Fender SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 4 of 1496

Downloaded from www.Manualslib.com manuals search engine 00

0

1

2

3

4

5

6

7

8

9

10

11

Vo l u m e 1

Precautions............................................................... 00-iPrecautions ............................................................ 00-1

General Information ................ ................................... 0-i

General Information ............................................... 0A-1

Maintenance and Lubricatio n ................................. 0B-1

Engine ......................................................................... 1-i Precautions .............................................................. 1-1

Engine General Information and Diagnosis ........... 1A-1

Aux. Emission Control Devices .............................. 1B-1

Engine Electrical Devices....................................... 1C-1

Engine Mechanical ................................................. 1D-1

Engine Lubrication System .................................... 1E-1

Engine Cooling System .......................................... 1F-1

Fuel System ...........................................................1G-1

Ignition System....................................................... 1H-1

Starting System ....................................................... 1I-1

Charging System.....................................................1J-1

Exhaust System ..................................................... 1K-1

Suspension ................................................................. 2-i Precautions .............................................................. 2-1

Suspension General Diagnosis .............................. 2A-1

Front Suspension ................................................... 2B-1

Rear Suspension................ .................................... 2C-1

Wheels and Tires ................................................... 2D-1

Driveline / Axle ........................................................... 3-i Precautions .............................................................. 3-1

Drive Shaft / Axle ................................................... 3A-1

Brakes ......................................................................... 4-i Precautions .............................................................. 4-1

Brake Control System and Diagnosis .................... 4A-1

Front Brakes........................................................... 4B-1

Rear Brakes ........................................................... 4C-1

Parking Brake......................................................... 4D-1

ABS ........................................................................ 4E-1

Electronic Stability Program ................................... 4F-1

Vo l u m e 2

Precautions ............................................................... 00-iPrecautions ............................................................ 00-1

Transmission / Transaxle .... ...................................... 5-i

Precautions .............................................................. 5-1

Automatic Transmission/Transaxle ........................ 5A-1

Manual Transmission/Transaxle ............................ 5B-1

Clutch .....................................................................5C-1

Steering ....................................................................... 6-i Precautions .............................................................. 6-1

Steering General Diagnosis ................................... 6A-1

Steering Wheel and Column .................................. 6B-1

Power Assisted Steering System ...........................6C-1

HVAC ........................................................................... 7-i Precautions .............................................................. 7-1

Heater and Ventilation............................................ 7A-1

Air Conditioning System ......................................... 7B-1

Restraint ...................................................................... 8-i Precautions .............................................................. 8-1

Seat Belts ............................................................... 8A-1

Air Bag System ...................................................... 8B-1

Body, Cab and Accessories .... .................................. 9-i

Precautions .............................................................. 9-1

Wiring Systems ...................................................... 9A-1

Lighting Systems .................................................... 9B-1

Instrumentation / Driver Info. / Horn .......................9C-1

Wipers / Washers ...................................................9D-1

Glass / Windows / Mirrors ...................................... 9E-1

Security and Locks ................................................. 9F-1

Seats ..................................................................... 9G-1

Interior Trim ............................................................9H-1

Hood / Fenders / Doors .......................................... 9J-1

Body Structure ....................................................... 9K-1

Paint / Coatings ...................................................... 9L-1

Exterior Trim .......................................................... 9M-1

Control Systems ....................................................... 10-i Precautions ............................................................ 10-1

Body Electrical Control Sy stem ............................ 10B-1

Immobilizer Control System .................................10C-1

Keyless Start System ........................................... 10E-1

TABLE OF CONTENTS

Page 9 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-4

General PrecautionsS7RS0B0000002

The WARNING and CAUTION describe some general

precautions that you should observe when servicing a

vehicle. These general precautions apply to many of the

service procedures, and they will not necessarily be

repeated with each procedure to which they apply.

WARNING!

• Whenever raising a vehicle for service, be sure to follow the instructions under

“Vehicle Lifting Points in Section 0A”.

• When it is necessary to do service work with the engine running, make sure that

the parking brake is set fully and the

transmission is in Neutral (for manual

transmission vehicles) or Park (for

automatic transmission vehicles), Keep

hands, hair, clothing, tools, etc. away from

the fan and belts when the engine is

running.

• When it is necessary to run the engine indoors, make sure that the exhaust gas is

forced outdoors.

• Do not perform service work in areas where combustible materials can come in

contact with a hot exhaust system. When

working with toxic or flammable materials

(such as gasoline and refrigerant), make

sure that the area you work in is well-

ventilated.

• To avoid getting burned, keep away from hot metal parts such as the radiator,

exhaust manifold, tail pipe, muffler, etc.

• New and used engine oil can be hazardous. Children and pets may be

harmed by swallowing new or used oil.

Keep new and used oil and used engine oil

filters away from children and pets.

Continuous contact with used engine oil

has been found to cause [skin] cancer in

laboratory animals. Brief contact with used

oil may irritate skin. To minimize your

exposure to used engine oil, wear a long-

sleeve shirt and moisture-proof gloves

(such as dish washing gloves) when

changing engine oil. If engine oil contacts

your skin, wash thoroughly with soap and

water. Launder any clothing or rags if wet

with oil, recycle or properly dispose of

used oil and filters. • Be sure to observe following instructions

when handling service materials such as

fuel, oil, fluid, coolant, grease, sealant,

thread lock cement, etc. Otherwise, your

health may be ruined.

– Whenever handling any of these service materials, wear safety glasses to protect

your eyes. If it gets into your eye, it may

cause inflammation.

– Whenever handling any of these service materials, wear moistu re-proof gloves to

protect your skin. If it adheres to your

skin, it may cause inflammation.

– Do not swallow any of these service materials. It would cause diarrhea or

nausea.

– Keep all these materials out of children’s reach.

• Make sure the bonnet is fully closed and latched before driving. If it is not, it can fly

up unexpectedly during driving,

obstructing your view and resulting in an

accident.

• Before starting any service work, cover fenders, seats and any other parts that are likely to get scratched or

stained during servicing. Also, be aware that what you

wear (e.g., buttons) ma y cause damage to the

vehicle’s finish.

I2RH01010025-01

Page 364 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-1 Engine Cooling System:

Engine

Engine Cooling System

General Description

Cooling System DescriptionS7RS0B1601001

The cooling system consists of the radiator cap, radiator, coolant reservoir, hoses, water pump, cooling fan and

thermostat. The radiator is of tube-and-fin type.

Coolant DescriptionS7RS0B1601002

WARNING!

• Do not remove radiator cap to check engine coolant level; check coolant visually at the see-through coolant reservoir. Coolant should be added only to reservoir as necessary.

• As long as there is pressure in the cooling system, the temperature can be considerably higher than the boiling temperature of the solution in the radiator without causing the solution to boil. Removal

of the radiator cap while engine is hot and pressure is high will cause the solution to boil

instantaneously and possibly with explosive force, spewing the solution over engine, fenders and

person removing cap. If the solution contains flammable anti-freeze such as alcohol (not

recommended for use at any time), there is also the possibility of causing a serious fire.

• Check to make sure that engine coolant temperature is cold before removing any part of cooling system.

• Also be sure to disconnect negative cable from battery terminal before removing any part.

The coolant recovery system is standard. The coolant in the radiator expands with heat, and the coolant is overflowed

to the reservoir.

When the system cools down, the coolant is drawn back into the radiator.

The cooling system has be en filled with a quality coolant that is a 50/50 mixture of water and ethylene glycol

antifreeze.

This 50/50 mixture coolant solution provides freezing protection to –36 °C (–33 °F).

• Maintain cooling system freeze protection at –36 °C (–33 °F) to ensure protection against corrosion and loss of

coolant from boiling. This should be done even if freezing temperatures are not expected.

• Add ethylene glycol base coolant when coolant has to be added because of coolant loss or to provide added protection against freezing at temperature lower than –36 °C (–33 °F).

NOTE

• Alcohol or methanol base coolant or plain water alone should not be used in cooling system at any

time as damage to cooling system could occur.

• Coolant must be mixed with deminerated water or distilled water.

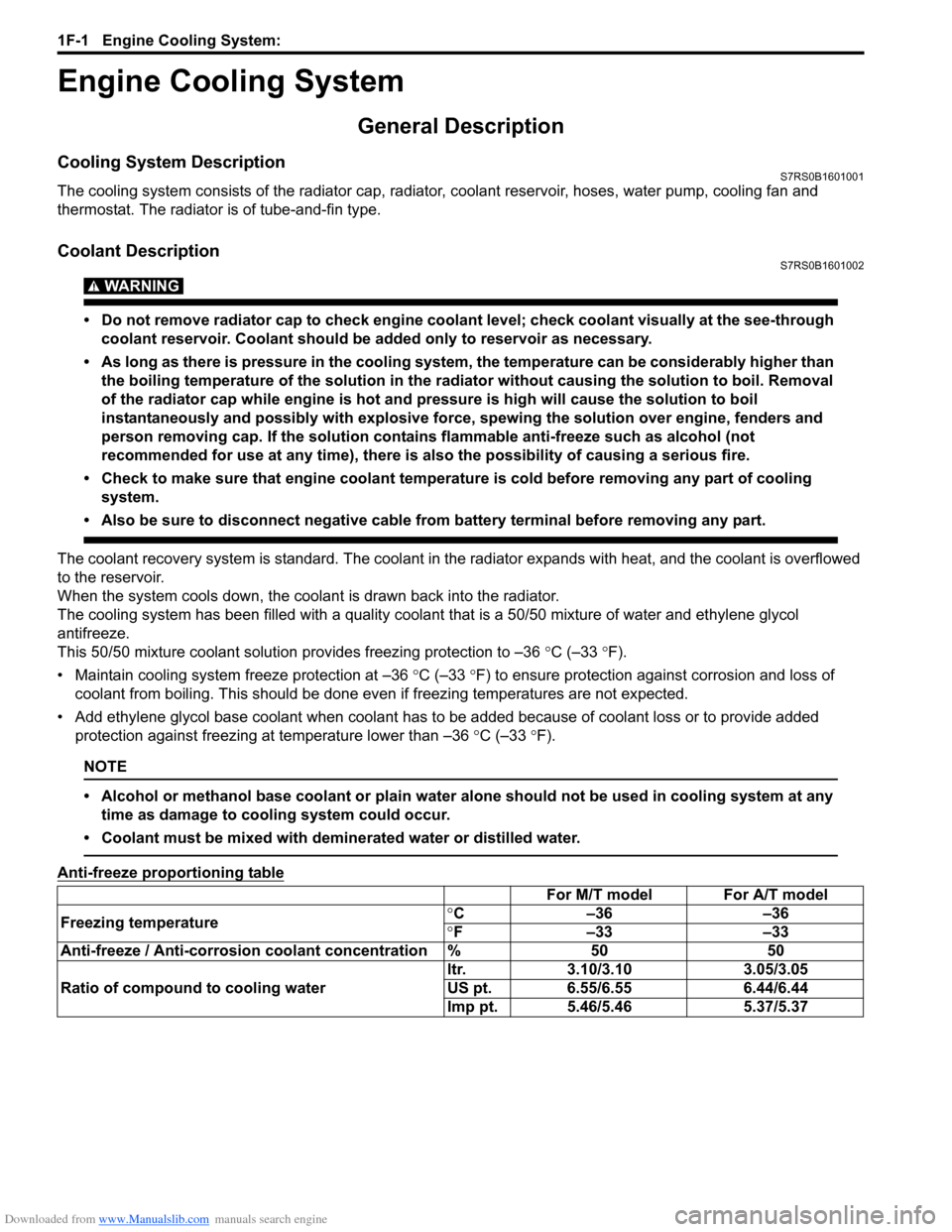

Anti-freeze proportioning table

For M/T model For A/T model

Freezing temperature °

C –36 –36

° F –33 –33

Anti-freeze / Anti-corrosion coolant concentration % 50 50

Ratio of compound to cooling water ltr. 3.10/3.10 3.05/3.05

US pt. 6.55/6.55 6.44/6.44

Imp pt. 5.46/5.46 5.37/5.37

Page 1170 of 1496

Downloaded from www.Manualslib.com manuals search engine 9-iv Table of Contents

Rear End Door Opener System Symptom Diagnosis .......................................................... 9F-5

Rear End Door Opener System Operation Inspection .......................................................... 9F-5

Repair Instructions ........... ................................... 9F-6

Front Door Lock Assembly Components ............ 9F-6

Front Door Lock Assembly Removal and Installation ......................................................... 9F-6

Front Door Lock Assembly Inspection ................ 9F-8

Power Door Lock Switch In spection.................... 9F-8

Door Key Cylinder Switch Inspection .................. 9F-8

Power Door Lock Actuator Inspection ................. 9F-9

Rear Door Lock Assembly Components ........... 9F-10

Rear Door Lock Assembly Removal and Installation ....................................................... 9F-10

Rear Door Lock Assembly Inspection ............... 9F-10

Rear End Door Lock Assembly Components.... 9F-11

Rear End Door Lock Assembly Removal and Installation ....................................................... 9F-11

Rear End Door Lock Assembly Inspection........ 9F-12

Rear End Door Opener Switch Inspection ........ 9F-12

Replacement of Transmitte r Battery ................. 9F-13

Programming Transmitter Code for Keyless Entry System (Vehicle without Keyless Start

System) ........................................................... 9F-13

Keyless Entry Answer Back Function

Change-over Procedure (If Equipped) ............ 9F-14

Keyless Entry Receiver Removal and

Installation ....................................................... 9F-14

Keyless Entry Receiver and Its Circuit Inspection ........................................................ 9F-15

Specifications .... ................................................. 9F-16

Tightening Torque Specifications ...................... 9F-16

Special Tools and Equipmen t ........................... 9F-16

Recommended Service Material ....................... 9F-16

Seats ............. ............................................ 9G-1

Repair Instructions ............................................. 9G-1

Front Seat Components ..................................... 9G-1

Front Seat Removal and In stallation .................. 9G-2

Rear Seat Components...................................... 9G-3

Rear Seat Removal and Installation................... 9G-4

Specifications .... .................................................. 9G-4

Tightening Torque Specifications ....................... 9G-4

Special Tools and Equipmen t ............................ 9G-4

Recommended Service Material ........................ 9G-4

Interior Trim ................. ............................ 9H-1

Repair Instructions ............ ..................................9H-1

Floor Carpet Removal and Installation ................9H-1

Head Lining Removal and Installation.................9H-1

Console Box Components ..................................9H-2

Specifications ..................... ..................................9H-3

Tightening Torque Specifications ........................9H-3

Hood / Fenders / Doors ...... ...................... 9J-1

Repair Instructions ............ .................................. 9J-1

Hood Removal and Installation ........................... 9J-1

Hood Inspection and Adjustment ........................ 9J-1

Front Fender Components .................................. 9J-2

Front Fender Removal and Installation ............... 9J-2

Front Door Assembly Comp onents ..................... 9J-3

Front Door Assembly Removal and Installation ......................................................... 9J-3

Rear Door Assembly Components...................... 9J-5

Rear Door Assembly Removal and Installation ......................................................... 9J-5

Rear End Door Assembly Components .............. 9J-6

Rear End Door Assembly Removal and Installation ......................................................... 9J-6

Specifications ..................... .................................. 9J-8

Tightening Torque Specifications ........................ 9J-8

Special Tools and Equipmen t ............................. 9J-8

Recommended Service Material ......................... 9J-8

Body Structure............... .......................... 9K-1

Repair Instructions ............ ..................................9K-1

Front Bumper and Rear Bumper Components .... 9K-1

Cowl Top Components........................................ 9K-2

Specifications ..................... ..................................9K-3

Body Dimensions ................................................ 9K-3

Panel Clearance................................................ 9K-10

Paint / Coatings ............. ...........................9L-1

General Description ............................................. 9L-1

Anti-Corrosion Treatment Construction............... 9L-1

Plastic Parts Finishing ......................................... 9L-2

Component Location ............ ............................... 9L-3

Sealant Application Areas ................................... 9L-3

Under Coating Application Areas ........................ 9L-8

Anti-Corrosion Compound Application Area ..... 9L-10

Exterior Trim ...... ...................................... 9M-1

Repair Instructions ......... .................................... 9M-1

Roof Molding Components................................. 9M-1

Splash Guard (If Equipped) Components .......... 9M-2

Page 1370 of 1496

Downloaded from www.Manualslib.com manuals search engine 9J-1 Hood / Fenders / Doors:

Body, Cab and Accessories

Hood / Fenders / Doors

Repair Instructions

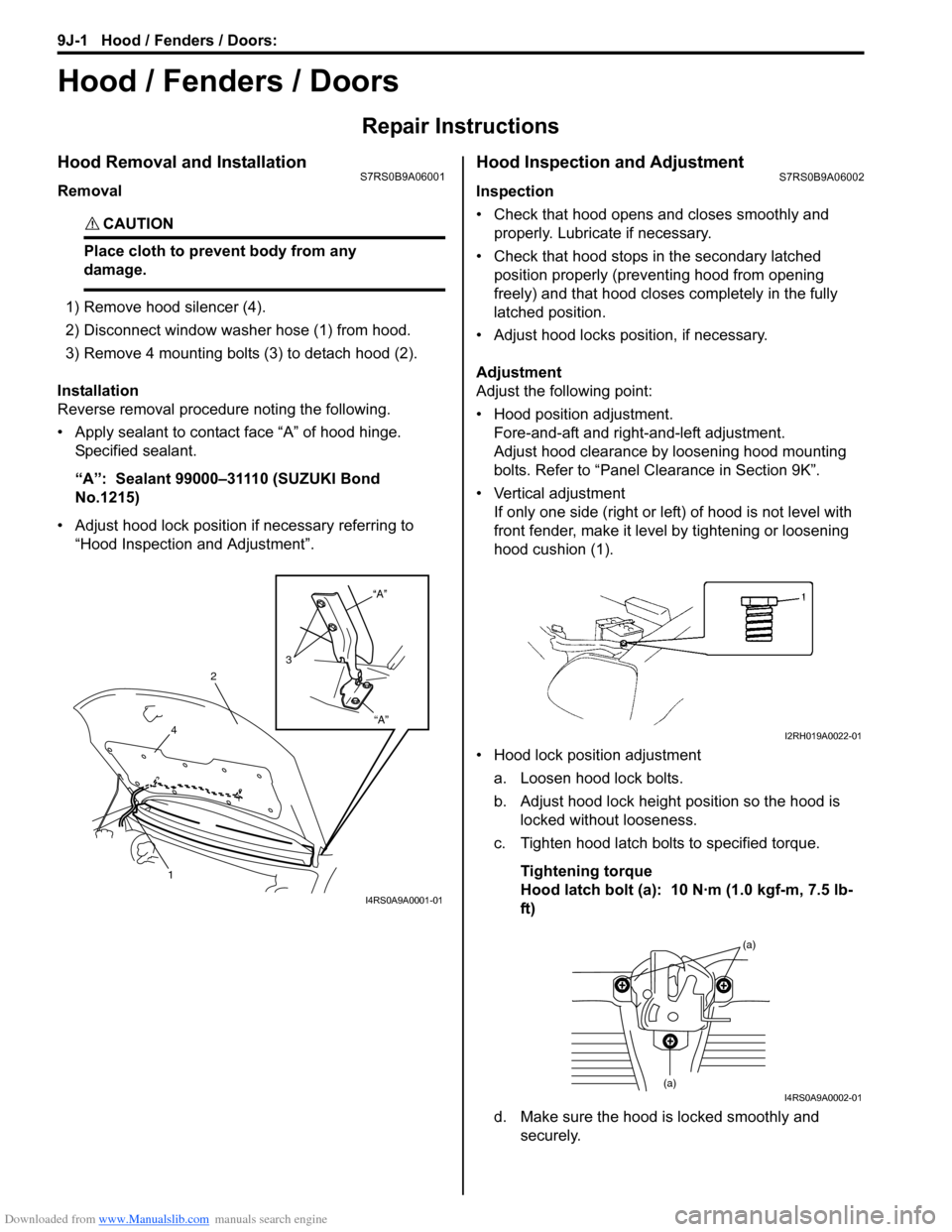

Hood Removal and InstallationS7RS0B9A06001

Removal

CAUTION!

Place cloth to prevent body from any

damage.

1) Remove hood silencer (4).

2) Disconnect window washer hose (1) from hood.

3) Remove 4 mounting bolts (3) to detach hood (2).

Installation

Reverse removal procedure noting the following.

• Apply sealant to contact face “A” of hood hinge. Specified sealant.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

• Adjust hood lock position if necessary referring to “Hood Inspection and Adjustment”.

Hood Inspection and AdjustmentS7RS0B9A06002

Inspection

• Check that hood opens and closes smoothly and properly. Lubricate if necessary.

• Check that hood stops in the secondary latched position properly (preventing hood from opening

freely) and that hood closes completely in the fully

latched position.

• Adjust hood locks position, if necessary.

Adjustment

Adjust the following point:

• Hood position adjustment. Fore-and-aft and right-and-left adjustment.

Adjust hood clearance by loosening hood mounting

bolts. Refer to “Panel Clearance in Section 9K”.

• Vertical adjustment If only one side (right or left) of hood is not level with

front fender, make it level by tightening or loosening

hood cushion (1).

• Hood lock position adjustment a. Loosen hood lock bolts.

b. Adjust hood lock height position so the hood is locked without looseness.

c. Tighten hood latch bolts to specified torque.

Tightening torque

Hood latch bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-

ft)

d. Make sure the hood is locked smoothly and securely.

“A”

“A”

3

2

4

1

I4RS0A9A0001-01

I2RH019A0022-01

(a)

(a)I4RS0A9A0002-01

Page 1371 of 1496

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-2

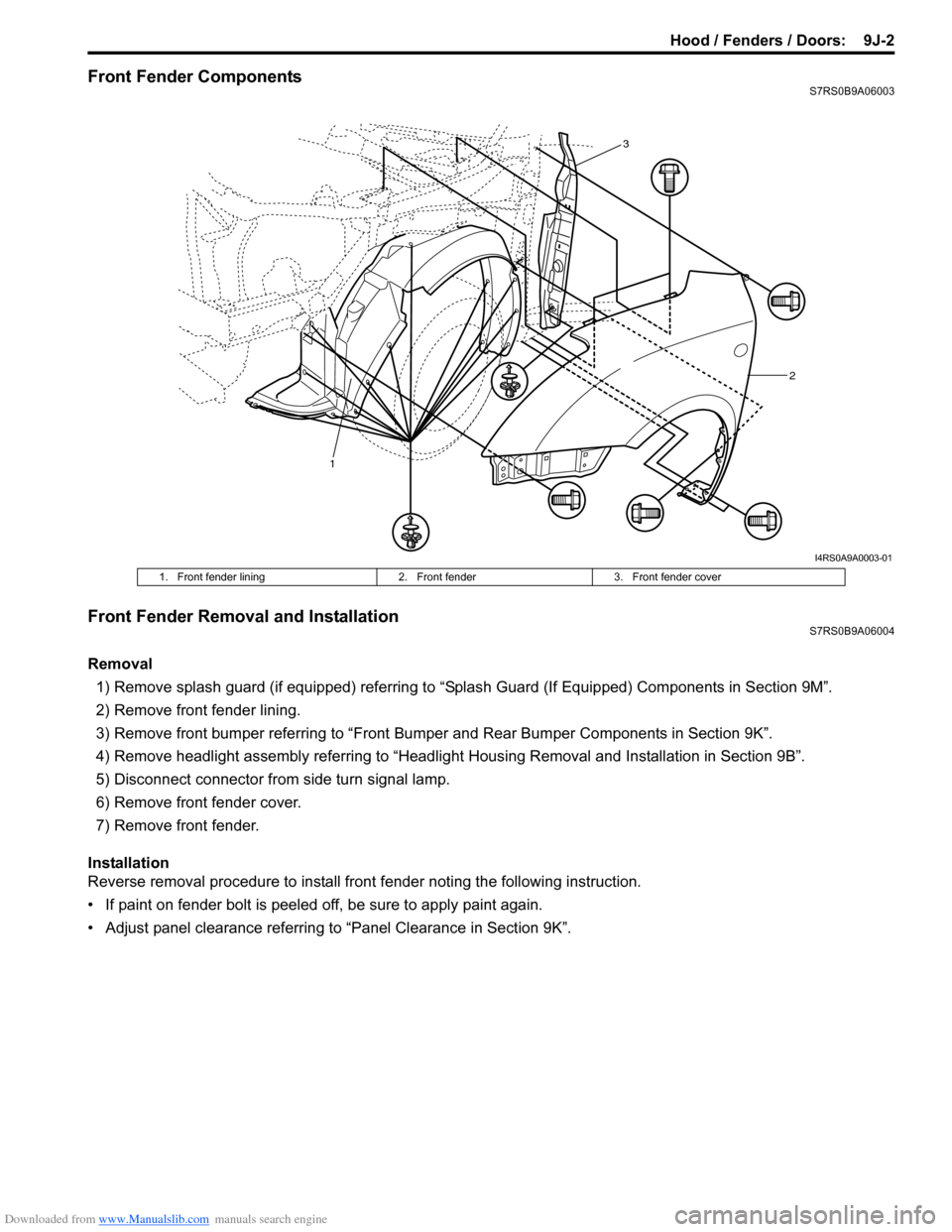

Front Fender ComponentsS7RS0B9A06003

Front Fender Removal and InstallationS7RS0B9A06004

Removal1) Remove splash guard (if equipped) referring to “Splash Guard (If Equipped) Components in Section 9M”.

2) Remove front fender lining.

3) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

4) Remove headlight assembly referring to “Headlig ht Housing Removal and Installation in Section 9B”.

5) Disconnect connector from side turn signal lamp.

6) Remove front fender cover.

7) Remove front fender.

Installation

Reverse removal procedure to install fron t fender noting the following instruction.

• If paint on fender bolt is peeled off, be sure to apply paint again.

• Adjust panel clearance referring to “Panel Clearance in Section 9K”.

1 2

3

I4RS0A9A0003-01

1. Front fender lining

2. Front fender3. Front fender cover

Page 1372 of 1496

Downloaded from www.Manualslib.com manuals search engine 9J-3 Hood / Fenders / Doors:

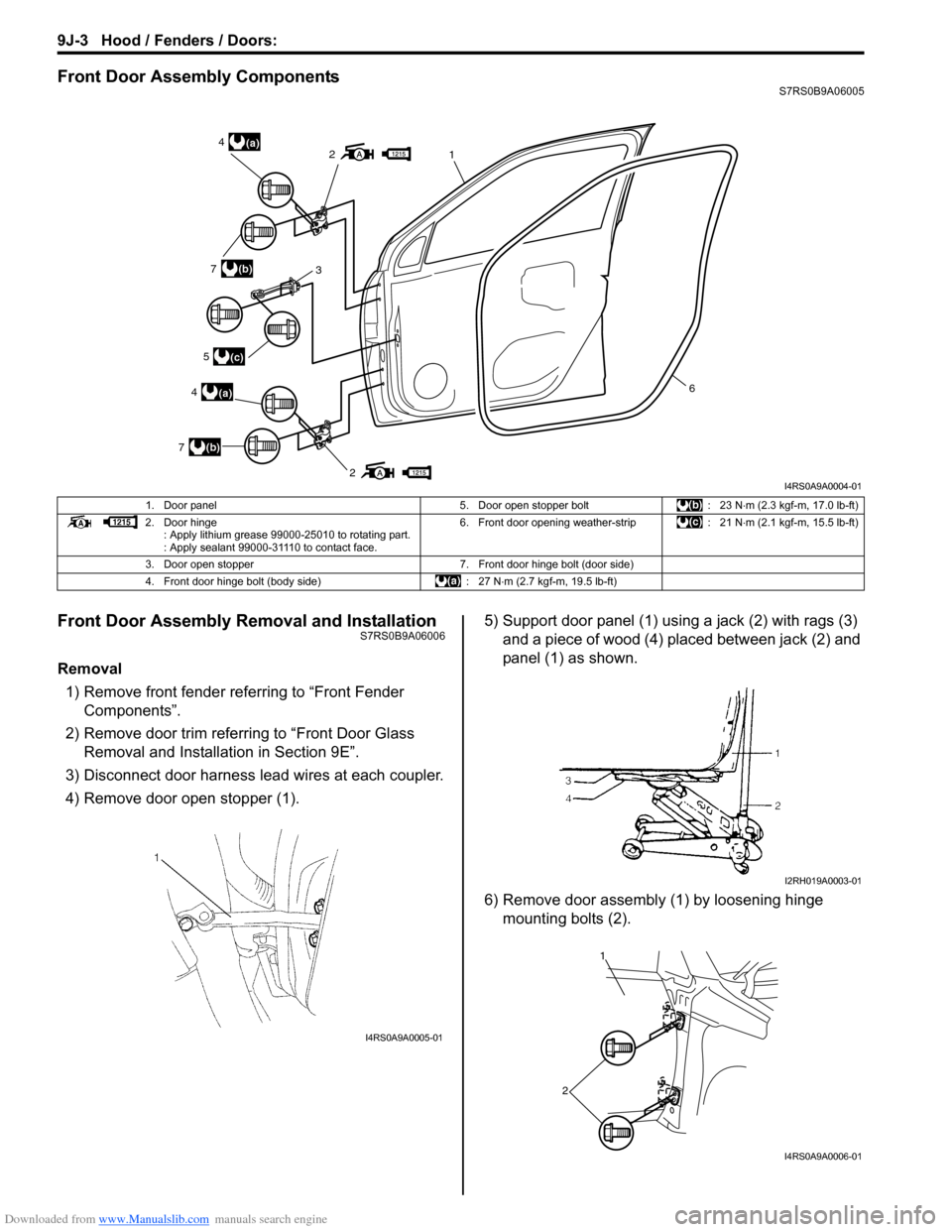

Front Door Assembly ComponentsS7RS0B9A06005

Front Door Assembly Removal and InstallationS7RS0B9A06006

Removal1) Remove front fender referring to “Front Fender Components”.

2) Remove door trim referring to “Front Door Glass Removal and Installa tion in Section 9E”.

3) Disconnect door harness lead wires at each coupler.

4) Remove door open stopper (1). 5) Support door panel (1) using a jack (2) with rags (3)

and a piece of wood (4) placed between jack (2) and

panel (1) as shown.

6) Remove door assembly (1) by loosening hinge mounting bolts (2).

2

21(a)4

(a)4

3(b)7

(b)7

(c)5

6

I4RS0A9A0004-01

1. Door panel 5. Door open stopper bolt: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

2. Door hinge : Apply lithium grease 99000-25010 to rotating part.

: Apply sealant 99000-31110 to contact face. 6. Front door opening weather-strip

: 21 N⋅m (2.1 kgf-m, 15.5 lb-ft)

3. Door open stopper 7. Front door hinge bolt (door side)

4. Front door hinge bolt (body side) : 27 N⋅m (2.7 kgf-m, 19.5 lb-ft)

I4RS0A9A0005-01

I2RH019A0003-01

1

2

I4RS0A9A0006-01

Page 1373 of 1496

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-4

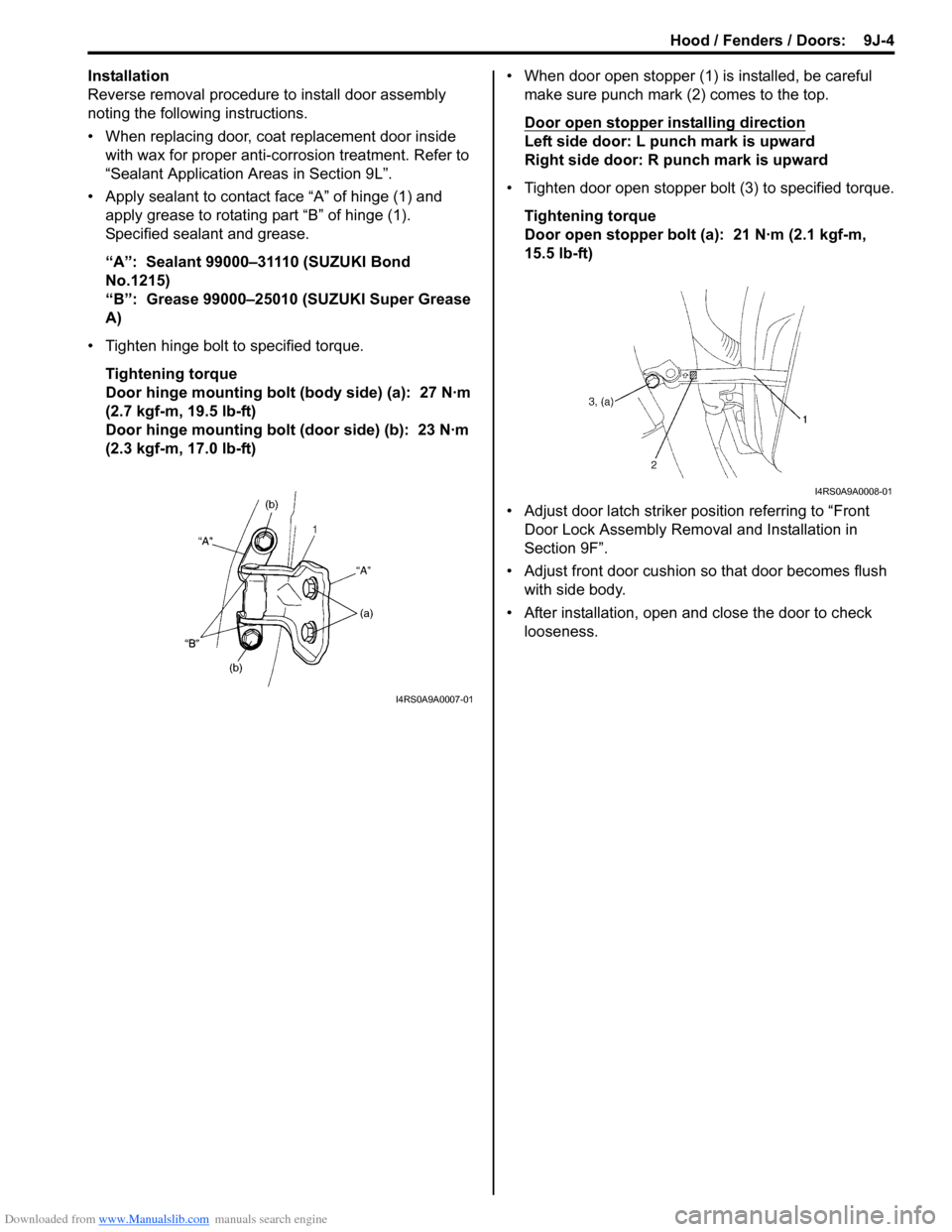

Installation

Reverse removal procedure to install door assembly

noting the following instructions.

• When replacing door, coat replacement door inside with wax for proper anti-cor rosion treatment. Refer to

“Sealant Application Areas in Section 9L”.

• Apply sealant to contact face “A” of hinge (1) and apply grease to rotating part “B” of hinge (1).

Specified sealant and grease.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

“B”: Grease 99000–25010 (SUZUKI Super Grease

A)

• Tighten hinge bolt to specified torque. Tightening torque

Door hinge mounting bolt (body side) (a): 27 N·m

(2.7 kgf-m, 19.5 lb-ft)

Door hinge mounting bolt (door side) (b): 23 N·m

(2.3 kgf-m, 17.0 lb-ft) • When door open stopper (1) is installed, be careful

make sure punch mark (2) comes to the top.

Door open stopper installing direction

Left side door: L punch mark is upward

Right side door: R punch mark is upward

• Tighten door open stopper bolt (3) to specified torque. Tightening torque

Door open stopper bolt (a): 21 N·m (2.1 kgf-m,

15.5 lb-ft)

• Adjust door latch striker position referring to “Front Door Lock Assembly Removal and Installation in

Section 9F”.

• Adjust front door cushion so that door becomes flush with side body.

• After installation, open and close the door to check looseness.

I4RS0A9A0007-01

I4RS0A9A0008-01

Page 1374 of 1496

Downloaded from www.Manualslib.com manuals search engine 9J-5 Hood / Fenders / Doors:

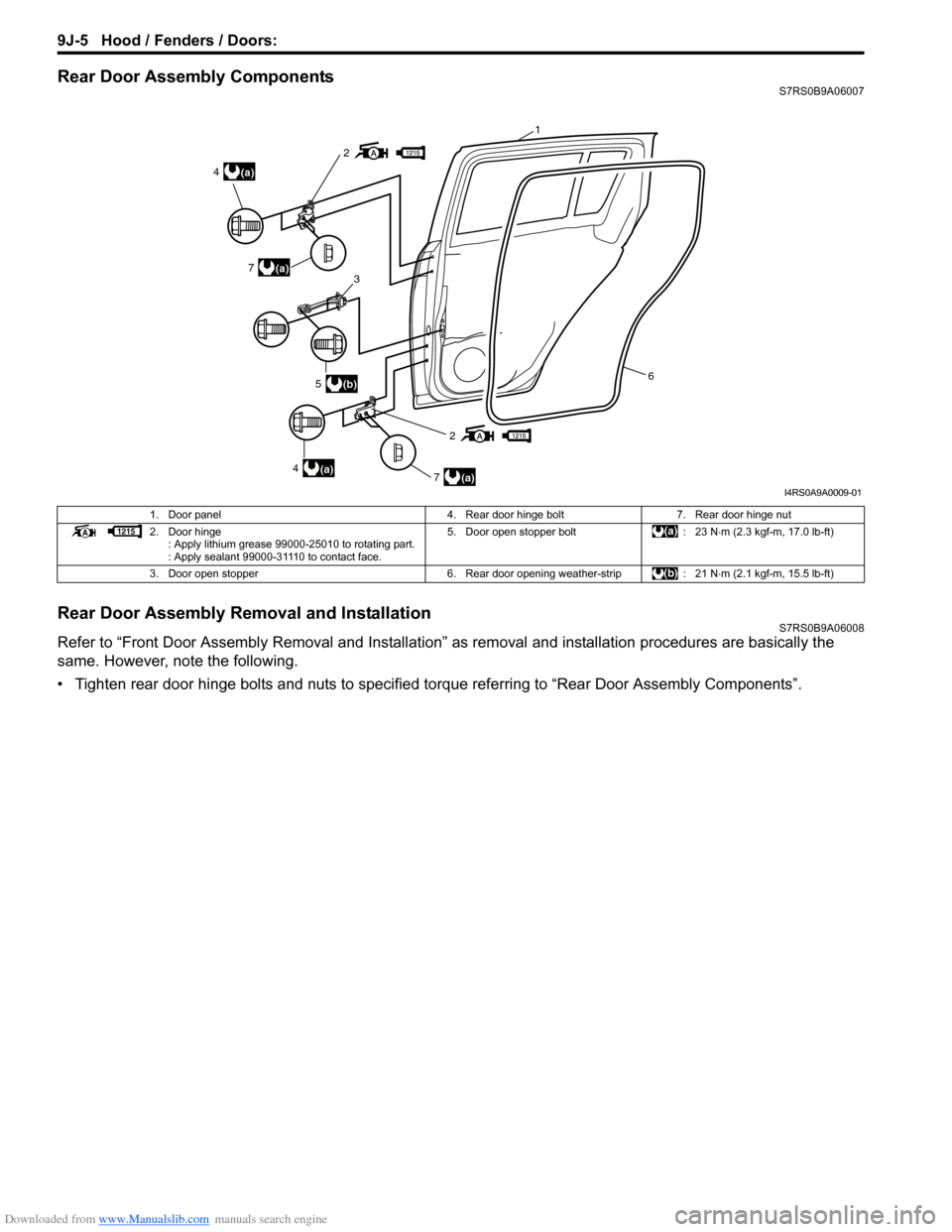

Rear Door Assembly ComponentsS7RS0B9A06007

Rear Door Assembly Removal and InstallationS7RS0B9A06008

Refer to “Front Door Assembly Removal and Installation” as removal and installation procedures are basically the

same. However, note the following.

• Tighten rear door hinge bolts and nuts to specified torque referring to “Rear Door Assembly Components”.

2

2

(a)4

(a)4

(a)7

(a)7

(b)53

6

1

I4RS0A9A0009-01

1. Door panel 4. Rear door hinge bolt7. Rear door hinge nut

2. Door hinge : Apply lithium grease 99000-25010 to rotating part.

: Apply sealant 99000-31110 to contact face. 5. Door open stopper bolt

: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Door open stopper 6. Rear door opening weather-strip: 21 N⋅m (2.1 kgf-m, 15.5 lb-ft)

Page 1375 of 1496

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-6

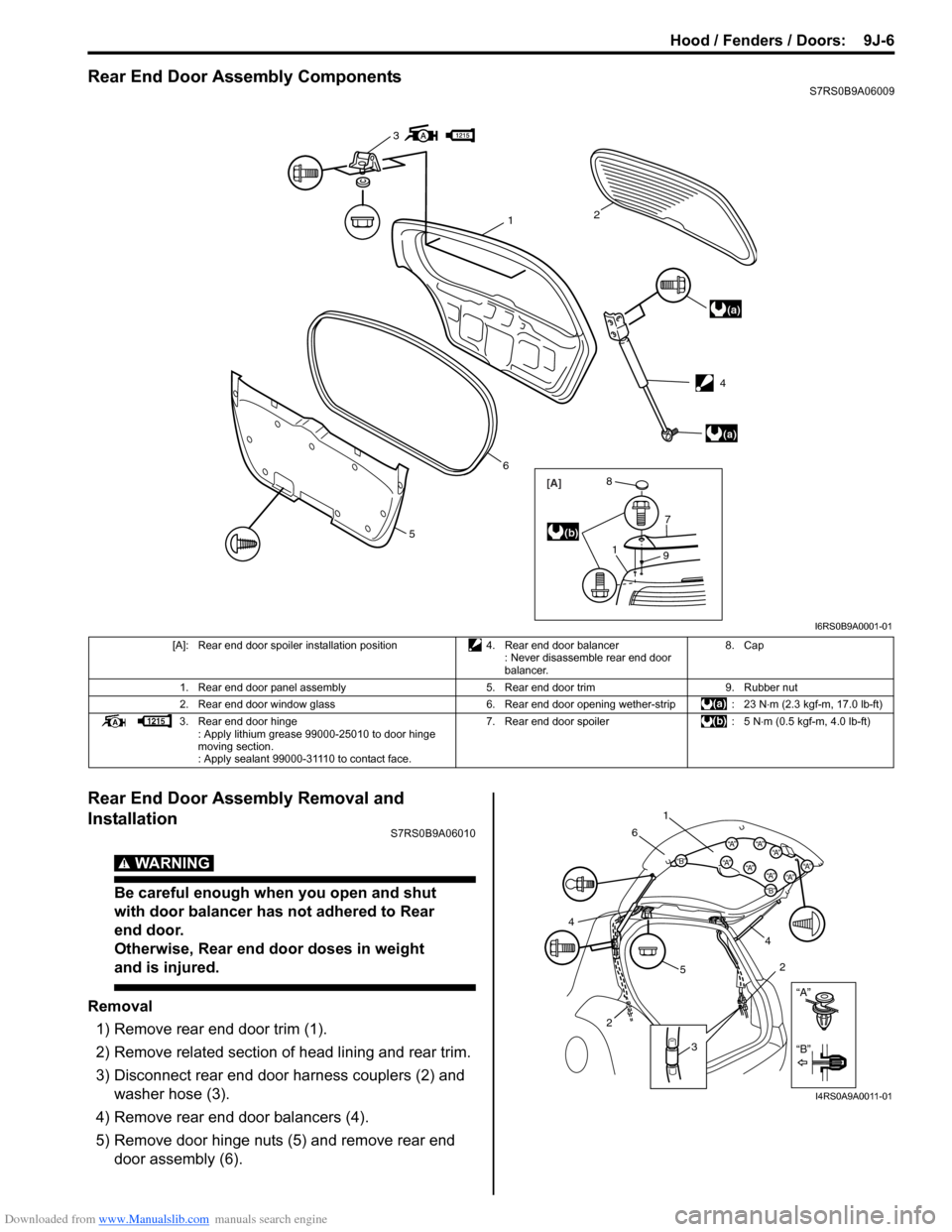

Rear End Door Assembly ComponentsS7RS0B9A06009

Rear End Door Assembly Removal and

Installation

S7RS0B9A06010

WARNING!

Be careful enough when you open and shut

with door balancer has not adhered to Rear

end door.

Otherwise, Rear end door doses in weight

and is injured.

Removal1) Remove rear end door trim (1).

2) Remove related section of head lining and rear trim.

3) Disconnect rear end door harness couplers (2) and washer hose (3).

4) Remove rear end door balancers (4).

5) Remove door hinge nuts (5) and remove rear end door assembly (6).

3

(a)

(a)

12

6

5

[A]

1

7

9

8

(b)

4

I6RS0B9A0001-01

[A]: Rear end door spoiler installation position 4. Rear end door balancer

: Never disassemble rear end door

balancer. 8. Cap

1. Rear end door panel assembly 5. Rear end door trim9. Rubber nut

2. Rear end door window glass 6. Rear end door opening wether-strip: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Rear end door hinge : Apply lithium grease 99000-25010 to door hinge

moving section.

: Apply sealant 99000-31110 to contact face. 7. Rear end door spoiler

: 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

“A”

“B”

“B”

“A”“B”“A”“A”“A”

“A”“A”“A”

“A”

1

6

5 4

2

3

2

4

I4RS0A9A0011-01