ECU SUZUKI SWIFT 2007 2.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 876 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-5 Steering Wheel and Column:

Contact Coil Cable Assembly Removal and

Installation

S7RS0B6206003

CAUTION!

Do not turn contact coil more than allowable

number of turns (about two and a half turns

from the center position clockwise or

counterclockwise respectively), or coil will

break.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering wheel from steering column referring to “Steering Wheel Removal and

Installation”.

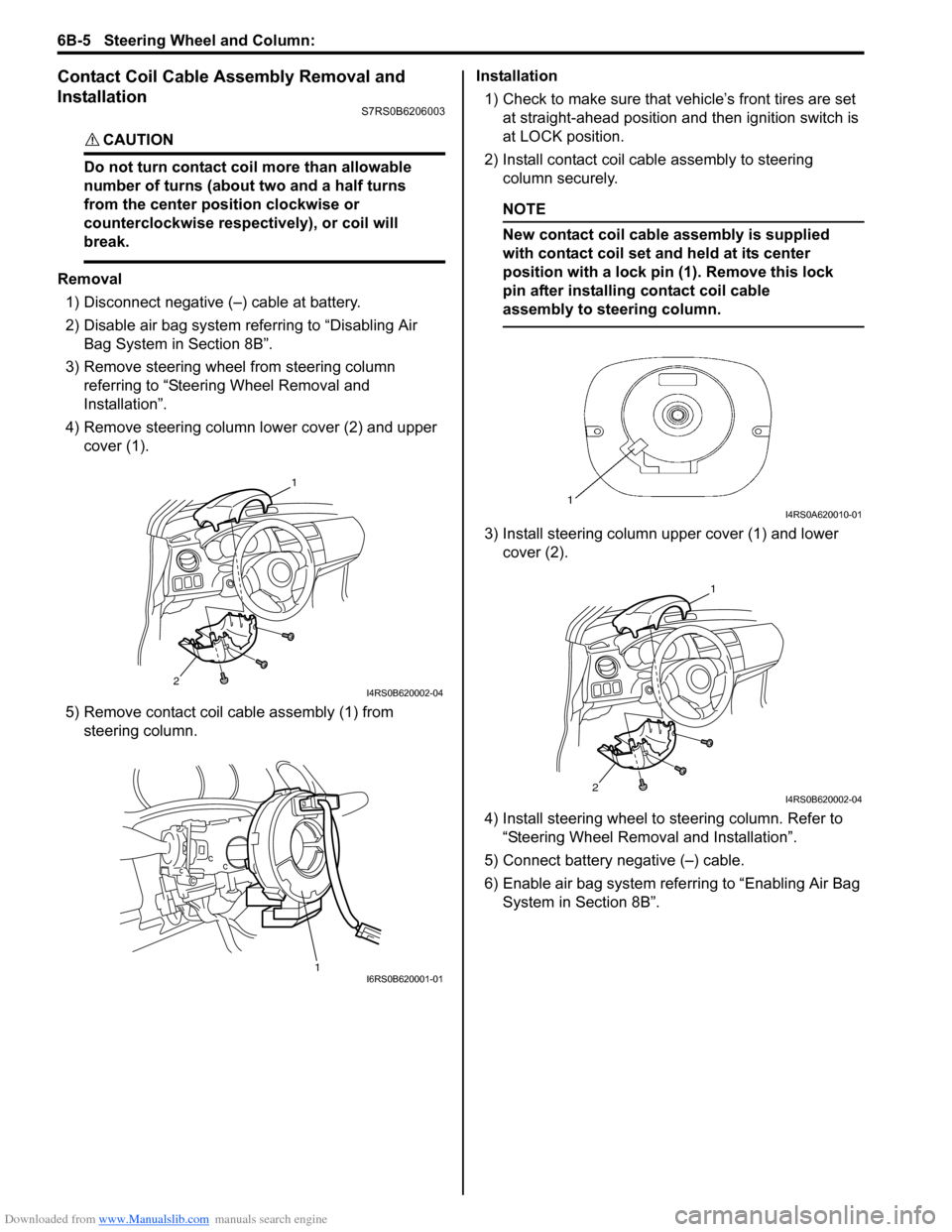

4) Remove steering column lower cover (2) and upper cover (1).

5) Remove contact coil cable assembly (1) from steering column. Installation

1) Check to make sure that vehicle’s front tires are set

at straight-ahead position and then ignition switch is

at LOCK position.

2) Install contact coil cable assembly to steering column securely.

NOTE

New contact coil cable assembly is supplied

with contact coil set and held at its center

position with a lock pin (1). Remove this lock

pin after installing contact coil cable

assembly to steering column.

3) Install steering column upper cover (1) and lower cover (2).

4) Install steering wheel to steering column. Refer to

“Steering Wheel Removal and Installation”.

5) Connect battery negative (–) cable.

6) Enable air bag system refe rring to “Enabling Air Bag

System in Section 8B”.

2

1

I4RS0B620002-04

1I6RS0B620001-01

I4RS0A620010-01

2

1

I4RS0B620002-04

Page 885 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-3

EPS Diagnosis General DescriptionS7RS0B6301002

The P/S system in this vehicle is controlled by the P/S control module. T he P/S control module has an on-board

diagnostic system which detects a malfunction in this system. When diagnosing troubles, be sure to have full

understanding of the outline of “On-Board Diagnostic Sy stem Description” and each item in “Precautions in

Diagnosing Troubles”, and then execute diagnosis according to “EPS System Check”.

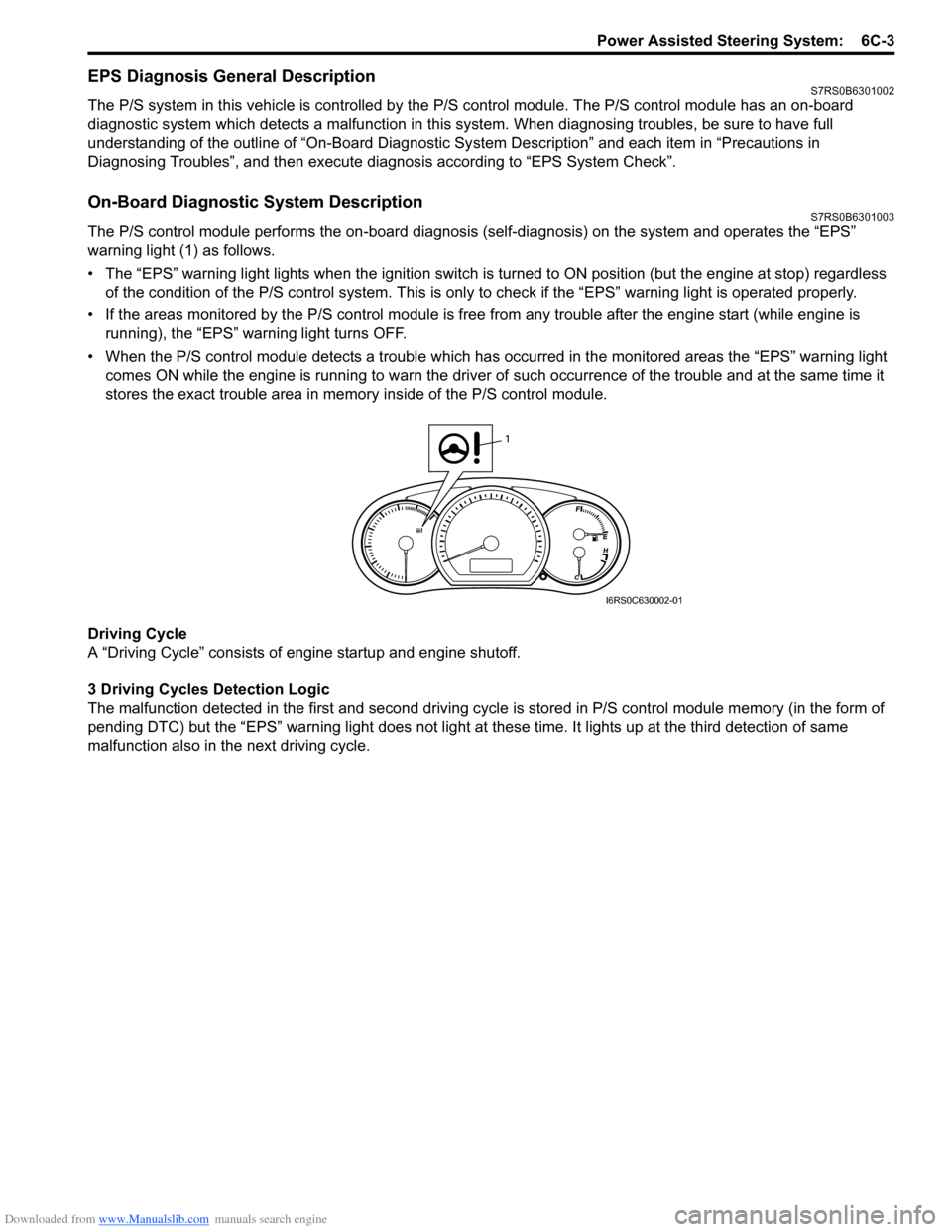

On-Board Diagnostic System DescriptionS7RS0B6301003

The P/S control module performs the on -board diagnosis (self-diagnosis) on the system and operates the “EPS”

warning light (1) as follows.

• The “EPS” warning light lights when the ignition switch is turned to ON position (but the engine at stop) regardless

of the condition of the P/S co ntrol system. This is only to check if the “EPS” warning light is operated properly.

• If the areas monitored by the P/S control module is free from any trouble after the engine start (while engine is

running), the “EPS” warning light turns OFF.

• When the P/S control module detects a trouble which has occurred in th e monitored areas the “EPS” warning light

comes ON while the engine is running to warn the driver of such occurrence of the trouble and at the same time it

stores the exact trouble area in memory inside of the P/S control module.

Driving Cycle

A “Driving Cycle” consists of en gine startup and engine shutoff.

3 Driving Cycles Detection Logic

The malfunction detected in the first and second driving cycl e is stored in P/S control module memory (in the form of

pending DTC) but the “EPS” wa rning light does not light at these time. It lights up at t he third detection of same

malfunction also in the next driving cycle.

1

I6RS0C630002-01

Page 888 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-6 Power Assisted Steering System:

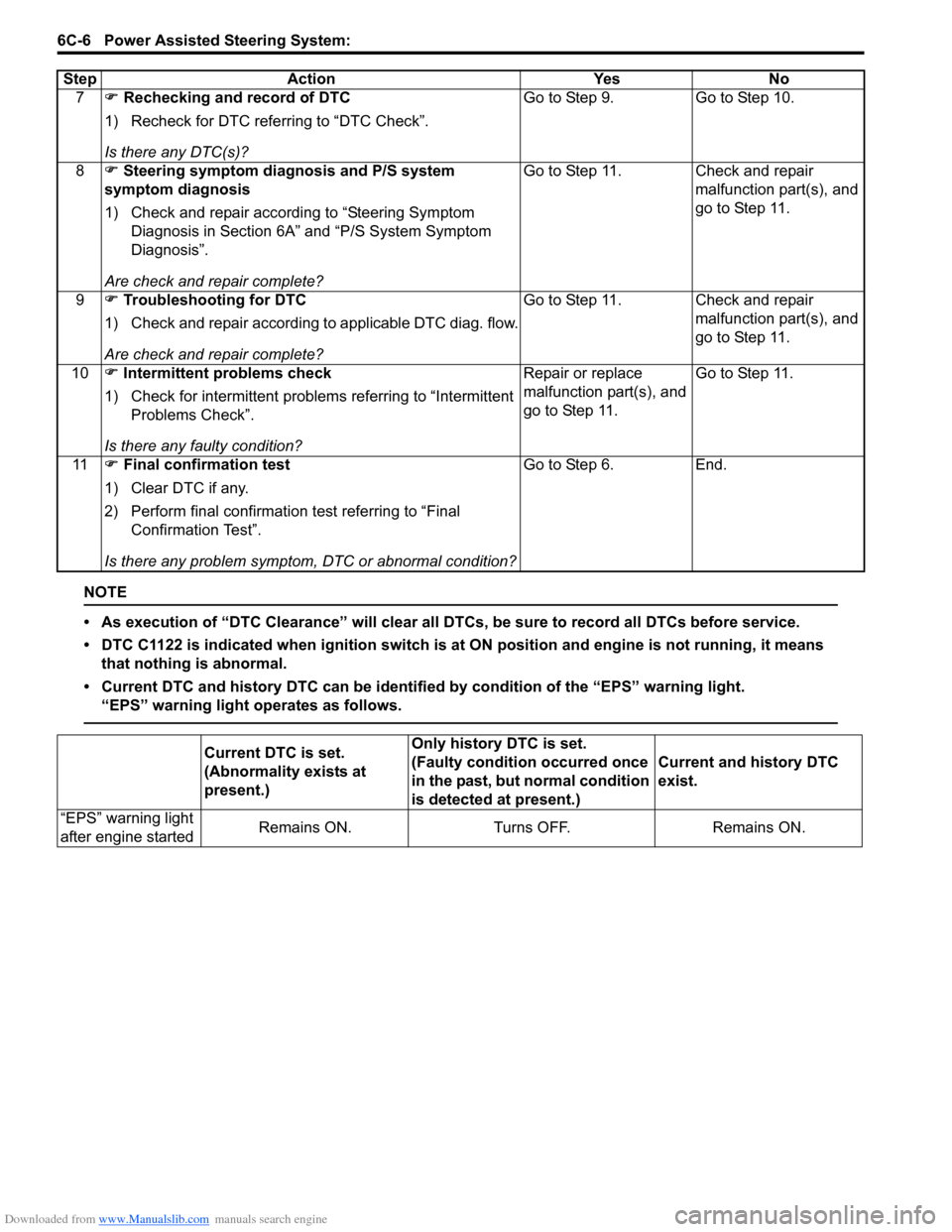

NOTE

• As execution of “DTC Clearance” will clear all DTCs, be sure to record all DTCs before service.

• DTC C1122 is indicated when ignition switch is at ON position and engine is not running, it means

that nothing is abnormal.

• Current DTC and history DTC ca n be identified by condition of the “EPS” warning light.

“EPS” warning light operates as follows.

7 �) Rechecking and record of DTC

1) Recheck for DTC referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9. Go to Step 10.

8 �) Steering symptom diagnosis and P/S system

symptom diagnosis

1) Check and repair according to “Steering Symptom Diagnosis in Section 6A” and “P/S System Symptom

Diagnosis”.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s), and

go to Step 11.

9 �) Troubleshooting for DTC

1) Check and repair according to applicable DTC diag. flow.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s), and

go to Step 11.

10 �) Intermittent problems check

1) Check for intermittent problems referring to “Intermittent Problems Check”.

Is there any faulty condition? Repair or replace

malfunction part(s), and

go to Step 11.

Go to Step 11.

11 �) Final confirmation test

1) Clear DTC if any.

2) Perform final confirmation test referring to “Final Confirmation Test”.

Is there any problem symptom, DTC or abnormal condition? Go to Step 6. End.

Step Action Yes No

Current DTC is set.

(Abnormality exists at

present.)

Only history DTC is set.

(Faulty condition occurred once

in the past, but normal condition

is detected at present.)

Current and history DTC

exist.

“EPS” warning light

after engine started Remains ON. Turns OFF. Remains ON.

Page 926 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-44 Power Assisted Steering System:

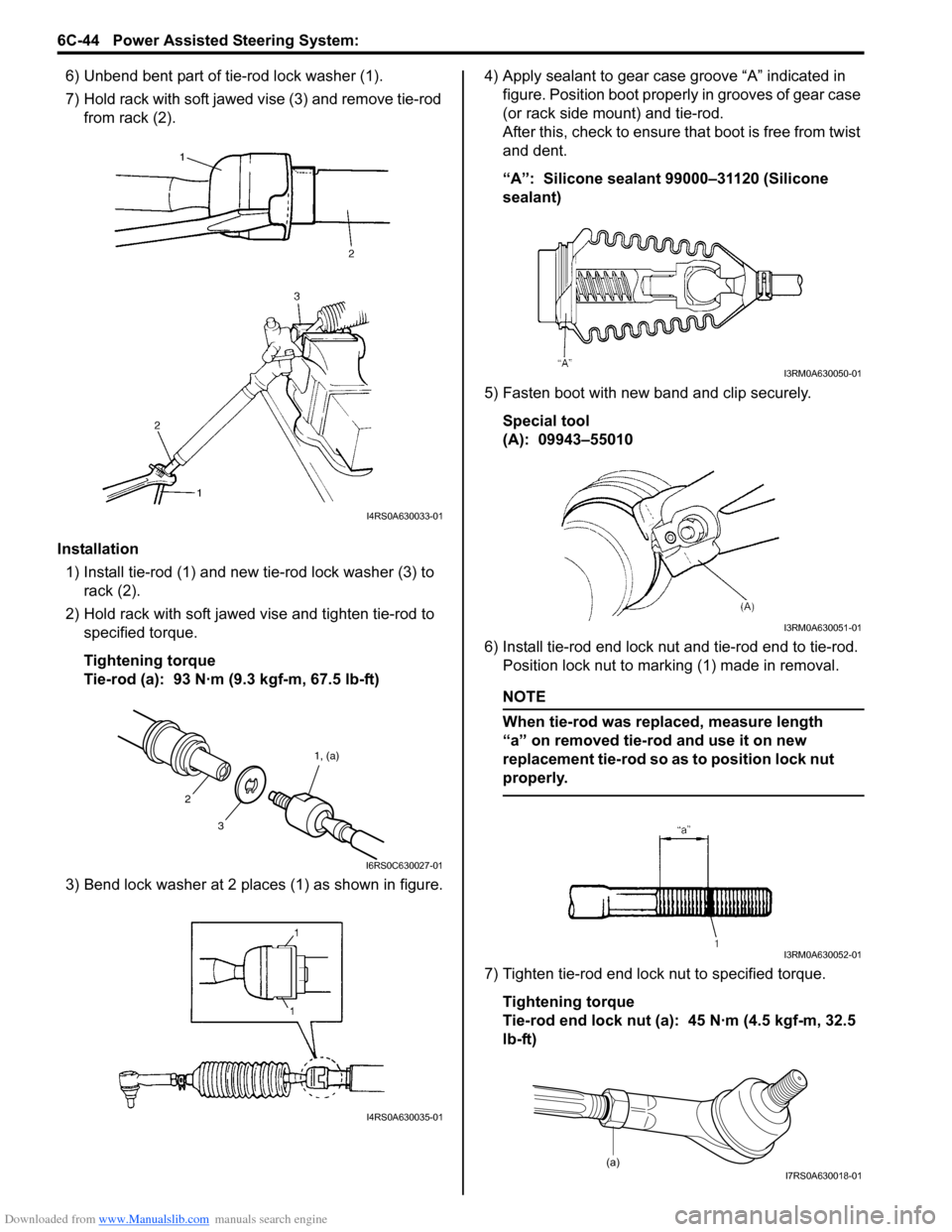

6) Unbend bent part of tie-rod lock washer (1).

7) Hold rack with soft jawed vise (3) and remove tie-rod

from rack (2).

Installation 1) Install tie-rod (1) and new tie-rod lock washer (3) to rack (2).

2) Hold rack with soft jawed vise and tighten tie-rod to specified torque.

Tightening torque

Tie-rod (a): 93 N·m (9.3 kgf-m, 67.5 lb-ft)

3) Bend lock washer at 2 places (1) as shown in figure. 4) Apply sealant to gear case groove “A” indicated in

figure. Position boot properly in grooves of gear case

(or rack side mount) and tie-rod.

After this, check to ensure that boot is free from twist

and dent.

“A”: Silicone sealant 99000–31120 (Silicone

sealant)

5) Fasten boot with new band and clip securely. Special tool

(A): 09943–55010

6) Install tie-rod end lock nut and tie-rod end to tie-rod. Position lock nut to marking (1) made in removal.

NOTE

When tie-rod was replaced, measure length

“a” on removed tie-rod and use it on new

replacement tie-rod so as to position lock nut

properly.

7) Tighten tie-rod end lock nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

I4RS0A630033-01

3 1, (a)

2

I6RS0C630027-01

I4RS0A630035-01

I3RM0A630050-01

I3RM0A630051-01

I3RM0A630052-01

(a)I7RS0A630018-01

Page 967 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-19

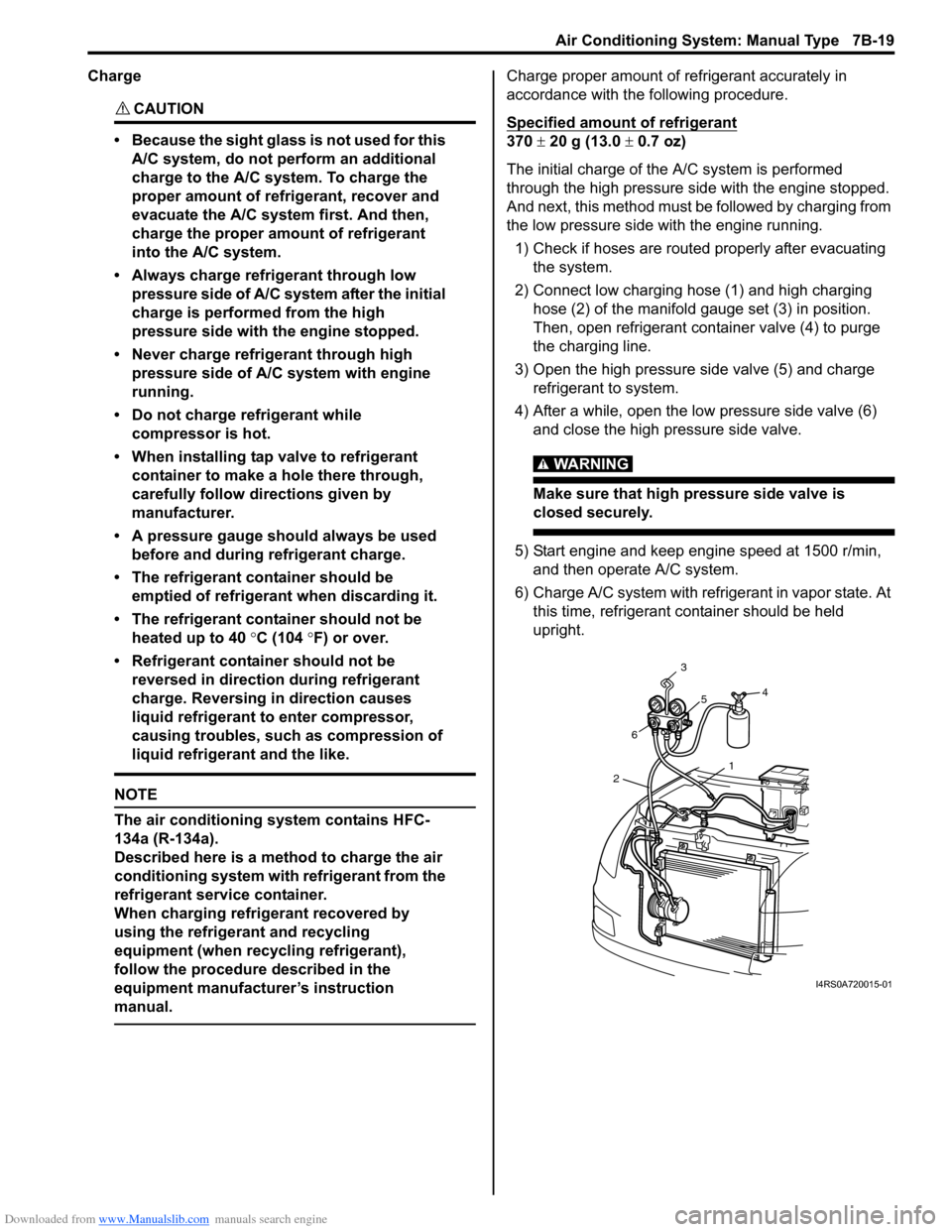

Charge

CAUTION!

• Because the sight glass is not used for this A/C system, do not perform an additional

charge to the A/C system. To charge the

proper amount of refrigerant, recover and

evacuate the A/C system first. And then,

charge the proper amount of refrigerant

into the A/C system.

• Always charge refrigerant through low pressure side of A/C system after the initial

charge is performed from the high

pressure side with the engine stopped.

• Never charge refrigerant through high pressure side of A/C system with engine

running.

• Do not charge refrigerant while compressor is hot.

• When installing tap valve to refrigerant container to make a hole there through,

carefully follow dire ctions given by

manufacturer.

• A pressure gauge should always be used before and during refrigerant charge.

• The refrigerant container should be emptied of refrigerant when discarding it.

• The refrigerant container should not be heated up to 40 °C (104 °F) or over.

• Refrigerant container should not be reversed in direction during refrigerant

charge. Reversing in direction causes

liquid refrigerant to enter compressor,

causing troubles, such as compression of

liquid refrigerant and the like.

NOTE

The air conditioning system contains HFC-

134a (R-134a).

Described here is a method to charge the air

conditioning system with refrigerant from the

refrigerant service container.

When charging refrigerant recovered by

using the refrigerant and recycling

equipment (when recycling refrigerant),

follow the procedure described in the

equipment manufacturer’s instruction

manual.

Charge proper amount of refrigerant accurately in

accordance with the following procedure.

Specified amount of refrigerant

370 ± 20 g (13.0 ± 0.7 oz)

The initial charge of the A/C system is performed

through the high pressure side with the engine stopped.

And next, this method must be followed by charging from

the low pressure side with the engine running.

1) Check if hoses are routed properly after evacuating the system.

2) Connect low charging hose (1) and high charging hose (2) of the manifold gauge set (3) in position.

Then, open refrigerant container valve (4) to purge

the charging line.

3) Open the high pressure side valve (5) and charge refrigerant to system.

4) After a while, open the low pressure side valve (6) and close the high pressure side valve.

WARNING!

Make sure that high pressure side valve is

closed securely.

5) Start engine and keep engine speed at 1500 r/min, and then operate A/C system.

6) Charge A/C system with refrigerant in vapor state. At this time, refrigerant container should be held

upright.

1

2 6 3

5 4

I4RS0A720015-01

Page 1018 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-70 Air Conditioning System: Automatic Type

A/C System Performance InspectionS7RS0B7224027

Refer to “A/C System Performance Inspection”.

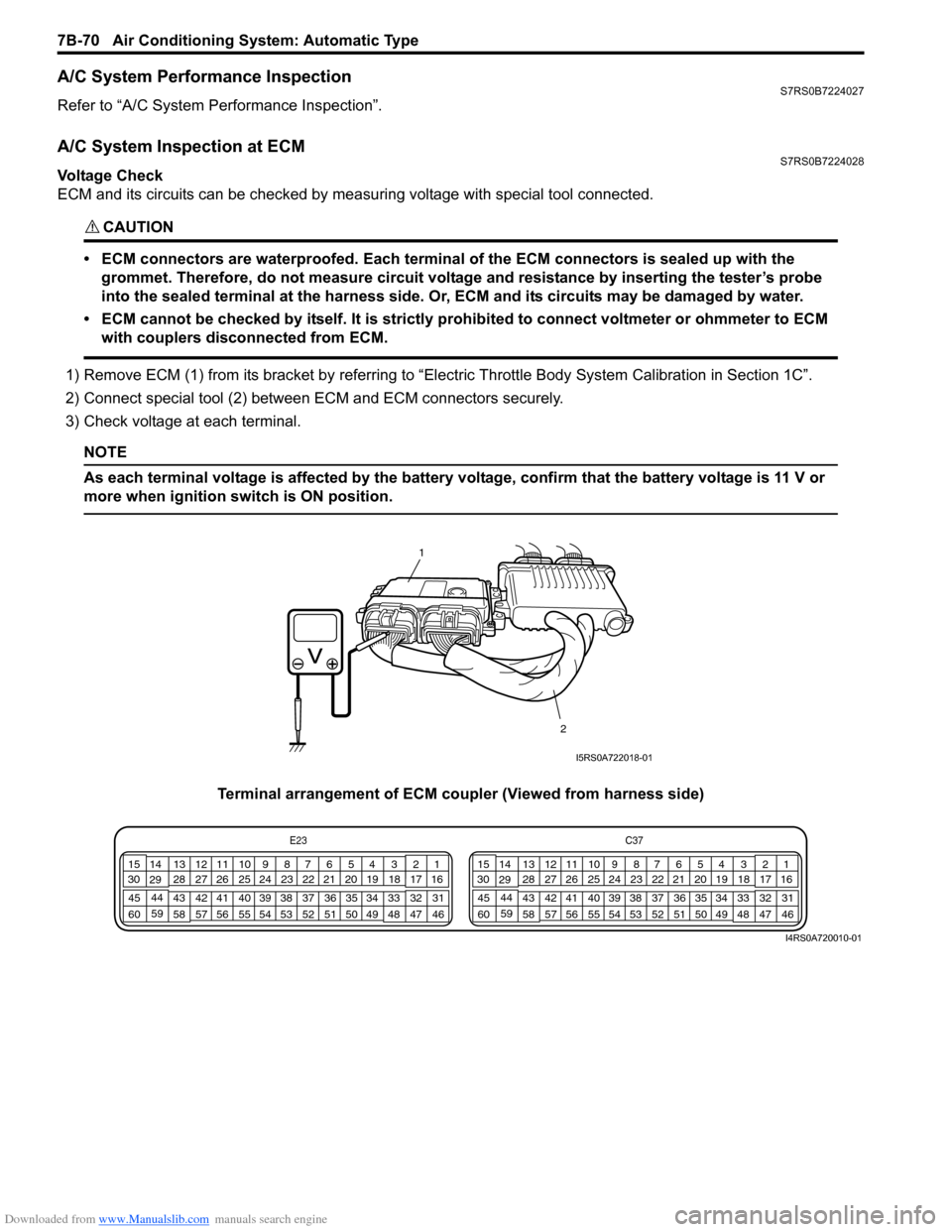

A/C System Inspection at ECMS7RS0B7224028

Voltage Check

ECM and its circuits can be checked by measuring voltage with special tool connected.

CAUTION!

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the

grommet. Therefore, do not measure circuit voltage and resistance by inserting the tester’s probe

into the sealed terminal at the harness side. Or, ECM and its circuits may be damaged by water.

• ECM cannot be checked by itself. It is strictly prohibited to connect voltmeter or ohmmeter to ECM with couplers disconnected from ECM.

1) Remove ECM (1) from its bracket by referring to “Electric Throttle Body System Calibration in Section 1C”.

2) Connect special tool (2) between ECM and ECM connectors securely.

3) Check voltage at each terminal.

NOTE

As each terminal voltage is affected by the battery voltage, confirm that the battery voltage is 11 V or

more when ignition sw itch is ON position.

Terminal arrangement of ECM coupler (Viewed from harness side)

1

2

I5RS0A722018-01

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A720010-01

Page 1035 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-4

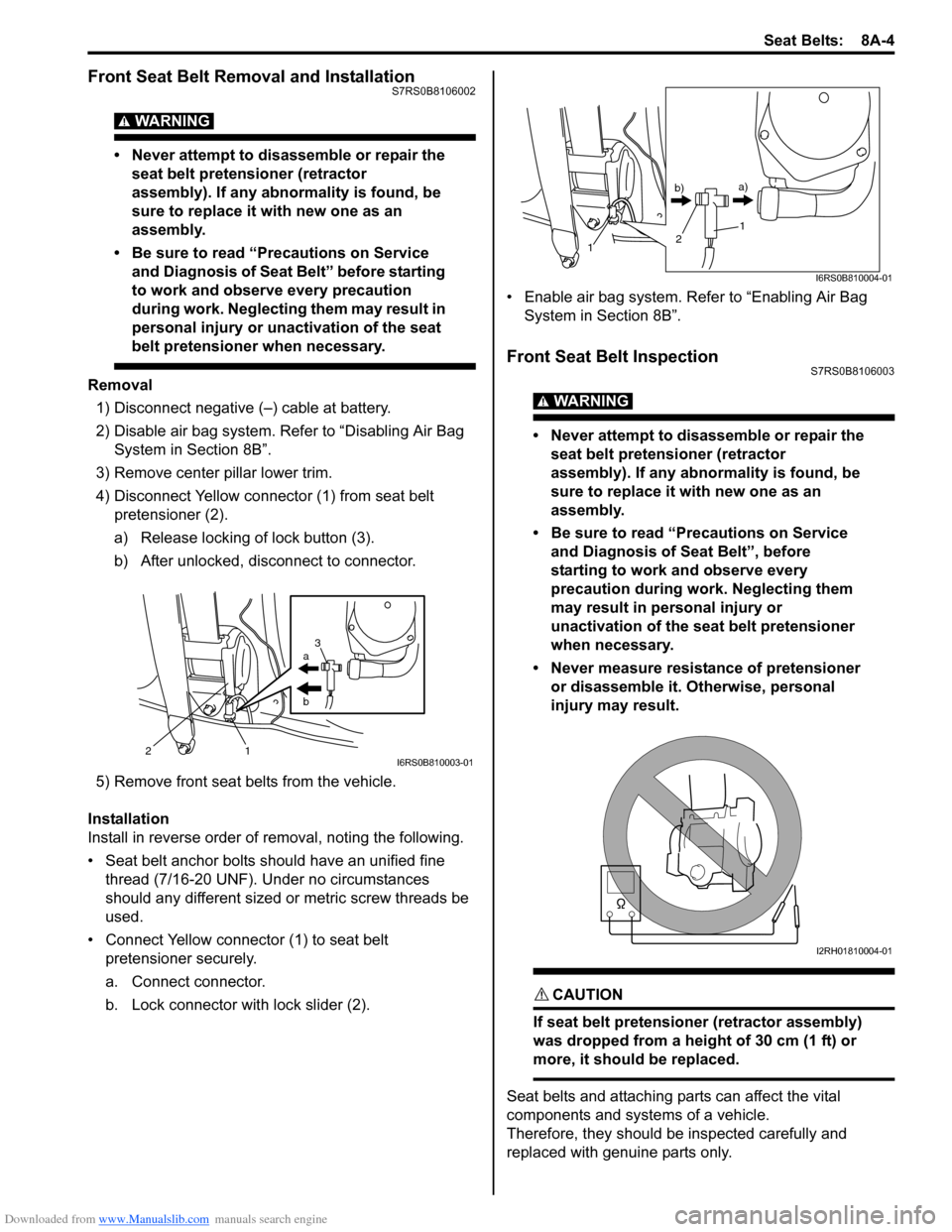

Front Seat Belt Removal and InstallationS7RS0B8106002

WARNING!

• Never attempt to disassemble or repair the seat belt pretensioner (retractor

assembly). If any abnormality is found, be

sure to replace it with new one as an

assembly.

• Be sure to read “Precautions on Service and Diagnosis of Seat Belt” before starting

to work and observe every precaution

during work. Ne glecting them may result in

personal injury or una ctivation of the seat

belt pretensioner when necessary.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Refer to “Disabling Air Bag System in Section 8B”.

3) Remove center pillar lower trim.

4) Disconnect Yellow connector (1) from seat belt pretensioner (2).

a) Release locking of lock button (3).

b) After unlocked, disconnect to connector.

5) Remove front seat belts from the vehicle.

Installation

Install in reverse order of removal, noting the following.

• Seat belt anchor bolts should have an unified fine thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.

• Connect Yellow connector (1) to seat belt pretensioner securely.

a. Connect connector.

b. Lock connector with lock slider (2). • Enable air bag system. Refer to “Enabling Air Bag

System in Section 8B”.

Front Seat Belt InspectionS7RS0B8106003

WARNING!

• Never attempt to disassemble or repair the seat belt pretensioner (retractor

assembly). If any abnormality is found, be

sure to replace it with new one as an

assembly.

• Be sure to read “Precautions on Service and Diagnosis of Seat Belt”, before

starting to work and observe every

precaution during work. Neglecting them

may result in personal injury or

unactivation of the seat belt pretensioner

when necessary.

• Never measure resistance of pretensioner or disassemble it. Otherwise, personal

injury may result.

CAUTION!

If seat belt pretensioner (retractor assembly)

was dropped from a height of 30 cm (1 ft) or

more, it should be replaced.

Seat belts and attaching parts can affect the vital

components and systems of a vehicle.

Therefore, they should be inspected carefully and

replaced with genuine parts only.

a

b

21 3I6RS0B810003-01

1

1

2

b)

a)

I6RS0B810004-01

I2RH01810004-01

Page 1036 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-5 Seat Belts:

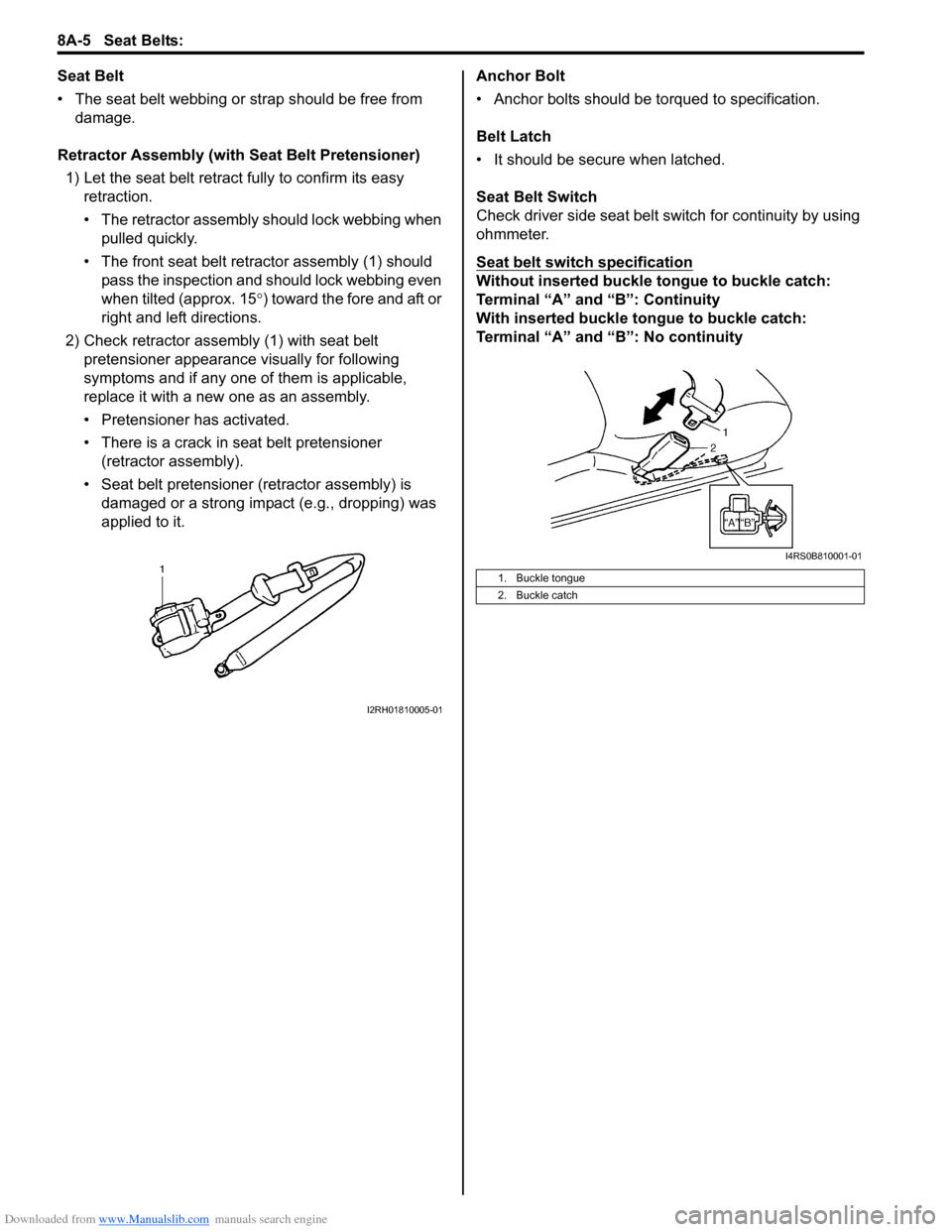

Seat Belt

• The seat belt webbing or strap should be free from damage.

Retractor Assembly (with Seat Belt Pretensioner) 1) Let the seat belt retract fully to confirm its easy retraction.

• The retractor assembly should lock webbing when

pulled quickly.

• The front seat belt retractor assembly (1) should pass the inspection and should lock webbing even

when tilted (approx. 15 °) toward the fore and aft or

right and left directions.

2) Check retractor assembly (1) with seat belt pretensioner appearance visually for following

symptoms and if any one of them is applicable,

replace it with a new one as an assembly.

• Pretensioner has activated.

• There is a crack in seat belt pretensioner (retractor assembly).

• Seat belt pretensioner (retractor assembly) is damaged or a strong impact (e.g., dropping) was

applied to it. Anchor Bolt

• Anchor bolts should be torqued to specification.

Belt Latch

• It should be secure when latched.

Seat Belt Switch

Check driver side seat belt s

witch for continuity by using

ohmmeter.

Seat belt switch specification

Without inserted buckle tongue to buckle catch:

Terminal “A” and “B”: Continuity

With inserted buckle tongue to buckle catch:

Terminal “A” and “B”: No continuity

I2RH01810005-01

1. Buckle tongue

2. Buckle catch

I4RS0B810001-01

Page 1041 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-3

• Never attempt disassembly of the air bag (inflator) modules.

• If any abnormality is found, be sure to replace it with

new one as an assembly.

• When an abnormality is noted as existing in the live (undeployed) air bag (inflator) module, be sure to

deploy it before discarding it.

• When grease, cleaning agent, oil, water, etc., got on the air bag (inflator) modules (driver, passenger, side

of both sides and curtain of both sides), wipe it off

immediately with a dry cloth.

• If air bag (inflator) module was dropped from a height of 90 cm (3 ft) or more, it should be replaced with a

new one as an assembly.

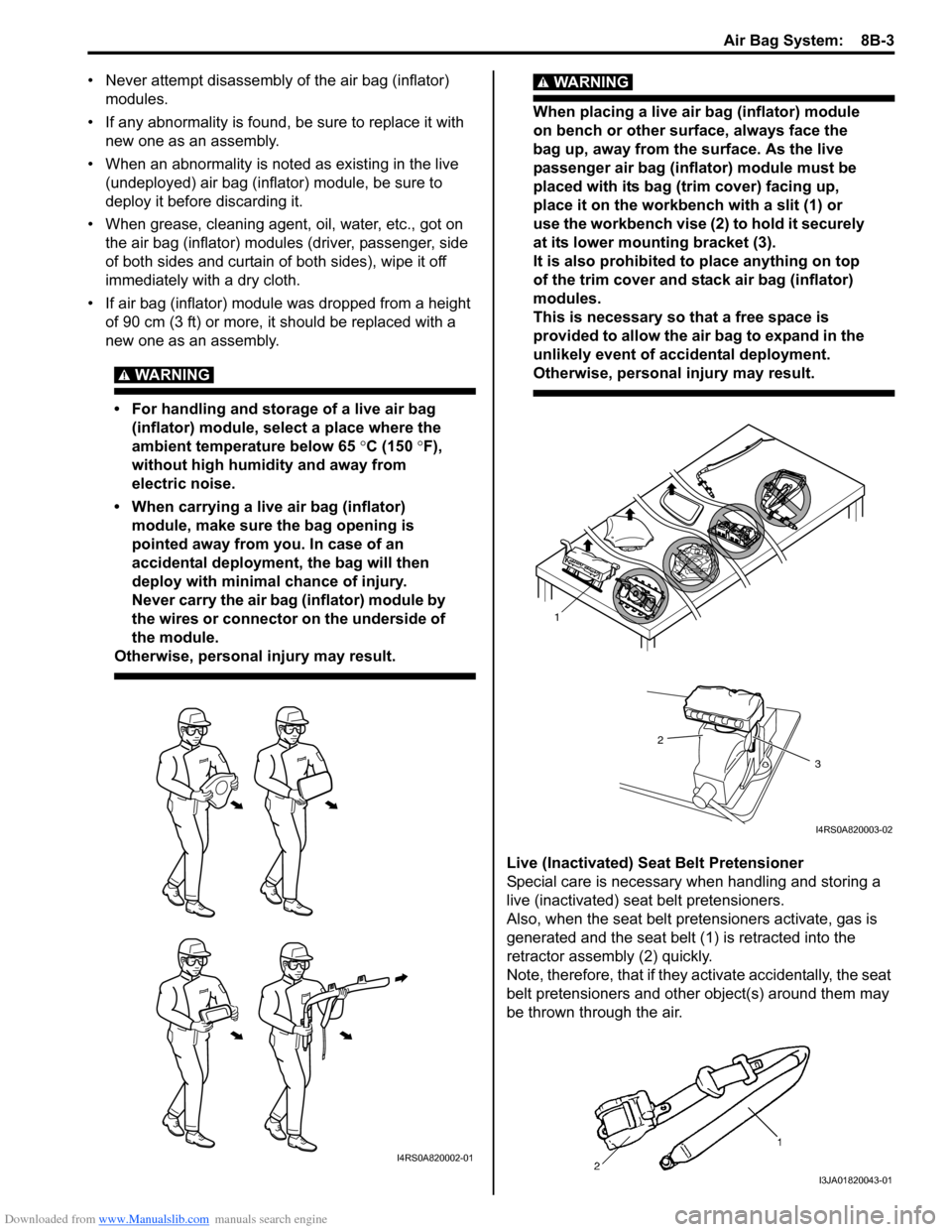

WARNING!

• For handling and storage of a live air bag (inflator) module, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you. In case of an

accidental deployment, the bag will then

deploy with minimal chance of injury.

Never carry the air bag (inflator) module by

the wires or connector on the underside of

the module.

Otherwise, personal injury may result.

WARNING!

When placing a live air bag (inflator) module

on bench or other surface, always face the

bag up, away from the surface. As the live

passenger air bag (inflator) module must be

placed with its bag (trim cover) facing up,

place it on the workbench with a slit (1) or

use the workbench vise (2) to hold it securely

at its lower mounting bracket (3).

It is also prohibited to place anything on top

of the trim cover and stack air bag (inflator)

modules.

This is necessary so that a free space is

provided to allow the air bag to expand in the

unlikely event of accidental deployment.

Otherwise, personal injury may result.

Live (Inactivated) Seat Belt Pretensioner

Special care is necessary when handling and storing a

live (inactivated) seat belt pretensioners.

Also, when the seat belt pretensioners activate, gas is

generated and the seat belt (1) is retracted into the

retractor assembly (2) quickly.

Note, therefore, that if they activate accidentally, the seat

belt pretensioners and other object(s) around them may

be thrown through the air.

I4RS0A820002-01

1

2

3

I4RS0A820003-02

I3JA01820043-01

Page 1043 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-5

• When an open in air bag wire harness, damaged wire harness, connector or terminal is found, replace wire

harness, connectors and terminals as an assembly.

• When installing it, be careful so that the air bag wire harness is not caught or does not interfere with other

parts.

• Make sure air bag system grounding point (2) is clean and ground is securely fastened for optimum metal-to-

metal contact. Poor grounding can cause intermittent

problems that are difficult to diagnose.Precautions on Disposal of Air Bag and Seat

Belt Pretensioner

S7RS0B8200003

Do not dispose of the live (undeployed) air bag (inflator)

modules and the live (inactivated) seat belt

pretensioners.

When disposal is necessary, be sure to deploy / activate

the air bag and seat belt pretensioner according to

deployment / activation procedure described in “Air Bag

(Inflator) Module and Seat Belt Pretensioner Disposal”.

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which could

cause personal injury. Undeployed air bag

(inflator) module and inactivated seat belt

pretensioner must not be disposed of

through normal refuse channels.

The undeployed air bag (inflator) module and

inactivated seat belt pretensioner contain

substances that can cause severe illness or

personal injury if the sealed container is

damaged during disposal.

General Description

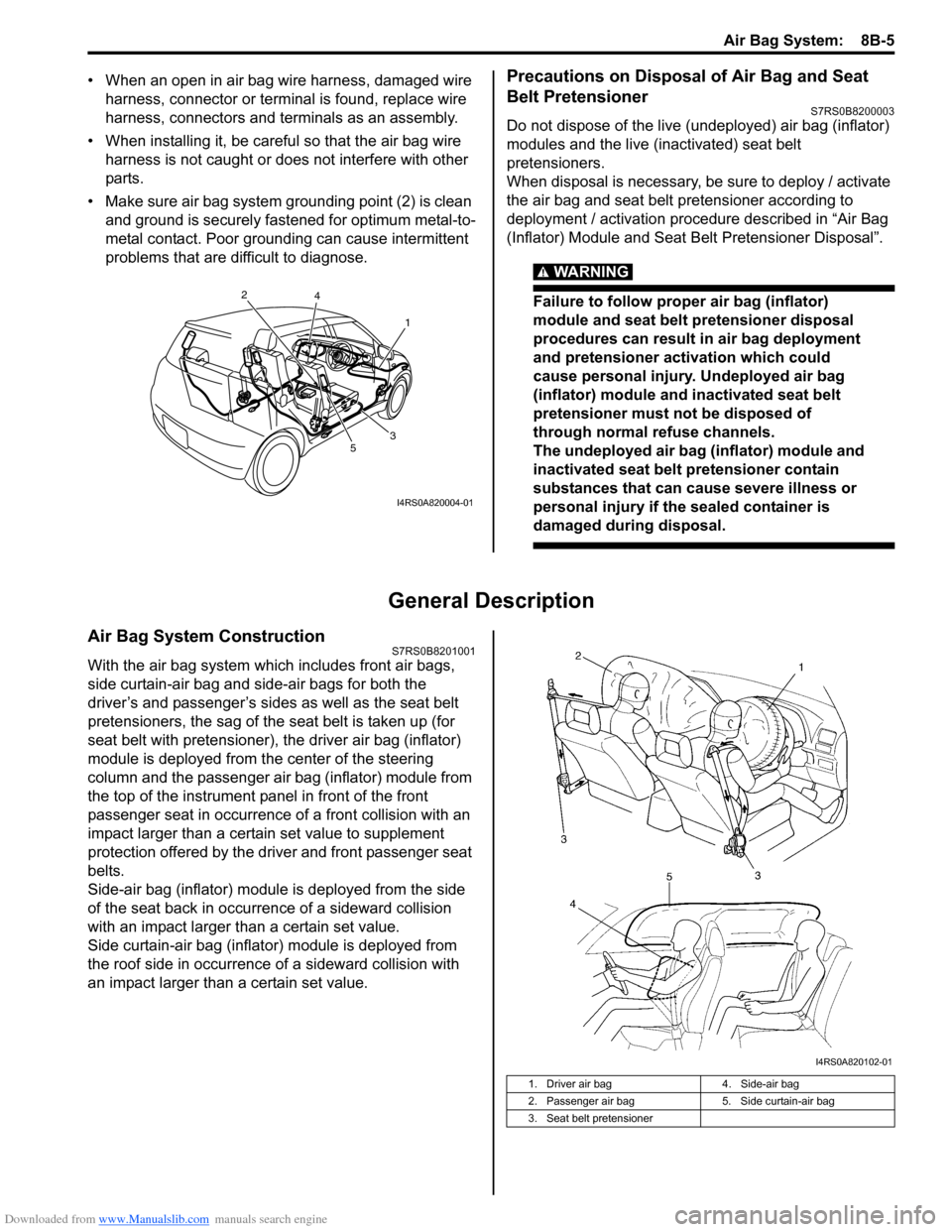

Air Bag System ConstructionS7RS0B8201001

With the air bag system which includes front air bags,

side curtain-air bag and side-air bags for both the

driver’s and passenger’s sides as well as the seat belt

pretensioners, the sag of the s eat belt is taken up (for

seat belt with pretensioner), the driver air bag (inflator)

module is deployed from th e center of the steering

column and the passenger air bag (inflator) module from

the top of the instrument panel in front of the front

passenger seat in occurrence of a front collision with an

impact larger than a certain set value to supplement

protection offered by the driver and front passenger seat

belts.

Side-air bag (inflator) module is deployed from the side

of the seat back in occurrence of a sideward collision

with an impact larger than a certain set value.

Side curtain-air bag (inflator) module is deployed from

the roof side in occurrence of a sideward collision with

an impact larger than a certain set value.

1

2

3

4

5

I4RS0A820004-01

1. Driver air bag 4. Side-air bag

2. Passenger air bag 5. Side curtain-air bag

3. Seat belt pretensioner

I4RS0A820102-01