Oul SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 751 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-107

Remounting1) Make sure that torque converter is installed correctly to transaxle.

Refer to “Automatic Transaxle Unit Assembly”.

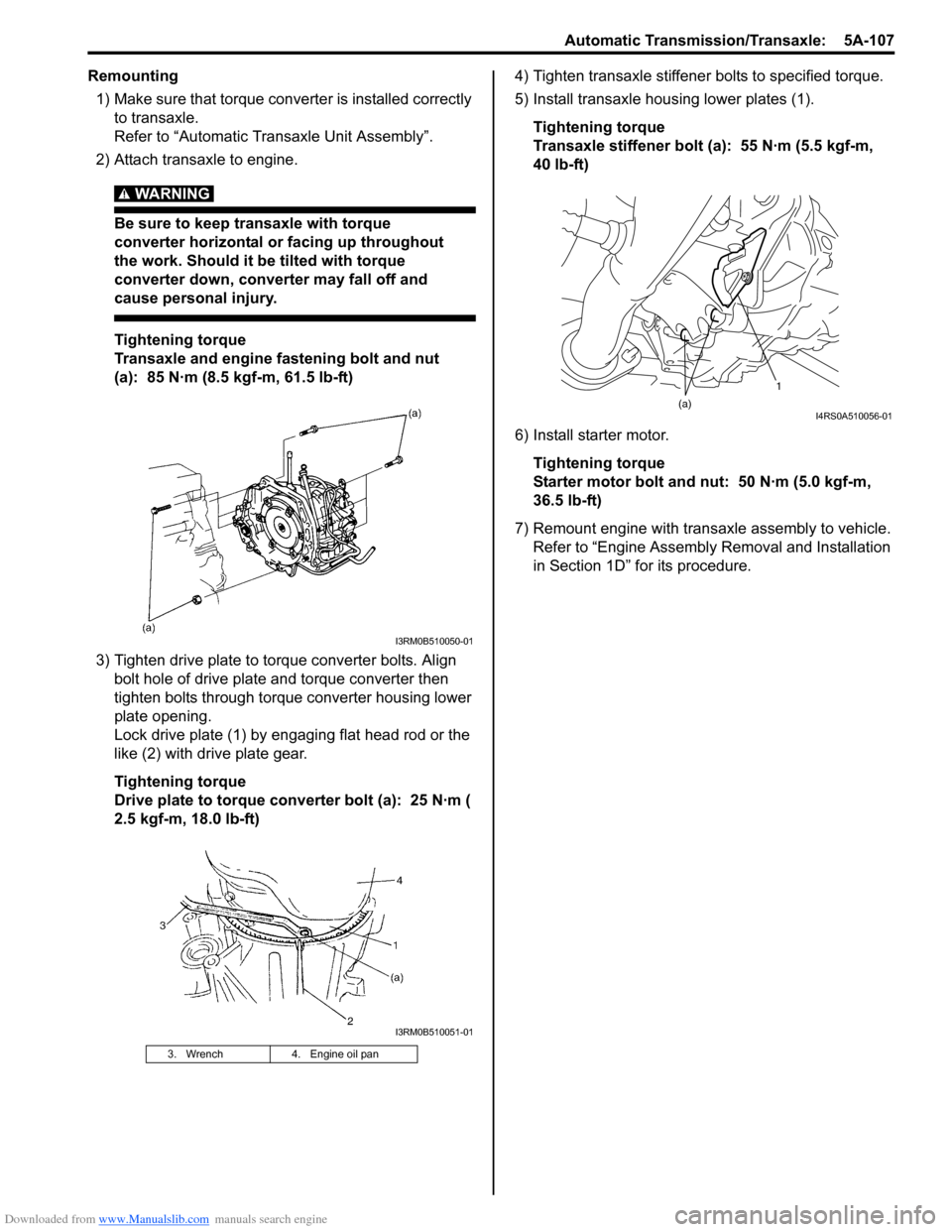

2) Attach transaxle to engine.

WARNING!

Be sure to keep transaxle with torque

converter horizontal or facing up throughout

the work. Should it be tilted with torque

converter down, converter may fall off and

cause personal injury.

Tightening torque

Transaxle and engine fastening bolt and nut

(a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

3) Tighten drive plate to torque converter bolts. Align bolt hole of drive plate and torque converter then

tighten bolts through torque converter housing lower

plate opening.

Lock drive plate (1) by engaging flat head rod or the

like (2) with drive plate gear.

Tightening torque

Drive plate to torque converter bolt (a): 25 N·m (

2.5 kgf-m, 18.0 lb-ft) 4) Tighten transaxle stiffener bolts to specified torque.

5) Install transaxle housing lower plates (1).

Tightening torque

Transaxle stiffener bolt (a): 55 N·m (5.5 kgf-m,

40 lb-ft)

6) Install starter motor. Tightening torque

Starter motor bolt and nut: 50 N·m (5.0 kgf-m,

36.5 lb-ft)

7) Remount engine with transaxle assembly to vehicle. Refer to “Engine Assembly Removal and Installation

in Section 1D” for its procedure.

3. Wrench 4. Engine oil pan

I3RM0B510050-01

I3RM0B510051-01

1

(a)

I4RS0A510056-01

Page 763 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-119

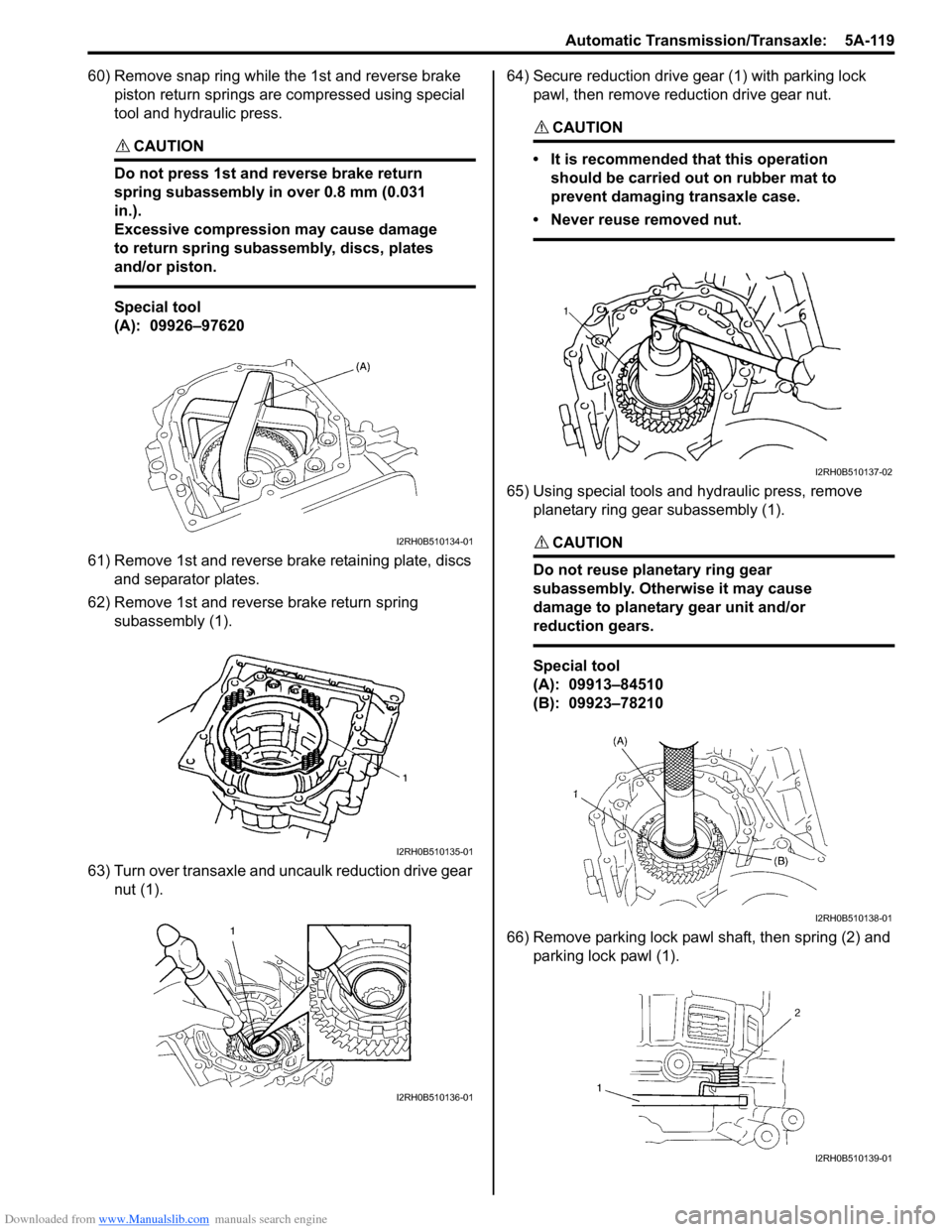

60) Remove snap ring while the 1st and reverse brake piston return springs are compressed using special

tool and hydraulic press.

CAUTION!

Do not press 1st and reverse brake return

spring subassembly in over 0.8 mm (0.031

in.).

Excessive compression may cause damage

to return spring subassembly, discs, plates

and/or piston.

Special tool

(A): 09926–97620

61) Remove 1st and reverse brake retaining plate, discs and separator plates.

62) Remove 1st and reverse brake return spring subassembly (1).

63) Turn over transaxle and uncaulk reduction drive gear nut (1). 64) Secure reduction drive gear (1) with parking lock

pawl, then remove reduction drive gear nut.

CAUTION!

• It is recommended that this operation should be carried out on rubber mat to

prevent damaging transaxle case.

• Never reuse removed nut.

65) Using special tools and hydraulic press, remove planetary ring gear subassembly (1).

CAUTION!

Do not reuse planetary ring gear

subassembly. Otherwise it may cause

damage to planetary gear unit and/or

reduction gears.

Special tool

(A): 09913–84510

(B): 09923–78210

66) Remove parking lock pawl shaft, then spring (2) and parking lock pawl (1).

I2RH0B510134-01

I2RH0B510135-01

I2RH0B510136-01

I2RH0B510137-02

I2RH0B510138-01

I2RH0B510139-01

Page 767 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-123

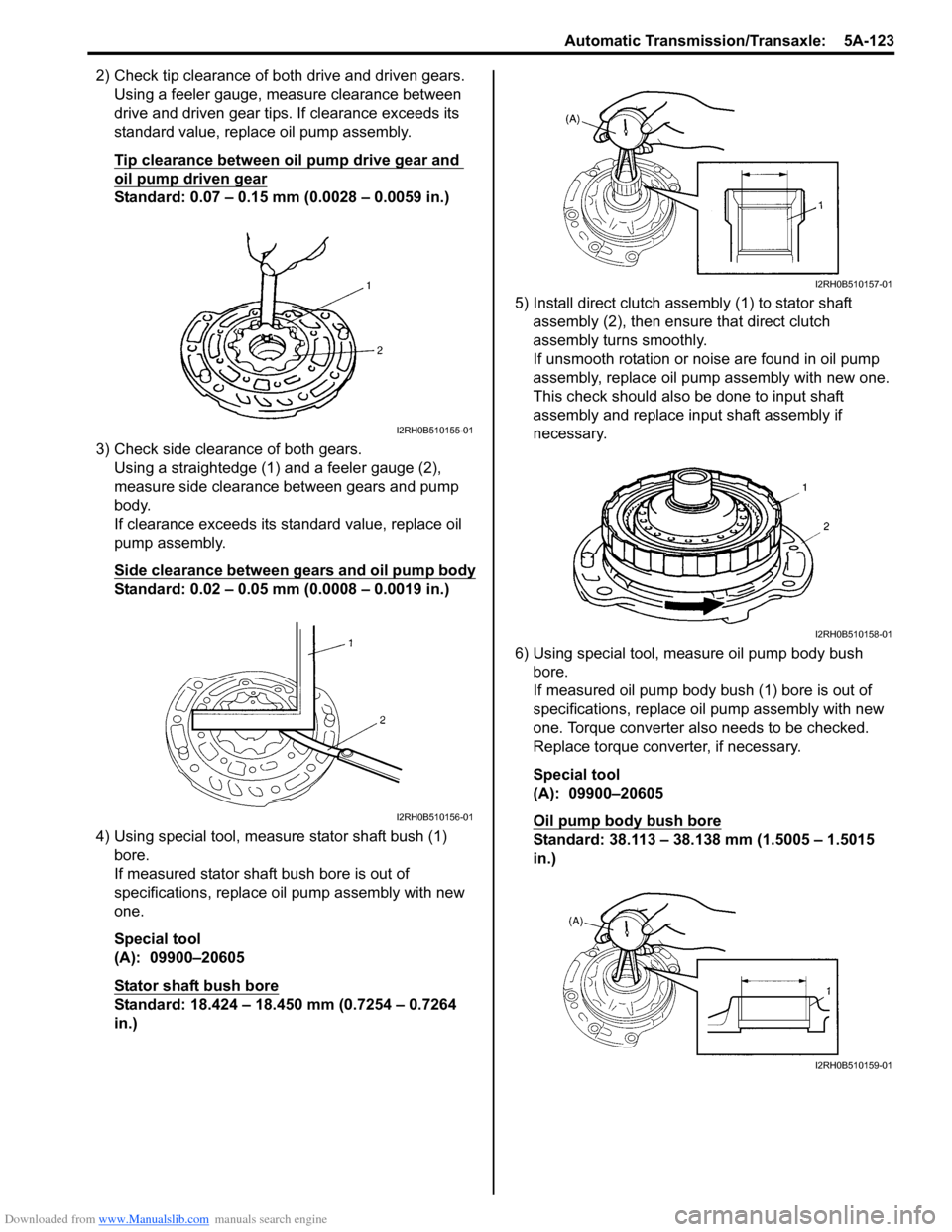

2) Check tip clearance of both drive and driven gears.Using a feeler gauge, m easure clearance between

drive and driven gear tips. If clearance exceeds its

standard value, replace oil pump assembly.

Tip clearance between oil pump drive gear and

oil pump driven gear

Standard: 0.07 – 0.15 mm (0.0028 – 0.0059 in.)

3) Check side clearance of both gears. Using a straightedge (1) and a feeler gauge (2),

measure side clearance between gears and pump

body.

If clearance exceeds its standard value, replace oil

pump assembly.

Side clearance between gears and oil pump body

Standard: 0.02 – 0.05 mm (0.0008 – 0.0019 in.)

4) Using special tool, measure stator shaft bush (1) bore.

If measured stator shaft bush bore is out of

specifications, replace oil pump assembly with new

one.

Special tool

(A): 09900–20605

Stator shaft bush bore

Standard: 18.424 – 18.450 mm (0.7254 – 0.7264

in.) 5) Install direct clutch asse

mbly (1) to stator shaft

assembly (2), then ensure that direct clutch

assembly turns smoothly.

If unsmooth rotation or noise are found in oil pump

assembly, replace oil pump assembly with new one.

This check should also be done to input shaft

assembly and replace input shaft assembly if

necessary.

6) Using special tool, measure oil pump body bush bore.

If measured oil pump body bush (1) bore is out of

specifications, replace o il pump assembly with new

one. Torque converter also needs to be checked.

Replace torque converter, if necessary.

Special tool

(A): 09900–20605

Oil pump body bush bore

Standard: 38.113 – 38.138 mm (1.5005 – 1.5015

in.)

I2RH0B510155-01

I2RH0B510156-01

I2RH0B510157-01

I2RH0B510158-01

I2RH0B510159-01

Page 770 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-126 Automatic Transmission/Transaxle:

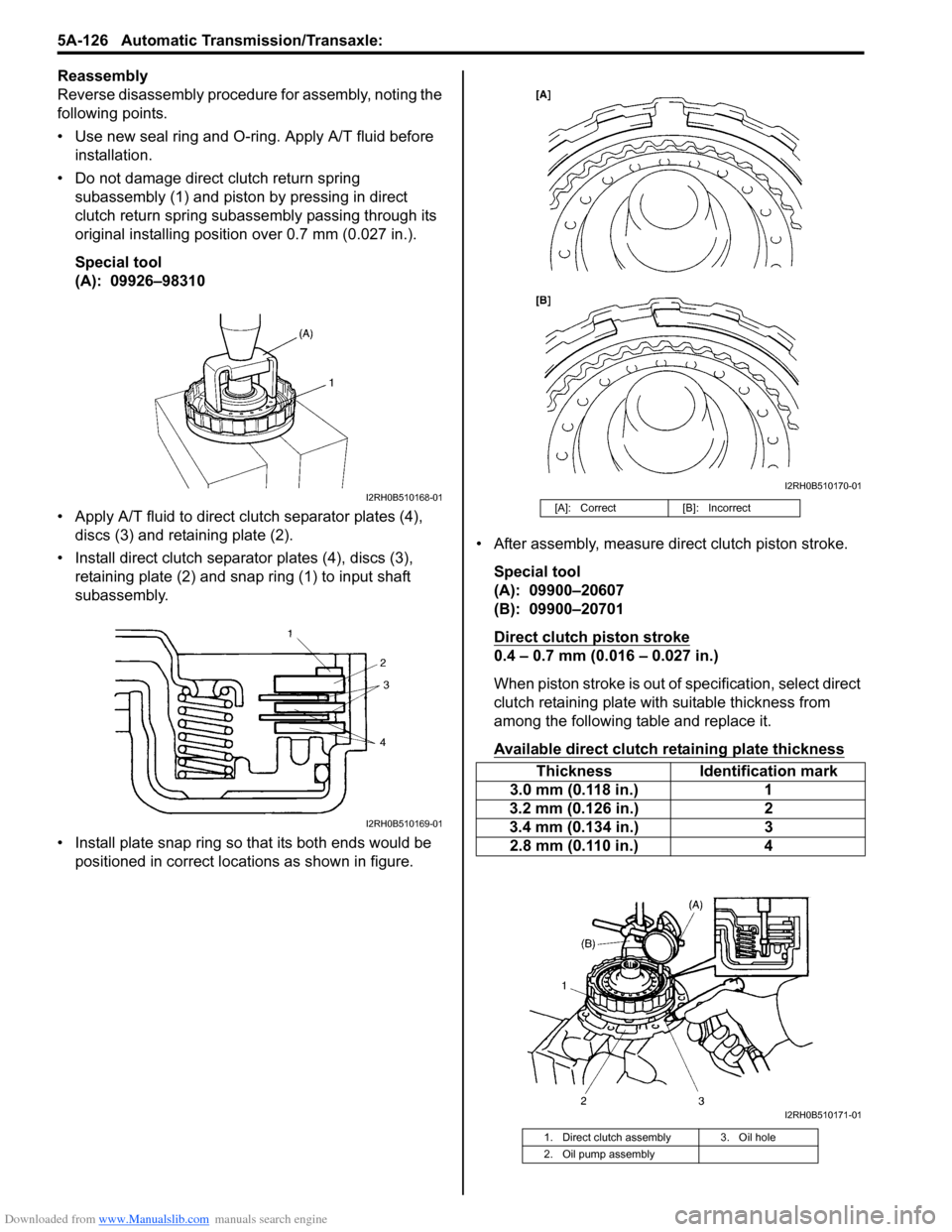

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Use new seal ring and O-ring. Apply A/T fluid before installation.

• Do not damage direct clutch return spring subassembly (1) and piston by pressing in direct

clutch return spring subassembly passing through its

original installing position over 0.7 mm (0.027 in.).

Special tool

(A): 09926–98310

• Apply A/T fluid to direct cl utch separator plates (4),

discs (3) and retaining plate (2).

• Install direct clutch separator plates (4), discs (3), retaining plate (2) and snap ring (1) to input shaft

subassembly.

• Install plate snap ring so that its both ends would be positioned in correct locations as shown in figure. • After assembly, measure direct clutch piston stroke.

Special tool

(A): 09900–20607

(B): 09900–20701

Direct clutch piston stroke

0.4 – 0.7 mm (0.016 – 0.027 in.)

When piston stroke is out of specification, select direct

clutch retaining plate with suitable thickness from

among the following table and replace it.

Available direct clutch retaining plate thickness

I2RH0B510168-01

I2RH0B510169-01

[A]: Correct [B]: Incorrect

ThicknessIdentification mark

3.0 mm (0.118 in.) 1

3.2 mm (0.126 in.) 2

3.4 mm (0.134 in.) 3

2.8 mm (0.110 in.) 4

1. Direct clutch assembly 3. Oil hole

2. Oil pump assembly

I2RH0B510170-01

I2RH0B510171-01

Page 775 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-131

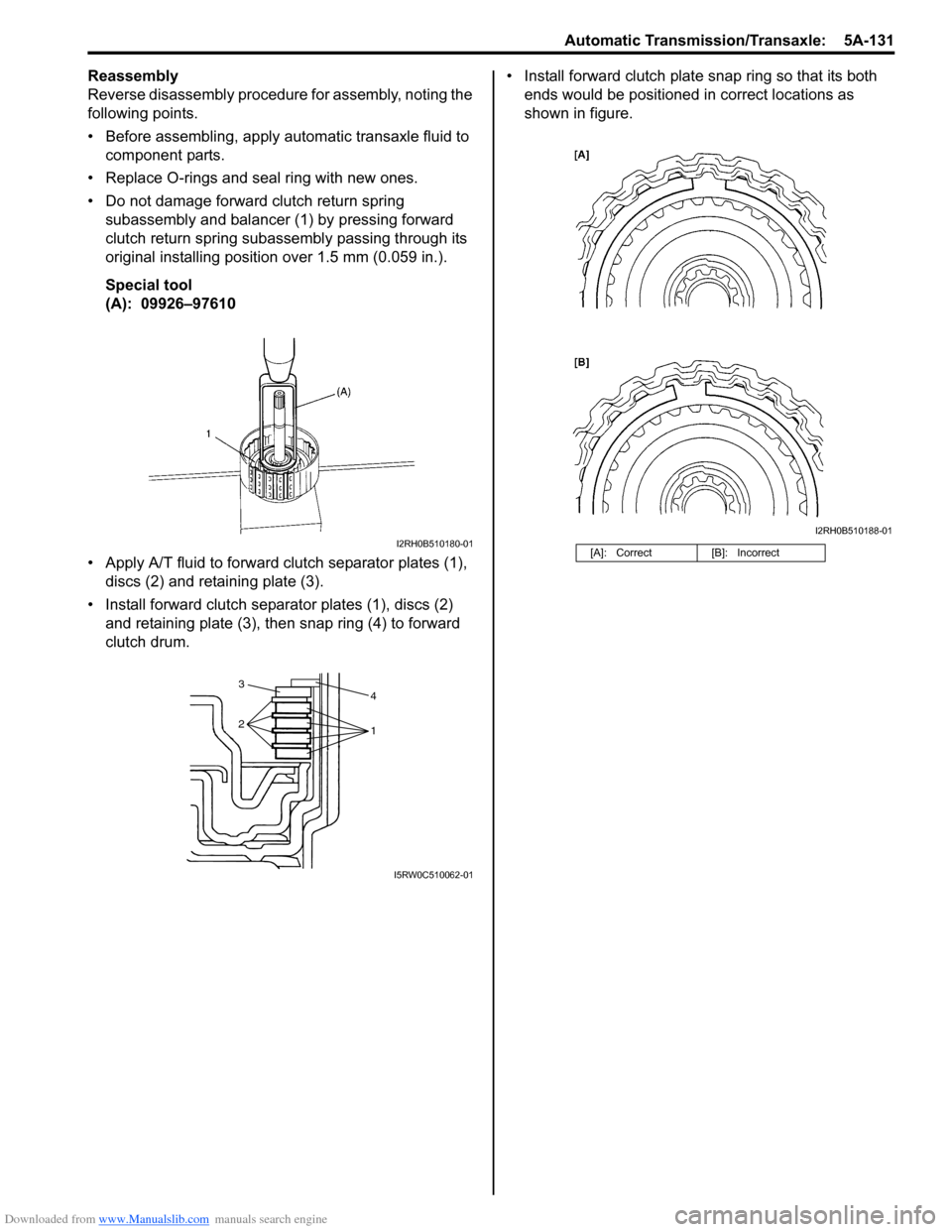

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Before assembling, apply automatic transaxle fluid to component parts.

• Replace O-rings and seal ring with new ones.

• Do not damage forward clutch return spring subassembly and balancer (1) by pressing forward

clutch return spring subassembly passing through its

original installing position over 1.5 mm (0.059 in.).

Special tool

(A): 09926–97610

• Apply A/T fluid to forward clutch separator plates (1), discs (2) and retaining plate (3).

• Install forward clutch separator plates (1), discs (2) and retaining plate (3), then snap ring (4) to forward

clutch drum. • Install forward clutch plate snap ring so that its both

ends would be positioned in correct locations as

shown in figure.

I2RH0B510180-01

4

1

2 3

I5RW0C510062-01

[A]: Correct

[B]: Incorrect

I2RH0B510188-01

Page 776 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-132 Automatic Transmission/Transaxle:

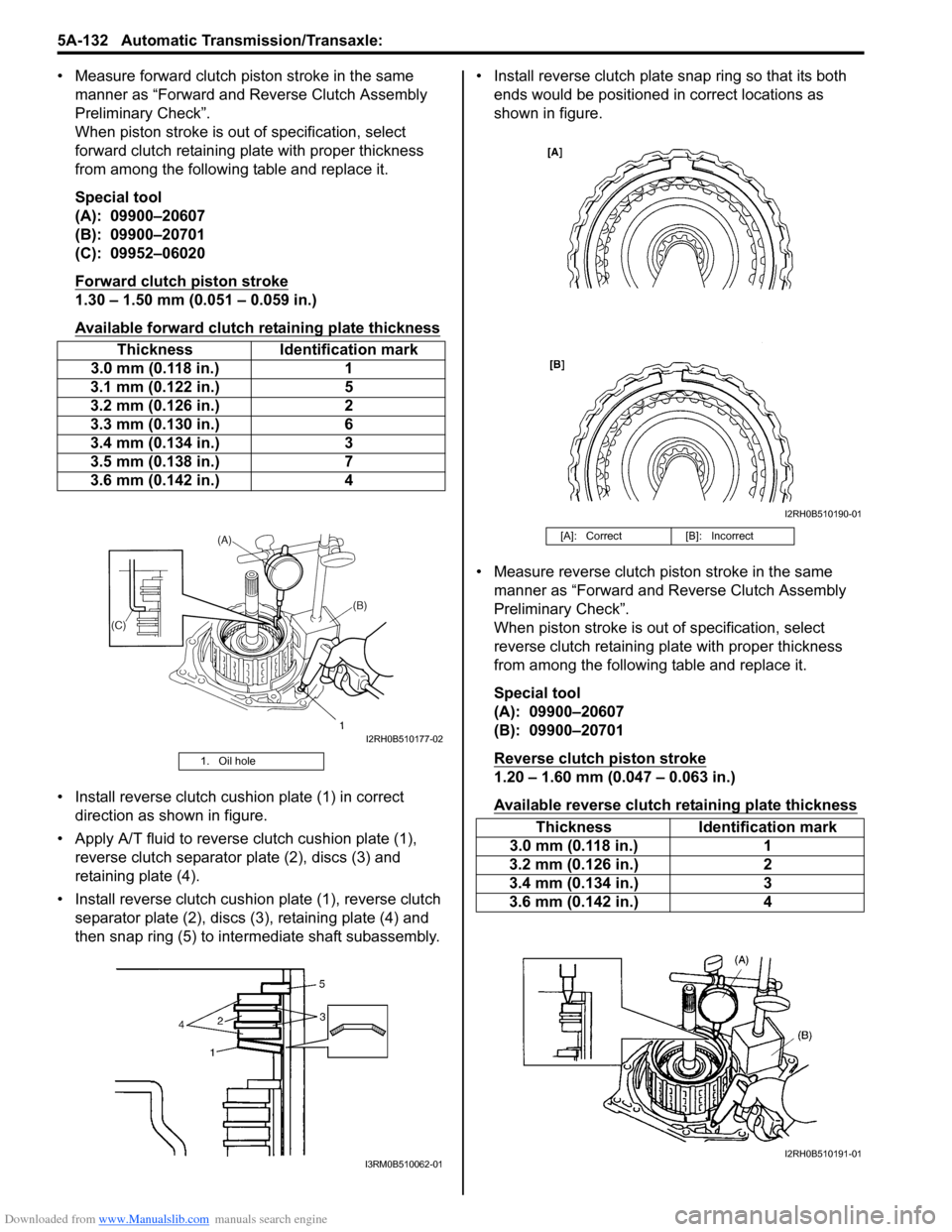

• Measure forward clutch piston stroke in the same manner as “Forward and Reverse Clutch Assembly

Preliminary Check”.

When piston stroke is out of specification, select

forward clutch retaining plate with proper thickness

from among the following table and replace it.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06020

Forward clutch piston stroke

1.30 – 1.50 mm (0.051 – 0.059 in.)

Available forward clutch retaining plate thickness

• Install reverse clutch cushion plate (1) in correct direction as shown in figure.

• Apply A/T fluid to reverse clutch cushion plate (1),

reverse clutch separator plate (2), discs (3) and

retaining plate (4).

• Install reverse clutch cushio n plate (1), reverse clutch

separator plate (2), discs (3), retaining plate (4) and

then snap ring (5) to inte rmediate shaft subassembly. • Install reverse clutch plate snap ring so that its both

ends would be positioned in correct locations as

shown in figure.

• Measure reverse clutch piston stroke in the same manner as “Forward and Reverse Clutch Assembly

Preliminary Check”.

When piston stroke is out of specification, select

reverse clutch retaining plate with proper thickness

from among the following table and replace it.

Special tool

(A): 09900–20607

(B): 09900–20701

Reverse clutch piston stroke

1.20 – 1.60 mm (0.047 – 0.063 in.)

Available reverse clutch retaining plate thickness

Thickness Identification mark

3.0 mm (0.118 in.) 1

3.1 mm (0.122 in.) 5

3.2 mm (0.126 in.) 2

3.3 mm (0.130 in.) 6

3.4 mm (0.134 in.) 3

3.5 mm (0.138 in.) 7

3.6 mm (0.142 in.) 4

1. Oil hole

I2RH0B510177-02

I3RM0B510062-01

[A]: Correct[B]: Incorrect

ThicknessIdentification mark

3.0 mm (0.118 in.) 1

3.2 mm (0.126 in.) 2

3.4 mm (0.134 in.) 3

3.6 mm (0.142 in.) 4

I2RH0B510190-01

I2RH0B510191-01

Page 791 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-147

3) Install new differential side oil seal to transaxle case by using special tools.

Special tool

(A): 09924–74510

(B): 09944–88220

Differential side oil seal installing depth

“a”: 3.8 – 4.8 mm (0.15 – 0.19 in.)

4) Apply grease to oil seal lip. : Grease 99000–25030 (SUZUKI Super Grease C)

Automatic Transaxle Unit Inspection and

Adjustment

S7RS0B5106059

Inspection

Brake discs

Dry and inspect them for pitting, burn flaking, significant

wear, glazing, cracking, charring and chips or metal

particles imbedded in lining.

If discs show any of the ab ove conditions, replacement

is required.

NOTE

• If disc lining is exfoliated or discolored, replace all discs.

• Before assembling new discs, soak them in A/T fluid for at least two hours.

Brake separator plates and retaining plates

Dry plates and check for discol oration. If plate surface is

smooth and even color smear is indicated, plate should

be reused. If severe heat spot discoloration or surface

scuffing is indicated, plate must be replaced.

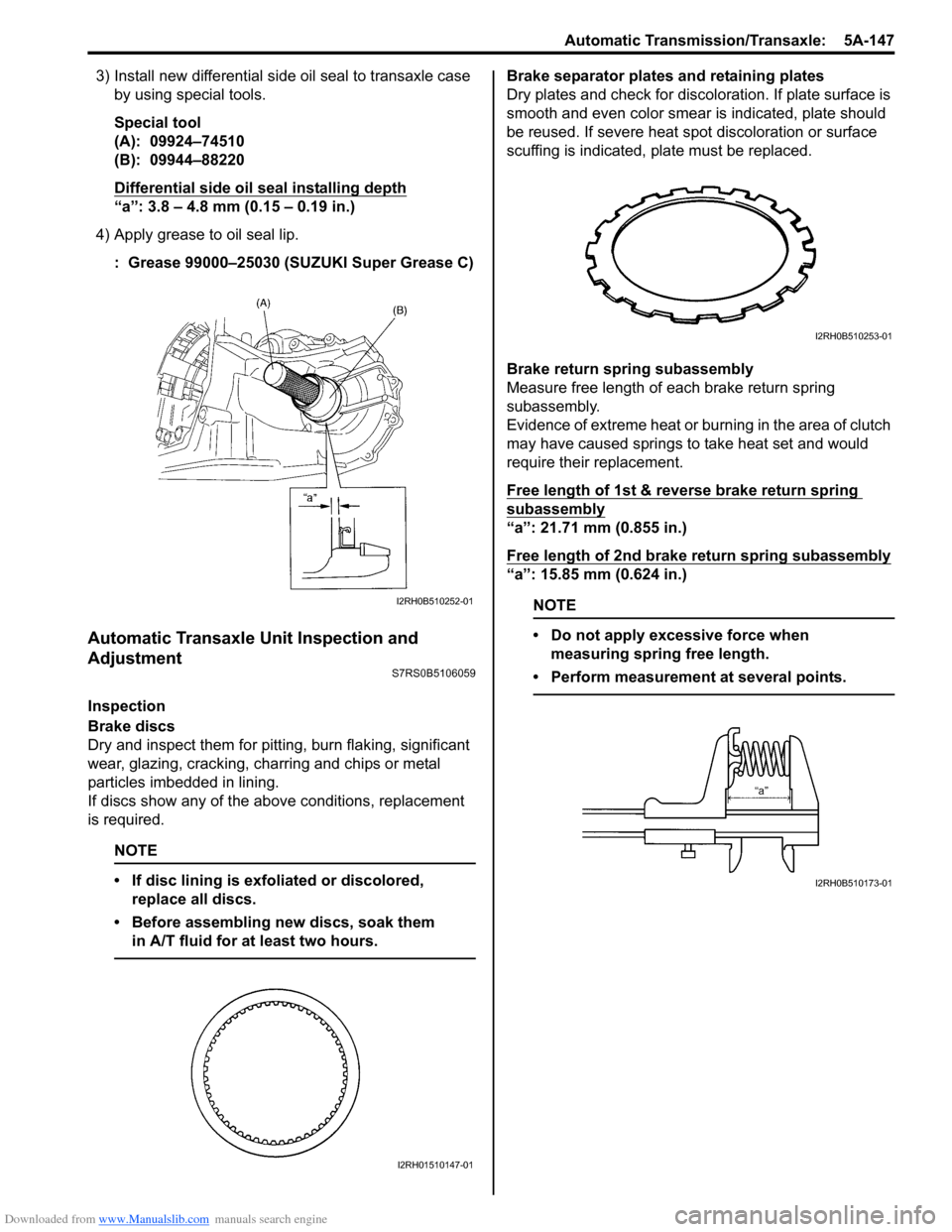

Brake return spring subassembly

Measure free length of each brake return spring

subassembly.

Evidence of extreme heat or burning in the area of clutch

may have caused springs to take heat set and would

require their replacement.

Free length of 1st & reverse brake return spring

subassembly

“a”: 21.71 mm (0.855 in.)

Free length of 2nd brake return spring subassembly

“a”: 15.85 mm (0.624 in.)

NOTE

• Do not apply excessive force when measuring spring free length.

• Perform measurement at several points.

I2RH0B510252-01

I2RH01510147-01

I2RH0B510253-01

I2RH0B510173-01

Page 796 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-152 Automatic Transmission/Transaxle:

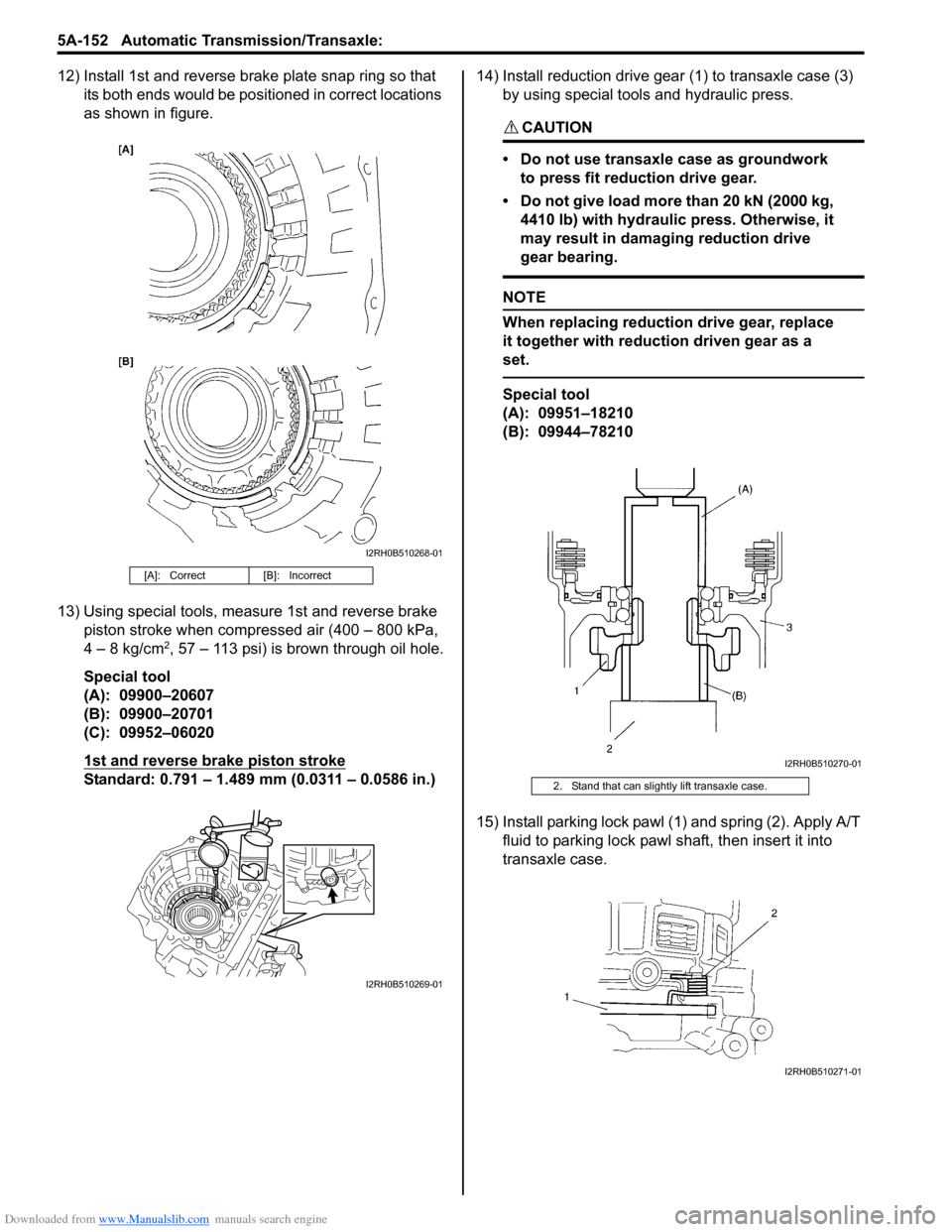

12) Install 1st and reverse brake plate snap ring so that its both ends would be positioned in correct locations

as shown in figure.

13) Using special tools, meas ure 1st and reverse brake

piston stroke when compressed air (400 – 800 kPa,

4 – 8 kg/cm

2, 57 – 113 psi) is brown through oil hole.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06020

1st and reverse brake piston stroke

Standard: 0.791 – 1.489 mm (0.0311 – 0.0586 in.) 14) Install reduction drive gear (1) to transaxle case (3)

by using special tools and hydraulic press.

CAUTION!

• Do not use transaxle case as groundwork to press fit reduction drive gear.

• Do not give load more than 20 kN (2000 kg, 4410 lb) with hydraulic press. Otherwise, it

may result in damaging reduction drive

gear bearing.

NOTE

When replacing reduction drive gear, replace

it together with reduction driven gear as a

set.

Special tool

(A): 09951–18210

(B): 09944–78210

15) Install parking lock pawl (1) and spring (2). Apply A/T fluid to parking lock pawl sh aft, then insert it into

transaxle case.

[A]: Correct [B]: Incorrect

I2RH0B510268-01

I2RH0B510269-01

2. Stand that can slightly lift transaxle case.

I2RH0B510270-01

I2RH0B510271-01

Page 797 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-153

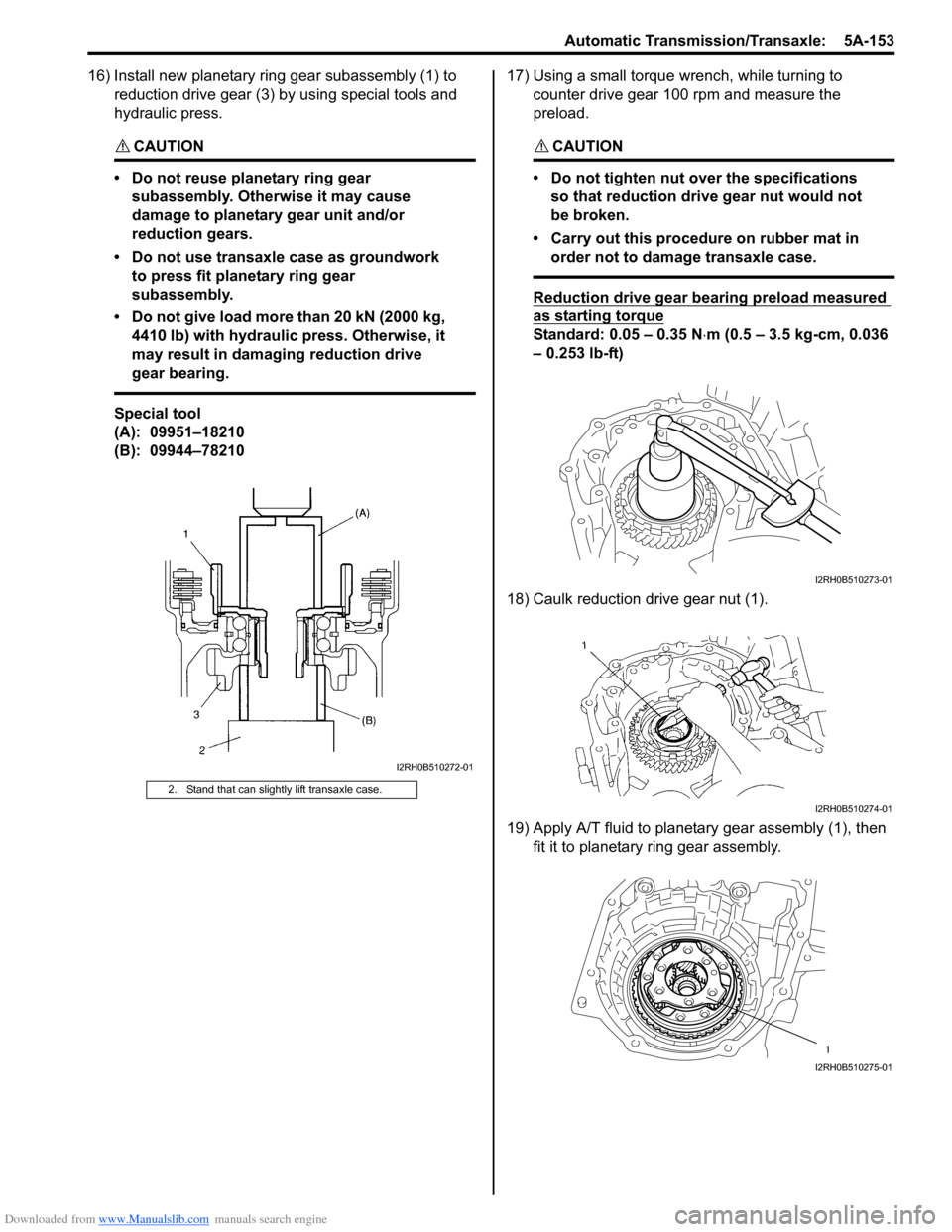

16) Install new planetary ring gear subassembly (1) to reduction drive gear (3) by using special tools and

hydraulic press.

CAUTION!

• Do not reuse planetary ring gear subassembly. Otherwise it may cause

damage to planetary gear unit and/or

reduction gears.

• Do not use transaxle case as groundwork to press fit planetary ring gear

subassembly.

• Do not give load more than 20 kN (2000 kg, 4410 lb) with hydraulic press. Otherwise, it

may result in damaging reduction drive

gear bearing.

Special tool

(A): 09951–18210

(B): 09944–78210 17) Using a small torque

wrench, while turning to

counter drive gear 100 rpm and measure the

preload.

CAUTION!

• Do not tighten nut over the specifications so that reduction drive gear nut would not

be broken.

• Carry out this procedure on rubber mat in order not to damage transaxle case.

Reduction drive gear bearing preload measured

as starting torque

Standard: 0.05 – 0.35 N ⋅m (0.5 – 3.5 kg-cm, 0.036

– 0.253 lb-ft)

18) Caulk reduction drive gear nut (1).

19) Apply A/T fluid to planetary gear assembly (1), then fit it to planetary ring gear assembly.

2. Stand that can slightly lift transaxle case.

I2RH0B510272-01

I2RH0B510273-01

I2RH0B510274-01

1

I2RH0B510275-01

Page 810 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-166 Automatic Transmission/Transaxle:

91) Bend dents of lock washer (1) in order to prevent displacement of lock washer.

92) Install manual select lever (1). Tightening torque

Manual select lever nut (a): 13 N·m (1.3 kgf-m,

9.5 lb-ft)

93) Install engine mounting LH bracket (1). Tightening torque

Engine mounting LH bracket bolt (a): 55 N·m (

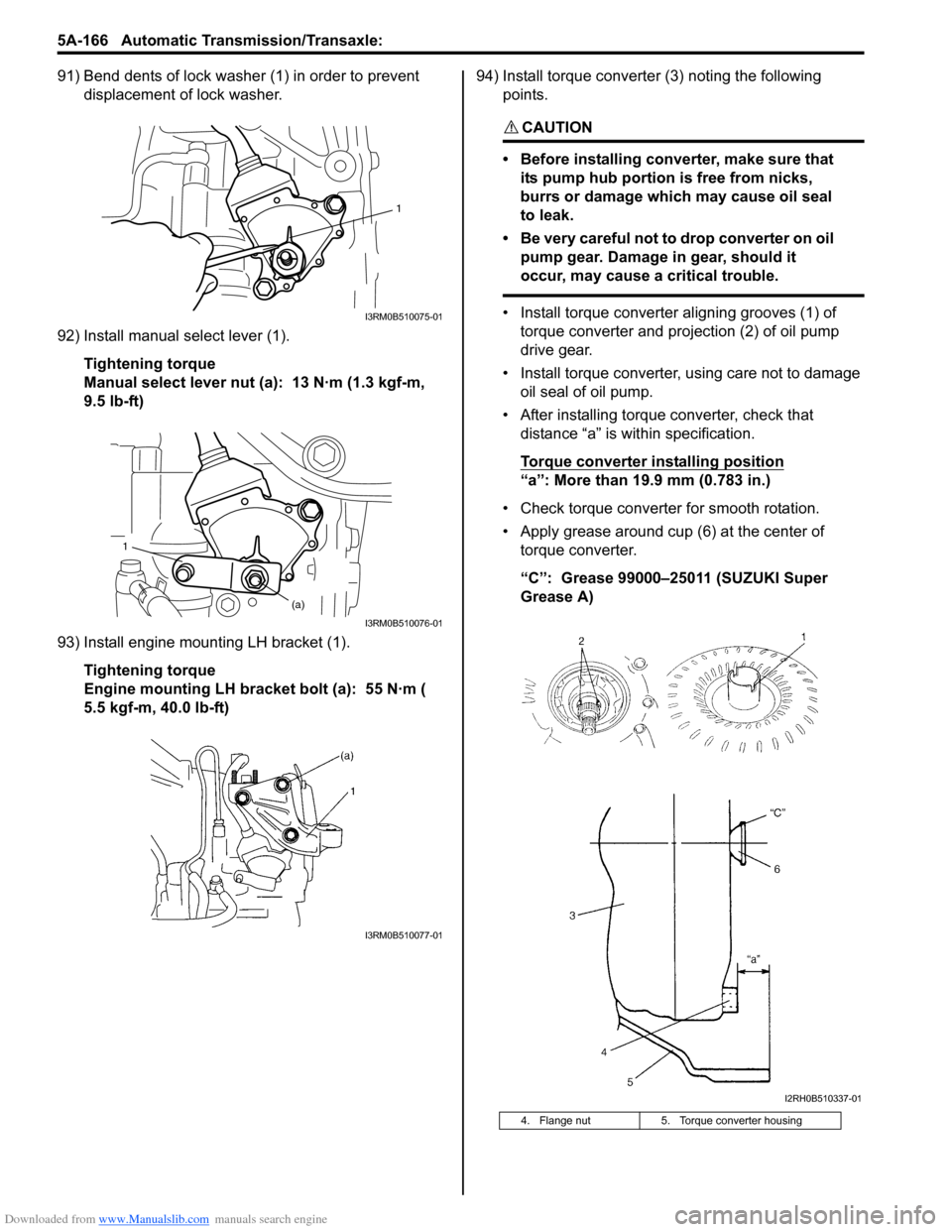

5.5 kgf-m, 40.0 lb-ft) 94) Install torque converter (3) noting the following

points.

CAUTION!

• Before installing converter, make sure that its pump hub portion is free from nicks,

burrs or damage which may cause oil seal

to leak.

• Be very careful not to drop converter on oil pump gear. Damage in gear, should it

occur, may cause a critical trouble.

• Install torque converter aligning grooves (1) of torque converter and projection (2) of oil pump

drive gear.

• Install torque converter, using care not to damage oil seal of oil pump.

• After installing torque converter, check that distance “a” is within specification.

Torque converter installing position

“a”: More than 19.9 mm (0.783 in.)

• Check torque converter for smooth rotation.

• Apply grease around cup (6) at the center of torque converter.

“C”: Grease 99000–25011 (SUZUKI Super

Grease A)

1

I3RM0B510075-01

1

(a)

I3RM0B510076-01

I3RM0B510077-01

4. Flange nut 5. Torque converter housing

I2RH0B510337-01