Purge control valve SUZUKI SWIFT 2007 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 243 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-193

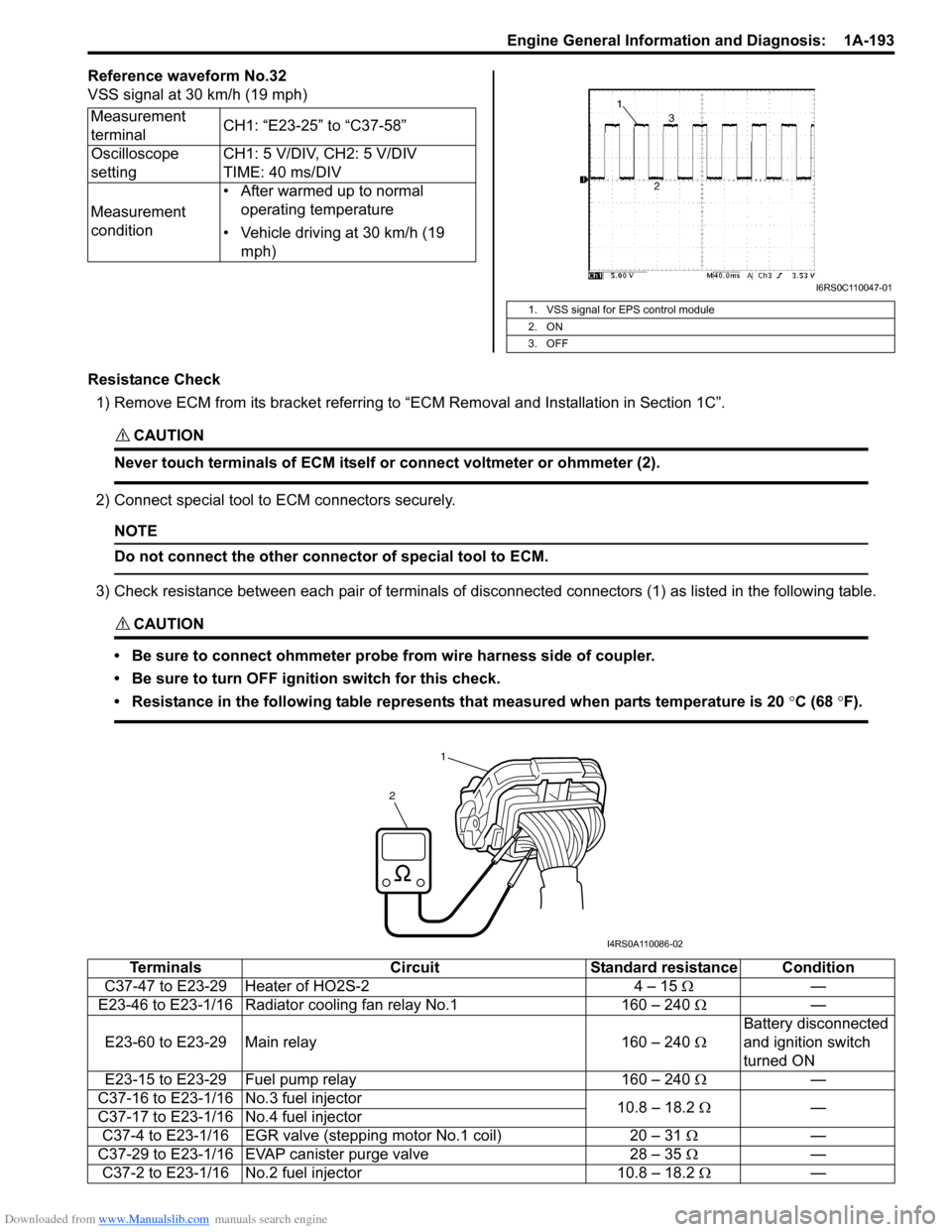

Reference waveform No.32

VSS signal at 30 km/h (19 mph)

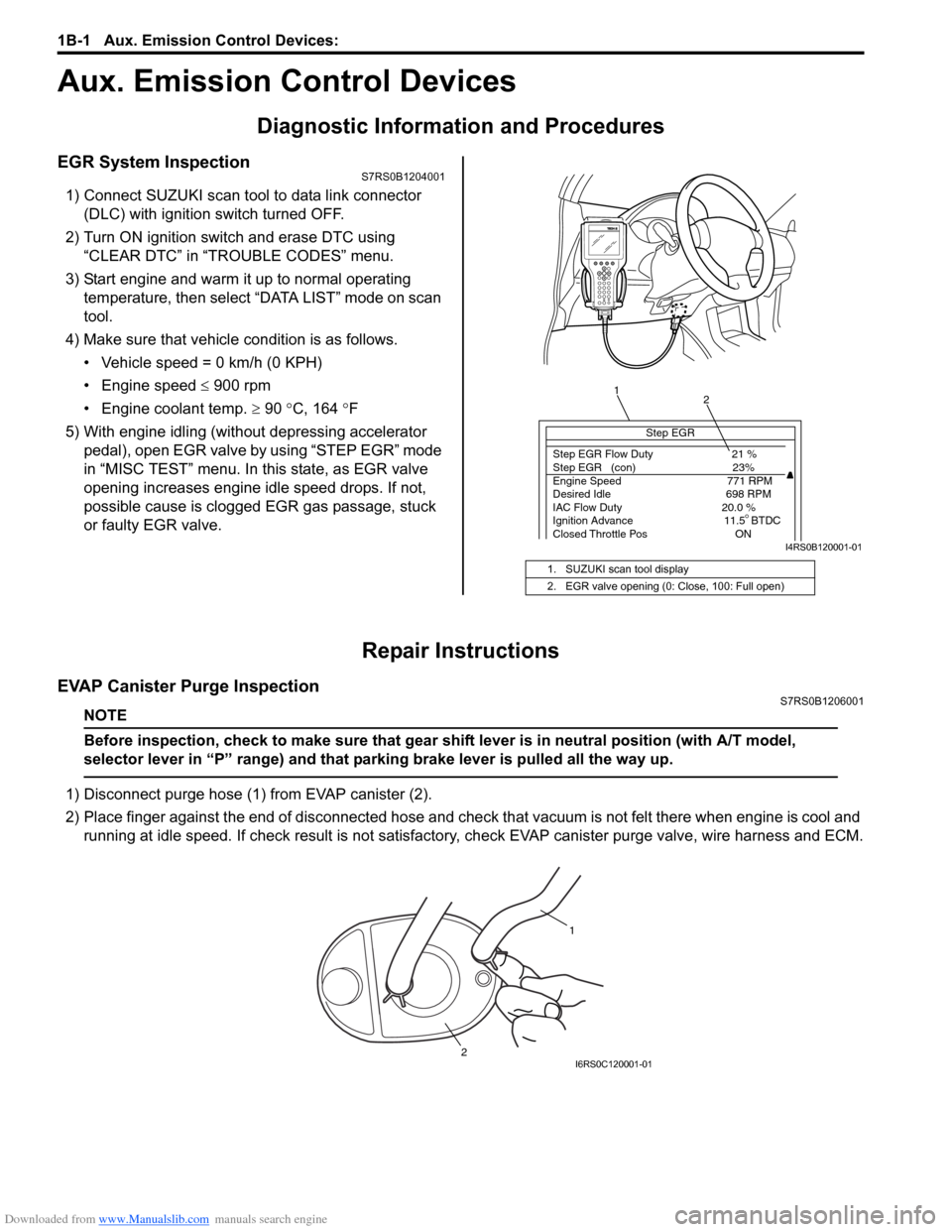

Resistance Check1) Remove ECM from its bracket referring to “ECM Removal and Installation in Section 1C”.

CAUTION!

Never touch terminals of ECM itself or connect voltmeter or ohmmeter (2).

2) Connect special tool to ECM connectors securely.

NOTE

Do not connect the other connector of special tool to ECM.

3) Check resistance between each pair of terminals of disconnected connectors (1) as listed in the following table.

CAUTION!

• Be sure to connect ohmmeter probe from wire harness side of coupler.

• Be sure to turn OFF ignition switch for this check.

• Resistance in the following table represents that measured when parts temperature is 20 °C (68 °F).

Measurement

terminal CH1: “E23-25” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Vehicle driving at 30 km/h (19 mph)

1. VSS signal for EPS control module

2. ON

3. OFF

I6RS0C110047-01

1

2

I4RS0A110086-02

Terminals CircuitStandard resistance Condition

C37-47 to E23-29 Heater of HO2S-2 4 – 15 Ω—

E23-46 to E23-1/16 Radiator cooling fan relay No.1 160 – 240 Ω —

E23-60 to E23-29 Main relay 160 – 240 ΩBattery disconnected

and ignition switch

turned ON

E23-15 to E23-29 Fuel pump relay 160 – 240 Ω —

C37-16 to E23-1/16 No.3 fuel injector 10.8 – 18.2 Ω —

C37-17 to E23-1/16 No.4 fuel injector

C37-4 to E23-1/16 EGR valve (st epping motor No.1 coil) 20 – 31 Ω —

C37-29 to E23-1/16 EVAP canister purge valve 28 – 35 Ω —

C37-2 to E23-1/16 No.2 fuel injector 10.8 – 18.2 Ω—

Page 268 of 1496

Downloaded from www.Manualslib.com manuals search engine 1B-1 Aux. Emission Control Devices:

Engine

Aux. Emission Control Devices

Diagnostic Information and Procedures

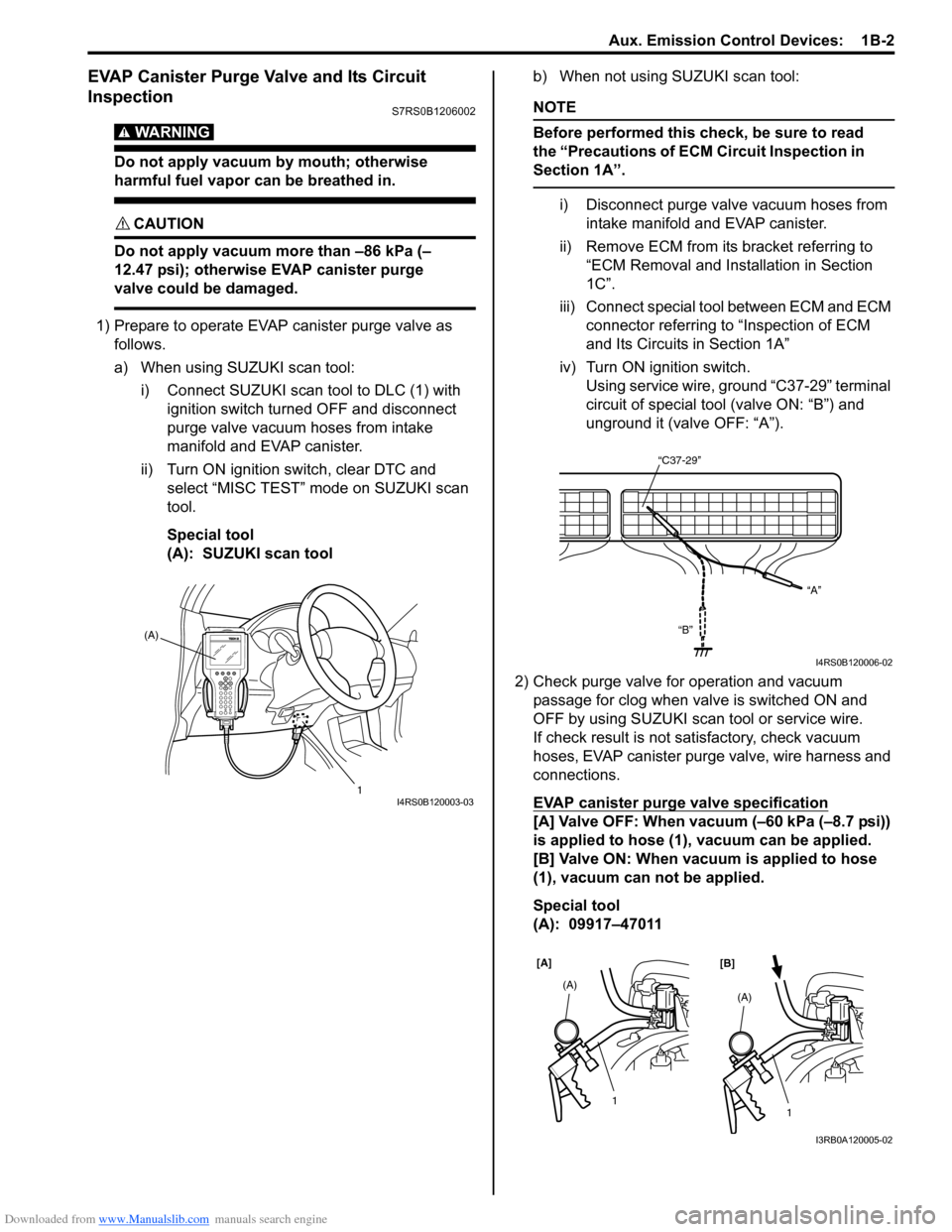

EGR System InspectionS7RS0B1204001

1) Connect SUZUKI scan tool to data link connector (DLC) with ignition switch turned OFF.

2) Turn ON ignition switch and erase DTC using “CLEAR DTC” in “TROUBLE CODES” menu.

3) Start engine and warm it up to normal operating temperature, then select “DATA LIST” mode on scan

tool.

4) Make sure that vehicle condition is as follows.

• Vehicle speed = 0 km/h (0 KPH)

• Engine speed ≤ 900 rpm

• Engine coolant temp. ≥ 90 °C, 164 °F

5) With engine idling (without depressing accelerator pedal), open EGR valve by using “STEP EGR” mode

in “MISC TEST” menu. In this state, as EGR valve

opening increases engine idle speed drops. If not,

possible cause is clogged EGR gas passage, stuck

or faulty EGR valve.

Repair Instructions

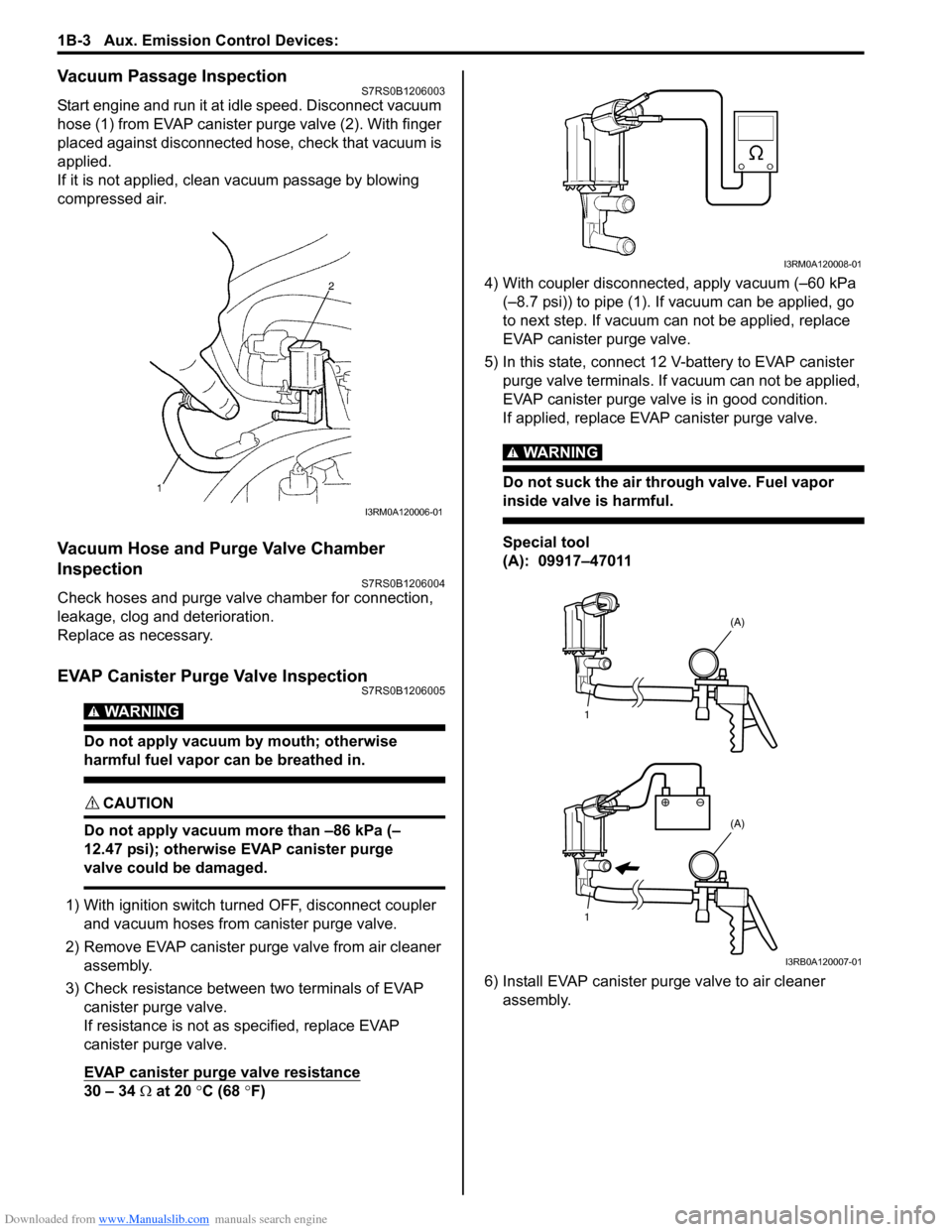

EVAP Canister Purge InspectionS7RS0B1206001

NOTE

Before inspection, check to make sure that gear shift lever is in neutral position (with A/T model,

selector lever in “P” range) and that parking brake lever is pulled all the way up.

1) Disconnect purge hose (1) from EVAP canister (2).

2) Place finger against the end of disconne cted hose and check that vacuum is not felt there when engine is cool and

running at idle speed. If check result is not satisfacto ry, check EVAP canister purge valve, wire harness and ECM.

1. SUZUKI scan tool display

2. EGR valve opening (0: Close, 100: Full open)

Step EGR

Step EGR Flow Duty 21 %

Step EGR (con) 23%

Engine Speed 771 RPM

Desired Idle 698 RPM

IAC Flow Duty 20.0 %

Ignition Advance 11.5 BTDC

Closed Throttle Pos ON

1 2

I4RS0B120001-01

1

2

I6RS0C120001-01

Page 269 of 1496

Downloaded from www.Manualslib.com manuals search engine Aux. Emission Control Devices: 1B-2

EVAP Canister Purge Valve and Its Circuit

Inspection

S7RS0B1206002

WARNING!

Do not apply vacuum by mouth; otherwise

harmful fuel vapor can be breathed in.

CAUTION!

Do not apply vacuum more than –86 kPa (–

12.47 psi); otherwise EVAP canister purge

valve could be damaged.

1) Prepare to operate EVAP canister purge valve as follows.

a) When using SUZUKI scan tool:

i) Connect SUZUKI scan tool to DLC (1) with ignition switch turned OFF and disconnect

purge valve vacuum hoses from intake

manifold and EVAP canister.

ii) Turn ON ignition switch, clear DTC and select “MISC TEST” mode on SUZUKI scan

tool.

Special tool

(A): SUZUKI scan tool b) When not using SUZUKI scan tool:

NOTE

Before performed this check, be sure to read

the “Precautions of ECM Circuit Inspection in

Section 1A”.

i) Disconnect purge valve vacuum hoses from

intake manifold and EVAP canister.

ii) Remove ECM from it s bracket referring to

“ECM Removal and Inst allation in Section

1C”.

iii) Connect special tool between ECM and ECM connector referring to “Inspection of ECM

and Its Circuits in Section 1A”

iv) Turn ON ignition switch. Using service wire, ground “C37-29” terminal

circuit of special tool (valve ON: “B”) and

unground it (valve OFF: “A”).

2) Check purge valve for operation and vacuum passage for clog when valve is switched ON and

OFF by using SUZUKI scan tool or service wire.

If check result is not satisfactory, check vacuum

hoses, EVAP canister purge valve, wire harness and

connections.

EVAP canister purge valve specification

[A] Valve OFF: When vacuum (–60 kPa (–8.7 psi))

is applied to hose (1), vacuum can be applied.

[B] Valve ON: When vacuum is applied to hose

(1), vacuum can not be applied.

Special tool

(A): 09917–47011

(A)

1

I4RS0B120003-03

“C37-29”“A”

“B”

I4RS0B120006-02

[A] [B]

1

(A)1

(A)

I3RB0A120005-02

Page 270 of 1496

Downloaded from www.Manualslib.com manuals search engine 1B-3 Aux. Emission Control Devices:

Vacuum Passage InspectionS7RS0B1206003

Start engine and run it at idle speed. Disconnect vacuum

hose (1) from EVAP canister purge valve (2). With finger

placed against disconnected hose, check that vacuum is

applied.

If it is not applied, clean vacuum passage by blowing

compressed air.

Vacuum Hose and Purge Valve Chamber

Inspection

S7RS0B1206004

Check hoses and purge valv e chamber for connection,

leakage, clog and deterioration.

Replace as necessary.

EVAP Canister Purge Valve InspectionS7RS0B1206005

WARNING!

Do not apply vacuum by mouth; otherwise

harmful fuel vapor can be breathed in.

CAUTION!

Do not apply vacuum more than –86 kPa (–

12.47 psi); otherwise EVAP canister purge

valve could be damaged.

1) With ignition switch turned OFF, disconnect coupler and vacuum hoses from canister purge valve.

2) Remove EVAP canister purge valve from air cleaner assembly.

3) Check resistance between two terminals of EVAP canister purge valve.

If resistance is not as specified, replace EVAP

canister purge valve.

EVAP canister purge valve resistance

30 – 34 Ω at 20 °C (68 °F) 4) With coupler disconnected, apply vacuum (–60 kPa

(–8.7 psi)) to pipe (1). If vacuum can be applied, go

to next step. If vacuum can not be applied, replace

EVAP canister purge valve.

5) In this state, connect 12 V-battery to EVAP canister purge valve terminals. If vacuum can not be applied,

EVAP canister purge valve is in good condition.

If applied, replace EVAP canister purge valve.

WARNING!

Do not suck the air through valve. Fuel vapor

inside valve is harmful.

Special tool

(A): 09917–47011

6) Install EVAP canister purge valve to air cleaner assembly.

I3RM0A120006-01

I3RM0A120008-01

1

1 (A)

(A)

I3RB0A120007-01

Page 271 of 1496

Downloaded from www.Manualslib.com manuals search engine Aux. Emission Control Devices: 1B-4

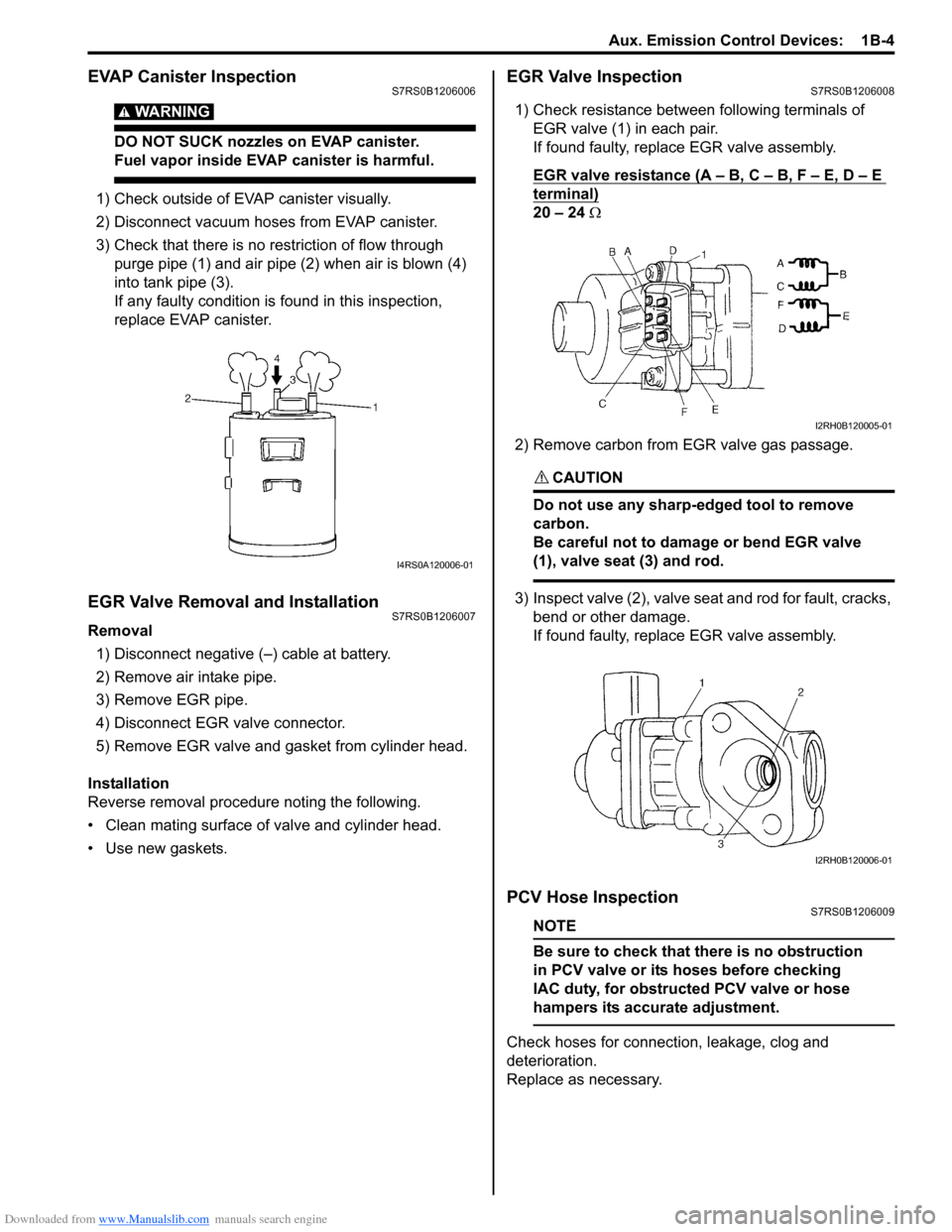

EVAP Canister InspectionS7RS0B1206006

WARNING!

DO NOT SUCK nozzles on EVAP canister.

Fuel vapor inside EVAP canister is harmful.

1) Check outside of EVAP canister visually.

2) Disconnect vacuum hoses from EVAP canister.

3) Check that there is no restriction of flow through purge pipe (1) and air pipe (2) when air is blown (4)

into tank pipe (3).

If any faulty condition is found in this inspection,

replace EVAP canister.

EGR Valve Removal and InstallationS7RS0B1206007

Removal

1) Disconnect negative (–) cable at battery.

2) Remove air intake pipe.

3) Remove EGR pipe.

4) Disconnect EGR valve connector.

5) Remove EGR valve and gasket from cylinder head.

Installation

Reverse removal procedure noting the following.

• Clean mating surface of valve and cylinder head.

• Use new gaskets.

EGR Valve InspectionS7RS0B1206008

1) Check resistance between following terminals of EGR valve (1) in each pair.

If found faulty, replace EGR valve assembly.

EGR valve resistance (A – B, C – B, F – E, D – E

terminal)

20 – 24 Ω

2) Remove carbon from EGR valve gas passage.

CAUTION!

Do not use any sharp-edged tool to remove

carbon.

Be careful not to damage or bend EGR valve

(1), valve seat (3) and rod.

3) Inspect valve (2), valve seat and rod for fault, cracks, bend or other damage.

If found faulty, replace EGR valve assembly.

PCV Hose InspectionS7RS0B1206009

NOTE

Be sure to check that there is no obstruction

in PCV valve or its hoses before checking

IAC duty, for obstructed PCV valve or hose

hampers its accurate adjustment.

Check hoses for connection, leakage, clog and

deterioration.

Replace as necessary.

I4RS0A120006-01

I2RH0B120005-01

I2RH0B120006-01

Page 302 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-17 Engine Mechanical:

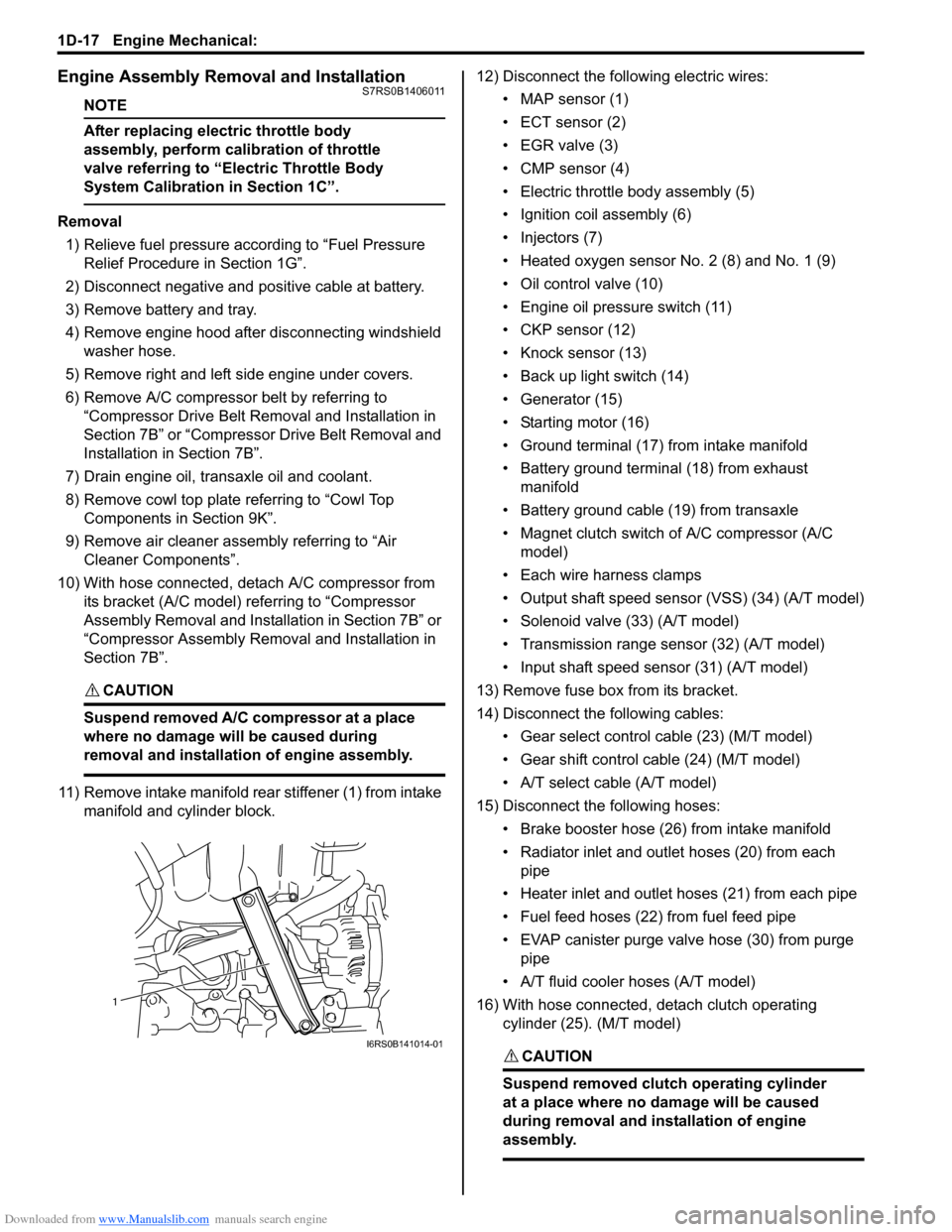

Engine Assembly Removal and InstallationS7RS0B1406011

NOTE

After replacing electric throttle body

assembly, perform calibration of throttle

valve referring to “Electric Throttle Body

System Calibration in Section 1C”.

Removal1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure in Section 1G”.

2) Disconnect negative and pos itive cable at battery.

3) Remove battery and tray.

4) Remove engine hood after disconnecting windshield washer hose.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to “Compressor Drive Belt Remo val and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil, transaxle oil and coolant.

8) Remove cowl top plate referring to “Cowl Top Components in Section 9K”.

9) Remove air cleaner assembly referring to “Air Cleaner Components”.

10) With hose connected, detach A/C compressor from its bracket (A/C model) referring to “Compressor

Assembly Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

11) Remove intake manifold rear stiffener (1) from intake manifold and cylinder block. 12) Disconnect the following electric wires:

• MAP sensor (1)

• ECT sensor (2)

•EGR valve (3)

• CMP sensor (4)

• Electric throttle body assembly (5)

• Ignition coil assembly (6)

• Injectors (7)

• Heated oxygen sensor No. 2 (8) and No. 1 (9)

• Oil control valve (10)

• Engine oil pressure switch (11)

• CKP sensor (12)

• Knock sensor (13)

• Back up light switch (14)

• Generator (15)

• Starting motor (16)

• Ground terminal (17) from intake manifold

• Battery ground terminal (18) from exhaust manifold

• Battery ground cable (19) from transaxle

• Magnet clutch switch of A/C compressor (A/C model)

• Each wire harness clamps

• Output shaft speed sensor (VSS) (34) (A/T model)

• Solenoid valve (33) (A/T model)

• Transmission range sensor (32) (A/T model)

• Input shaft speed sensor (31) (A/T model)

13) Remove fuse box from its bracket.

14) Disconnect the following cables: • Gear select control cable (23) (M/T model)

• Gear shift control cable (24) (M/T model)

• A/T select cable (A/T model)

15) Disconnect the following hoses: • Brake booster hose (26) from intake manifold

• Radiator inlet and outlet hoses (20) from each pipe

• Heater inlet and outlet hoses (21) from each pipe

• Fuel feed hoses (22) from fuel feed pipe

• EVAP canister purge valve hose (30) from purge pipe

• A/T fluid cooler hoses (A/T model)

16) With hose connected, detach clutch operating cylinder (25). (M/T model)

CAUTION!

Suspend removed clutch operating cylinder

at a place where no damage will be caused

during removal and installation of engine

assembly.

1

I6RS0B141014-01

Page 377 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-2

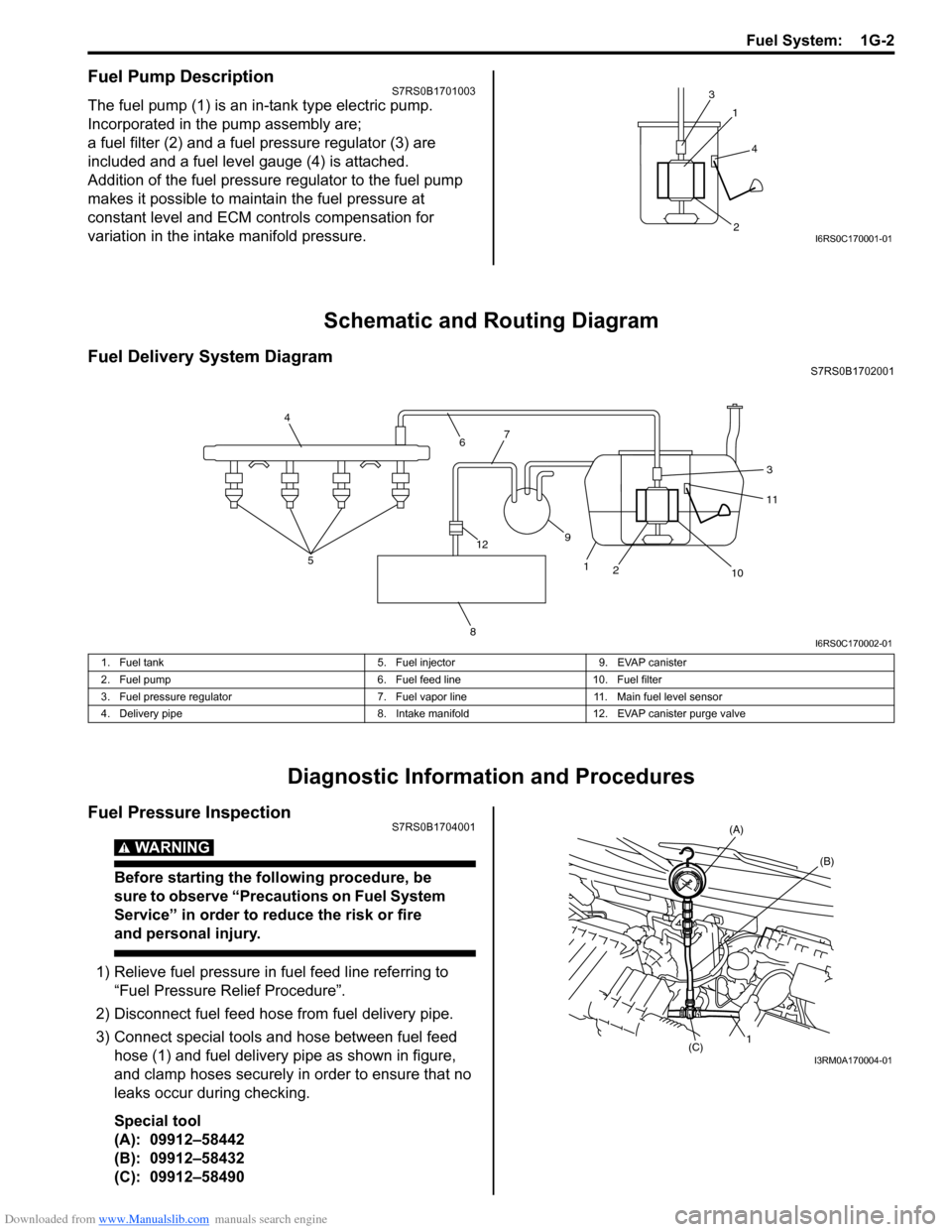

Fuel Pump DescriptionS7RS0B1701003

The fuel pump (1) is an in-tank type electric pump.

Incorporated in the pump assembly are;

a fuel filter (2) and a fuel pressure regulator (3) are

included and a fuel level gauge (4) is attached.

Addition of the fuel pressure regulator to the fuel pump

makes it possible to mainta in the fuel pressure at

constant level and ECM controls compensation for

variation in the intake manifold pressure.

Schematic and Routing Diagram

Fuel Delivery System DiagramS7RS0B1702001

Diagnostic Information and Procedures

Fuel Pressure InspectionS7RS0B1704001

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

1) Relieve fuel pressure in fuel feed line referring to

“Fuel Pressure Relief Procedure”.

2) Disconnect fuel feed hose from fuel delivery pipe.

3) Connect special tools and hose between fuel feed hose (1) and fuel delivery pipe as shown in figure,

and clamp hoses securely in order to ensure that no

leaks occur during checking.

Special tool

(A): 09912–58442

(B): 09912–58432

(C): 09912–58490

1

3

2

4

I6RS0C170001-01

4

6 7

8

12

2 3

11

10

5

1

9

I6RS0C170002-01

1. Fuel tank

5. Fuel injector9. EVAP canister

2. Fuel pump 6. Fuel feed line10. Fuel filter

3. Fuel pressure regulator 7. Fuel vapor line 11. Main fuel level sensor

4. Delivery pipe 8. Intake manifold12. EVAP canister purge valve

1

(C) (B)

(A)

I3RM0A170004-01

Page 1222 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-51 Wiring Systems:

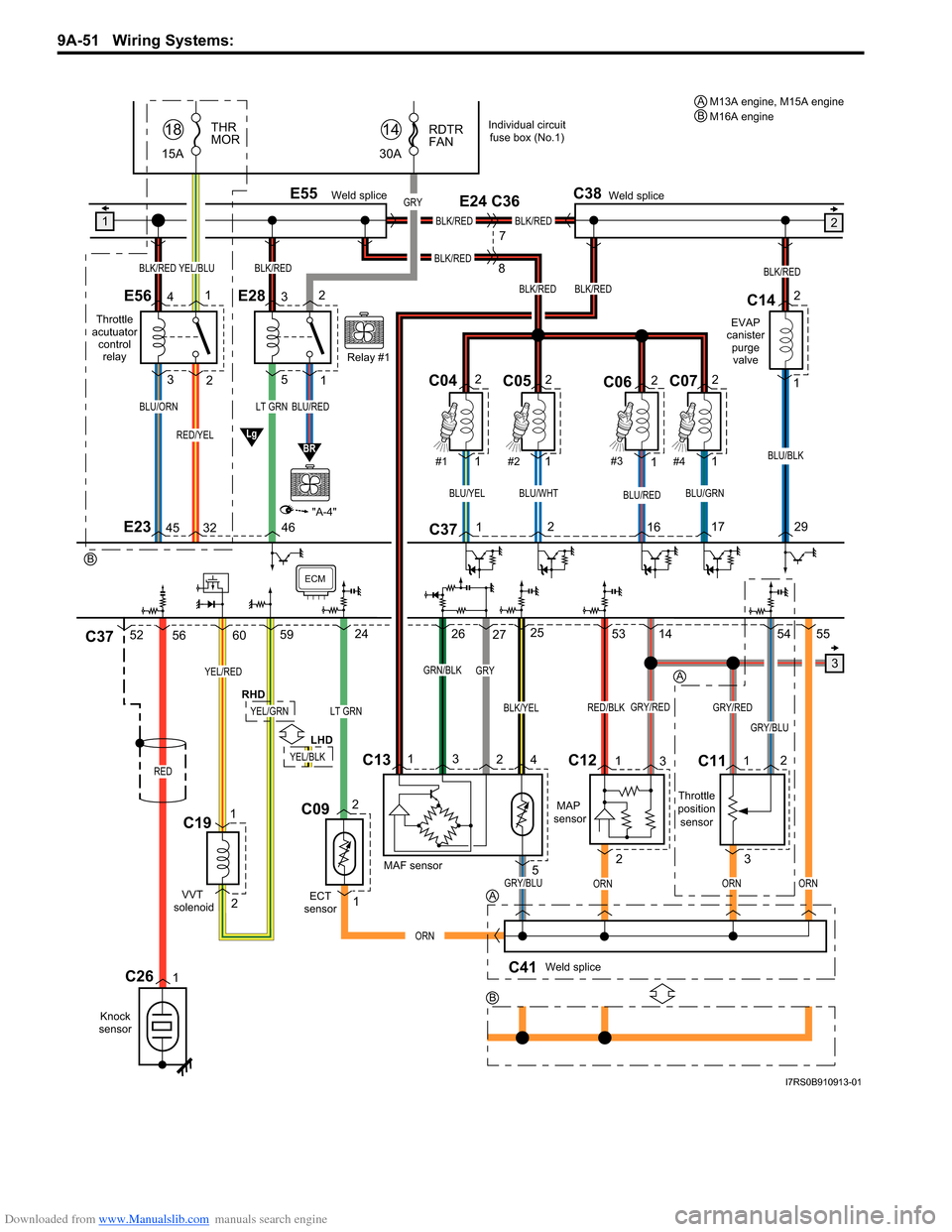

Throttle

acutuator controlrelay

4532

BLK/REDYEL/BLU

1

243E562

135E28

15A THR

MOR

18

M13A engine, M15A engine

M16A engine

A

B

A

A

B

B

2C09

LT GRN

1

C12

C13

C11

E23

C37

C37

Knock

sensor

C19

ECM

C042

1C052

1C062

1C072

1

#2

#1 #3

#4

BLU/REDBLU/WHTBLU/YELBLU/GRN

BLK/RED

BLU/BLK

EVAP

canister purgevalve

C14

ECT

sensor

ORN

MAF sensor

MAP

sensorThrottle

position sensor

Weld spliceC41

ORNORNORN

LT GRNBLU/REDBLU/ORN

RED/YEL

GRY

"A-4"

Lg

30A RDTR

FAN

14

Relay #1

BR

46

1

2

1

29

17

16

2

1

2425

26 27

4

3

2

1

5

1

2 3

1

32

2

3

54 55

RED/BLKGRY/REDGRY/RED

GRY/BLU

53 14

E24 C36

8

7

C26

RED

1

56

VVT

solenoid

1

2

60 59

BLK/RED

E55Weld spliceC38Weld splice

BLK/REDBLK/RED

BLK/REDBLK/RED

BLK/RED

GRN/BLKGRY

BLK/YEL

GRY/BLU

52

YEL/RED

Individual circuit

fuse box (No.1)

YEL/GRN

YEL/BLK

RHD

LHD

I7RS0B910913-01