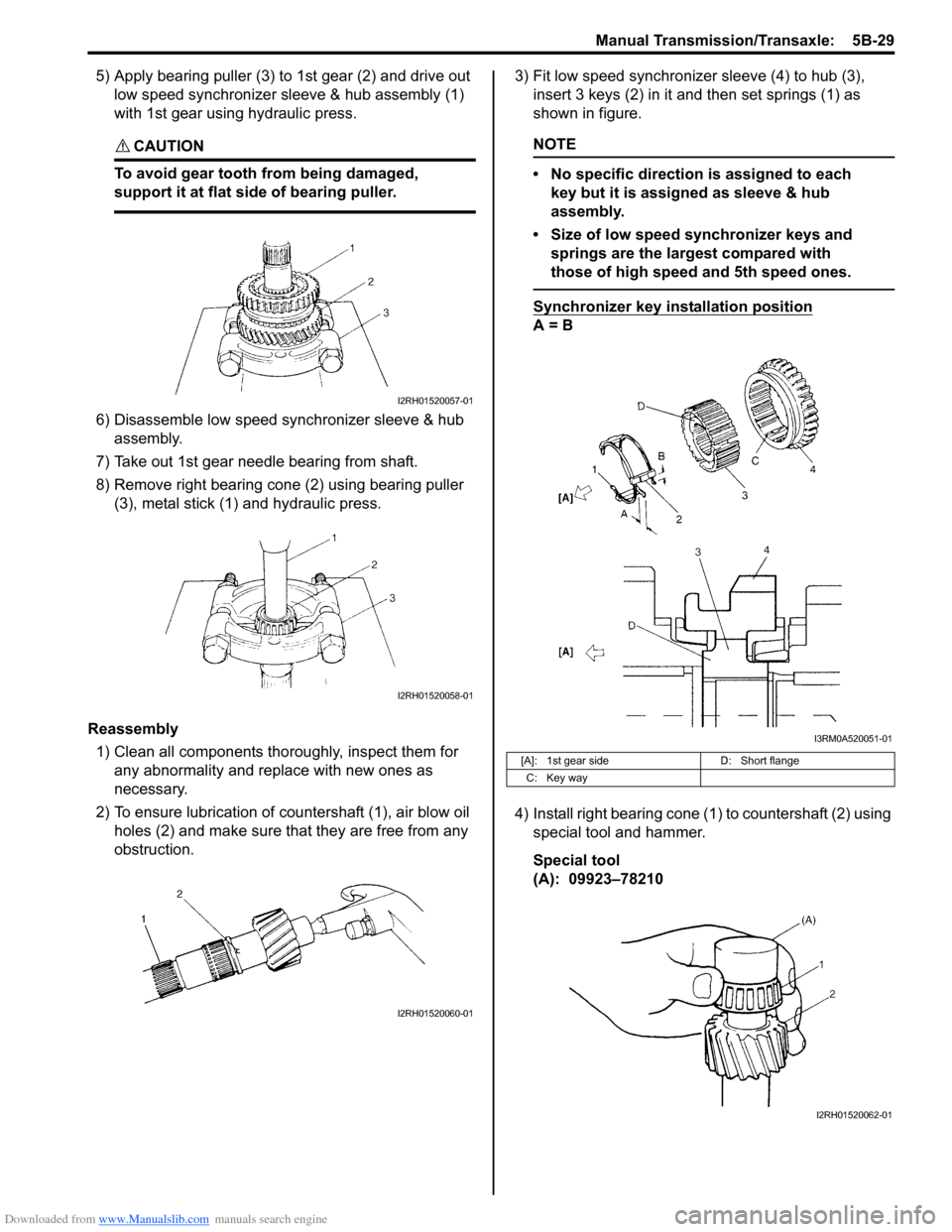

5) Apply bearing puller (3) to 1st gear (2) and drive out low speed synchronizer sleeve & hub assembly (1)

with 1st gear using hydraulic press.

CAUTION!

To avoid gear tooth from being damaged,

support it at flat side of bearing puller.

6) Disassemble low speed synchronizer sleeve & hub assembly.

7) Take out 1st gear needle bearing from shaft.

8) Remove right bearing cone (2) using bearing puller (3), metal stick (1) and hydraulic press.

Reassembly 1) Clean all components thor oughly, inspect them for

any abnormality and replace with new ones as

necessary.

2) To ensure lubrication of countershaft (1), air blow oil holes (2) and make sure that they are free from any

obstruction. 3) Fit low speed synchronizer sleeve (4) to hub (3),

insert 3 keys (2) in it and then set springs (1) as

shown in figure.

NOTE

• No specific direction is assigned to each key but it is assigned as sleeve & hub

assembly.

• Size of low speed synchronizer keys and springs are the largest compared with

those of high speed and 5th speed ones.

Synchronizer key installation position

A = B

4) Install right bearing cone (1) to countershaft (2) using special tool and hammer.

Special tool

(A): 09923–78210

I2RH01520057-01

I2RH01520058-01

I2RH01520060-01

[A]: 1st gear side D: Short flange

C: Key way

I3RM0A520051-01

I2RH01520062-01

Page 844 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-30 Manual Transmission/Transaxle:

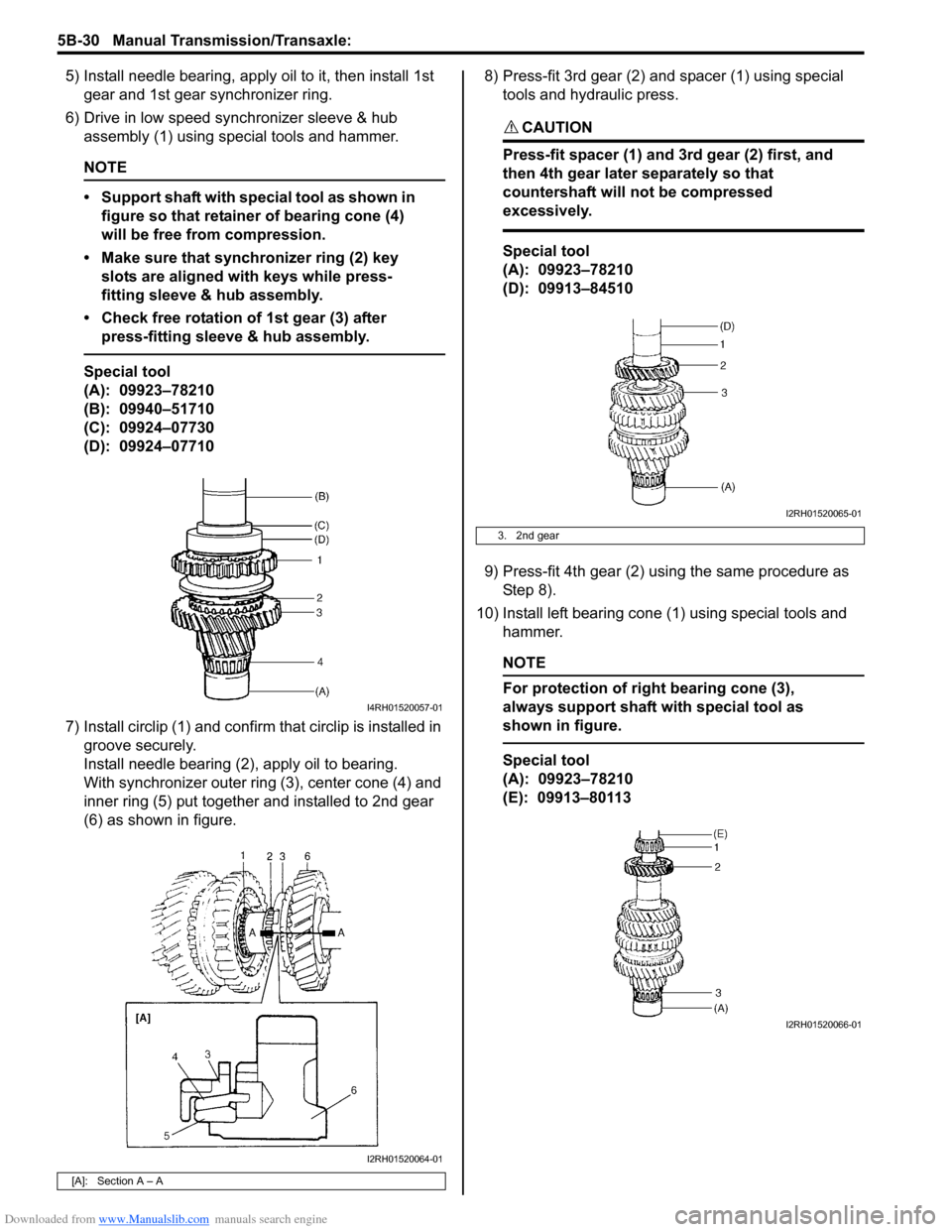

5) Install needle bearing, apply oil to it, then install 1st gear and 1st gear synchronizer ring.

6) Drive in low speed synchronizer sleeve & hub assembly (1) using special tools and hammer.

NOTE

• Support shaft with special tool as shown in figure so that retainer of bearing cone (4)

will be free from compression.

• Make sure that synchronizer ring (2) key slots are aligned with keys while press-

fitting sleeve & hub assembly.

• Check free rotation of 1st gear (3) after press-fitting sleeve & hub assembly.

Special tool

(A): 09923–78210

(B): 09940–51710

(C): 09924–07730

(D): 09924–07710

7) Install circlip (1) and confirm that circlip is installed in groove securely.

Install needle bearing (2), apply oil to bearing.

With synchronizer outer ring (3), center cone (4) and

inner ring (5) put together and installed to 2nd gear

(6) as shown in figure. 8) Press-fit 3rd gear (2) and spacer (1) using special

tools and hydraulic press.

CAUTION!

Press-fit spacer (1) and 3rd gear (2) first, and

then 4th gear later separately so that

countershaft will not be compressed

excessively.

Special tool

(A): 09923–78210

(D): 09913–84510

9) Press-fit 4th gear (2) using the same procedure as Step 8).

10) Install left bearing cone (1) using special tools and hammer.

NOTE

For protection of right bearing cone (3),

always support shaft with special tool as

shown in figure.

Special tool

(A): 09923–78210

(E): 09913–80113

[A]: Section A – A

I4RH01520057-01

I2RH01520064-01

3. 2nd gear

I2RH01520065-01

I2RH01520066-01

Page 867 of 1496

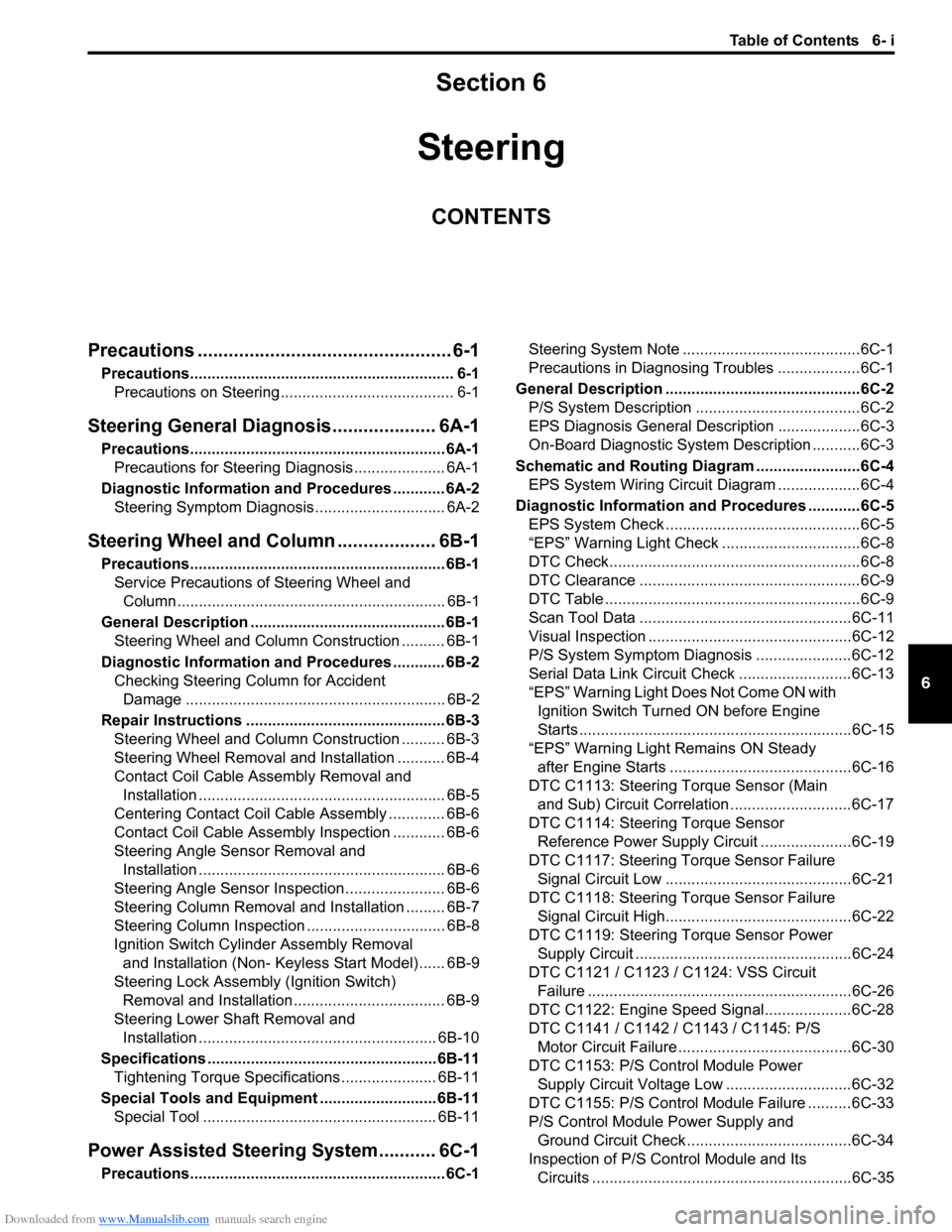

Downloaded from www.Manualslib.com manuals search engine Table of Contents 6- i

6

Section 6

CONTENTS

Steering

Precautions ................................................. 6-1

Precautions............................................................. 6-1

Precautions on Steering........................................ 6-1

Steering General Diagnosi s.................... 6A-1

Precautions........................................................... 6A-1

Precautions for Steering Diagnosis ..................... 6A-1

Diagnostic Information and Procedures ............ 6A-2 Steering Symptom Diagnosis .............................. 6A-2

Steering Wheel and Column ................... 6B-1

Precautions........................................................... 6B-1

Service Precautions of Steering Wheel and Column.............................................................. 6B-1

General Description ............................................. 6B-1 Steering Wheel and Column Construction .......... 6B-1

Diagnostic Information and Procedures ............ 6B-2 Checking Steering Column for Accident Damage ............................................................ 6B-2

Repair Instructions .............................................. 6B-3 Steering Wheel and Column Construction .......... 6B-3

Steering Wheel Removal and Installation ........... 6B-4

Contact Coil Cable Assembly Removal and Installation ......................................................... 6B-5

Centering Contact Coil Cable Assembly ............. 6B-6

Contact Coil Cable Assembly Inspection ............ 6B-6

Steering Angle Sensor Removal and Installation ......................................................... 6B-6

Steering Angle Sensor Inspection ....................... 6B-6

Steering Column Removal and Installation ......... 6B-7

Steering Column Inspecti on ................................ 6B-8

Ignition Switch Cylinder Assembly Removal and Installation (Non- Keyless Start Model)...... 6B-9

Steering Lock Assembly (Ignition Switch) Removal and Installation................................... 6B-9

Steering Lower Shaft Removal and Installation ....................................................... 6B-10

Specifications ..................................................... 6B-11

Tightening Torque Specifications ...................... 6B-11

Special Tools and Equipmen t ........................... 6B-11

Special Tool ...................................................... 6B-11

Power Assisted Steering System........... 6C-1

Precautions........................................................... 6C-1 Steering System Note .........................................6C-1

Precautions in Diagnosing Troubles ...................6C-1

General Description .............................................6C-2 P/S System Description ......................................6C-2

EPS Diagnosis General Descr iption ...................6C-3

On-Board Diagnostic System Description ...........6C-3

Schematic and Routing Diagram ........................6C-4 EPS System Wiring Circuit Diagram ...................6C-4

Diagnostic Information and Procedures ............6C-5 EPS System Check .............. ...............................6C-5

“EPS” Warning Light Check . ...............................6C-8

DTC Check..........................................................6C-8

DTC Clearance ...................................................6C-9

DTC Table ...........................................................6C-9

Scan Tool Data .................................................6C-11

Visual Inspection ...............................................6C-12

P/S System Symptom Diagnosis ......................6C-12

Serial Data Link Circuit Check ..........................6C-13

“EPS” Warning Light Do es Not Come ON with

Ignition Switch Turn ed ON before Engine

Starts ...............................................................6C-15

“EPS” Warning Light Remains ON Steady after Engine Starts ..........................................6C-16

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit Correlation ............................6C-17

DTC C1114: Steering Torque Sensor Reference Power Supply Circuit .....................6C-19

DTC C1117: Steering Torque Sensor Failure Signal Circuit Low ...........................................6C-21

DTC C1118: Steering Torque Sensor Failure Signal Circuit High...........................................6C-22

DTC C1119: Steering Torque Sensor Power Supply Circuit ..................................................6C-24

DTC C1121 / C1123 / C1124: VSS Circuit

Failure .............................................................6C-26

DTC C1122: Engine Speed Signal....................6C-28

DTC C1141 / C1142 / C1143 / C1145: P/S Motor Circuit Failure ........................................6C-30

DTC C1153: P/S Control Module Power Supply Circuit Voltage Low .............................6C-32

DTC C1155: P/S Control Module Failure ..........6C-33

P/S Control Module Power Supply and Ground Circuit Check ......................................6C-34

Inspection of P/S Control Module and Its Circuits ............................................................6C-35