key SUZUKI SWIFT 2006 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 880 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-9 Steering Wheel and Column:

Ignition Switch Cylinder Assembly Removal

and Installation (Non- Keyless Start Model)

S7RS0B6206008

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column upper and lower covers.

4) Remove immobilizer co ntrol module referring to

“Immobilizer Control Modu le (ICM) Removal and

Installation in Section 10C”.

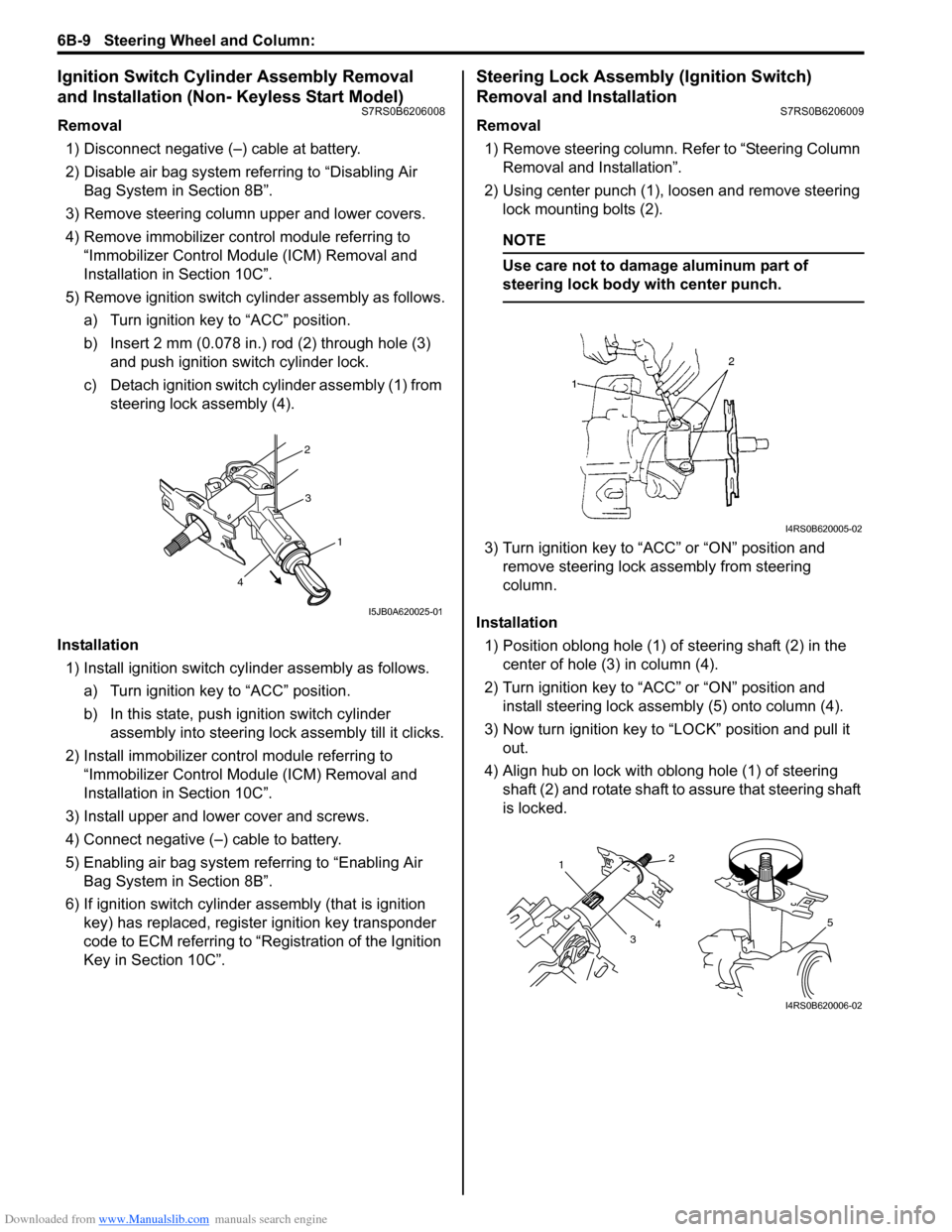

5) Remove ignition switch cy linder assembly as follows.

a) Turn ignition key to “ACC” position.

b) Insert 2 mm (0.078 in.) rod (2) through hole (3) and push ignition switch cylinder lock.

c) Detach ignition switch cylinder assembly (1) from steering lock assembly (4).

Installation 1) Install ignition switch cy linder assembly as follows.

a) Turn ignition key to “ACC” position.

b) In this state, push ignition switch cylinder assembly into steering lock assembly till it clicks.

2) Install immobilizer cont rol module referring to

“Immobilizer Control Modu le (ICM) Removal and

Installation in Section 10C”.

3) Install upper and lower cover and screws.

4) Connect negative (–) cable to battery.

5) Enabling air bag system referring to “Enabling Air Bag System in Section 8B”.

6) If ignition switch cylinder assembly (that is ignition

key) has replaced, register ignition key transponder

code to ECM referring to “R egistration of the Ignition

Key in Section 10C”.

Steering Lock Assembly (Ignition Switch)

Removal and Installation

S7RS0B6206009

Removal

1) Remove steering column. Refer to “Steering Column

Removal and Installation”.

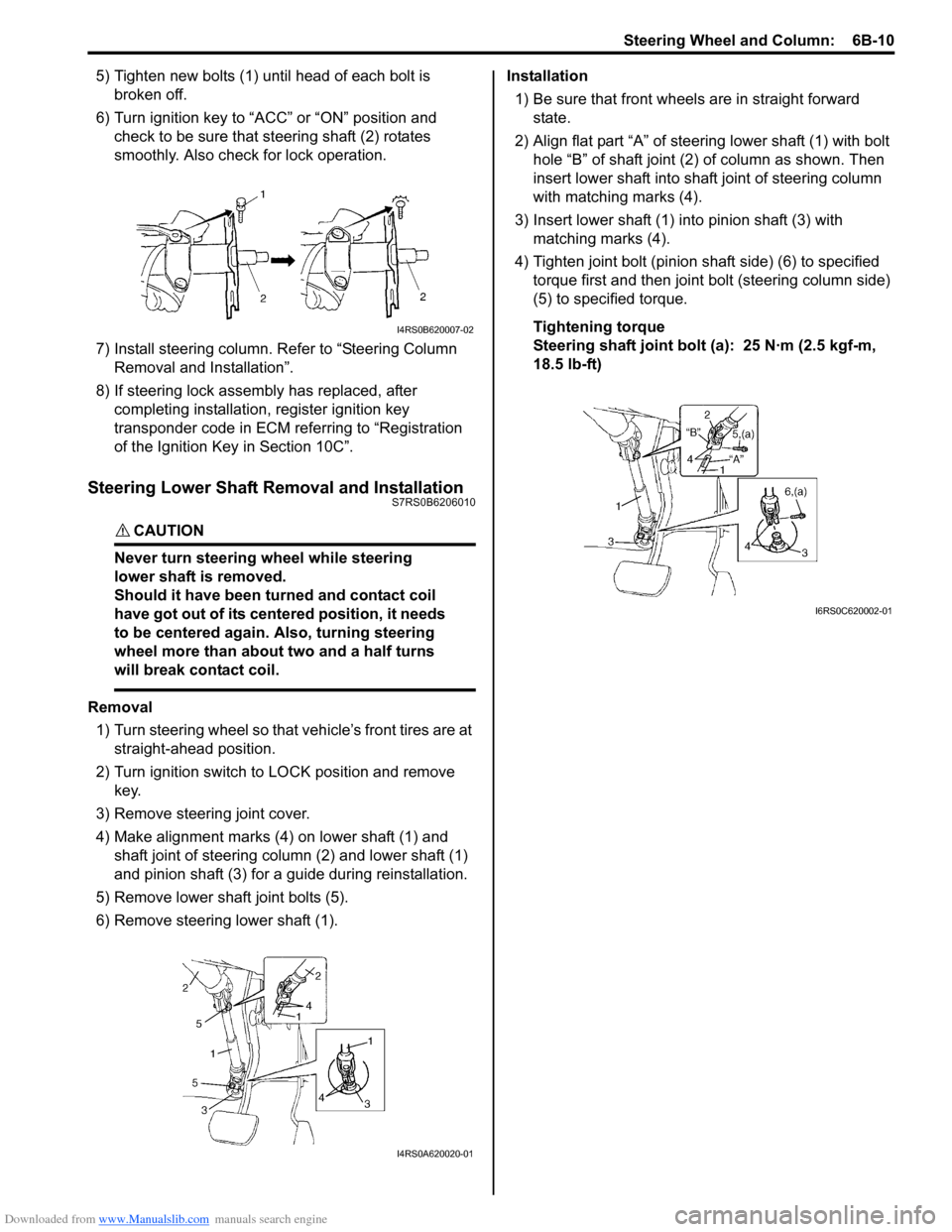

2) Using center punch (1), loosen and remove steering lock mounting bolts (2).

NOTE

Use care not to damage aluminum part of

steering lock body with center punch.

3) Turn ignition key to “ACC” or “ON” position and remove steering lock a ssembly from steering

column.

Installation 1) Position oblong hole (1) of steering shaft (2) in the center of hole (3) in column (4).

2) Turn ignition key to “ACC” or “ON” position and install steering lock assemb ly (5) onto column (4).

3) Now turn ignition key to “LOCK” position and pull it out.

4) Align hub on lock with oblong hole (1) of steering shaft (2) and rotate shaft to assure that steering shaft

is locked.

2

3

1

4

I5JB0A620025-01

I4RS0B620005-02

1

32

4

5

I4RS0B620006-02

Page 881 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-10

5) Tighten new bolts (1) until head of each bolt is broken off.

6) Turn ignition key to “ACC” or “ON” position and check to be sure that st eering shaft (2) rotates

smoothly. Also check for lock operation.

7) Install steering column. Re fer to “Steering Column

Removal and Installation”.

8) If steering lock assembly has replaced, after completing installation, register ignition key

transponder code in ECM referring to “Registration

of the Ignition Key in Section 10C”.

Steering Lower Shaft Removal and InstallationS7RS0B6206010

CAUTION!

Never turn steering wheel while steering

lower shaft is removed.

Should it have been turned and contact coil

have got out of its centered position, it needs

to be centered again. Also, turning steering

wheel more than about two and a half turns

will break contact coil.

Removal

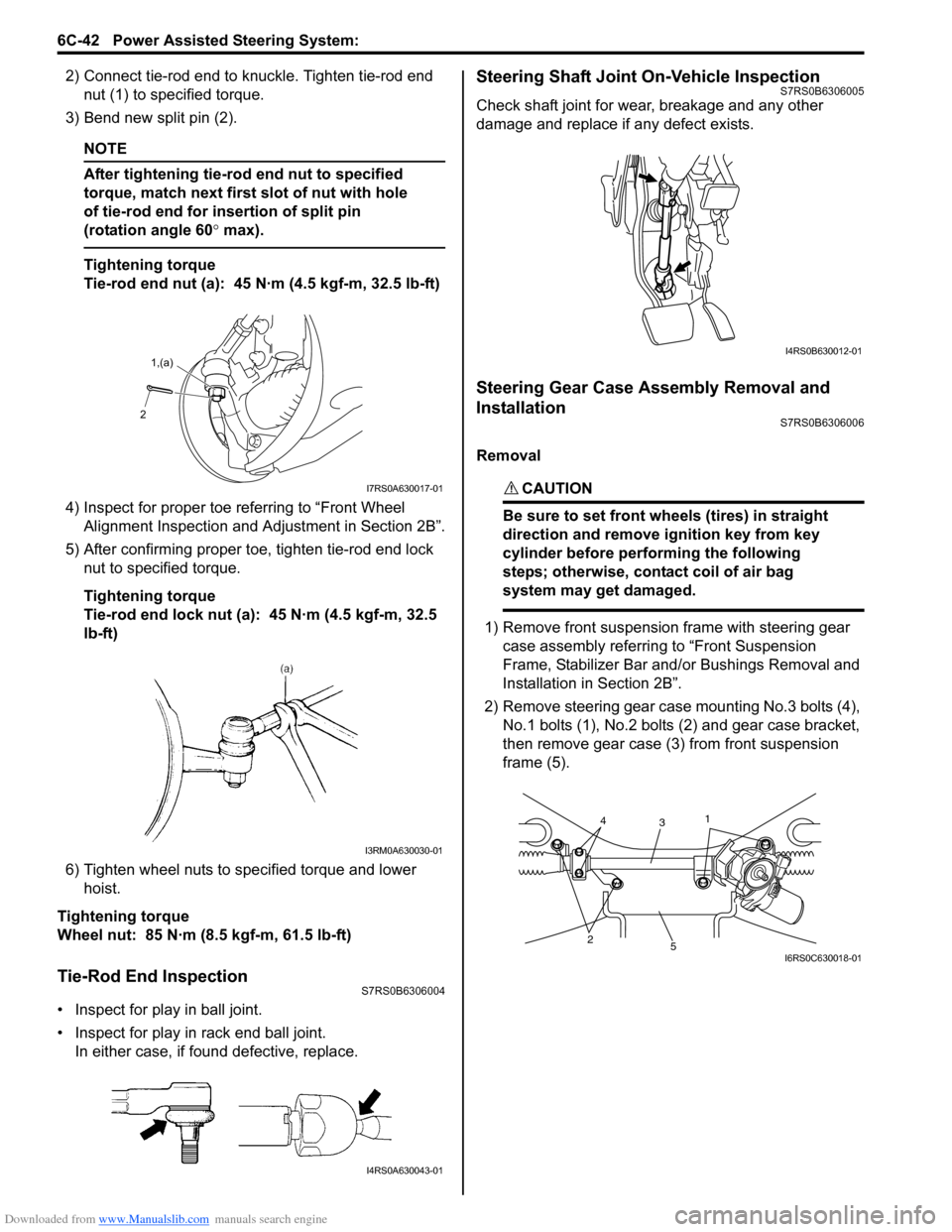

1) Turn steering wheel so that vehicle’s front tires are at straight-ahead position.

2) Turn ignition switch to LOCK position and remove key.

3) Remove steering joint cover.

4) Make alignment marks (4) on lower shaft (1) and shaft joint of steering colu mn (2) and lower shaft (1)

and pinion shaft (3) for a guide during reinstallation.

5) Remove lower shaf t joint bolts (5).

6) Remove steering lower shaft (1). Installation

1) Be sure that front wheels are in straight forward state.

2) Align flat part “A” of steering lower shaft (1) with bolt hole “B” of shaft joint (2) of column as shown. Then

insert lower shaft into shaf t joint of steering column

with matching marks (4).

3) Insert lower shaft (1) into pinion shaft (3) with matching marks (4).

4) Tighten joint bolt (pinion shaft side) (6) to specified

torque first and then joint bolt (steering column side)

(5) to specified torque.

Tightening torque

Steering shaft joint bolt (a ): 25 N·m (2.5 kgf-m,

18.5 lb-ft)

I4RS0B620007-02

I4RS0A620020-01

I6RS0C620002-01

Page 924 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-42 Power Assisted Steering System:

2) Connect tie-rod end to knuckle. Tighten tie-rod end nut (1) to spec ified torque.

3) Bend new split pin (2).

NOTE

After tightening tie-rod end nut to specified

torque, match next first slot of nut with hole

of tie-rod end for insertion of split pin

(rotation angle 60 ° max).

Tightening torque

Tie-rod end nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-ft)

4) Inspect for proper toe re ferring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

5) After confirming proper toe, tighten tie-rod end lock nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

6) Tighten wheel nuts to specified torque and lower hoist.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

Tie-Rod End InspectionS7RS0B6306004

• Inspect for play in ball joint.

• Inspect for play in rack end ball joint. In either case, if found defective, replace.

Steering Shaft Joint On-Vehicle InspectionS7RS0B6306005

Check shaft joint for wear, breakage and any other

damage and replace if any defect exists.

Steering Gear Case Assembly Removal and

Installation

S7RS0B6306006

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps; otherwise, contact coil of air bag

system may get damaged.

1) Remove front suspension frame with steering gear case assembly referrin g to “Front Suspension

Frame, Stabilizer Bar and/ or Bushings Removal and

Installation in Section 2B”.

2) Remove steering gear case mounting No.3 bolts (4), No.1 bolts (1), No.2 bolts (2) and gear case bracket,

then remove gear case (3) from front suspension

frame (5).

2 1,(a)

I7RS0A630017-01

I3RM0A630030-01

I4RS0A630043-01

I4RS0B630012-01

25

3

14

I6RS0C630018-01

Page 1033 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-2

Seat Belt with ELR

The seat belt with emergency locking retractor (ELR) is

designed so that it locks immediately (to prevent the

webbing from being pulled out of the retractor any

further) when any of the following items is detected as

exceeding each set value;

• Speed at which the webbing is pulled out of the retractor.

• Acceleration or deceleration of the vehicle speed.

• Inclination.

Seat Belt with A-ELR

The automatic and emergency locking retractor (A-ELR)

works as an Emergency Locking Retractor (ELR) till its

webbing is pulled all the way out and then on as an

Automatic Locking Retractor (ALR ) till it is retracted fully.

ALR: Automatically locks when the webbing is pulled out

from the retractor and allowed to retract even a little.

Then the webbing can not be pulled out any further,

unless it is wound all the way back into the retractor,

which releases the lock and allows the webbing to be

pulled out.

Seat Belt with ELR and Pretensioner

The seat belt with ELR and a pretensioner has a

pretensioner mechanism whic h operates in linkage with

the air bag in addition to the described ELR.

The pretensioner is incorporated in retractor assembly

and controlled by SDM as one of air bag system

components. It will be activated at the same time as the

driver and passenger air bag module when an impact at

the front of vehicle exceeds the specified value.

When servicing seat belt (retractor assembly) with

pretensioner, be sure to observe all WARNINGS and

CAUTIONS and “Precautions on Service and Diagnosis

of Air Bag System in Section 8B”. CAUTION!

Do not reuse the seat belt pretensioner

(retractor assembly) that has activated.

Replace it with a new seat belt assembly and

buckle together as a set. For checking

procedure of its activation, refer to “Repair

and Inspection Required after Accident in

Section 8B”.

Seat Belt Remainder

When driver’s seat belt is unfastened (under the

following conditions), seat belt reminder light and

warning buzzer inform that driver’s seat belt is

unfastened. Seat belt reminder light located in

combination meter and warning buzzer located inside

BCM operate as follows:

• Seat belt reminder light comes on when driver’s seat belt is unfastened while igni tion key switch is at ON

position.

• If vehicle speed exceeds 15 km/h with seat belt unfastened, warning buzzer operates for

approximately 95 seconds and seat belt reminder light

flashes synchronously with buzzer. When warning

buzzer stops operating, seat belt reminder light is

turned on.

• If driver’s seat belt state is changed from “fastened” to “unfastened” while vehicle speed is above 15 km/h,

warning buzzer operates for approximately 95

seconds and seat belt reminder light flashes

synchronously with buzzer. When warning buzzer

stops operating, seat belt reminder light is turned on.

Diagnostic Information and Procedures

Repair and Inspection Required after AccidentS7RS0B8104001

After an accident, whether the seat belt pretensioner has been activated or not, be sure to perform checks and repairs

described on “Repair and Inspection Required after Accident in Section 8B”.

Page 1136 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-98 Air Bag System:

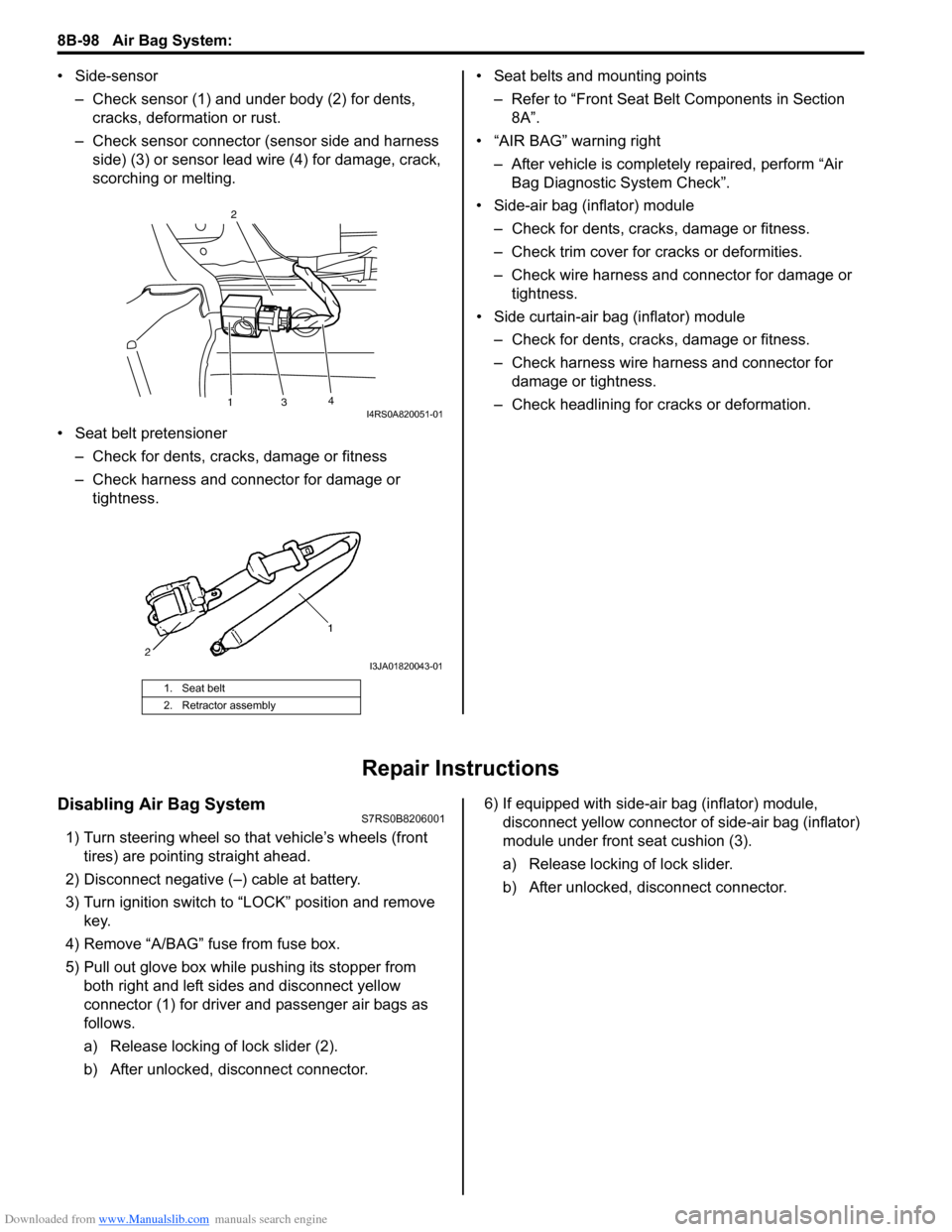

• Side-sensor– Check sensor (1) and under body (2) for dents, cracks, deformation or rust.

– Check sensor connector (sensor side and harness side) (3) or sensor lead wire (4) for damage, crack,

scorching or melting.

• Seat belt pretensioner – Check for dents, cracks , damage or fitness

– Check harness and connector for damage or tightness. • Seat belts and mounting points

– Refer to “Front Seat Belt Components in Section 8A”.

• “AIR BAG” warning right

– After vehicle is completely repaired, perform “Air Bag Diagnostic System Check”.

• Side-air bag (inflator) module – Check for dents, cra cks, damage or fitness.

– Check trim cover for cracks or deformities.

– Check wire harness and connector for damage or tightness.

• Side curtain-air bag (inflator) module – Check for dents, cra cks, damage or fitness.

– Check harness wire harness and connector for damage or tightness.

– Check headlining for cracks or deformation.

Repair Instructions

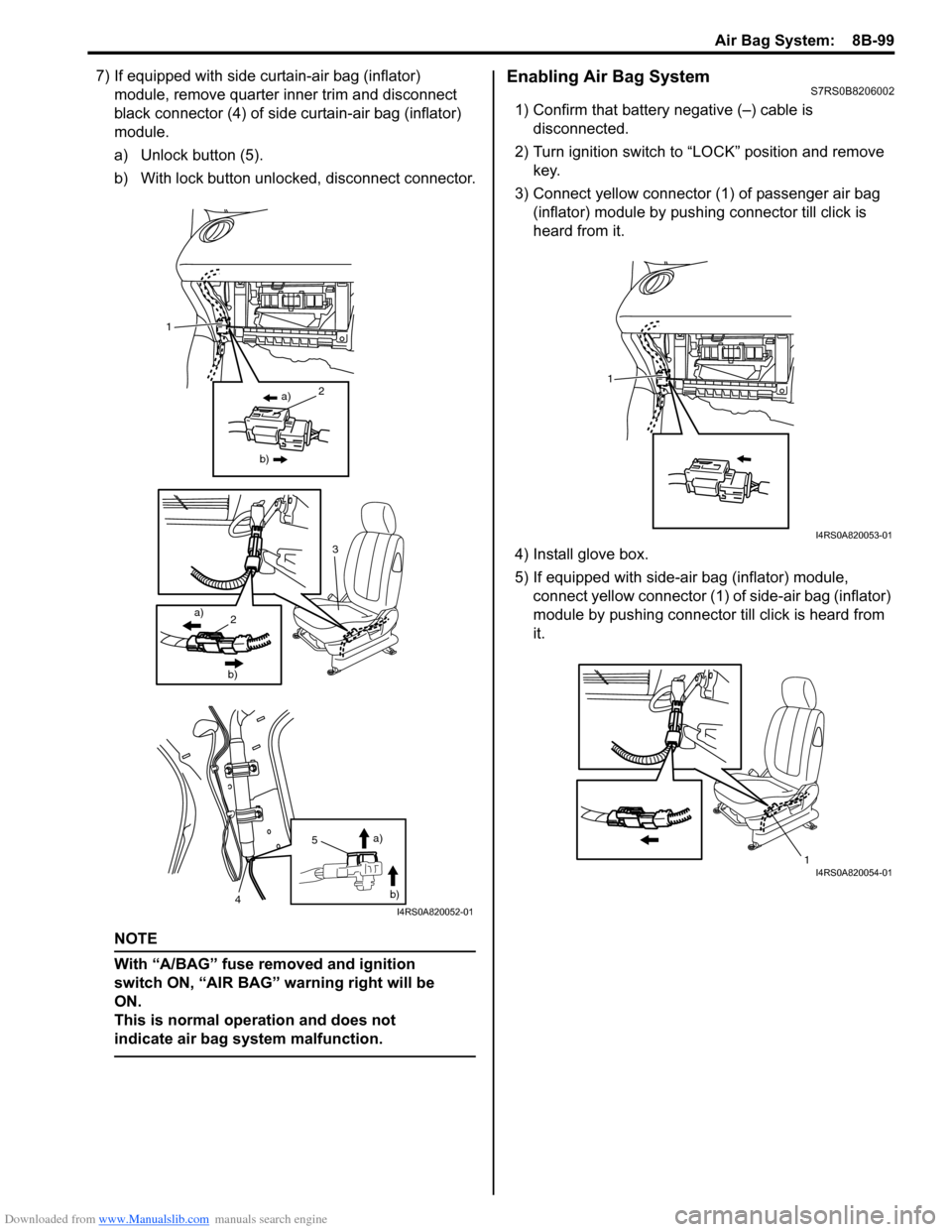

Disabling Air Bag SystemS7RS0B8206001

1) Turn steering wheel so that vehicle’s wheels (front tires) are pointing straight ahead.

2) Disconnect negative (–) cable at battery.

3) Turn ignition switch to “LOCK” position and remove key.

4) Remove “A/BAG” fu se from fuse box.

5) Pull out glove box while pushing its stopper from

both right and left sides and disconnect yellow

connector (1) for driver and passenger air bags as

follows.

a) Release locking of lock slider (2).

b) After unlocked, disconnect connector. 6) If equipped with side-air bag (inflator) module,

disconnect yellow connector of side-air bag (inflator)

module under front seat cushion (3).

a) Release locking of lock slider.

b) After unlocked, disconnect connector.

1. Seat belt

2. Retractor assembly

13 4

2I4RS0A820051-01

I3JA01820043-01

Page 1137 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-99

7) If equipped with side curtain-air bag (inflator) module, remove quarter inner trim and disconnect

black connector (4) of side curtain-air bag (inflator)

module.

a) Unlock button (5).

b) With lock button unlocked, disconnect connector.

NOTE

With “A/BAG” fuse removed and ignition

switch ON, “AIR BAG” warning right will be

ON.

This is normal operation and does not

indicate air bag system malfunction.

Enabling Air Bag SystemS7RS0B8206002

1) Confirm that battery negative (–) cable is disconnected.

2) Turn ignition switch to “LOCK” position and remove key.

3) Connect yellow connector (1) of passenger air bag (inflator) module by push ing connector till click is

heard from it.

4) Install glove box.

5) If equipped with side-air bag (inflator) module, connect yellow connector (1) of side-air bag (inflator)

module by pushing connector till click is heard from

it.

a)

b)2

3

2a)

b)

1

5

4 a)

b)

I4RS0A820052-01

1

I4RS0A820053-01

1I4RS0A820054-01

Page 1152 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-114 Air Bag System:

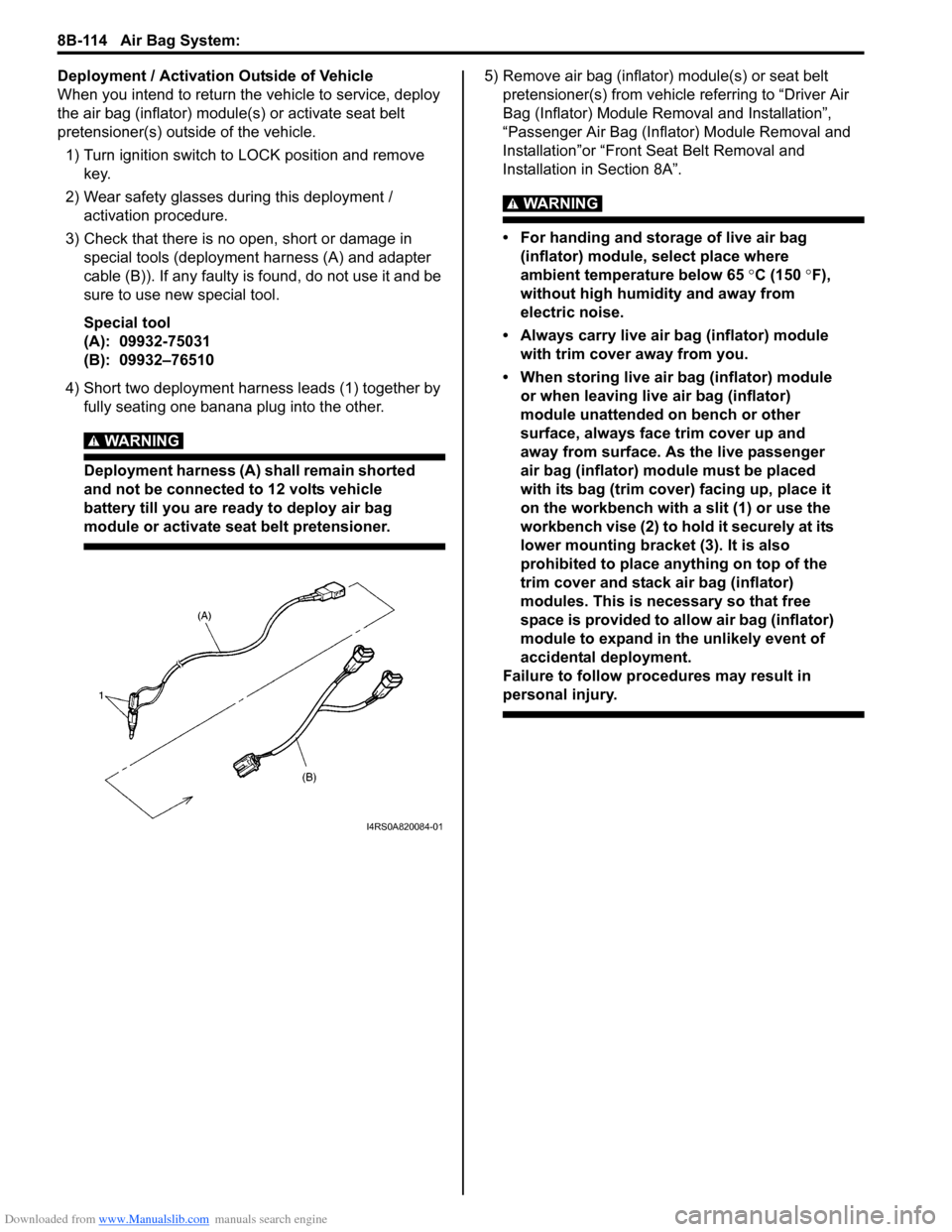

Deployment / Activation Outside of Vehicle

When you intend to return the vehicle to service, deploy

the air bag (inflator) module(s) or activate seat belt

pretensioner(s) outside of the vehicle.1) Turn ignition switch to LOCK position and remove key.

2) Wear safety glasses during this deployment / activation procedure.

3) Check that there is no open, short or damage in special tools (deployment harness (A) and adapter

cable (B)). If any faulty is found, do not use it and be

sure to use new special tool.

Special tool

(A): 09932-75031

(B): 09932–76510

4) Short two deployment harness leads (1) together by fully seating one banana plug into the other.

WARNING!

Deployment harness (A) shall remain shorted

and not be connected to 12 volts vehicle

battery till you are ready to deploy air bag

module or activate seat belt pretensioner.

5) Remove air bag (inflator) module(s) or seat belt pretensioner(s) from vehicle referring to “Driver Air

Bag (Inflator) Module Re moval and Installation”,

“Passenger Air Bag (Inflator) Module Removal and

Installation”or “Front Seat Belt Removal and

Installation in Section 8A”.

WARNING!

• For handing and storage of live air bag (inflator) module, select place where

ambient temperature below 65 °C (150 °F),

without high humidity and away from

electric noise.

• Always carry live air bag (inflator) module with trim cover away from you.

• When storing live air bag (inflator) module or when leaving live air bag (inflator)

module unattended on bench or other

surface, always face trim cover up and

away from surface. As the live passenger

air bag (inflator) module must be placed

with its bag (trim cover) facing up, place it

on the workbench with a slit (1) or use the

workbench vise (2) to hold it securely at its

lower mounting bracket (3). It is also

prohibited to place anything on top of the

trim cover and stack air bag (inflator)

modules. This is necessary so that free

space is provided to allow air bag (inflator)

module to expand in the unlikely event of

accidental deployment.

Failure to follow procedures may result in

personal injury.

I4RS0A820084-01

Page 1159 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-121

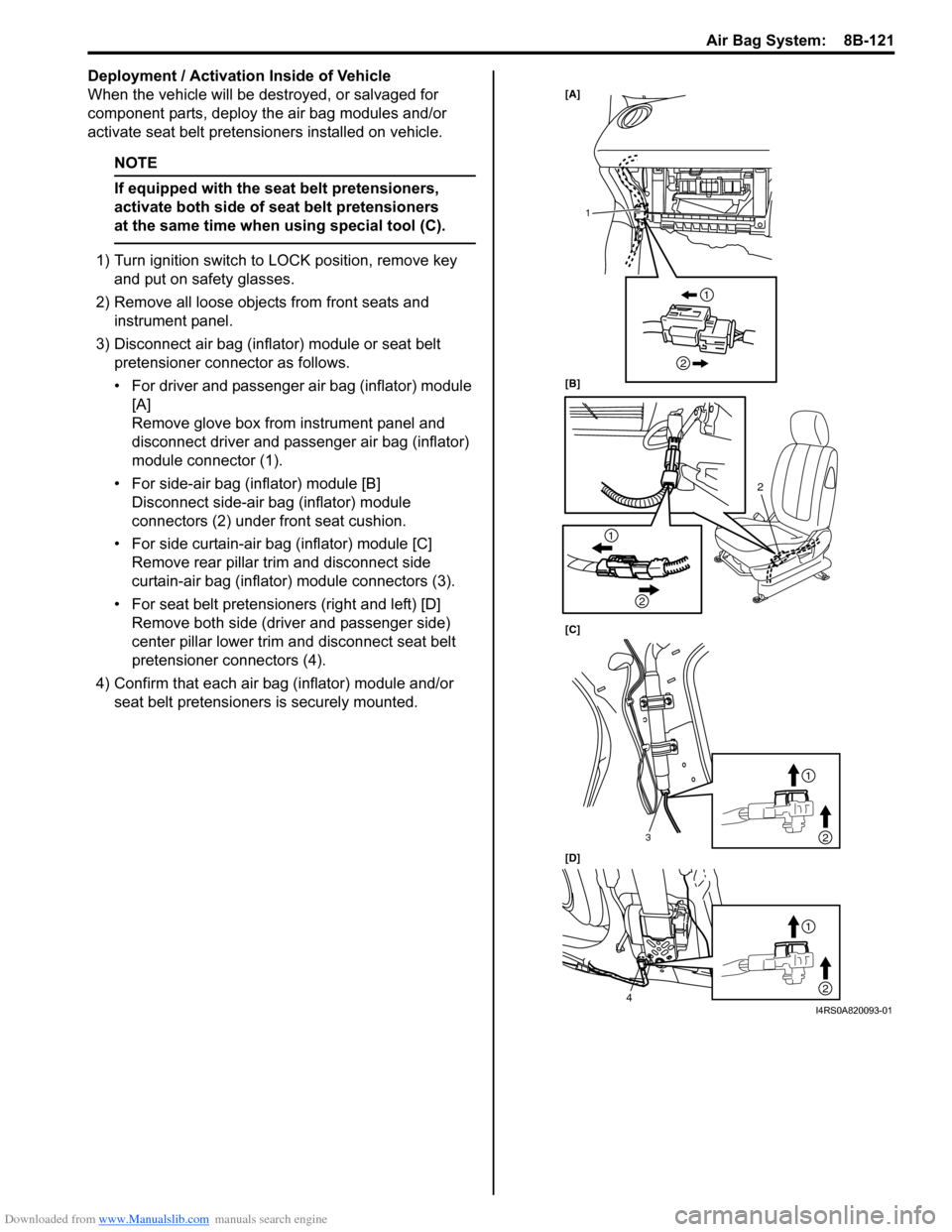

Deployment / Activation Inside of Vehicle

When the vehicle will be destroyed, or salvaged for

component parts, deploy the air bag modules and/or

activate seat belt pretensioners installed on vehicle.

NOTE

If equipped with the seat belt pretensioners,

activate both side of seat belt pretensioners

at the same time when using special tool (C).

1) Turn ignition switch to LOCK position, remove key

and put on safety glasses.

2) Remove all loose objects from front seats and instrument panel.

3) Disconnect air bag (inflator) module or seat belt pretensioner connector as follows.

• For driver and passenger air bag (inflator) module [A]

Remove glove box from instrument panel and

disconnect driver and passenger air bag (inflator)

module connector (1).

• For side-air bag (inflator) module [B] Disconnect side-air bag (inflator) module

connectors (2) under front seat cushion.

• For side curtain-air bag (inflator) module [C] Remove rear pillar trim and disconnect side

curtain-air bag (inflator) module connectors (3).

• For seat belt pretensioners (right and left) [D] Remove both side (driver and passenger side)

center pillar lower trim an d disconnect seat belt

pretensioner connectors (4).

4) Confirm that each air bag (inflator) module and/or seat belt pretensioners is securely mounted.

[A]

[B]

[C]

[D]

2

1

3

4

1

2

1

2

1

2

1

2

I4RS0A820093-01

Page 1167 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9- i

9

Section 9

CONTENTS

Body, Cab and Accessories

Precautions ................................................. 9-1

Precautions............................................................. 9-1

Precautions on Body, Cab and Accessories ......... 9-1

Precautions for Body Service ................................ 9-1

Fastener Caution for Body Service ....................... 9-1

Wiring Systems............... ......................... 9A-1

Precautions........................................................... 9A-1

Cautions in Body Electrical System Servicing..... 9A-1

General Description ............................................. 9A-1 Abbreviations ...................................................... 9A-1

Wire / Connector Color Sy mbols ......................... 9A-1

Symbols and Marks ............................................ 9A-2

How to Read Connector Layout Diagram ........... 9A-4

How to Read Connector Codes and Terminal Nos.................................................................... 9A-5

How to Read Ground Point ................................. 9A-7

How to Read Power Supply Diagram.................. 9A-8

How to Read System Circuit Diagram................. 9A-8

Connector Layout Diagram . .............................. 9A-10

Connector Layout Diagram ............................... 9A-10

Engine Compartment .......... .............................. 9A-10

Instrument Panel ............................................... 9A-16

Door, Roof......................................................... 9A-20

Floor .................................................................. 9A-23

Rear .................................................................. 9A-29

Ground Point ...................................................... 9A-30 Ground (earth) Point ......................................... 9A-30

Power Supply Diagram ........ .............................. 9A-31

Power Supply Diagram ....... .............................. 9A-31

Fuses and the Protected Parts ......................... 9A-33

Fuses in Main Fuse Box (RHD) ........................ 9A-33

Fuses in Main Fuse Box (LHD) ......................... 9A-33

Individual Circuit Fuse Box No. 1 ...................... 9A-34

Individual Circuit Fuse Box No. 2 (In J/B) ......... 9A-35

Junction Block (J/B) Connector / Fuse Layout .. 9A-37

Junction Block Inner Circuit (Overview) ............ 9A-38

Junction Block Inner Circuit (Detail) .................. 9A-40

System Circuit Diagram... .................................. 9A-45

System Circuit Diagram .. .................................. 9A-45

A-1 Cranking System Circ uit Diagram .............. 9A-46

A-2 Charging System Circu it Diagram .............. 9A-47

A-3 Ignition System Circu it Diagram ................. 9A-48

A-4 Cooling System Circuit Diagram................. 9A-49 A-5 Engine and A/C Control System Circuit

Diagram........................................................... 9A-50

A-6 A/T Control System Circuit Diagram........... 9A-55

A-7 Immobilizer System Circuit Diagram .......... 9A-57

A-8 Body Control System Circuit Diagram ........ 9A-58

B-1 Windshield Wiper and Washer Circuit Diagram........................................................... 9A-62

B-2 Rear Wiper and Washer Circuit Diagram ... 9A-63

B-3 Rear Defogger Circuit Diagram .................. 9A-64

B-4 Power Window Circuit Diagram .................. 9A-65

B-5 Power Door Lock Circu it Diagram .............. 9A-67

B-6 Power Mirror Circuit Diagram ..................... 9A-69

B-7 Horn Circuit Diagram .................................. 9A-70

B-8 Seat Heater Circuit Diagram....................... 9A-71

B-9 Keyless Start System Circuit Diagram........ 9A-72

C-1 Combination Mete r Circuit Diagram

(Meter)............................................................. 9A-73

C-2 Combination Mete r Circuit Diagram

(Indicator) ........................................................ 9A-74

C-3 Combination Mete r Circuit Diagram

(Warning Light)................................................ 9A-75

D-1 Headlight System Circuit Diagram ............. 9A-77

D-2 Position, Tail and Licence Plate Light System Circuit Diagram .................................. 9A-79

D-3 Front Fog Light System Circuit Diagram .... 9A-80

D-4 Illumination Light System Circuit Diagram .. 9A-81

D-5 Interior Light System Circuit Diagram......... 9A-82

D-6 Turn Signal and Hazard Warning Light System Circuit Diagram .................................. 9A-83

D-7 Brake Light System Circuit Diagram .......... 9A-85

D-8 Back-Up Light System Circuit Diagram ...... 9A-86

D-9 Headlight Beam Leveling System Circuit Diagram........................................................... 9A-87

D-10 Rear Fog Light Circuit Diagram ................ 9A-88

E-1 Heater System Circuit Diagram .................. 9A-89

E-2 Auto A/C System Circuit Diagram .............. 9A-91

F-1 Air-Bag System Circuit Diagram ................. 9A-93

F-2 Anti-Lock Brake System Circuit Diagram.... 9A-95

F-3 Electronic Stab ility Program System

Circuit Diagram .................. ............................. 9A-97

F-4 Power Steering System Circuit Diagram .... 9A-99

G-1 Audio System Circuit Diagram ................. 9A-101

G-2 Multi Information Display / Accessory Socket System Circuit Diagram .................... 9A-102

List of Connector .............................................9A-103

Page 1169 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9-iii

Door Switch (Front / Rear Door) Inspection ...... 9C-17

Rear End Door Switch Inspection ..................... 9C-17

Outside Air Temperature Sensor Removal and Installation (If Equipped) .......................... 9C-17

Outside Air Temperature Sensor Inspection (If Equipped) ................................................... 9C-17

Instrument Panel Removal and Installation....... 9C-18

Information Display (Clock) Removal and Installation ....................................................... 9C-19

Audio Unit Removal and In stallation ................. 9C-19

Front Speaker Removal and Installation ........... 9C-19

Rear Speaker Removal and Installation............ 9C-20

Horn Removal and Installation .......................... 9C-20

Horn Inspection ................................................. 9C-20

Horn Relay Inspection ....................................... 9C-20

Antenna Amplifier Removal and Installation ..... 9C-21

Remote Audio Control Switch Removal and Installation (If Equipped) ................................. 9C-21

Remote Audio Control Switch Inspection (If Equipped)........................................................ 9C-22

Vehicle Speed Signal Inspection (For Audio Unit) (If Equipped) ........................................... 9C-22

Specifications ..................................................... 9C-22

Tightening Torque Specifications ...................... 9C-22

Wipers / Washers............ ......................... 9D-1

Diagnostic Information and Procedures ............ 9D-1

Front Wiper and Washer Symptom Diagnosis .... 9D-1

Rear Wiper and Washer Symptom Diagnosis..... 9D-1

Repair Instructions .............................................. 9D-2 Wipers and Washers Components ..................... 9D-2

Washer Tank and Washer Pump Removal and Installation .................................................. 9D-3

Washer Pump Inspection .................................... 9D-3

Windshield Wiper Removal and Installation ........ 9D-4

Windshield Wiper Motor Inspection..................... 9D-5

Rear Wiper Removal and Installation.................. 9D-6

Rear Wiper Motor Inspection .............................. 9D-7

Windshield Wiper and Washer Switch Removal and Installation................................... 9D-7

Windshield Wiper and Washer Switch Inspection.......................................................... 9D-8

Rear Wiper and Washer Switch Removal and Installation ......................................................... 9D-9

Rear Wiper and Washer Switch Inspection......... 9D-9

Rear Wiper Relay Removal and Installation ..... 9D-10

Rear Wiper Relay Inspection ............................ 9D-10

Specifications ..................................................... 9D-10

Tightening Torque Specifications ...................... 9D-10

Glass / Windows / Mirrors.. ..................... 9E-1

General Description ............................................. 9E-1

Rear End Door Window Defogger System Description ........................................................ 9E-1

Windshield Construction ..................................... 9E-1

Diagnostic Information and Procedures ............ 9E-2 Rear End door Window Defogger Symptom Diagnosis .......................................................... 9E-2 Power Window Control System Symptom

Diagnosis .......................................................... 9E-2

Power Door Mirror Control System Symptom Diagnosis .......................................................... 9E-3

Door Mirror Heater Symptom Diagnosis (If

Equipped) .......................................................... 9E-3

Repair Instructions ........... ................................... 9E-4

Windshield Removal and In stallation .................. 9E-4

Front Door Window Components ........................ 9E-8

Front Door Glass Removal and Installation ........ 9E-8

Front Door Window Re gulator Removal and

Installation ......................................................... 9E-9

Front Door Window Regula tor Inspection ......... 9E-10

Rear Door Window Components ...................... 9E-10

Rear Door Glass Removal and Installation ....... 9E-11

Rear Door Window Regulator Removal and Installation ....................................................... 9E-12

Rear Door Window Regulato r Inspection .......... 9E-12

Rear End Door Window Components ............... 9E-13

Rear End Door Glass Removal and Installation ....................................................... 9E-13

Rear End Door Window Defogger Switch Inspection ........................................................ 9E-14

Rear End Door Window Defogger Relay Inspection ........................................................ 9E-14

Rear End Door Window Defogger Wire Inspection ........................................................ 9E-15

Rear End Door Window Defogger Wire

Repair.............................................................. 9E-15

Power Window Main Switch Inspection ............ 9E-16

Power Window Sub Switch Inspection .............. 9E-17

Door Mirror Components.. ................................. 9E-18

Door Mirror Removal and In stallation................ 9E-18

Power Door Mirror Switch Inspection ................ 9E-18

Power Door Mirror Actuator Inspection ............. 9E-19

Door Mirror Heater Switch Inspection (If Equipped) ........................................................ 9E-19

Door Mirror Heater Inspec tion (If Equipped) ..... 9E-19

Special Tools and Equipmen t ........................... 9E-19

Recommended Service Material ....................... 9E-19

Security and Locks......... ..........................9F-1

General Description ............................................. 9F-1

Key Coding Construction .................................... 9F-1

Rear End Door Opener System Description ....... 9F-1

Component Location ............ ............................... 9F-2

Power Door Lock and Keyless Entry System

Component Location ......................................... 9F-2

Diagnostic Information and Procedures ............ 9F-3 Power Door Lock System Symptom Diagnosis .......................................................... 9F-3

Power Door Lock System Operation Inspection .......................................................... 9F-3

Keyless Entry System Symptom Diagnosis (If

Equipped) .......................................................... 9F-4

Keyless Entry System Operation Inspection ....... 9F-5

Door Lock Function of Keyless Start System Symptom Diagnosis (If Equipped)..................... 9F-5