Cam SUZUKI SWIFT 2007 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 739 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-95

5) Shift select lever to “N” position.

NOTE

If select lever is in “P” position, shift select

lever referring to “Select Lever Inspection”.

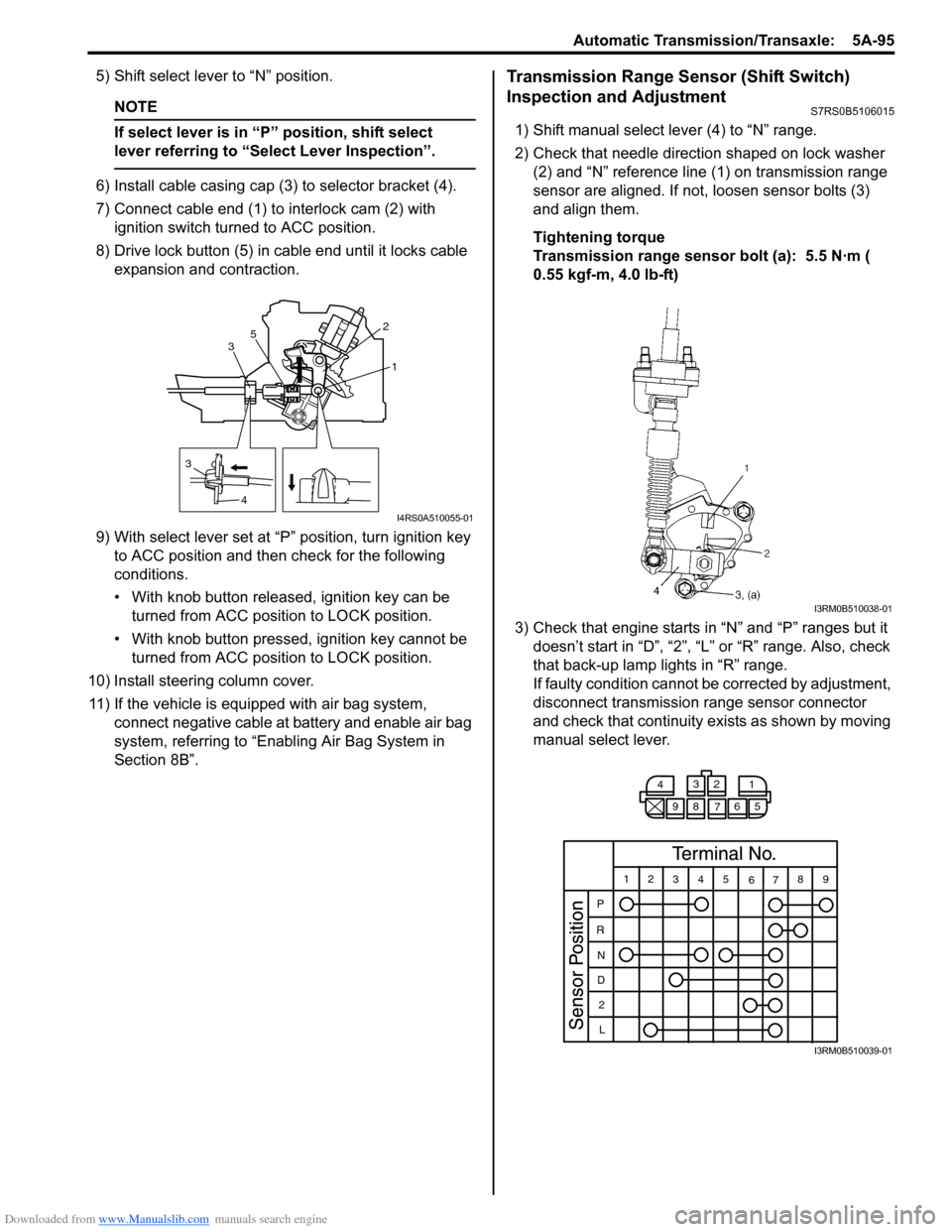

6) Install cable casing cap (3) to selector bracket (4).

7) Connect cable end (1) to interlock cam (2) with ignition switch turned to ACC position.

8) Drive lock button (5) in cable end until it locks cable expansion and contraction.

9) With select lever set at “P ” position, turn ignition key

to ACC position and then check for the following

conditions.

• With knob button released, ignition key can be turned from ACC position to LOCK position.

• With knob button pressed, ignition key cannot be

turned from ACC position to LOCK position.

10) Install steering column cover. 11) If the vehicle is equipped with air bag system, connect negative cable at battery and enable air bag

system, referring to “Enabling Air Bag System in

Section 8B”.

Transmission Range Sensor (Shift Switch)

Inspection and Adjustment

S7RS0B5106015

1) Shift manual select lever (4) to “N” range.

2) Check that needle direction shaped on lock washer (2) and “N” reference line (1) on transmission range

sensor are aligned. If not, loosen sensor bolts (3)

and align them.

Tightening torque

Transmission range sensor bolt (a): 5.5 N·m (

0.55 kgf-m, 4.0 lb-ft)

3) Check that engine starts in “N” and “P” ranges but it doesn’t start in “D”, “2”, “L” or “R” range. Also, check

that back-up lamp lights in “R” range.

If faulty condition cannot be corrected by adjustment,

disconnect transmission range sensor connector

and check that continuity ex ists as shown by moving

manual select lever.

3

4 1

2

3 5

I4RS0A510055-01

I3RM0B510038-01

4

3

2

1

98 76 5

12 345

6789

P

R N

D 2

L

I3RM0B510039-01

Page 825 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-11

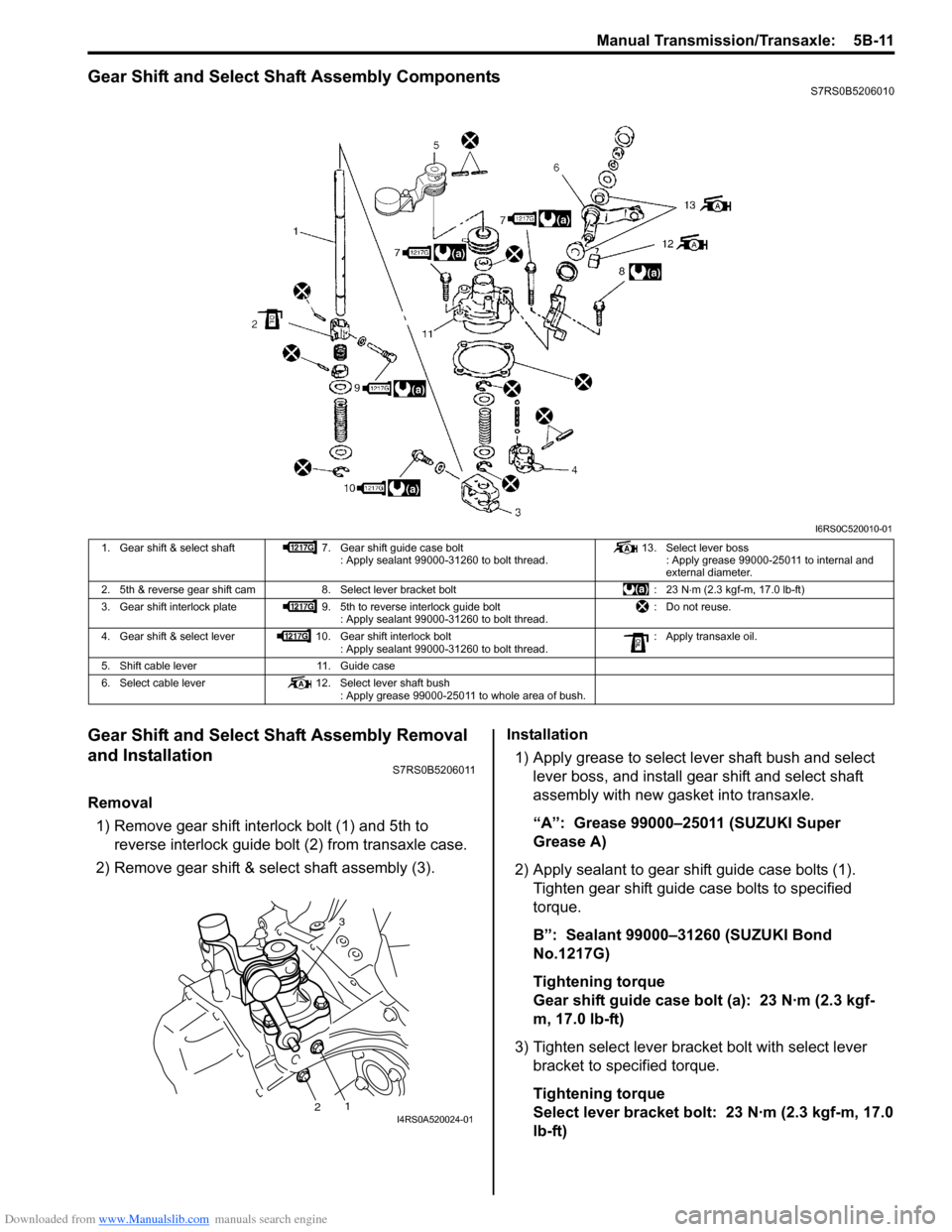

Gear Shift and Select Shaft Assembly ComponentsS7RS0B5206010

Gear Shift and Select Shaft Assembly Removal

and Installation

S7RS0B5206011

Removal1) Remove gear shift interlock bolt (1) and 5th to reverse interlock guide bolt (2) from transaxle case.

2) Remove gear shift & select shaft assembly (3). Installation

1) Apply grease to select lever shaft bush and select lever boss, and install gear shift and select shaft

assembly with new gasket into transaxle.

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

2) Apply sealant to gear shift guide case bolts (1). Tighten gear shift guide case bolts to specified

torque.

B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Gear shift guide case bolt (a): 23 N·m (2.3 kgf-

m, 17.0 lb-ft)

3) Tighten select lever brac ket bolt with select lever

bracket to specified torque.

Tightening torque

Select lever bracket bolt: 23 N·m (2.3 kgf-m, 17.0

lb-ft)

I6RS0C520010-01

1. Gear shift & select shaft 7. Gear shift guide case bolt

: Apply sealant 99000-31260 to bolt thread. 13. Select lever boss

: Apply grease 99000-25011 to internal and

external diameter.

2. 5th & reverse gear shift cam 8. Select lever bracket bolt : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Gear shift interlock plate 9. 5th to reverse interlock guide bolt

: Apply sealant 99000-31260 to bolt thread. : Do not reuse.

4. Gear shift & select lever 10. Gear shift interlock bolt

: Apply sealant 99000-31260 to bolt thread. : Apply transaxle oil.

5. Shift cable lever 11. Guide case

6. Select cable lever 12. Select lever shaft bush

: Apply grease 99000-25011 to whole area of bush.

3

12I4RS0A520024-01

Page 826 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-12 Manual Transmission/Transaxle:

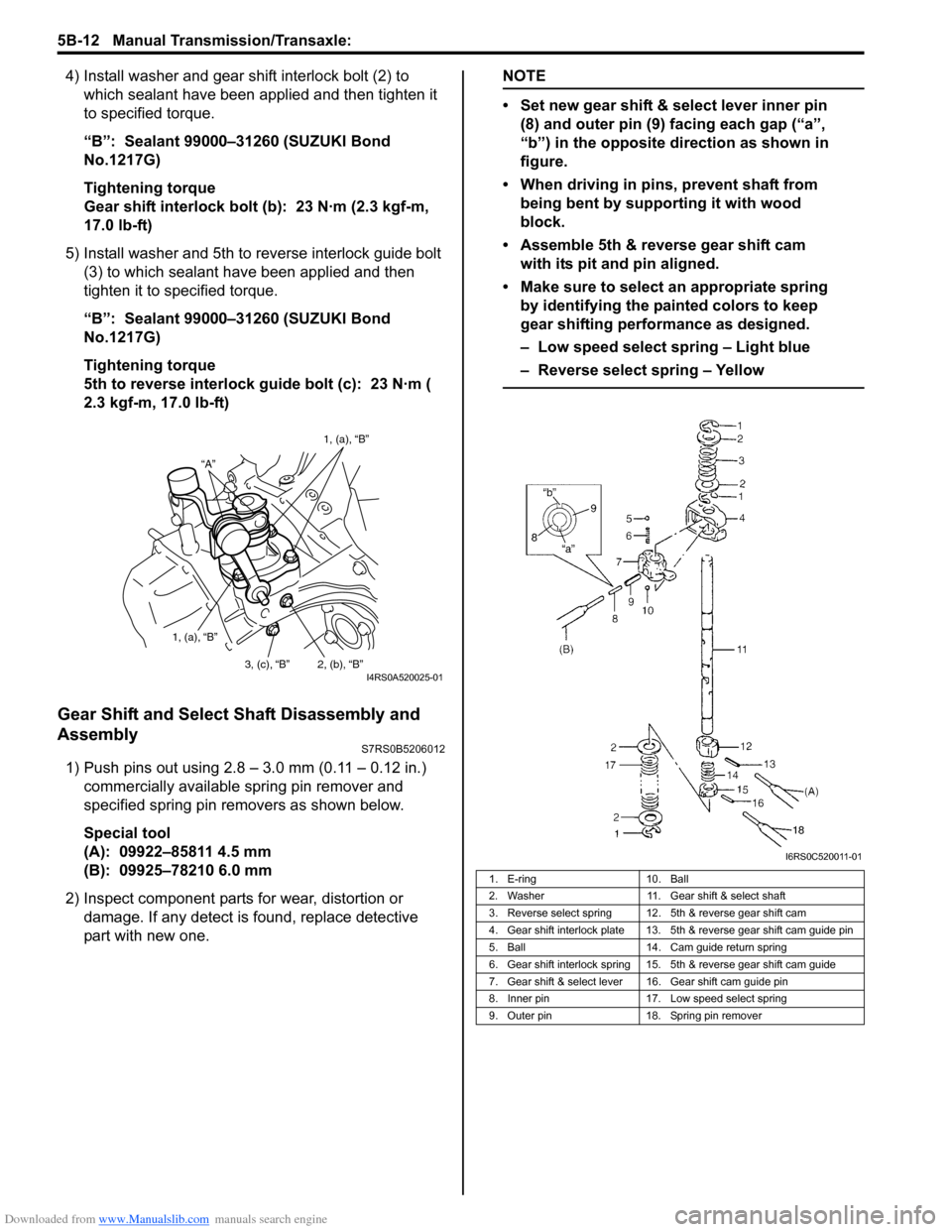

4) Install washer and gear shift interlock bolt (2) to which sealant have been app lied and then tighten it

to specified torque.

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Gear shift interlock bolt (b): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

5) Install washer and 5th to reverse interlock guide bolt (3) to which sealant have been applied and then

tighten it to specified torque.

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

5th to reverse interlock guide bolt (c): 23 N·m (

2.3 kgf-m, 17.0 lb-ft)

Gear Shift and Select Shaft Disassembly and

Assembly

S7RS0B5206012

1) Push pins out using 2.8 – 3.0 mm (0.11 – 0.12 in.) commercially available spring pin remover and

specified spring pin removers as shown below.

Special tool

(A): 09922–85811 4.5 mm

(B): 09925–78210 6.0 mm

2) Inspect component parts for wear, distortion or

damage. If any detect is found, replace detective

part with new one.

NOTE

• Set new gear shift & select lever inner pin (8) and outer pin (9) facing each gap (“a”,

“b”) in the opposite direction as shown in

figure.

• When driving in pins, prevent shaft from being bent by supporting it with wood

block.

• Assemble 5th & reverse gear shift cam with its pit and pin aligned.

• Make sure to select an appropriate spring by identifying the painted colors to keep

gear shifting performance as designed.

– Low speed select spring – Light blue

– Reverse select spring – Yellow

“A” 1, (a), “B”

1, (a), “B” 2, (b), “B”

3, (c), “B”

I4RS0A520025-01

1. E-ring 10. Ball

2. Washer 11. Gear shift & select shaft

3. Reverse select spring 12. 5th & reverse gear shift cam

4. Gear shift interlock plate 13. 5th & reverse gear shift cam guide pin

5. Ball 14. Cam guide return spring

6. Gear shift interlock spring 15. 5th & reverse gear shift cam guide

7. Gear shift & select lever 16. Gear shift cam guide pin

8. Inner pin 17. Low speed select spring

9. Outer pin 18. Spring pin remover

I6RS0C520011-01

Page 877 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-6

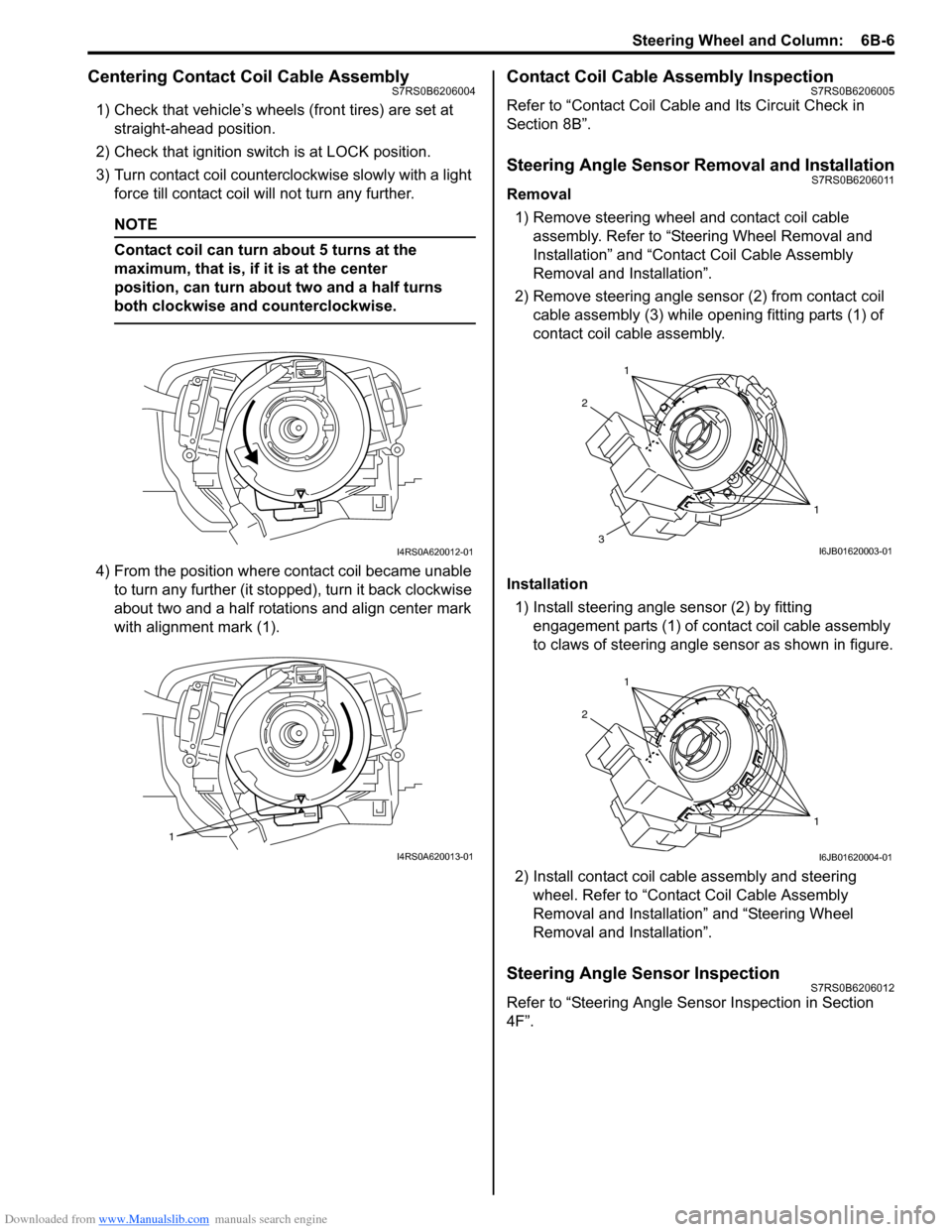

Centering Contact Coil Cable AssemblyS7RS0B6206004

1) Check that vehicle’s wheels (front tires) are set at straight-ahead position.

2) Check that ignition swit ch is at LOCK position.

3) Turn contact coil counterclockwise slowly with a light force till contact coil will not turn any further.

NOTE

Contact coil can turn about 5 turns at the

maximum, that is, if it is at the center

position, can turn about two and a half turns

both clockwise and counterclockwise.

4) From the position where contact coil became unable to turn any further (it stopped), turn it back clockwise

about two and a half rotations and align center mark

with alignment mark (1).

Contact Coil Cable Assembly InspectionS7RS0B6206005

Refer to “Contact Coil Cable and Its Circuit Check in

Section 8B”.

Steering Angle Sensor Removal and InstallationS7RS0B6206011

Removal

1) Remove steering wheel and contact coil cable assembly. Refer to “Ste ering Wheel Removal and

Installation” and “Contact Coil Cable Assembly

Removal and Installation”.

2) Remove steering angle sensor (2) from contact coil cable assembly (3) while op ening fitting parts (1) of

contact coil cable assembly.

Installation 1) Install steering angle sensor (2) by fitting engagement parts (1) of contact coil cable assembly

to claws of steering angle sensor as shown in figure.

2) Install contact coil cable assembly and steering wheel. Refer to “Contact Coil Cable Assembly

Removal and Installation” and “Steering Wheel

Removal and Installation”.

Steering Angle Sensor InspectionS7RS0B6206012

Refer to “Steering Angle Sens or Inspection in Section

4F”.

I4RS0A620012-01

1

I4RS0A620013-01

1

1

2

3I6JB01620003-01

1

1

2

I6JB01620004-01