Oul SUZUKI SWIFT 2007 2.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 509 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-11

Brake Hose and Pipe InspectionS7RS0B4106009

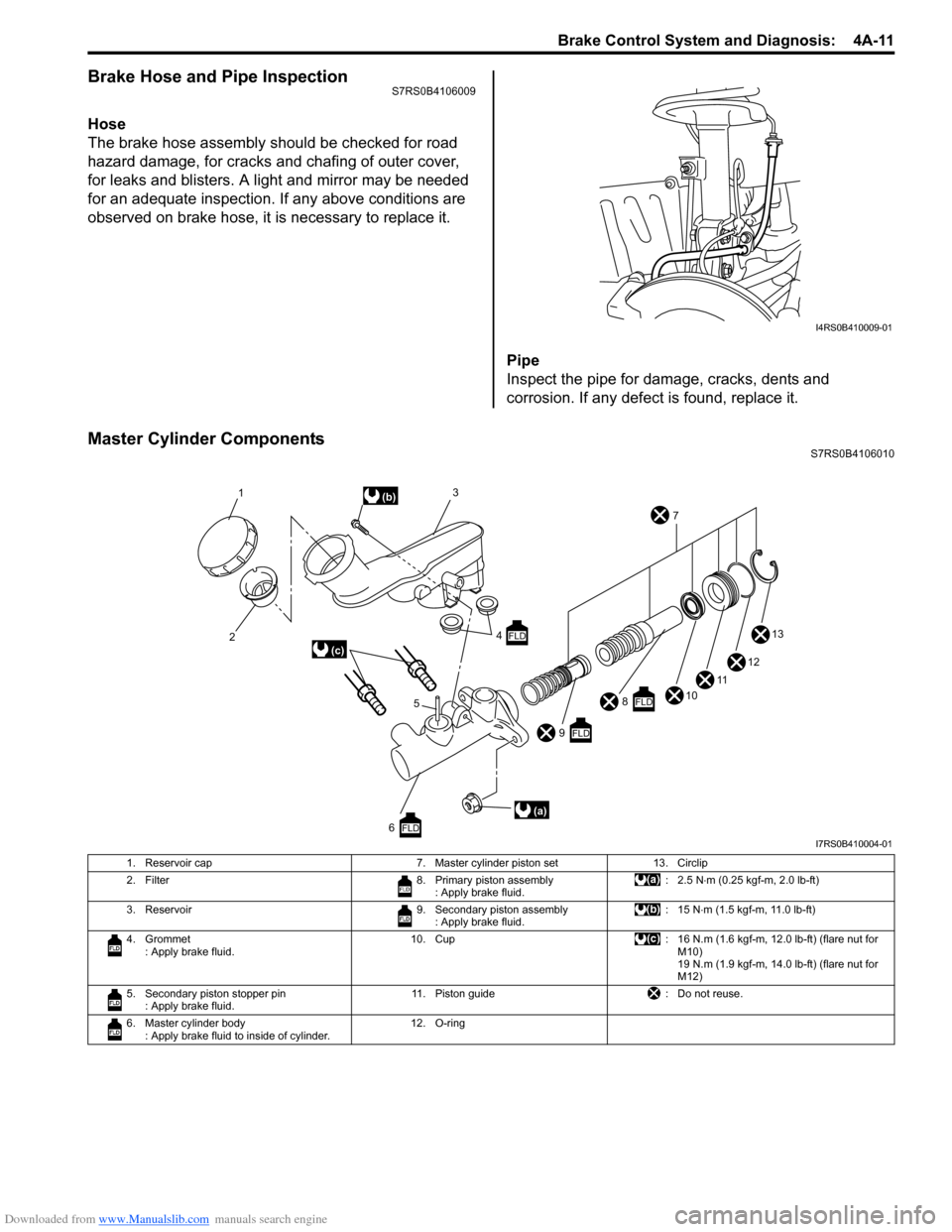

Hose

The brake hose assembly should be checked for road

hazard damage, for cracks and chafing of outer cover,

for leaks and blisters. A light and mirror may be needed

for an adequate inspection. If any above conditions are

observed on brake hose, it is necessary to replace it.

Pipe

Inspect the pipe for damage, cracks, dents and

corrosion. If any defect is found, replace it.

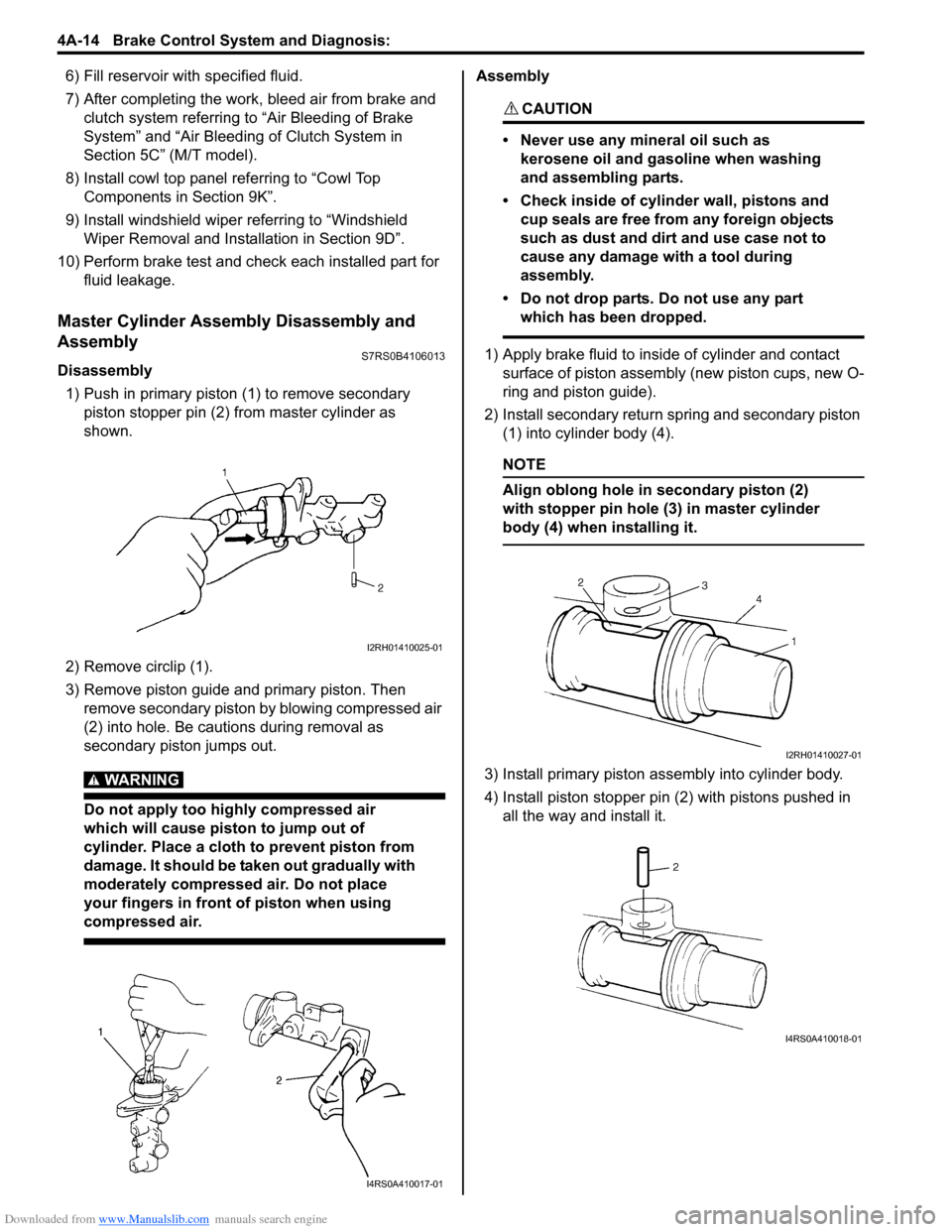

Master Cylinder ComponentsS7RS0B4106010

I4RS0B410009-01

10

11

1

2 3

4

5 7

13

12

9

FLD

8FLD

6FLD

(b)

(a)

(c)FLD

I7RS0B410004-01

1. Reservoir cap 7. Master cylinder piston set13. Circlip

2. Filter 8. Primary piston assembly

: Apply brake fluid. :2.5 N

⋅m (0.25 kgf-m, 2.0 lb-ft)

3. Reservoir 9. Secondary piston assembly

: Apply brake fluid. : 15 N

⋅m (1.5 kgf-m, 11.0 lb-ft)

4. Grommet : Apply brake fluid. 10. Cup

: 16 N.m (1.6 kgf-m, 12.0 lb-ft) (flare nut for

M10)

19 N.m (1.9 kgf-m, 14.0 lb-ft) (flare nut for

M12)

5. Secondary piston stopper pin : Apply brake fluid. 11. Piston guide

: Do not reuse.

6. Master cylinder body : Apply brake fluid to inside of cylinder. 12. O-ring

Page 512 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-14 Brake Control System and Diagnosis:

6) Fill reservoir with specified fluid.

7) After completing the work, bleed air from brake and clutch system referring to “Air Bleeding of Brake

System” and “Air Bleeding of Clutch System in

Section 5C” (M/T model).

8) Install cowl top panel referring to “Cowl Top Components in Section 9K”.

9) Install windshield wiper referring to “Windshield

Wiper Removal and Insta llation in Section 9D”.

10) Perform brake test and check each installed part for fluid leakage.

Master Cylinder Assembly Disassembly and

Assembly

S7RS0B4106013

Disassembly

1) Push in primary piston (1) to remove secondary

piston stopper pin (2) from master cylinder as

shown.

2) Remove circlip (1).

3) Remove piston guide and primary piston. Then remove secondary piston by blowing compressed air

(2) into hole. Be cautions during removal as

secondary piston jumps out.

WARNING!

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. Place a cloth to prevent piston from

damage. It should be taken out gradually with

moderately compressed air. Do not place

your fingers in front of piston when using

compressed air.

Assembly

CAUTION!

• Never use any mineral oil such as kerosene oil and gasoline when washing

and assembling parts.

• Check inside of cylinder wall, pistons and cup seals are free from any foreign objects

such as dust and dirt and use case not to

cause any damage with a tool during

assembly.

• Do not drop parts. Do not use any part which has been dropped.

1) Apply brake fluid to inside of cylinder and contact surface of piston assembly (new piston cups, new O-

ring and piston guide).

2) Install secondary return spring and secondary piston (1) into cylinder body (4).

NOTE

Align oblong hole in secondary piston (2)

with stopper pin hole (3) in master cylinder

body (4) when installing it.

3) Install primary piston assembly into cylinder body.

4) Install piston stopper pin (2) with pistons pushed in all the way and install it.

I2RH01410025-01

I4RS0A410017-01

I2RH01410027-01

I4RS0A410018-01

Page 520 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-4 Front Brakes:

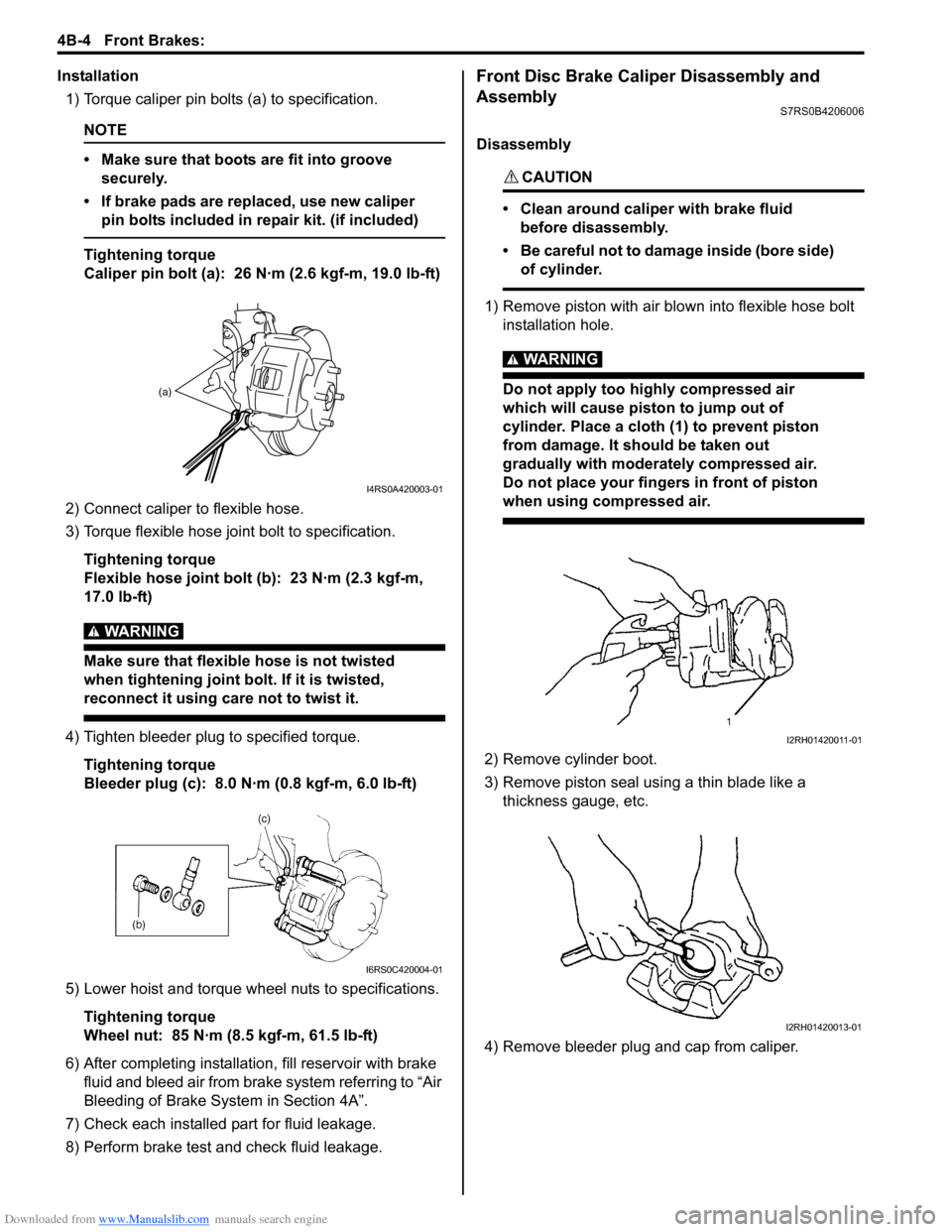

Installation1) Torque caliper pin bolts (a) to specification.

NOTE

• Make sure that boots are fit into groove securely.

• If brake pads are replaced, use new caliper pin bolts included in repair kit. (if included)

Tightening torque

Caliper pin bolt (a): 26 N·m (2.6 kgf-m, 19.0 lb-ft)

2) Connect caliper to flexible hose.

3) Torque flexible hose jo int bolt to specification.

Tightening torque

Flexible hose joint bolt (b): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

WARNING!

Make sure that flexible hose is not twisted

when tightening joint bolt. If it is twisted,

reconnect it using care not to twist it.

4) Tighten bleeder plug to specified torque. Tightening torque

Bleeder plug (c): 8.0 N·m (0.8 kgf-m, 6.0 lb-ft)

5) Lower hoist and torque wheel nuts to specifications. Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) After completing installation, fill reservoir with brake

fluid and bleed air from brake system referring to “Air

Bleeding of Brake System in Section 4A”.

7) Check each installed part for fluid leakage.

8) Perform brake test and check fluid leakage.

Front Disc Brake Caliper Disassembly and

Assembly

S7RS0B4206006

Disassembly

CAUTION!

• Clean around caliper with brake fluid before disassembly.

• Be careful not to damage inside (bore side) of cylinder.

1) Remove piston with air blown into flexible hose bolt installation hole.

WARNING!

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. Place a cloth (1) to prevent piston

from damage. It should be taken out

gradually with moderately compressed air.

Do not place your fingers in front of piston

when using compressed air.

2) Remove cylinder boot.

3) Remove piston seal using a thin blade like a thickness gauge, etc.

4) Remove bleeder plug and cap from caliper.

(a)

I4RS0A420003-01

I6RS0C420004-01

I2RH01420011-01

I2RH01420013-01

Page 522 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-6 Front Brakes:

5) To confirm that boot is fitted in its groove in cylinder

properly, pull piston out of cylinder a little but do not

take it all out.

NOTE

Boot’s face (1) should be at the same level

from cylinder’s face (2) all around.

6) Insert piston into cylinder by hand.

Front Disc Brake Caliper InspectionS7RS0B4206007

Pin Boot and Cylinder Boot

Check boots for breakage, crack and damage.

If defective, replace.

Piston Seal

Excessive or uneven wear of pad lining may indicate

unsmooth return of piston.

In such case, replace rubber seal.

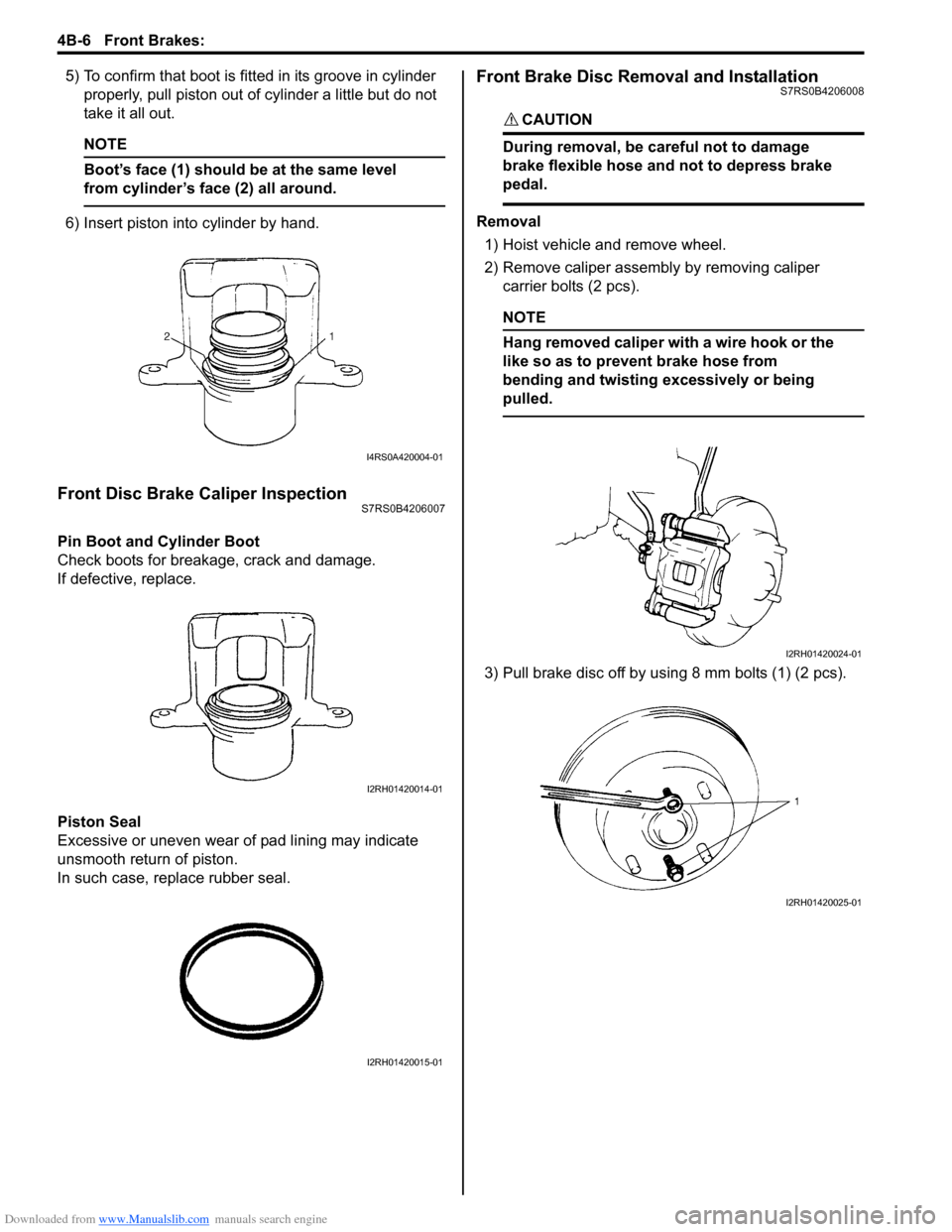

Front Brake Disc Removal and InstallationS7RS0B4206008

CAUTION!

During removal, be care ful not to damage

brake flexible hose and not to depress brake

pedal.

Removal

1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by removing caliper carrier bolts (2 pcs).

NOTE

Hang removed caliper with a wire hook or the

like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs).

I4RS0A420004-01

I2RH01420014-01

I2RH01420015-01

I2RH01420024-01

I2RH01420025-01

Page 532 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-8 Rear Brakes:

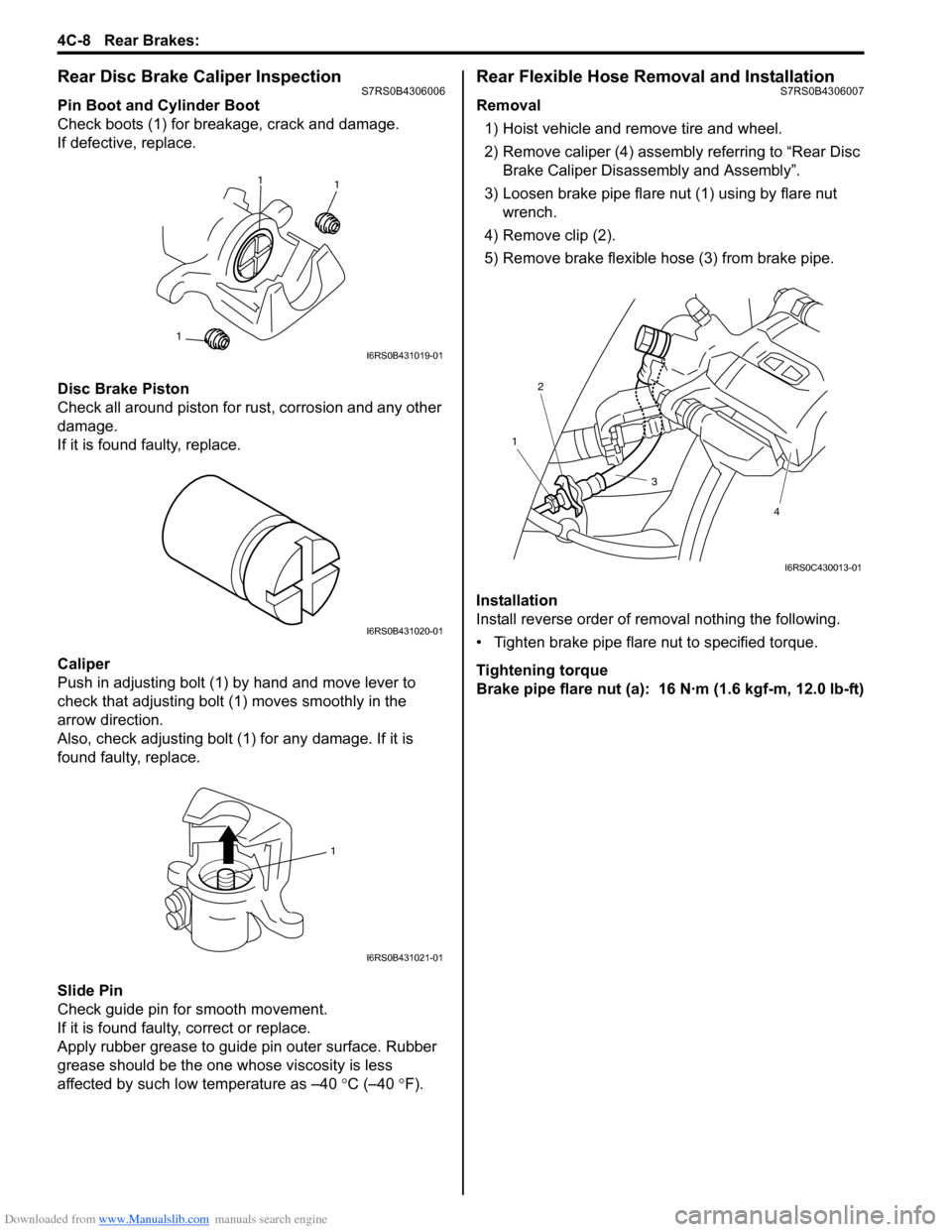

Rear Disc Brake Caliper InspectionS7RS0B4306006

Pin Boot and Cylinder Boot

Check boots (1) for breakage, crack and damage.

If defective, replace.

Disc Brake Piston

Check all around piston for rust, corrosion and any other

damage.

If it is found faulty, replace.

Caliper

Push in adjusting bolt (1) by hand and move lever to

check that adjusting bolt (1) moves smoothly in the

arrow direction.

Also, check adjusting bolt (1) for any damage. If it is

found faulty, replace.

Slide Pin

Check guide pin for smooth movement.

If it is found faulty, correct or replace.

Apply rubber grease to guide pin outer surface. Rubber

grease should be the one whose viscosity is less

affected by such low temperature as –40 °C (–40 ° F).

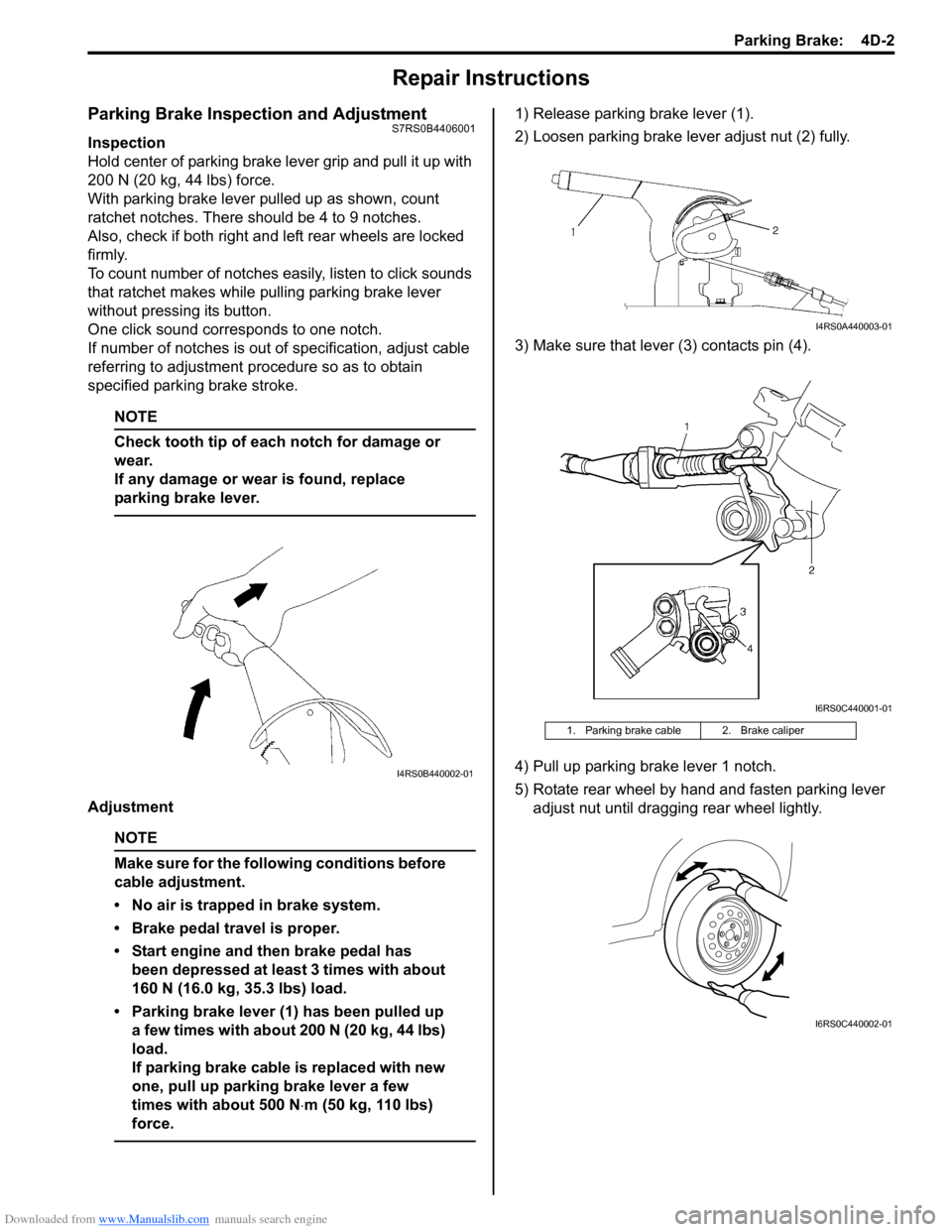

Rear Flexible Hose Removal and InstallationS7RS0B4306007

Removal

1) Hoist vehicle and remove tire and wheel.

2) Remove caliper (4) assembly referring to “Rear Disc Brake Caliper Disassembly and Assembly”.

3) Loosen brake pipe flare nut (1) using by flare nut wrench.

4) Remove clip (2).

5) Remove brake flexible hose (3) from brake pipe.

Installation

Install reverse order of removal nothing the following.

• Tighten brake pipe flare nut to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 12.0 lb-ft)

1 1

1

I6RS0B431019-01

I6RS0B431020-01

1

I6RS0B431021-01

1

2

3

4

I6RS0C430013-01

Page 537 of 1496

Downloaded from www.Manualslib.com manuals search engine Parking Brake: 4D-2

Repair Instructions

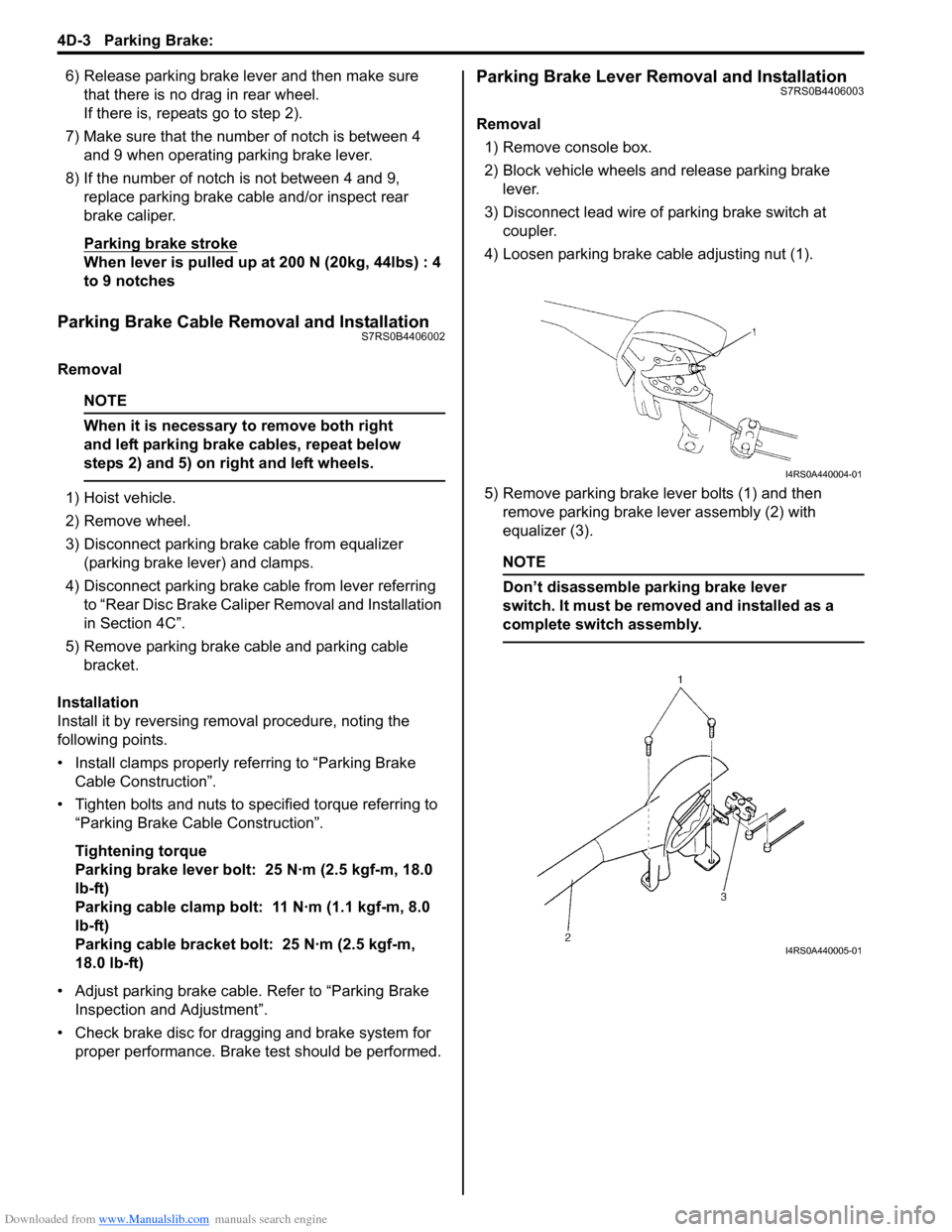

Parking Brake Inspection and AdjustmentS7RS0B4406001

Inspection

Hold center of parking brake lever grip and pull it up with

200 N (20 kg, 44 lbs) force.

With parking brake lever pulled up as shown, count

ratchet notches. There should be 4 to 9 notches.

Also, check if both right and left rear wheels are locked

firmly.

To count number of notches easily, listen to click sounds

that ratchet makes while pulling parking brake lever

without pressing its button.

One click sound corresponds to one notch.

If number of notches is out of specification, adjust cable

referring to adjustment procedure so as to obtain

specified parking brake stroke.

NOTE

Check tooth tip of each notch for damage or

wear.

If any damage or wear is found, replace

parking brake lever.

Adjustment

NOTE

Make sure for the following conditions before

cable adjustment.

• No air is trapped in brake system.

• Brake pedal travel is proper.

• Start engine and then brake pedal has been depressed at least 3 times with about

160 N (16.0 kg, 35.3 lbs) load.

• Parking brake lever (1) has been pulled up a few times with about 200 N (20 kg, 44 lbs)

load.

If parking brake cable is replaced with new

one, pull up parking brake lever a few

times with about 500 N ⋅m (50 kg, 110 lbs)

force.

1) Release parking brake lever (1).

2) Loosen parking brake lever adjust nut (2) fully.

3) Make sure that lever (3) contacts pin (4).

4) Pull up parking brake lever 1 notch.

5) Rotate rear wheel by hand and fasten parking lever adjust nut until dragging rear wheel lightly.

I4RS0B440002-01

1. Parking brake cable 2. Brake caliper

I4RS0A440003-01

I6RS0C440001-01

I6RS0C440002-01

Page 538 of 1496

Downloaded from www.Manualslib.com manuals search engine 4D-3 Parking Brake:

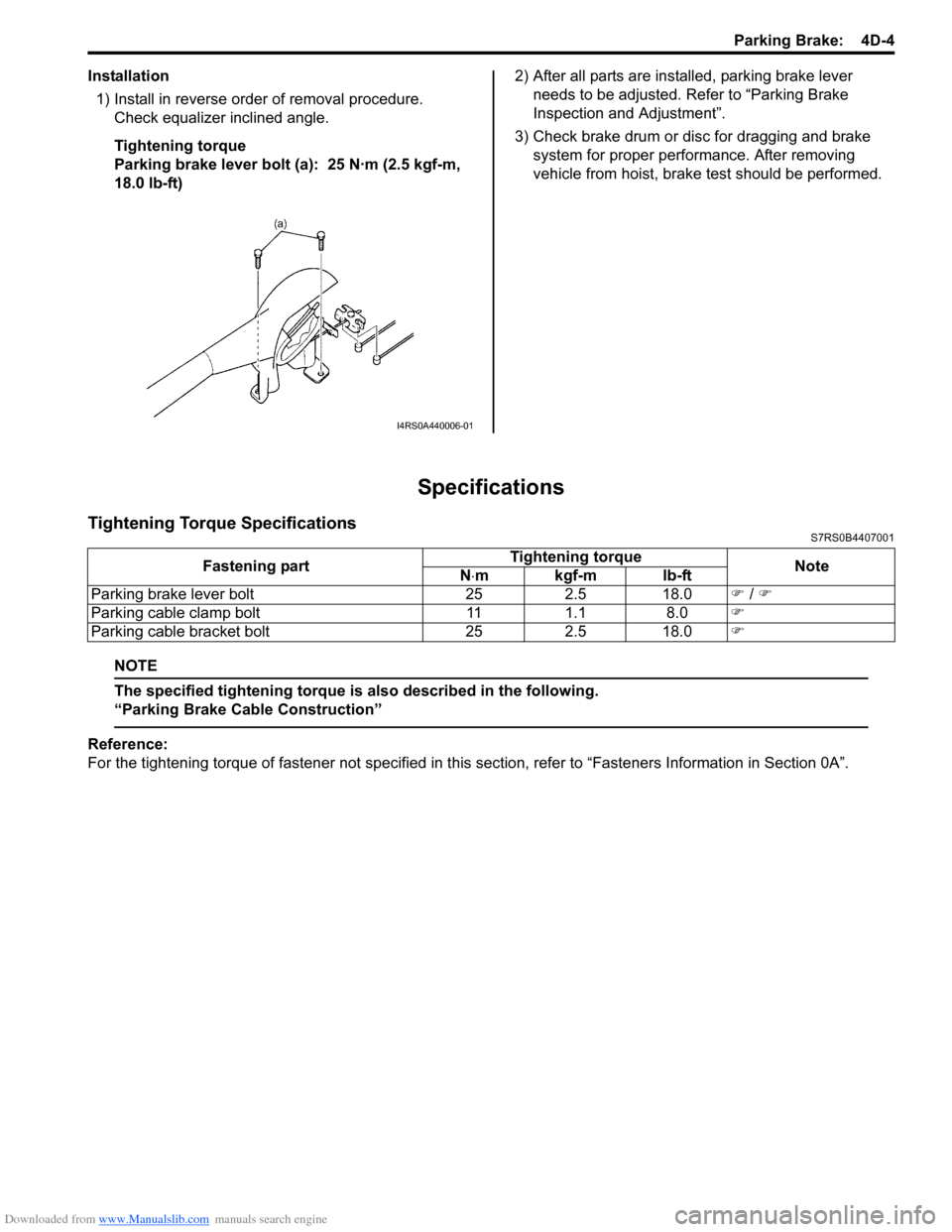

6) Release parking brake lever and then make sure that there is no drag in rear wheel.

If there is, repeats go to step 2).

7) Make sure that the number of notch is between 4 and 9 when operating parking brake lever.

8) If the number of notch is not between 4 and 9, replace parking brake cable and/or inspect rear

brake caliper.

Parking brake stroke

When lever is pulled up at 200 N (20kg, 44lbs) : 4

to 9 notches

Parking Brake Cable Removal and InstallationS7RS0B4406002

Removal

NOTE

When it is necessary to remove both right

and left parking brake cables, repeat below

steps 2) and 5) on right and left wheels.

1) Hoist vehicle.

2) Remove wheel.

3) Disconnect parking brake cable from equalizer (parking brake lever) and clamps.

4) Disconnect parking brake cable from lever referring to “Rear Disc Brake Caliper Removal and Installation

in Section 4C”.

5) Remove parking brake cable and parking cable bracket.

Installation

Install it by reversing removal procedure, noting the

following points.

• Install clamps properly referring to “Parking Brake Cable Construction”.

• Tighten bolts and nuts to specified torque referring to “Parking Brake Cable Construction”.

Tightening torque

Parking brake lever bolt: 25 N·m (2.5 kgf-m, 18.0

lb-ft)

Parking cable clamp bolt: 11 N·m (1.1 kgf-m, 8.0

lb-ft)

Parking cable bracket bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Adjust parking brake cable. Refer to “Parking Brake Inspection and Adjustment”.

• Check brake disc for dragging and brake system for proper performance. Brake test should be performed.

Parking Brake Lever Removal and InstallationS7RS0B4406003

Removal

1) Remove console box.

2) Block vehicle wheels and release parking brake lever.

3) Disconnect lead wire of parking brake switch at coupler.

4) Loosen parking brake cable adjusting nut (1).

5) Remove parking brake lever bolts (1) and then remove parking brake lever assembly (2) with

equalizer (3).

NOTE

Don’t disassemble parking brake lever

switch. It must be removed and installed as a

complete switch assembly.

I4RS0A440004-01

I4RS0A440005-01

Page 539 of 1496

Downloaded from www.Manualslib.com manuals search engine Parking Brake: 4D-4

Installation1) Install in reverse order of removal procedure. Check equalizer inclined angle.

Tightening torque

Parking brake lever bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft) 2) After all parts are installed, parking brake lever

needs to be adjusted. Refer to “Parking Brake

Inspection and Adjustment”.

3) Check brake drum or disc for dragging and brake system for proper performance. After removing

vehicle from hoist, brake test should be performed.

Specifications

Tightening Torque SpecificationsS7RS0B4407001

NOTE

The specified tightening torque is also described in the following.

“Parking Brake Cable Construction”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I4RS0A440006-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Parking brake lever bolt 25 2.5 18.0 �) / �)

Parking cable clamp bolt 11 1.1 8.0 �)

Parking cable bracket bolt 25 2.5 18.0 �)

Page 540 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-1 ABS:

Brakes

ABS

Precautions

Precautions in Diagnosing TroublesS7RS0B4500001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow “ABS

Check”.

• Diagnostic information stored in ABS cont rol module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ABS warning light may light momentarily but

this does not indicate anything abnormal in ABS.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• Be sure to use the trouble diagnosis procedure as described in “ABS Check”. Failure to follow it may

result in incorrect diagnosis. (Some other diagnosis

trouble code may be stored by mistake in the memory

of ABS control module during inspection.)

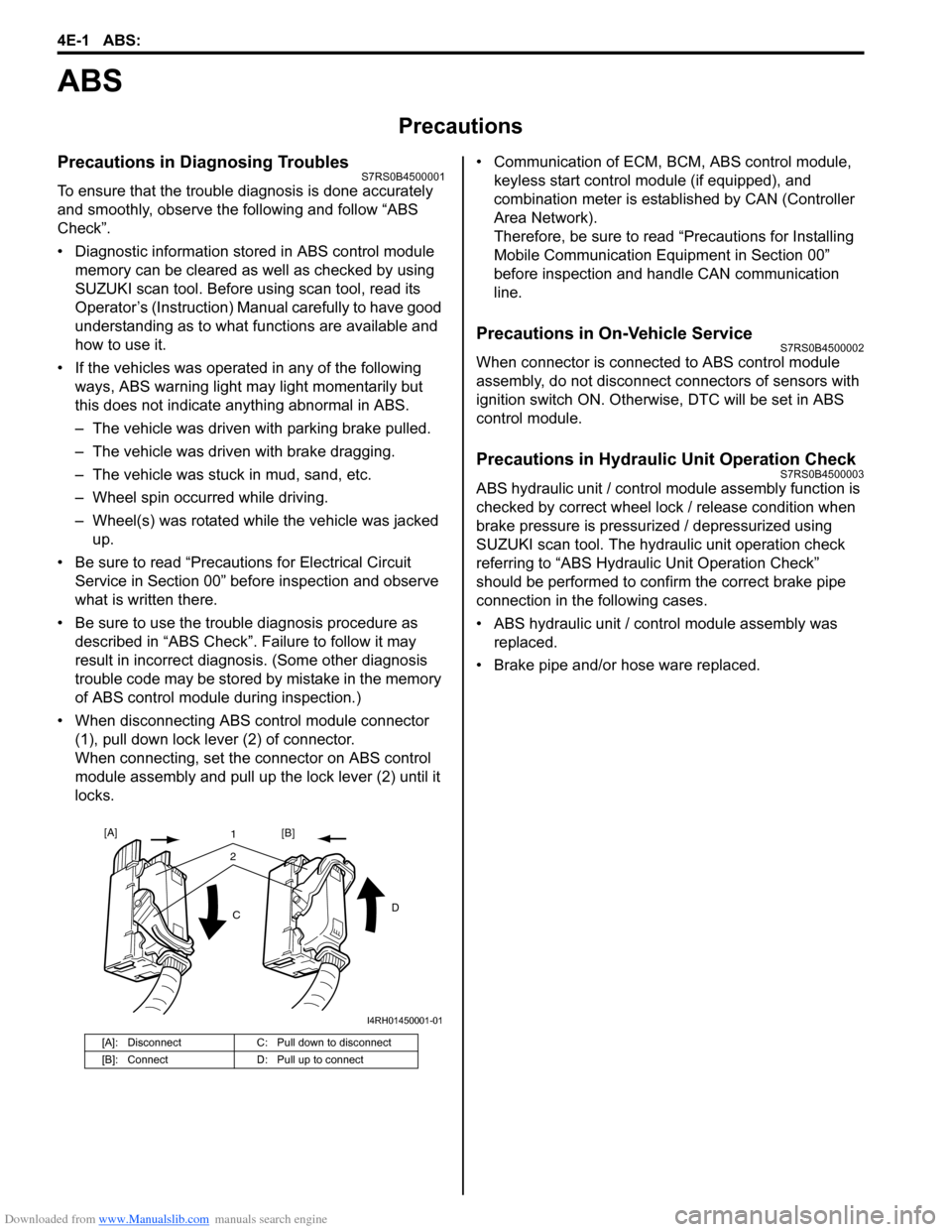

• When disconnecting ABS co ntrol module connector

(1), pull down lock lever (2) of connector.

When connecting, set the connector on ABS control

module assembly and pull up the lock lever (2) until it

locks. • Communication of ECM,

BCM, ABS control module,

keyless start control module (if equipped), and

combination meter is established by CAN (Controller

Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handle CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4500002

When connector is connected to ABS control module

assembly, do not disconnect connectors of sensors with

ignition switch ON. Otherwise, DTC will be set in ABS

control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4500003

ABS hydraulic unit / control module assembly function is

checked by correct wheel lock / release condition when

brake pressure is pressurized / depressurized using

SUZUKI scan tool. The hydraulic unit operation check

referring to “ABS Hydraulic Unit Operation Check”

should be performed to confirm the correct brake pipe

connection in the following cases.

• ABS hydraulic unit / cont rol module assembly was

replaced.

• Brake pipe and/or hose ware replaced.

[A]: Disconnect C: Pull down to disconnect

[B]: Connect D: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01

Page 549 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-10

Problem symptom confirmation

Check if what the customer claimed in “Customer

Questionnaire” is actually found in the vehicle and if that

symptom is found, whether it is identified as a failure.

(This step should be shared with the customer if

possible.) Check warning lights related to brake system

referring to “EBD Warning Light (Brake Warning Light)

Check” and “ABS Warning Light Check”.

DTC check, record and clearance

Perform “DTC Check” proced ure, record it and then

clear it referring to “DTC Clearance”.

Recheck DTC referring to “DTC Check”.

When DTC which is recorded at DTC check procedure is

detected again after performi ng DTC clearance, go to

“Step 4: ABS Check: ” to proceed the diagnosis.

When DTC which is recorded at DTC check procedure is

not indicated anymore after performing DTC clearance,

ABS control module does not perform the system

diagnosis, or temporary abnormality may occur,

therefore go to “Step 2: Driving Test: ” to proceed the

diagnosis.

Step 2: Driving Test

Test drive the vehicle at 40 km/h for more than a minute

and check if any trouble symptom (such as abnormal

lighting of ABS warn ing light) exists.

If the malfunction DTC is co nfirmed again at ignition

switch ON, driving test as described is not necessary.

Proceed to Step 3.

Step 3: DTC Check

Recheck DTC referring to “DTC Check”.

Step 4: ABS Check

According to ABS Check for the DTC confirmation in

Step 3, locate the cause of the trouble, namely in a

sensor, switch, wire harness, connector, actuator

assembly or other part and repair or replace faulty parts.

Step 5: Brakes Diagnosis

Check the parts or system suspected as a possible

cause referring to “Brakes Symptom Diagnosis in

Section 4A” and based on symptoms appearing on the

vehicle (symptom obtained through Steps 1 and 2 and

repair or replace faulty parts, if any).

Step 6: Check for Intermittent Problem

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, con nector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of trouble code recorded in Step 1

to 3.

Step 7: Final Confirmation Test

Confirm that the problem symptom has gone and the

ABS is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear

the DTC once referring to “DTC Clearance” and perform

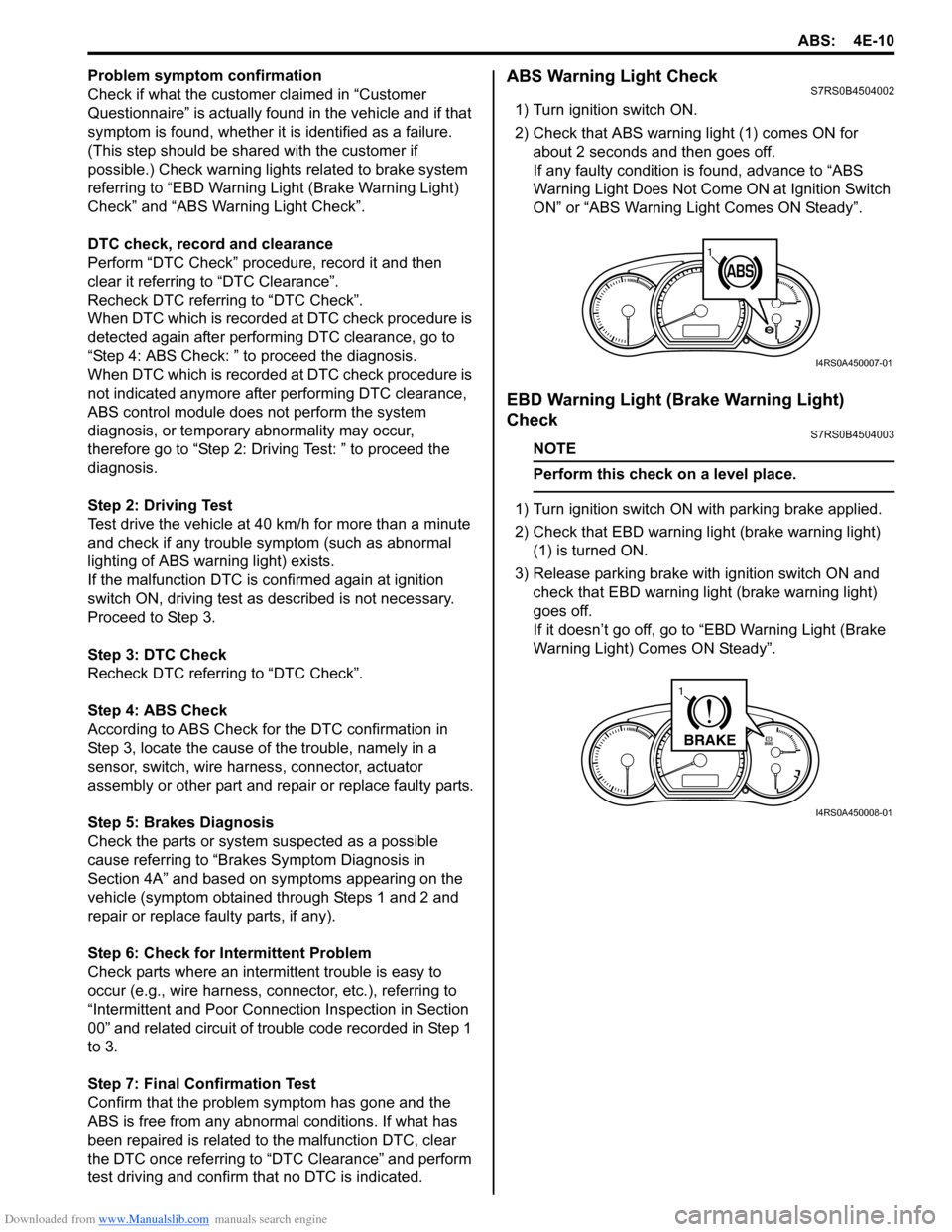

test driving and confirm that no DTC is indicated.ABS Warning Light CheckS7RS0B4504002

1) Turn ignition switch ON.

2) Check that ABS warning light (1) comes ON for

about 2 seconds and then goes off.

If any faulty condition is found, advance to “ABS

Warning Light Does Not Come ON at Ignition Switch

ON” or “ABS Warning Light Comes ON Steady”.

EBD Warning Light (Brake Warning Light)

Check

S7RS0B4504003

NOTE

Perform this check on a level place.

1) Turn ignition switch ON with parking brake applied.

2) Check that EBD warning lig ht (brake warning light)

(1) is turned ON.

3) Release parking brake with ignition switch ON and check that EBD warning lig ht (brake warning light)

goes off.

If it doesn’t go off, go to “EBD Warning Light (Brake

Warning Light) Comes ON Steady”.

11

I4RS0A450007-01

BRAKE

1

I4RS0A450008-01