air line SUZUKI SWIFT 2006 2.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1294 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-12 Lighting Systems:

Front Fog Light Aiming Adjustment with Screen

(If Equipped)

S7RS0B9206018

Basic Aiming

NOTE

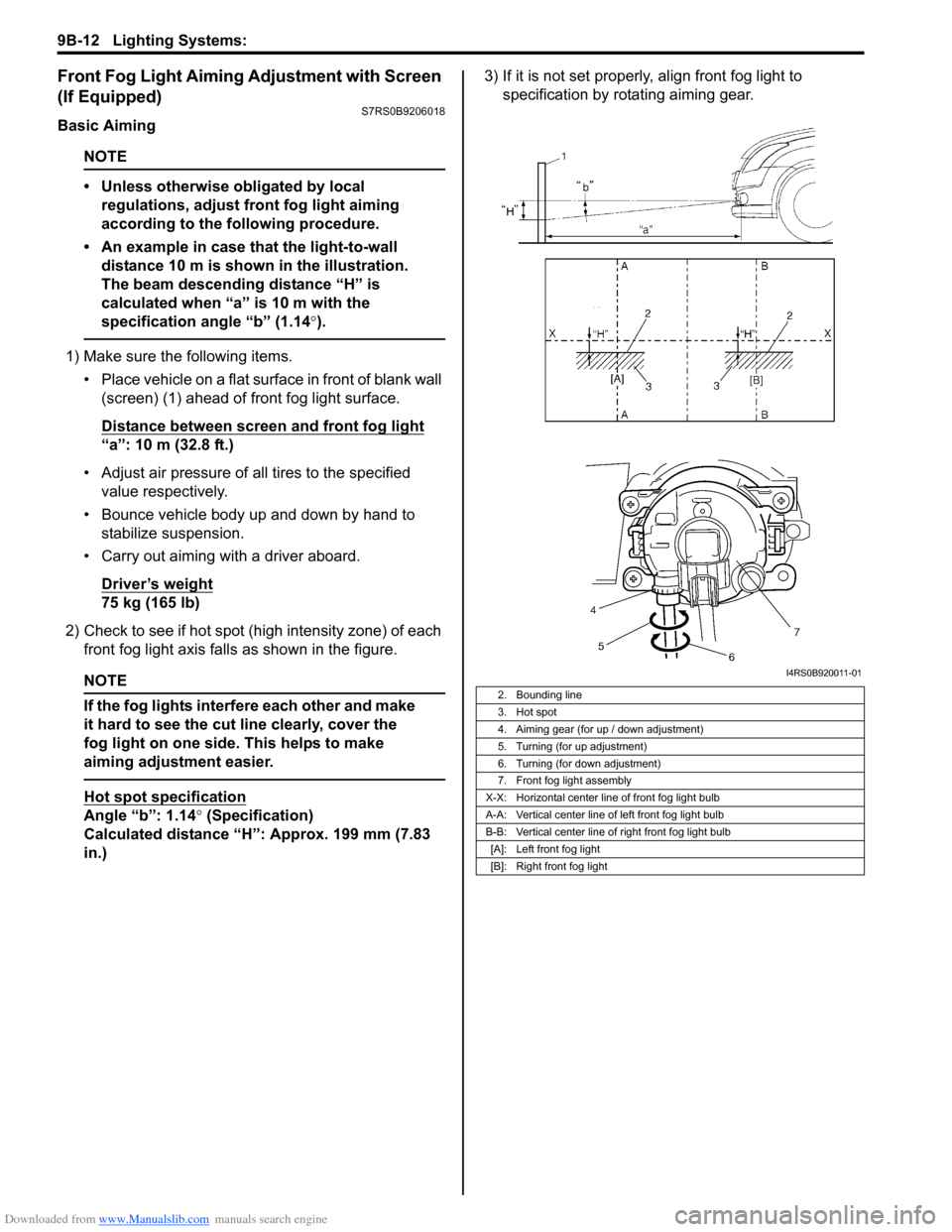

• Unless otherwise obligated by local regulations, adjust front fog light aiming

according to the following procedure.

• An example in case that the light-to-wall distance 10 m is shown in the illustration.

The beam descending distance “H” is

calculated when “a” is 10 m with the

specification angle “b” (1.14 °).

1) Make sure the following items.

• Place vehicle on a flat surface in front of blank wall (screen) (1) ahead of front fog light surface.

Distance between screen and front fog light

“a”: 10 m (32.8 ft.)

• Adjust air pressure of all tires to the specified value respectively.

• Bounce vehicle body up and down by hand to stabilize suspension.

• Carry out aiming with a driver aboard.

Driver’s weight

75 kg (165 lb)

2) Check to see if hot spot (h igh intensity zone) of each

front fog light axis falls as shown in the figure.

NOTE

If the fog lights interfere each other and make

it hard to see the cut line clearly, cover the

fog light on one side. This helps to make

aiming adjustment easier.

Hot spot specification

Angle “b”: 1.14° (Specification)

Calculated distance “H”: Approx. 199 mm (7.83

in.) 3) If it is not set properly

, align front fog light to

specification by rotating aiming gear.

2. Bounding line

3. Hot spot

4. Aiming gear (for up / down adjustment)

5. Turning (for up adjustment)

6. Turning (for down adjustment)

7. Front fog light assembly

X-X: Horizontal center line of front fog light bulb

A-A: Vertical center line of left front fog light bulb

B-B: Vertical center line of right front fog light bulb [A]: Left front fog light

[B]: Right front fog light

I4RS0B920011-01

Page 1300 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-5 Instrumentation / Driver Info. / Horn:

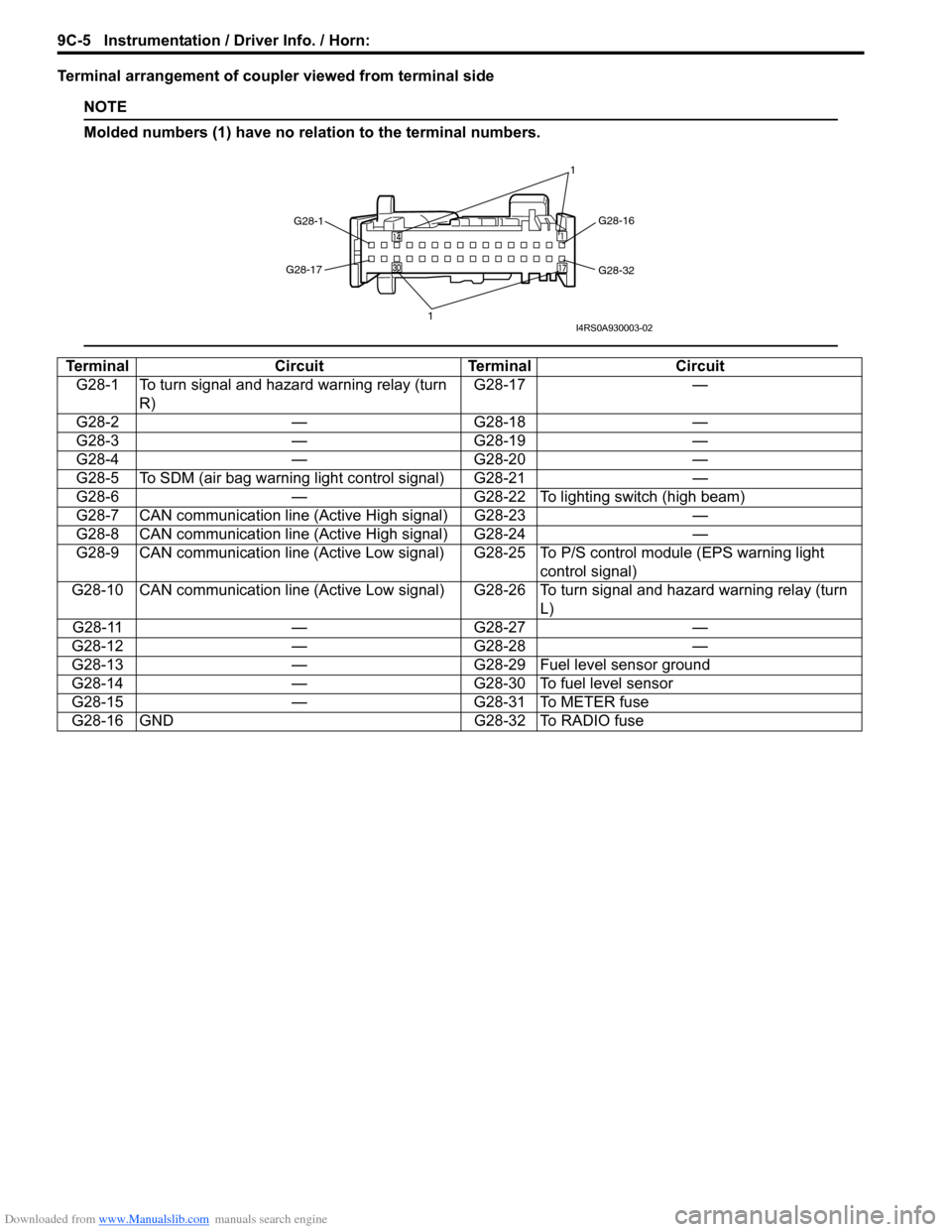

Terminal arrangement of coupler viewed from terminal side

NOTE

Molded numbers (1) have no relation to the terminal numbers.

TerminalCircuitTerminal Circuit

G28-1 To turn signal and hazard warning relay (turn R) G28-17

—

G28-2 —G28-18 —

G28-3 —G28-19 —

G28-4 —G28-20 —

G28-5 To SDM (air bag warning light control signal) G28-21 —

G28-6 —G28-22 To lighting switch (high beam)

G28-7 CAN communication line (Active High signal) G28-23 —

G28-8 CAN communication line (Active High signal) G28-24 —

G28-9 CAN communication line (Active Low signal) G 28-25 To P/S control module (EPS warning light

control signal)

G28-10 CAN communication line (Active Low signal) G28-26 To turn signal and hazard warning relay (turn L)

G28-11 —G28-27 —

G28-12 —G28-28 —

G28-13 —G28-29 Fuel level sensor ground

G28-14 —G28-30 To fuel level sensor

G28-15 —G28-31 To METER fuse

G28-16 GND G28-32 To RADIO fuse

G28-1 G28-16

G28-32

G28-17

1 1I4RS0A930003-02

Page 1342 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-15 Glass / Windows / Mirrors:

Rear End Door Window Defogger Wire

Inspection

S7RS0B9506014

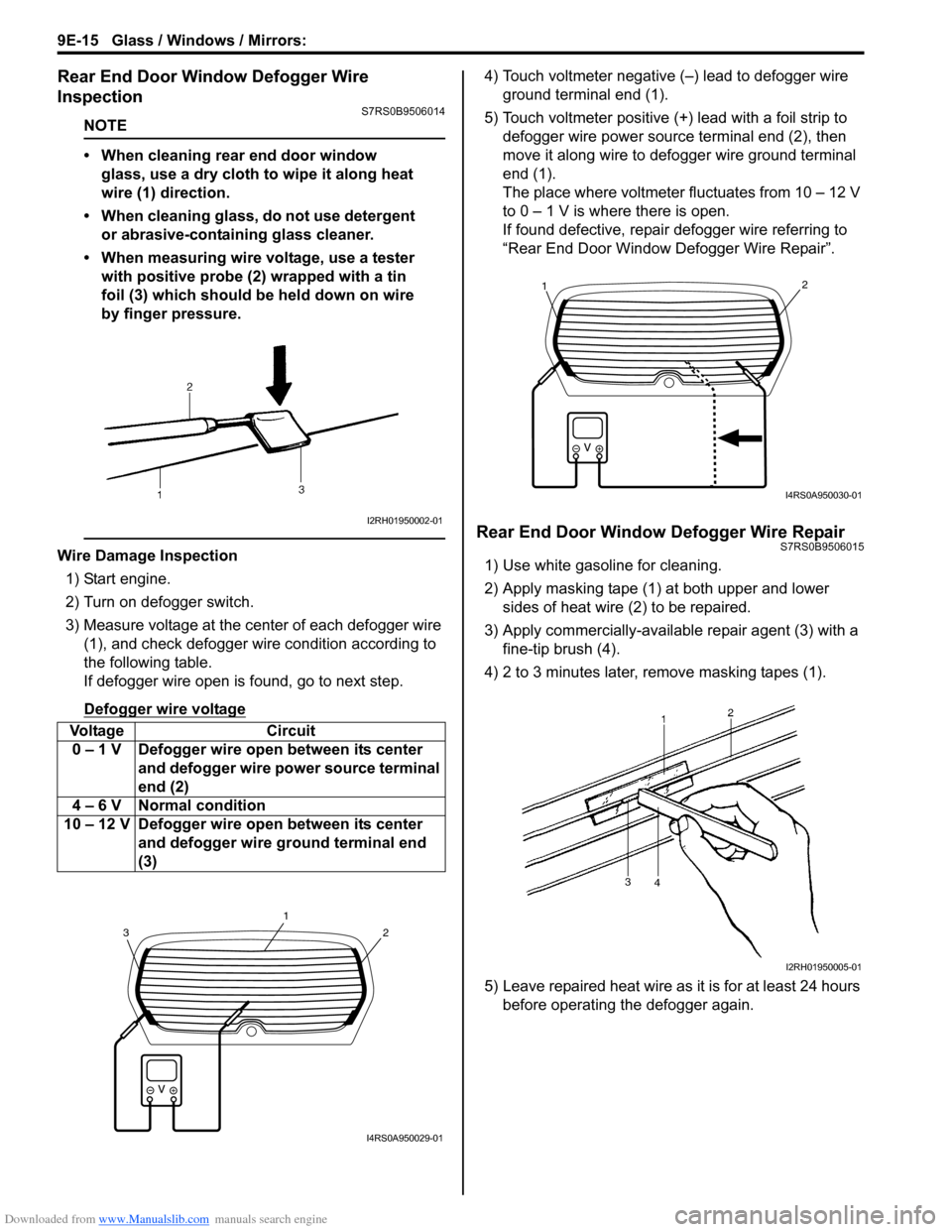

NOTE

• When cleaning rear end door window glass, use a dry cloth to wipe it along heat

wire (1) direction.

• When cleaning glass, do not use detergent or abrasive-containing glass cleaner.

• When measuring wire voltage, use a tester with positive probe (2) wrapped with a tin

foil (3) which should be held down on wire

by finger pressure.

Wire Damage Inspection

1) Start engine.

2) Turn on defogger switch.

3) Measure voltage at the center of each defogger wire (1), and check defogger wire condition according to

the following table.

If defogger wire open is found, go to next step.

Defogger wire voltage

4) Touch voltmeter negative (–) lead to defogger wire ground terminal end (1).

5) Touch voltmeter positive (+) lead with a foil strip to defogger wire power source terminal end (2), then

move it along wire to defogger wire ground terminal

end (1).

The place where voltmeter fluctuates from 10 – 12 V

to 0 – 1 V is where there is open.

If found defective, repair defogger wire referring to

“Rear End Door Window Defogger Wire Repair”.

Rear End Door Window Defogger Wire RepairS7RS0B9506015

1) Use white gasoline for cleaning.

2) Apply masking tape (1) at both upper and lower sides of heat wire (2) to be repaired.

3) Apply commercially-available repair agent (3) with a fine-tip brush (4).

4) 2 to 3 minutes later, remove masking tapes (1).

5) Leave repaired heat wire as it is for at least 24 hours before operating the defogger again.

Voltage Circuit

0 – 1 V Defogger wire open between its center and defogger wire power source terminal

end (2)

4 – 6 V Normal condition

10 – 12 V Defogger wire open between its center and defogger wire ground terminal end

(3)

I2RH01950002-01

2

1

3

I4RS0A950029-01

21

I4RS0A950030-01

I2RH01950005-01

Page 1402 of 1496

Downloaded from www.Manualslib.com manuals search engine 10-ii Table of Contents

DTC P1615: ID Code Does Not Registered (Vehicle equipped with keyless start system

only) ................................................................10C-9

DTC P1616: Different Registration ID Codes (Vehicle equipped with keyless start system

only) ..............................................................10C-10

DTC P1618: CAN Communication Error (Reception Error for Keyless Start Control

Module) (Vehicle equipped with keyless

start system only) ..........................................10C-11

DTC P1621: Immobilizer Communication Line Error ......................................................10C-12

DTC P1622: EEPROM Reading / Writing Error ..............................................................10C-13

DTC P1623: Unregistered Transponder .........10C-13

DTC P1625: Immobilizer An tenna Error..........10C-14

DTC P1636: Immobilizer Information Registration Failure .......................................10C-14

DTC P1638: Immobilizer Information Mismatched ...................................................10C-15

Inspection of Immobilizer Control Module (ICM) and Its Circuit ....... ...............................10C-16

Repair Instructions ........... ...............................10C-18

Immobilizer Control Mo dule (ICM) Removal

and Installation ..............................................10C-18

Registration of the Ignition Key .......................10C-18

Procedure after ECM Replacement ................10C-18

Special Tools and Equipmen t .........................10C-19

Special Tool ....................................................10C-19

Keyless Start System ....... ......................10E-1

General Description ........................................... 10E-1

Keyless Start System Description ..................... 10E-1

Parts and Functions .......................................... 10E-2

Keyless Engine Start Function .......................... 10E-3

Door Lock Function of Keyless Start System .... 10E-4

Operation Area of Remote Controller................ 10E-5

Alarm Function .................................................. 10E-6

CAN Communication System Description......... 10E-6

Schematic and Routing Diagram ...................... 10E-7 Keyless Start System El ectric Wiring Circuit

Diagram .......................................................... 10E-7

Diagnostic Information and Procedures .......... 10E-8 Precautions in Diagnosing Troubles ................. 10E-8

Self-Diagnosis Function .................................... 10E-8

Keyless Start System Diagn osis Introduction ... 10E-8 Keyless Start System Chec

k ............................. 10E-8

Customer Questionnaire (E xample) .................. 10E-9

Key Indicator Lamp Check .............................. 10E-10

DTC Check...................................................... 10E-10

DTC Table ....................................................... 10E-11

DTC Clearance ............................................... 10E-12

Keyless Start System Symp tom Diagnosis ..... 10E-12

Keyless Start System Operation Inspection .... 10E-13

Door Lock Operation (Keyless Start System) . 10E-14

Inspection of Keyless Start Control Module and Its Circuits .............................................. 10E-14

No DTC Detection After Performing DTC Check ............................................................ 10E-18

Key Indicator Lamp Circuit Check (Key indicator lamp doesn’t light when ignition

knob switch is pushed.) ................................. 10E-20

Keyless Start Control Module Power and Ground Circuit Check .................................... 10E-22

DTC No. 11: Communi cation Error with

Steering Lock Unit ......................................... 10E-23

DTC No. 13 / No. 14: Release Signal Error from Steering Lock Unit / Steering Lock Unit

Malfunction .................................................... 10E-24

DTC No. 21 / No. 22: Internal Error of Keyless Start Control Module (EEPROM reading

error) / (EEPROM writing error) ............ ........ 10E-24

DTC No. 31: Lost Commun ication with BCM .. 10E-25

DTC No. 33: Control Module Communication

Bus Off .......................................................... 10E-27

DTC No. 51 / No. 52 / No. 53: Driver Side / Passenger Side / Rear End Door Request

Switch Failure................................................ 10E-28

Repair Instructions ............ .............................. 10E-30

Antennas and Request Switches Removal and Installation .............................................. 10E-30

Front Door (Driver and Passenger Side), Rear End Door Request Switch Inspection............ 10E-31

Steering Lock Unit Removal and Installation .. 10E-31

Steering Lock Unit Inspection ......................... 10E-31

Front Door Lock Switch In spection ................. 10E-31

Keyless Start Control Module Removal and Installation ..................................................... 10E-32

Remote Controller Inspection.......................... 10E-32

Replacement of Remote Controller Battery .... 10E-32

Registration Procedure for Remote Controller

ID Code ......................................................... 10E-33

Page 1417 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-14

DTC TableS7RS0BA204004

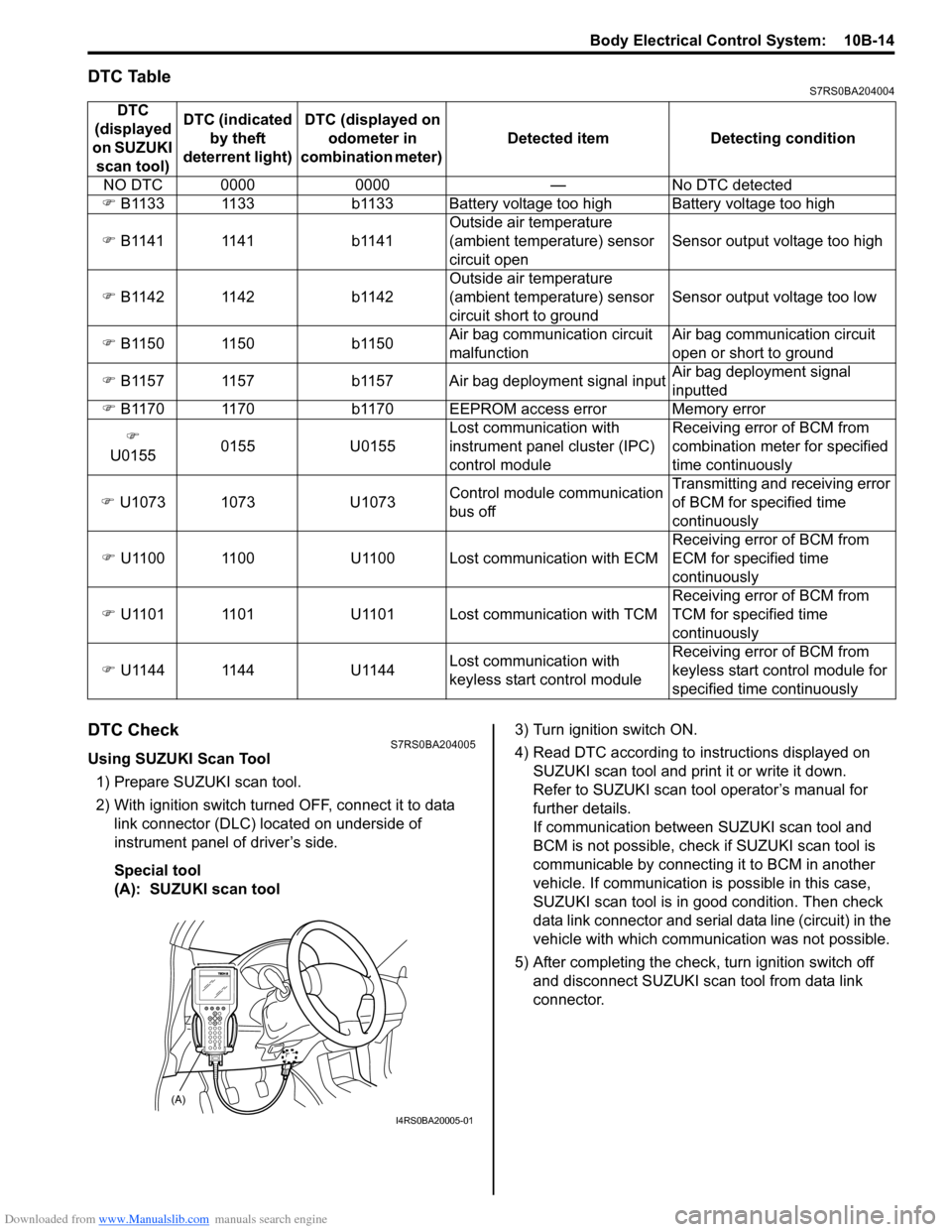

DTC CheckS7RS0BA204005

Using SUZUKI Scan Tool1) Prepare SUZUKI scan tool.

2) With ignition switch turned OFF, connect it to data link connector (DLC) located on underside of

instrument panel of driver’s side.

Special tool

(A): SUZUKI scan tool 3) Turn ignition switch ON.

4) Read DTC according to

instructions displayed on

SUZUKI scan tool and print it or write it down.

Refer to SUZUKI scan tool operator’s manual for

further details.

If communication between SUZUKI scan tool and

BCM is not possible, check if SUZUKI scan tool is

communicable by connecting it to BCM in another

vehicle. If communication is possible in this case,

SUZUKI scan tool is in good condition. Then check

data link connector and serial data line (circuit) in the

vehicle with which communica tion was not possible.

5) After completing the check, turn ignition switch off and disconnect SUZUKI scan tool from data link

connector.

DTC

(displayed

on SUZUKI scan tool) DTC (indicated

by theft

deterrent light) DTC (displayed on

odometer in

combination meter) Detected item Detecting condition

NO DTC 0000 0000 — No DTC detected

�) B1133 1133 b1133 Battery voltage too high Battery voltage too high

�) B1141 1141 b1141 Outside air temperature

(ambient temperature) sensor

circuit openSensor output voltage too high

�) B1142 1142 b1142 Outside air temperature

(ambient temperature) sensor

circuit short to groundSensor output voltage too low

�) B1150 1150 b1150 Air bag communication circuit

malfunctionAir bag communication circuit

open or short to ground

�) B1157 1157 b1157 Air bag deployment signal input Air bag deployment signal

inputted

�) B1170 1170 b1170 EEPROM access error Memory error

�)

U0155 0155 U0155 Lost communication with

instrument panel cluster (IPC)

control moduleReceiving error of BCM from

combination mete

r for specified

time continuously

�) U1073 1073 U1073 Control module communication

bus offTransmitting and receiving error

of BCM for specified time

continuously

�) U1100 1100 U1100 Lost communication with ECM Receiving error of BCM from

ECM for specified time

continuously

�) U1101 1101 U1101 Lost communication with TCM Receiving error of BCM from

TCM for specified time

continuously

�) U1144 1144 U1144 Lost communication with

keyless start control moduleReceiving error of BCM from

keyless start control module for

specified time continuously

(A)

I4RS0BA20005-01

Page 1435 of 1496

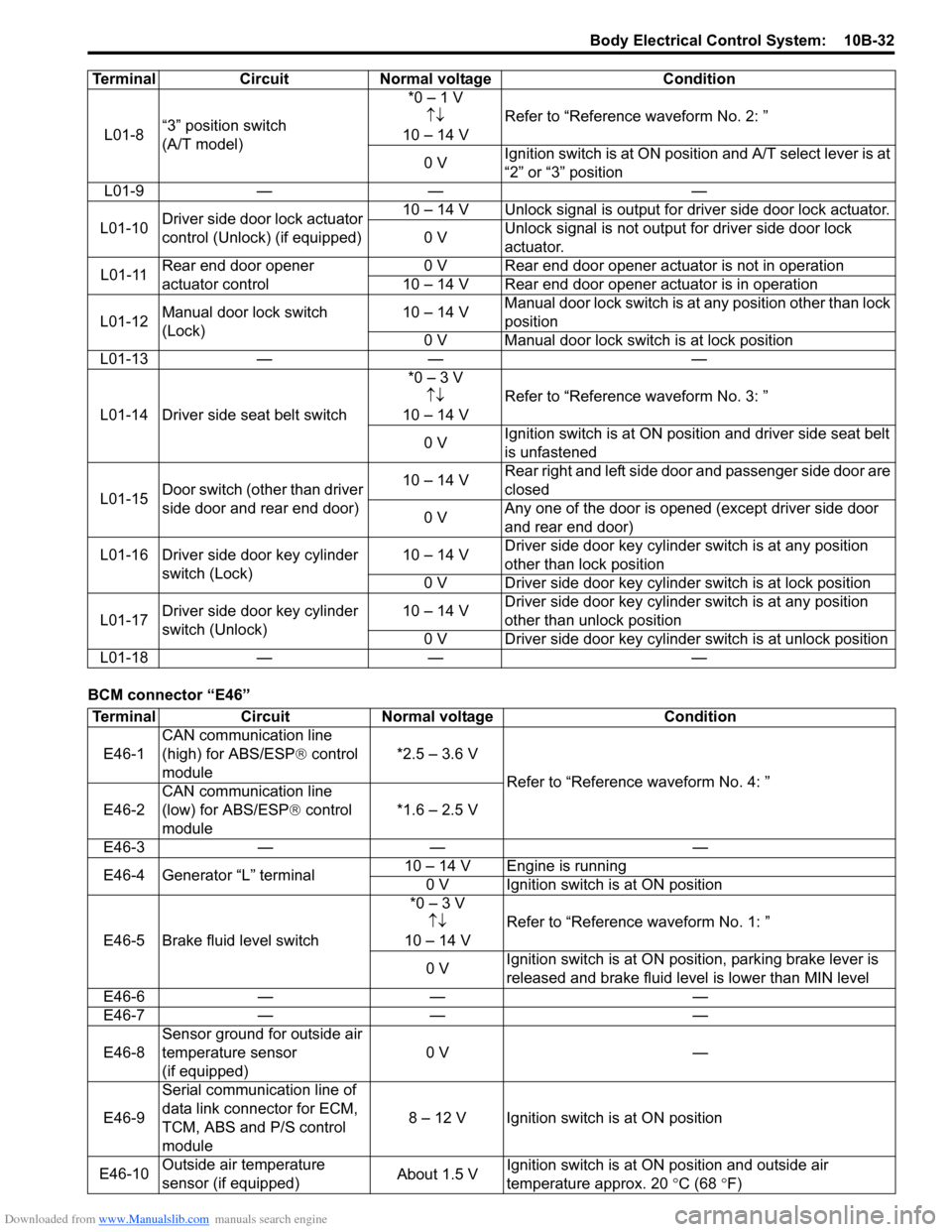

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-32

BCM connector “E46”L01-8

“3” position switch

(A/T model) *0 – 1 V

↑↓

10 – 14 V Refer to “Reference waveform No. 2: ”

0 V Ignition switch is at ON positi

on and A/T select lever is at

“2” or “3” position

L01-9 — — —

L01-10 Driver side door lock actuator

control (Unlock) (if equipped) 10 – 14 V Unlock signal is output for driver side door lock actuator.

0 V Unlock signal is not output for driver side door lock

actuator.

L01-11 Rear end door opener

actuator control 0 V Rear end door opener actuator is not in operation

10 – 14 V Rear end door opener actuator is in operation

L01-12 Manual door lock switch

(Lock) 10 – 14 V

Manual door lock switch is at any position other than lock

position

0 V Manual door lock swit ch is at lock position

L01-13 — — —

L01-14 Driver side seat belt switch *0 – 3 V

↑↓

10 – 14 V Refer to “Reference waveform No. 3: ”

0 V Ignition switch is at ON position and driver side seat belt

is unfastened

L01-15 Door switch (other than driver

side door and rear end door) 10 – 14 V

Rear right and left side door and passenger side door are

closed

0 V Any one of the door is opened (except driver side door

and rear end door)

L01-16 Driver side door key cylinder switch (Lock) 10 – 14 V

Driver side door key cylinder switch is at any position

other than lock position

0 V Driver side door key cylinder switch is at lock position

L01-17 Driver side door key cylinder

switch (Unlock) 10 – 14 V

Driver side door key cylinder switch is at any position

other than unlock position

0 V Driver side door key cylinder switch is at unlock position

L01-18 — — —

Terminal Circuit Normal voltage Condition

Terminal

CircuitNormal voltage Condition

E46-1 CAN communication line

(high) for ABS/ESP

® control

module *2.5 – 3.6 V

Refer to “Reference waveform No. 4: ”

E46-2 CAN communication line

(low) for ABS/ESP

® control

module *1.6 – 2.5 V

E46-3 — — —

E46-4 Generator “L” terminal 10 – 14 V Engine is running

0 V Ignition switch is at ON position

E46-5 Brake fluid level switch *0 – 3 V

↑↓

10 – 14 V Refer to “Reference waveform No. 1: ”

0 V Ignition switch is at ON position, parking brake lever is

released and brake fluid level is lower than MIN level

E46-6 — — —

E46-7 — — —

E46-8 Sensor ground for outside air

temperature sensor

(if equipped) 0 V

—

E46-9 Serial communication line of

data link connector for ECM,

TCM, ABS and

P/S control

module 8 – 12 V Ignition switch is at ON position

E46-10 Outside air temperature

sensor (if equipped) About 1.5 VIgnition switch is at ON position and outside air

temperature approx. 20

°C (68 °F)

Page 1437 of 1496

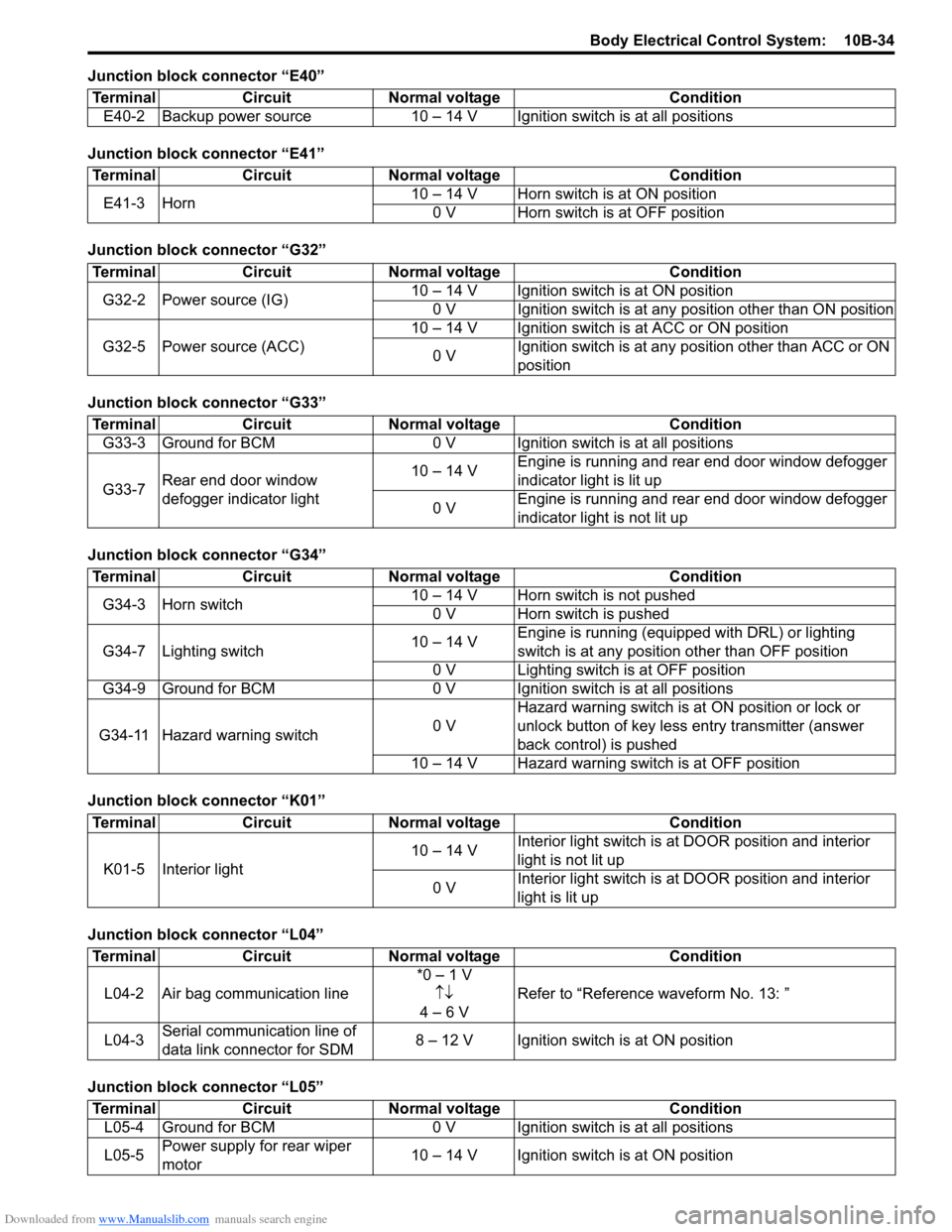

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-34

Junction block connector “E40”

Junction block connector “E41”

Junction block connector “G32”

Junction block connector “G33”

Junction block connector “G34”

Junction block connector “K01”

Junction block connector “L04”

Junction block connector “L05”Terminal Circuit Normal voltage Condition

E40-2 Backup power source 10 – 14 V Igni tion switch is at all positions

TerminalCircuitNormal voltage Condition

E41-3 Horn 10 – 14 V Horn switch is at ON position

0 V Horn switch is at OFF position

Terminal CircuitNormal voltage Condition

G32-2 Power source (IG) 10 – 14 V Ignition switch is at ON position

0 V Ignition switch is at any position other than ON position

G32-5 Power source (ACC) 10 – 14 V Ignition switch is at ACC or ON position

0 V Ignition switch is at any position other than ACC or ON

position

Terminal

CircuitNormal voltage Condition

G33-3 Ground for BCM 0 V Ignition switch is at all positions

G33-7 Rear end door window

defogger indicator light 10 – 14 V

Engine is running and rear end door window defogger

indicator light is lit up

0 V Engine is running and rear end door window defogger

indicator light is not lit up

Terminal

CircuitNormal voltage Condition

G34-3 Horn switch 10 – 14 V Horn switch is not pushed

0 V Horn switch is pushed

G34-7 Lighting switch 10 – 14 VEngine is running (equipped with DRL) or lighting

switch is at any position other than OFF position

0 V Lighting switch is at OFF position

G34-9 Ground for BCM 0 V Ignition switch is at all positions

G34-11 Hazard warning switch 0 VHazard warning switch is at

ON position or lock or

unlock button of key less entry transmitter (answer

back control) is pushed

10 – 14 V Hazard warning switch is at OFF position

Terminal CircuitNormal voltage Condition

K01-5 Interior light 10 – 14 V

Interior light switch is at

DOOR position and interior

light is not lit up

0 V Interior light switch is at

DOOR position and interior

light is lit up

Terminal CircuitNormal voltage Condition

L04-2 Air bag communication line *0 – 1 V

↑↓

4 – 6 V Refer to “Reference

waveform No. 13: ”

L04-3 Serial communication line of

data link connector for SDM 8 – 12 V Ignition switch is at ON position

Terminal

CircuitNormal voltage Condition

L05-4 Ground for BCM 0 V Ignition switch is at all positions

L05-5 Power supply for rear wiper

motor 10 – 14 V Ignition switch is at ON position

Page 1455 of 1496

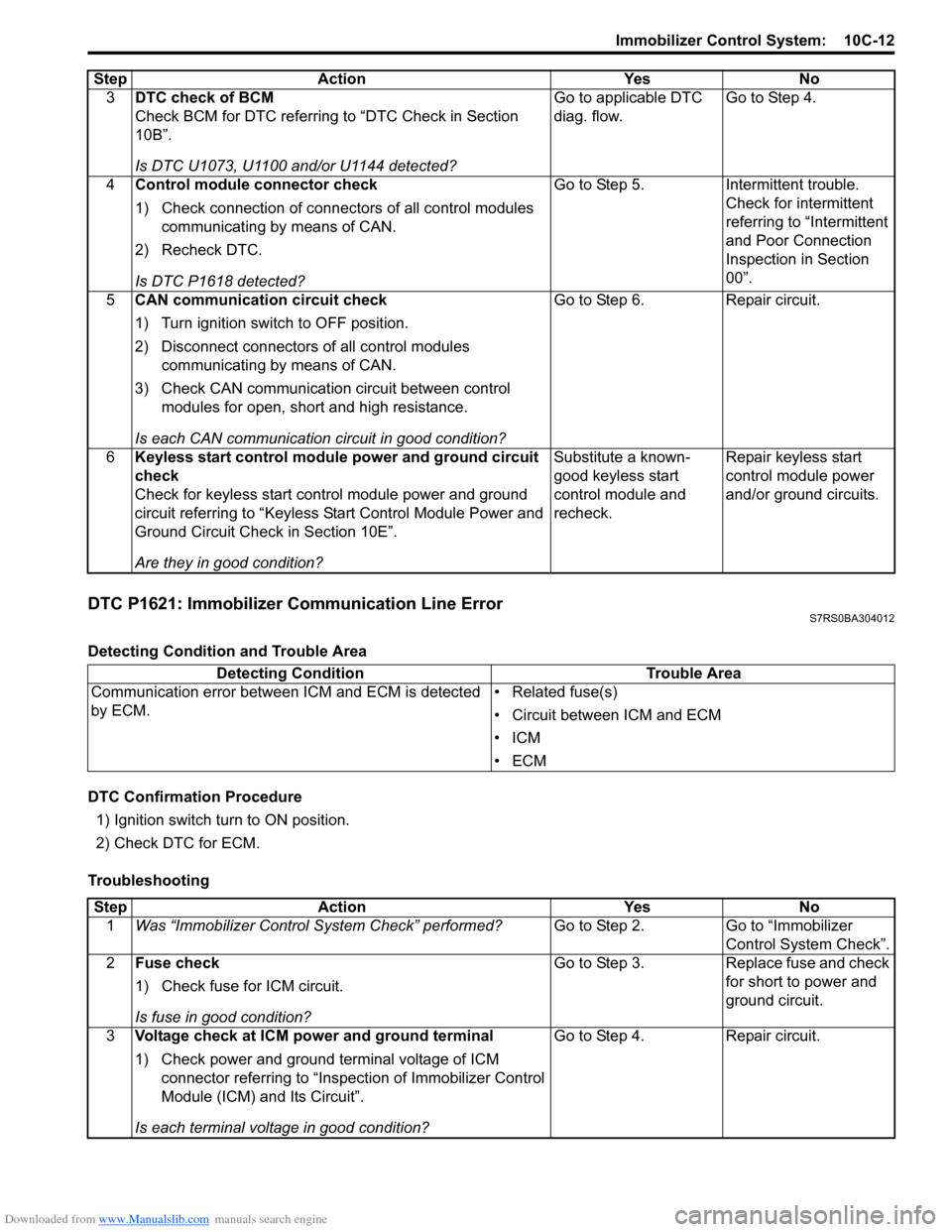

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-12

DTC P1621: Immobilizer Communication Line ErrorS7RS0BA304012

Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Ignition switch turn to ON position.

2) Check DTC for ECM.

Troubleshooting 3

DTC check of BCM

Check BCM for DTC referring to “DTC Check in Section

10B”.

Is DTC U1073, U1100 and/or U1144 detected? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is DTC P1618 detected? Go to Step 5. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 6. Repair circuit.

6 Keyless start control module power and ground circuit

check

Check for keyless start control module power and ground

circuit referring to “Keyless St art Control Module Power and

Ground Circuit Check in Section 10E”.

Are they in good condition? Substitute a known-

good keyless start

control module and

recheck.

Repair keyless start

control module power

and/or ground circuits.

Step Action Yes No

Detecting Condition

Trouble Area

Communication error between ICM and ECM is detected

by ECM. • Related fuse(s)

• Circuit between ICM and ECM

•ICM

•ECM

Step

Action YesNo

1 Was “Immobilizer Control S ystem Check” performed? Go to Step 2.Go to “Immobilizer

Control System Check”.

2 Fuse check

1) Check fuse for ICM circuit.

Is fuse in good condition? Go to Step 3.

Replace fuse and check

for short to power and

ground circuit.

3 Voltage check at ICM power and ground terminal

1) Check power and ground terminal voltage of ICM

connector referring to “Inspe ction of Immobilizer Control

Module (ICM) and Its Circuit”.

Is each terminal voltage in good condition? Go to Step 4.

Repair circuit.

Page 1470 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-8 Keyless Start System:

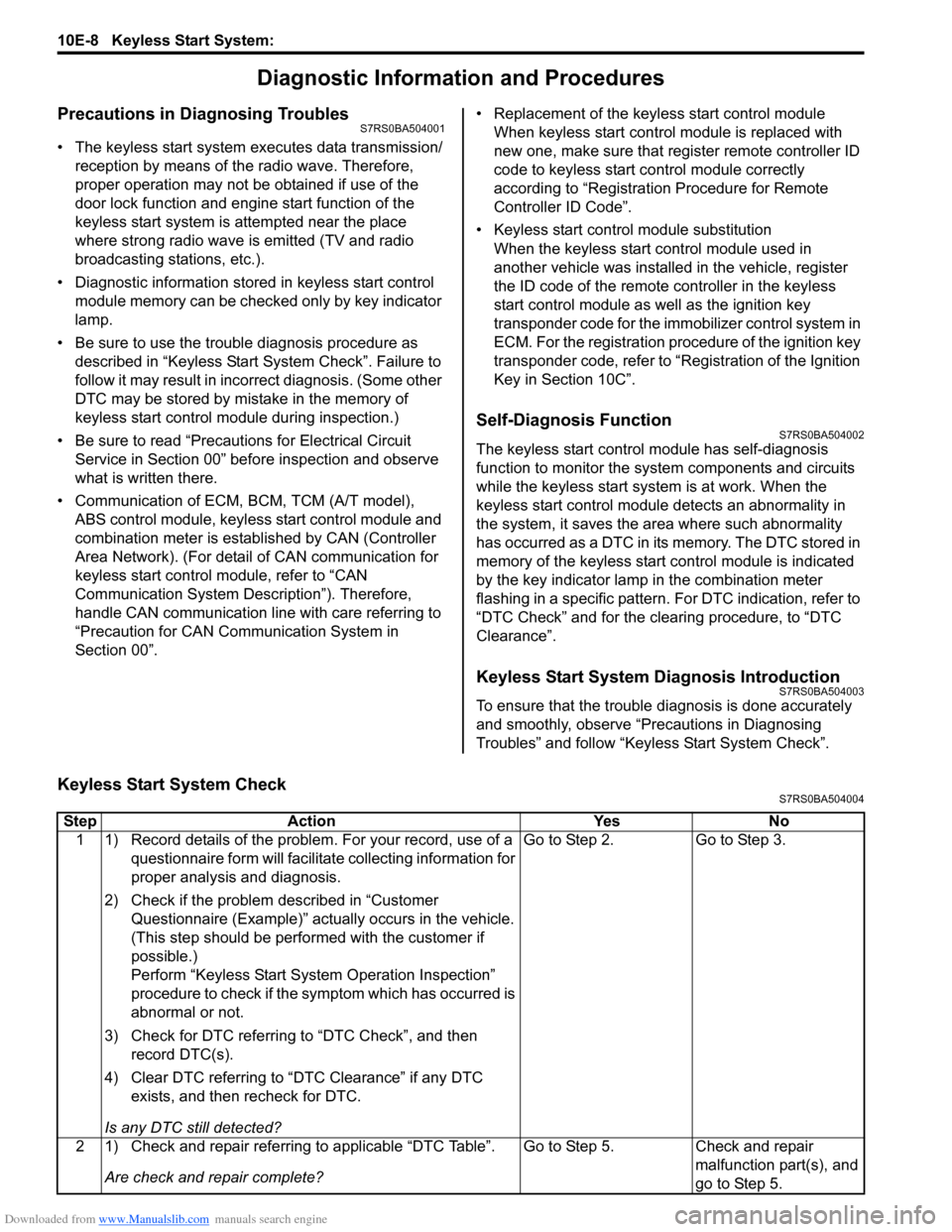

Diagnostic Information and Procedures

Precautions in Diagnosing TroublesS7RS0BA504001

• The keyless start system executes data transmission/reception by means of th e radio wave. Therefore,

proper operation may not be obtained if use of the

door lock function and engine start function of the

keyless start system is attempted near the place

where strong radio wave is emitted (TV and radio

broadcasting stations, etc.).

• Diagnostic information stored in keyless start control

module memory can be checked only by key indicator

lamp.

• Be sure to use the trouble diagnosis procedure as described in “Keyless Start System Check”. Failure to

follow it may result in incorrect diagnosis. (Some other

DTC may be stored by mistake in the memory of

keyless start control module during inspection.)

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• Communication of ECM, BCM, TCM (A/T model), ABS control module, keyless start control module and

combination meter is estab lished by CAN (Controller

Area Network). (For detail of CAN communication for

keyless start control module, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”. • Replacement of the keyless start control module

When keyless start control module is replaced with

new one, make sure that r egister remote controller ID

code to keyless start co ntrol module correctly

according to “Registration Procedure for Remote

Controller ID Code”.

• Keyless start control module substitution When the keyless start control module used in

another vehicle was installed in the vehicle, register

the ID code of the remote controller in the keyless

start control module as well as the ignition key

transponder code fo r the immobilizer control system in

ECM. For the registration procedure of the ignition key

transponder code, refer to “Registration of the Ignition

Key in Section 10C”.

Self-Diagnosis FunctionS7RS0BA504002

The keyless start control module has self-diagnosis

function to monitor the system components and circuits

while the keyless start system is at work. When the

keyless start control module detects an abnormality in

the system, it saves the ar ea where such abnormality

has occurred as a DTC in its memory. The DTC stored in

memory of the keyless start control module is indicated

by the key indicator lamp in the combination meter

flashing in a specific pattern. For DTC indication, refer to

“DTC Check” and for the clearing procedure, to “DTC

Clearance”.

Keyless Start System Diagnosis IntroductionS7RS0BA504003

To ensure that the trouble diagnosis is done accurately

and smoothly, observe “Precautions in Diagnosing

Troubles” and follow “Keyless Start System Check”.

Keyless Start System CheckS7RS0BA504004

Step Action YesNo

1 1) Record details of the problem. For your record, use of a questionnaire form will facilit ate collecting information for

proper analysis and diagnosis.

2) Check if the problem described in “Customer Questionnaire (Example)” actually occurs in the vehicle.

(This step should be performed with the customer if

possible.)

Perform “Keyless Start System Operation Inspection”

procedure to check if the symptom which has occurred is

abnormal or not.

3) Check for DTC referring to “DTC Check”, and then record DTC(s).

4) Clear DTC referring to “DTC Clearance” if any DTC exists, and then recheck for DTC.

Is any DTC still detected? Go to Step 2.

Go to Step 3.

2 1) Check and repair referring to applicable “DTC Table”. Are check and repair complete? Go to Step 5.

Check and repair

malfunction part(s), and

go to Step 5.