body harness SUZUKI SWIFT 2007 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 217 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-167

4ECM voltage check

1) Disconnect connector from APP sensor with ignition

switch turned OFF.

2) Check for proper connection to APP sensor at “RED”, “YEL” and “WHT” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of APP sensor connector and vehicle body ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6. Go to Step 5.

5 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 34” terminal.

3) If OK, measure voltage between “E23-34” terminal of ECM connector and engine ground with ignition switch

turned ON.

Is voltage 0 V? Substitute a known-

good ECM and recheck.

“RED” wire is shorted to

power circuit.

6 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 35”, “E23-36” and “E23-34” terminals.

3) If OK, measure resistance between “YEL” wire terminal and each “BRN”, “RED” wire terminals of APP sensor

connector.

Is each resistance infinity? Go to Step 7. “YEL” wire is shorted to

“BRN” wire and/or

“RED” wire.

7 Wire harness check

1) Turn ON ignition switch.

2) Measure voltage between “E23-36” terminal of ECM

connector and engine ground.

Is voltage 0 V? Go to Step 8. “YEL” wire is shorted to

power circuit.

8 Ground circuit check

1) Connect connectors to ECM with ignition switch turned

OFF.

2) Measure resistance between “WHT” wire terminal of APP sensor connector and vehicle body ground.

Is resistance below 5

Ω? Go to Step 10. Go to Step 9.

Step Action Yes No

"GRN"

"BLU"

"BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 220 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-170 Engine General Information and Diagnosis:

4Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “C37-43” terminal of ECM connector and engine ground.

Is resistance infinity? Go to Step 5. “RED” wire is shorted to

other circuit.

5 Wire harness check

1) Measure voltage between “C37-43” terminal of ECM

connector and engine ground with ignition switch turned

ON.

Is voltage 0 V? Substitute a known-

good ECM and recheck.

“RED” wire is shorted to

other circuit.

6 Wire harness check

1) Measure voltage between “GRN” wire terminal of electric

throttle body connector and engine ground, between

“WHT” wire terminal of electric throttle body connector

and engine ground with ignition switch turned ON.

Is each voltage 4 – 6 V? Go to Step 9. Go to Step 7.

7 Wire harness check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

3) Check for proper connection of ECM connector at “C37-

54” and “C37-40” terminals.

4) If OK, measure voltage between “C37-54” terminal of ECM connector and engine ground, between “C37-40”

terminal of ECM connector and engine ground.

Is each voltage 0 V? Go to Step 8. “GRN” wire or “WHT”

wire is shorted to other

circuit.

8 Wire harness check

1) Measure resistance between “GRN” wire terminal of

electric throttle body connector and engine ground,

between “WHT” wire terminal of electric throttle body

connector and engine ground with ignition switch turned

OFF.

Is each resistance infinity? Substitute a known-

good ECM and recheck.

“GRN” wire or “WHT”

wire is shorted to other

circuit.

9 Electric throttle body check

1) Check TP sensor referring to “Throttle Position Sensor

Performance Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is each output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

Step Action Yes No

Page 222 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-172 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 APP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check each voltage of “APP Sensor 1 Volt” and “APP Sensor 2 Volt” displayed on scan tool when accelerator

pedal is idle position and fully depressed.

Is displayed each APP sensor value as described voltage in

“Scan Tool Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

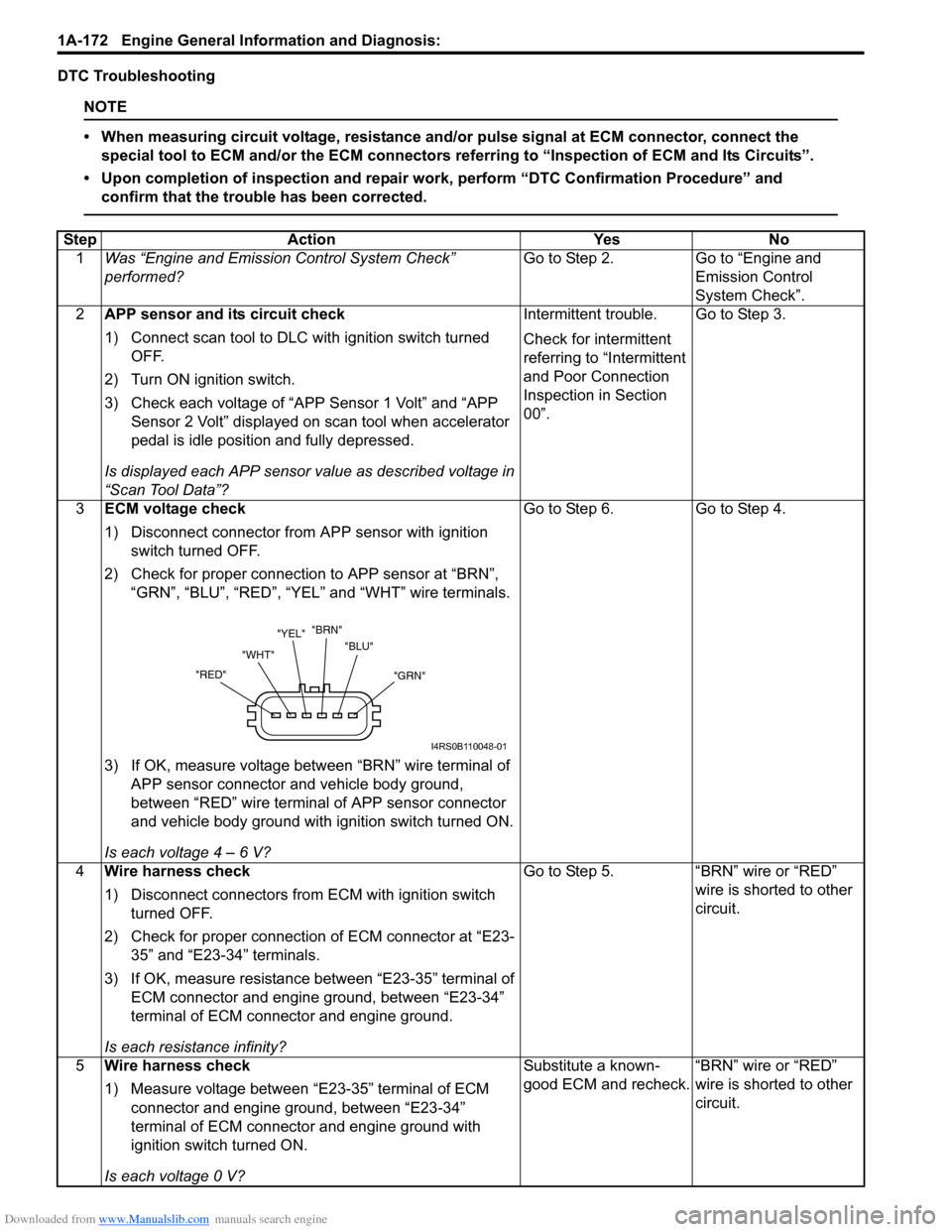

3 ECM voltage check

1) Disconnect connector from APP sensor with ignition

switch turned OFF.

2) Check for proper connection to APP sensor at “BRN”, “GRN”, “BLU”, “RED”, “YEL” and “WHT” wire terminals.

3) If OK, measure voltage between “BRN” wire terminal of APP sensor connector and vehicle body ground,

between “RED” wire terminal of APP sensor connector

and vehicle body ground with ignition switch turned ON.

Is each voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

4 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 35” and “E23-34” terminals.

3) If OK, measure resistance between “E23-35” terminal of ECM connector and engine ground, between “E23-34”

terminal of ECM connector and engine ground.

Is each resistance infinity? Go to Step 5.

“BRN” wire or “RED”

wire is shorted to other

circuit.

5 Wire harness check

1) Measure voltage between “E23-35” terminal of ECM

connector and engine ground, between “E23-34”

terminal of ECM connector and engine ground with

ignition switch turned ON.

Is each voltage 0 V? Substitute a known-

good ECM and recheck.

“BRN” wire or “RED”

wire is shorted to other

circuit.

"GRN"

"BLU"

"BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 223 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-173

DTC P2227 / P2228 / P2229: Barometric Pressure Circuit MalfunctionS7RS0B1104078

DTC P2227: Barometric Pressure Circuit Range / Performance

DTC P2228: Barometric Pressure Circuit Low

DTC P2229: Barometric Pressure Circuit High

System Description

Barometric pressure sensor is installed in ECM.

DTC Detecting Condition and Trouble Area6

Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 37”, “E23-52”, “E23-36” and “E23-51” terminals.

3) If OK, measure resistance between “GRN” wire terminal of APP sensor connector and vehicle body ground,

between “YEL” wire terminal of APP sensor connector

and vehicle body ground.

Is each resistance infinity? Go to Step 7. “GRN” wire or “YEL”

wire is shorted to other

circuit.

7 Wire harness check

1) Turn ON ignition switch.

2) Measure voltage between “E23-37” terminal of ECM

connector and engine ground, between “E23-36”

terminal of ECM connector and engine ground.

Is each voltage 0 V? Go to Step 8. “GRN” wire or “YEL”

wire is shorted to other

circuit.

8 APP sensor check

1) Check APP sensor referring to “APP Sensor Assembly

Inspection in Section 1C”.

Is output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace APP sensor

assembly.

Step Action Yes No

DTC detecting condition

Trouble area

DTC P2227:

Difference of barometric pressure value and intake manifold

pressure value is higher than specified value while engine

cranking.

(*2 driving cycle detection logic, monitoring once par driving cycle) • Manifold absolute pressure sensor

performance problem

• Barometric pressure sensor in ECM

DTC P2228:

Barometric pressure signal less than specified value is detected.

(1 driving cycle detection logic) • Barometric pressure sensor in ECM

DTC P2229:

Barometric pressure signal more than specified value is detected.

(1 driving cycle detection logic)

Page 302 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-17 Engine Mechanical:

Engine Assembly Removal and InstallationS7RS0B1406011

NOTE

After replacing electric throttle body

assembly, perform calibration of throttle

valve referring to “Electric Throttle Body

System Calibration in Section 1C”.

Removal1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure in Section 1G”.

2) Disconnect negative and pos itive cable at battery.

3) Remove battery and tray.

4) Remove engine hood after disconnecting windshield washer hose.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to “Compressor Drive Belt Remo val and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil, transaxle oil and coolant.

8) Remove cowl top plate referring to “Cowl Top Components in Section 9K”.

9) Remove air cleaner assembly referring to “Air Cleaner Components”.

10) With hose connected, detach A/C compressor from its bracket (A/C model) referring to “Compressor

Assembly Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

11) Remove intake manifold rear stiffener (1) from intake manifold and cylinder block. 12) Disconnect the following electric wires:

• MAP sensor (1)

• ECT sensor (2)

•EGR valve (3)

• CMP sensor (4)

• Electric throttle body assembly (5)

• Ignition coil assembly (6)

• Injectors (7)

• Heated oxygen sensor No. 2 (8) and No. 1 (9)

• Oil control valve (10)

• Engine oil pressure switch (11)

• CKP sensor (12)

• Knock sensor (13)

• Back up light switch (14)

• Generator (15)

• Starting motor (16)

• Ground terminal (17) from intake manifold

• Battery ground terminal (18) from exhaust manifold

• Battery ground cable (19) from transaxle

• Magnet clutch switch of A/C compressor (A/C model)

• Each wire harness clamps

• Output shaft speed sensor (VSS) (34) (A/T model)

• Solenoid valve (33) (A/T model)

• Transmission range sensor (32) (A/T model)

• Input shaft speed sensor (31) (A/T model)

13) Remove fuse box from its bracket.

14) Disconnect the following cables: • Gear select control cable (23) (M/T model)

• Gear shift control cable (24) (M/T model)

• A/T select cable (A/T model)

15) Disconnect the following hoses: • Brake booster hose (26) from intake manifold

• Radiator inlet and outlet hoses (20) from each pipe

• Heater inlet and outlet hoses (21) from each pipe

• Fuel feed hoses (22) from fuel feed pipe

• EVAP canister purge valve hose (30) from purge pipe

• A/T fluid cooler hoses (A/T model)

16) With hose connected, detach clutch operating cylinder (25). (M/T model)

CAUTION!

Suspend removed clutch operating cylinder

at a place where no damage will be caused

during removal and installation of engine

assembly.

1

I6RS0B141014-01

Page 597 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-23

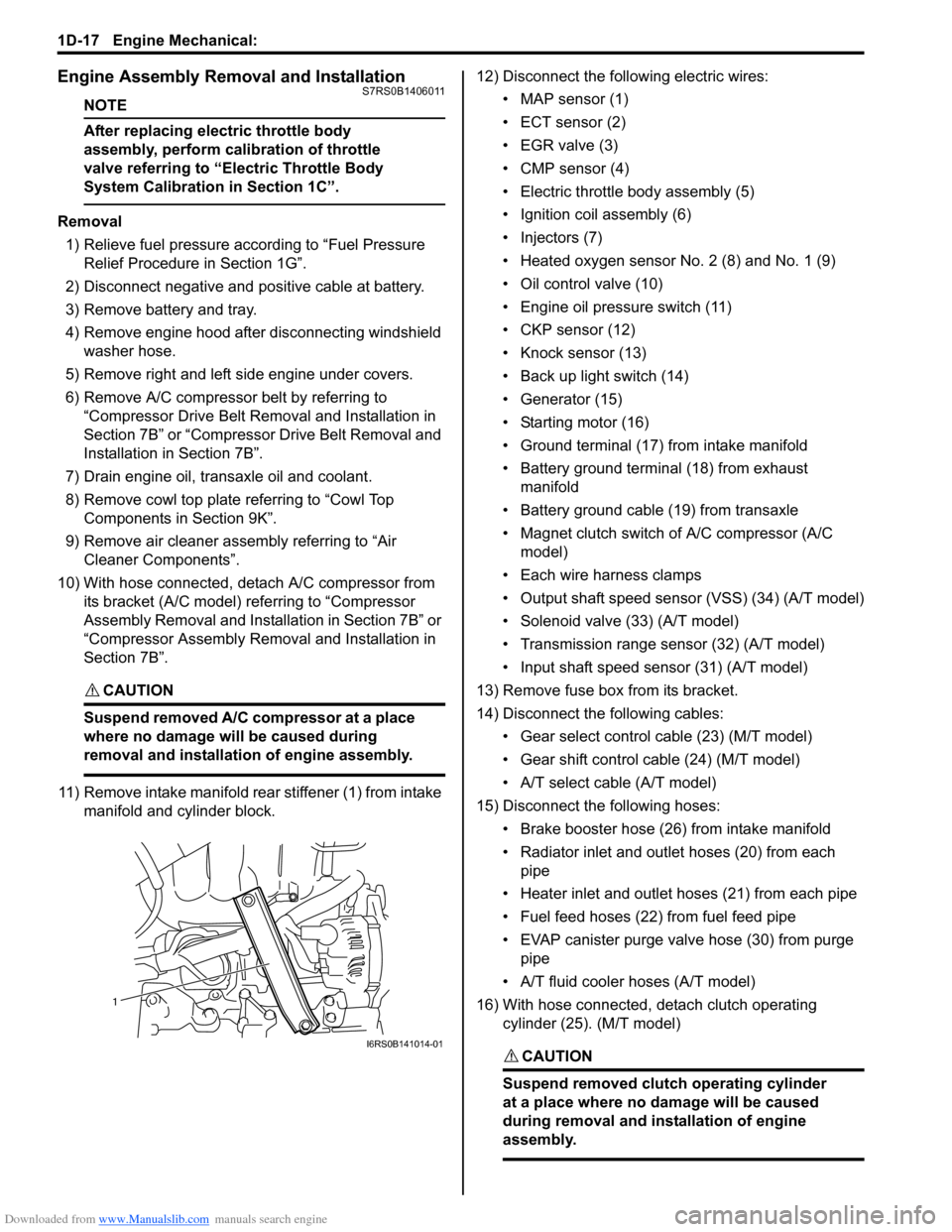

ABS Warning Lamp Does Not Come ON at Ignition Switch ONS7RS0B4604048

Wiring Diagram4

Check ESP ® control module power supply circuit

1) Turn ignition switch to OFF position.

2) Check for proper connection to ESP ® control module

connector at terminals “E85-1” and “E85-32”.

3) If OK, then turn ignition switch to ON position and measure voltage between each terminal of “E85-1”,

“E85-32” and vehicle body ground.

Are they 10 – 14 V? Go to Step 5. “WHT/BLU” and/or

“WHT/RED” circuit

open.

5 Check ESP ® control module ground circuit

1) Turn ignition switch to OFF and measure resistance between each terminal of “E85-16”, “E85-47” and vehicle

body ground.

Is resistance less than 2

Ω? Go to Step 6.

Ground circuit for ESP®

control module open or

high resistance.

6 CAN communication circuit check

1) Check CAN communication circuit between combination

meter and ESP ® control module referring to “DTC

U1073: Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Substitute a known-

good combination meter

and recheck. If warning

lamp remains ON,

substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Repair or replace.

Step

Action YesNo

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

WHTGRN

3

E85-13

E85-44REDWHT6 5E46-1E46-2

4 10

6

E85-16

E85-47BLKBLK

8

9

BLK/ORN

REDWHT

REDWHT

G37-4G37-2

G28-10G28-8

G28-16

12V

12VE85-32E85-1

E85-35

WHT/REDWHT/BLU

GRN/ORN

6

2

1

7 1112[B]

G37

E46124

53

67

891011121314124

53

67

891011

1213141516171819202122

[C] G28

12345678910111213141516

17181920212223242526272829303132

G28-31

RED/BLK

I6RS0B460010-01

[A]: ESP ® control module connector (viewed

from terminal side) 3. Ignition switch 8. ABS warning lamp

[B]: BCM connector (viewed from harness side) 4. Junction block assembly 9. Lamp driver module

[C]: Combination meter connector (viewed from harness side) 5. BCM (included in junction block

assembly) 10. ESP

® hydraulic unit / control module

assembly

1. Battery 6. CAN driver11. Junction connector

2. Main fuse box 7. Combination meter12. To steering angle sensor

Page 600 of 1496

![SUZUKI SWIFT 2007 2.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 4F-26 Electronic Stability Program:

Serial Data Link Circuit CheckS7RS0B4604012

Wiring Diagram

Inspection

[A]E85

161

15

2

3

4

5

6

7

8

9

10

11

SUZUKI SWIFT 2007 2.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 4F-26 Electronic Stability Program:

Serial Data Link Circuit CheckS7RS0B4604012

Wiring Diagram

Inspection

[A]E85

161

15

2

3

4

5

6

7

8

9

10

11](/img/20/7607/w960_7607-599.png)

Downloaded from www.Manualslib.com manuals search engine 4F-26 Electronic Stability Program:

Serial Data Link Circuit CheckS7RS0B4604012

Wiring Diagram

Inspection

[A]E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47WHTGRN

3

E85-13REDWHT6 5E46-1E46-2

4

10

6

E85-16

E85-47BLKBLK

8

9

BLK/ORN

REDWHT

REDWHT

G37-4G37-2

G28-10G28-8

G28-16

G28-31

12V

12VE85-32E85-1

E85-35

WHT/REDWHT/BLU

GRN/ORN

6

2

1

7 1415 [B]

G37

E46

124

53

67

891011121314124

53

67

891011

1213141516171819202122

[C] G28

12345678910111213141516

17181920212223242526272829303132

12V

11

PPL/WHT

PPL/WHT

E85-33

E85-44

12

13

WHTWHT/REDB

G G1

RED/BLK

I6RS0B460012-01

[A]: ESP

® control module connector (viewed

from terminal side) 4. Junction block assembly 10. ESP

® hydraulic unit / control module assembly

[B]: BCM connector (viewed from harness side) 5. BCM (included in junction block

assembly) 11. Data link connector (DLC)

[C]: Combination meter connector (viewed from harness side) 6. CAN driver 12. To SDM

1. Battery 7. Combination meter 13. To ECM and P/S control module

2. Main fuse box 8. ESP ® warning lamp 14. Junction connector

3. Ignition switch 9. Lamp driver module 15. To steering angle sensor

Step Action YesNo

1 Check ESP ® warning lamp

1) Turn ignition switch to ON position.

Does ESP

® warning lamp come ON? Go to Step 2. Go to Step 6.

2 Check fuse

1) Turn ignition switch to OFF position.

Are main fuses for good condition? Go to Step 3. Replace fuse and check

for short.

3 Check ESP ® control module power supply circuit

1) Disconnect ESP ® control module connector.

2) Check for proper connection to ESP ® control module

connector at terminal “E85-35”.

3) If OK, then turn ignition switch to ON position and measure voltage between terminal “E85-35” and vehicle

body ground.

Is it 10 – 14 V? Go to Step 4.

“GRN/ORN” wire circuit

open.

Page 605 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-31

DTC Troubleshooting

DTC 1020: Master Cylinder Pressure Sensor Power Supply FailureS7RS0B4604028

DTC Detecting Condition and Trouble Area

DTC Troubleshooting1) Turn ignition switch to OFF position.

2) Check for proper connection from harness to ESP ® control module.

3) If OK, substitute an ESP ® hydraulic unit / control module assembly with correct part number.

4) Recheck system.

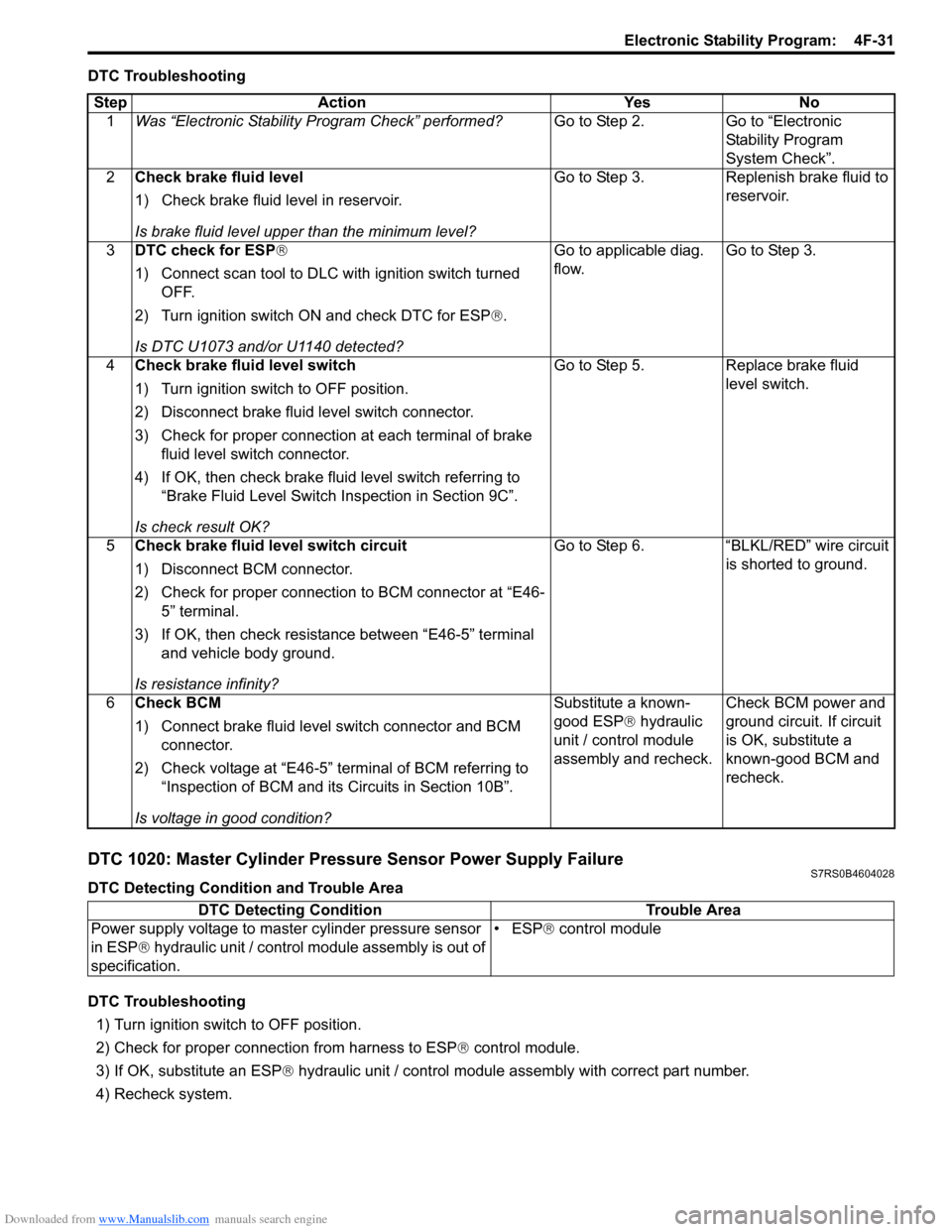

Step Action Yes No

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 Check brake fluid level

1) Check brake fluid level in reservoir.

Is brake fluid level upper than the minimum level? Go to Step 3. Replenish brake fluid to

reservoir.

3 DTC check for ESP®

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC for ESP ®.

Is DTC U1073 and/or U1140 detected? Go to applicable diag.

flow.

Go to Step 3.

4 Check brake fluid level switch

1) Turn ignition switch to OFF position.

2) Disconnect brake fluid level switch connector.

3) Check for proper connection at each terminal of brake

fluid level switch connector.

4) If OK, then check brake fluid level switch referring to “Brake Fluid Level Switch Inspection in Section 9C”.

Is check result OK? Go to Step 5. Replace brake fluid

level switch.

5 Check brake fluid level switch circuit

1) Disconnect BCM connector.

2) Check for proper connection to BCM connector at “E46-

5” terminal.

3) If OK, then check resistance between “E46-5” terminal and vehicle body ground.

Is resistance infinity? Go to Step 6. “BLKL/RED” wire circuit

is shorted to ground.

6 Check BCM

1) Connect brake fluid level switch connector and BCM

connector.

2) Check voltage at “E46-5” terminal of BCM referring to “Inspection of BCM and its Circuits in Section 10B”.

Is voltage in good condition? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Check BCM power and

ground circuit. If circuit

is OK, substitute a

known-good BCM and

recheck.

DTC Detecting Condition

Trouble Area

Power supply voltage to master cylinder pressure sensor

in ESP® hydraulic unit / control mo dule assembly is out of

specification. • ESP

® control module

Page 607 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-33

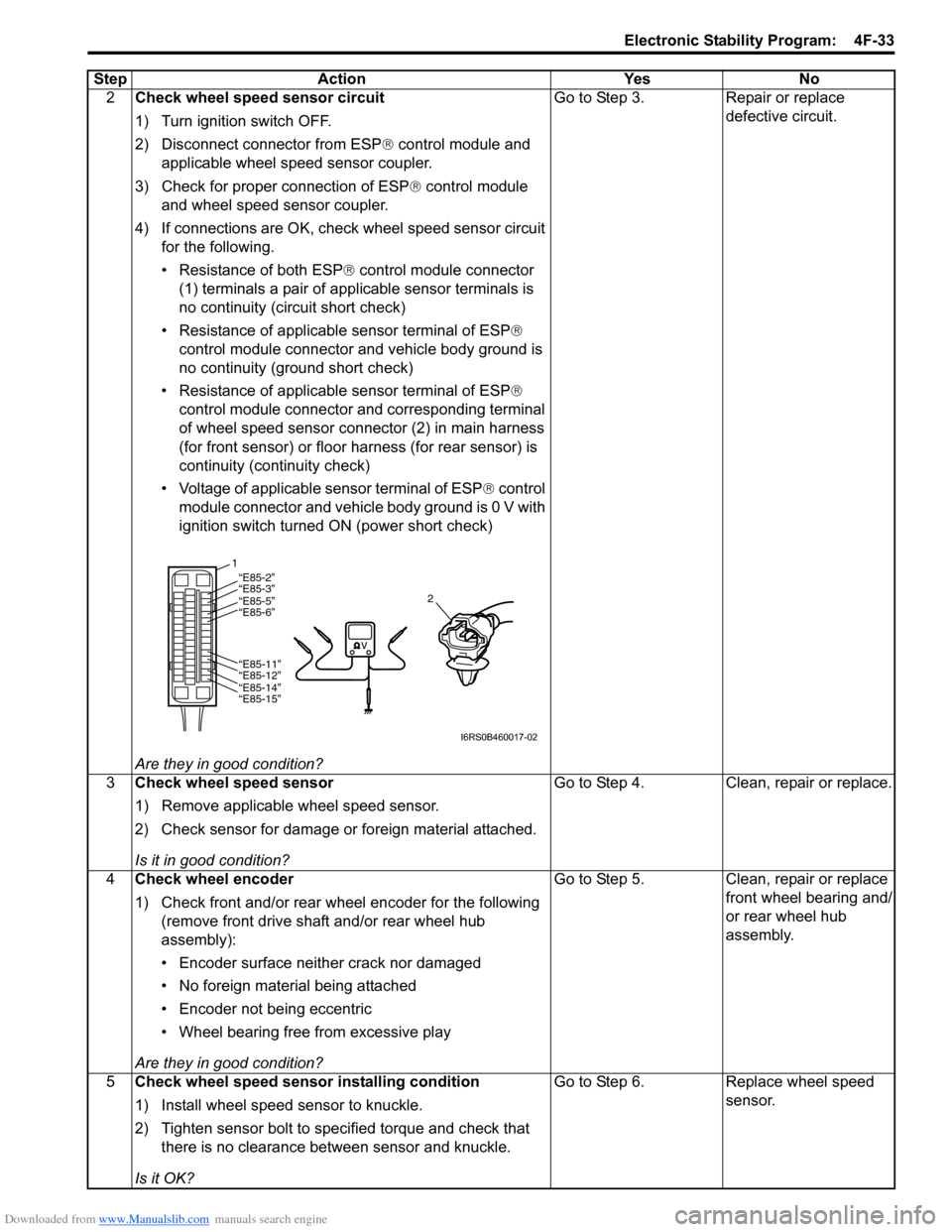

2Check wheel speed sensor circuit

1) Turn ignition switch OFF.

2) Disconnect connector from ESP ® control module and

applicable wheel speed sensor coupler.

3) Check for proper connection of ESP ® control module

and wheel speed sensor coupler.

4) If connections are OK, che ck wheel speed sensor circuit

for the following.

• Resistance of both ESP ® control module connector

(1) terminals a pair of app licable sensor terminals is

no continuity (circuit short check)

• Resistance of applicable sensor terminal of ESP ®

control module connector and vehicle body ground is

no continuity (ground short check)

• Resistance of applicable sensor terminal of ESP ®

control module connector and corresponding terminal

of wheel speed sensor connector (2) in main harness

(for front sensor) or floor harness (for rear sensor) is

continuity (continuity check)

• Voltage of applicable sensor terminal of ESP ® control

module connector and vehicle body ground is 0 V with

ignition switch turned ON (power short check)

Are they in good condition? Go to Step 3. Repair or replace

defective circuit.

3 Check wheel speed sensor

1) Remove applicable wheel speed sensor.

2) Check sensor for damage or foreign material attached.

Is it in good condition? Go to Step 4. Clean, repair or replace.

4 Check wheel encoder

1) Check front and/or rear wheel encoder for the following

(remove front drive shaft and/or rear wheel hub

assembly):

• Encoder surface neither crack nor damaged

• No foreign material being attached

• Encoder not being eccentric

• Wheel bearing free from excessive play

Are they in good condition? Go to Step 5. Clean, repair or replace

front wheel bearing and/

or rear wheel hub

assembly.

5 Check wheel speed sensor installing condition

1) Install wheel speed sensor to knuckle.

2) Tighten sensor bolt to specified torque and check that

there is no clearance between sensor and knuckle.

Is it OK? Go to Step 6. Replace wheel speed

sensor.

Step Action Yes No

1

2“E85-2”“E85-3”“E85-5”

“E85-6”

“E85-11”

“E85-12”

“E85-14”

“E85-15”

I6RS0B460017-02

Page 610 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-36 Electronic Stability Program:

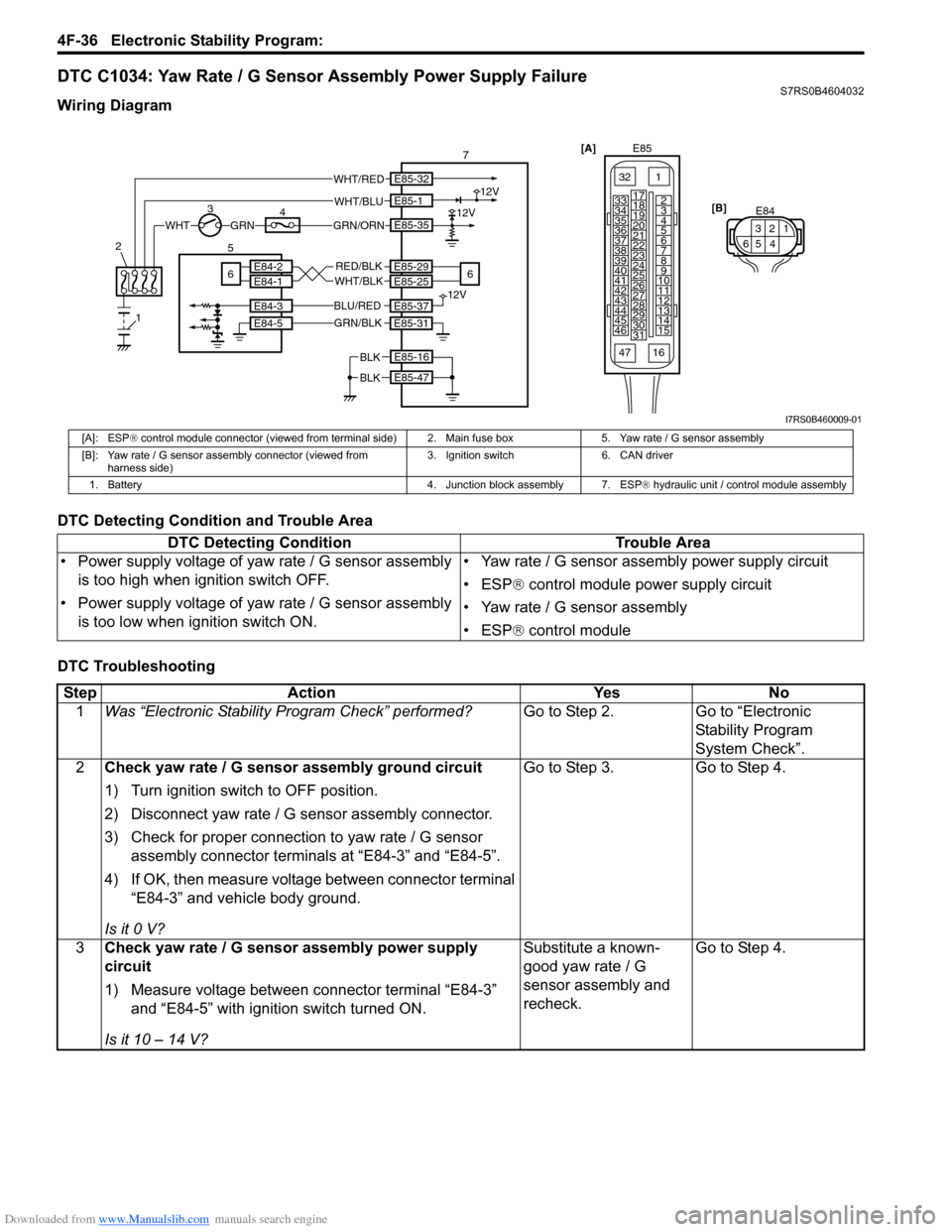

DTC C1034: Yaw Rate / G Sensor Assembly Power Supply FailureS7RS0B4604032

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

[A]E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47 [B]

E84

3

521

46

1

E85-16

E85-47

12V

12VE85-32

E85-1

E85-35GRNWHT

WHT/RED

WHT/BLU

E85-29E85-25

E85-37

E85-31

E84-3

E84-5

RED/BLK

BLK

BLK

WHT/BLKE84-2E84-1 12V

GRN/BLK

BLU/RED

23

5

6 4

7

6

GRN/ORN

I7RS0B460009-01

[A]: ESP ® control module connector (viewed from terminal side ) 2. Main fuse box 5. Yaw rate / G sensor assembly

[B]: Yaw rate / G sensor assembly connector (viewed from harness side) 3. Ignition switch 6. CAN driver

1. Battery 4. Junction block assembly 7. ESP ® hydraulic unit / control module assembly

DTC Detecting Condition Trouble Area

• Power supply voltage of yaw rate / G sensor assembly is too high when ignition switch OFF.

• Power supply voltage of yaw rate / G sensor assembly is too low when ignition switch ON. • Yaw rate / G sensor assembly power supply circuit

• ESP

® control module power supply circuit

• Yaw rate / G sensor assembly

• ESP ® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 Check yaw rate / G sensor assembly ground circuit

1) Turn ignition switch to OFF position.

2) Disconnect yaw rate / G se nsor assembly connector.

3) Check for proper connection to yaw rate / G sensor assembly connector terminals at “E84-3” and “E84-5”.

4) If OK, then measure voltage between connector terminal “E84-3” and vehicle body ground.

Is it 0 V? Go to Step 3.

Go to Step 4.

3 Check yaw rate / G sensor assembly power supply

circuit

1) Measure voltage between connector terminal “E84-3”

and “E84-5” with ignition switch turned ON.

Is it 10 – 14 V? Substitute a known-

good yaw rate / G

sensor assembly and

recheck.

Go to Step 4.