Vin SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 3 of 1496

Downloaded from www.Manualslib.com manuals search engine FOREWORD

This manual (Volumes 1 and 2) contains procedures for diagnosis, maintenance, adjustments, minor service

operations, replacement of components (Service) and for disassembly and reassembly of major components

(Unit Repair-Overhaul).

Applicable Model:

SWIFT (RS416) produced at KOSAI plant in Japan wi th the following vehicle identification numbers

(VINs).

JSAEZC31S############

The contents are classified into sectio ns each of which is given a section number as indicated in the Table of

Contents on following page. And on the first page of ea ch individual section is an index of that section.

This manual should be kept in a handy place for ready reference of the service work.

Strict observance of the so specif ied items will enable one to obtain the full performance of the vehicle.

When replacing parts or servicing by disassembling, it is recommended to use SUZUKI genuine parts, tools and

service materials as specif ied in each description.

All information, illustrations and specif ications contained in this literature are based on the late st product infor-

mation available at the time of publication approval. And used as the main subject of description is the vehicle of

standard specificatio ns among others.

Therefore, note that illustrations may differ from the vehicle being actually serviced.

The right is reserved to make changes at any time without notice.

JSAEZC31S########

Page 9 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-4

General PrecautionsS7RS0B0000002

The WARNING and CAUTION describe some general

precautions that you should observe when servicing a

vehicle. These general precautions apply to many of the

service procedures, and they will not necessarily be

repeated with each procedure to which they apply.

WARNING!

• Whenever raising a vehicle for service, be sure to follow the instructions under

“Vehicle Lifting Points in Section 0A”.

• When it is necessary to do service work with the engine running, make sure that

the parking brake is set fully and the

transmission is in Neutral (for manual

transmission vehicles) or Park (for

automatic transmission vehicles), Keep

hands, hair, clothing, tools, etc. away from

the fan and belts when the engine is

running.

• When it is necessary to run the engine indoors, make sure that the exhaust gas is

forced outdoors.

• Do not perform service work in areas where combustible materials can come in

contact with a hot exhaust system. When

working with toxic or flammable materials

(such as gasoline and refrigerant), make

sure that the area you work in is well-

ventilated.

• To avoid getting burned, keep away from hot metal parts such as the radiator,

exhaust manifold, tail pipe, muffler, etc.

• New and used engine oil can be hazardous. Children and pets may be

harmed by swallowing new or used oil.

Keep new and used oil and used engine oil

filters away from children and pets.

Continuous contact with used engine oil

has been found to cause [skin] cancer in

laboratory animals. Brief contact with used

oil may irritate skin. To minimize your

exposure to used engine oil, wear a long-

sleeve shirt and moisture-proof gloves

(such as dish washing gloves) when

changing engine oil. If engine oil contacts

your skin, wash thoroughly with soap and

water. Launder any clothing or rags if wet

with oil, recycle or properly dispose of

used oil and filters. • Be sure to observe following instructions

when handling service materials such as

fuel, oil, fluid, coolant, grease, sealant,

thread lock cement, etc. Otherwise, your

health may be ruined.

– Whenever handling any of these service materials, wear safety glasses to protect

your eyes. If it gets into your eye, it may

cause inflammation.

– Whenever handling any of these service materials, wear moistu re-proof gloves to

protect your skin. If it adheres to your

skin, it may cause inflammation.

– Do not swallow any of these service materials. It would cause diarrhea or

nausea.

– Keep all these materials out of children’s reach.

• Make sure the bonnet is fully closed and latched before driving. If it is not, it can fly

up unexpectedly during driving,

obstructing your view and resulting in an

accident.

• Before starting any service work, cover fenders, seats and any other parts that are likely to get scratched or

stained during servicing. Also, be aware that what you

wear (e.g., buttons) ma y cause damage to the

vehicle’s finish.

I2RH01010025-01

Page 10 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-5 Precautions:

• When performing service to electrical parts that does not require use of battery power, disconnect the

negative cable of the battery.

• When disconnecting the negative cable from the battery, be careful to the following.

– Check and record DTCs in ECM and HVAC control module if necessary before disconnecting.

– Record displayed contents of the clock and/or audio system, etc. before disconnecting and reset it

as before after connecting.

– For vehicle equipped with electric throttle body system, perform electric throttle body system

calibration referring to “Electric Throttle Body

System Calibration in Section 1C” after

reconnecting the negative cable to the battery.

– For vehicle equipped with ESP ®, calibrate steering

angle sensor referring to “Sensor Calibration in

Section 4F” after reconnecting the negative cable

to the battery.

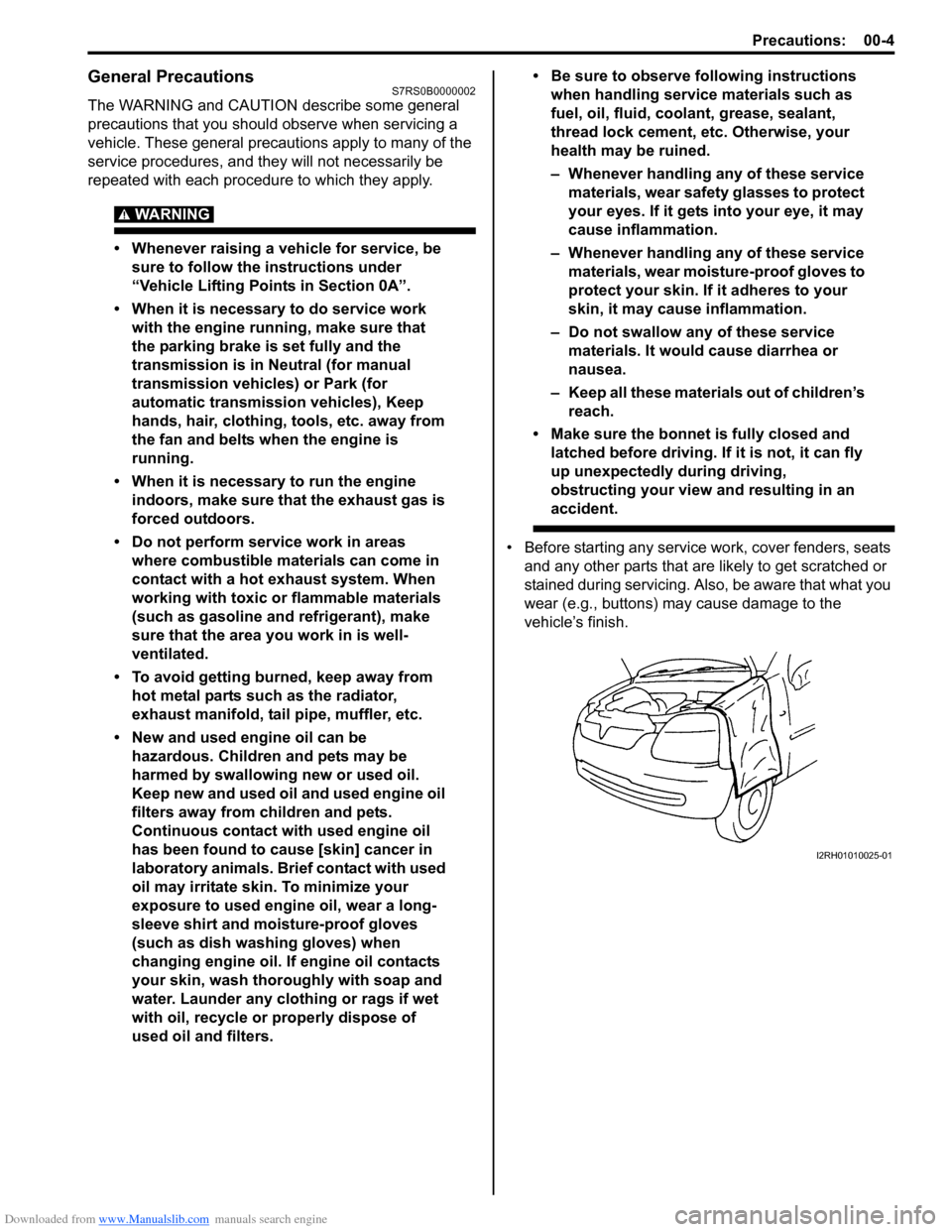

• When removing the battery, be sure to disconnect the negative cable first and then the positive cable. When

reconnecting the battery, connect the positive cable

first and then the negative cable, and replace the

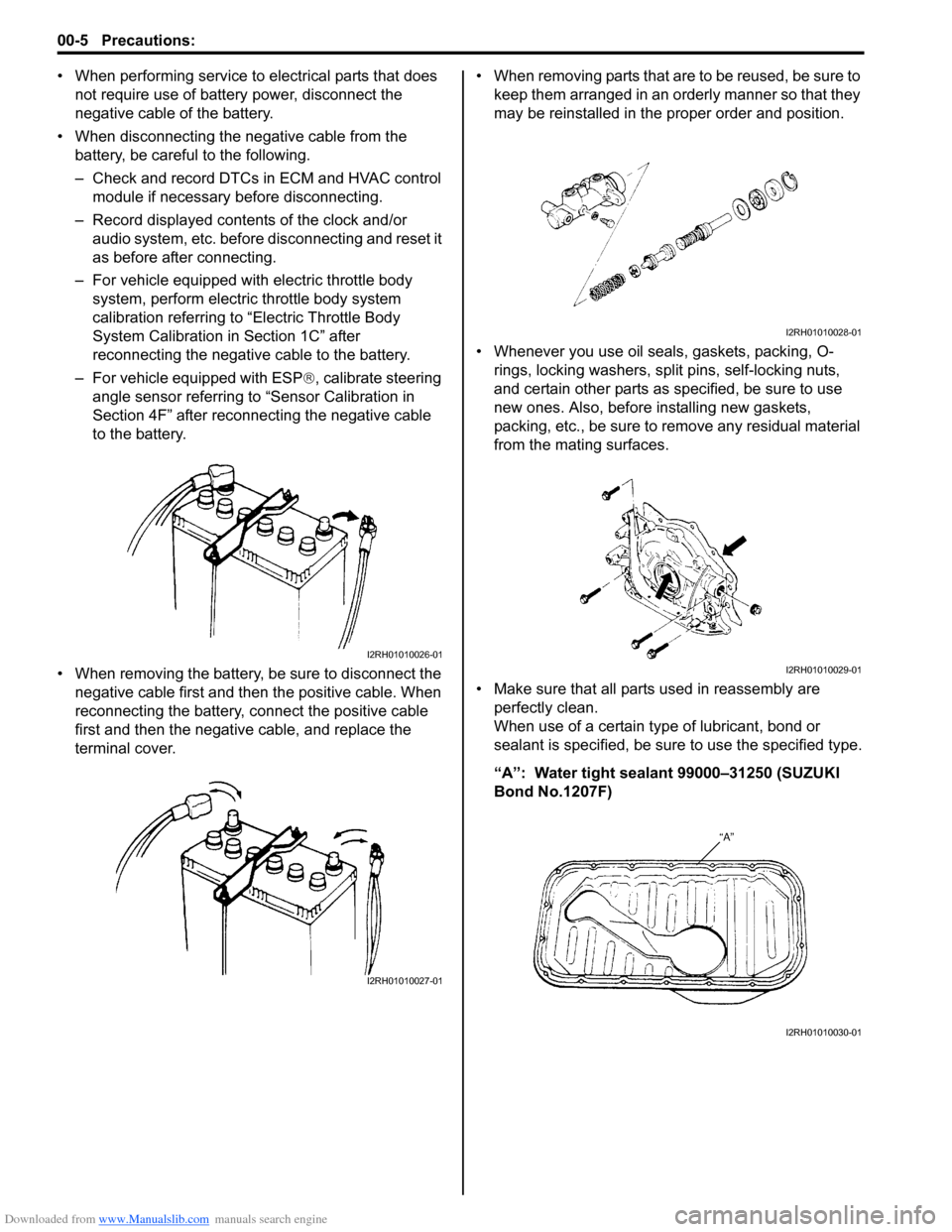

terminal cover. • When removing parts that are to be reused, be sure to

keep them arranged in an orderly manner so that they

may be reinstalled in the proper order and position.

• Whenever you use oil seals, gaskets, packing, O- rings, locking washers, split pins, self-locking nuts,

and certain other parts as specified, be sure to use

new ones. Also, before installing new gaskets,

packing, etc., be sure to remove any residual material

from the mating surfaces.

• Make sure that all parts used in reassembly are perfectly clean.

When use of a certain type of lubricant, bond or

sealant is specified, be sure to use the specified type.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

I2RH01010026-01

I2RH01010027-01

I2RH01010028-01

I2RH01010029-01

I2RH01010030-01

Page 12 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-7 Precautions:

Warning for Wheel (with tire) RemovalS7RS0B0000003

WARNING!

When removing any of these wheels installed

with wheel bolts, never remove all wheel

bolts at the same time. Leave at least 1 bolt

for each wheel as it is to prevent wheel from

dropping. When removing this remaining 1

bolt, hold wheel and tire so as not to allow

them to come off.

Warning for Handling Emergency Flat Tire

Repair Kit

S7RS0B0000004

WARNING!

If vehicle is equipped with Emergency Flat

Tire Repair Kit instead of spare tire, be sure

to observe “Precaution for Emergency Flat

Tire Repair Kit in Section 2D” when handling

Emergency Flat Tire Repair Kit and repairing

flat tire.

Otherwise, your health may be ruined or it

will be impossible to repair flat tire.

Precautions for Catalytic ConverterS7RS0B0000005

For vehicles equipped with a catalytic converter, use

only unleaded gasoline and be careful not to let a large

amount of unburned gasoline enter the converter or it

can be damaged.

• Conduct a spark jump test only when necessary, make it as short as possible, and do not open the

throttle.

• Conduct engine compression checks within the shortest possible time.

• Avoid situations which can result in engine misfire (e.g. starting the engine when the fuel tank is nearly

empty.)

Precautions for Installing Mobile

Communication Equipment

S7RS0B0000006

When installing mobile communication equipment such

as CB (Citizens-Band)-radi o or cellular-telephone, be

sure to observe the following precautions.

Failure to follow cautions may adversely affect electronic

control system.

• Keep the antenna as far away as possible from the vehicle’s electronic control unit.

• Keep the antenna feeder more than 20 cm (7.9 in.) away from electronic control unit and its wire

harnesses.

• Do not run the antenna feeder parallel with other wire harnesses.

• Confirm that the antenna and feeder are correctly adjusted.

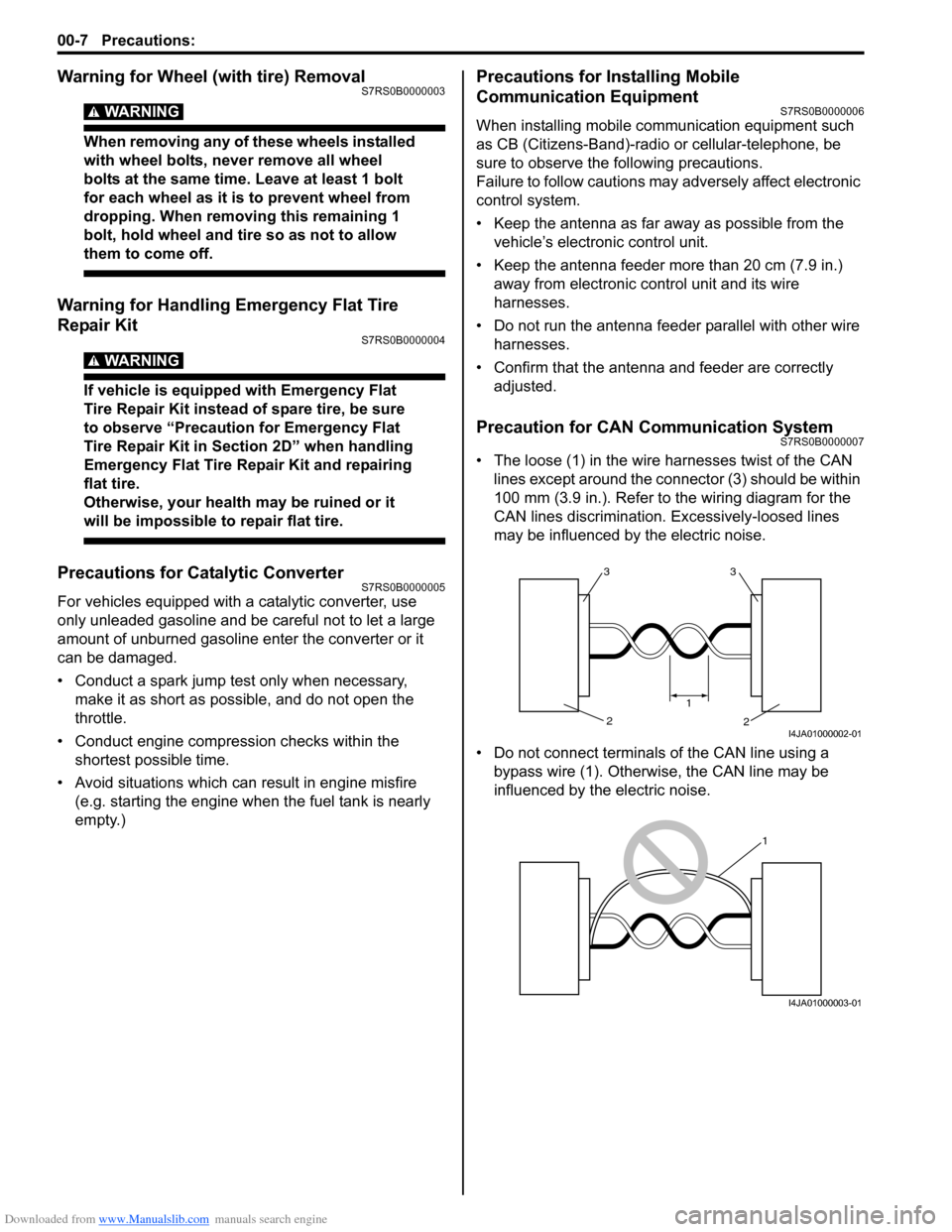

Precaution for CAN Communication SystemS7RS0B0000007

• The loose (1) in the wire harnesses twist of the CAN lines except around the connector (3) should be within

100 mm (3.9 in.). Refer to the wiring diagram for the

CAN lines discrimination. Excessively-loosed lines

may be influenced by the electric noise.

• Do not connect terminals of the CAN line using a bypass wire (1). Otherwise, the CAN line may be

influenced by the electric noise.

33

2

2

1

I4JA01000002-01

1

I4JA01000003-01

Page 16 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-11 Precautions:

Precaution for Vehicle Equipped with ESP®

System

S7RS0B0000015

• When testing with any of the following equipments

(when vehicle is tested by rotating wheels (tires)

under vehicle stop), be sure to deactivate ESP ®

system referring to “Precautions in Speedometer Test

or Other Tests in Section 4F” to obtain correct data.

– 2 or 4-wheel chassis dynamometer

– Speedometer tester

– Brake tester

–Etc.

ESP ® control module

• When ESP ® control module is removed / installed, do

not use impact wrenches which generate shock or

impact to avoid damaging sensors in ESP ® control

module.

• When any of the following operation is done, calibrate steering angle sensor referring to “Sensor Calibration

in Section 4F”.

– When battery or dome fuse is removed.

– When steering angle sensor is replaced.

Brake CautionS7RS0B0000014

CAUTION!

All brake fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of same part

number or with an eq uivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts. There is

to be no welding as it may result in extensive

damage and weakening of the metal.

Repair Instructions

Electrical Circuit Inspection ProcedureS7RS0B0006001

While there are various electrical circuit inspection

methods, described here is a general method to check

its open and short circuit by using an ohmmeter and a

voltmeter.

Open Circuit Check

Possible causes for the open circuit are as follows. As

the cause is in the connector or terminal in many cases,

they need to be checked particularly carefully.

• Loose connection of connector

• Poor contact of terminal (due to dirt, corrosion or rust

on it, poor contact tension, entry of foreign object etc.)

• Wire harness being open

When checking system circuits including an electronic

control unit such as ECM, TCM, ABS control module,

etc., it is important to perfor m careful check, starting with

items which are easier to check.

1) Disconnect negative (–) cable from battery

2) Check each connector at both ends of the circuit being checked for loose connection. Also check lock

condition of connector if equipped with connector

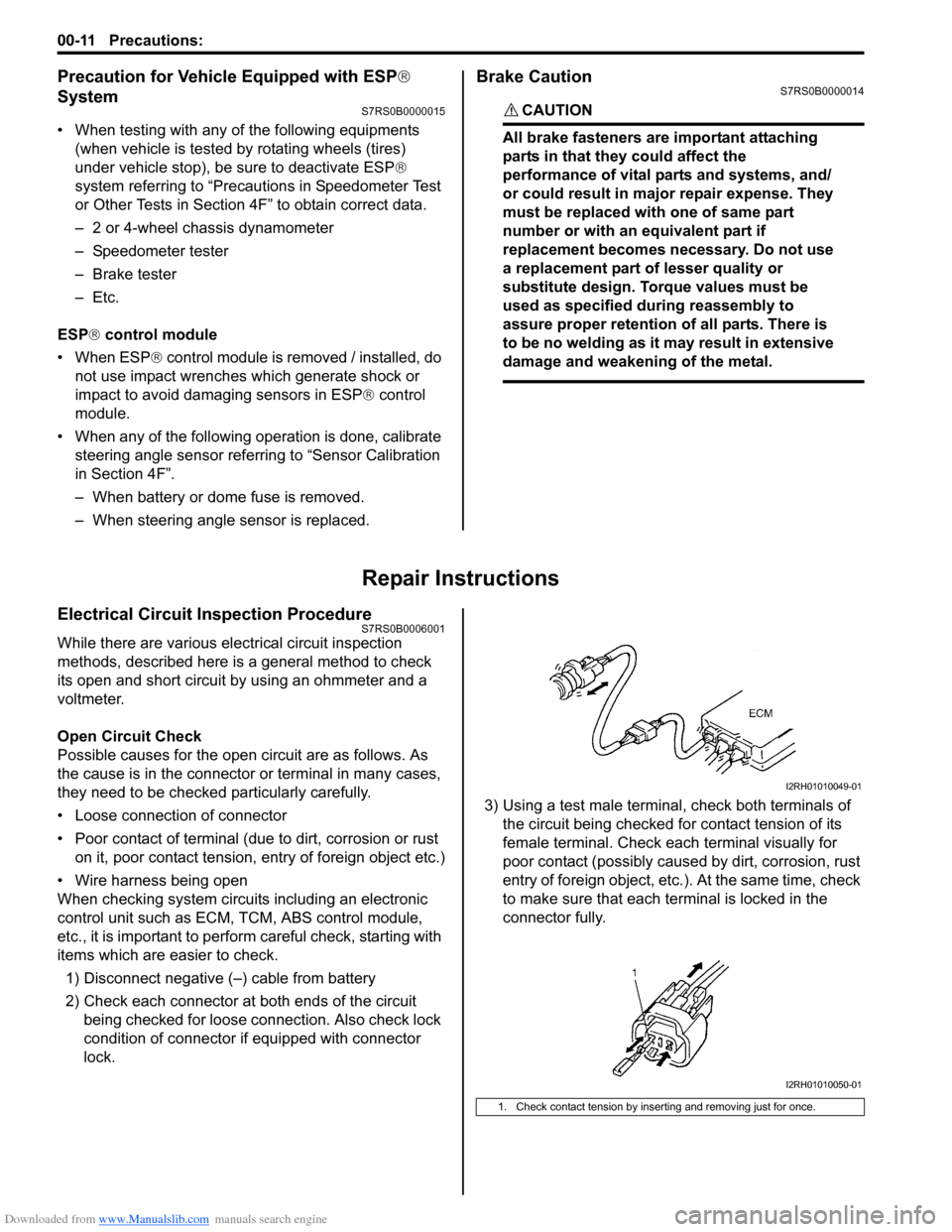

lock. 3) Using a test male terminal

, check both terminals of

the circuit being checked for contact tension of its

female terminal. Check each terminal visually for

poor contact (possibly caused by dirt, corrosion, rust

entry of foreign object, etc.). At the same time, check

to make sure that each te rminal is locked in the

connector fully.

1. Check contact tension by inserting and removing just for once.

I2RH01010049-01

I2RH01010050-01

Page 19 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-14

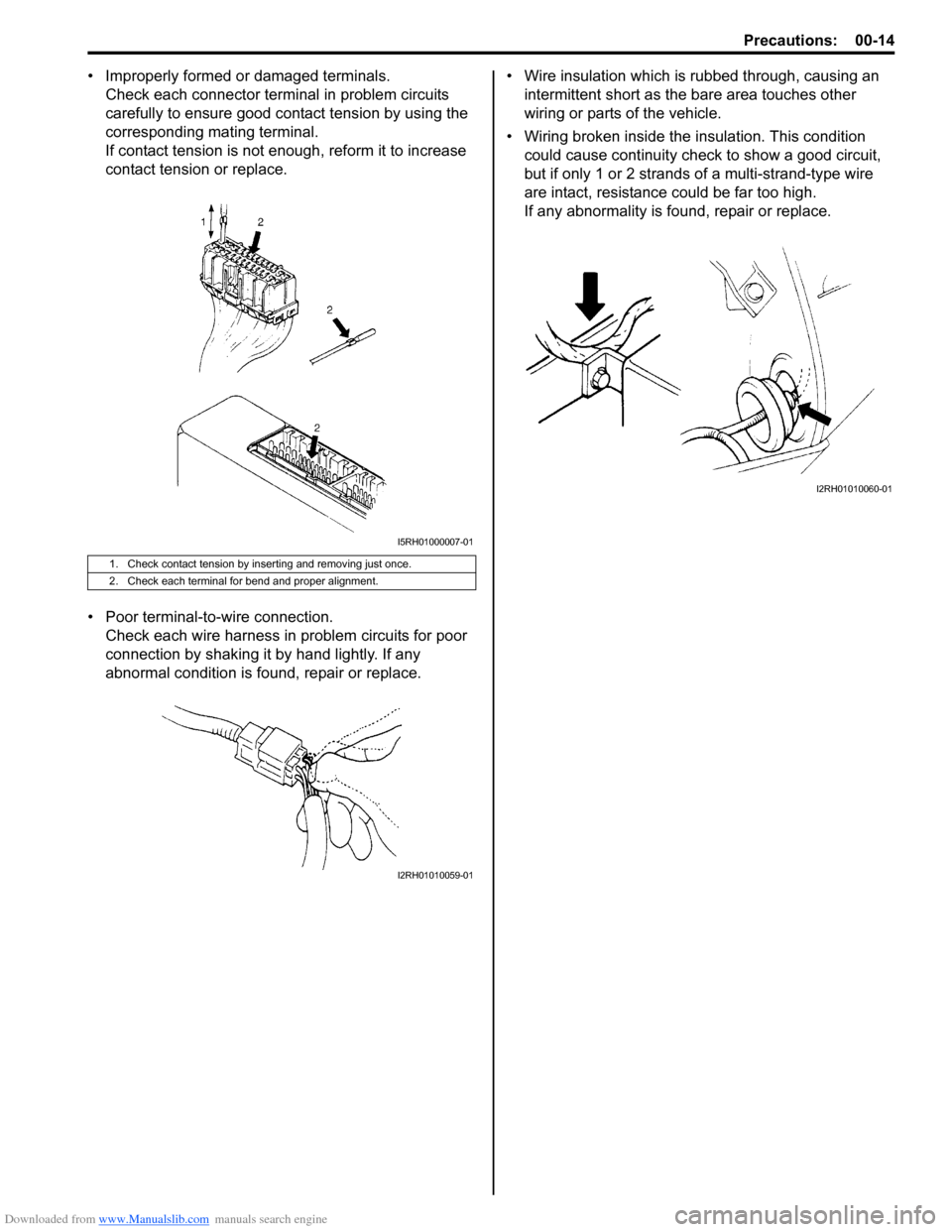

• Improperly formed or damaged terminals.Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal.

If contact tension is not enough, reform it to increase

contact tension or replace.

• Poor terminal-to -wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, repair or replace. • Wire insulation which is rubbed through, causing an

intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wiring broken inside the insulation. This condition

could cause continuity check to show a good circuit,

but if only 1 or 2 strands of a multi-strand-type wire

are intact, resistance could be far too high.

If any abnormality is found, repair or replace.

1. Check contact tension by inserting and removing just once.

2. Check each terminal for bend and proper alignment.

I5RH01000007-01

I2RH01010059-01

I2RH01010060-01

Page 21 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 0- i

0

Section 0

CONTENTS

General Information

General Information ................................ 0A-1

General Description ............................................. 0A-1

Abbreviations ...................................................... 0A-1

Symbols .............................................................. 0A-2

Wire Color Symbols ............................................ 0A-2

Fasteners Information ......................................... 0A-3

Vehicle Lifting Points ........................................... 0A-5

Engine Supporting Points ................................... 0A-7

Vehicle Identification Number ............................. 0A-7

Engine Identification Number .............................. 0A-7

Transmission Identification Number .................... 0A-7

Component Locatio n ........................................... 0A-8

Warning, Caution and Information Labels Location ............................................................ 0A-8

Maintenance and Lubricat ion ................. 0B-1

Precautions........................................................... 0B-1

Precautions for Maintenance and Lubrication ..... 0B-1

Scheduled Maintenance ...................................... 0B-1 Maintenance Schedule under Normal Driving Conditions ......................................................... 0B-1

Maintenance Recommended under Severe Driving Conditions ............................................. 0B-2

Repair Instructions .............................................. 0B-3 Accessory Drive Belt Inspection.......................... 0B-3

Accessory Drive Belt Repl acement ..................... 0B-4

Valve Lash (Clearance) Inspection ..................... 0B-4

Engine Oil and Filter Change .............................. 0B-4

Engine Coolant Change ...... ................................ 0B-5

Exhaust System Inspection ................................. 0B-6

Spark Plug Replacement .................................... 0B-6

Air Cleaner Filter Inspection ................................ 0B-6

Air Cleaner Filter Replac ement ........................... 0B-6 Fuel Lines and Connections Inspection .............. 0B-6

Fuel Filter Replacement ...................................... 0B-7

Fuel Tank Inspection ........................................... 0B-7

PCV Valve Inspection ......................................... 0B-7

Fuel Evaporative Emission Control System

Inspection .......................................................... 0B-7

Brake Discs and Pads Inspection ....................... 0B-7

Brake Hoses and Pipes Inspection ..................... 0B-7

Brake Fluid Inspection......................................... 0B-8

Brake Fluid Replacement .................................... 0B-8

Brake Lever and Cable Inspection ...................... 0B-8

Clutch Fluid Inspection ........................................ 0B-8

Tires Inspection ................................................... 0B-9

Wheel Discs Inspection ....................................... 0B-9

Wheel Bearing Inspection ................................... 0B-9

Suspension System Inspection ........................... 0B-9

Steering System Inspection .............................. 0B-10

Drive Shaft (Axle) Boots Inspection .................. 0B-10

Manual Transaxle Oil Inspection ....................... 0B-10

Manual Transaxle Oil Replacement .................. 0B-10

Automatic Transaxle Fluid Level Inspection...... 0B-11

Automatic Transaxle Fluid Replacement .......... 0B-11

Automatic Transaxle Fluid Cooler Hose Inspection ........................................................ 0B-11

All Latches, Hinges and Locks Inspection......... 0B-11

HVAC Air Filter (If Equipped) Inspection ........... 0B-12

HVAC Air Filter (If Equipped) Replacement ...... 0B-12

Final Inspection for Maint enance Service ......... 0B-12

Specifications .................... .................................0B-13

Tightening Torque Specifications ...................... 0B-13

Special Tools and Equipmen t ...........................0B-13

Recommended Fluids and Lubricants............... 0B-13

Special Tool ...................................................... 0B-14

Page 23 of 1496

Downloaded from www.Manualslib.com manuals search engine General Information: 0A-2

SAS: Steering Angle Sensor

SDM: Sensing and Diagnostic Module (Air Bag Controller, Air bag Control Module)

SDT: Smart Diagnostic Tester

SFI: Sequential Multipor t Fuel Injection

SOHC: Single Over Head Camshaft

T:

TBI: Throttle Body Fuel Injection (Single-Point Fuel

Injection, SPI)

TCC: Torque Converter Clutch

TCM: Transmission Control Module (A/T Controller, A/T

Control Module)

TDC: Top Dead Center

TP Sensor: Throttle Position Sensor TVV:

Thermal Vacuum Valve (Thermal Vacuum

Switching Valve, TVSV, Bi metal Vacuum Switching

Valve, BVSV)

TWC: Three Way Catalytic Converter (Three Way

Catalyst)

2WD: 2 Wheel Drive

U:

USB: Universal Serial Bus

V:

VIN: Vehicle Identification Number

VSS: Vehicle Speed Sensor

VVT: Variable Valve Timing (Camshaft Position Control)

W:

WU-OC: Warm Up Oxidation Catalytic Converter

WU-TWC: Warm Up Three Way Catalytic Converter

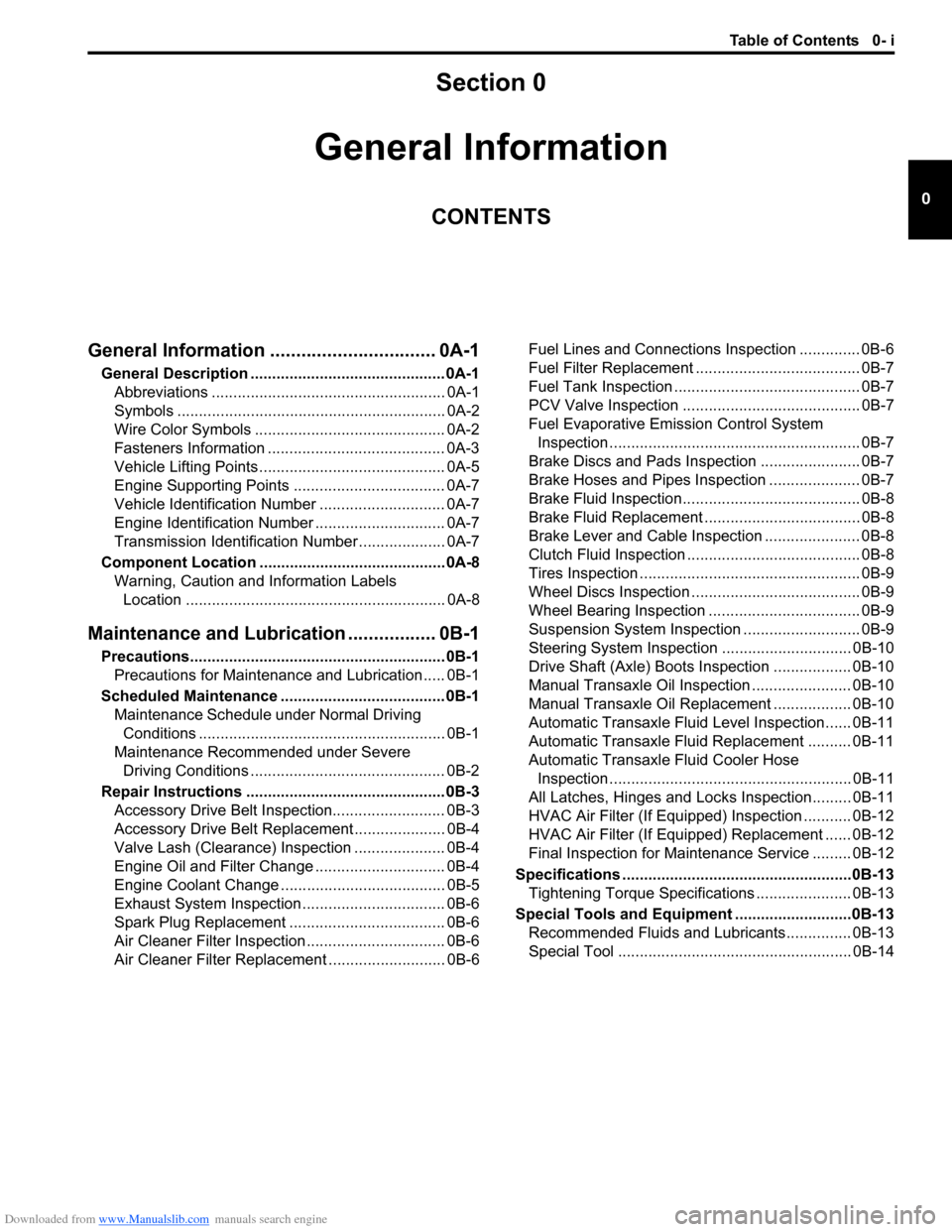

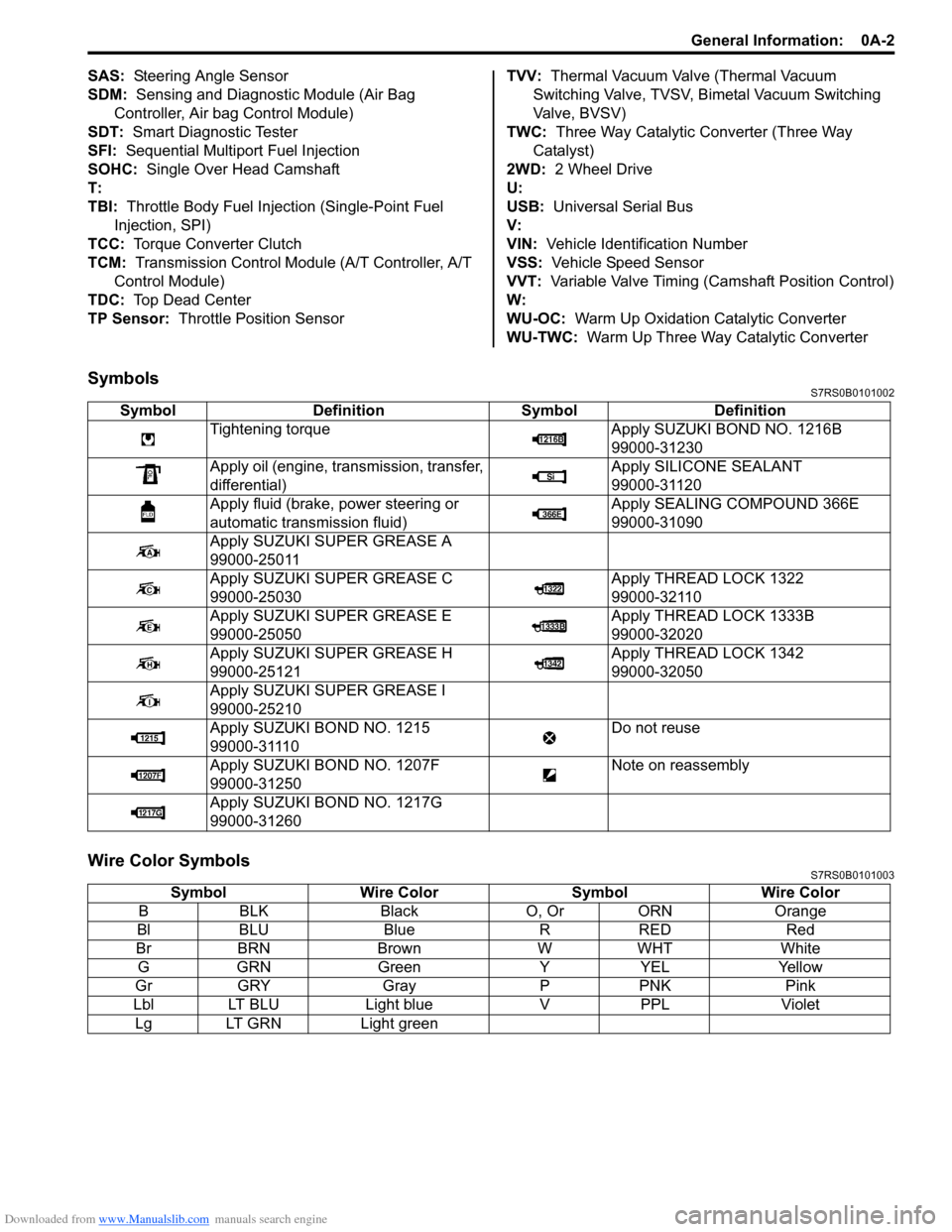

SymbolsS7RS0B0101002

Wire Color SymbolsS7RS0B0101003

Symbol Definition SymbolDefinition

Tightening torque Apply SUZUKI BOND NO. 1216B

99000-31230

Apply oil (engine, transmission, transfer,

differential) Apply SILICONE SEALANT

99000-31120

Apply fluid (brake, power steering or

automatic transmission fluid) Apply SEALING COMPOUND 366E

99000-31090

Apply SUZUKI SUPER GREASE A

99000-25011

Apply SUZUKI SUPER GREASE C

99000-25030 Apply THREAD LOCK 1322

99000-32110

Apply SUZUKI SUPER GREASE E

99000-25050 Apply THREAD LOCK 1333B

99000-32020

Apply SUZUKI SUPER GREASE H

99000-25121 Apply THREAD LOCK 1342

99000-32050

Apply SUZUKI SUPER GREASE I

99000-25210

Apply SUZUKI BOND NO. 1215

99000-31110 Do not reuse

Apply SUZUKI BO ND NO. 1207F

99000-31250 Note on reassembly

Apply SUZUKI BO ND NO. 1217G

99000-31260

Symbol Wire Color SymbolWire Color

B BLK Black O, Or ORN Orange

Bl BLU Blue RRED Red

Br BRN Brown WWHT White

G GRN Green YYEL Yellow

Gr GRY Gray PPNK Pink

Lbl LT BLU Light blueVPPL Violet

Lg LT GRN Light green

Page 31 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-1

General Information

Maintenance and Lubrication

Precautions

Precautions for Maintenance and LubricationS7RS0B0200001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.

Scheduled Maintenance

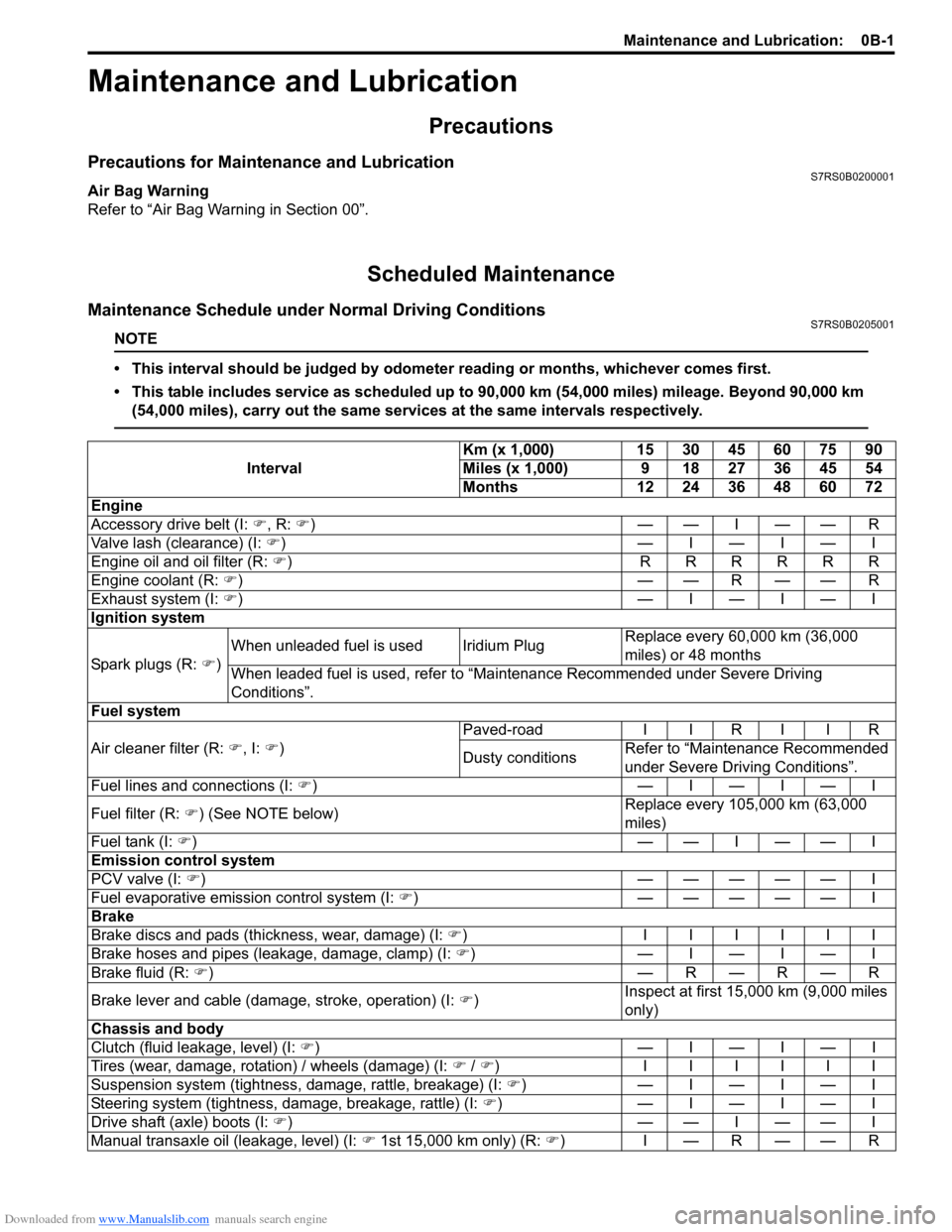

Maintenance Schedule under Normal Driving ConditionsS7RS0B0205001

NOTE

• This interval should be judged by odometer reading or months, whichever comes first.

• This table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km

(54,000 miles), carry out the same services at the same intervals respectively.

Interval Km (x 1,000) 15 30 45 60 75 90

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Engine

Accessory drive belt (I: �), R: �))——I——R

Valve lash (clearance) (I: �)) —I—I—I

Engine oil and oil filter (R: �)) RRRRRR

Engine coolant (R: �))— —R— — R

Exhaust system (I: �)) —I—I—I

Ignition system

Spark plugs (R: �) )When unleaded fuel is used Iridium Plug

Replace every 60,000 km (36,000

miles) or 48 months

When leaded fuel is used, refer to “Maintenance Recommended under Severe Driving

Conditions”.

Fuel system

Air cleaner filter (R: �), I: �)) Paved-road

I I R I I R

Dusty conditions Refer to “Maintenance Recommended

under Severe Driv

ing Conditions”.

Fuel lines and connections (I: �)) —I—I—I

Fuel filter (R: �)) (See NOTE below) Replace every 105,000 km (63,000

miles)

Fuel tank (I: �))— —I— — I

Emission control system

PCV valve (I: �)) ————— I

Fuel evaporative emission control system (I: �)) ————— I

Brake

Brake discs and pads (thickness, wear, damage) (I: �)) IIIIII

Brake hoses and pipes (leakage, damage, clamp) (I: �)) —I—I—I

Brake fluid (R: �)) —R—R—R

Brake lever and cable (damage, stroke, operation) (I: �)) Inspect at first 15,000 km (9,000 miles

only)

Chassis and body

Clutch (fluid leakage, level) (I: �)) —I—I—I

Tires (wear, damage, rotation) / wheels (damage) (I: �) / �) ) IIIIII

Suspension system (tightness, damage, rattle, breakage) (I: �)) —I—I—I

Steering system (tightness, damage, breakage, rattle) (I: �)) —I—I—I

Drive shaft (axle) boots (I: �))— —I— — I

Manual transaxle oil (leakage, level) (I: �) 1st 15,000 km only) (R: �))I—R——R

Page 32 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-2 Maintenance and Lubrication:

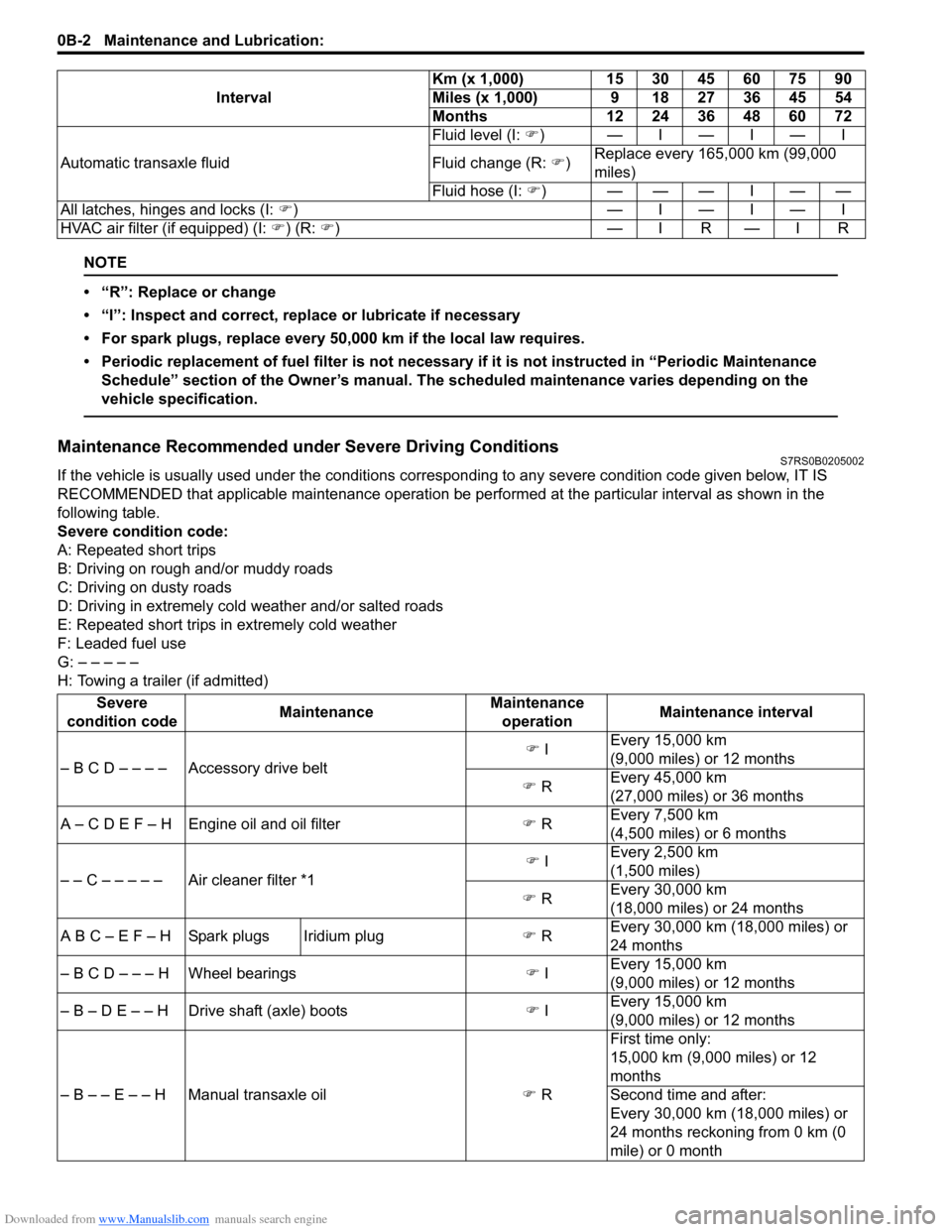

NOTE

• “R”: Replace or change

• “I”: Inspect and correct, replace or lubricate if necessary

• For spark plugs, replace every 50,000 km if the local law requires.

• Periodic replacement of fuel filter is not necessary if it is not instructed in “Periodic Maintenance Schedule” section of the Owner’s manual. The scheduled maintenance varies depending on the

vehicle specification.

Maintenance Recommended under Severe Driving ConditionsS7RS0B0205002

If the vehicle is usually used under the conditions corres ponding to any severe condition code given below, IT IS

RECOMMENDED that applicable maintenance operation be per formed at the particular interval as shown in the

following table.

Severe condition code:

A: Repeated short trips

B: Driving on rough and/or muddy roads

C: Driving on dusty roads

D: Driving in extremely cold weather and/or salted roads

E: Repeated short trips in extremely cold weather

F: Leaded fuel use

G: – – – – –

H: Towing a trailer (if admitted) Automatic transaxle fluid

Fluid level (I:

�)) —I—I—I

Fluid change (R: �)) Replace every 165,000 km (99,000

miles)

Fluid hose (I: �))———I——

All latches, hinges and locks (I: �)) —I—I—I

HVAC air filter (if equipped) (I: �) ) (R: �))— IR — IR

Interval

Km (x 1,000)

15 30 45 60 75 90

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Severe

condition code MaintenanceMaintenance

operation Maintenance interval

– B C D – – – – Accessory drive belt �)

I Every 15,000 km

(9,000 miles) or 12 months

�) R Every 45,000 km

(27,000 miles) or 36 months

A – C D E F – H Engine oil and oil filter �) R Every 7,500 km

(4,500 miles) or 6 months

– – C – – – – – Air cleaner filter *1 �)

I Every 2,500 km

(1,500 miles)

�) R Every 30,000 km

(18,000 miles) or 24 months

A B C – E F – H Spark plugs Iridium plug �) R Every 30,000 km (18,000 miles) or

24 months

– B C D – – – H Wheel bearings �) I Every 15,000 km

(9,000 miles) or 12 months

– B – D E – – H Drive shaft (axle) boots �) I Every 15,000 km

(9,000 miles) or 12 months

– B – – E – – H Manual transaxle oil �) R First time only:

15,000 km (9,000 miles) or 12

months

Second time and after:

Every 30,000 km (18,000 miles) or

24 months reckoning from 0 km (0

mile) or 0 month