warning light SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 2 of 1496

Downloaded from www.Manualslib.com manuals search engine IMPORTANT

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the words , and NOTE have special meanings. Pay specia l attention to the messages high-

lighted by these signal words.

The circle with a slash in this manual me ans “Don’t do this” or “Don’t let this happen”.

WARNING!CAUTION!

Indicates a potential hazard that could result in death or injury.

WARNING!

Indicates a potential hazard that could result in vehicle damage.

CAUTION!

NOTE:

Indicates special information to make main tenance easier or instructions clearer.

This service manual is intended for authorized Su zuki dealers and qualified service technicians only.

Inexperienced technicians or technicians without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the technician and may render the vehicle unsafe for the driver

and passengers.

WARNING!

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed only by an authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicl e Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could re nder the system inoperative. Either of these two

conditions may result in severe injury.

If the air bag system and another vehicle system both need repair, Suzuki recommends that the air

bag system be repaired first, to help av oid unintended air bag system activation.

Do not modify the steering wheel, instrument pa nel or any other air bag system component on or

around air bag system components or wiring. Modi fications can adversely affect air bag system

performance and lead to injury.

If the vehicle will be exposed to temperatures over 93 °C (200 °F), for example, during a paint baking

process, remove the air bag system components, th at is air bag (inflator) modules, SDM and/or seat

belt with pretensioner, beforehand to avoid component damage or unintended activation.

WARNING!

Page 8 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-3 Precautions:

WARNING!

SDM

• For handling and storage of a SDM, select a place where the ambient temperature

below 65 °C (150 °F), without high humidity

and away from electric noise.

• During service procedures, be very careful when handling a Sensing and Diagnostic

Module (SDM). Never strike or jar the SDM.

• Never power up the air bag system when the SDM is not rigidly attached to the

vehicle. All SDM and mounting bracket

fasteners must be carefully torqued and

the arrow must be pointing toward the

front of the vehicle to ensure proper

operation of the air bag system.

The SDM could be activated when powered

while not rigidly att ached to the vehicle

which could cause deployment and result

in personal injury.

WARNING!

Driver and Passenger Seat Belt

Pretensioners

• For handling and storage of a live seat belt pretensioner, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

• Never carry seat belt pretensioner by wire or connector of pretensioner. When

placing a live seat belt pretensioner on the

workbench or some place like that, never

put something on seat belt pretensioner.

Otherwise, personal injury may result.

• Never dispose of live (inactivated) seat belt pretensioners (drive and passenger). If

disposal is necessary, be sure to activate

them according to activation procedures

described in “Air Bag (Inflator) Module and

Seat Belt Pretensioner Disposal in Section

8B” before disposal.

• The seat belt pretensioner immediately after activation is very hot. Wait for at least

half an hour to cool it off before

proceeding the work.

• With many service procedures, gloves and safety glasses should be worn to prevent

any possible irritation of the skin or eyes.

• Even when the accident was light enough not to cause air bags to activate, be sure to inspect system

parts and other related parts according to instructions

under “Repair and Inspection Required after Accident

in Section 8B”.

• When servicing parts other than air bag system, if shocks may be applied to air bag system component

parts, remove those parts beforehand.

• When handling the air bag (inflator) modules (driver, passenger, side and curtain), seat belt pretensioners

(driver and passenger), forward sensor, side sensors

or SDM, be careful not to drop it or apply an impact to

it. If an excessive impact was applied, never attempt

disassembly or repair but replace it with a new one.

• When grease, cleaning agent, oil, water, etc. has got onto air bag (inflator) modules (driver, passenger, side

and curtain) or seat belt pretensioners (drive and

passenger), wipe off immediately with a dry cloth.

• Air bag wire harness is included in floor and instrument panel wire harnesses. Air bag wire

harness branched off from floor and instrument panel

wire harnesses can be identifie d easily as it is covered

with a yellow protection tube and it has yellow

connectors. Be very ca reful when handling it.

• When an open in air bag wire harness, damaged wire harness, connector or terminal is found, replace wire

harness, connectors and terminals as an assembly.

• Do not apply power to the air bag system unless all components are connected or a diagnostic flow

requests it, as this will set a DTC.

• Never use air bag system component parts from another vehicle.

• When using electric welding, be sure to disconnect all air bag (inflator) module connectors and pretensioner

connectors from air bag wire harness respectively.

• Never expose air bag system component parts directly to hot air (drying or baking the vehicle after

painting) or flames.

• WARNING / CAUTION labels are attached on each

part of air bag system components. Be sure to follow

the instructions.

• After vehicle is completely repaired, perform “Air Bag Diagnostic System Check in Section 8B”.

Page 43 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-13

Brake

Foot brake

Check the following:

• that brake pedal has proper travel,

• that brake works properly,

• that it is free from noise,

• that vehicle does not pull to one side when brake is applied.

• and that brake do not drag.

Parking brake

Check that lever has proper travel.

WARNING!

With vehicle parked on a fairly steep slope,

make sure nothing is in the way downhill to

avoid any personal injury or property

damage. Be prepared to apply regular brake

quickly even if vehicle should start to move.

Check to ensure that parking brake is fully effective

when the vehicle is stopped on the safe slope and brake

lever is pulled all the way.

Steering

• Check to ensure that steering wheel is free from instability, or abnormally heavy feeling. • Check that the vehicle does not wander or pull to one

side.

Engine

• Check that engine responds readily at all speeds.

• Check that engine is free from abnormal noise and abnormal vibration.

Body, Wheels and Power Transmitting System

Check that body, wheels and power transmitting system

are free from abnormal noise and abnormal vibration or

any other abnormal condition.

Meters and Gauge

Check that speedometer, odometer, fuel meter,

temperature gauge, etc. are operating accurately.

Lights

Check that all lights operate properly.

Windshield Defroster

Periodically check that ai r comes out from defroster

outlet when operating heater or air conditioning.

Set mode control lever to defroster position and fan

switch lever to “HI” position for this check.

Specifications

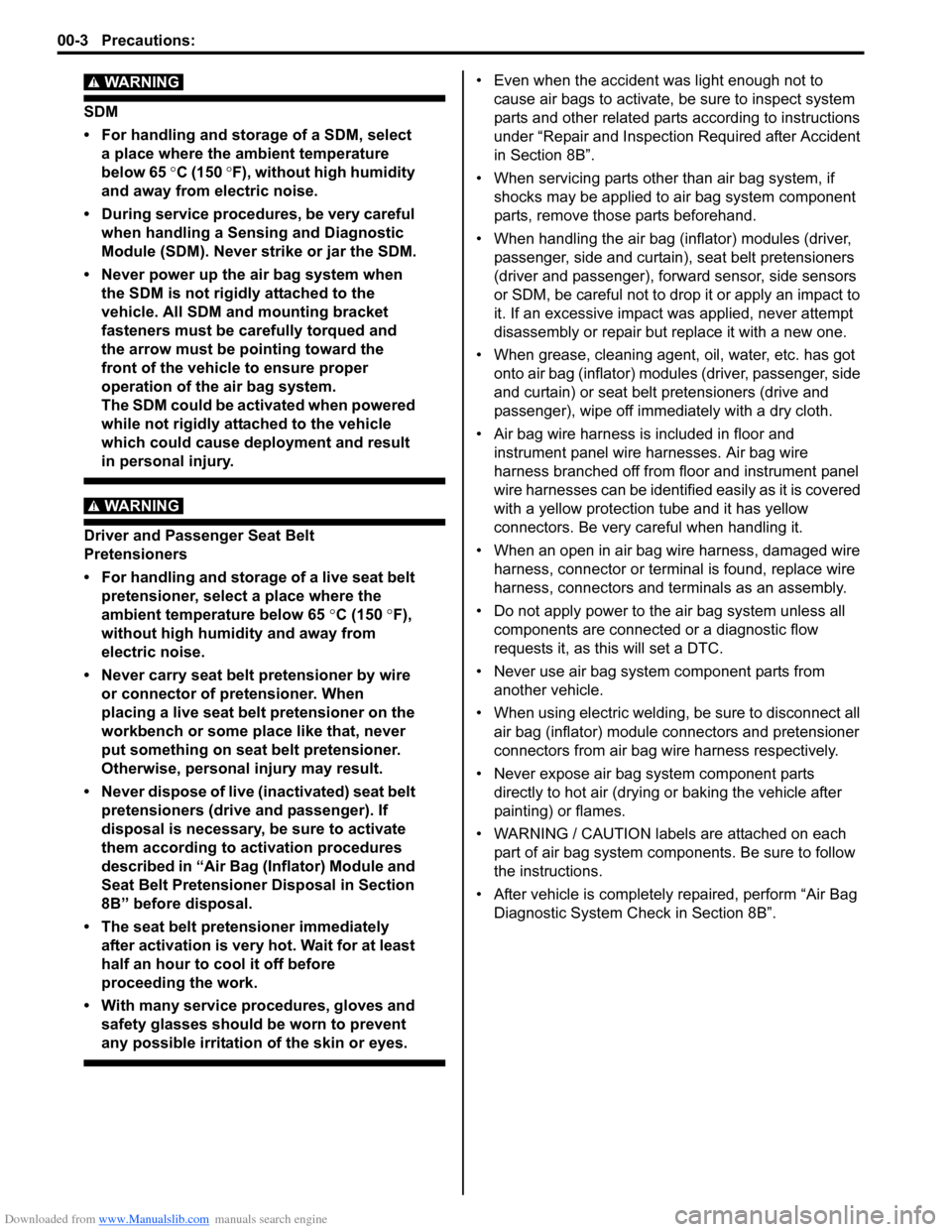

Tightening Torque SpecificationsS7RS0B0207001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Fluids and LubricantsS7RS0B0208001

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Engine oil drain plug 35 3.5 25.5 �)

Oil filter 14 1.4 10.5 for reference �)

Engine oilSG, SH, SJ, SL or SM grade (Refer to “Engine Oil and Filter Change” for engine

oil viscosity.)

Engine coolant

(Ethylene glycol base coolant) “Antifreeze/Antico

rrosion coolant”

Brake fluid Refer to reservoir cap of brake master cylinder.

Manual transaxle oil Refer to “Manual Transaxle Oil Change in Section 5B”.

Automatic transaxle fluid Refer to “A/T Fluid Change in Section 5A”.

Door hinges Engine oil or water resistance chassis grease

Hood latch assembly Engine oil or water resistance chassis grease

Key lock cylinder Spray lubricant

Page 98 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-48 Engine General Information and Diagnosis:

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

Malfunction Indicator Lamp Remains ON after Engine StartsS7RS0B1104012

Wiring Diagram and Circuit Description

Refer to “MIL Does Not Come ON wit h Ignition Switch ON and Engine Stop (but Engine Can Be Started)”.

Step

Action YesNo

1 MIL power supply check

1) Turn ignition switch to ON position.

Do other warning lights come ON? Go to Step 2.

Go to Step 3.

2 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there DTC(s) P1674, P1676, P1678 and/or P1685? Go to applicable DTC

diag. flow.

Substitute a known-

good combination meter

and recheck. If MIL still

remains OFF, substitute

a known-good ECM and

recheck.

3 CAN communication line circuit check

1) Check CAN communication circuit between combination

meter and ECM, TCM (A/T model) referring to Step 3 of

“DTC P1674: CAN Communication (Bus Off Error)”

Is circuit in good condition? Go to Step 4.

Repair or replace.

4 “METER” fuse check

1) Turn ignition switch to OFF position.

2) Check for fuse blown at “M ETER” fuse in junction block

assembly.

Is “METER” fuse in good condition? Go to Step 5.

Replace “METER” fuse

and check for short.

5 Combination meter power supply check

1) Remove combination meter referring to “Combination

Meter Removal and Installation in Section 9C”.

2) Check for proper connection to combination meter connector at “G28-31” and “G28-16” terminals.

3) If OK, then turn ignition switch to ON position and measure voltage between combination meter connector

at “G28-31” terminal and vehicle body ground.

Is it 10 – 14 V? Go to Step 6.

“RED/BLK” wire is open

circuit.

6 Combination meter circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “G28-16” terminal of

combination meter connector and vehicle body ground.

Is resistance 1

Ω or less? Substitute a known-

good combination meter

and recheck. If MIL still

remains OFF, substitute

a known-good ECM and

recheck.

“BLK/ORN” wire is open

or high resistance

circuit.

Page 416 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-6 Charging System:

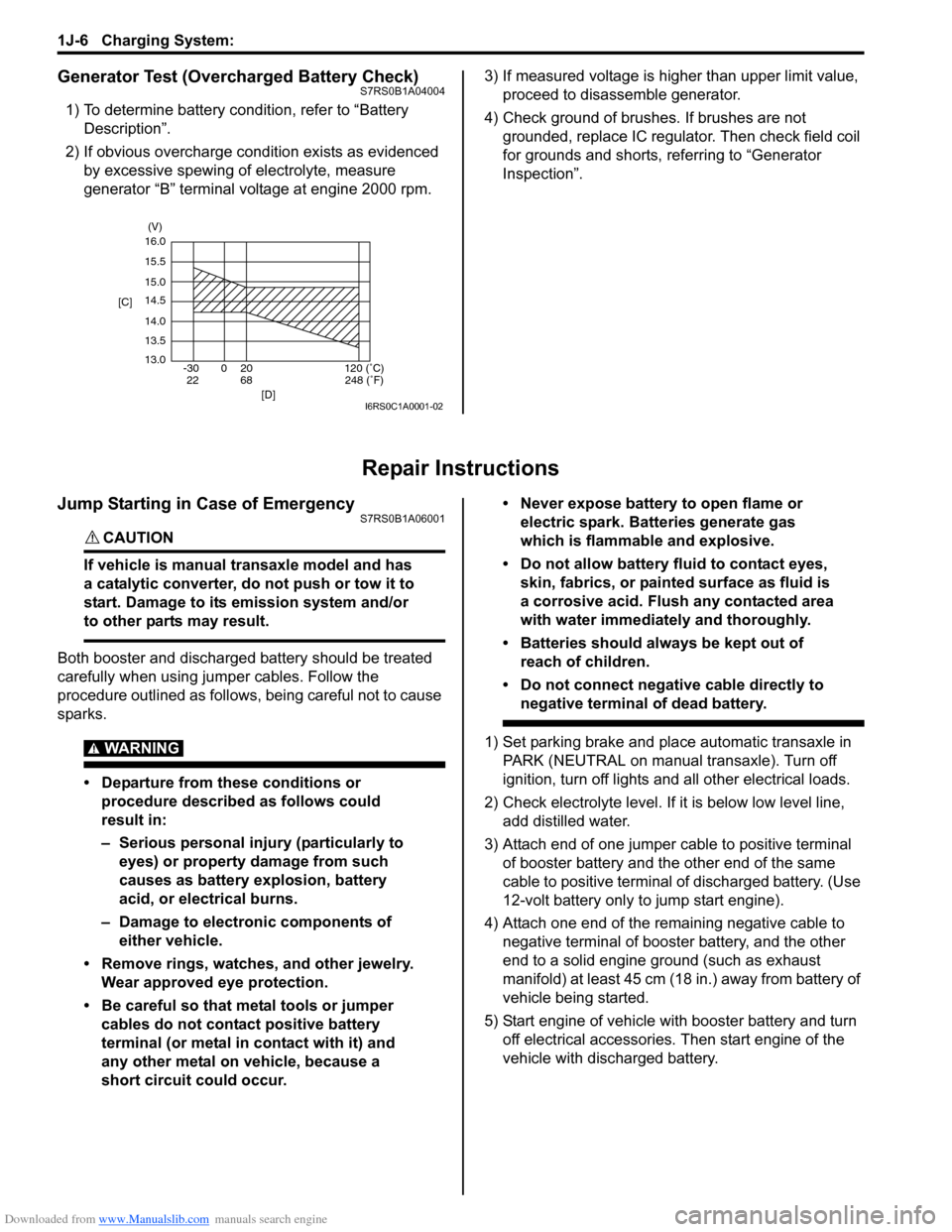

Generator Test (Overcharged Battery Check)S7RS0B1A04004

1) To determine battery condition, refer to “Battery Description”.

2) If obvious overcharge condition exists as evidenced by excessive spewing of electrolyte, measure

generator “B” terminal voltage at engine 2000 rpm. 3) If measured voltage is higher than upper limit value,

proceed to disassemble generator.

4) Check ground of brushes. If brushes are not grounded, replace IC regulator. Then check field coil

for grounds and shorts, referring to “Generator

Inspection”.

Repair Instructions

Jump Starting in Case of EmergencyS7RS0B1A06001

CAUTION!

If vehicle is manual transaxle model and has

a catalytic converter, do not push or tow it to

start. Damage to its emission system and/or

to other parts may result.

Both booster and discharged battery should be treated

carefully when using ju mper cables. Follow the

procedure outlined as follows, being careful not to cause

sparks.

WARNING!

• Departure from these conditions or procedure described as follows could

result in:

– Serious personal injury (particularly to eyes) or property damage from such

causes as battery explosion, battery

acid, or electrical burns.

– Damage to electronic components of either vehicle.

• Remove rings, watches, and other jewelry. Wear approved eye protection.

• Be careful so that metal tools or jumper cables do not contact positive battery

terminal (or metal in contact with it) and

any other metal on vehicle, because a

short circuit could occur. • Never expose battery to open flame or

electric spark. Batteries generate gas

which is flammable and explosive.

• Do not allow battery fluid to contact eyes, skin, fabrics, or painted surface as fluid is

a corrosive acid. Flush any contacted area

with water immediately and thoroughly.

• Batteries should always be kept out of reach of children.

• Do not connect negative cable directly to negative terminal of dead battery.

1) Set parking brake and place automatic transaxle in PARK (NEUTRAL on manual transaxle). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line, add distilled water.

3) Attach end of one jumper cable to positive terminal of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

5) Start engine of vehicle with booster battery and turn off electrical accessories. Then start engine of the

vehicle with discharged battery.

16.0

15.5

15.0

14.5

14.0

13.5

13.0 -30 0 20

[C]

[D]

68

22120 (˚C)

248 (˚F)

(V)

I6RS0C1A0001-02

Page 475 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-8

Tire Mounting and DismountingS7RS0B2406004

CAUTION!

When installing tire which has arrow

indicating tire rotation direction to wheel,

make sure that this tire rotation direction is

same as actual tire rotation direction when

vehicle is moving forward. Otherwise, it is

not possible to install wheel with tire to

vehicle in specified direction.

Use a tire changing machine to mount or dismount tires.

Follow equipment manufacturer’s instructions. Do not

use hand tools or tire irons al one to change tires as they

may damage tire beads or wheel rim.

Rim bead seats should be cleaned with a wire brush or

coarse steel wool to remove lubricants, old rubber and

light rust. Before mounting or dismounting a tire, bead

area should be well lubricated with approved tire

lubricant.

After mounting, inflate to specified pressure shown on

tire placard so that beads are completely seated.

WARNING!

Do not stand over tire when inflating. Bead

may break when bead snaps over rim’s safety

hump and cause serious personal injury.

Do not exceed 330 kpa (47.9 psi) pressure

when inflating. If 330 kpa (47.9 psi) pressure

will not seat beads, deflate, re-lubricate and

reinflate.

Over inflation may cause bead to break and

cause serious personal injury.

Install valve core and inflate to proper pressure.

Tire RepairS7RS0B2406005

There are many different materials and techniques on

the market to repair tires. As not all of these work on all

types of tires, tire manufacturers have published detailed

instructions on how and when to repair tires. These

instructions can be obtained from each tire

manufacturer.

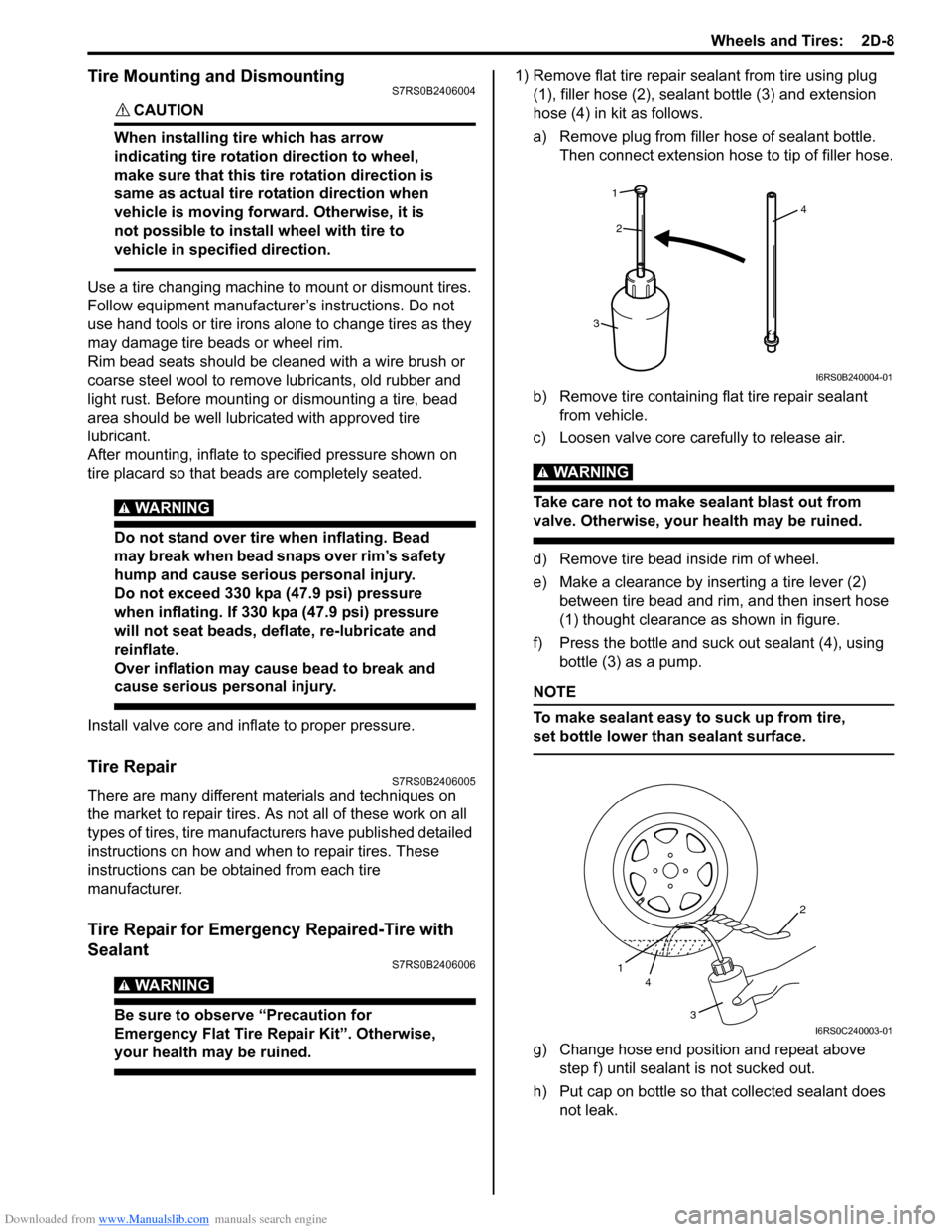

Tire Repair for Emergency Repaired-Tire with

Sealant

S7RS0B2406006

WARNING!

Be sure to observe “Precaution for

Emergency Flat Tire Repair Kit”. Otherwise,

your health may be ruined.

1) Remove flat tire repair sealant from tire using plug (1), filler hose (2), sealant bottle (3) and extension

hose (4) in kit as follows.

a) Remove plug from fille r hose of sealant bottle.

Then connect ext ension hose to tip of filler hose.

b) Remove tire containing flat tire repair sealant from vehicle.

c) Loosen valve core carefully to release air.

WARNING!

Take care not to make sealant blast out from

valve. Otherwise, your health may be ruined.

d) Remove tire bead inside rim of wheel.

e) Make a clearance by inserting a tire lever (2) between tire bead and rim, and then insert hose

(1) thought clearance as shown in figure.

f) Press the bottle and suck out sealant (4), using bottle (3) as a pump.

NOTE

To make sealant easy to suck up from tire,

set bottle lower than sealant surface.

g) Change hose end position and repeat above step f) until sealant is not sucked out.

h) Put cap on bottle so that collected sealant does not leak.

4

1

2

3

I6RS0B240004-01

1 4

3 2

I6RS0C240003-01

Page 496 of 1496

Downloaded from www.Manualslib.com manuals search engine 4-ii Table of Contents

Repair Instructions ..............................................4D-2Parking Brake Inspection and Adjustment ..........4D-2

Parking Brake Cable Removal and Installation ......................................................... 4D-3

Parking Brake Lever Removal and Installation ....4D-3

Specifications .... ...................................................4D-4

Tightening Torque Specifications ........................4D-4

ABS ........................................... .................4E-1

Precautions........................................................... 4E-1

Precautions in Diagnosing Troubles ................... 4E-1

Precautions in On-Vehicle Service...................... 4E-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4E-1

General Description ............................................. 4E-2 ABS Description .................................................. 4E-2

ABS Hydraulic Unit / Control Module Assembly Description ....................................... 4E-2

CAN Communication System Description........... 4E-3

Schematic and Routing Diagram ........................ 4E-4 ABS Schematic ................................................... 4E-4

ABS Wiring Circuit Diagram ................................ 4E-5

Component Location ........... ................................ 4E-7

ABS Components Location ................................. 4E-7

Front Wheel Speed Sensor Components Location ............................................................ 4E-7

Rear Wheel Speed Sensor Components Location ............................................................ 4E-8

Diagnostic Information and Procedures ............ 4E-8 ABS Check .......................................................... 4E-8

ABS Warning Light Check................................. 4E-10

EBD Warning Light (Brake Warning Light) Check .............................................................. 4E-10

DTC Check........................................................ 4E-11

DTC Table ......................................................... 4E-11

DTC Clearance ................................................. 4E-12

Scan Tool Data ................................................. 4E-12

ABS Warning Light Does Not Come ON at Ignition Switch ON .......................................... 4E-13

ABS Warning Light Comes ON Steady ............. 4E-14

EBD Warning Light (Brake Warning Light) Comes ON Steady .......................................... 4E-15

Serial Data Link Circuit Check .......................... 4E-16

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Right-Front / Left-

Front / Right-Rear / Left-Rear Wheel Speed

Sensor Circuit or Sensor Ring ........................ 4E-18

DTC C1041 / C1045 / C1051 / C1055, DTC C1042 / C1046 / C1052 / C1056: Right-Front

/ Left-Front / Right-Rear / Left-Rear Inlet

Solenoid Circuit, Right-Front / Left-Front /

Right-Rear / Left-Rear Outlet Solenoid

Circuit .............................................................. 4E-20

DTC C1057: Power Source Circuit ................... 4E-21

DTC C1061: ABS Pump Motor and/or Motor Driver Circuit ................................................... 4E-22

DTC C1063: Solenoid Valve Power Supply Driver Circuit ................................................... 4E-23

DTC C1071: ABS Control Module..................... 4E-24 DTC U1073: Control Module Communication

Bus Off ............................................................ 4E-25

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4E-27

Repair Instructions ............ ................................ 4E-28

ABS Hydraulic Unit Operati on Check................ 4E-28

ABS Hydraulic Unit / Control Module

Assembly Components ...... ............................. 4E-29

ABS Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4E-29

ABS Hydraulic Unit / Control Module

Assembly Removal and Inst allation ................ 4E-29

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4E-31

Front Wheel Speed Sensor Removal and Installation ....................................................... 4E-32

Front Wheel Speed Sensor Inspection ............. 4E-32

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4E-33

Rear Wheel Speed Sensor Inspection .............. 4E-34

Front Wheel Encoder On-Veh icle Inspection .... 4E-34

Front wheel Enco der Removal and

Installation ....................................................... 4E-34

Rear Wheel Encoder On-Veh icle Inspection..... 4E-34

Rear Wheel Encoder Removal and Installation ....................................................... 4E-34

Specifications ..................... ................................ 4E-35

Tightening Torque Specifications ...................... 4E-35

Special Tools and Equipmen t ........................... 4E-35

Special Tool ...................................................... 4E-35

Electronic Stability Prog ram ...................4F-1

Precautions ........................................................... 4F-1

Precautions in Diagnosing Troubles ................... 4F-1

Precautions in On-Vehicle Service...................... 4F-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4F-1

Precautions in Sensor Calibration ....................... 4F-1

Precautions in Speedometer Test or Other Tests ................................................................. 4F-2

General Description ............................................. 4F-2 Electronic Stability Program Description ............. 4F-2

Electronic Stability Program Construction ........... 4F-3

ESP® Hydraulic Unit / Control Module

Assembly Description........................................ 4F-5

Warning Lamp, Indicator Lamp Description ........ 4F-6

CAN Communication System Description........... 4F-6

CAN Communication System For Electronic Stability Program Description ............................ 4F-7

Schematic and Routing Diagram ........................ 4F-8 Electronic Stability Program Schematic .............. 4F-8

Electronic Stability Program Wiring Circuit Diagram............................................................. 4F-9

Component Location ............ ............................. 4F-11

Electronic Stability Program Component

Location........................................................... 4F-11

Diagnostic Information and Procedures .......... 4F-12 Electronic Stability Program System Check ...... 4F-12

ESP® Warning lamp Check .............................. 4F-14

Page 504 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-6 Brake Control System and Diagnosis:

Pedal pulsation (Pedal

pulsates when depressed

for braking)Damaged or loose wheel bearings

Replace wheel bearings.

Distorted steering knuckle or rear wheel

spindle Replace knuckle or rear wheel spindle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine disc.

Parallelism between brake pad and disc

not within specifications Check per instructions. If not within

specifications, replace or machine disc.

Brake caliper piston sticking Repair as necessary.

Braking noise Worn or distorted brake pad Replace pads.

Loose front wheel bearings Replace wheel bearings.

Distorted backing plates or loose

mounting bolts Replace or retighten securing bolts.

Contact wear indicator to brake disc Replace brake pad.

Brake warning light lights

after engine start Parking brake applied

Release parking brake and check that brake

warning light turns off.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake fluid leaking Investigate leaky point, correct it and add

brake fluid.

Brake warning light circuit faulty Repair circuit.

Malfunctioning EBD system Check system referring to “EBD Warning Light

(Brake Warning Light) Comes ON Steady in

Section 4E”.

Brake warning light turns

on when brake is applied Brake fluid leaking

Investigate leaky point, correct it and add

brake fluid.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake warning light fails

to turn on even when

parking brake is applied Brake warning light circuit faulty

Replace bulb or repair circuit.

ABS warning light or

ESP

® warning light turns

on after engine start Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light turns

on when brake is applied Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light does

not turn on for 2 sec. after

ignition switch has turned

ON Bulb burnt out

Replace bulb.

Malfunctioning ABS (ESP ®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light flashes New ABS hydraulic unit / control module

assembly installed. Perform “ABS Hydraulic

Unit Operation Check

in Section 4E”.

Condition Possible cause Correction / Reference Item

Page 506 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-8 Brake Control System and Diagnosis:

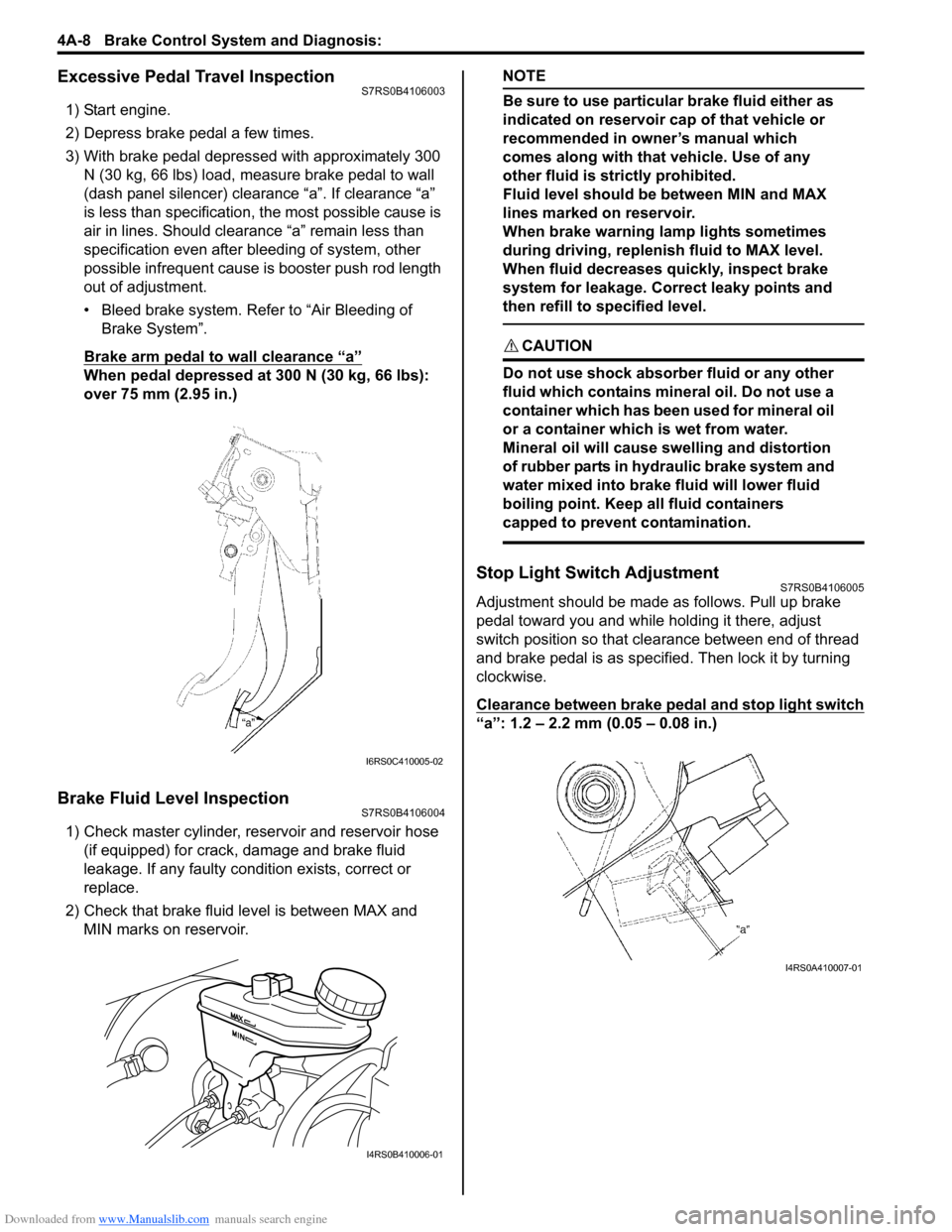

Excessive Pedal Travel InspectionS7RS0B4106003

1) Start engine.

2) Depress brake pedal a few times.

3) With brake pedal depressed with approximately 300 N (30 kg, 66 lbs) load, measure brake pedal to wall

(dash panel silencer) clearance “a”. If clearance “a”

is less than specification, the most possible cause is

air in lines. Should clearance “a” remain less than

specification even after bleeding of system, other

possible infrequent cause is booster push rod length

out of adjustment.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

Brake arm pedal to wall clearance “a”

When pedal depressed at 300 N (30 kg, 66 lbs):

over 75 mm (2.95 in.)

Brake Fluid Level InspectionS7RS0B4106004

1) Check master cylinder, reservoir and reservoir hose (if equipped) for crack, damage and brake fluid

leakage. If any faulty condition exists, correct or

replace.

2) Check that brake fluid level is between MAX and MIN marks on reservoir.

NOTE

Be sure to use particular brake fluid either as

indicated on reservoir cap of that vehicle or

recommended in owner’s manual which

comes along with that vehicle. Use of any

other fluid is strictly prohibited.

Fluid level should be between MIN and MAX

lines marked on reservoir.

When brake warning lamp lights sometimes

during driving, replenis h fluid to MAX level.

When fluid decreases quickly, inspect brake

system for leakage. Correct leaky points and

then refill to specified level.

CAUTION!

Do not use shock absorber fluid or any other

fluid which contains mineral oil. Do not use a

container which has been used for mineral oil

or a container which is wet from water.

Mineral oil will cause swelling and distortion

of rubber parts in hydraulic brake system and

water mixed into brake fluid will lower fluid

boiling point. Keep all fluid containers

capped to prevent contamination.

Stop Light Switch AdjustmentS7RS0B4106005

Adjustment should be made as follows. Pull up brake

pedal toward you and while holding it there, adjust

switch position so that clea rance between end of thread

and brake pedal is as specified. Then lock it by turning

clockwise.

Clearance between brake pedal and stop light switch

“a”: 1.2 – 2.2 mm (0.05 – 0.08 in.)

I6RS0C410005-02

I4RS0B410006-01

I4RS0A410007-01

Page 540 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-1 ABS:

Brakes

ABS

Precautions

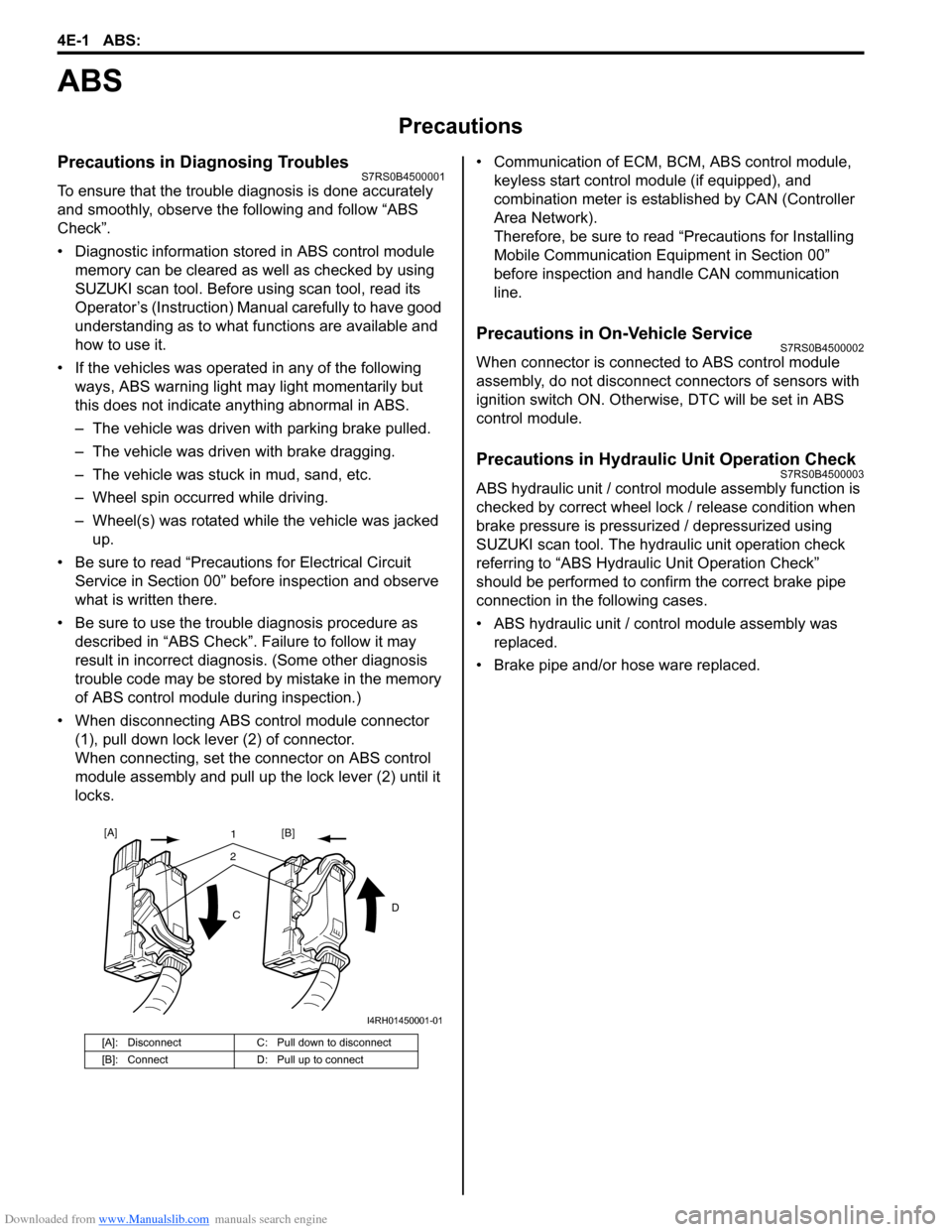

Precautions in Diagnosing TroublesS7RS0B4500001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow “ABS

Check”.

• Diagnostic information stored in ABS cont rol module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ABS warning light may light momentarily but

this does not indicate anything abnormal in ABS.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• Be sure to use the trouble diagnosis procedure as described in “ABS Check”. Failure to follow it may

result in incorrect diagnosis. (Some other diagnosis

trouble code may be stored by mistake in the memory

of ABS control module during inspection.)

• When disconnecting ABS co ntrol module connector

(1), pull down lock lever (2) of connector.

When connecting, set the connector on ABS control

module assembly and pull up the lock lever (2) until it

locks. • Communication of ECM,

BCM, ABS control module,

keyless start control module (if equipped), and

combination meter is established by CAN (Controller

Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handle CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4500002

When connector is connected to ABS control module

assembly, do not disconnect connectors of sensors with

ignition switch ON. Otherwise, DTC will be set in ABS

control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4500003

ABS hydraulic unit / control module assembly function is

checked by correct wheel lock / release condition when

brake pressure is pressurized / depressurized using

SUZUKI scan tool. The hydraulic unit operation check

referring to “ABS Hydraulic Unit Operation Check”

should be performed to confirm the correct brake pipe

connection in the following cases.

• ABS hydraulic unit / cont rol module assembly was

replaced.

• Brake pipe and/or hose ware replaced.

[A]: Disconnect C: Pull down to disconnect

[B]: Connect D: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01