Steering panel SUZUKI SWIFT 2007 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 1134 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-96 Air Bag System:

Repair and Inspection Required after AccidentS7RS0B8204049

CAUTION!

• All air bag system components, including the electrical harness (component

mounting points), must be inspected after

an accident. If any components are

damaged or bent, they must be replaced

even if air bag system activation did not

occur.

• Never use air bag system parts from another vehicle.

• Do not attempt to service the parts below. Service of these parts is by replacement

only.

– Driver / Passenger air bag (inflator) modules

– Driver / Passenger side-air bag (inflator) modules

– Driver / Passenger side curtain-air bag (inflator) modules

– Driver / Passenger seat belt pretensioners

–Forward-sensor

– Driver / Passenger side-sensors

–SDM

– Contact coil and combination switch assembly

– Air bag wire harness in main harness, instrument panel harness and floor

harness.

• Proper operation of the sensors and air bag system requires that any repairs to the

vehicle structure return it to its original

production configuration.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, the SDM

must not be used.

Refer to “Air Bag Diagnostic System Check”

when checking the SDM.

Accident with Deployment / Activation – Component

Replacement

When driver and passenger air bags are deployed, the

following components must be replaced.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• SDM after detecting such collision as to meet

deployment conditions

• Forward-sensor

• Instrument panel When side-air bag and side curtain-air bag are deployed,

the following components must be replaced.

• Deployed side-air bag (inflator) module

• Deployed side curtain-air bag (inflator) module

• Side-sensor

•SDM

Accident with or without Deployment / Activation –

Component Inspections

Certain air bag and restraint system components must

be inspected after any crash, whether the air bag system

activated or not. If any faul

ty condition is found in the

following checks, replace faulty part.

Those components are:

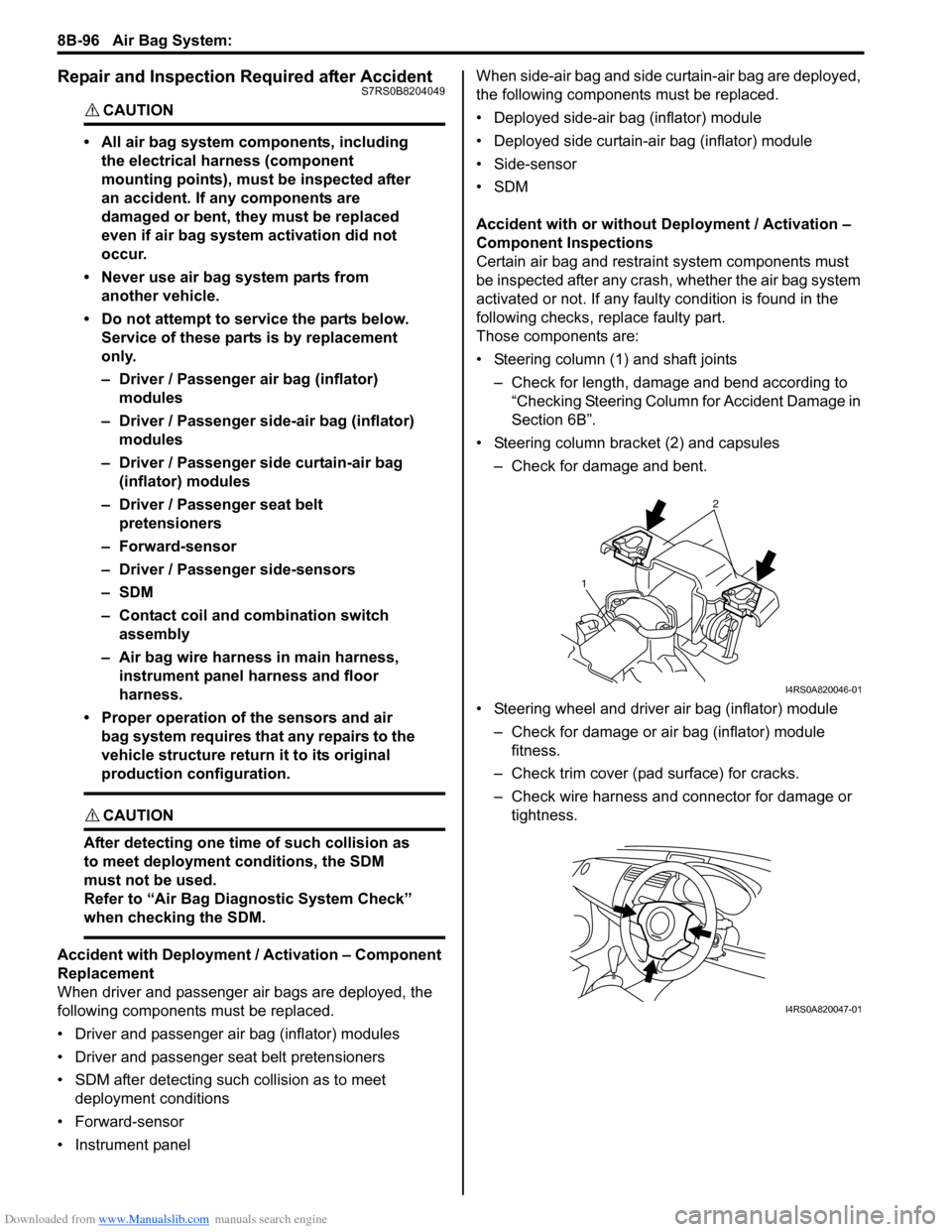

• Steering column (1) and shaft joints

– Check for length, damage and bend according to “Checking Steering Column for Accident Damage in

Section 6B”.

• Steering column bracket (2) and capsules – Check for damage and bent.

• Steering wheel and driver air bag (inflator) module – Check for damage or air bag (inflator) module fitness.

– Check trim cover (pad surface) for cracks.

– Check wire harness and connector for damage or tightness.

2

1

I4RS0A820046-01

I4RS0A820047-01

Page 1164 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-126 Air Bag System:

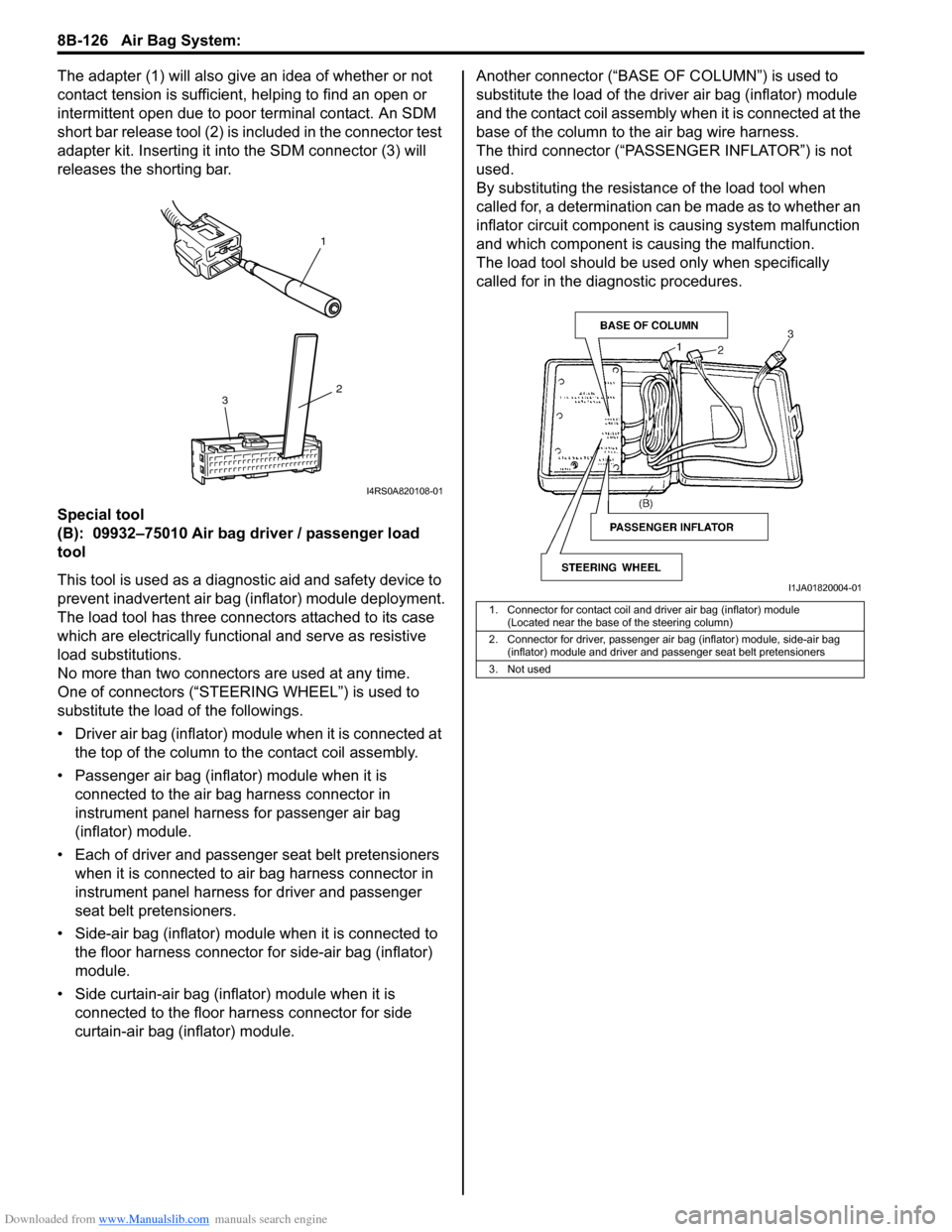

The adapter (1) will also give an idea of whether or not

contact tension is sufficient, helping to find an open or

intermittent open due to poor terminal contact. An SDM

short bar release tool (2) is included in the connector test

adapter kit. Inserting it in to the SDM connector (3) will

releases the shorting bar.

Special tool

(B): 09932–75010 Air bag driver / passenger load

tool

This tool is used as a diagno stic aid and safety device to

prevent inadvertent air bag (inflator) module deployment.

The load tool has three connectors attached to its case

which are electrically functional and serve as resistive

load substitutions.

No more than two connectors are used at any time.

One of connectors (“STEER ING WHEEL”) is used to

substitute the load of the followings.

• Driver air bag (inflator) module when it is connected at the top of the column to the contact coil assembly.

• Passenger air bag (inflator) module when it is connected to the air bag harness connector in

instrument panel harness for passenger air bag

(inflator) module.

• Each of driver and passen ger seat belt pretensioners

when it is connected to air bag harness connector in

instrument panel harness for driver and passenger

seat belt pretensioners.

• Side-air bag (inflator) module when it is connected to the floor harness connector for side-air bag (inflator)

module.

• Side curtain-air bag (inflator) module when it is connected to the floor harness connector for side

curtain-air bag (inflator) module. Another connec

tor (“BASE OF COLUMN ”) is used to

substitute the load of the driver air bag (inflator) module

and the contact coil assembly when it is connected at the

base of the column to the air bag wire harness.

The third connector (“PASSENGER INFLATOR”) is not

used.

By substituting the resistan ce of the load tool when

called for, a determination can be made as to whether an

inflator circuit component is causing system malfunction

and which component is causing the malfunction.

The load tool should be used only when specifically

called for in the diagnostic procedures.

1

2

3

I4RS0A820108-01

1. Connector for contact coil and driver air bag (inflator) module

(Located near the base of the steering column)

2. Connector for driver, passenger air bag (inflator) module, side-air bag (inflator) module and driver and passenger seat belt pretensioners

3. Not used

I1JA01820004-01

Page 1167 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9- i

9

Section 9

CONTENTS

Body, Cab and Accessories

Precautions ................................................. 9-1

Precautions............................................................. 9-1

Precautions on Body, Cab and Accessories ......... 9-1

Precautions for Body Service ................................ 9-1

Fastener Caution for Body Service ....................... 9-1

Wiring Systems............... ......................... 9A-1

Precautions........................................................... 9A-1

Cautions in Body Electrical System Servicing..... 9A-1

General Description ............................................. 9A-1 Abbreviations ...................................................... 9A-1

Wire / Connector Color Sy mbols ......................... 9A-1

Symbols and Marks ............................................ 9A-2

How to Read Connector Layout Diagram ........... 9A-4

How to Read Connector Codes and Terminal Nos.................................................................... 9A-5

How to Read Ground Point ................................. 9A-7

How to Read Power Supply Diagram.................. 9A-8

How to Read System Circuit Diagram................. 9A-8

Connector Layout Diagram . .............................. 9A-10

Connector Layout Diagram ............................... 9A-10

Engine Compartment .......... .............................. 9A-10

Instrument Panel ............................................... 9A-16

Door, Roof......................................................... 9A-20

Floor .................................................................. 9A-23

Rear .................................................................. 9A-29

Ground Point ...................................................... 9A-30 Ground (earth) Point ......................................... 9A-30

Power Supply Diagram ........ .............................. 9A-31

Power Supply Diagram ....... .............................. 9A-31

Fuses and the Protected Parts ......................... 9A-33

Fuses in Main Fuse Box (RHD) ........................ 9A-33

Fuses in Main Fuse Box (LHD) ......................... 9A-33

Individual Circuit Fuse Box No. 1 ...................... 9A-34

Individual Circuit Fuse Box No. 2 (In J/B) ......... 9A-35

Junction Block (J/B) Connector / Fuse Layout .. 9A-37

Junction Block Inner Circuit (Overview) ............ 9A-38

Junction Block Inner Circuit (Detail) .................. 9A-40

System Circuit Diagram... .................................. 9A-45

System Circuit Diagram .. .................................. 9A-45

A-1 Cranking System Circ uit Diagram .............. 9A-46

A-2 Charging System Circu it Diagram .............. 9A-47

A-3 Ignition System Circu it Diagram ................. 9A-48

A-4 Cooling System Circuit Diagram................. 9A-49 A-5 Engine and A/C Control System Circuit

Diagram........................................................... 9A-50

A-6 A/T Control System Circuit Diagram........... 9A-55

A-7 Immobilizer System Circuit Diagram .......... 9A-57

A-8 Body Control System Circuit Diagram ........ 9A-58

B-1 Windshield Wiper and Washer Circuit Diagram........................................................... 9A-62

B-2 Rear Wiper and Washer Circuit Diagram ... 9A-63

B-3 Rear Defogger Circuit Diagram .................. 9A-64

B-4 Power Window Circuit Diagram .................. 9A-65

B-5 Power Door Lock Circu it Diagram .............. 9A-67

B-6 Power Mirror Circuit Diagram ..................... 9A-69

B-7 Horn Circuit Diagram .................................. 9A-70

B-8 Seat Heater Circuit Diagram....................... 9A-71

B-9 Keyless Start System Circuit Diagram........ 9A-72

C-1 Combination Mete r Circuit Diagram

(Meter)............................................................. 9A-73

C-2 Combination Mete r Circuit Diagram

(Indicator) ........................................................ 9A-74

C-3 Combination Mete r Circuit Diagram

(Warning Light)................................................ 9A-75

D-1 Headlight System Circuit Diagram ............. 9A-77

D-2 Position, Tail and Licence Plate Light System Circuit Diagram .................................. 9A-79

D-3 Front Fog Light System Circuit Diagram .... 9A-80

D-4 Illumination Light System Circuit Diagram .. 9A-81

D-5 Interior Light System Circuit Diagram......... 9A-82

D-6 Turn Signal and Hazard Warning Light System Circuit Diagram .................................. 9A-83

D-7 Brake Light System Circuit Diagram .......... 9A-85

D-8 Back-Up Light System Circuit Diagram ...... 9A-86

D-9 Headlight Beam Leveling System Circuit Diagram........................................................... 9A-87

D-10 Rear Fog Light Circuit Diagram ................ 9A-88

E-1 Heater System Circuit Diagram .................. 9A-89

E-2 Auto A/C System Circuit Diagram .............. 9A-91

F-1 Air-Bag System Circuit Diagram ................. 9A-93

F-2 Anti-Lock Brake System Circuit Diagram.... 9A-95

F-3 Electronic Stab ility Program System

Circuit Diagram .................. ............................. 9A-97

F-4 Power Steering System Circuit Diagram .... 9A-99

G-1 Audio System Circuit Diagram ................. 9A-101

G-2 Multi Information Display / Accessory Socket System Circuit Diagram .................... 9A-102

List of Connector .............................................9A-103

Page 1187 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-16

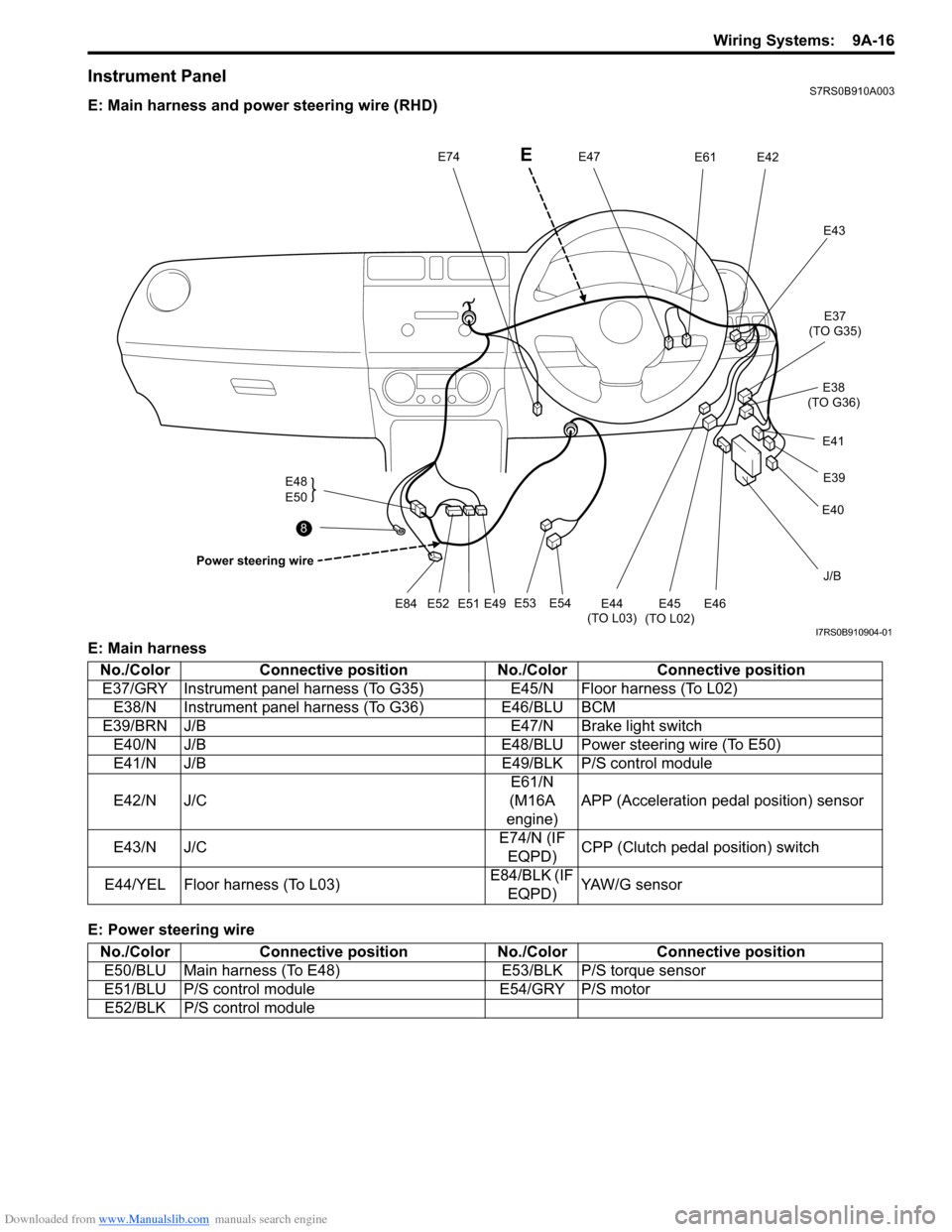

Instrument PanelS7RS0B910A003

E: Main harness and power steering wire (RHD)

E: Main harness

E: Power steering wire

J/B

E54

E53

E49

E51E52E84

E48

E50

Power steering wire

E47E74E42E61

E43

E45

(TO L02)

E44

(TO L03)E46

E40 E39

E41 E37

(TO G35)

E38

(TO G36)

8

E

I7RS0B910904-01

No./Color Connective position No./ColorConnective position

E37/GRY Instrument panel harness (To G35) E45/N Floor harness (To L02)

E38/N Instrument panel harness (To G36) E46/BLU BCM

E39/BRN J/B E47/N Brake light switch

E40/N J/B E48/BLU Power steering wire (To E50)

E41/N J/B E49/BLK P/S control module

E42/N J/C E61/N

(M16A

engine) APP (Acceleration pedal position) sensor

E43/N J/C E74/N (IF

EQPD) CPP (Clutch pedal position) switch

E44/YEL Floor harness (To L03) E84/BLK (IF

EQPD) YAW/G sensor

No./Color Connective position No./ColorConnective position

E50/BLU Main harness (To E48) E53/BLK P/S torque sensor

E51/BLU P/S control module E54/GRY P/S motor

E52/BLK P/S control module

Page 1188 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-17 Wiring Systems:

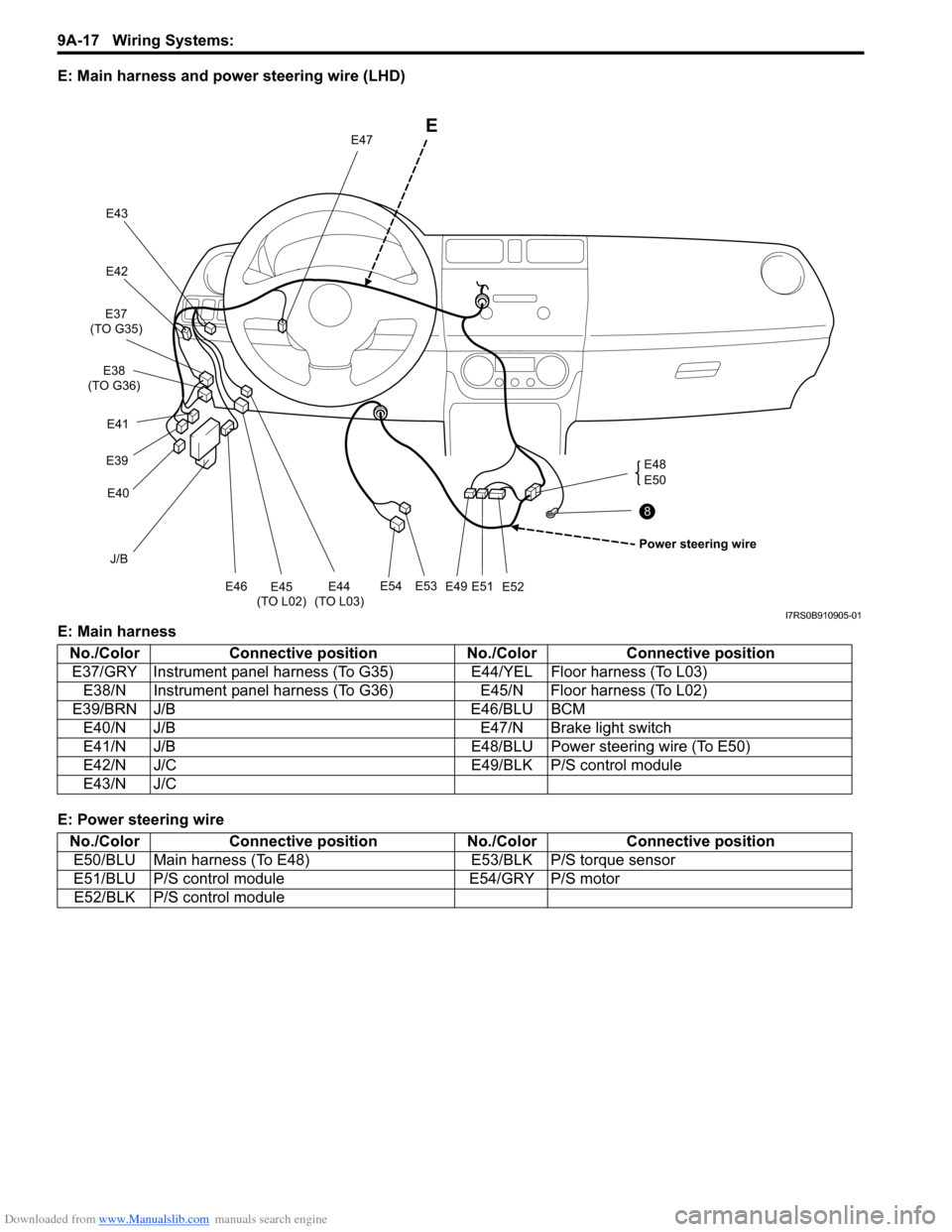

E: Main harness and power steering wire (LHD)

E: Main harness

E: Power steering wire

J/B

E54E53

E49E51E52 E48

E50

E

Power steering wire

E47

E43

E42

E45

(TO L02) E44

(TO L03)E46

E40

E39 E41

E37

(TO G35)

E38

(TO G36)

8

I7RS0B910905-01

No./Color Connective position No./ColorConnective position

E37/GRY Instrument panel harness (T o G35)E44/YEL Floor harness (To L03)

E38/N Instrument panel harness (To G36) E45/N Floor harness (To L02)

E39/BRN J/B E46/BLU BCM

E40/N J/B E47/N Brake light switch

E41/N J/B E48/BLU Power steering wire (To E50)

E42/N J/C E49/BLK P/S control module

E43/N J/C

No./Color Connective position No./ColorConnective position

E50/BLU Main harness (To E48) E53/BLK P/S torque sensor

E51/BLU P/S control module E54/GRY P/S motor

E52/BLK P/S control module

Page 1189 of 1496

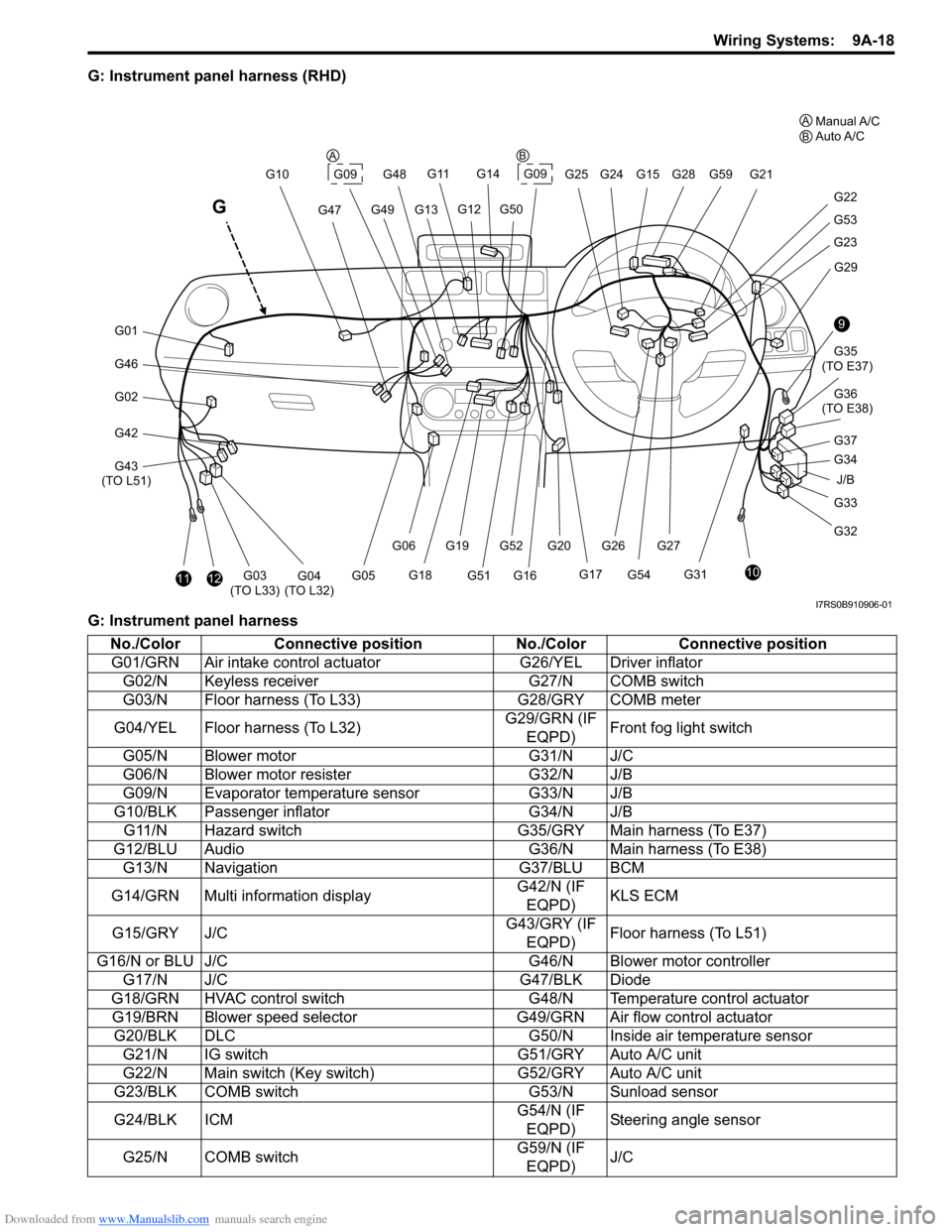

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-18

G: Instrument panel harness (RHD)

G: Instrument panel harness

J/B

9

10

G33

G32 G34 G35

(TO E37)

G36

(TO E38)

G31 G29

G23

G53

G22

G21

G28G59

G20G52G27

G54

G261112G03

(TO L33)G04

(TO L32)

G46

G01

G02

G42

G43

(TO L51) G10

G47

G11

G13G49

G14

G09G25 G24G15

G12G50

G48

G17

G16G51

G19

G18

G06

G05

G

G09

G37

A

BManual A/C

Auto A/C

AB

I7RS0B910906-01

No./Color Connective position No./ColorConnective position

G01/GRN Air intake control ac tuatorG26/YEL Driver inflator

G02/N Keyless receiver G27/N COMB switch

G03/N Floor harness (To L33) G28/GRY COMB meter

G04/YEL Floor harness (To L32) G29/GRN (IF

EQPD) Front fog light switch

G05/N Blower motor G31/N J/C

G06/N Blower motor resister G32/N J/B

G09/N Evaporator temperature sensor G33/N J/B

G10/BLK Passenger inflator G34/N J/B

G11/N Hazard switch G35/GRY Main harness (To E37)

G12/BLU Audio G36/N Main harness (To E38)

G13/N Navigation G37/BLU BCM

G14/GRN Multi information display G42/N (IF

EQPD) KLS ECM

G15/GRY J/C G43/GRY (IF

EQPD) Floor harness (To L51)

G16/N or BLU J/C G46/N Blower motor controller

G17/N J/C G47/BLK Diode

G18/GRN HVAC control switch G48/N Temperature control actuator

G19/BRN Blower speed selector G49/GRN Air flow control actuator

G20/BLK DLC G50/N Inside air temperature sensor

G21/N IG switch G51/GRY Auto A/C unit

G22/N Main switch (Key switch) G52/GRY Auto A/C unit

G23/BLK COMB switch G53/N Sunload sensor

G24/BLK ICM G54/N (IF

EQPD) Steering angle sensor

G25/N COMB switch G59/N (IF

EQPD) J/C

Page 1310 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-15 Instrumentation / Driver Info. / Horn:

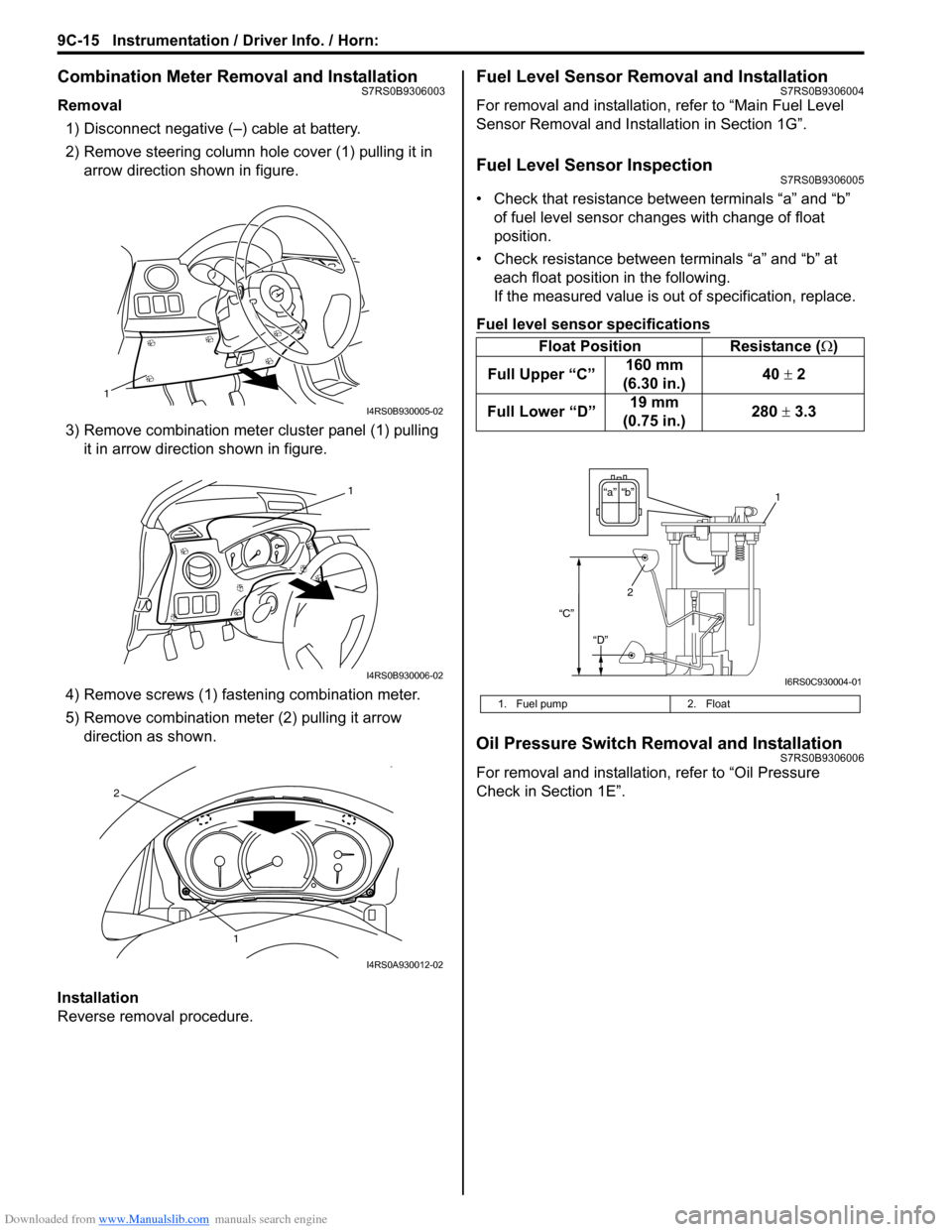

Combination Meter Removal and InstallationS7RS0B9306003

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover (1) pulling it in arrow direction shown in figure.

3) Remove combination mete r cluster panel (1) pulling

it in arrow direction shown in figure.

4) Remove screws (1) fast ening combination meter.

5) Remove combination me ter (2) pulling it arrow

direction as shown.

Installation

Reverse removal procedure.

Fuel Level Sensor Removal and InstallationS7RS0B9306004

For removal and installation, refer to “Main Fuel Level

Sensor Removal and Installation in Section 1G”.

Fuel Level Sensor InspectionS7RS0B9306005

• Check that resistance between terminals “a” and “b” of fuel level sensor changes with change of float

position.

• Check resistance between terminals “a” and “b” at each float position in the following.

If the measured value is out of specification, replace.

Fuel level sensor specifications

Oil Pressure Switch Removal and InstallationS7RS0B9306006

For removal and installation , refer to “Oil Pressure

Check in Section 1E”.

1

I4RS0B930005-02

1

I4RS0B930006-02

1

2

I4RS0A930012-02

Float Position Resistance (Ω)

Full Upper “C” 160 mm

(6.30 in.) 40

± 2

Full Lower “D” 19 mm

(0.75 in.) 280

± 3.3

1. Fuel pump 2. Float

“b”“a”

2

“C”

“D”

1

I6RS0C930004-01

Page 1313 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-18

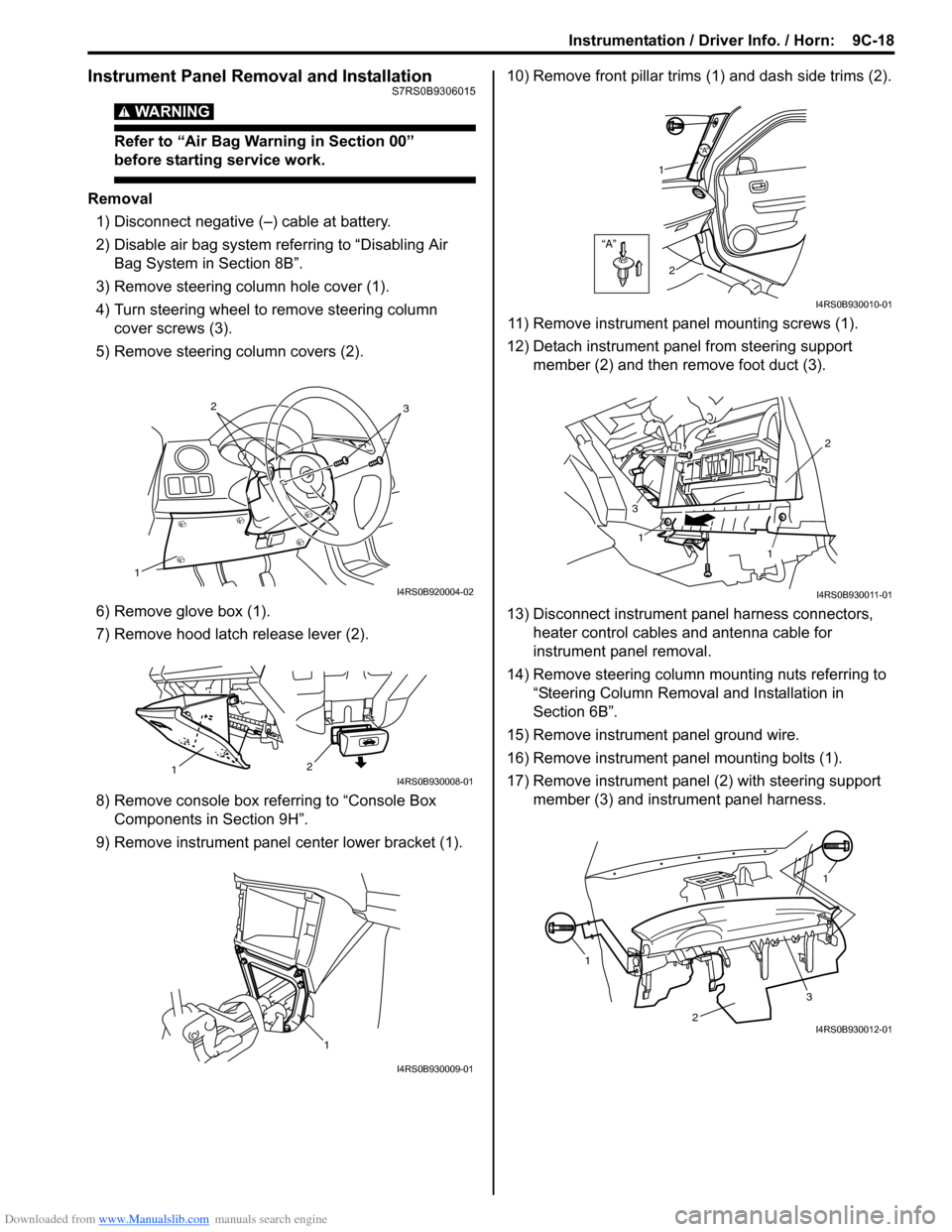

Instrument Panel Removal and InstallationS7RS0B9306015

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column hole cover (1).

4) Turn steering wheel to remove steering column cover screws (3).

5) Remove steering column covers (2).

6) Remove glove box (1).

7) Remove hood latch release lever (2).

8) Remove console box referring to “Console Box Components in Section 9H”.

9) Remove instrument panel center lower bracket (1). 10) Remove front pillar trims

(1) and dash side trims (2).

11) Remove instrument panel mounting screws (1).

12) Detach instrument panel from steering support member (2) and then remove foot duct (3).

13) Disconnect instrument panel harness connectors, heater control cables and antenna cable for

instrument panel removal.

14) Remove steering column mounting nuts referring to “Steering Column Remova l and Installation in

Section 6B”.

15) Remove instrument panel ground wire.

16) Remove instrument panel mounting bolts (1).

17) Remove instrument panel (2) with steering support member (3) and instrument panel harness.

1

32

I4RS0B920004-02

2

1I4RS0B930008-01

1

I4RS0B930009-01

“A”

“A”

1

2

I4RS0B930010-01

1

1 2

3

I4RS0B930011-01

1 1

2

3I4RS0B930012-01

Page 1314 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-19 Instrumentation / Driver Info. / Horn:

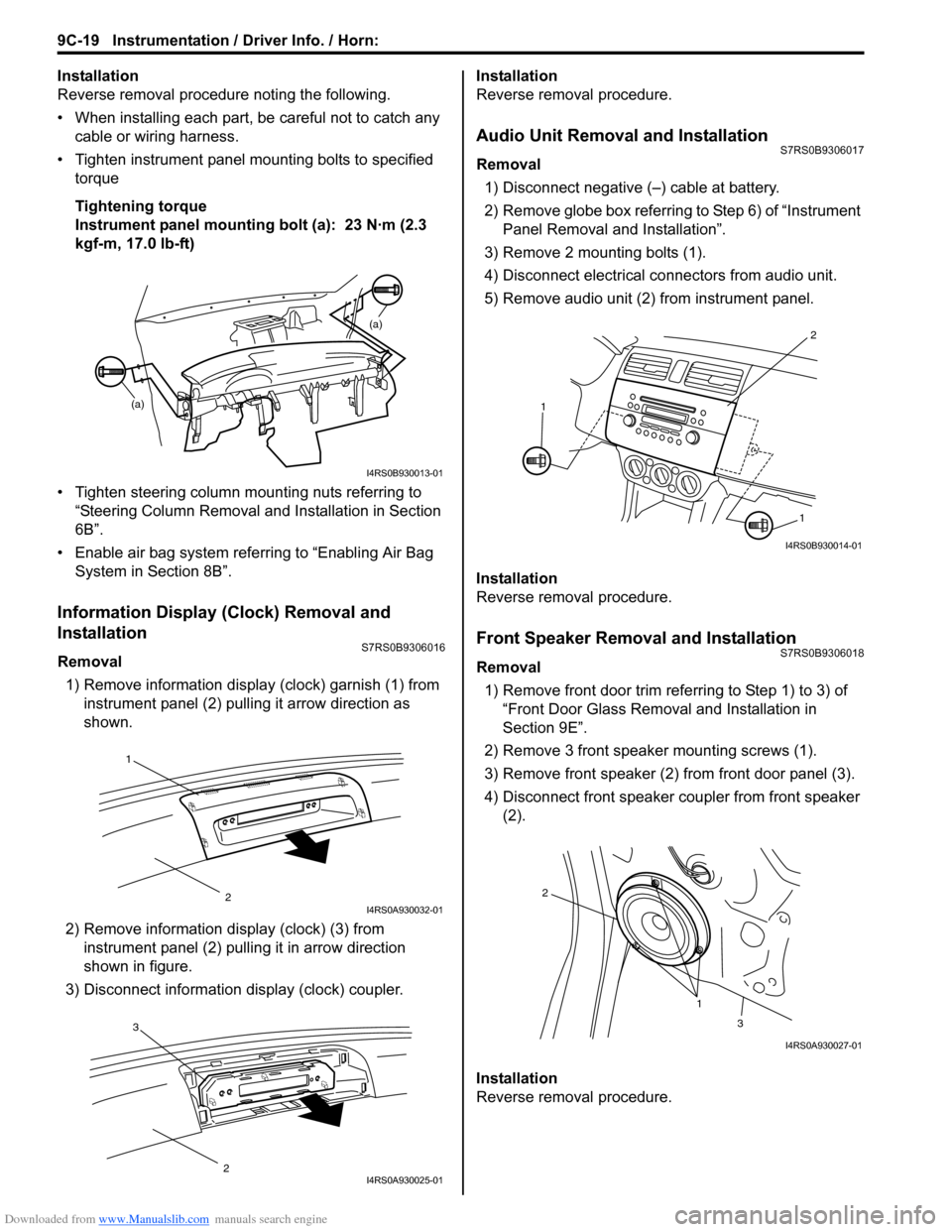

Installation

Reverse removal procedure noting the following.

• When installing each part, be careful not to catch any

cable or wiring harness.

• Tighten instrument panel mounting bolts to specified

torque

Tightening torque

Instrument panel mounting bolt (a): 23 N·m (2.3

kgf-m, 17.0 lb-ft)

• Tighten steering column mounting nuts referring to “Steering Column Removal an d Installation in Section

6B”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Information Display (Clock) Removal and

Installation

S7RS0B9306016

Removal

1) Remove information display (clock) garnish (1) from instrument panel (2) pulling it arrow direction as

shown.

2) Remove information di splay (clock) (3) from

instrument panel (2) pulli ng it in arrow direction

shown in figure.

3) Disconnect information display (clock) coupler. Installation

Reverse removal procedure.

Audio Unit Removal and InstallationS7RS0B9306017

Removal

1) Disconnect negative (–) cable at battery.

2) Remove globe box referring to Step 6) of “Instrument Panel Removal and Installation”.

3) Remove 2 mounting bolts (1).

4) Disconnect electrical connectors from audio unit.

5) Remove audio unit (2) from instrument panel.

Installation

Reverse removal procedure.

Front Speaker Removal and InstallationS7RS0B9306018

Removal 1) Remove front door trim refe rring to Step 1) to 3) of

“Front Door Glass Remo val and Installation in

Section 9E”.

2) Remove 3 front speaker mounting screws (1).

3) Remove front speaker (2) from front door panel (3).

4) Disconnect front speaker coupler from front speaker (2).

Installation

Reverse removal procedure.

(a) (a)

I4RS0B930013-01

1

2I4RS0A930032-01

3

2I4RS0A930025-01

2

1

1

I4RS0B930014-01

1

2

3

I4RS0A930027-01

Page 1344 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-17 Glass / Windows / Mirrors:

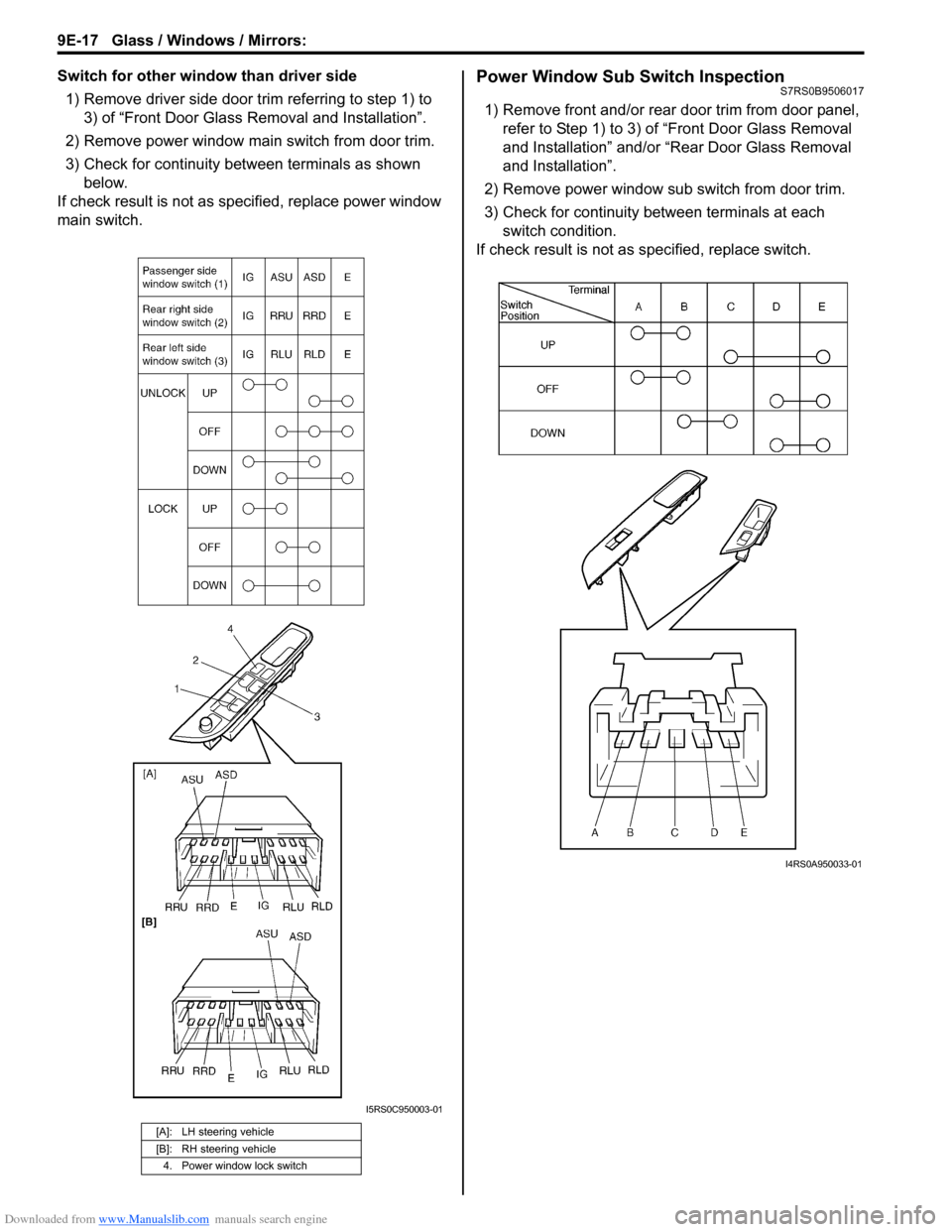

Switch for other window than driver side1) Remove driver side door trim referring to step 1) to 3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Check for continuity between terminals as shown below.

If check result is not as sp ecified, replace power window

main switch.Power Window Sub Switch InspectionS7RS0B9506017

1) Remove front and/or rear door trim from door panel, refer to Step 1) to 3) of “Front Door Glass Removal

and Installation” and/or “Rear Door Glass Removal

and Installation”.

2) Remove power window sub switch from door trim.

3) Check for continuity between terminals at each switch condition.

If check result is not as specified, replace switch.

[A]: LH steering vehicle

[B]: RH steering vehicle

4. Power window lock switch

I5RS0C950003-01

I4RS0A950033-01