Cam SUZUKI SWIFT 2007 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 353 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-1

Engine

Engine Lubrication System

General Description

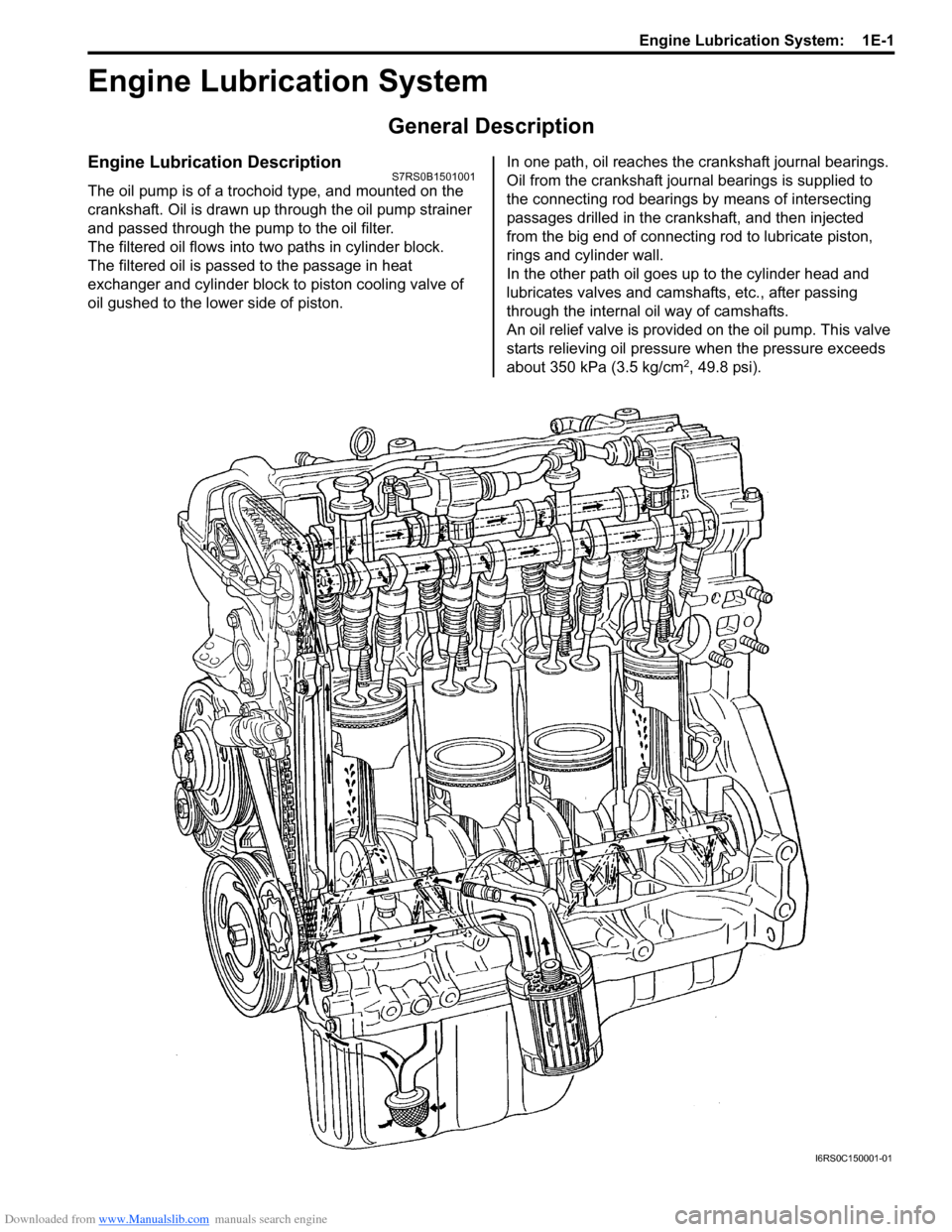

Engine Lubrication DescriptionS7RS0B1501001

The oil pump is of a trochoid type, and mounted on the

crankshaft. Oil is drawn up through the oil pump strainer

and passed through the pump to the oil filter.

The filtered oil flows into two paths in cylinder block.

The filtered oil is passed to the passage in heat

exchanger and cylinder block to piston cooling valve of

oil gushed to the lower side of piston. In one path, oil reaches the crankshaft journal bearings.

Oil from the crankshaft journal bearings is supplied to

the connecting rod bearings by means of intersecting

passages drilled in the cran

kshaft, and then injected

from the big end of connecting rod to lubricate piston,

rings and cylinder wall.

In the other path oil goes up to the cylinder head and

lubricates valves and camshafts, etc., after passing

through the internal oil way of camshafts.

An oil relief valve is provided on the oil pump. This valve

starts relieving oil pressure when the pressure exceeds

about 350 kPa (3.5 kg/cm

2, 49.8 psi).

I6RS0C150001-01

Page 393 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-1

Engine

Ignition System

General Description

Ignition System ConstructionS7RS0B1801001

The ignition system is an electronic (distributorless) ignition system. It consists of the parts as described below.

• ECM

It detects the engine and vehicle conditions through the si gnals from the sensors, determines the most suitable

ignition timing and time for electricity to flow to the primar y coil and sends a signal to the ignitor (power unit) in the

ignition coil assembly.

• Ignition coil assembly (including an ignitor)

The ignition coil assembly has a built -in ignitor which turns ON and OFF the current flow to the primary coil

according to the signal from ECM. When the current flow to the primary coil is turned OFF, a high voltage is induced

in the secondary coil.

• High-tension cords and spark plugs

• CMP sensor (Camshaft position sensor) and CKP sensor (Crankshaft position sensor)

Using signals from these sensors, ECM identifies the specific cylinder whose piston is in the compression stroke,

detects the crank angle and adjusts in itial ignition timing automatically.

• TP sensor, ECT sensor, MAP sensor, MAF sensor, IAT sensor, knock sensor and other sensors / switches

Although this ignition system does not have a distributor, it has two ignition coil assemblies (one is for No.1 and No.4

spark plugs and the other is for No.2 and No.3 spark plugs). W hen an ignition signal is sent from ECM to the ignitor in

the ignition coil assembly for No.1 and No.4 spark plugs, a high voltage is induced in the secondary coil and that

passes through the high-tension cords and causes No.1 and No.4 spark plugs to spark simultaneously. Likewise,

when an ignition signal is sent to the ignitor in the ot her ignition coil assembly, No.2 and No.3 spark plugs spark

simultaneously.

Page 396 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-4 Ignition System:

Diagnostic Information and Procedures

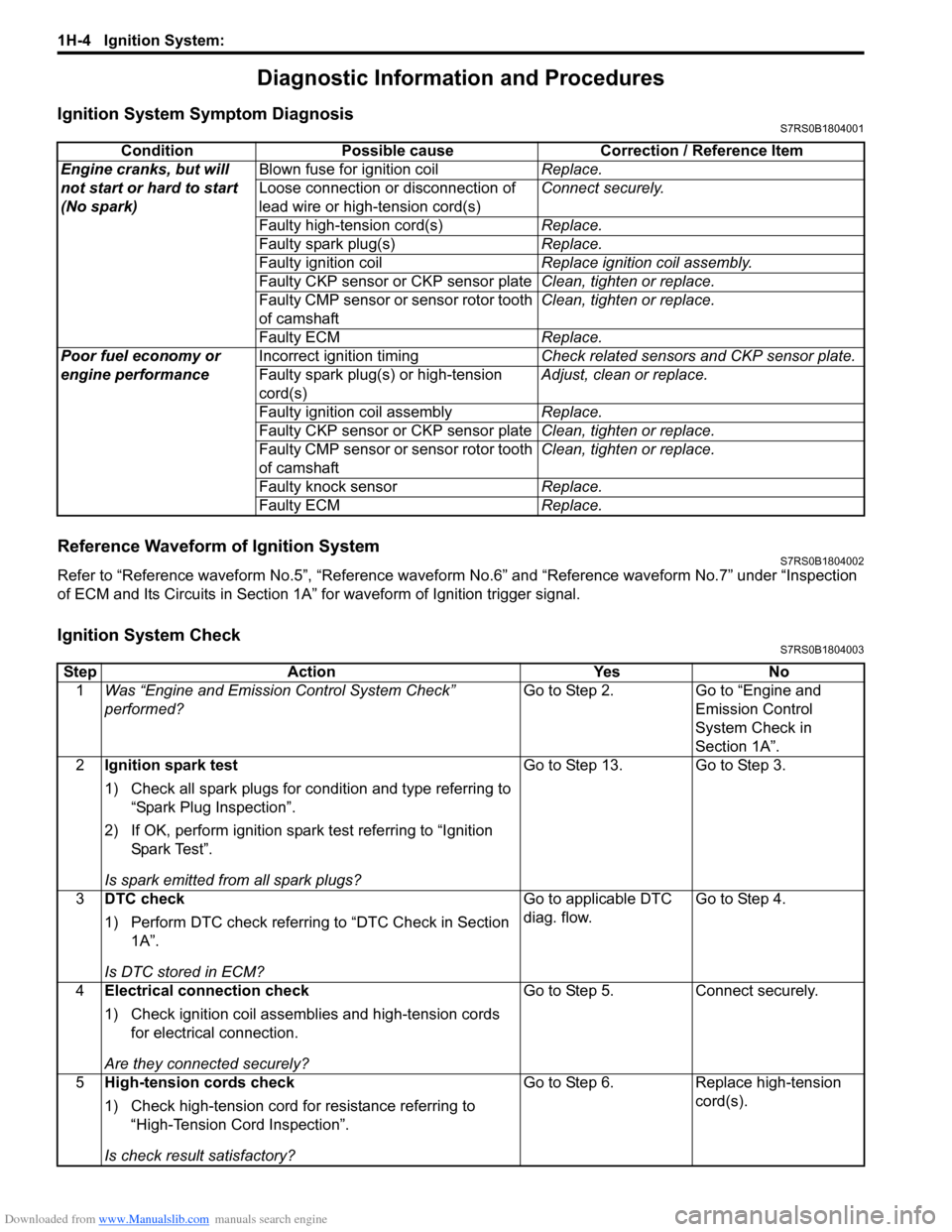

Ignition System Symptom DiagnosisS7RS0B1804001

Reference Waveform of Ignition SystemS7RS0B1804002

Refer to “Reference waveform No.5”, “Reference waveform No.6” and “Reference waveform No.7” under “Inspection

of ECM and Its Circuits in Section 1A” for waveform of Ignition trigger signal.

Ignition System CheckS7RS0B1804003

Condition Possible cause Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark) Blown fuse for ignition coil

Replace.

Loose connection or disconnection of

lead wire or high-tension cord(s) Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performance Incorrect ignition timing

Check related sensors and CKP sensor plate.

Faulty spark plug(s) or high-tension

cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty knock sensor Replace.

Faulty ECM Replace.

StepAction YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check in

Section 1A”.

2 Ignition spark test

1) Check all spark plugs for condition and type referring to

“Spark Plug Inspection”.

2) If OK, perform ignition spark test referring to “Ignition Spar k Tes t”.

Is spark emitted from all spark plugs? Go to Step 13. Go to Step 3.

3 DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Electrical connection check

1) Check ignition coil assemblies and high-tension cords

for electrical connection.

Are they connected securely? Go to Step 5.

Connect securely.

5 High-tension cords check

1) Check high-tension cord for resistance referring to

“High-Tension Cord Inspection”.

Is check result satisfactory? Go to Step 6.

Replace high-tension

cord(s).

Page 397 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-5

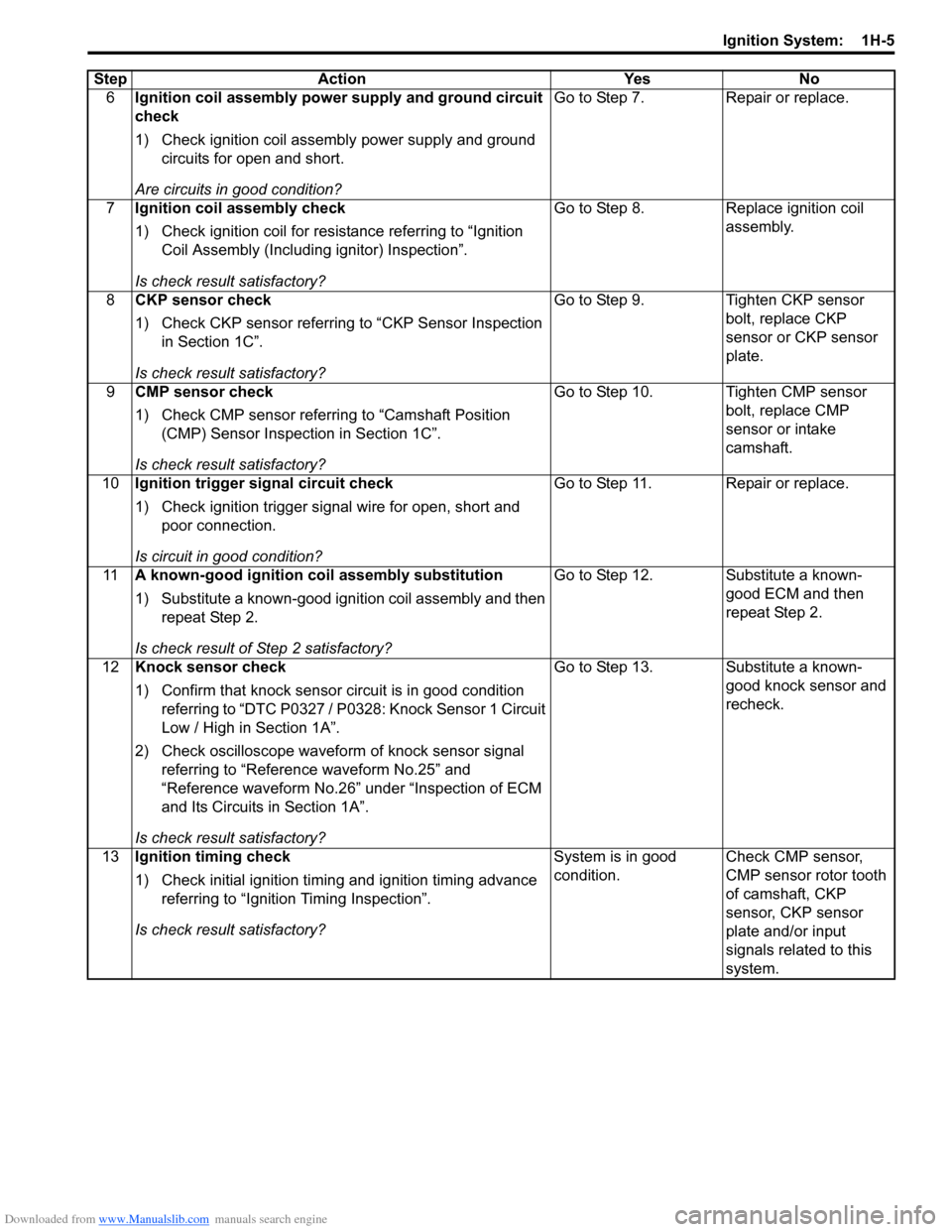

6Ignition coil assembly power supply and ground circuit

check

1) Check ignition coil assembly power supply and ground

circuits for open and short.

Are circuits in good condition? Go to Step 7.

Repair or replace.

7 Ignition coil assembly check

1) Check ignition coil for resistance referring to “Ignition

Coil Assembly (Including ignitor) Inspection”.

Is check result satisfactory? Go to Step 8.

Replace ignition coil

assembly.

8 CKP sensor check

1) Check CKP sensor referring to “CKP Sensor Inspection

in Section 1C”.

Is check result satisfactory? Go to Step 9.

Tighten CKP sensor

bolt, replace CKP

sensor or CKP sensor

plate.

9 CMP sensor check

1) Check CMP sensor referring to “Camshaft Position

(CMP) Sensor Inspection in Section 1C”.

Is check result satisfactory? Go to Step 10. Tighten CMP sensor

bolt, replace CMP

sensor or intake

camshaft.

10 Ignition trigger signal circuit check

1) Check ignition trigger signal wire for open, short and

poor connection.

Is circuit in good condition? Go to Step 11. Repair or replace.

11 A known-good ignition coil assembly substitution

1) Substitute a known-good ignition coil assembly and then

repeat Step 2.

Is check result of Step 2 satisfactory? Go to Step 12. Substitute a known-

good ECM and then

repeat Step 2.

12 Knock sensor check

1) Confirm that knock sensor circuit is in good condition

referring to “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High in Section 1A”.

2) Check oscilloscope waveform of knock sensor signal

referring to “Reference waveform No.25” and

“Reference waveform No.26” under “Inspection of ECM

and Its Circuits in Section 1A”.

Is check result satisfactory? Go to Step 13. Substitute a known-

good knock sensor and

recheck.

13 Ignition timing check

1) Check initial ignition timing and ignition timing advance

referring to “Ignition Timing Inspection”.

Is check result satisfactory? System is in good

condition.

Check CMP sensor,

CMP sensor rotor tooth

of camshaft, CKP

sensor, CKP sensor

plate and/or input

signals related to this

system.

Step

Action YesNo

Page 401 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-9

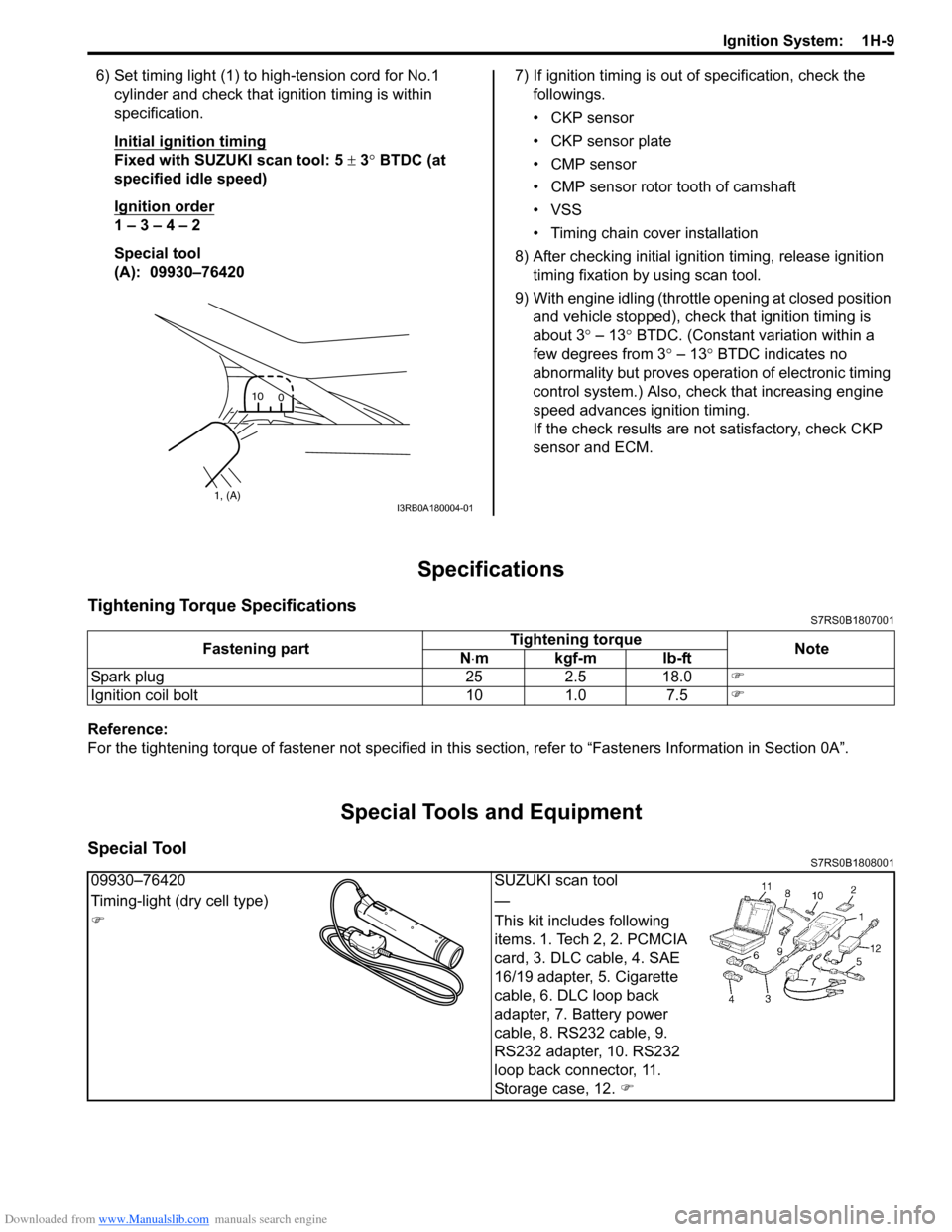

6) Set timing light (1) to high-tension cord for No.1 cylinder and check that ignition timing is within

specification.

Initial ignition timing

Fixed with SUZUKI scan tool: 5 ± 3° BTDC (at

specified idle speed)

Ignition order

1 – 3 – 4 – 2

Special tool

(A): 09930–76420 7) If ignition timing is out

of specification, check the

followings.

• CKP sensor

• CKP sensor plate

• CMP sensor

• CMP sensor rotor tooth of camshaft

• VSS

• Timing chain cover installation

8) After checking initial igniti on timing, release ignition

timing fixation by using scan tool.

9) With engine idling (throttl e opening at closed position

and vehicle stopped), check that ignition timing is

about 3 ° – 13° BTDC. (Constant variation within a

few degrees from 3 ° – 13° BTDC indicates no

abnormality but proves operation of electronic timing

control system.) Also, check that increasing engine

speed advances ignition timing.

If the check results are not satisfactory, check CKP

sensor and ECM.

Specifications

Tightening Torque SpecificationsS7RS0B1807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B1808001

1, (A)10

0I3RB0A180004-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Spark plug 25 2.5 18.0 �)

Ignition coil bolt 10 1.0 7.5 �)

09930–76420SUZUKI scan tool

Timing-light (dry cell type) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)

Page 435 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-2

Front Wheel Alignment ConstructionS7RS0B2201002

Among factors for front wheel alignment, only toe setting

can be adjusted. Camber and caster are not adjustable.

Therefore, should camber or caster be out of

specification due to the damage caused by hazardous

road conditions or collision, whether the damage is in

body or in suspension should be determined and

damaged body should be repaired or damaged

suspension should be replaced.

Preliminary Checks Prior to Adjustment Front Wheel

Alignment

Steering and vibration complaints are not always the

result of improper wheel alignment. An additional item to

be checked is the possibility of tire lead due to worn or

improperly manufactured tires. “Lead” is the vehicle

deviation from a straight path on a level road without

hand pressure on the steering wheel. Refer to “Radial

Tire Lead / Pull Description in Section 2D” in order to

determine if the vehicle has a tire lead problem. Before

making any adjustment affecting wheel alignment, the

following checks and inspections should be made to

ensure correctness of alignment readings and alignment

adjustments:

• Check all tires for proper inflation pressures and approximately the same tread wear. • Check for loose of ball join

ts. Check tie-rod ends; if

excessive looseness is noted, it must be corrected

before adjusting.

• Check for run-out of wheels and tires.

• Check vehicle trim heights; if it is out of limit and a

correction is needed, it must be done before adjusting

toe.

• Check for loose of suspension control arms.

• Check for loose or missin g stabilizer bar attachments.

• Consideration must be given to excess loads, such as

tool boxes. If this excess load is normally carried in

vehicle, it should remain in vehicle during alignment

checks.

• Consider condition of equipment being used to check alignment and follow manufa cturer’s instructions.

• Regardless of equipment used to check alignment, vehicle must be placed on a level surface.

NOTE

To prevent possible incorrect reading of toe,

camber or caster, vehicle front and rear end

must be moved up and down a few times

before inspection.

Repair Instructions

Front Wheel Alignment Inspection and

Adjustment

S7RS0B2206001

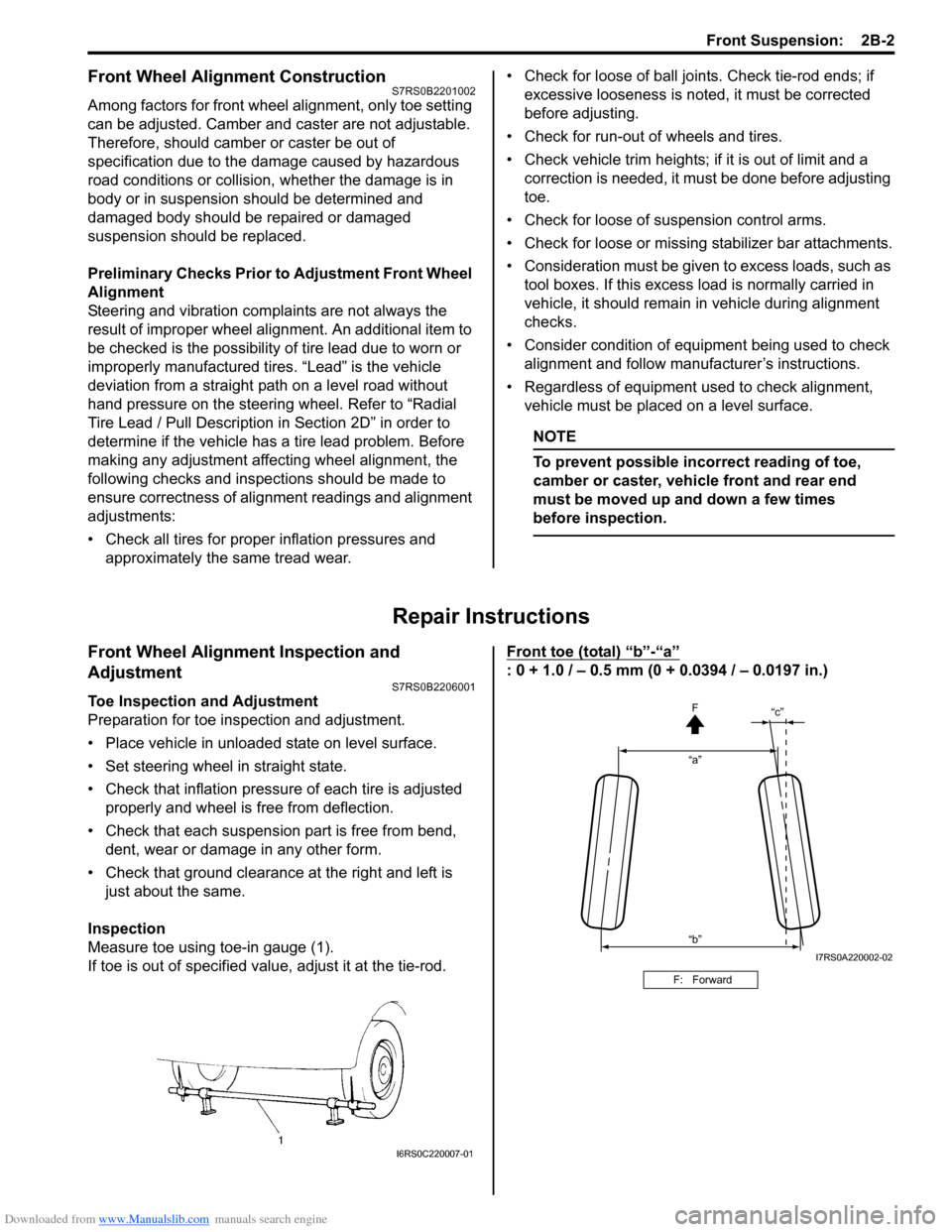

Toe Inspection and Adjustment

Preparation for toe inspection and adjustment.

• Place vehicle in unloaded state on level surface.

• Set steering wheel in straight state.

• Check that inflation pressure of each tire is adjusted properly and wheel is free from deflection.

• Check that each suspension part is free from bend, dent, wear or damage in any other form.

• Check that ground clearance at the right and left is just about the same.

Inspection

Measure toe using toe-in gauge (1).

If toe is out of specified value, adjust it at the tie-rod. Front toe (total) “b”-“a”

: 0 + 1.0 / – 0.5 mm (0 + 0.0394 / – 0.0197 in.)

I6RS0C220007-01

F: Forward

“a”

“c”

“b” F

I7RS0A220002-02

Page 436 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-3 Front Suspension:

Adjustment1) Loosen right and left tie-rod end lock nuts (1) first.

2) Rotate right and left tie-rods (2) by the same amount to align toe to specification. In this adjustment, the

lengths “A” of both right and left tie-rod should be

equal.

NOTE

Before rotating tie-rods (2), apply grease

between tie-rods and rack boots so that

boots won’t be twisted.

3) After adjustment, tighten lock nuts (1) to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-

ft)

NOTE

Make sure that rack boots are not twisted.

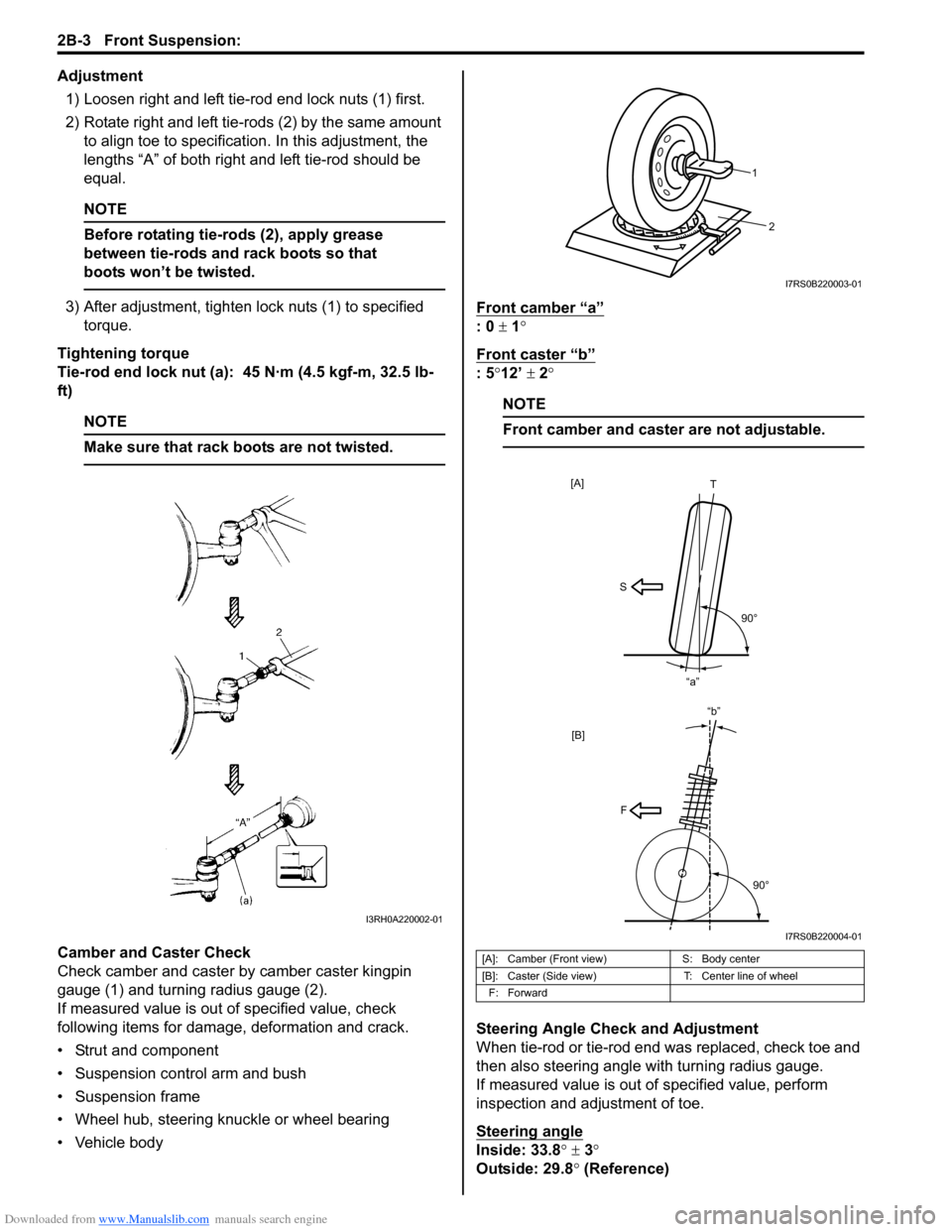

Camber and Caster Check

Check camber and caster by camber caster kingpin

gauge (1) and turning radius gauge (2).

If measured value is out of specified value, check

following items for damage, deformation and crack.

• Strut and component

• Suspension control arm and bush

• Suspension frame

• Wheel hub, steering knuckle or wheel bearing

• Vehicle body Front camber “a”

: 0

± 1°

Front caster “b”

: 5 °12’ ± 2°

NOTE

Front camber and caster are not adjustable.

Steering Angle Check and Adjustment

When tie-rod or tie-rod end was replaced, check toe and

then also steering angle with turning radius gauge.

If measured value is out of specified value, perform

inspection and adjustment of toe.

Steering angle

Inside: 33.8 ° ± 3 °

Outside: 29.8 ° (Reference)

I3RH0A220002-01

[A]: Camber (Front view) S: Body center

[B]: Caster (Side view) T: Center line of wheel

F: Forward

2

1

I7RS0B220003-01

[B]

S T

90°

“a”

[A]

F

90°

“b”

I7RS0B220004-01

Page 456 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-2 Rear Suspension:

Repair Instructions

Rear Wheel Alignment InspectionS7RS0B2306017

Measure toe and camber referring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

NOTE

Rear suspension is not adjustable structure.

Rear toe (total)

: IN 3.8 ± 3.8 mm (IN 0.1969 ± 0.1969 in)

Rear camber

: –1 ° ± 1

If measured value is out of specified value, check

following items for damage, deformation and crack.

• Rear axle (torsion beam)

• Spindle, wheel hub or wheel bearing

• Vehicle body

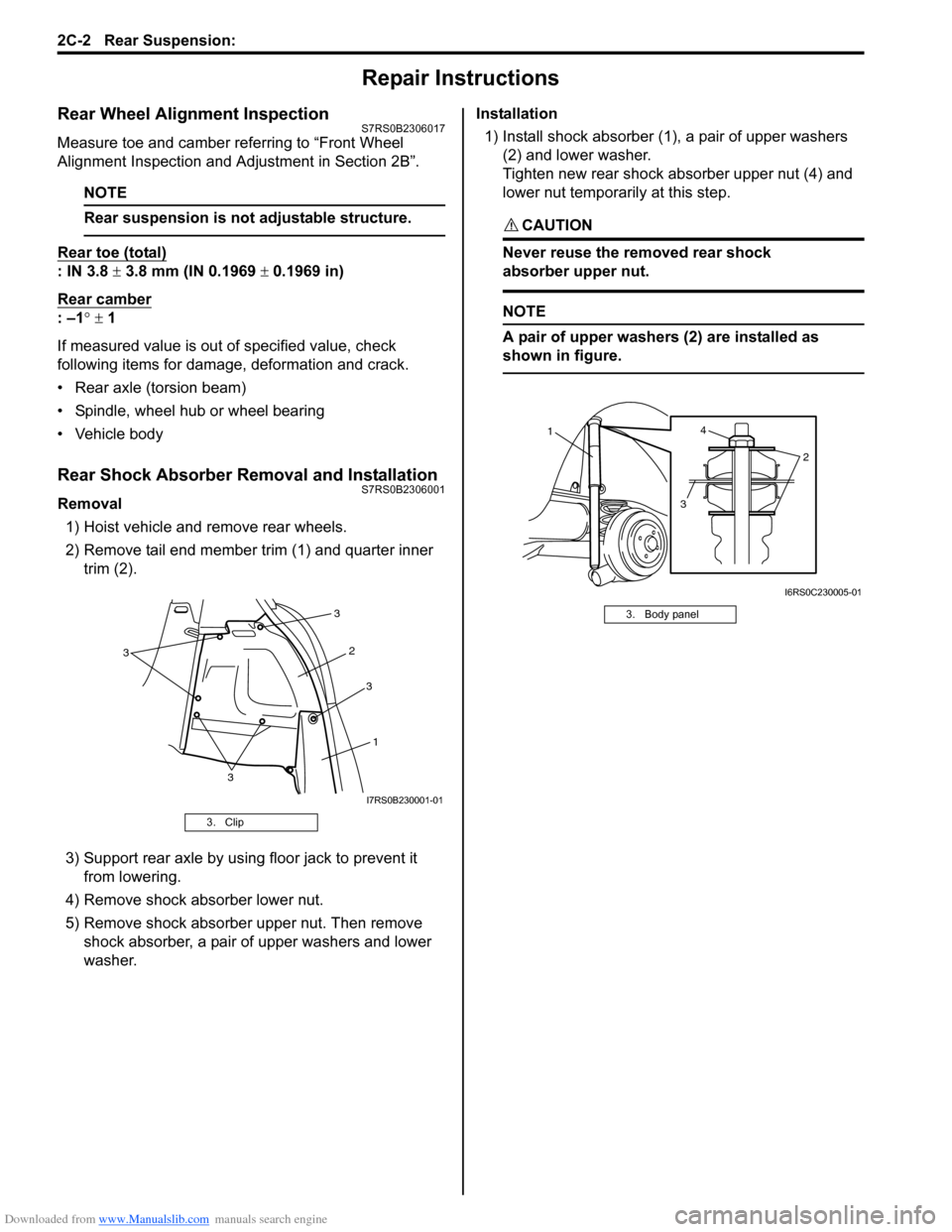

Rear Shock Absorber Removal and InstallationS7RS0B2306001

Removal 1) Hoist vehicle and remove rear wheels.

2) Remove tail end member trim (1) and quarter inner trim (2).

3) Support rear axle by using floor jack to prevent it from lowering.

4) Remove shock absorber lower nut.

5) Remove shock absorber upper nut. Then remove shock absorber, a pair of upper washers and lower

washer. Installation

1) Install shock absorber (1), a pair of upper washers (2) and lower washer.

Tighten new rear shock absorber upper nut (4) and

lower nut temporarily at this step.

CAUTION!

Never reuse the removed rear shock

absorber upper nut.

NOTE

A pair of upper washers (2) are installed as

shown in figure.

3. Clip

3

3 2

3

1

3

I7RS0B230001-01

3. Body panel

14

3 2

I6RS0C230005-01

Page 476 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-9 Wheels and Tires:

2) Check tire if it can be repaired, referring to “Tire

Repair”. If it cannot be repaired, replace it with new

one.

3) Replace valve core of flat tire with new one if tire is reused after repairing.CAUTION!

Be sure to use new valve core. Otherwise, air

leak may occur due to sealant attached to

valve core.

4) Install tire to ri m of wheel, check that there is no air

leakage and adjust it to specified pressure shown on

tire placard.

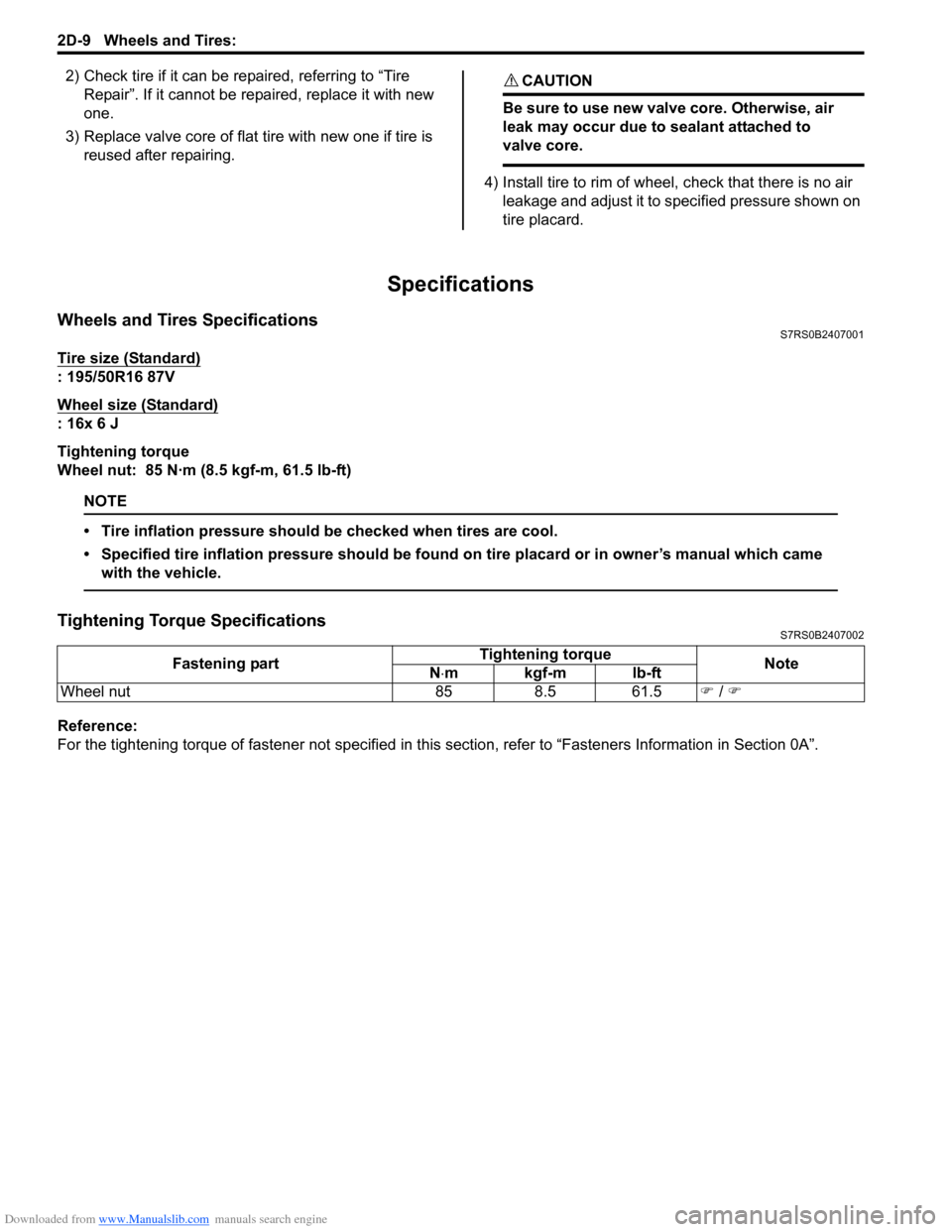

Specifications

Wheels and Tires SpecificationsS7RS0B2407001

Tire size (Standard)

: 195/50R16 87V

Wheel size (Standard)

: 16x 6 J

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

NOTE

• Tire inflation pressure should be checked when tires are cool.

• Specified tire inflation pressure should be found on tire placard or in owner’s manual which came

with the vehicle.

Tightening Torque SpecificationsS7RS0B2407002

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Wheel nut 858.5 61.5 �) / �)

Page 738 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-94 Automatic Transmission/Transaxle:

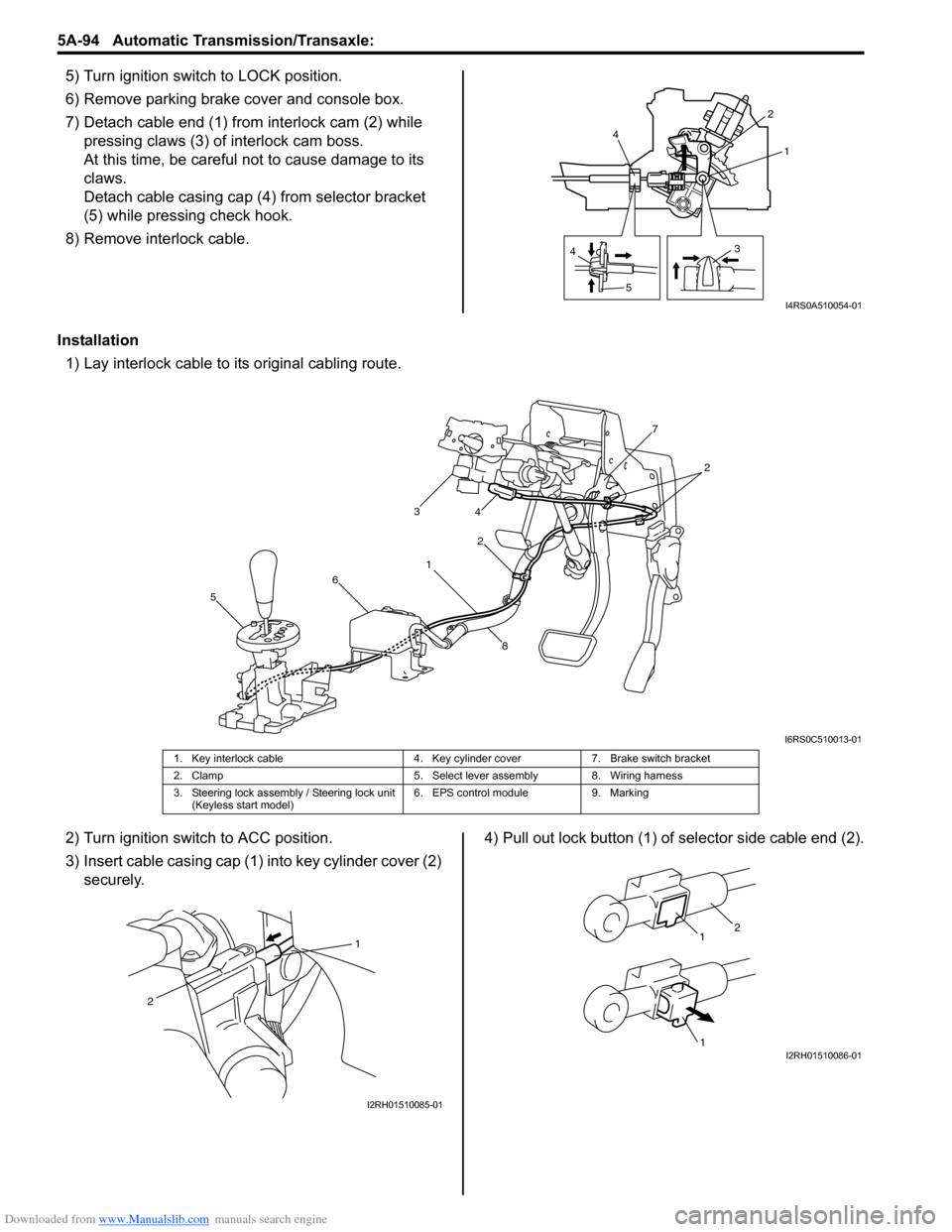

5) Turn ignition switch to LOCK position.

6) Remove parking brake cover and console box.

7) Detach cable end (1) from interlock cam (2) while

pressing claws (3) of interlock cam boss.

At this time, be careful no t to cause damage to its

claws.

Detach cable casing cap (4 ) from selector bracket

(5) while pressing check hook.

8) Remove interlock cable.

Installation 1) Lay interlock cable to its original cabling route.

2) Turn ignition switch to ACC position.

3) Insert cable casing cap (1) into key cylinder cover (2) securely. 4) Pull out lock button (1) of selector side cable end (2).

4

5 31

2

4

I4RS0A510054-01

1 2

3

4

5 6 7

8

2

I6RS0C510013-01

1. Key interlock cable 4. Key cylinder cover7. Brake switch bracket

2. Clamp 5. Select lever assembly 8. Wiring harness

3. Steering lock assembly / Steering lock unit (Keyless start model) 6. EPS control module

9. Marking

1

2

I2RH01510085-01

1

1

2

I2RH01510086-01