Door card SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 468 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-1 Wheels and Tires:

Suspension

Wheels and Tires

Precautions

Precaution for Emergency Flat Tire Repair KitS7RS0B2400001

WARNING!

Flat tire repair sealant including in kit is

harmful. Be sure to observe the following.

Otherwise, your health may be ruined.

• If swallowed, get medical attention immediately.

• Keep out of reach of children.

• Select place where there is good ventilation for this work.

• If it enters eye or contacts skin, wash thoroughly with water. If anything

abnormal still rema ins, get medical

attention immediately.

• Do not discard tire containing sealant as it is. Make sure to remove sealant from tire,

referring to “Tire Repair for Emergency

Repaired-Tire with Sealant”.

• Dispose of sealant as waste oil.

CAUTION!

• When tire repaired with Emergency Flat Tire Repair Kit is brought in, remove flat

tire repair sealant from tire and repair flat

tire referring to “Tire Repair for Emergency

Repaired-Tire with Sealant”.

• Sealant expiration date is printed on bottle label. if it expires, sealant should be

replaced with a new one to ensure

emergency flat tire repair.

General Description

Tires DescriptionS7RS0B2401001

The tire is of tubeless type. The tire is designed to

operate satisfactorily with loads up to the full rated load

capacity when inflated to the recommended inflation

pressures.

Correct tire pressures and driving habits have an

important influence on tire life. Heavy cornering,

excessively rapid acceleration, and unnecessary sharp

braking increase tire wear.

Tire Placard

The “Tire Placard” is located on the left or right door lock

pillar and should be referred to tire information.

The placard lists the maximum load, tire size and cold

tire pressure where applicable.

NOTE

Whether rim size and/or maximum load are

listed or not depends on regulations of each

country.

Inflation of Tires

The pressure recommended for any model is carefully

calculated to give a satisfacto ry ride, stability, steering,

tread wear, tire life and resistance to bruises.

Tire pressure, with tires cold, (after vehicle has set for 3

hours or more, or driven less than one mile) should be

checked monthly or before any extended trip. Set to the

specifications on the “Tire Placard” located on the left

door lock pillar.

It is normal for tire pressure to increase when the tires

become hot during driving.

Do not bleed or reduce tire pressure after driving.

Bleeding reduces the “Cold Inflation Pressure”.

Higher than recommended pressure can cause:

• Hard ride

• Tire bruising or carcass damage

• Rapid tread wear at center of tire

Unequal pressure on same axle can cause:

• Uneven braking

• Steering lead

• Reduced handling

• Swerve on acceleration

Page 1161 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-123

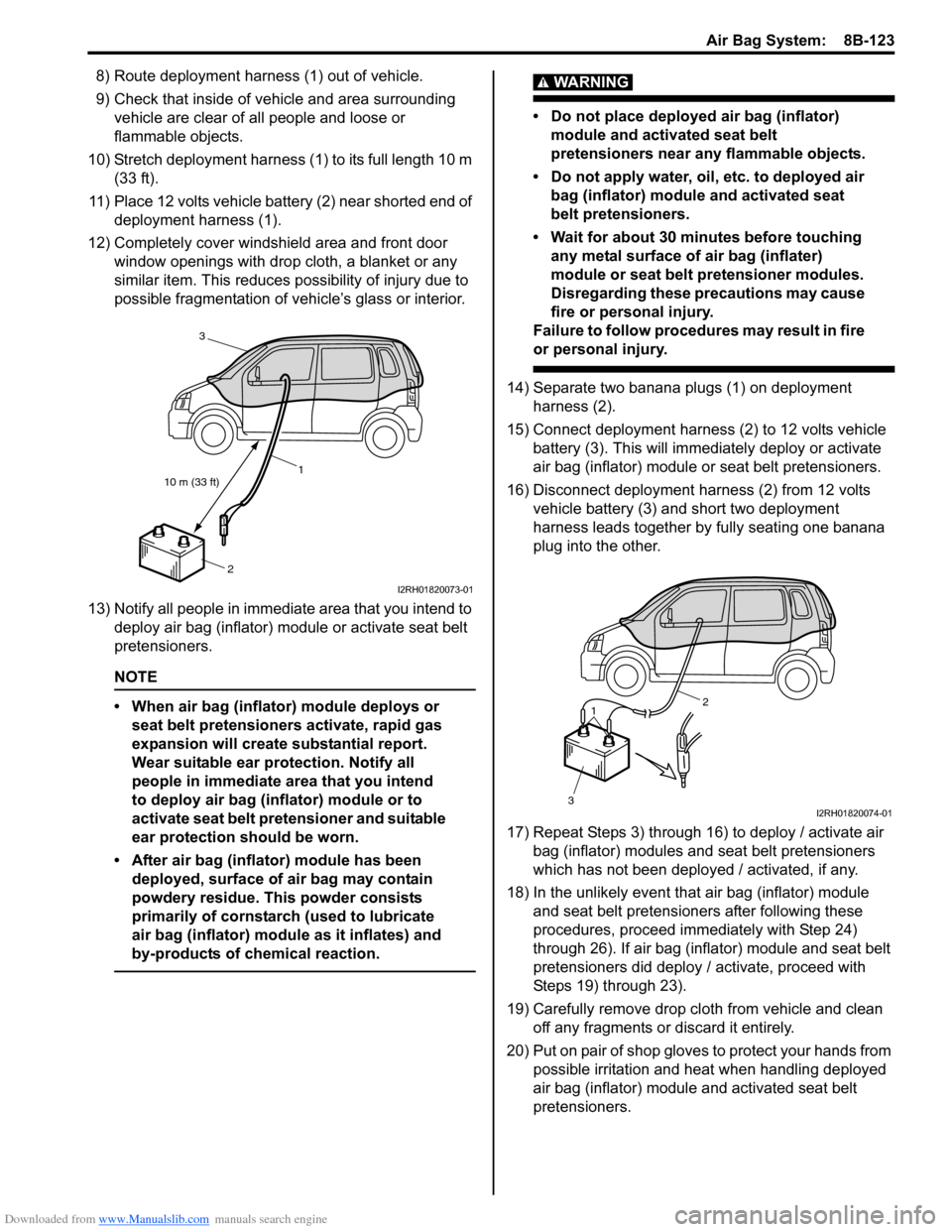

8) Route deployment harness (1) out of vehicle.

9) Check that inside of vehicle and area surrounding vehicle are clear of all people and loose or

flammable objects.

10) Stretch deployment harness (1) to its full length 10 m (33 ft).

11) Place 12 volts vehicle battery (2) near shorted end of deployment harness (1).

12) Completely cover windshield area and front door window openings with drop cloth, a blanket or any

similar item. This reduces possibility of injury due to

possible fragmentation of vehicle’s glass or interior.

13) Notify all people in immediate area that you intend to deploy air bag (inflator) module or activate seat belt

pretensioners.

NOTE

• When air bag (inflator) module deploys or seat belt pretensioners activate, rapid gas

expansion will create substantial report.

Wear suitable ear protection. Notify all

people in immediate area that you intend

to deploy air bag (inflator) module or to

activate seat belt pretensioner and suitable

ear protection should be worn.

• After air bag (inflator) module has been deployed, surface of air bag may contain

powdery residue. This powder consists

primarily of cornstarch (used to lubricate

air bag (inflator) module as it inflates) and

by-products of chemical reaction.

WARNING!

• Do not place deployed air bag (inflator) module and activated seat belt

pretensioners near any flammable objects.

• Do not apply water, oil, etc. to deployed air bag (inflator) module and activated seat

belt pretensioners.

• Wait for about 30 minutes before touching any metal surface of air bag (inflater)

module or seat belt pretensioner modules.

Disregarding these precautions may cause

fire or personal injury.

Failure to follow procedures may result in fire

or personal injury.

14) Separate two banana plugs (1) on deployment harness (2).

15) Connect deployment harness (2) to 12 volts vehicle battery (3). This will immedi ately deploy or activate

air bag (inflator) module or seat belt pretensioners.

16) Disconnect deployment harness (2) from 12 volts vehicle battery (3) and short two deployment

harness leads together by fully seating one banana

plug into the other.

17) Repeat Steps 3) through 16) to deploy / activate air bag (inflator) modules and seat belt pretensioners

which has not been deployed / activated, if any.

18) In the unlikely event that air bag (inflator) module and seat belt pretensioners after following these

procedures, proceed immediately with Step 24)

through 26). If air bag (inflator) module and seat belt

pretensioners did deploy / activate, proceed with

Steps 19) through 23).

19) Carefully remove drop cloth from vehicle and clean off any fragments or discard it entirely.

20) Put on pair of shop gloves to protect your hands from

possible irritation and heat when handling deployed

air bag (inflator) module and activated seat belt

pretensioners.

10 m (33 ft) 1

2

3

I2RH01820073-01

1

3 2

I2RH01820074-01

Page 1359 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-13

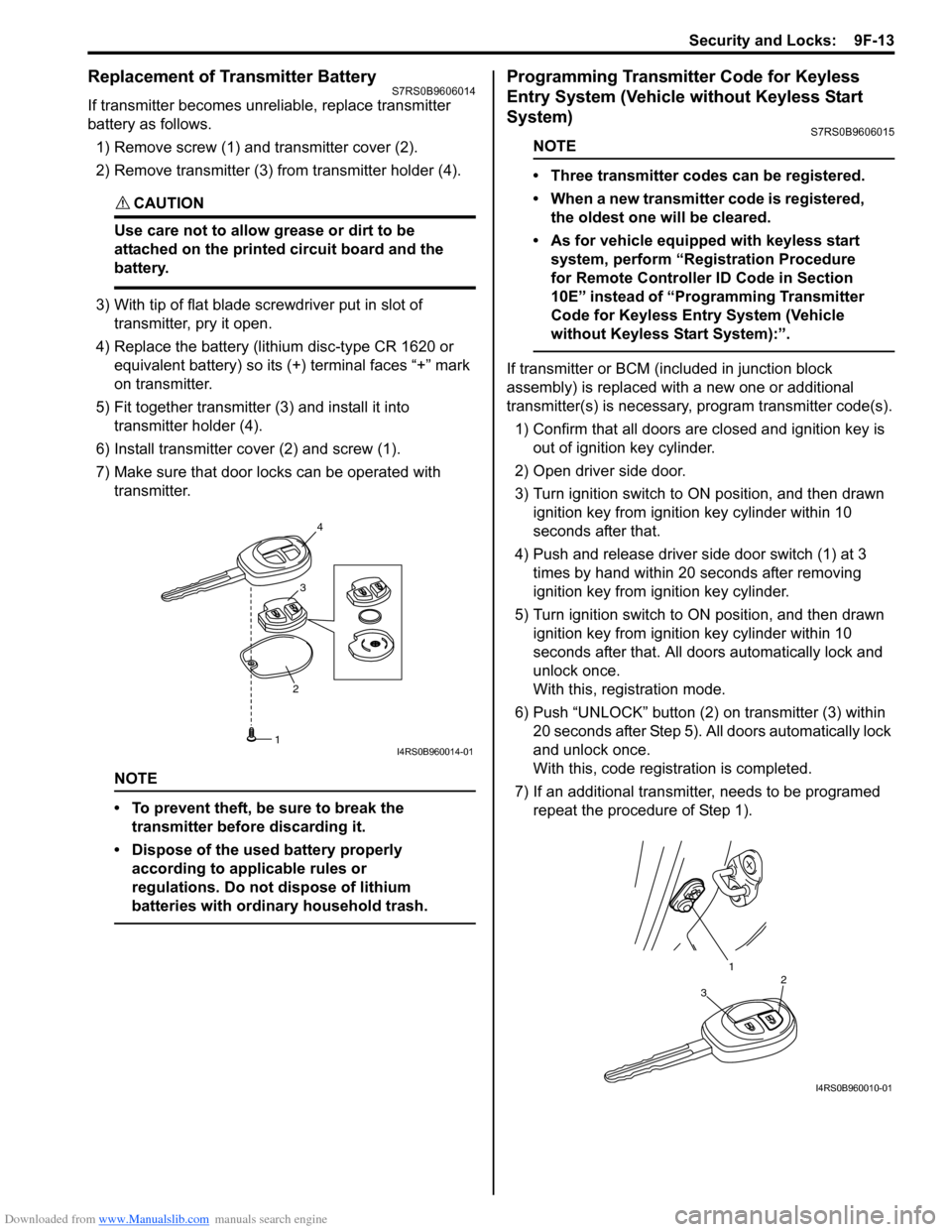

Replacement of Transmitter Battery S7RS0B9606014

If transmitter becomes unreliable, replace transmitter

battery as follows.

1) Remove screw (1) and transmitter cover (2).

2) Remove transmitter (3) from transmitter holder (4).

CAUTION!

Use care not to allow grease or dirt to be

attached on the printed circuit board and the

battery.

3) With tip of flat blade screwdriver put in slot of transmitter, pry it open.

4) Replace the battery (lithium disc-type CR 1620 or equivalent battery) so its (+) terminal faces “+” mark

on transmitter.

5) Fit together transmitter (3) and install it into

transmitter holder (4).

6) Install transmitter co ver (2) and screw (1).

7) Make sure that door locks can be operated with transmitter.

NOTE

• To prevent theft, be sure to break the transmitter before discarding it.

• Dispose of the used battery properly according to applicable rules or

regulations. Do not dispose of lithium

batteries with ordinary household trash.

Programming Transmitter Code for Keyless

Entry System (Vehicle without Keyless Start

System)

S7RS0B9606015

NOTE

• Three transmitter codes can be registered.

• When a new transmitter code is registered, the oldest one will be cleared.

• As for vehicle equipped with keyless start system, perform “Registration Procedure

for Remote Controller ID Code in Section

10E” instead of “Programming Transmitter

Code for Keyless Entry System (Vehicle

without Keyless Start System):”.

If transmitter or BCM (included in junction block

assembly) is replaced with a new one or additional

transmitter(s) is necessary, program transmitter code(s).

1) Confirm that all doors are closed and ignition key is

out of ignition key cylinder.

2) Open driver side door.

3) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that.

4) Push and release driver side door switch (1) at 3 times by hand within 20 seconds after removing

ignition key from ig nition key cylinder.

5) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that. All d oors automatically lock and

unlock once.

With this, registration mode.

6) Push “UNLOCK” button (2) on transmitter (3) within

20 seconds after Step 5). All doors automatically lock

and unlock once.

With this, code registration is completed.

7) If an additional transmitter, needs to be programed repeat the procedure of Step 1).

23

4

1I4RS0B960014-01

1

32

I4RS0B960010-01

Page 1376 of 1496

Downloaded from www.Manualslib.com manuals search engine 9J-7 Hood / Fenders / Doors:

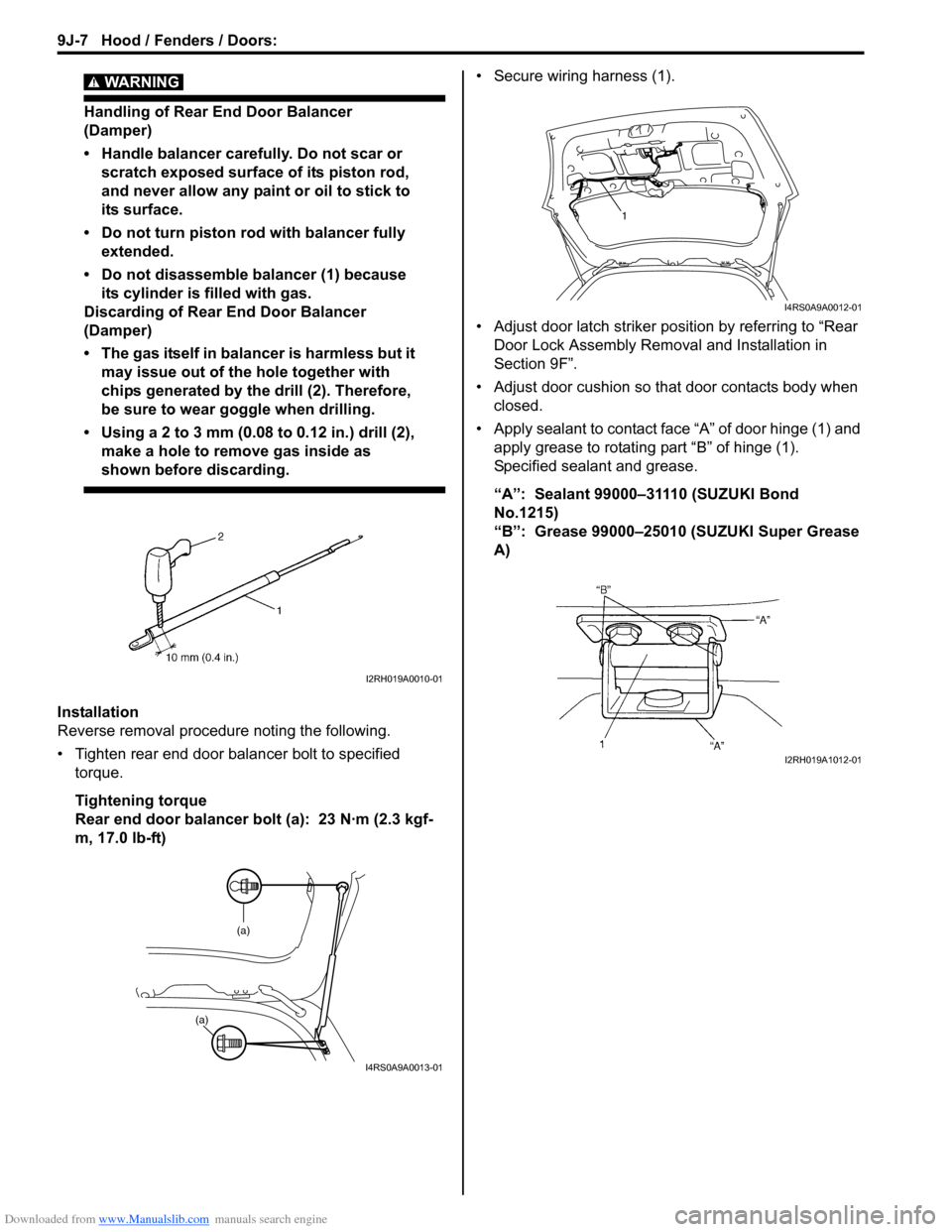

WARNING!

Handling of Rear End Door Balancer

(Damper)

• Handle balancer carefully. Do not scar or scratch exposed surface of its piston rod,

and never allow any paint or oil to stick to

its surface.

• Do not turn piston rod with balancer fully extended.

• Do not disassemble balancer (1) because its cylinder is filled with gas.

Discarding of Rear End Door Balancer

(Damper)

• The gas itself in balancer is harmless but it may issue out of the hole together with

chips generated by th e drill (2). Therefore,

be sure to wear goggle when drilling.

• Using a 2 to 3 mm (0.08 to 0.12 in.) drill (2),

make a hole to remove gas inside as

shown before discarding.

Installation

Reverse removal procedure noting the following.

• Tighten rear end door balancer bolt to specified torque.

Tightening torque

Rear end door balancer bolt (a): 23 N·m (2.3 kgf-

m, 17.0 lb-ft) • Secure wiring harness (1).

• Adjust door latch striker position by referring to “Rear

Door Lock Assembly Removal and Installation in

Section 9F”.

• Adjust door cushion so that door contacts body when closed.

• Apply sealant to contact face “A” of door hinge (1) and apply grease to rotating part “B” of hinge (1).

Specified sealant and grease.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

“B”: Grease 99000–25010 (SUZUKI Super Grease

A)

I2RH019A0010-01

(a)

(a)

I4RS0A9A0013-01

1

I4RS0A9A0012-01

I2RH019A1012-01