temperature sensor replace SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 6 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-1 Precautions:

Precautions

Precautions

Precautions

Precautions for Vehicles Equipped with a

Supplemental Restraint (Air Bag) System

S7RS0B0000001

WARNING!

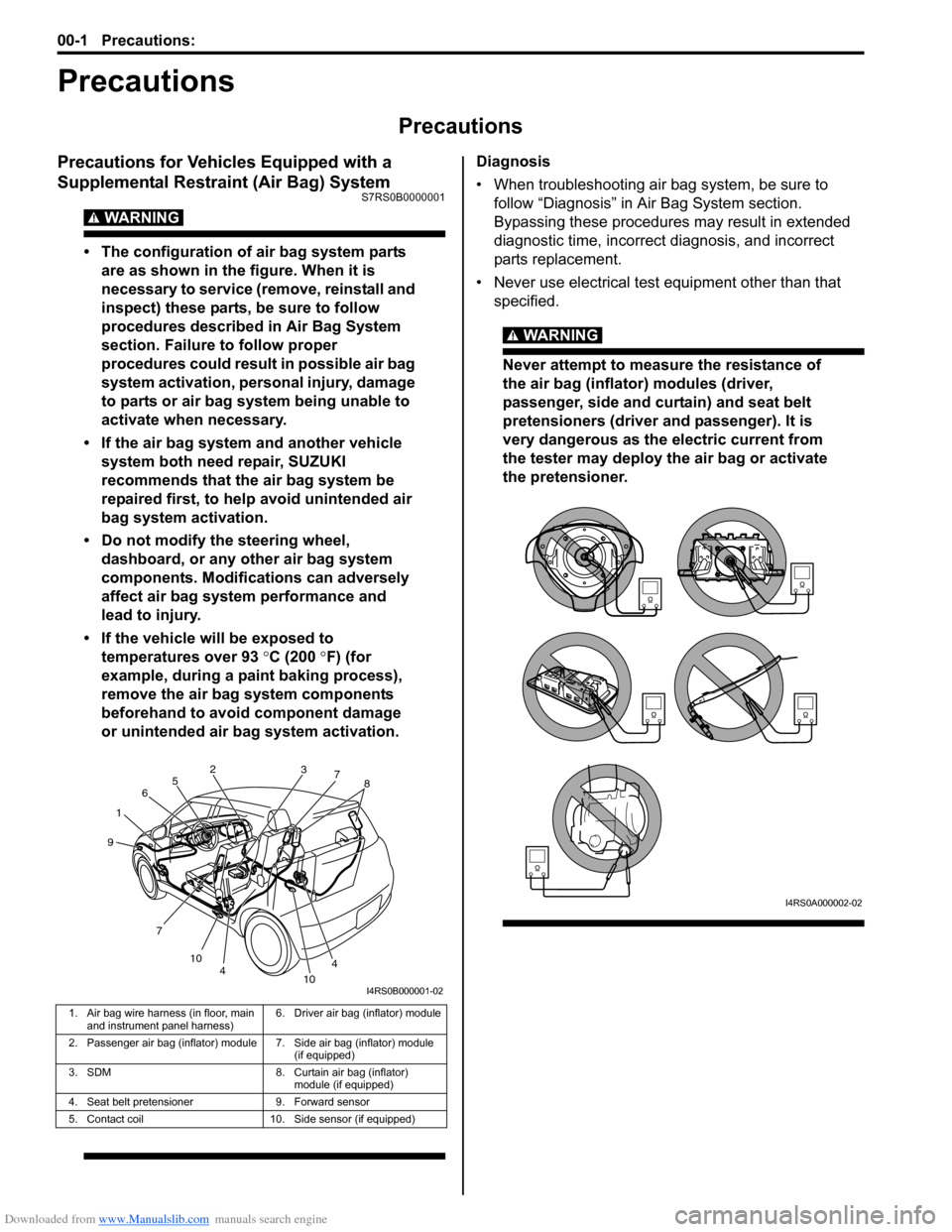

• The configuration of air bag system parts are as shown in the figure. When it is

necessary to service (remove, reinstall and

inspect) these parts, be sure to follow

procedures described in Air Bag System

section. Failure to follow proper

procedures could result in possible air bag

system activation, personal injury, damage

to parts or air bag system being unable to

activate when necessary.

• If the air bag system and another vehicle system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel, dashboard, or any other air bag system

components. Modifications can adversely

affect air bag system performance and

lead to injury.

• If the vehicle will be exposed to temperatures over 93 °C (200 °F) (for

example, during a paint baking process),

remove the air bag system components

beforehand to avoid component damage

or unintended air bag system activation.

Diagnosis

• When troubleshooting air bag system, be sure to follow “Diagnosis” in Air Bag System section.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacement.

• Never use electrical test equipment other than that specified.

WARNING!

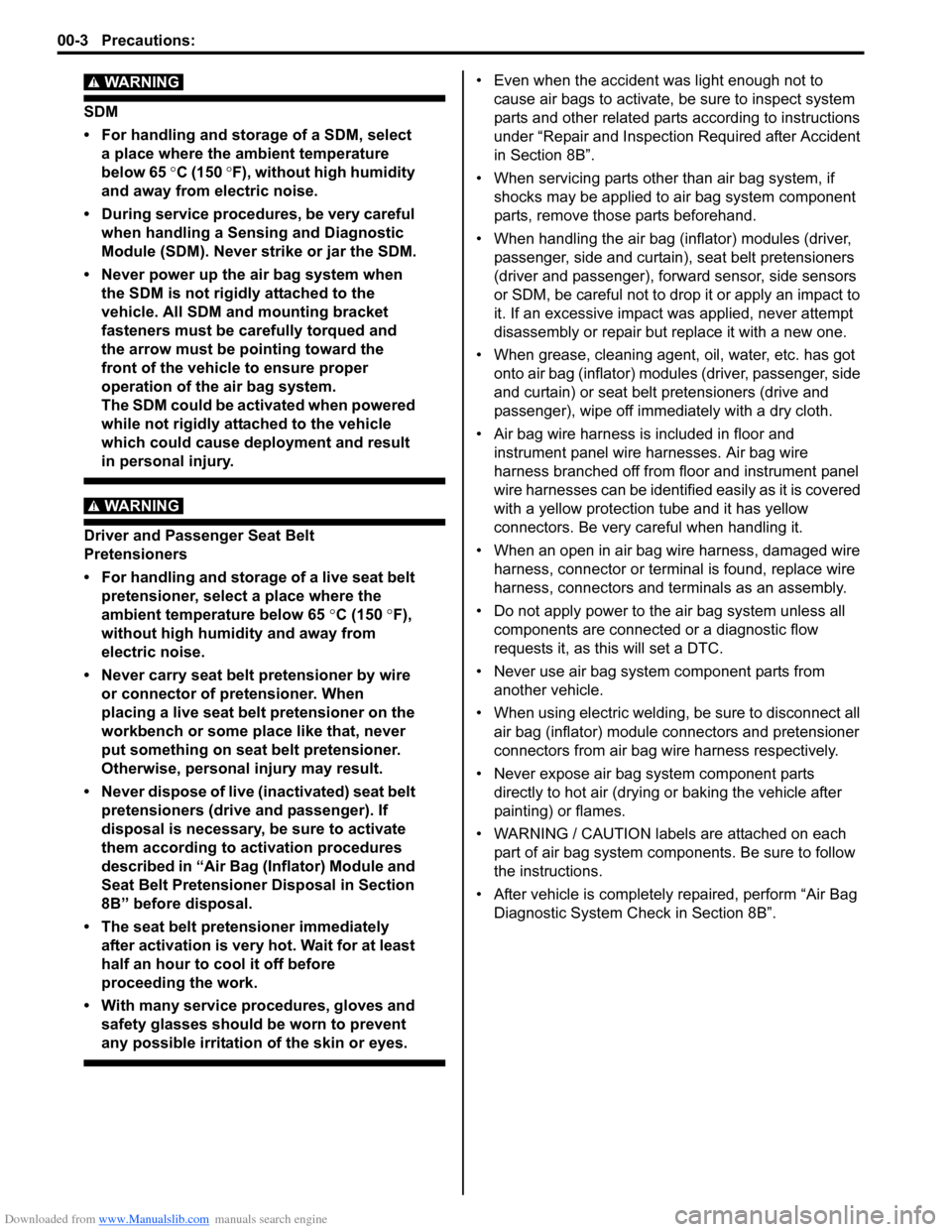

Never attempt to measure the resistance of

the air bag (inflator) modules (driver,

passenger, side and curtain) and seat belt

pretensioners (driver and passenger). It is

very dangerous as the electric current from

the tester may deploy the air bag or activate

the pretensioner.

1. Air bag wire harness (in floor, main and instrument panel harness) 6. Driver air bag (inflator) module

2. Passenger air bag (inflator) module 7. Side air bag (inflator) module (if equipped)

3. SDM 8. Curtain air bag (inflator) module (if equipped)

4. Seat belt pretensioner 9. Forward sensor

5. Contact coil 10. Side sensor (if equipped)

1 2

3

4

4

5

6

7 7

8

9

10 10

I4RS0B000001-02

I4RS0A000002-02

Page 8 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-3 Precautions:

WARNING!

SDM

• For handling and storage of a SDM, select a place where the ambient temperature

below 65 °C (150 °F), without high humidity

and away from electric noise.

• During service procedures, be very careful when handling a Sensing and Diagnostic

Module (SDM). Never strike or jar the SDM.

• Never power up the air bag system when the SDM is not rigidly attached to the

vehicle. All SDM and mounting bracket

fasteners must be carefully torqued and

the arrow must be pointing toward the

front of the vehicle to ensure proper

operation of the air bag system.

The SDM could be activated when powered

while not rigidly att ached to the vehicle

which could cause deployment and result

in personal injury.

WARNING!

Driver and Passenger Seat Belt

Pretensioners

• For handling and storage of a live seat belt pretensioner, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

• Never carry seat belt pretensioner by wire or connector of pretensioner. When

placing a live seat belt pretensioner on the

workbench or some place like that, never

put something on seat belt pretensioner.

Otherwise, personal injury may result.

• Never dispose of live (inactivated) seat belt pretensioners (drive and passenger). If

disposal is necessary, be sure to activate

them according to activation procedures

described in “Air Bag (Inflator) Module and

Seat Belt Pretensioner Disposal in Section

8B” before disposal.

• The seat belt pretensioner immediately after activation is very hot. Wait for at least

half an hour to cool it off before

proceeding the work.

• With many service procedures, gloves and safety glasses should be worn to prevent

any possible irritation of the skin or eyes.

• Even when the accident was light enough not to cause air bags to activate, be sure to inspect system

parts and other related parts according to instructions

under “Repair and Inspection Required after Accident

in Section 8B”.

• When servicing parts other than air bag system, if shocks may be applied to air bag system component

parts, remove those parts beforehand.

• When handling the air bag (inflator) modules (driver, passenger, side and curtain), seat belt pretensioners

(driver and passenger), forward sensor, side sensors

or SDM, be careful not to drop it or apply an impact to

it. If an excessive impact was applied, never attempt

disassembly or repair but replace it with a new one.

• When grease, cleaning agent, oil, water, etc. has got onto air bag (inflator) modules (driver, passenger, side

and curtain) or seat belt pretensioners (drive and

passenger), wipe off immediately with a dry cloth.

• Air bag wire harness is included in floor and instrument panel wire harnesses. Air bag wire

harness branched off from floor and instrument panel

wire harnesses can be identifie d easily as it is covered

with a yellow protection tube and it has yellow

connectors. Be very ca reful when handling it.

• When an open in air bag wire harness, damaged wire harness, connector or terminal is found, replace wire

harness, connectors and terminals as an assembly.

• Do not apply power to the air bag system unless all components are connected or a diagnostic flow

requests it, as this will set a DTC.

• Never use air bag system component parts from another vehicle.

• When using electric welding, be sure to disconnect all air bag (inflator) module connectors and pretensioner

connectors from air bag wire harness respectively.

• Never expose air bag system component parts directly to hot air (drying or baking the vehicle after

painting) or flames.

• WARNING / CAUTION labels are attached on each

part of air bag system components. Be sure to follow

the instructions.

• After vehicle is completely repaired, perform “Air Bag Diagnostic System Check in Section 8B”.

Page 109 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-59

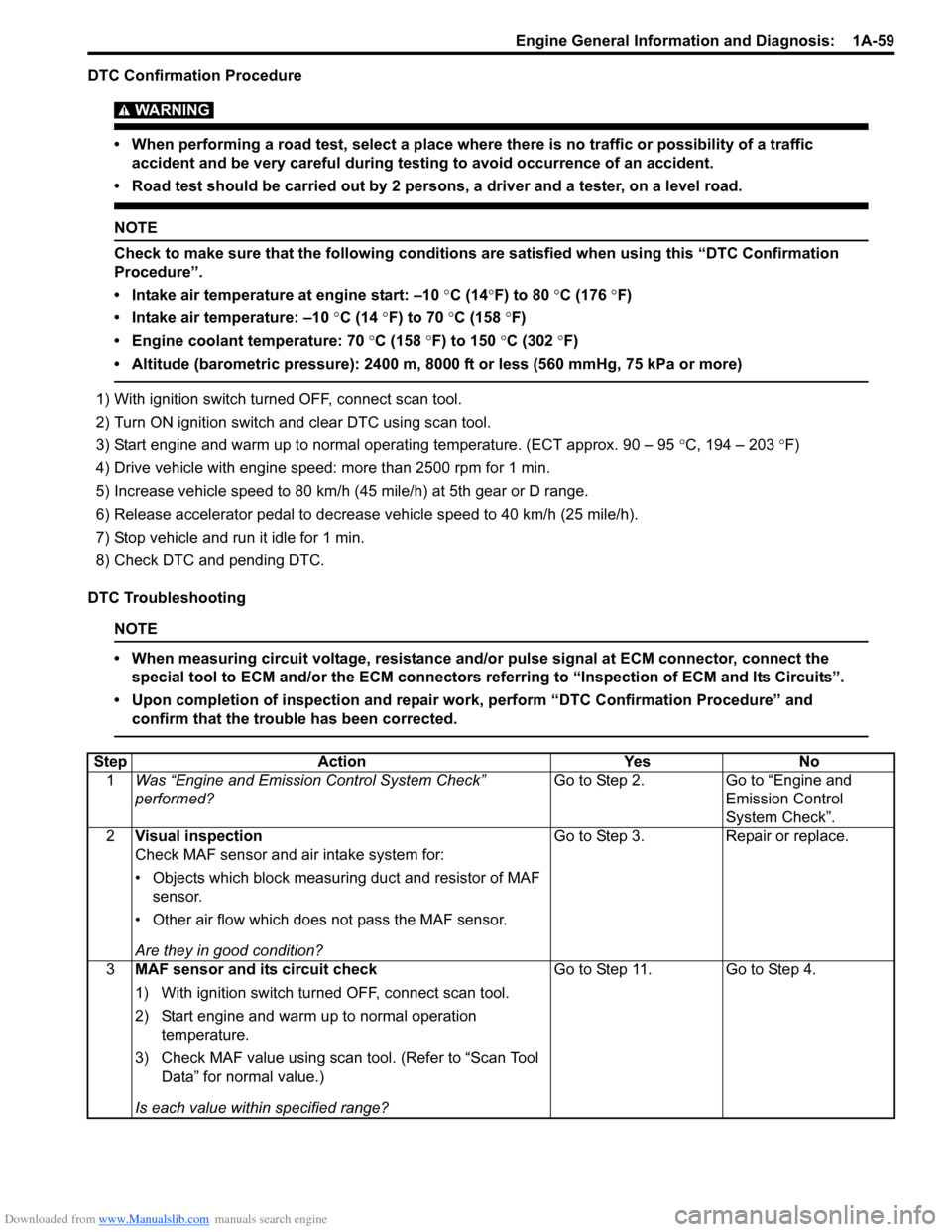

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that the following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 °F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 70 °C (158 °F) to 150 °C (302 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up to normal operating temperature. (ECT approx. 90 – 95 °C, 194 – 203 °F)

4) Drive vehicle with engine speed: more than 2500 rpm for 1 min.

5) Increase vehicle speed to 80 km/h (45 mile/h) at 5th gear or D range.

6) Release accelerator pedal to decrease vehicle speed to 40 km/h (25 mile/h).

7) Stop vehicle and run it idle for 1 min.

8) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Visual inspection

Check MAF sensor and air intake system for:

• Objects which block measuring duct and resistor of MAF

sensor.

• Other air flow which does not pass the MAF sensor.

Are they in good condition? Go to Step 3.

Repair or replace.

3 MAF sensor and its circuit check

1) With ignition switch turned OFF, connect scan tool.

2) Start engine and warm up to normal operation

temperature.

3) Check MAF value using scan tool. (Refer to “Scan Tool Data” for normal value.)

Is each value within specified range? Go to Step 11. Go to Step 4.

Page 115 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-65

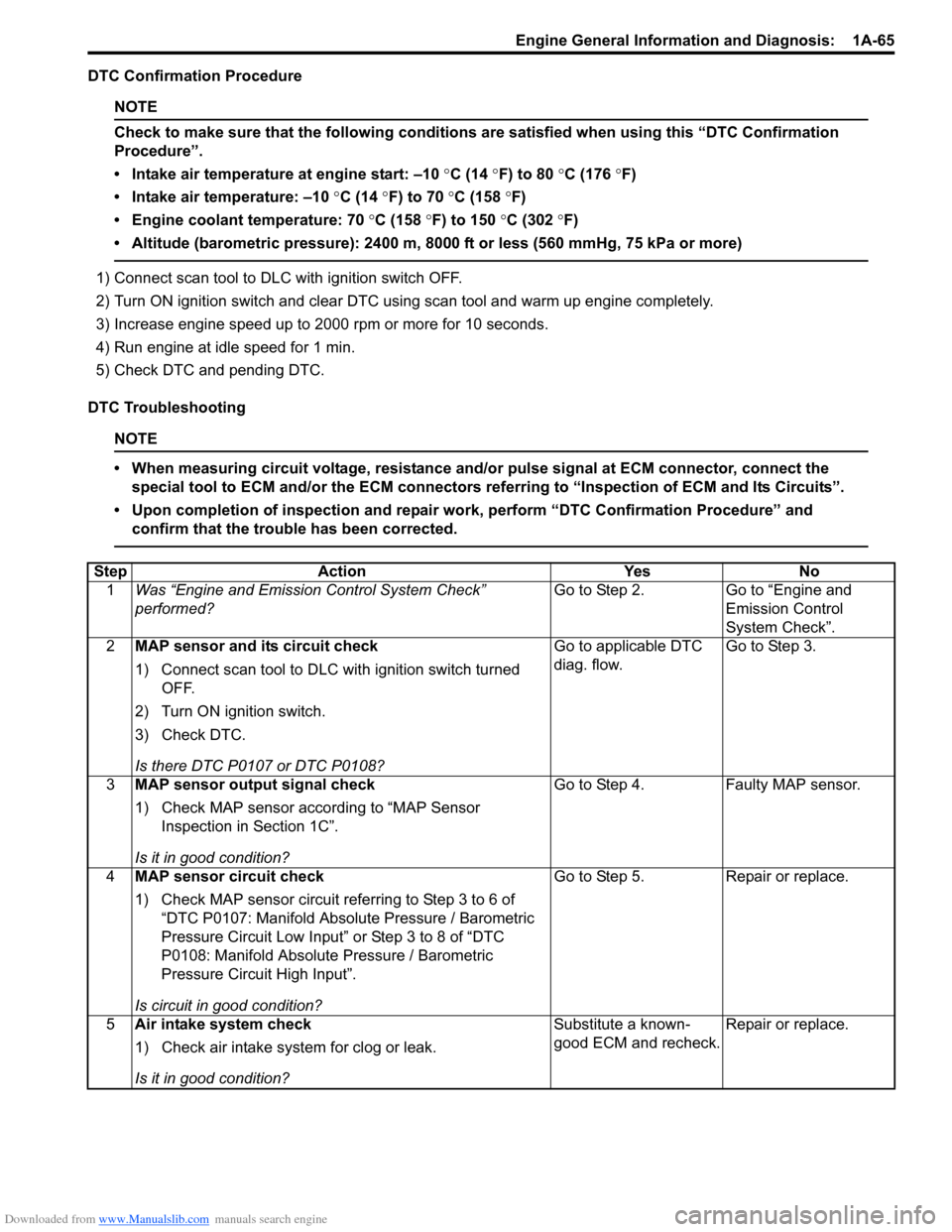

DTC Confirmation Procedure

NOTE

Check to make sure that the following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 70 °C (158 °F) to 150 °C (302 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC using scan tool and warm up engine completely.

3) Increase engine speed up to 2000 rpm or more for 10 seconds.

4) Run engine at idle speed for 1 min.

5) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 MAP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check DTC.

Is there DTC P0107 or DTC P0108? Go to applicable DTC

diag. flow.

Go to Step 3.

3 MAP sensor output signal check

1) Check MAP sensor acco rding to “MAP Sensor

Inspection in Section 1C”.

Is it in good condition? Go to Step 4.

Faulty MAP sensor.

4 MAP sensor circuit check

1) Check MAP sensor circuit referring to Step 3 to 6 of

“DTC P0107: Manifold Absolute Pressure / Barometric

Pressure Circuit Low Input” or Step 3 to 8 of “DTC

P0108: Manifold Absolute Pressure / Barometric

Pressure Circuit High Input”.

Is circuit in good condition? Go to Step 5.

Repair or replace.

5 Air intake system check

1) Check air intake system for clog or leak.

Is it in good condition? Substitute a known-

good ECM and recheck.

Repair or replace.

Page 122 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-72 Engine General Information and Diagnosis:

DTC P0112: Intake Air Temperature Sensor 1 Circuit LowS7RS0B1104024

Wiring Diagram

Refer to “DTC P0111: Intake Air Temperature Sensor 1 Circuit Range / Performance”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and run it for 10 sec.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

8 Ground circuit check

1) Connect connectors to ECM.

2) Check for proper connection of MAF and IAT sensor

connector at “GRY/BLU” wire terminal.

3) Measure resistance between “GRY/BLU” wire terminal of MAF and IAT sensor connector and vehicle body

ground with ignition switch turned OFF.

Is resistance below 5

Ω? Go to Step 10. Go to Step 9.

9 Ground circuit check

1) Remove ECM from its br acket with ECM connectors

connected.

2) Measure resistance between “C37-55” terminal of ECM connector and vehicle body ground.

Is resistance below 3

Ω? “GRY/BLU” wire and/or

“ORN” wire is open or

high resistance circuit.

Poor “C37-55”

connection.

Faulty ECM ground

circuit.

If circuit is OK,

substitute a known-

good ECM and recheck.

10 IAT sensor check

1) Check IAT sensor according to “MAF and IAT Sensor

Inspection in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace MAF and IAT

sensor.

Step Action Yes No

DTC detecting condition

Trouble area

IAT sensor output voltage is less than 0.15 V for 0.5 seconds

continuously.

(High intake air temperature (low voltage/low resistance))

(1 driving cycle detection logic) • IAT sensor circuit

• IAT sensor

•ECM

Page 126 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-76 Engine General Information and Diagnosis:

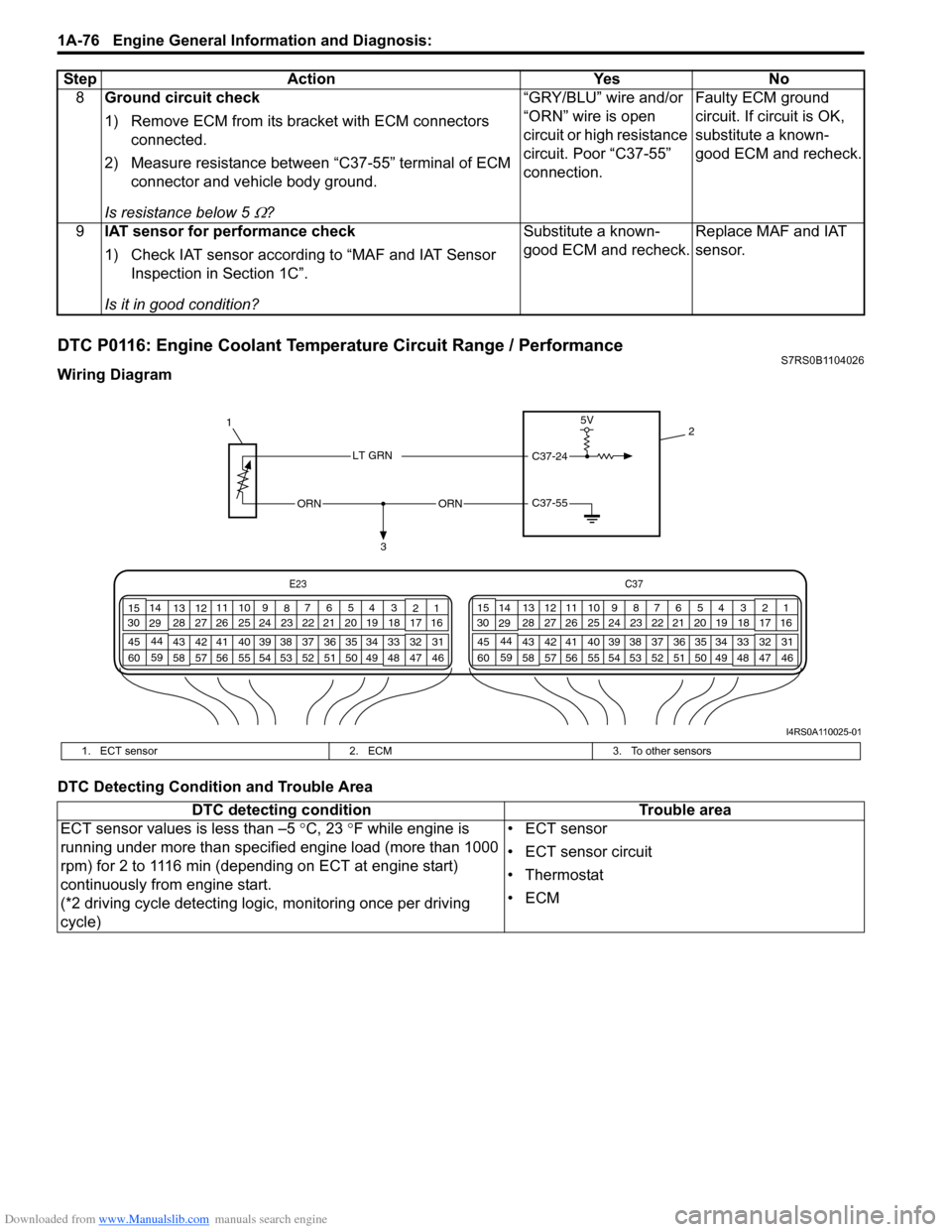

DTC P0116: Engine Coolant Temperature Circuit Range / PerformanceS7RS0B1104026

Wiring Diagram

DTC Detecting Condition and Trouble Area8

Ground circuit check

1) Remove ECM from its br acket with ECM connectors

connected.

2) Measure resistance between “C37-55” terminal of ECM connector and vehicle body ground.

Is resistance below 5

Ω? “GRY/BLU” wire and/or

“ORN” wire is open

circuit or high resistance

circuit. Poor “C37-55”

connection.

Faulty ECM ground

circuit. If circuit is OK,

substitute a known-

good ECM and recheck.

9 IAT sensor for performance check

1) Check IAT sensor according to “MAF and IAT Sensor

Inspection in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace MAF and IAT

sensor.

Step Action Yes No

C37-55ORNORN

3

1

2

5V

C37-24LT GRN

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 48 32 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A110025-01

1. ECT sensor

2. ECM3. To other sensors

DTC detecting condition Trouble area

ECT sensor values is less than –5 °C, 23 °F while engine is

running under more than specified engine load (more than 1000

rpm) for 2 to 1116 min (depending on ECT at engine start)

continuously from engine start.

(*2 driving cycle detecting logi c, monitoring once per driving

cycle) • ECT sensor

• ECT sensor circuit

•Thermostat

•ECM

Page 129 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-79

DTC P0117: Engine Coolant Temperature Circuit LowS7RS0B1104027

Wiring Diagram

Refer to “DTC P0116: Engine Coolant Temperature Circuit Range / Performance”

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and run it for 10 sec. or more.

4) Check DTC.10

Ground circuit check

1) Remove ECM from its br acket with ECM connectors

connected.

2) Measure resistance between “C37-55” terminal of ECM connector and vehicle body ground.

Is resistance below 5

Ω? “ORN” wire is high

resistance circuit.

Poor “C37-55”

connection.

Faulty ECM ground

circuit.

If circuit is OK,

substitute a known-

good ECM and recheck.

11 ECT sensor check

1) Check ECT sensor according to “ECT Sensor Inspection

in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace ECT sensor.

Step Action Yes No

DTC detecting condition

Trouble area

ECT sensor output voltage is less than 0.15 V for 0.5 seconds

continuously.

(High engine coolant temperature (low voltage / low resistance))

(1 driving cycle detection logic) • ECT sensor circuit

• ECT sensor

•ECM

Page 141 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-91

DTC P0133: O2 Sensor (HO2S) Circuit Slow Response (Sensor-1)S7RS0B1104032

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 70 °C (158 °F) to 150 °C (302 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up to normal operating temperature.

4) Drive vehicle at 40 mph (60 km/h) or higher. (engine speed: 2500 – 3000 r/min.)

5) Keep above vehicle speed for 6 min. or more. (Throt tle valve opening is kept constant in this step.)

6) Release accelerator pedal and with engine brake applied, keep vehicle coasting (with fuel cut for 3 sec. or more)

and then stop vehicle.

7) Check if DTC and pending DTC exist by using scan tool. If not, check if oxygen sensor monitoring test has been

completed by using scan tool. If not in both of above c hecks (i.e., no DTC and pending DTC and oxygen sensor

monitoring test not completed), check vehicle cond ition (environmental) and repeat Step 3) through 6).

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Response time (time to change from lean to rich or from rich to lean) of HO2S-1 output

voltage is about 1 sec. at minimum or aver age time of 1 cycle is 5 sec. at minimum.

(*2 driving cycle detection logic, monitoring once per driving cycle) Heated oxygen sensor-1

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Is there DTC(s) other than HO2S-1 (DTC P0133)? Go to applicable DTC

diag. flow.Replace HO2S-1.

Page 143 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-93

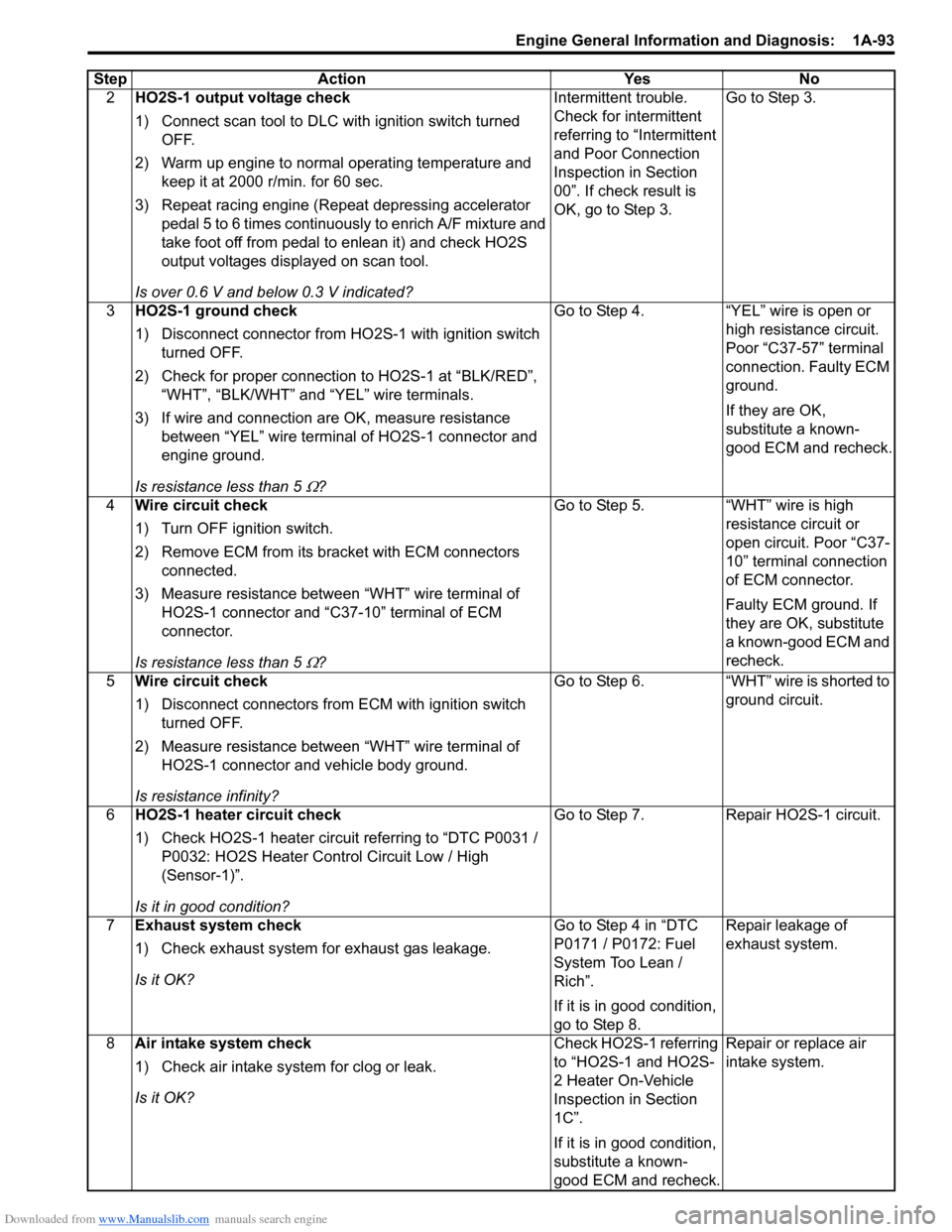

2HO2S-1 output voltage check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Warm up engine to normal operating temperature and keep it at 2000 r/min. for 60 sec.

3) Repeat racing engine (Repeat depressing accelerator pedal 5 to 6 times continuous ly to enrich A/F mixture and

take foot off from pedal to enlean it) and check HO2S

output voltages displayed on scan tool.

Is over 0.6 V and below 0.3 V indicated? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”. If check result is

OK, go to Step 3.

Go to Step 3.

3 HO2S-1 ground check

1) Disconnect connector from HO 2S-1 with ignition switch

turned OFF.

2) Check for proper connection to HO2S-1 at “BLK/RED”, “WHT”, “BLK/WHT” and “YEL” wire terminals.

3) If wire and connection are OK, measure resistance between “YEL” wire terminal of HO2S-1 connector and

engine ground.

Is resistance less than 5

Ω? Go to Step 4. “YEL” wire is open or

high resistance circuit.

Poor “C37-57” terminal

connection. Faulty ECM

ground.

If they are OK,

substitute a known-

good ECM and recheck.

4 Wire circuit check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Measure resistance between “WHT” wire terminal of HO2S-1 connector and “C37-10” terminal of ECM

connector.

Is resistance less than 5

Ω? Go to Step 5. “WHT” wire is high

resistance circuit or

open circuit. Poor “C37-

10” terminal connection

of ECM connector.

Faulty ECM ground. If

they are OK, substitute

a known-good ECM and

recheck.

5 Wire circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “WHT” wire terminal of HO2S-1 connector and vehicle body ground.

Is resistance infinity? Go to Step 6. “WHT” wire is shorted to

ground circuit.

6 HO2S-1 heater circuit check

1) Check HO2S-1 heater circuit referring to “DTC P0031 /

P0032: HO2S Heater Control Circuit Low / High

(Sensor-1)”.

Is it in good condition? Go to Step 7. Repair HO2S-1 circuit.

7 Exhaust system check

1) Check exhaust system for exhaust gas leakage.

Is it OK? Go to Step 4 in “DTC

P0171 / P0172: Fuel

System Too Lean /

Rich”.

If it is in good condition,

go to Step 8.Repair leakage of

exhaust system.

8 Air intake system check

1) Check air intake system for clog or leak.

Is it OK? Check HO2S-1 referring

to “HO2S-1 and HO2S-

2 Heater On-Vehicle

Inspection in Section

1C”.

If it is in good condition,

substitute a known-

good ECM and recheck.Repair or replace air

intake system.

Step Action Yes No

Page 148 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-98 Engine General Information and Diagnosis:

DTC P0171 / P0172: Fuel System Too Lean / RichS7RS0B1104036

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 40 °C (104 °F) to 120 °C (248 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

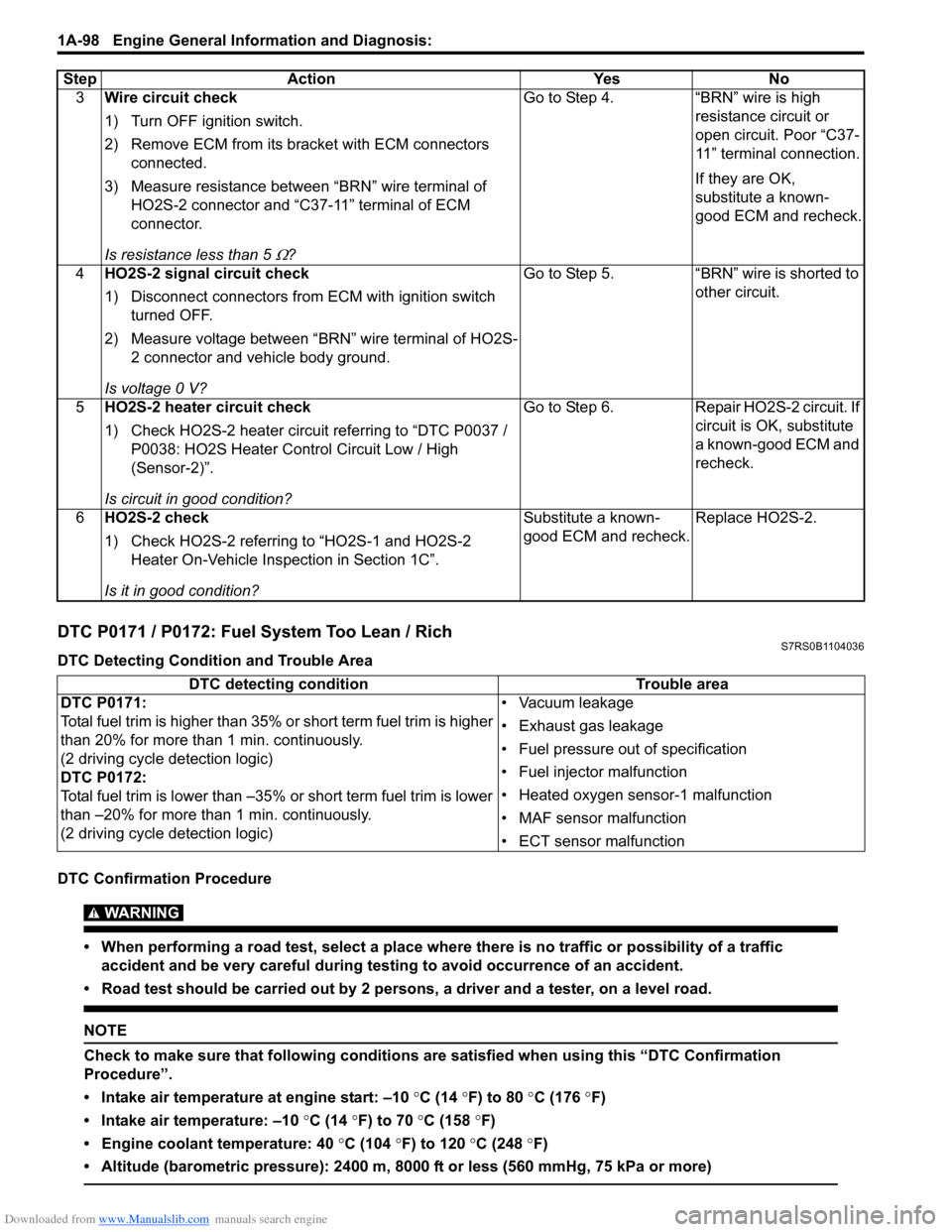

3 Wire circuit check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Measure resistance between “BRN” wire terminal of HO2S-2 connector and “C37-11” terminal of ECM

connector.

Is resistance less than 5

Ω? Go to Step 4. “BRN” wire is high

resistance circuit or

open circuit. Poor “C37-

11” terminal connection.

If they are OK,

substitute a known-

good ECM and recheck.

4 HO2S-2 signal circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure voltage between “BRN” wire terminal of HO2S- 2 connector and vehicle body ground.

Is voltage 0 V? Go to Step 5. “BRN” wire is shorted to

other circuit.

5 HO2S-2 heater circuit check

1) Check HO2S-2 heater circuit referring to “DTC P0037 /

P0038: HO2S Heater Control Circuit Low / High

(Sensor-2)”.

Is circuit in good condition? Go to Step 6. Repair HO2S-2 circuit. If

circuit is OK, substitute

a known-good ECM and

recheck.

6 HO2S-2 check

1) Check HO2S-2 referring to “HO2S-1 and HO2S-2

Heater On-Vehicle Inspection in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace HO2S-2.

Step Action Yes No

DTC detecting condition

Trouble area

DTC P0171:

Total fuel trim is higher than 35% or short term fuel trim is higher

than 20% for more than 1 min. continuously.

(2 driving cycle detection logic)

DTC P0172:

Total fuel trim is lower than –35% or short term fuel trim is lower

than –20% for more than 1 min. continuously.

(2 driving cycle detection logic) • Vacuum leakage

• Exhaust gas leakage

• Fuel pressure out of specification

• Fuel injector malfunction

• Heated oxygen sensor-1 malfunction

• MAF sensor malfunction

• ECT sensor malfunction