starting system SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 1217 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-46

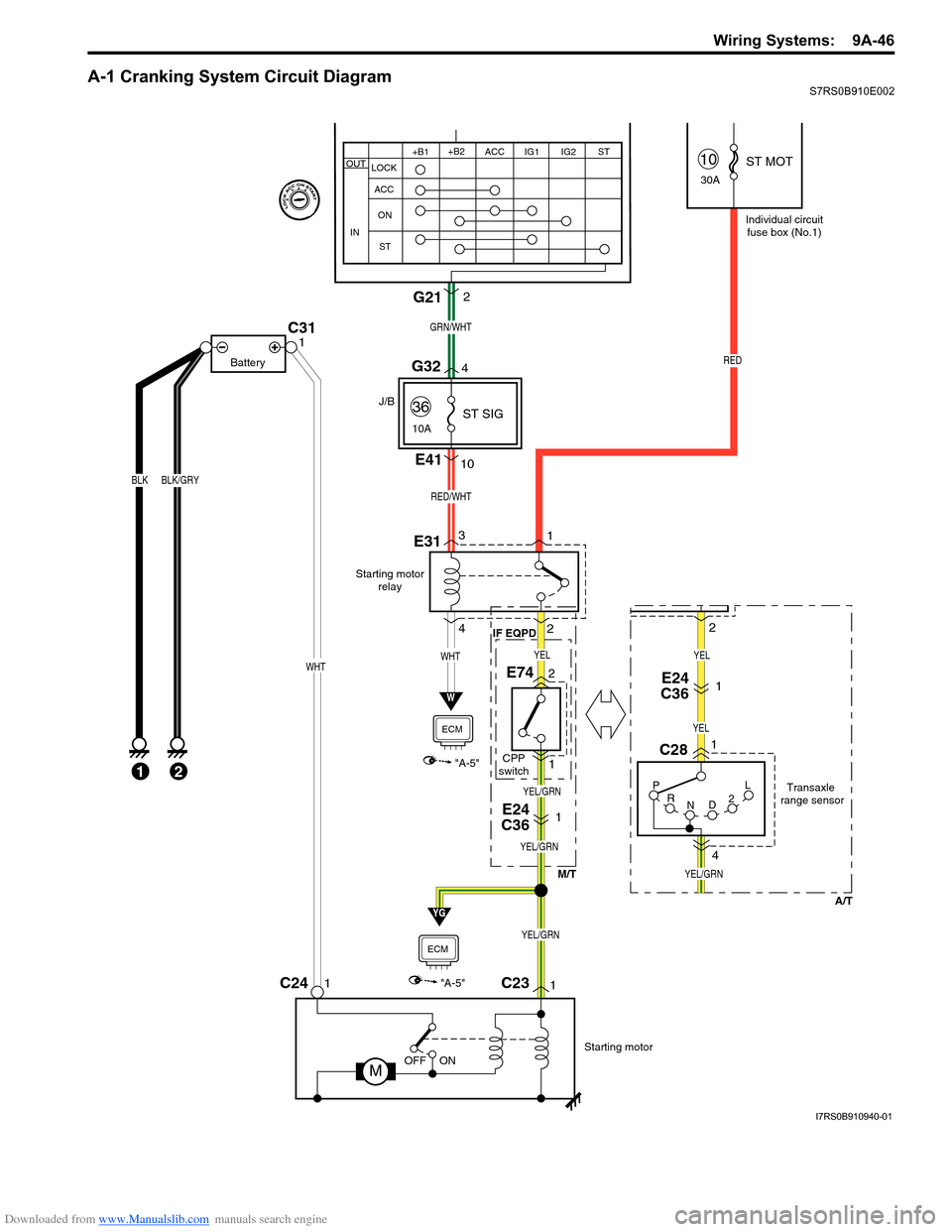

A-1 Cranking System Circuit DiagramS7RS0B910E002

Starting motorrelay

W

"A-5"

ECM

P

R N D2LTransaxle

range sensor

C28

E741

4

E31

C231C241

Starting motor

MOFF ON

BLK

1

BLK/GRY

C311

Battery

E24

C361

RED

Individual circuit

fuse box (No.1)

10

30A

36

10A

WHTWHT

M/T

IF EQPD

E24

C361

J/B

A/T

E4110

13

2

4

RED/WHT

2 ST MOT

ST SIG

YEL/GRN

YG

"A-5"

ECM

GRN/WHT

G212

YEL/GRN

YEL/GRN

YEL

YEL/GRN

YEL

YEL

G324

+B1

LOCK

ACC

ON

ST ACC IG1 IG2

STOUT

IN

+B2

21CPP

switch

2

I7RS0B910940-01

Page 1224 of 1496

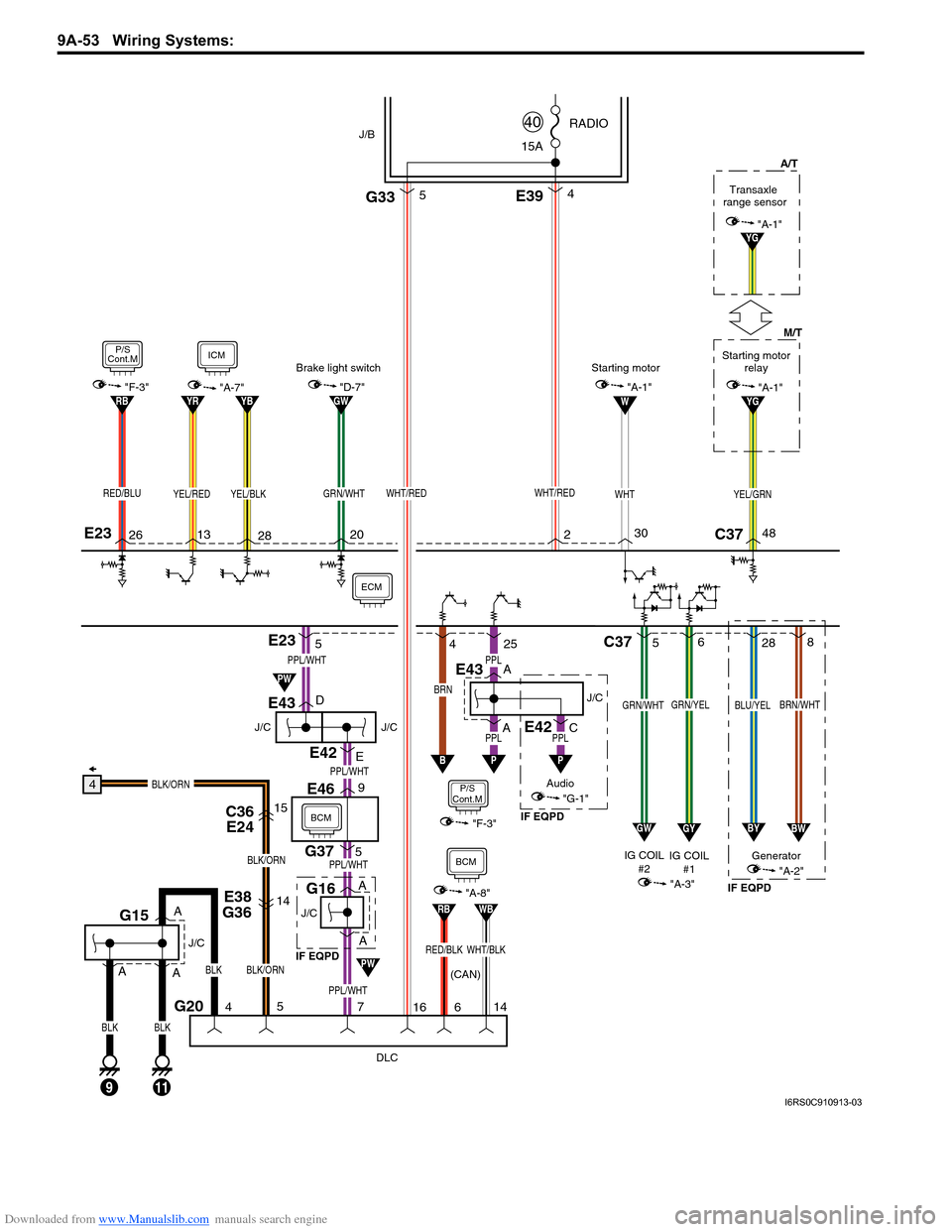

Downloaded from www.Manualslib.com manuals search engine 9A-53 Wiring Systems:

J/C

E43

J/C

G16

DLC

G20

G375

E469

E38

G3614

C36 E2415

BLK/ORN

BLK/ORN

BLK/ORN

4

BLK

11

J/C

G15

5

4

516

WHT/RED

C37

GRN/YELGRN/WHT

5 6

YG

BRN

B

P/S

Cont.M

4

"F-3"

25

A

A D

E

AA

PPL/WHT

PPL/WHT

PPL/WHT

PPL/WHT

YEL/GRNWHT/RED

BLK

9

A

PPL

E42

PPLJ/C

ECM

E394

J/B15A RADIO

40

E23

E23

YEL/BLKYEL/REDRED/BLU

13

282620

BLK

2C37

M/T

A/T

48

W

WHT

30

GYGW

BRN/WHTBLU/YEL

28

8

BWBY

IG COIL

#1 Generator

IG COIL

#2

(CAN) "A-3""A-2"

Audio

"G-1"

GRN/WHT

P

7

BCM

Starting motor relay

"A-1"

Transaxle

range sensor

YG"A-1"

ICM

"A-7"

P/S

Cont.M

"F-3"YBYRRBGW"D-7"

Brake light switch

"A-1"Starting motor

PW

PW

G335

WHT/BLKRED/BLK

RBWB

"A-8"

14

6

BCM

A

J/C

E43

APPL

P

E42C

IF EQPD IF EQPD

IF EQPD

I6RS0C910913-03

Page 1313 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-18

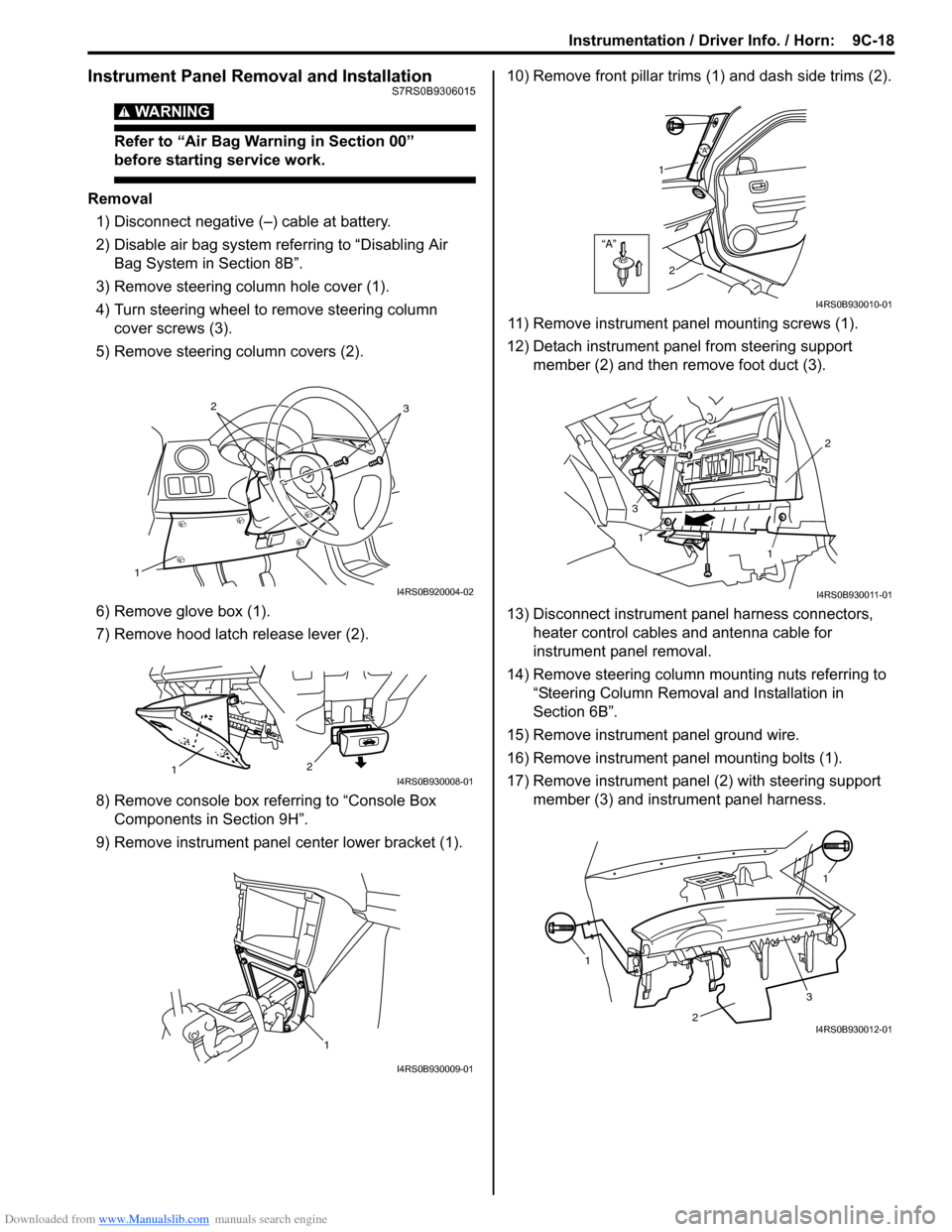

Instrument Panel Removal and InstallationS7RS0B9306015

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column hole cover (1).

4) Turn steering wheel to remove steering column cover screws (3).

5) Remove steering column covers (2).

6) Remove glove box (1).

7) Remove hood latch release lever (2).

8) Remove console box referring to “Console Box Components in Section 9H”.

9) Remove instrument panel center lower bracket (1). 10) Remove front pillar trims

(1) and dash side trims (2).

11) Remove instrument panel mounting screws (1).

12) Detach instrument panel from steering support member (2) and then remove foot duct (3).

13) Disconnect instrument panel harness connectors, heater control cables and antenna cable for

instrument panel removal.

14) Remove steering column mounting nuts referring to “Steering Column Remova l and Installation in

Section 6B”.

15) Remove instrument panel ground wire.

16) Remove instrument panel mounting bolts (1).

17) Remove instrument panel (2) with steering support member (3) and instrument panel harness.

1

32

I4RS0B920004-02

2

1I4RS0B930008-01

1

I4RS0B930009-01

“A”

“A”

1

2

I4RS0B930010-01

1

1 2

3

I4RS0B930011-01

1 1

2

3I4RS0B930012-01

Page 1364 of 1496

Downloaded from www.Manualslib.com manuals search engine 9G-2 Seats:

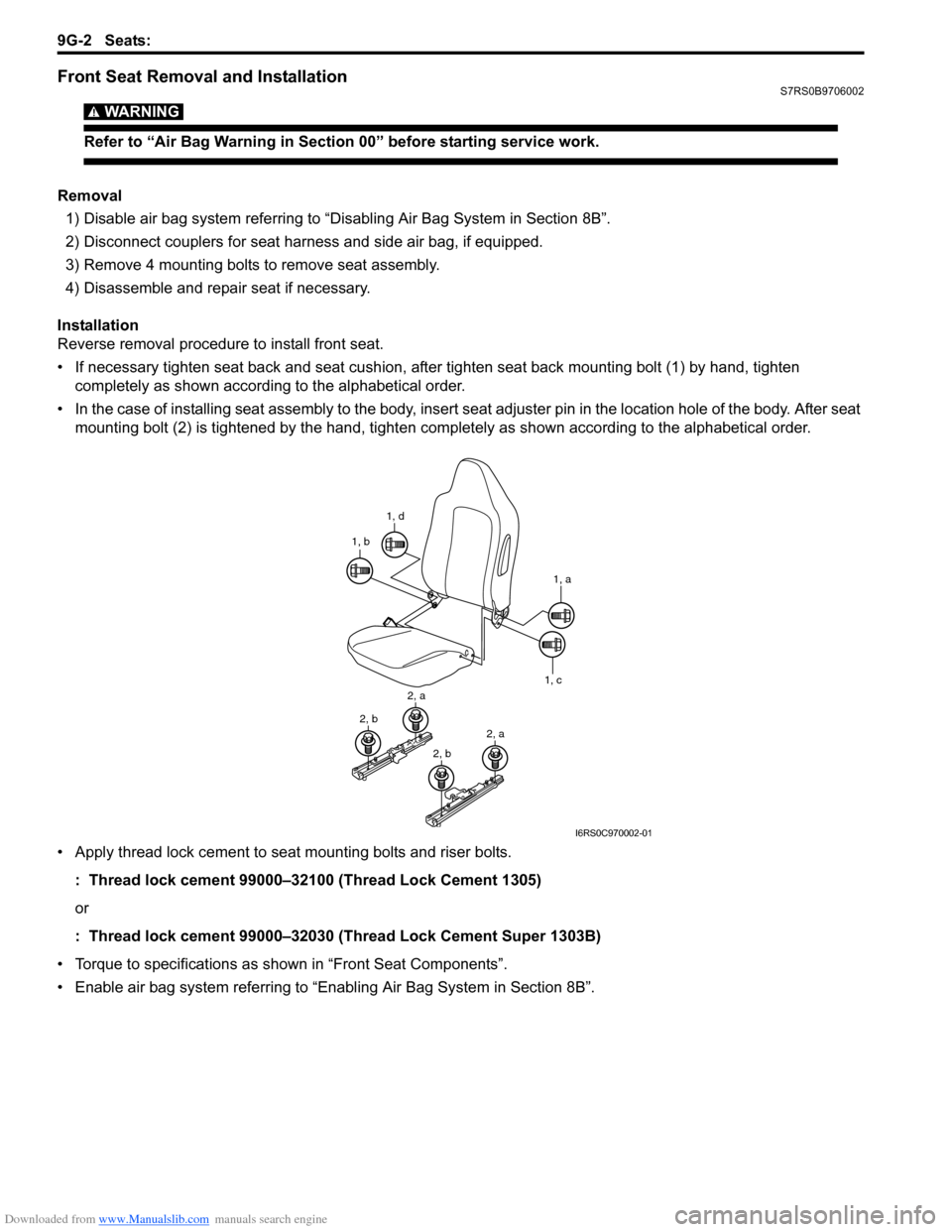

Front Seat Removal and InstallationS7RS0B9706002

WARNING!

Refer to “Air Bag Warning in Section 00” before starting service work.

Removal1) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

2) Disconnect couplers for seat harness and side air bag, if equipped.

3) Remove 4 mounting bolts to remove seat assembly.

4) Disassemble and repair seat if necessary.

Installation

Reverse removal procedure to install front seat.

• If necessary tighten seat back and seat cushion, after tighten seat back mounting bolt (1) by hand, tighten completely as shown according to the alphabetical order.

• In the case of installing seat assembly to the body, insert se at adjuster pin in the location hole of the body. After seat

mounting bolt (2) is tightened by t he hand, tighten completely as shown according to the alphabetical order.

• Apply thread lock cement to seat mounting bolts and riser bolts. : Thread lock cement 99000–32100 (Thread Lock Cement 1305)

or

: Thread lock cement 99000–32030 (Thread Lock Cement Super 1303B)

• Torque to specifications as shown in “Front Seat Components”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

1, d

1, b

1, a

1, c

2, a

2, b2, a

2, b

I6RS0C970002-01

Page 1444 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-1 Immobilizer Control System:

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing TroublesS7RS0BA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

• Communication of ECM, BCM, keyless start control module (if equipped), ABS / ESP ® control module,

steering angle sensor (ESP ® model), combination

meter and TCM (A/T model) is established by CAN

(Controller Area Network). Therefore, handle CAN

communication lines with care referring to “Precaution

for CAN Communication System in Section 00”. For

CAN communication system, refer to description on

“CAN Communication System Description in Section

1A”.

Precaution in Replacing ECMS7RS0BA300002

• If ECM is replaced with new or used one without immobilizer control function , the engine will not be

started. In case of the above, check if the newly

installed ECM has immobilizer control function.

• After ECM is replaced with new one or used one, the transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

Precautions in Handling Immobilizer Control

System

S7RS0BA300003

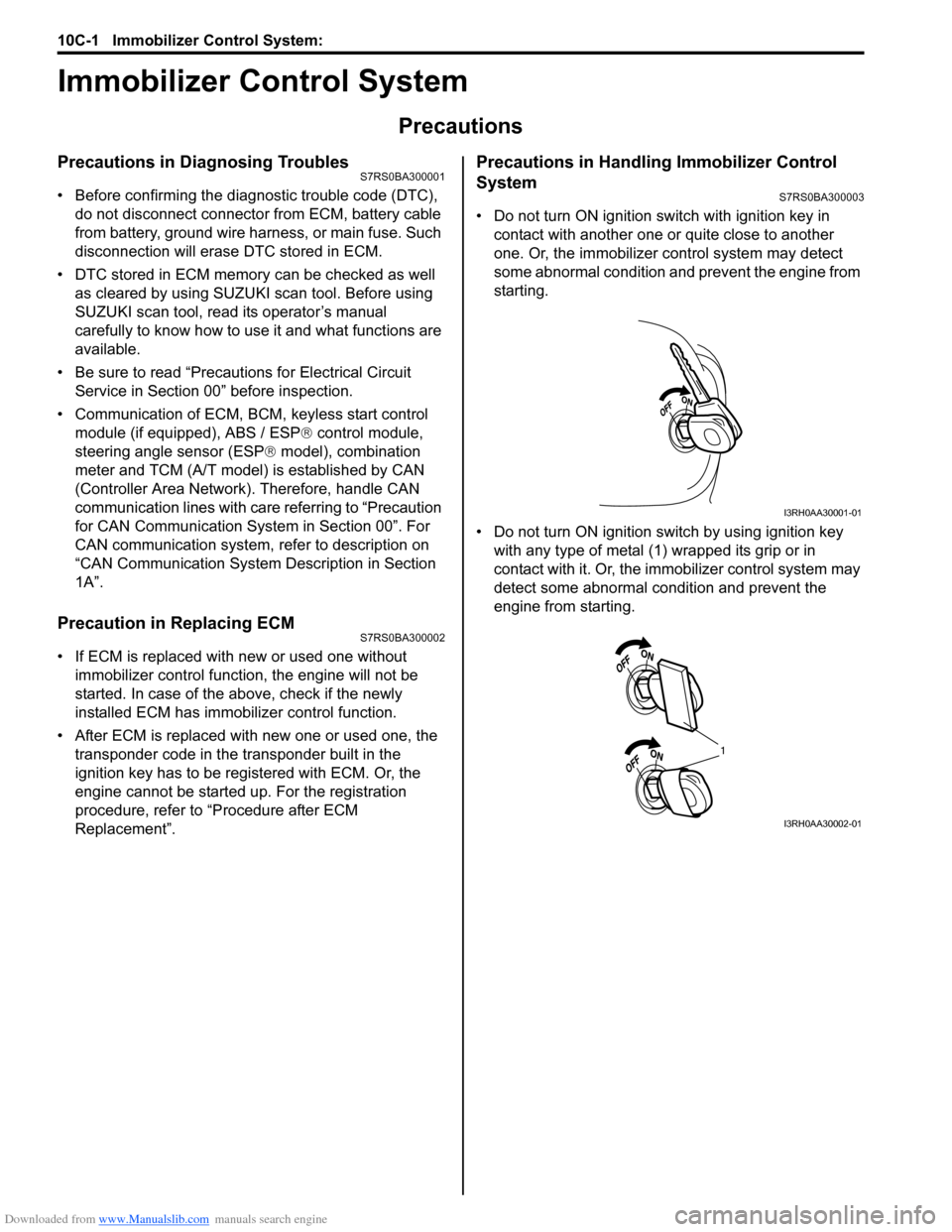

• Do not turn ON ignition sw itch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer co ntrol system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key with any type of metal (1) wrapped its grip or in

contact with it. Or, the i mmobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

I3RH0AA30001-01

1

I3RH0AA30002-01

Page 1445 of 1496

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-2

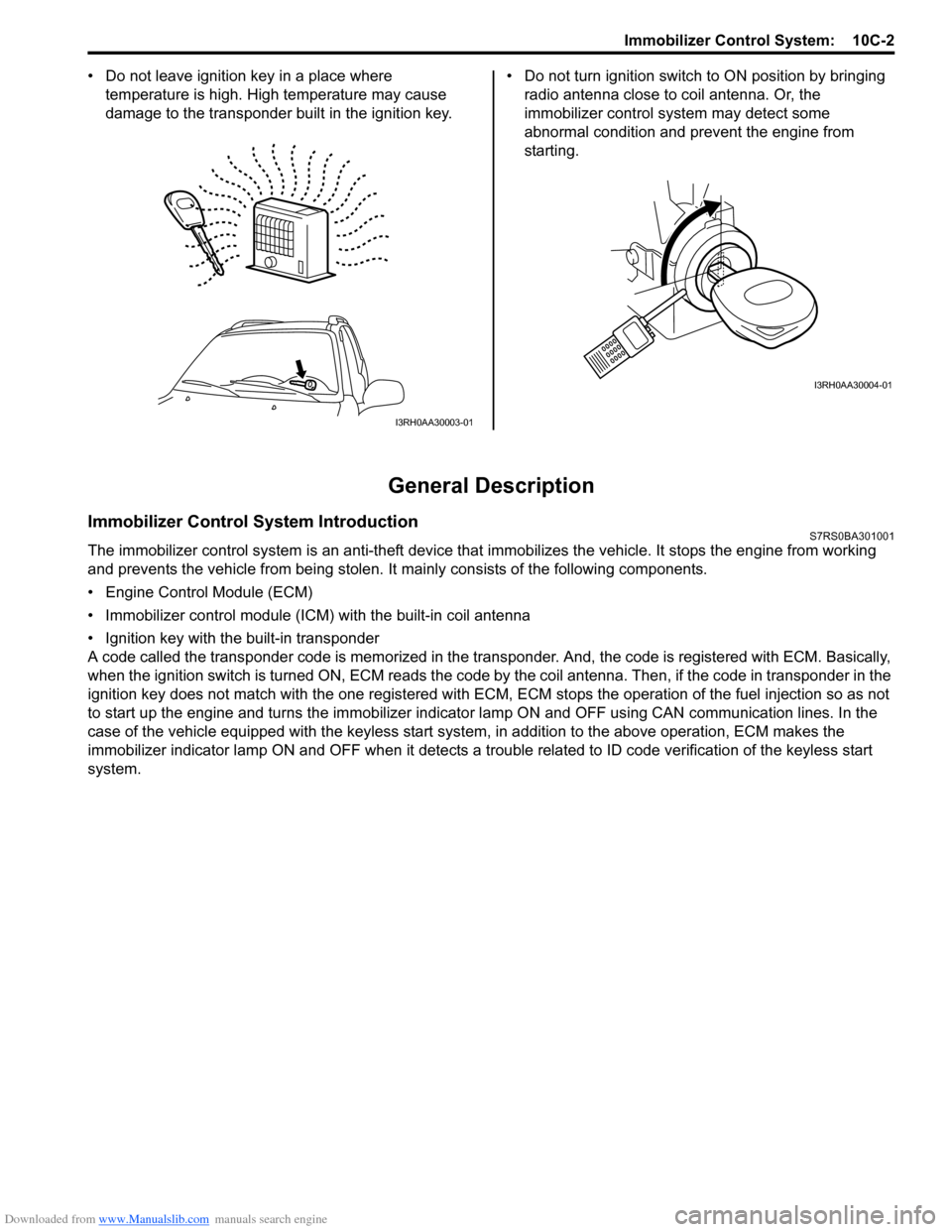

• Do not leave ignition key in a place where

temperature is high. High temperature may cause

damage to the transponder built in the ignition key. • Do not turn ignition switch to ON position by bringing

radio antenna close to coil antenna. Or, the

immobilizer control syst em may detect some

abnormal condition and prevent the engine from

starting.

General Description

Immobilizer Control System IntroductionS7RS0BA301001

The immobilizer control system is an anti-theft device that immobilizes the vehicle. It stops the engine from working

and prevents the vehicle from being stolen. It mainly consists of the following components.

• Engine Control Module (ECM)

• Immobilizer control module (ICM) with the built-in coil antenna

• Ignition key with the built-in transponder

A code called the transponder code is memorized in the tran sponder. And, the code is registered with ECM. Basically,

when the ignition switch is turned ON, ECM reads the code by the coil antenna. Then, if the code in transponder in the

ignition key does not match with the one registered with ECM, ECM stops the operati on of the fuel injection so as not

to start up the engine and turns the immobilizer indi cator lamp ON and OFF using CA N communication lines. In the

case of the vehicle equipped with the keyless start system , in addition to the above operation, ECM makes the

immobilizer indicator lamp ON and OFF when it detects a trouble related to ID code verification of the keyless start

system.

I3RH0AA30003-01

I3RH0AA30004-01

Page 1446 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-3 Immobilizer Control System:

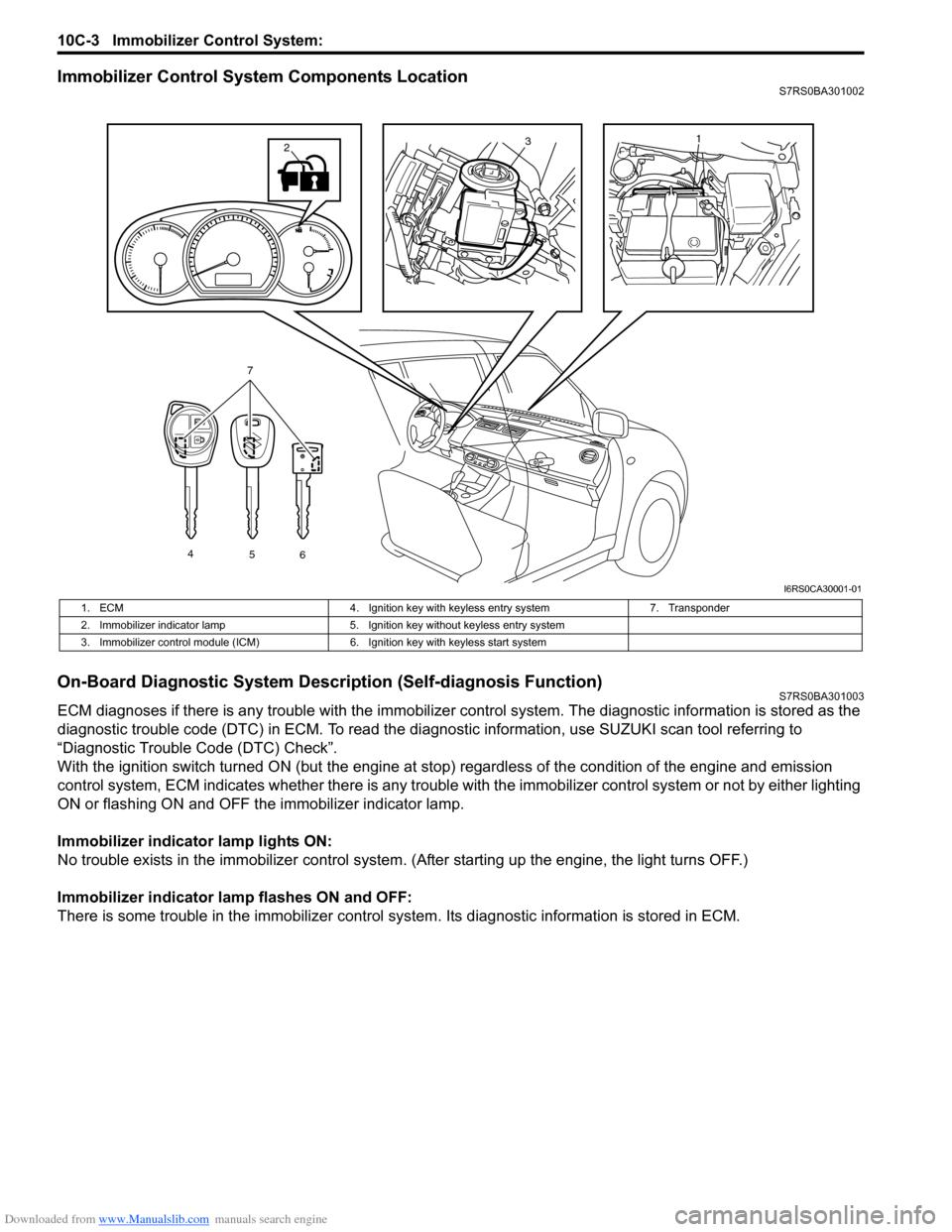

Immobilizer Control System Components LocationS7RS0BA301002

On-Board Diagnostic System Description (Self-diagnosis Function)S7RS0BA301003

ECM diagnoses if there is any trouble with the immobilizer control system. The diagnostic information is stored as the

diagnostic trouble code (DTC) in ECM. To read the di agnostic information, use SUZUKI scan tool referring to

“Diagnostic Trouble Code (DTC) Check”.

With the ignition switch turned ON (but the engine at stop) regardless of the condition of the engine and emission

control system, ECM indicates whether ther e is any trouble with the immobilizer control system or not by either lighting

ON or flashing ON and OFF t he immobilizer indicator lamp.

Immobilizer indicator lamp lights ON:

No trouble exists in the immobilizer control system. (After starting up the engine, the light turns OFF.)

Immobilizer indicator lamp flashes ON and OFF:

There is some trouble in the immo bilizer control system. Its diagnostic information is stored in ECM.

13

4

56

7

2

I6RS0CA30001-01

1. ECM 4. Ignition key with keyless entry system 7. Transponder

2. Immobilizer indicator lamp 5. Ignition key without keyless entry system

3. Immobilizer control module (ICM) 6. Ignition key with keyless start system

Page 1461 of 1496

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-18

Repair Instructions

Immobilizer Control Module (ICM) Removal and

Installation

S7RS0BA306001

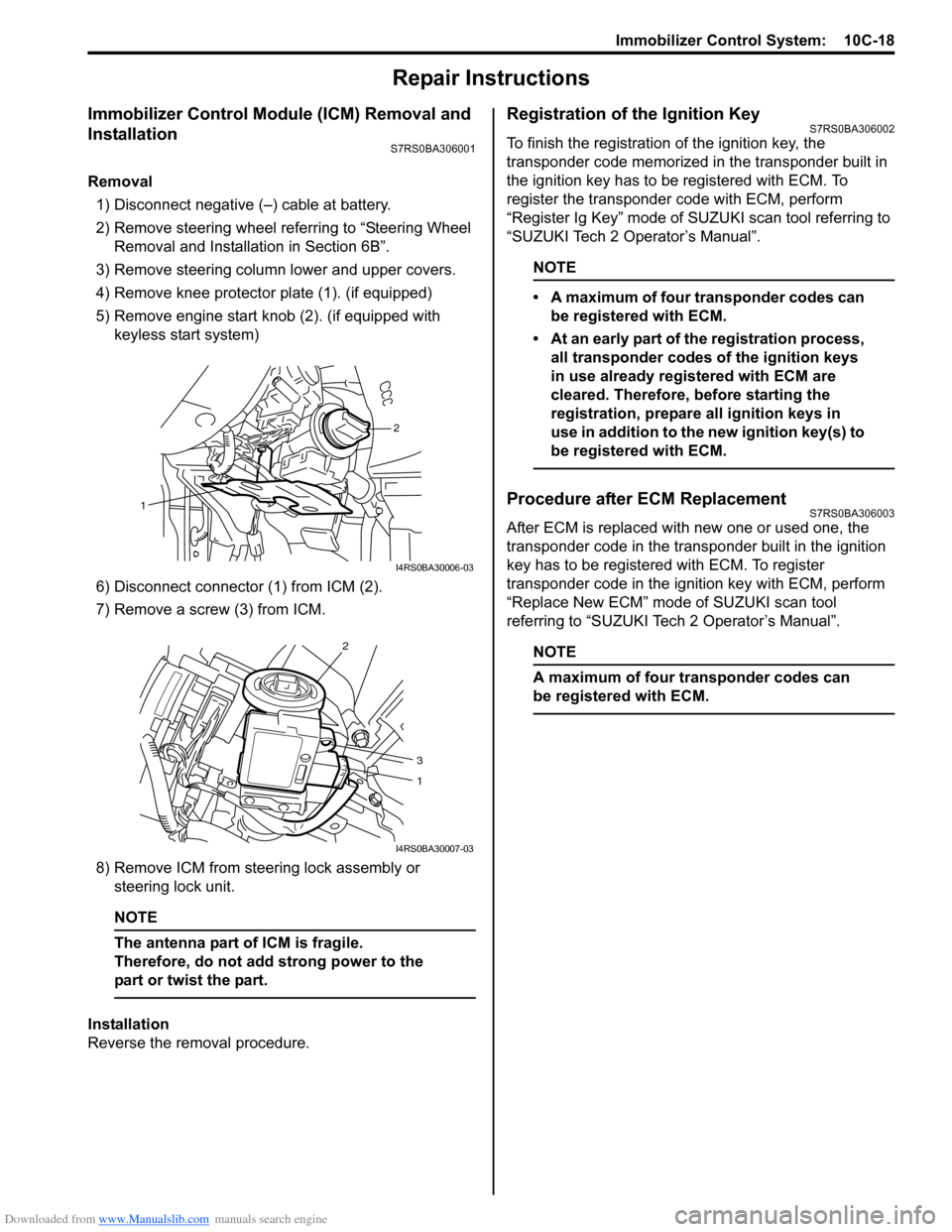

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering wheel referring to “Steering Wheel Removal and Installa tion in Section 6B”.

3) Remove steering column lower and upper covers.

4) Remove knee protector plate (1). (if equipped)

5) Remove engine start knob (2). (if equipped with keyless start system)

6) Disconnect connector (1) from ICM (2).

7) Remove a screw (3) from ICM.

8) Remove ICM from steering lock assembly or steering lock unit.

NOTE

The antenna part of ICM is fragile.

Therefore, do not add strong power to the

part or twist the part.

Installation

Reverse the removal procedure.

Registration of the Ignition KeyS7RS0BA306002

To finish the registration of the ignition key, the

transponder code memorized in the transponder built in

the ignition key has to be registered with ECM. To

register the transponder code with ECM, perform

“Register Ig Key” mode of SU ZUKI scan tool referring to

“SUZUKI Tech 2 Operator’s Manual”.

NOTE

• A maximum of four transponder codes can be registered with ECM.

• At an early part of the registration process, all transponder codes of the ignition keys

in use already registered with ECM are

cleared. Therefore, before starting the

registration, prepare all ignition keys in

use in addition to the new ignition key(s) to

be registered with ECM.

Procedure after ECM ReplacementS7RS0BA306003

After ECM is replaced with new one or used one, the

transponder code in the transponder built in the ignition

key has to be registered with ECM. To register

transponder code in the ignition key with ECM, perform

“Replace New ECM” mode of SUZUKI scan tool

referring to “SUZUKI Tech 2 Operator’s Manual”.

NOTE

A maximum of four transponder codes can

be registered with ECM.

2

1

I4RS0BA30006-03

2

3

1

I4RS0BA30007-03

Page 1473 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-11

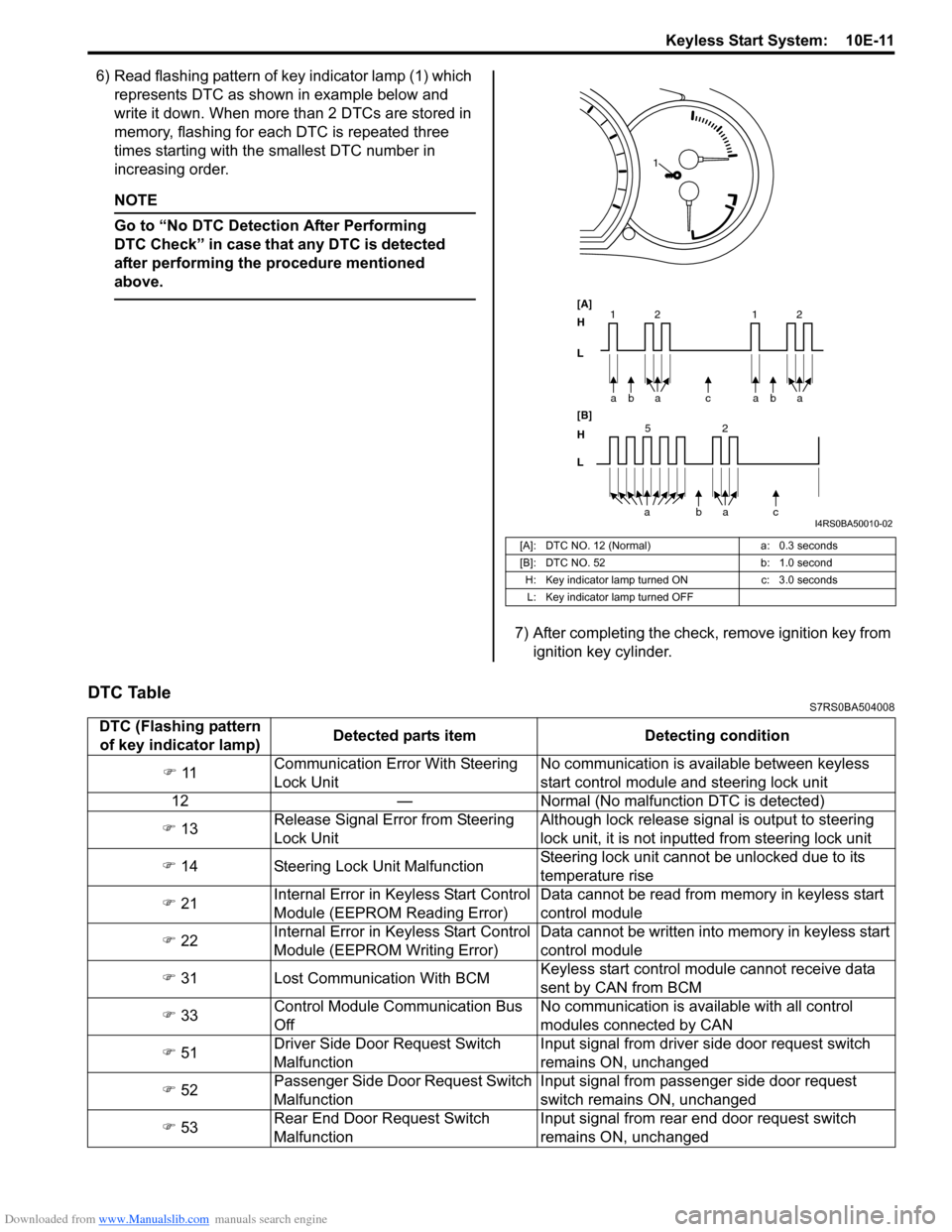

6) Read flashing pattern of key indicator lamp (1) which represents DTC as shown in example below and

write it down. When more than 2 DTCs are stored in

memory, flashing for each DTC is repeated three

times starting with the smallest DTC number in

increasing order.

NOTE

Go to “No DTC Detect ion After Performing

DTC Check” in case that any DTC is detected

after performing the procedure mentioned

above.

7) After completing the check, remove ignition key from ignition key cylinder.

DTC TableS7RS0BA504008

[A]: DTC NO. 12 (Normal)

a: 0.3 seconds

[B]: DTC NO. 52 b: 1.0 second

H: Key indicator lamp tu rned ONc: 3.0 seconds

L: Key indicator lamp turned OFF

bc

a

a

[A]

H

L

H

L [B]

52

bac

a

2

11baa 2

1

I4RS0BA50010-02

DTC (Flashing pattern

of key indicator lamp) Detected parts item Detecting condition

�) 11 Communication Error With Steering

Lock Unit No communication is available between keyless

start control module and steering lock unit

12 — Normal (No malfunct ion DTC is detected)

�) 13 Release Signal Error from Steering

Lock Unit Although lock release signal is output to steering

lock unit, it is not inputt

ed from steering lock unit

�) 14 Steering Lock Unit Malfunction Steering lock unit cannot be unlocked due to its

temperature rise

�) 21 Internal Error in Ke

yless Start Control

Module (EEPROM Reading Error) Data cannot be read from memory in keyless start

control module

�) 22 Internal Error in Ke

yless Start Control

Module (EEPROM Writing Error) Data cannot be written into memory in keyless start

control module

�) 31 Lost Communication With BCM Keyless start control module cannot receive data

sent by CAN from BCM

�) 33 Control Module Communication Bus

Off No communication is available with all control

modules connected by CAN

�) 51 Driver Side Door Request Switch

Malfunction Input signal from driver side door request switch

remains ON, unchanged

�) 52 Passenger Side Door Request Switch

Malfunction Input signal from passenger side door request

switch remains ON, unchanged

�) 53 Rear End Door Request Switch

Malfunction Input signal from rear end door request switch

remains ON, unchanged