engine bracket nut SUZUKI SWIFT 2006 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 879 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-8

Installation

CAUTION!

After tightening steering column mounting

nuts, shaft joint bolts should be tightened.

Wrong tightening order could cause a

damage to shaft joint.

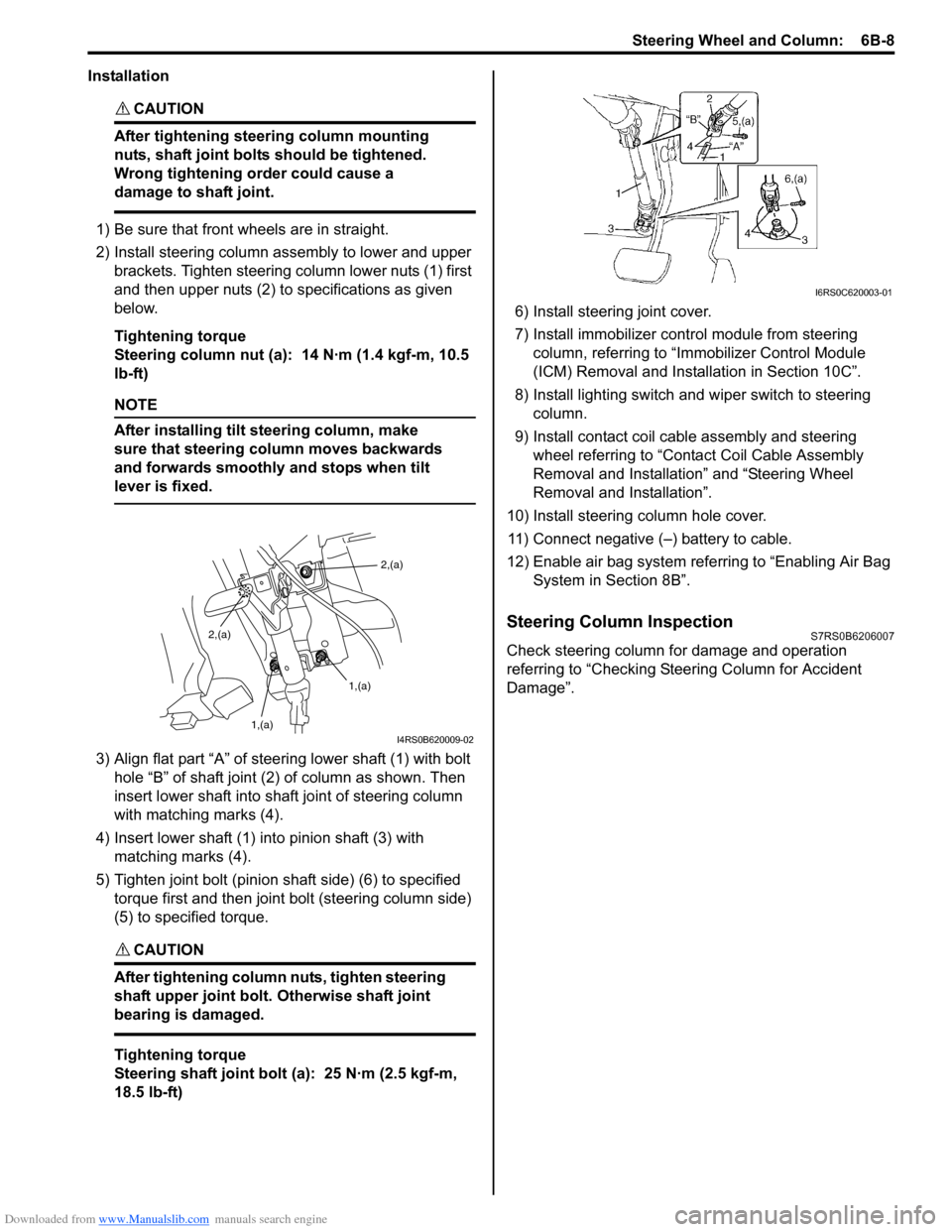

1) Be sure that front wheels are in straight.

2) Install steering column assembly to lower and upper brackets. Tighten steering column lower nuts (1) first

and then upper nuts (2) to specifications as given

below.

Tightening torque

Steering column nut (a): 14 N·m (1.4 kgf-m, 10.5

lb-ft)

NOTE

After installing tilt steering column, make

sure that steering column moves backwards

and forwards smoothly and stops when tilt

lever is fixed.

3) Align flat part “A” of stee ring lower shaft (1) with bolt

hole “B” of shaft joint (2) of column as shown. Then

insert lower shaft into shaf t joint of steering column

with matching marks (4).

4) Insert lower shaft (1) into pinion shaft (3) with matching marks (4).

5) Tighten joint bolt (pinion shaft side) (6) to specified torque first and then joint bolt (steering column side)

(5) to specified torque.

CAUTION!

After tightening column nuts, tighten steering

shaft upper joint bolt. Otherwise shaft joint

bearing is damaged.

Tightening torque

Steering shaft joint bolt (a): 25 N·m (2.5 kgf-m,

18.5 lb-ft) 6) Install steering joint cover.

7) Install immobilizer cont

rol module from steering

column, referring to “Immo bilizer Control Module

(ICM) Removal and Installation in Section 10C”.

8) Install lighting switch and wiper switch to steering column.

9) Install contact coil cable assembly and steering wheel referring to “Conta ct Coil Cable Assembly

Removal and Installation” and “Steering Wheel

Removal and Installation”.

10) Install steering column hole cover. 11) Connect negative (–) battery to cable.

12) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

Steering Column InspectionS7RS0B6206007

Check steering column for damage and operation

referring to “Checking Steering Column for Accident

Damage”.

2,(a)

1,(a)

1,(a)

2,(a)

I4RS0B620009-02

I6RS0C620003-01

Page 922 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-40 Power Assisted Steering System:

Repair Instructions

Steering Gear Case Assembly ComponentsS7RS0B6306001

3(a)

10

(c) 2

3

(a)

2 1

19

(g)

19 18(g) 6

11

8

9

(b) 7

(b)

22 23

24 4

5

14

15

16

(e)

17

(f)

12

(d) 21

(c)

20

4 6

5 7

(b)

9

(b)

8

13

22

23

24

A

A

1322

I7RS0B630013-02

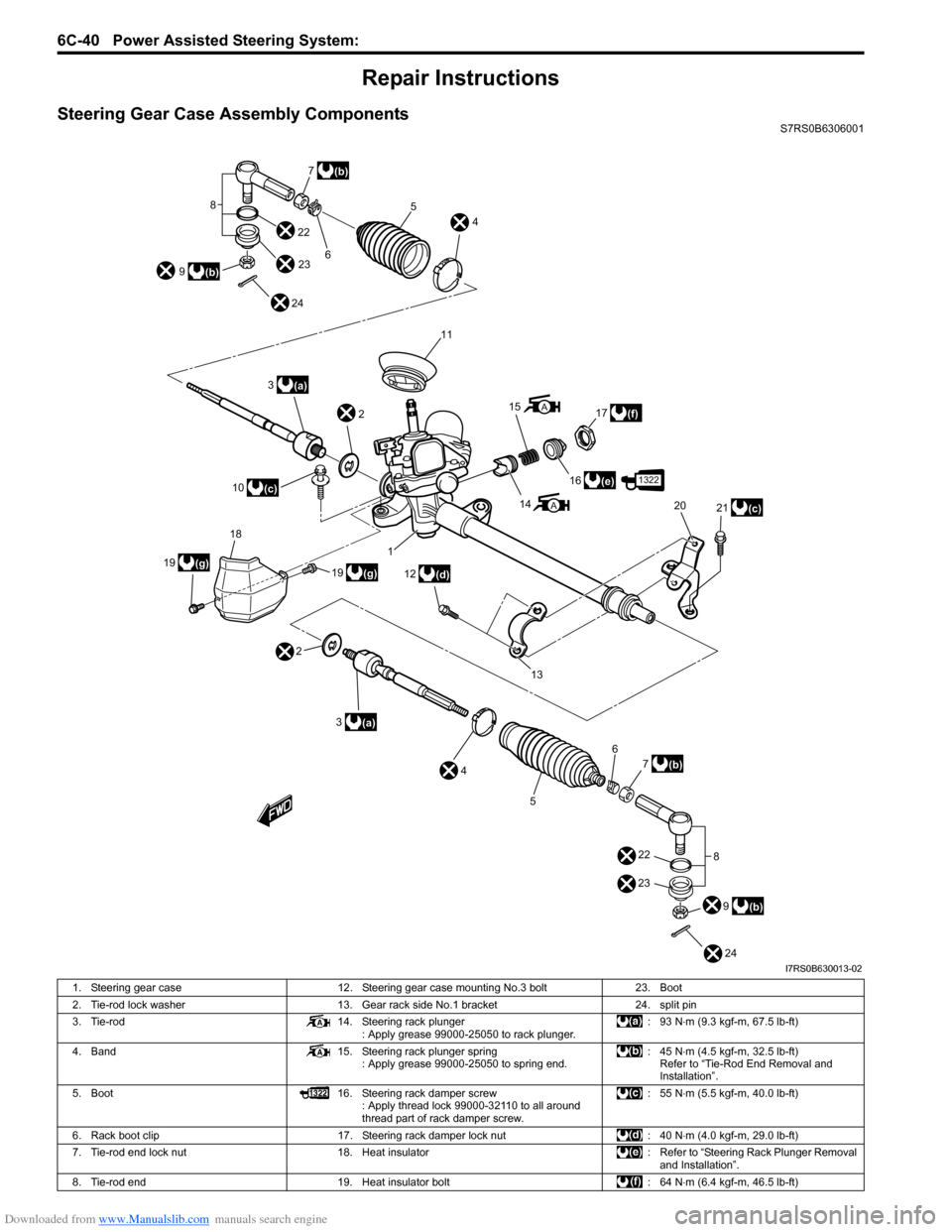

1. Steering gear case 12. Steering gear case mounting No.3 bolt 23. Boot

2. Tie-rod lock washer 13. Gear rack side No.1 bracket 24. split pin

3. Tie-rod 14. Steering rack plunger

: Apply grease 99000-25050 to rack plunger. : 93 N

⋅m (9.3 kgf-m, 67.5 lb-ft)

4. Band 15. Steering rack plunger spring

: Apply grease 99000-25050 to spring end. : 45 N

⋅m (4.5 kgf-m, 32.5 lb-ft)

Refer to “Tie-Rod End Removal and

Installation”.

5. Boot 16. Steering rack damper screw

: Apply thread lock 99000-32110 to all around

thread part of rack damper screw. : 55 N

⋅m (5.5 kgf-m, 40.0 lb-ft)

6. Rack boot clip 17. Steering rack damper lock nut : 40 N⋅m (4.0 kgf-m, 29.0 lb-ft)

7. Tie-rod end lock nut 18. Heat insulator : Refer to “Steering Rack Plunger Removal

and Installation”.

8. Tie-rod end 19. Heat insulator bolt : 64 N⋅m (6.4 kgf-m, 46.5 lb-ft)

Page 923 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-41

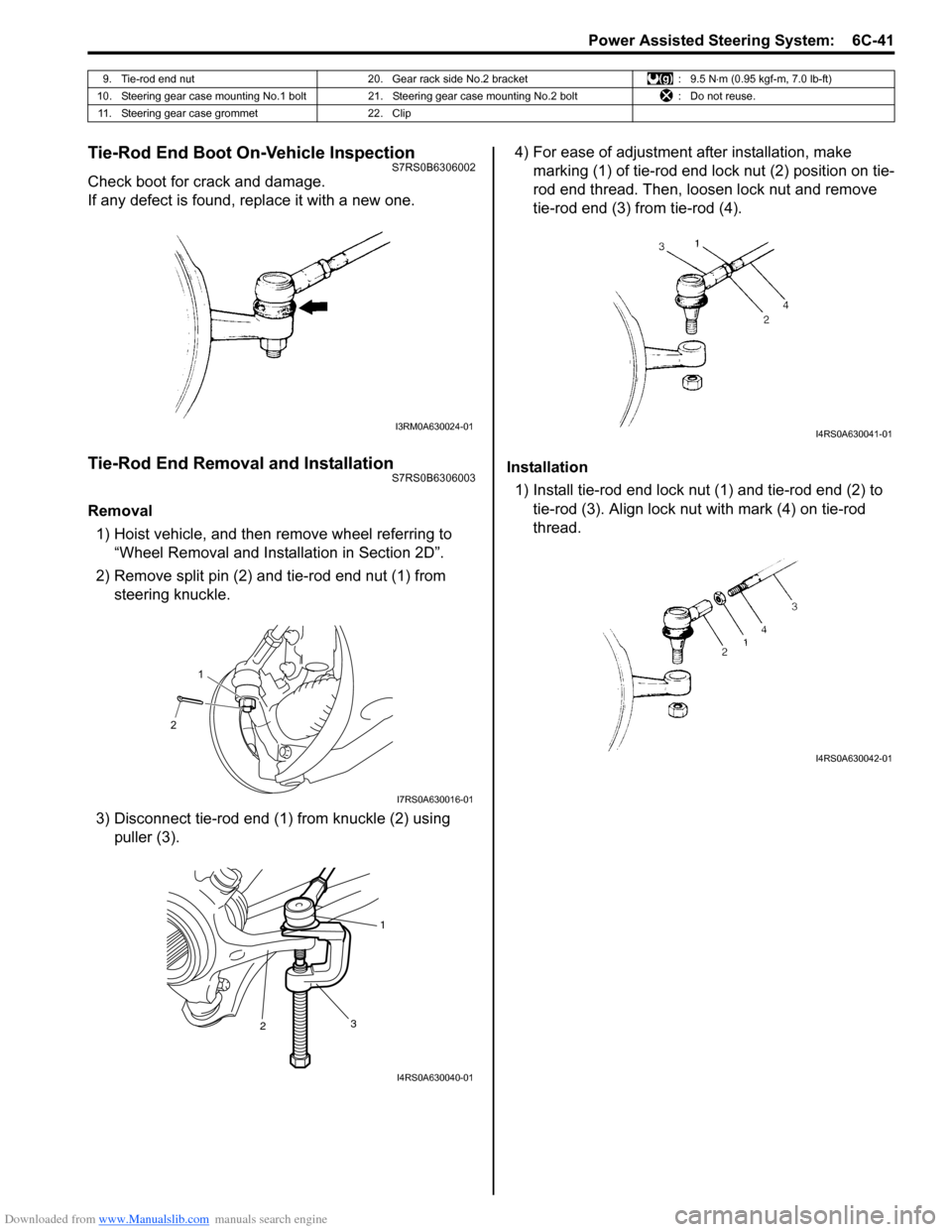

Tie-Rod End Boot On-Vehicle InspectionS7RS0B6306002

Check boot for crack and damage.

If any defect is found, replace it with a new one.

Tie-Rod End Removal and InstallationS7RS0B6306003

Removal1) Hoist vehicle, and then remove wheel referring to “Wheel Removal and Installation in Section 2D”.

2) Remove split pin (2) and tie-rod end nut (1) from steering knuckle.

3) Disconnect tie-rod end (1) from knuckle (2) using puller (3). 4) For ease of adjustment after installation, make

marking (1) of tie-rod end lock nut (2) position on tie-

rod end thread. Then, loosen lock nut and remove

tie-rod end (3) from tie-rod (4).

Installation 1) Install tie-rod end lock nut (1) and tie-rod end (2) to tie-rod (3). Align lock nut with mark (4) on tie-rod

thread.

9. Tie-rod end nut 20. Gear rack side No.2 bracket : 9.5 N⋅m (0.95 kgf-m, 7.0 lb-ft)

10. Steering gear case mounting No.1 bolt 21. Steering gear case mounting No.2 bolt : Do not reuse.

11. Steering gear case grommet 22. Clip

I3RM0A630024-01

21

I7RS0A630016-01

2 1

3

I4RS0A630040-01

I4RS0A630041-01

I4RS0A630042-01

Page 924 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-42 Power Assisted Steering System:

2) Connect tie-rod end to knuckle. Tighten tie-rod end nut (1) to spec ified torque.

3) Bend new split pin (2).

NOTE

After tightening tie-rod end nut to specified

torque, match next first slot of nut with hole

of tie-rod end for insertion of split pin

(rotation angle 60 ° max).

Tightening torque

Tie-rod end nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-ft)

4) Inspect for proper toe re ferring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

5) After confirming proper toe, tighten tie-rod end lock nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

6) Tighten wheel nuts to specified torque and lower hoist.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

Tie-Rod End InspectionS7RS0B6306004

• Inspect for play in ball joint.

• Inspect for play in rack end ball joint. In either case, if found defective, replace.

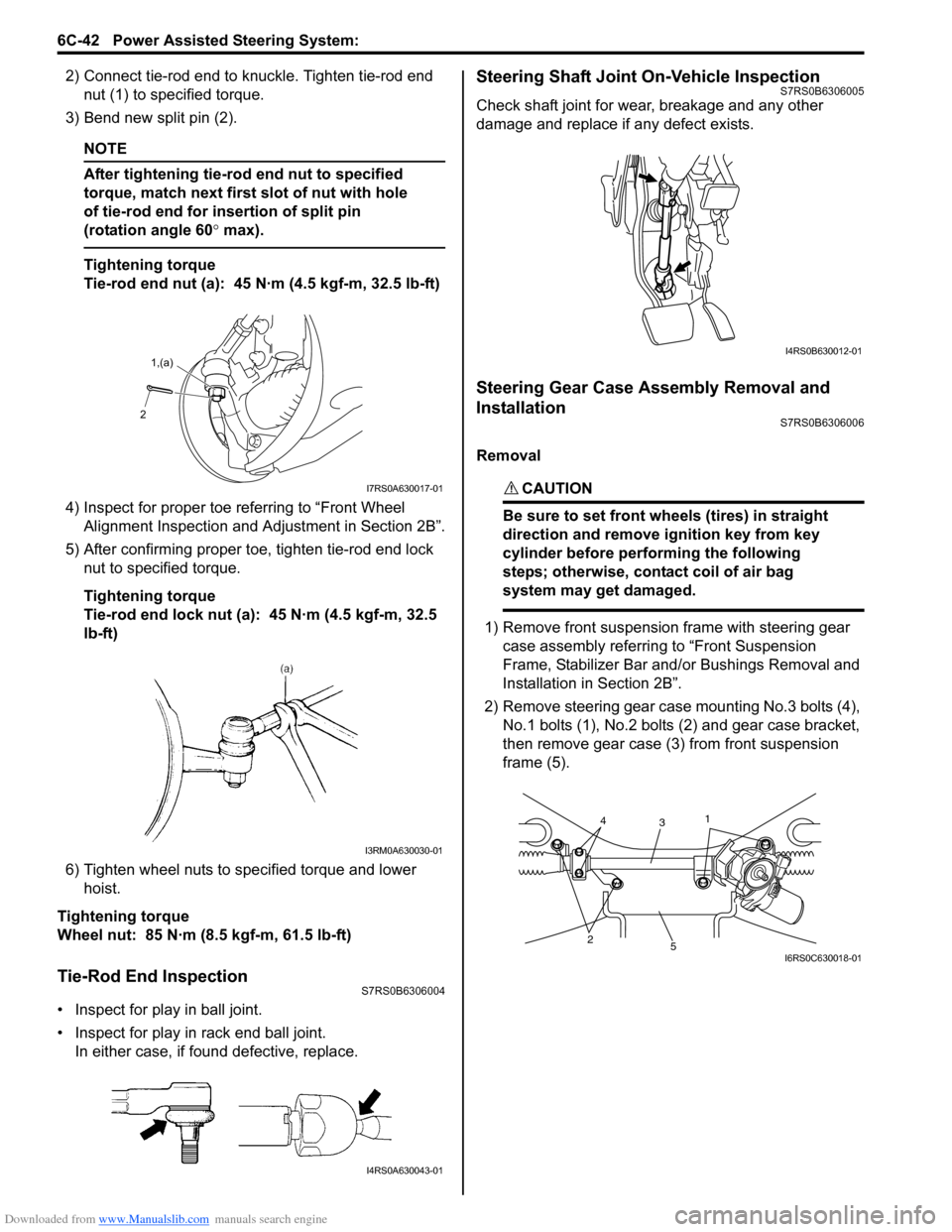

Steering Shaft Joint On-Vehicle InspectionS7RS0B6306005

Check shaft joint for wear, breakage and any other

damage and replace if any defect exists.

Steering Gear Case Assembly Removal and

Installation

S7RS0B6306006

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps; otherwise, contact coil of air bag

system may get damaged.

1) Remove front suspension frame with steering gear case assembly referrin g to “Front Suspension

Frame, Stabilizer Bar and/ or Bushings Removal and

Installation in Section 2B”.

2) Remove steering gear case mounting No.3 bolts (4), No.1 bolts (1), No.2 bolts (2) and gear case bracket,

then remove gear case (3) from front suspension

frame (5).

2 1,(a)

I7RS0A630017-01

I3RM0A630030-01

I4RS0A630043-01

I4RS0B630012-01

25

3

14

I6RS0C630018-01

Page 930 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-48 Power Assisted Steering System:

Specifications

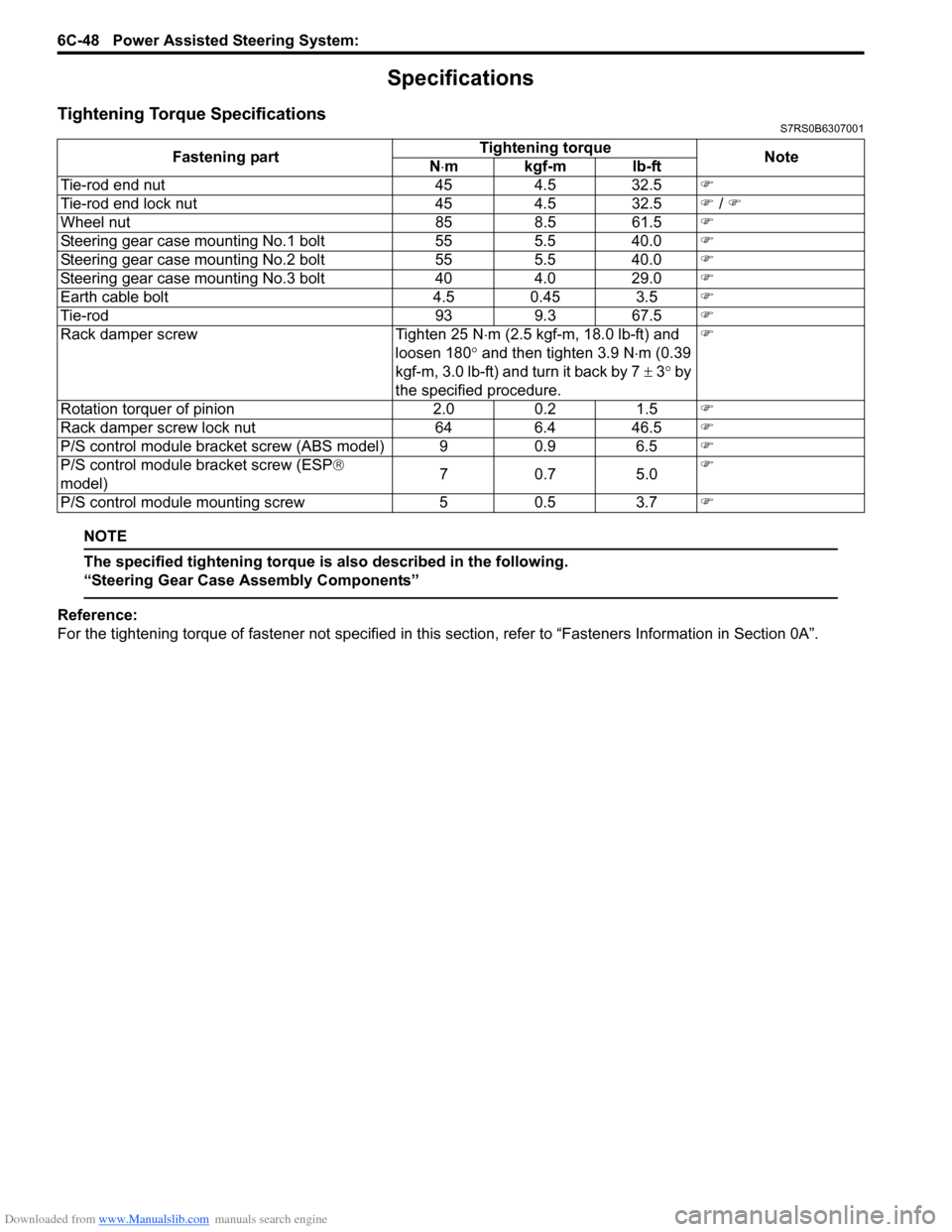

Tightening Torque SpecificationsS7RS0B6307001

NOTE

The specified tightening torque is also described in the following.

“Steering Gear Case Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Tie-rod end nut 454.5 32.5 �)

Tie-rod end lock nut 454.5 32.5 �) / �)

Wheel nut 858.5 61.5 �)

Steering gear case mounting No.1 bolt 555.5 40.0 �)

Steering gear case mounting No.2 bolt 555.5 40.0 �)

Steering gear case mounting No.3 bolt 404.0 29.0 �)

Earth cable bolt 4.5 0.45 3.5�)

Tie-rod 939.3 67.5 �)

Rack damper screw Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) and

loosen 180 ° and then tighten 3.9 N ⋅m (0.39

kgf-m, 3.0 lb-ft) and turn it back by 7 ± 3° by

the specified procedure. �)

Rotation torquer of pinion 2.00.2 1.5 �)

Rack damper screw lock nut 646.4 46.5 �)

P/S control module bracket screw (ABS model) 9 0.9 6.5�)

P/S control module bracket screw (ESP ®

model) 70

.7 5 .0 �)

P/S control module mounting screw 50.5 3.7 �)

Page 958 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-10 Air Conditioning System: Manual Type

Abnormal Noise from Tension Pulley

Abnormal Noise from A/C Evaporator

Abnormal Noise from Blower Motor

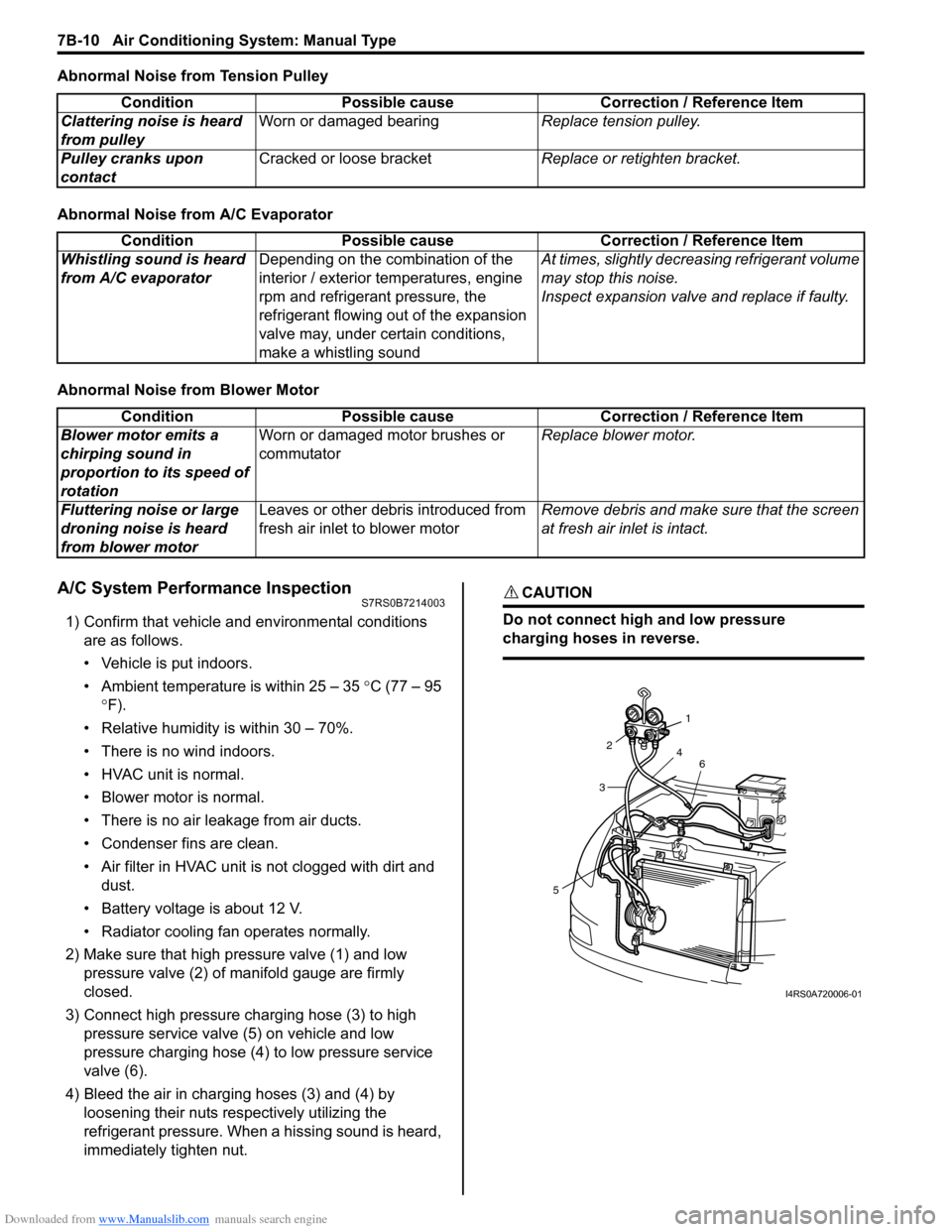

A/C System Performance InspectionS7RS0B7214003

1) Confirm that vehicle and environmental conditions are as follows.

• Vehicle is put indoors.

• Ambient temperature is within 25 – 35 °C (77 – 95

° F).

• Relative humidity is within 30 – 70%.

• There is no wind indoors.

• HVAC unit is normal.

• Blower motor is normal.

• There is no air leakage from air ducts.

• Condenser fins are clean.

• Air filter in HVAC unit is not clogged with dirt and

dust.

• Battery voltage is about 12 V.

• Radiator cooling fan operates normally.

2) Make sure that high pressure valve (1) and low pressure valve (2) of manifold gauge are firmly

closed.

3) Connect high pressure charging hose (3) to high pressure service valve (5) on vehicle and low

pressure charging hose (4) to low pressure service

valve (6).

4) Bleed the air in charging hoses (3) and (4) by loosening their nuts respectively utilizing the

refrigerant pressure. When a hissing sound is heard,

immediately tighten nut.

CAUTION!

Do not connect high and low pressure

charging hoses in reverse.

Condition Possible cause Correction / Reference Item

Clattering noise is heard

from pulley Worn or damaged bearing

Replace tension pulley.

Pulley cranks upon

contact Cracked or loose bracket

Replace or retighten bracket.

ConditionPossible cause Correction / Reference Item

Whistling sound is heard

from A/C evaporator Depending on the combination of the

interior / exterior temperatures, engine

rpm and refrigerant pressure, the

refrigerant flowing out of the expansion

valve may, under certain conditions,

make a whistling sound At times, slightly decrea

sing refrigerant volume

may stop this noise.

Inspect expansion valve and replace if faulty.

Condition Possible cause Correction / Reference Item

Blower motor emits a

chirping sound in

proportion to its speed of

rotation Worn or damaged motor brushes or

commutator

Replace blower motor.

Fluttering noise or large

droning noise is heard

from blower motor Leaves or other debris introduced from

fresh air inlet to blower motor

Remove debris and make sure that the screen

at fresh air inlet is intact.

53

2

1

4 6

I4RS0A720006-01

Page 976 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-28 Air Conditioning System: Manual Type

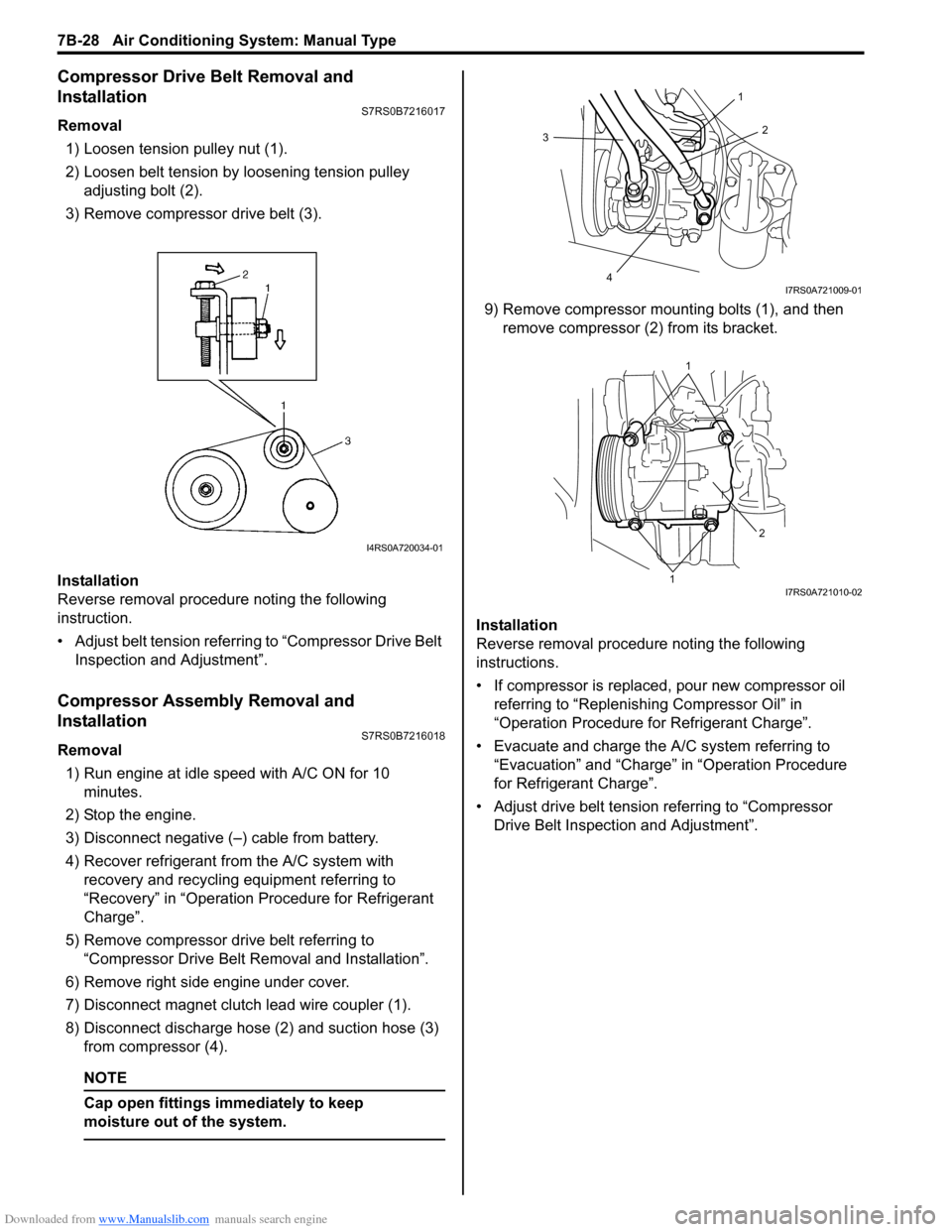

Compressor Drive Belt Removal and

Installation

S7RS0B7216017

Removal1) Loosen tension pulley nut (1).

2) Loosen belt tension by loosening tension pulley adjusting bolt (2).

3) Remove compressor drive belt (3).

Installation

Reverse removal procedure noting the following

instruction.

• Adjust belt tension referring to “Compressor Drive Belt Inspection and Adjustment”.

Compressor Assembly Removal and

Installation

S7RS0B7216018

Removal

1) Run engine at idle speed with A/C ON for 10 minutes.

2) Stop the engine.

3) Disconnect negative (–) cable from battery.

4) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

5) Remove compressor drive belt referring to “Compressor Drive Belt Re moval and Installation”.

6) Remove right side engine under cover.

7) Disconnect magnet clutch lead wire coupler (1).

8) Disconnect discharge hose (2) and suction hose (3) from compressor (4).

NOTE

Cap open fittings immediately to keep

moisture out of the system.

9) Remove compressor mounting bolts (1), and then remove compressor (2 ) from its bracket.

Installation

Reverse removal procedure noting the following

instructions.

• If compressor is replaced, pour new compressor oil referring to “Replenishi ng Compressor Oil” in

“Operation Procedure for Refrigerant Charge”.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

• Adjust drive belt tension referring to “Compressor Drive Belt Inspecti on and Adjustment”.

I4RS0A720034-01

3

4 2

1

I7RS0A721009-01

1

1 2

I7RS0A721010-02

Page 1143 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-105

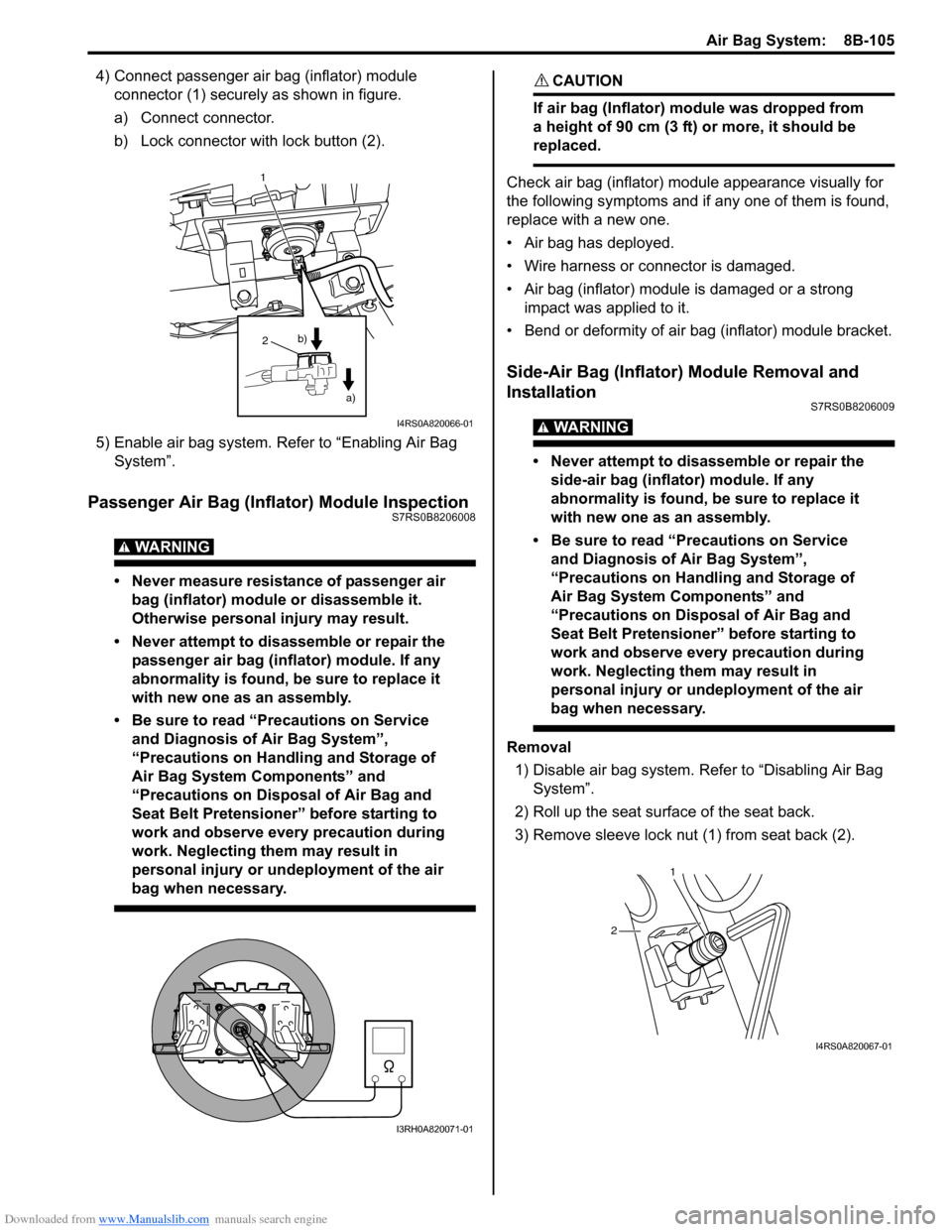

4) Connect passenger air bag (inflator) module connector (1) securely as shown in figure.

a) Connect connector.

b) Lock connector with lock button (2).

5) Enable air bag system. Refer to “Enabling Air Bag System”.

Passenger Air Bag (Inflator) Module InspectionS7RS0B8206008

WARNING!

• Never measure resistance of passenger air bag (inflator) module or disassemble it.

Otherwise personal injury may result.

• Never attempt to disassemble or repair the passenger air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

CAUTION!

If air bag (Inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• Wire harness or connector is damaged.

• Air bag (inflator) module is damaged or a strong impact was applied to it.

• Bend or deformity of air bag (inflator) module bracket.

Side-Air Bag (Inflator) Module Removal and

Installation

S7RS0B8206009

WARNING!

• Never attempt to disassemble or repair the side-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

Removal

1) Disable air bag system. Re fer to “Disabling Air Bag

System”.

2) Roll up the seat surface of the seat back.

3) Remove sleeve lock nut (1) from seat back (2).

1

2

a)

b)

I4RS0A820066-01

I3RH0A820071-01

1

2

I4RS0A820067-01

Page 1313 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-18

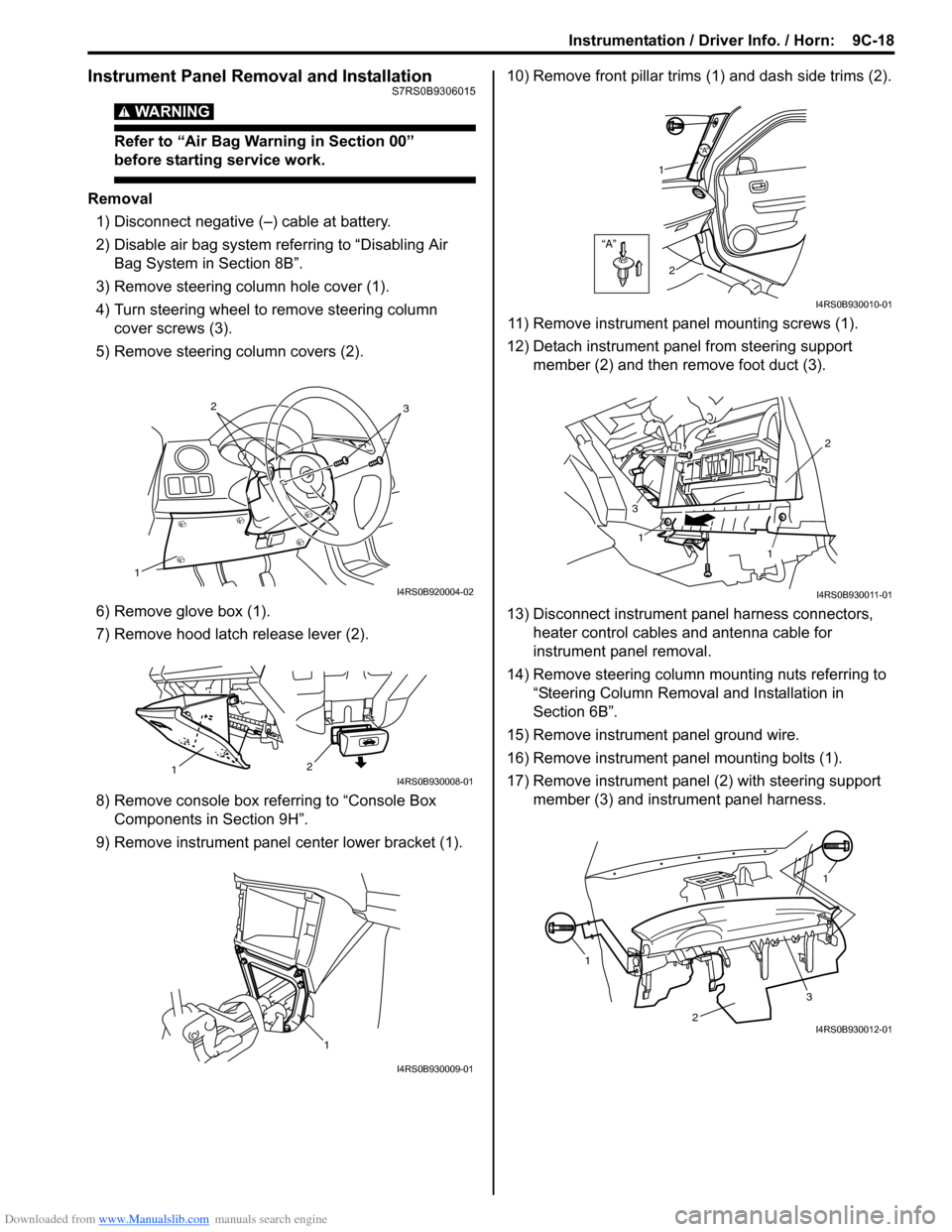

Instrument Panel Removal and InstallationS7RS0B9306015

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column hole cover (1).

4) Turn steering wheel to remove steering column cover screws (3).

5) Remove steering column covers (2).

6) Remove glove box (1).

7) Remove hood latch release lever (2).

8) Remove console box referring to “Console Box Components in Section 9H”.

9) Remove instrument panel center lower bracket (1). 10) Remove front pillar trims

(1) and dash side trims (2).

11) Remove instrument panel mounting screws (1).

12) Detach instrument panel from steering support member (2) and then remove foot duct (3).

13) Disconnect instrument panel harness connectors, heater control cables and antenna cable for

instrument panel removal.

14) Remove steering column mounting nuts referring to “Steering Column Remova l and Installation in

Section 6B”.

15) Remove instrument panel ground wire.

16) Remove instrument panel mounting bolts (1).

17) Remove instrument panel (2) with steering support member (3) and instrument panel harness.

1

32

I4RS0B920004-02

2

1I4RS0B930008-01

1

I4RS0B930009-01

“A”

“A”

1

2

I4RS0B930010-01

1

1 2

3

I4RS0B930011-01

1 1

2

3I4RS0B930012-01

Page 1366 of 1496

Downloaded from www.Manualslib.com manuals search engine 9G-4 Seats:

Rear Seat Removal and InstallationS7RS0B9706004

Removal1) Fold rear seat back forward.

2) Remove seat mounting bolts and nuts to remove seat assembly.

3) Disassemble and repair seat as necessary.

Installation

Reverse removal procedure to install rear seat.

• Tighten seat back striker mounting bolts according to “Rear Seat Components”.

• Torque to specifications in “Rear Seat Components”.

• When installing seat cushion, align seat cushion hook with center hinge bracket.

Specifications

Tightening Torque SpecificationsS7RS0B9707001

NOTE

The specified tightening torque is also described in the following.

“Front Seat Components”

“Rear Seat Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B9708001

NOTE

Required service material is also described in the following.

“Front Seat Components”

Material SUZUKI recommended product or Specification Note

Thread lock cement Thread Lock Cement Super 1303B P/No.: 99000–32030 �)

Thread Lock Cement 1305 P/No.: 99000–32100 �)