ECU SUZUKI SWIFT 2007 2.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 1052 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-14 Air Bag System:

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Flow Test Description

Step 1: Check for “A/BAG” fuse blown.

Step 2, 3: Check for loose connection between junction block assembly connector and junction block

assembly.

Step 4: Check for loose connection between SDM connector and SDM.

Step 5: Check for SDM power supply circuit.

Step 6: Check for short circuit between “A IR BAG” warning right circuit and ground.

Troubleshooting Step Action YesNo

1 1) Turn ignition switch OFF.

2) Remove and inspect “A/BAG” fuse.

Is fuse good? Go to Step 2.

“RED” wire short to

ground.

After repair, replace “A/

BAG” fuse.

2 1) Check for loose connection of junction block assembly connector “L04”.

Is it connected securely? Go to Step 3.

Correct connector “L04”

securely.

3 1) Check for loose connection of junction block assembly connector “G34”.

Is it connected securely? Go to Step 4.

Correct connector “G34”

securely.

4 1) Check for loose connection of SDM connector “L29”. Is it connected securely? Go to Step 5.

Correct connector “L29”

securely.

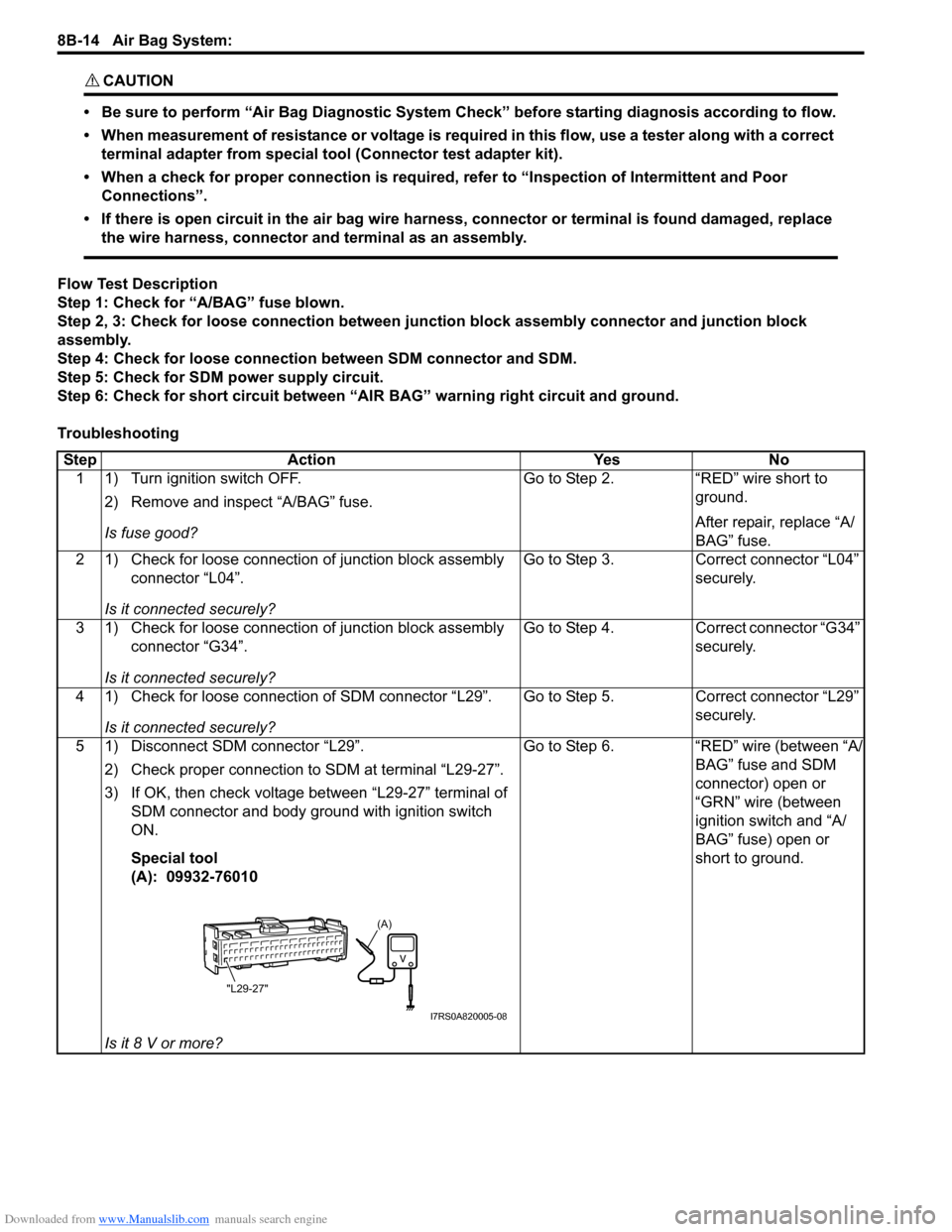

5 1) Disconnect SDM connector “L29”. 2) Check proper connection to SDM at terminal “L29-27”.

3) If OK, then check voltage between “L29-27” terminal of SDM connector and body ground with ignition switch

ON.

Special tool

(A): 09932-76010

Is it 8 V or more? Go to Step 6.

“RED” wire (between “A/

BAG” fuse and SDM

connector) open or

“GRN” wire (between

ignition switch and “A/

BAG” fuse) open or

short to ground.

(A)

"L29-27"

I7RS0A820005-08

Page 1060 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-22 Air Bag System:

DTC B1021: Front Air Bag Module DeployedS7RS0B8204014

DTC Will Set when

The SDM detects a frontal crash of sufficient force to warrant activation of the air bag system. (SDM outputs a

deployment command.)

Flow Test Description

Step 1: Check that DTC B1021 has been set although air bag has not been deployed.

Step 2: Check that DTC has been set due to failure of SDM.

NOTE

Before executing items in this flow, be sure to perform “Air Bag Diagnostic System Check”.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

• Clear DTCs of BCM referring to “DTC Clearance in Section 10B”

DTC B1024 / B1025: Side-Air Bag (Driver / Passenger) DeployedS7RS0B8204015

DTC Will Set when

The SDM detects a sideward crash (driver or passenger side) of sufficient force to warrant activation of the side-air

bag system (driver or pa ssenger). (SDM outputs a deployment command.)

Flow Test Description

Step 1: Check that DTC B1024 or B1025 has been set although side-air bag has not been deployed.

Step 2: Check that DTC has been set due to failure of SDM.

NOTE

Before executing items in this flow, be sure to perform “Air Bag Diagnostic System Check”.

Step Action YesNo

1 1) Turn ignition switch OFF.

Has air bag deployed? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Go to Step 2.

2 1) Inspect front of vehicle and undercarriage for signs of impact.

Are there signs of impact? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Substitute a known-

good SDM and recheck.

Page 1061 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-23

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

• Clear DTCs of BCM referring to “DTC Clearance in Section 10B”

DTC B1026: Pretensioner ActivatedS7RS0B8204016

DTC Will Set when

The SDM detects a frontal crash of sufficient force to warrant activation of the pr etensioner. (SDM outputs a

deployment command.)

Flow Test Description

Step 1: Check that DTC B1026 has been set although pretensioner has not been activated.

Step 2: Check that DTC has been set due to failure of SDM.

NOTE

Before executing items in this flow, be sure to perform “Air Bag Diagnostic System Check”.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

• Clear DTCs of BCM referring to “DTC Clearance in Section 10B”

StepAction YesNo

1 1) Turn ignition switch OFF.

Has air bag deployed? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Go to Step 2.

2 1) Inspect front of vehicle and undercarriage for signs of impact.

Are there signs of impact? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Substitute a known-

good SDM and recheck.

Step

Action YesNo

1 1) Turn ignition switch OFF.

Has pretensioner activated? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Go to Step 2.

2 1) Inspect front of vehicle and undercarriage for signs of impact.

Are there signs of impact? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Substitute a known-

good SDM and recheck.

Page 1135 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-97

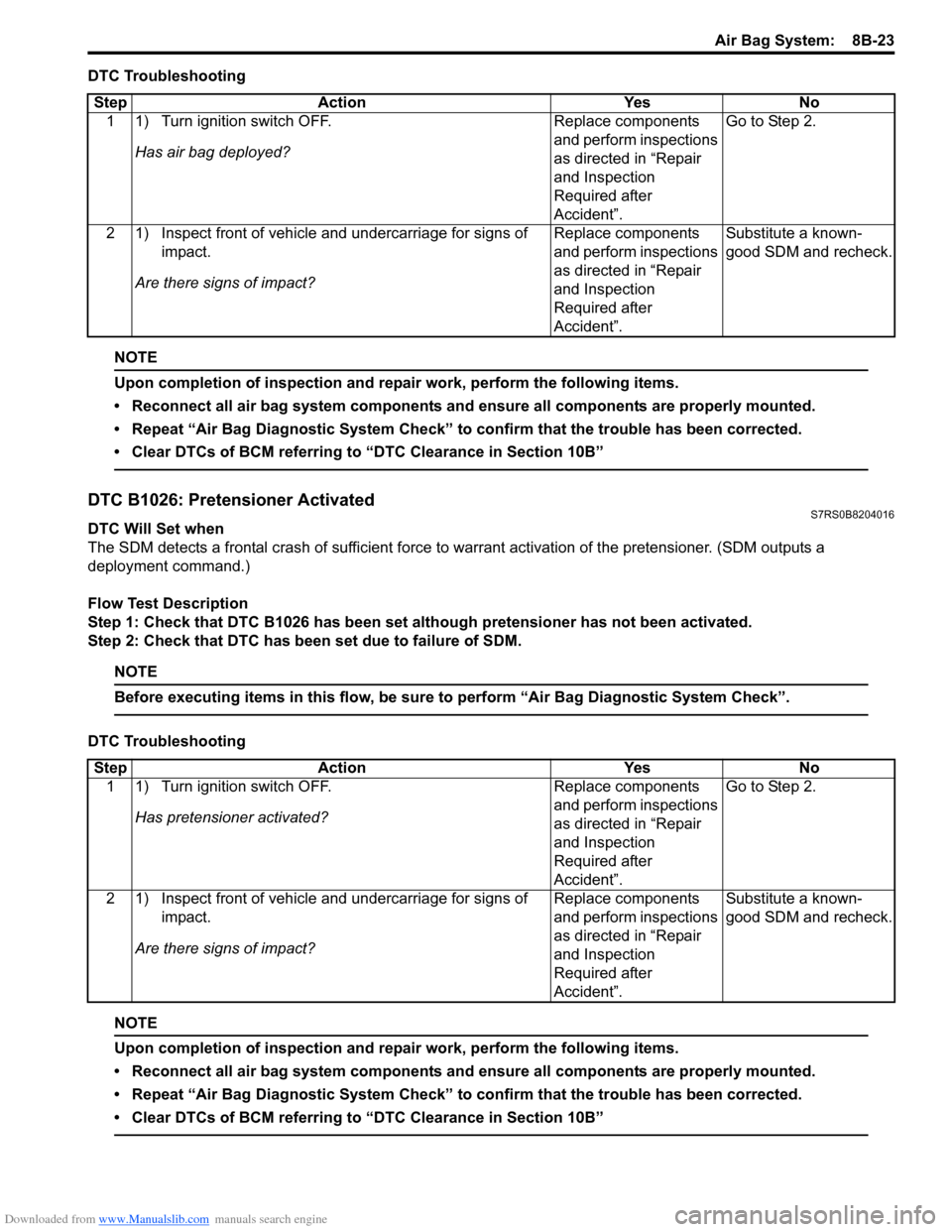

• Contact coil and combination switch assembly

– Check wire harness and connectors for damage or tightness.

– Check contact coil case for damage.

• Instrument panel member and reinforcement – Check for any distortion, bending, cracking or other damage.

– Check instrument panel fo r cracks or deformities.

• Passenger air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness and connector for damage or tightness.

•SDM – Check for external damage such as deformation, scratch, crack, peeled paint, etc.

– Check SDM for a cause in itself preventing its proper installation. (There is a gap between SDM

and SDM plate, or it cannot be fixed securely.)

– Check connector or lead wire of SDM for scorching, melting or damage.

– Check SDM connector and terminals for tightness.

– Check if SDM sets a DTC and is judged as malfunctioning according to the diagnostic flow. • Air bag wire harness and connections

– Check for damages, deformities or poor connections.

Refer to “Inspection of Intermittent and Poor

Connections”.

– Check wire harness clamps for tightness.

– For air bag harness including in instrument panel harness replacement, refer to “Passenger Air Bag

(Inflator) Module Repair Harness Installation”.

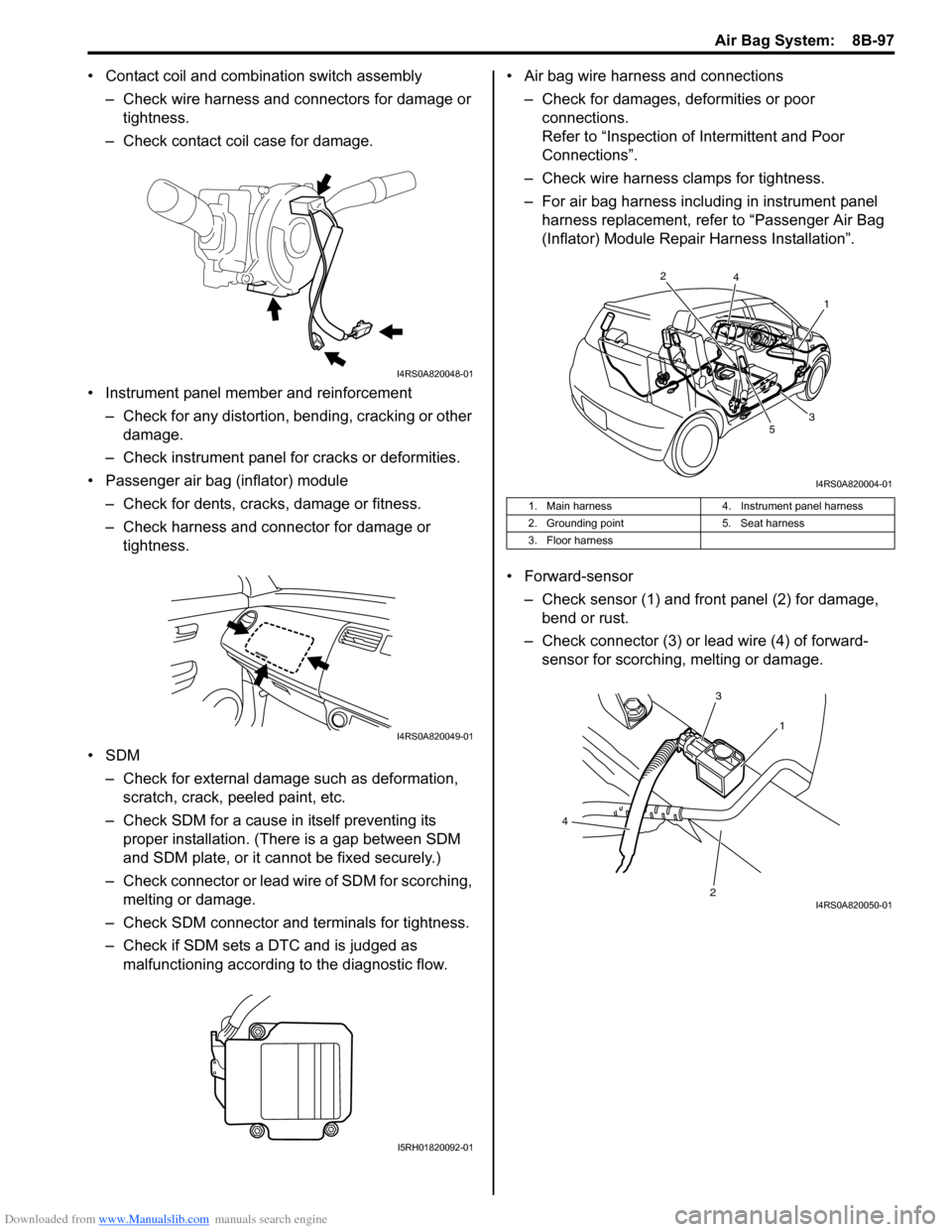

• Forward-sensor – Check sensor (1) and front panel (2) for damage, bend or rust.

– Check connector (3) or lead wire (4) of forward- sensor for scorching, melting or damage.

I4RS0A820048-01

I4RS0A820049-01

I5RH01820092-01

1. Main harness 4. Instrument panel harness

2. Grounding point 5. Seat harness

3. Floor harness

1

2

3

4

5

I4RS0A820004-01

1

3

2

4

I4RS0A820050-01

Page 1138 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-100 Air Bag System:

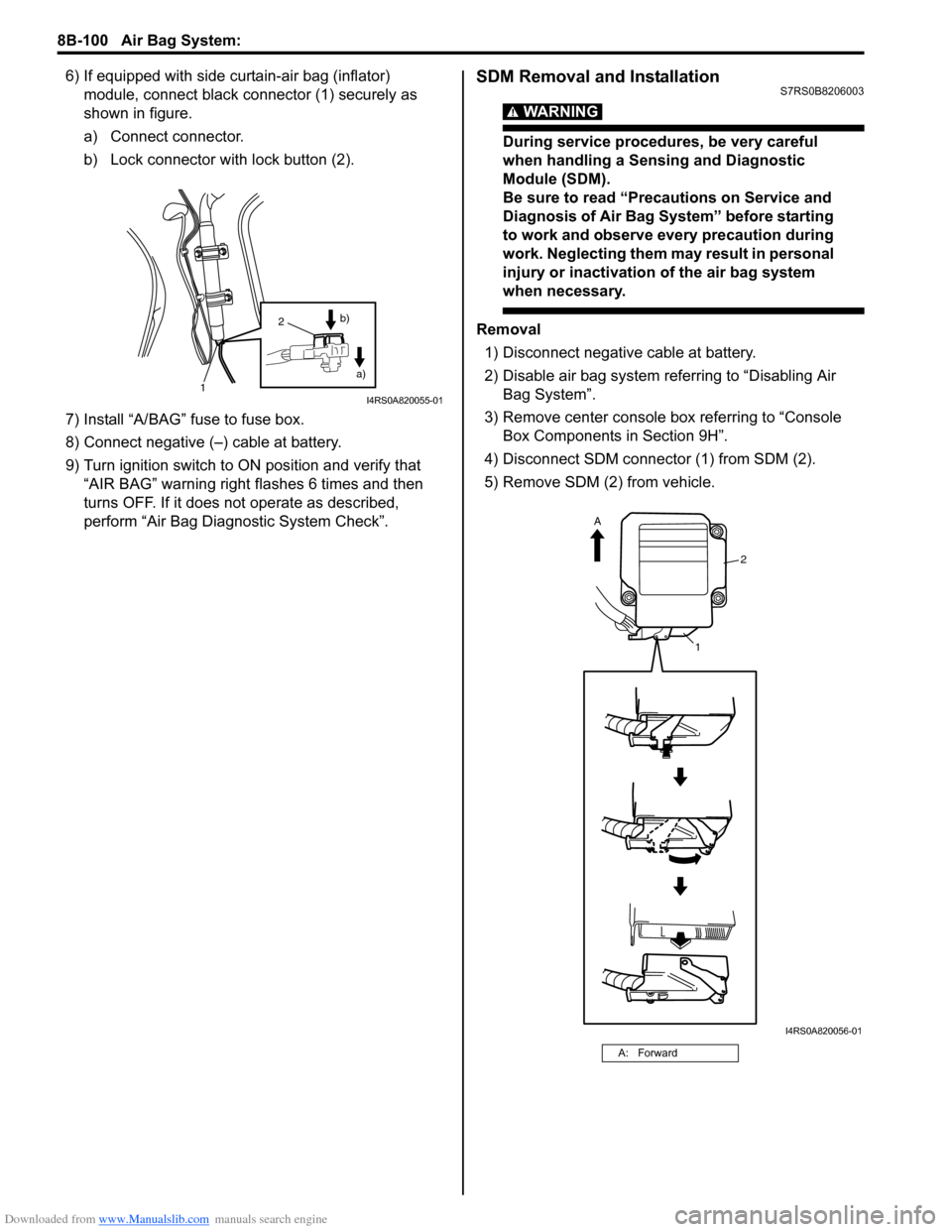

6) If equipped with side curtain-air bag (inflator) module, connect black connector (1) securely as

shown in figure.

a) Connect connector.

b) Lock connector with lock button (2).

7) Install “A/BAG” fuse to fuse box.

8) Connect negative (–) cable at battery.

9) Turn ignition switch to ON position and verify that “AIR BAG” warning right flashes 6 times and then

turns OFF. If it does not operate as described,

perform “Air Bag Diagn ostic System Check”.SDM Removal and InstallationS7RS0B8206003

WARNING!

During service procedures, be very careful

when handling a Sensing and Diagnostic

Module (SDM).

Be sure to read “Precautions on Service and

Diagnosis of Air Bag System” before starting

to work and observe every precaution during

work. Neglecting them ma y result in personal

injury or inactivation of the air bag system

when necessary.

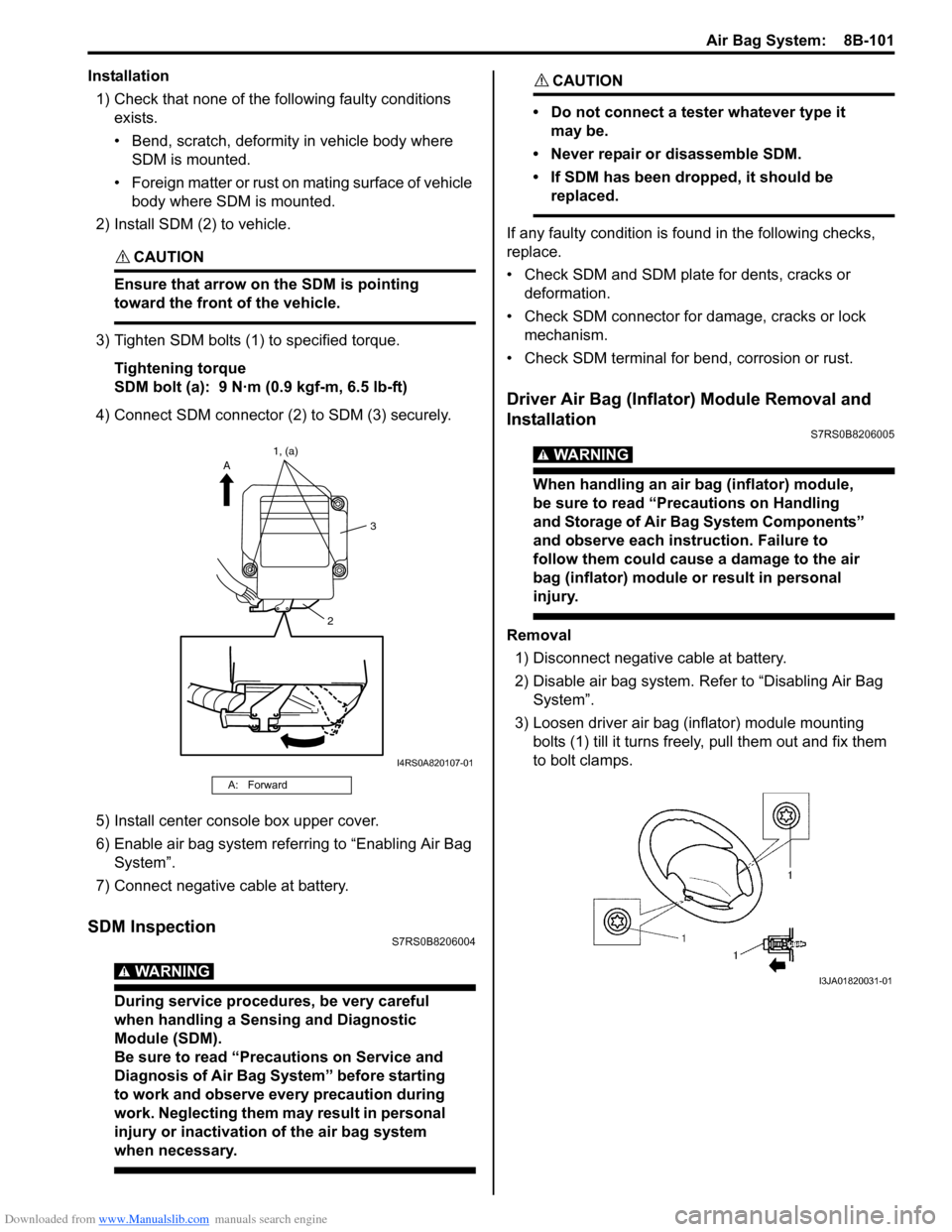

Removal

1) Disconnect negative cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System”.

3) Remove center console box referring to “Console Box Components in Section 9H”.

4) Disconnect SDM connector (1) from SDM (2).

5) Remove SDM (2) from vehicle.

1

2

a)

b)

I4RS0A820055-01

A: Forward

2

1

A

I4RS0A820056-01

Page 1139 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-101

Installation1) Check that none of the following faulty conditions exists.

• Bend, scratch, deformity in vehicle body where SDM is mounted.

• Foreign matter or rust on mating surface of vehicle body where SDM is mounted.

2) Install SDM (2) to vehicle.

CAUTION!

Ensure that arrow on the SDM is pointing

toward the front of the vehicle.

3) Tighten SDM bolts (1) to specified torque.

Tightening torque

SDM bolt (a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

4) Connect SDM connector (2) to SDM (3) securely.

5) Install center console box upper cover.

6) Enable air bag system referring to “Enabling Air Bag System”.

7) Connect negative cable at battery.

SDM InspectionS7RS0B8206004

WARNING!

During service procedures, be very careful

when handling a Sensing and Diagnostic

Module (SDM).

Be sure to read “Precautions on Service and

Diagnosis of Air Bag System” before starting

to work and observe every precaution during

work. Neglecting them ma y result in personal

injury or inactivation of the air bag system

when necessary.

CAUTION!

• Do not connect a tester whatever type it may be.

• Never repair or disassemble SDM.

• If SDM has been dropped, it should be replaced.

If any faulty condition is fo und in the following checks,

replace.

• Check SDM and SDM plate for dents, cracks or deformation.

• Check SDM connector for damage, cracks or lock mechanism.

• Check SDM terminal for bend, corrosion or rust.

Driver Air Bag (Inflator) Module Removal and

Installation

S7RS0B8206005

WARNING!

When handling an air bag (inflator) module,

be sure to read “Precautions on Handling

and Storage of Air Bag System Components”

and observe each instruction. Failure to

follow them could cause a damage to the air

bag (inflator) module or result in personal

injury.

Removal 1) Disconnect negative cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System”.

3) Loosen driver air bag (inflator) module mounting bolts (1) till it turns freely, pull them out and fix them

to bolt clamps.

A: Forward

2 3

A

1, (a)

I4RS0A820107-01

I3JA01820031-01

Page 1140 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-102 Air Bag System:

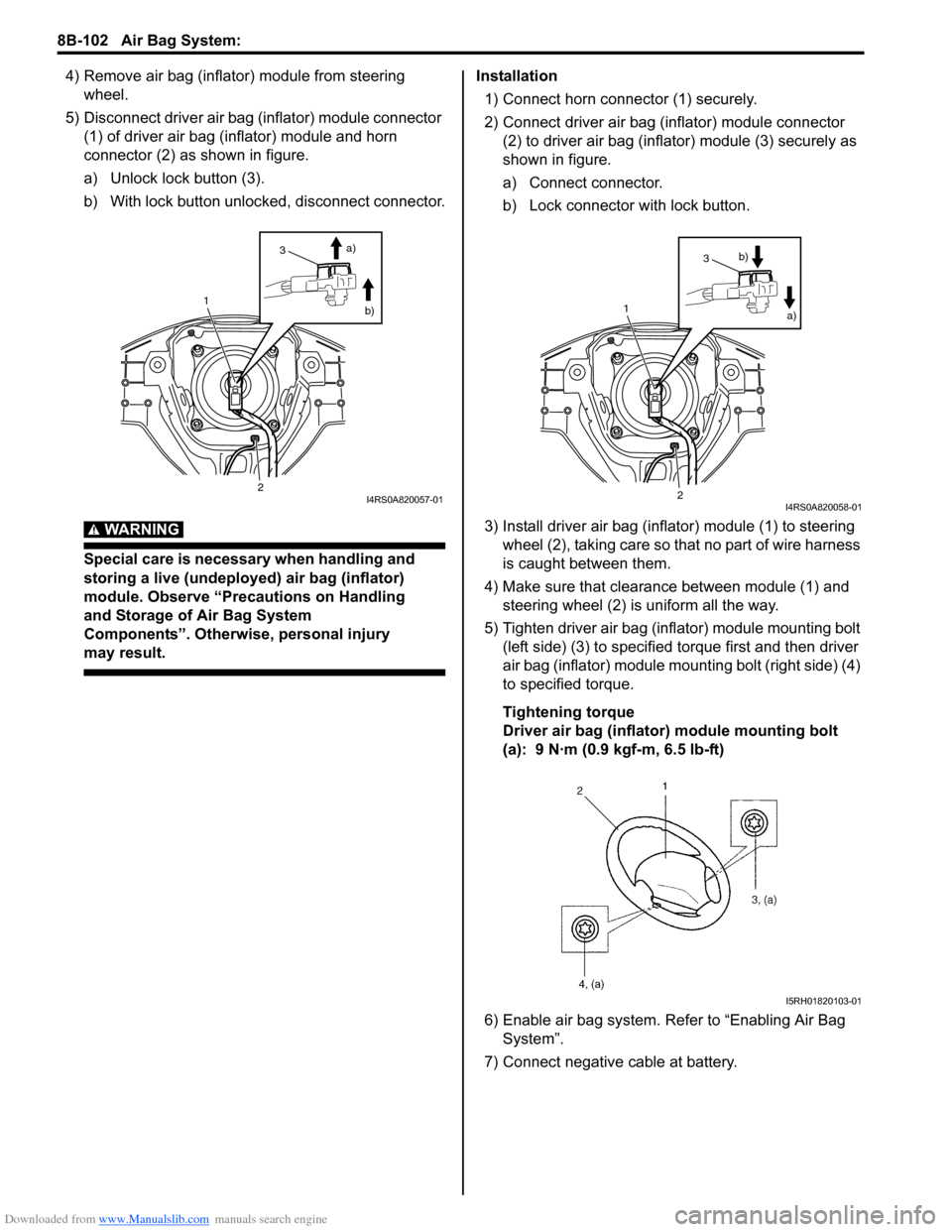

4) Remove air bag (inflator) module from steering wheel.

5) Disconnect driver air bag (inflator) module connector (1) of driver air bag (inflator) module and horn

connector (2) as shown in figure.

a) Unlock lock button (3).

b) With lock button unlocked, disconnect connector.

WARNING!

Special care is necessary when handling and

storing a live (undeployed) air bag (inflator)

module. Observe “Precautions on Handling

and Storage of Air Bag System

Components”. Otherwise, personal injury

may result.

Installation

1) Connect horn connector (1) securely.

2) Connect driver air bag (inflator) module connector (2) to driver air bag (inflator) module (3) securely as

shown in figure.

a) Connect connector.

b) Lock connector with lock button.

3) Install driver air bag (inflator) module (1) to steering wheel (2), taking care so t hat no part of wire harness

is caught between them.

4) Make sure that clearance between module (1) and steering wheel (2) is uniform all the way.

5) Tighten driver air bag (inflator) module mounting bolt (left side) (3) to specified torque first and then driver

air bag (inflator) module mounting bolt (right side) (4)

to specified torque.

Tightening torque

Driver air bag (inflator) module mounting bolt

(a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

6) Enable air bag system. Refer to “Enabling Air Bag System”.

7) Connect negative cable at battery.

1

2

3 a)

b)

I4RS0A820057-01

1

2

3 a)

b)

I4RS0A820058-01

I5RH01820103-01

Page 1142 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-104 Air Bag System:

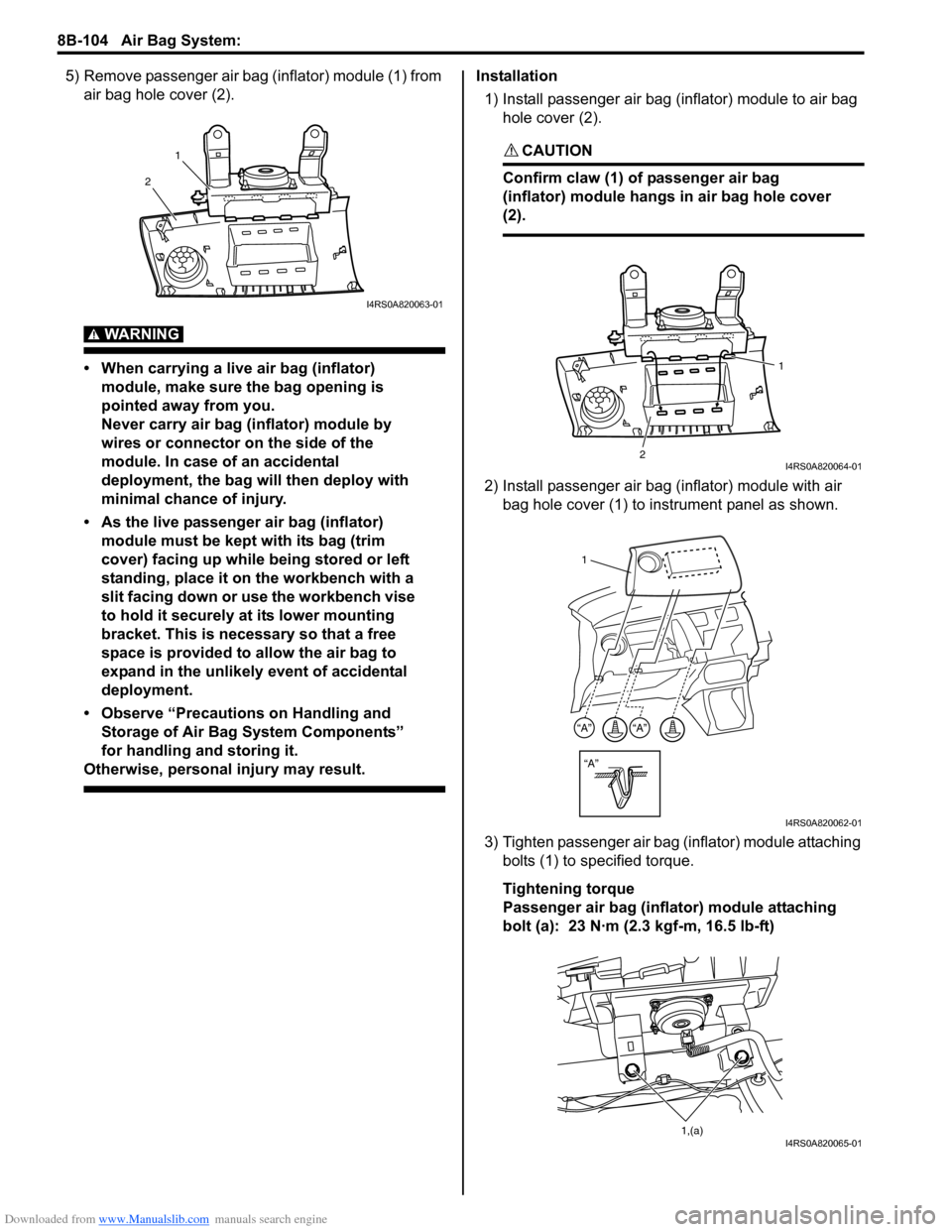

5) Remove passenger air bag (inflator) module (1) from air bag hole cover (2).

WARNING!

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you.

Never carry air bag (inflator) module by

wires or connector on the side of the

module. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury.

• As the live passenger air bag (inflator) module must be kept with its bag (trim

cover) facing up while being stored or left

standing, place it on the workbench with a

slit facing down or use the workbench vise

to hold it securely at its lower mounting

bracket. This is necessary so that a free

space is provided to allow the air bag to

expand in the unlikely event of accidental

deployment.

• Observe “Precautions on Handling and Storage of Air Bag System Components”

for handling and storing it.

Otherwise, personal injury may result.

Installation

1) Install passenger air bag (inflator) module to air bag hole cover (2).

CAUTION!

Confirm claw (1) of passenger air bag

(inflator) module hangs in air bag hole cover

(2).

2) Install passenger air bag (inflator) module with air bag hole cover (1) to instrument panel as shown.

3) Tighten passenger air bag (inflator) module attaching bolts (1) to sp ecified torque.

Tightening torque

Passenger air bag (inflator) module attaching

bolt (a): 23 N·m (2.3 kgf-m, 16.5 lb-ft)

1

2

I4RS0A820063-01

2 1I4RS0A820064-01

“A”

“A”“A”

1

I4RS0A820062-01

1,(a)I4RS0A820065-01

Page 1143 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-105

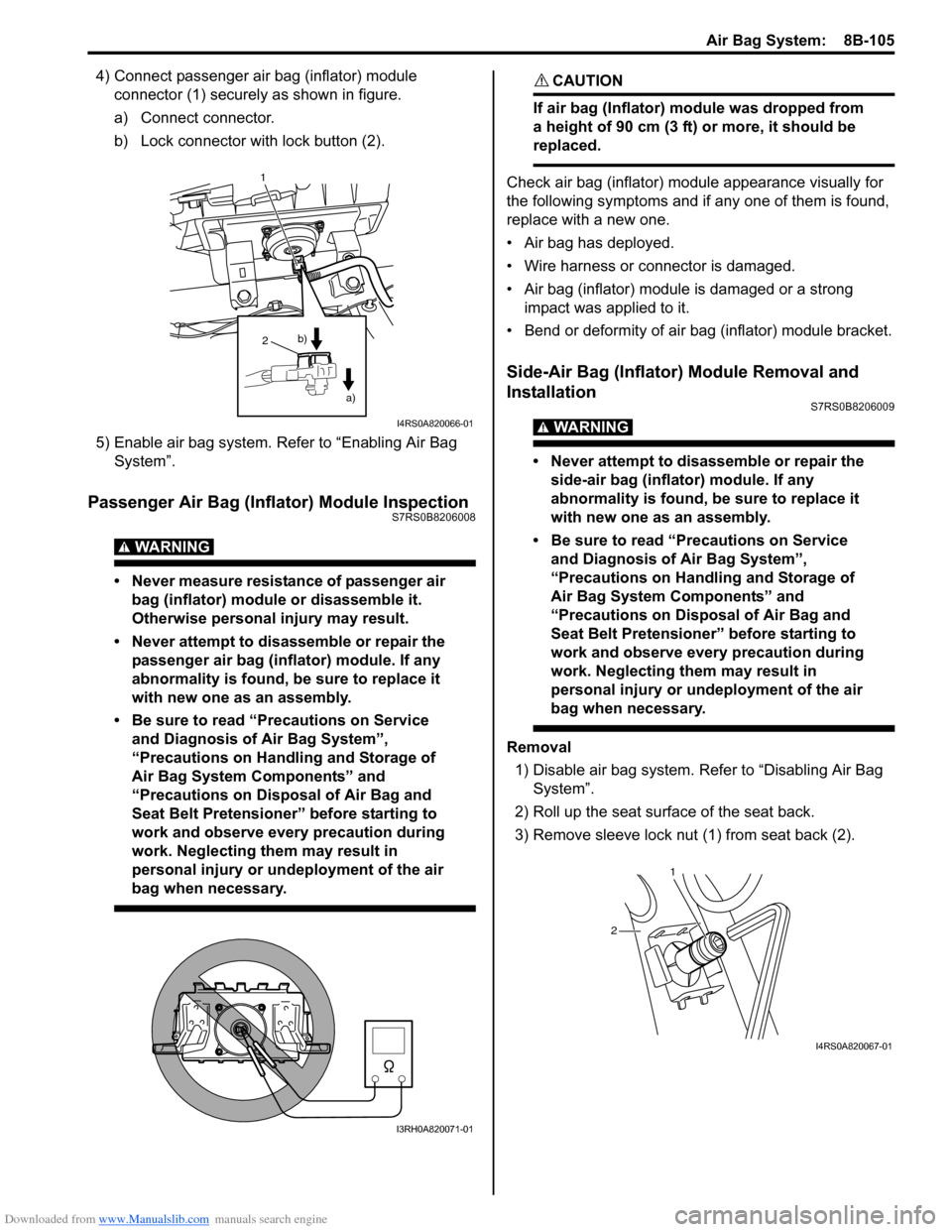

4) Connect passenger air bag (inflator) module connector (1) securely as shown in figure.

a) Connect connector.

b) Lock connector with lock button (2).

5) Enable air bag system. Refer to “Enabling Air Bag System”.

Passenger Air Bag (Inflator) Module InspectionS7RS0B8206008

WARNING!

• Never measure resistance of passenger air bag (inflator) module or disassemble it.

Otherwise personal injury may result.

• Never attempt to disassemble or repair the passenger air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

CAUTION!

If air bag (Inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• Wire harness or connector is damaged.

• Air bag (inflator) module is damaged or a strong impact was applied to it.

• Bend or deformity of air bag (inflator) module bracket.

Side-Air Bag (Inflator) Module Removal and

Installation

S7RS0B8206009

WARNING!

• Never attempt to disassemble or repair the side-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

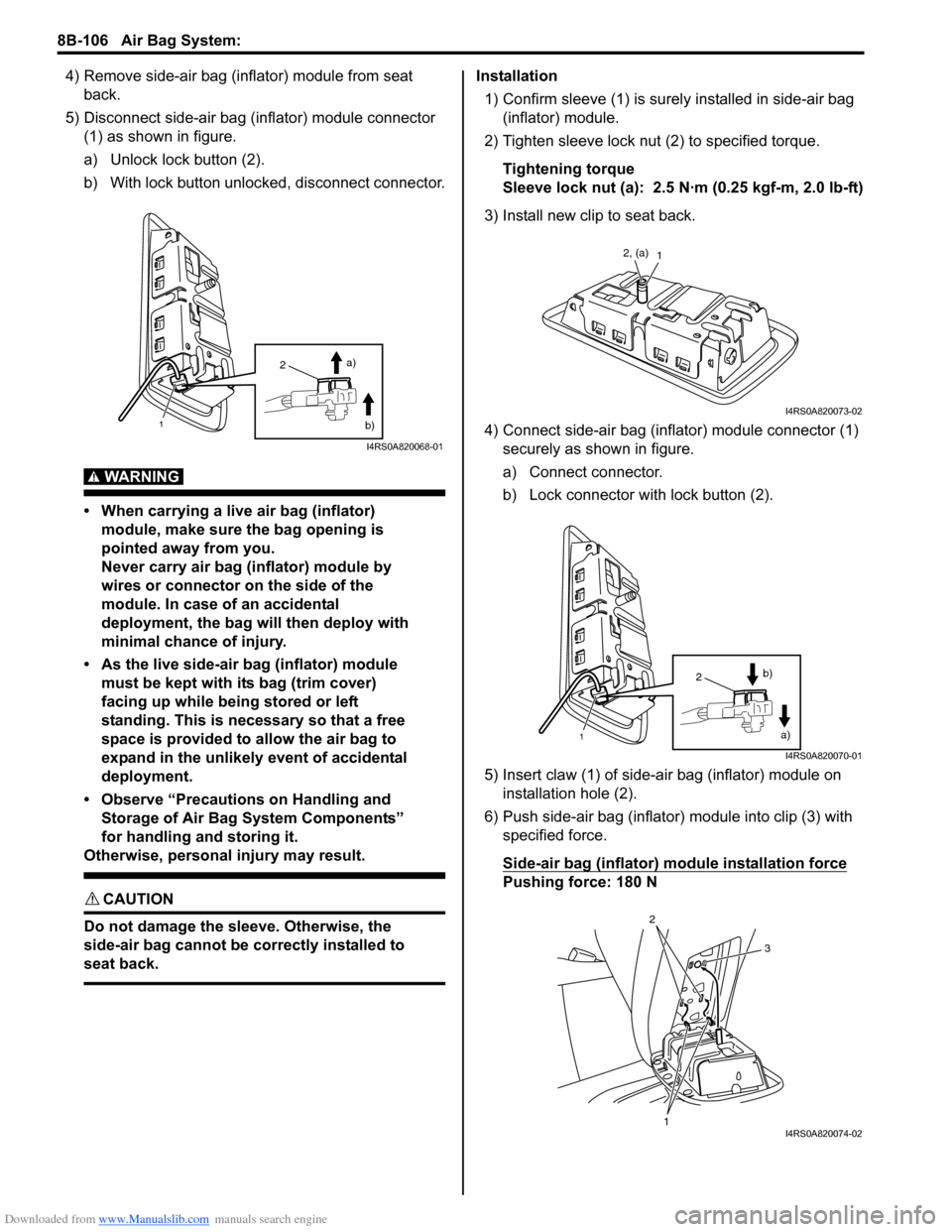

Removal

1) Disable air bag system. Re fer to “Disabling Air Bag

System”.

2) Roll up the seat surface of the seat back.

3) Remove sleeve lock nut (1) from seat back (2).

1

2

a)

b)

I4RS0A820066-01

I3RH0A820071-01

1

2

I4RS0A820067-01

Page 1144 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-106 Air Bag System:

4) Remove side-air bag (inflator) module from seat back.

5) Disconnect side-air bag (inflator) module connector (1) as shown in figure.

a) Unlock lock button (2).

b) With lock button unlocked, disconnect connector.

WARNING!

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you.

Never carry air bag (inflator) module by

wires or connector on the side of the

module. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury.

• As the live side-air bag (inflator) module must be kept with its bag (trim cover)

facing up while being stored or left

standing. This is necessary so that a free

space is provided to allow the air bag to

expand in the unlikely event of accidental

deployment.

• Observe “Precautions on Handling and Storage of Air Bag System Components”

for handling and storing it.

Otherwise, personal injury may result.

CAUTION!

Do not damage the sleeve. Otherwise, the

side-air bag cannot be correctly installed to

seat back.

Installation

1) Confirm sleeve (1) is surely installed in side-air bag (inflator) module.

2) Tighten sleeve lock nut (2) to specified torque.

Tightening torque

Sleeve lock nut (a): 2.5 N·m (0.25 kgf-m, 2.0 lb-ft)

3) Install new clip to seat back.

4) Connect side-air bag (inflator) module connector (1) securely as shown in figure.

a) Connect connector.

b) Lock connector wi th lock button (2).

5) Insert claw (1) of side-air bag (inflator) module on installation hole (2).

6) Push side-air bag (inflator) module into clip (3) with

specified force.

Side-air bag (inflator) module installation force

Pushing force: 180 N

2

1

a)

b)

I4RS0A820068-01

12, (a)

I4RS0A820073-02

1

2 a)

b)

I4RS0A820070-01

1

2

3

I4RS0A820074-02