Yaw sensor SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 497 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 4-iii

ABS Warning Lamp Check ............................... 4F-14

EBD Warning Lamp (Brake Warning Lamp) Check .............................................................. 4F-15

DTC Check ....................................................... 4F-15

DTC Table ......................................................... 4F-15

DTC Clearance ................................................. 4F-18

Fail-Safe Table ................ .................................. 4F-19

Scan Tool Data ................................................. 4F-20

Visual Inspection ............................................... 4F-21

ESP ® Warning Lamp Does Not Come ON at

Ignition Switch ON .......................................... 4F-21

ESP ® Warning Lamp Comes ON Steady......... 4F-22

ABS Warning Lamp Does Not Come ON at Ignition Switch ON .......................................... 4F-23

ABS Warning Lamp Comes ON Steady............ 4F-24

EBD Warning Lamp (Brake Warning Lamp) Comes ON Steady .......................................... 4F-24

Serial Data Link Circuit Check .......................... 4F-26

DTC C1016: Stop Lamp Swit ch Circuit Failure .. 4F-28

DTC C1017 / C1023: Yaw Rate / G Sensor Assembly Failure ............................................ 4F-29

DTC C1018: Brake Fluid Le vel Switch Failure .. 4F-30

DTC 1020: Master Cylinder Pressure Sensor Power Supply Failure ...................................... 4F-31

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Wheel Speed

Sensor Circuit or Encode r Failure ................... 4F-32

DTC C1024: Steering Angle Sensor Circuit

Failure ............................................................. 4F-34

DTC C1027: ESP ® OFF Switch Circuit

Failure ............................................................. 4F-34

DTC C1028: Master Cylinder Pressure Sensor Circuit Failure ....... .............................. 4F-35

DTC C1034: Yaw Rate / G Sensor Assembly Power Supply Failure ...................................... 4F-36

DTC C1037: Steering Angle Sensor Power Supply Failure ................................................. 4F-37

DTC C1038: Steering Angle Sensor Detect Rolling Counter Fa ilure from ESP® Control

Module ............................................................ 4F-38

DTC C1039: Yaw Rate / G Sensor Assembly Internal Failure .............. .................................. 4F-39

DTC C1040: Stability Control System Function Failure .............................................. 4F-39

DTC C1041 / C1042 / C1043 / C1044 / C1045 / C1046 / C1051 / C1052 / C1053 / C1054 /

C1055 / C1056: Solenoid Circuit Failure ......... 4F-40

DTC C1057: ESP ® Control Module Power

Supply Circuit Failure .... .................................. 4F-41

DTC C1061: Pump Motor and/or Motor Driver Circuit Failure .................................................. 4F-42

DTC C1063: Solenoid Valve Power Supply Driver Circuit Failure ....................................... 4F-43

DTC 1071: ESP ® Control Module Internal

Defect.............................................................. 4F-44 DTC C1073: Lost Communication With Yaw

Rate / G Sensor Assembly .............................. 4F-45

DTC C1075 / 1076 / 1078: Sensor Calibration Incomplete.......................... ............................. 4F-46

DTC C1090: Invalid Communication with

ECM ................................................................ 4F-47

DTC C1091 / C1094: ECM Data in CAN Line Failure / Invalid Torque Control

Communication with ECM .. ............................. 4F-48

DTC U1073: Control Module Communication Bus Off ............................................................ 4F-49

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4F-50

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)........ 4F-51

DTC U1140: Lost Communication with BCM (Reception Error)............................................. 4F-52

Repair Instructions ........... ................................. 4F-54

ESP® Hydraulic Unit Operation Check ............. 4F-54

Sensor Calibration............................................. 4F-54

ESP® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4F-55

ESP ® Hydraulic

Unit / Control Module

Assembly Removal and Inst allation ................ 4F-56

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4F-57

Front Wheel Speed Sensor Removal and Installation ....................................................... 4F-58

Front Wheel Speed Sensor Inspection ............. 4F-59

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4F-59

Rear Wheel Speed Sensor Inspection .............. 4F-60

Front Wheel Encode r On-Vehicle Inspection .... 4F-61

Front Wheel Encoder Removal and Installation ....................................................... 4F-61

Rear Wheel Encoder On-Veh icle Inspection..... 4F-61

Rear Wheel Encoder Removal and Installation ....................................................... 4F-61

Master Cylinder Pressure Sensor On-Vehicle

Inspection ........................................................ 4F-61

Yaw Rate / G Sensor Assembly On-Vehicle Inspection ........................................................ 4F-62

Yaw Rate / G Sensor Assembly Removal and Installation ....................................................... 4F-63

Yaw Rate / G Sensor Inspection ....................... 4F-64

Steering Angle Sensor On-Vehicle Inspection .. 4F-64

Steering Angle Sensor Removal and Installation ....................................................... 4F-65

Steering Angle Sensor Inspection ..................... 4F-65

ESP® OFF Switch Removal an d Installation .... 4F-65

ESP® OFF Switch Inspection ........................... 4F-65

Specifications .................... ................................. 4F-66

Tightening Torque Specifications ...................... 4F-66

Special Tools and Equipmen t ........................... 4F-66

Special Tool ...................................................... 4F-66

Page 575 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-1

Brakes

Electronic Stability Program

Precautions

Precautions in Diagnosing TroublesS7RS0B4600001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow

“Electronic Stability Program System Check”.

• Diagnostic information stored in ESP® control module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ESP ® warning lamp may light momentarily but

this does not indicate anything abnormal in ESP ®.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to use the trouble diagnosis procedure as described in “Electronic Stability Program System

Check”. Failure to follow it may resu lt in incorrect

diagnosis. (Some other diagnosis trouble code may

be stored by mistake in the memory of ESP ® control

module during inspection.)

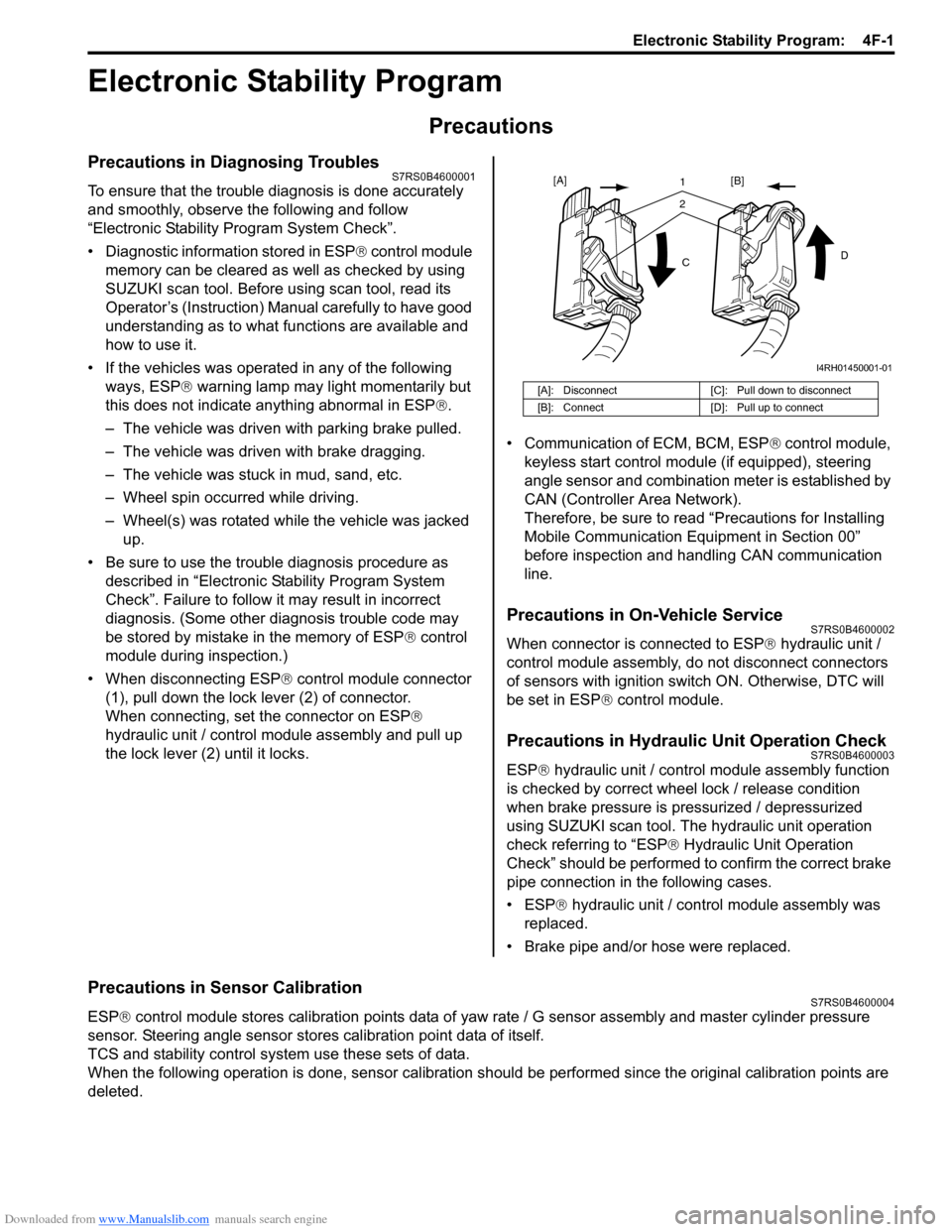

• When disconnecting ESP ® control module connector

(1), pull down the lock lever (2) of connector.

When connecting, set the connector on ESP ®

hydraulic unit / control module assembly and pull up

the lock lever (2) until it locks. • Communication of ECM, BCM, ESP

® control module,

keyless start control module (if equipped), steering

angle sensor and combination meter is established by

CAN (Controller Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handling CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4600002

When connector is connected to ESP ® hydraulic unit /

control module assembly, do not disconnect connectors

of sensors with ignition switch ON. Otherwise, DTC will

be set in ESP ® control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4600003

ESP® hydraulic unit / control module assembly function

is checked by correct wheel lock / release condition

when brake pressure is pressurized / depressurized

using SUZUKI scan tool. The hydraulic unit operation

check referring to “ESP ® Hydraulic Unit Operation

Check” should be performed to confirm the correct brake

pipe connection in the following cases.

• ESP® hydraulic unit / contro l module assembly was

replaced.

• Brake pipe and/or hose were replaced.

Precautions in Sensor CalibrationS7RS0B4600004

ESP ® control module stores calibration points data of yaw rate / G sensor assembly and master cylinder pressure

sensor. Steering angle sensor stores calibration point data of itself.

TCS and stability control system use these sets of data.

When the following operation is done, sensor calibration should be performed since the original calibration points are

deleted.

[A]: Disconnect [C]: Pull down to disconnect

[B]: Connect [D]: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01

Page 576 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-2 Electronic Stability Program:

Perform sensor calibration according to “Sensor Calibration”.

Precautions in Speedometer Test or Other TestsS7RS0B4600005

When performing speedometer or other tests using speedometer tester or chassis dynamometer, ESP® function must

be deactivated by ESP ® OFF switch or using SUZUKI scan to ol to complete the tests correctly.

When using SUZUKI scan tool, set to the “MISC. TEST” mode to stop the ESP ® function. Refer to SUZUKI scan tool

operator's manual for further details.

General Description

Electronic Stability Program DescriptionS7RS0B4601006

Electronic Stability Program (ESP ®) is an auxiliary function to enable the vehicle to av oid a danger safely while the

vehicle is running, stopping or turning.

Electronic Stability Program (ESP ®) consists of following functions.

ESP ® is a registered trademark of Daimler Chrysler AG.

Antilock Brake System (ABS)

This system prevents tire locking which may occur when br ake is applied suddenly or on slippery roads. With this

function, as the vehicle body is kept in the stable state an d tires unlocked, the driver can avoid any obstacle by turning

the steering wheel.

Electronic Brake force Distribution (EBD)

This function distributes braking force of front and rear wheels properly according to the vehicle load condition.

With this function, the braking force of the front and rear wheels is controlled for the optimum effect to secure the

maximum braking force regardless of the loadage.

Traction Control System (TCS)

This system controls the engine and brake to prevent the dr iving wheels from spinning at the time of starting and

accelerating. Particularly, this fu nction is helpful for safe driving on muddy or icy roads. When ESP ® control module

detects wheel spinning using information from the yaw rate sensor and wheel speed sensor, it lower the engine torque

by closing the electronic controlled thro ttle and controlling ignition. At the same time, brake is applied to the spinning

tire.

Stability Control

This function controls the vehicle body in the stable state by controlling the engine and braking so as to prevent the

vehicle from over-steering or under-steering while turning.

When under-steering occurs, this function lowers the engine torque and applies brake to the inner rear wheel in the

vehicle forward direction so as to pr event the vehicle from moving outward.

When over-steering occurs, this function applies brake to the outer front wheel in the vehicle forward direction so as to

prevent the vehicle from moving inward. Sensor Procedures required calibration

Steering angle sensor • Power is not su pplied to steering angle sensor. (battery, fuse and/or connector is

removed.)

• Steering angle sensor is replaced.

• Power is not supplied to ESP ® control module. (battery, fuse and/or connector is

removed.)

• ESP® hydraulic unit / control module assembly is replaced.

Master cylinder pressure sensor • ESP® hydraulic unit / control module assembly is removed or replaced.

Yaw rate / G sensor assembly • Yaw rate / G sensor assembly is removed or replaced.

• ESP® hydraulic unit / control module assembly is replaced.

Page 577 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-3

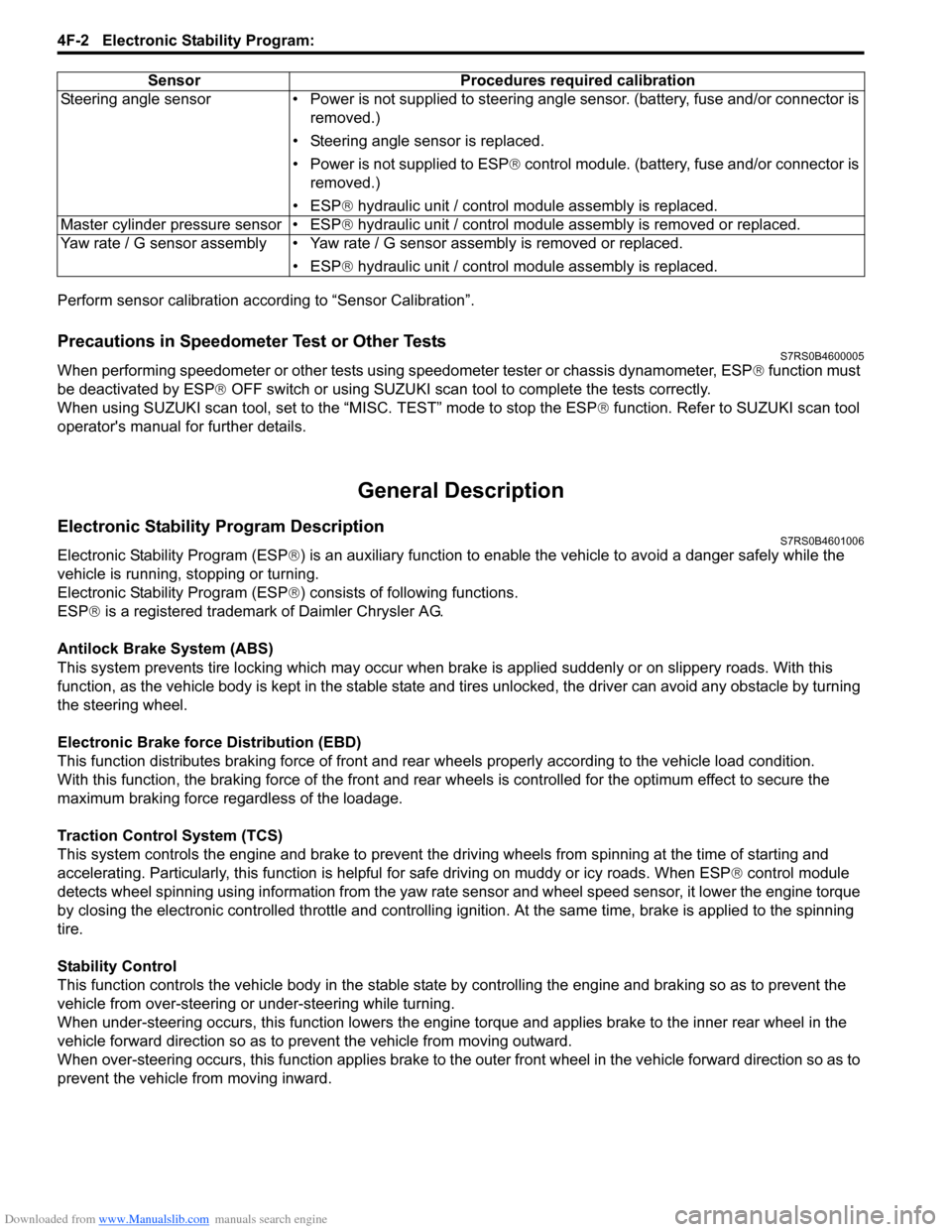

Electronic Stability Program ConstructionS7RS0B4601007

ESP® control module/ hydraulic unit

The control module receives signals from each wheel speed sensor, ESP O FF switch, brake master cylinder pressure

sensor, steering angle sensor and yaw rate / G sensor. Ba sed on these signals as information, the control module

judges the vehicle conditions and controls the brake hydraulic pressure by combining the ON/OFF operation of the

solenoid in the hydraulic unit and the pump motor operation.

The hydraulic unit contains an inlet so lenoid valve and an outlet solenoid valve for each wheel as well as a cut

solenoid valve and a low pressure solenoid valve for each hydraulic unit system. Also, a master cylinder pressure

sensor, pump motor, etc. are included. The hydraulic pre ssure control is done in 3 modes of pressure increase,

pressure keeping and pressure reduction.

7

1

2 3

4

5

6

8

9

10

1010

10

1312

11

14

I7RS0B460001-03

1. ESP ® control module 6. Steering angle sensor 11. ESP ® OFF switch

2. Hydraulic unit 7. Stop lamp switch 12. Electronic signal

3. ECM 8. Yaw rate / G sensor 13. CAN signal

4. BCM 9. Brake master cylinder pre ssure sensor 14. Hydraulic circuit

5. Combination meter 10. Wheel speed sensor

Page 579 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-5

Yaw rate / G sensor

The yaw rate / G sensor consists of the yaw rate (angular velocity in the vehicle turning direction) sensor and right-left

G (acceleration in right-left direction) sensor and is mounted to the P/S controller B/K at the lower part of the center

console. It detects the angular velocity in the vehicle turn ing direction and movement in the right-left direction, and

then it sends that information to ESP ® control module.

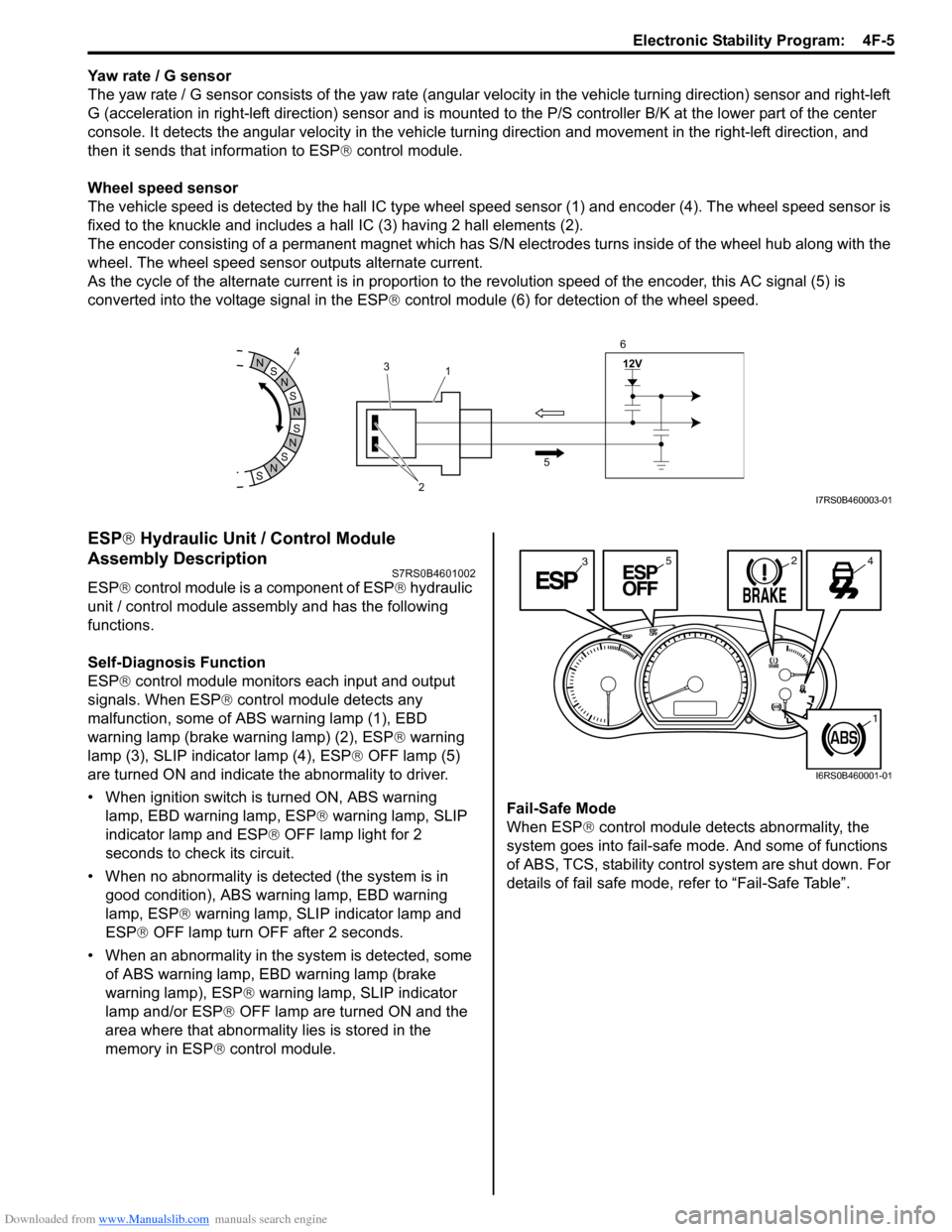

Wheel speed sensor

The vehicle speed is detected by the hall IC type wheel speed sensor (1) and encoder (4). The wheel speed sensor is

fixed to the knuckle and includes a hall IC (3) having 2 hall elements (2).

The encoder consisting of a permanent ma gnet which has S/N electrodes turns inside of the wheel hub along with the

wheel. The wheel speed sensor outputs alternate current.

As the cycle of the alternate current is in proportion to the revolution speed of the encoder, this AC signal (5) is

converted into the voltage signal in the ESP ® control module (6) for detection of the wheel speed.

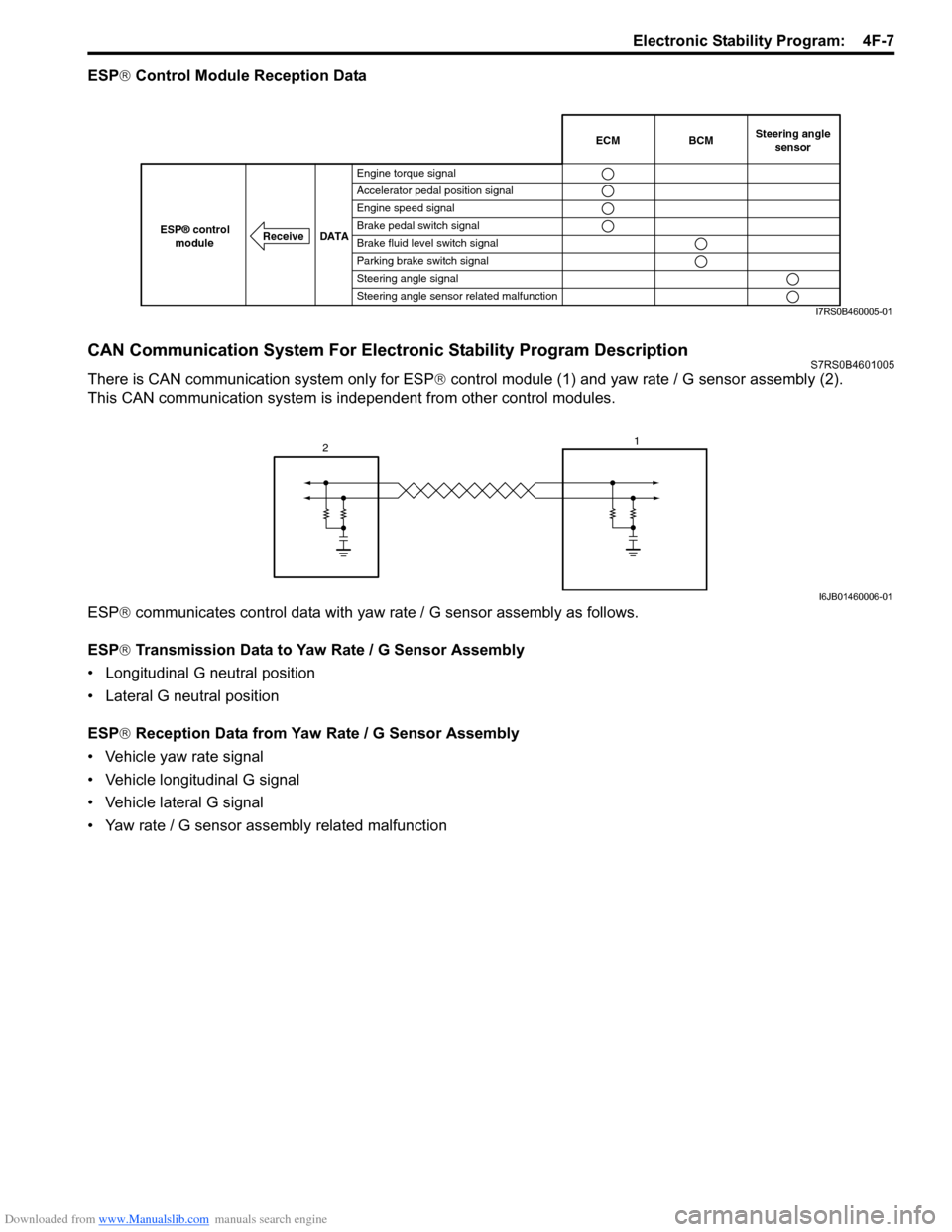

ESP ® Hydraulic Unit / Control Module

Assembly Description

S7RS0B4601002

ESP ® control module is a component of ESP ® hydraulic

unit / control module assembly and has the following

functions.

Self-Diagnosis Function

ESP ® control module monitors each input and output

signals. When ESP ® control module detects any

malfunction, some of ABS warning lamp (1), EBD

warning lamp (brake warning lamp) (2), ESP ® warning

lamp (3), SLIP indicator lamp (4), ESP ® OFF lamp (5)

are turned ON and indicate the abnormality to driver.

• When ignition switch is turned ON, ABS warning lamp, EBD warning lamp, ESP ® warning lamp, SLIP

indicator lamp and ESP ® OFF lamp light for 2

seconds to check its circuit.

• When no abnormality is detected (the system is in good condition), ABS warning lamp, EBD warning

lamp, ESP ® warning lamp, SLIP indicator lamp and

ESP ® OFF lamp turn OFF after 2 seconds.

• When an abnormality in the system is detected, some of ABS warning lamp, EBD warning lamp (brake

warning lamp), ESP ® warning lamp, SLIP indicator

lamp and/or ESP ® OFF lamp are turned ON and the

area where that abnormality lies is stored in the

memory in ESP ® control module. Fail-Safe Mode

When ESP

® control module detects abnormality, the

system goes into fail-safe mode. And some of functions

of ABS, TCS, stability control system are shut down. For

details of fail safe mode, re fer to “Fail-Safe Table”.

S

N

S

N

S

N

N

S

N

S

12V

2

3

1

5

4

6I7RS0B460003-01

3245

1

I6RS0B460001-01

Page 581 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-7

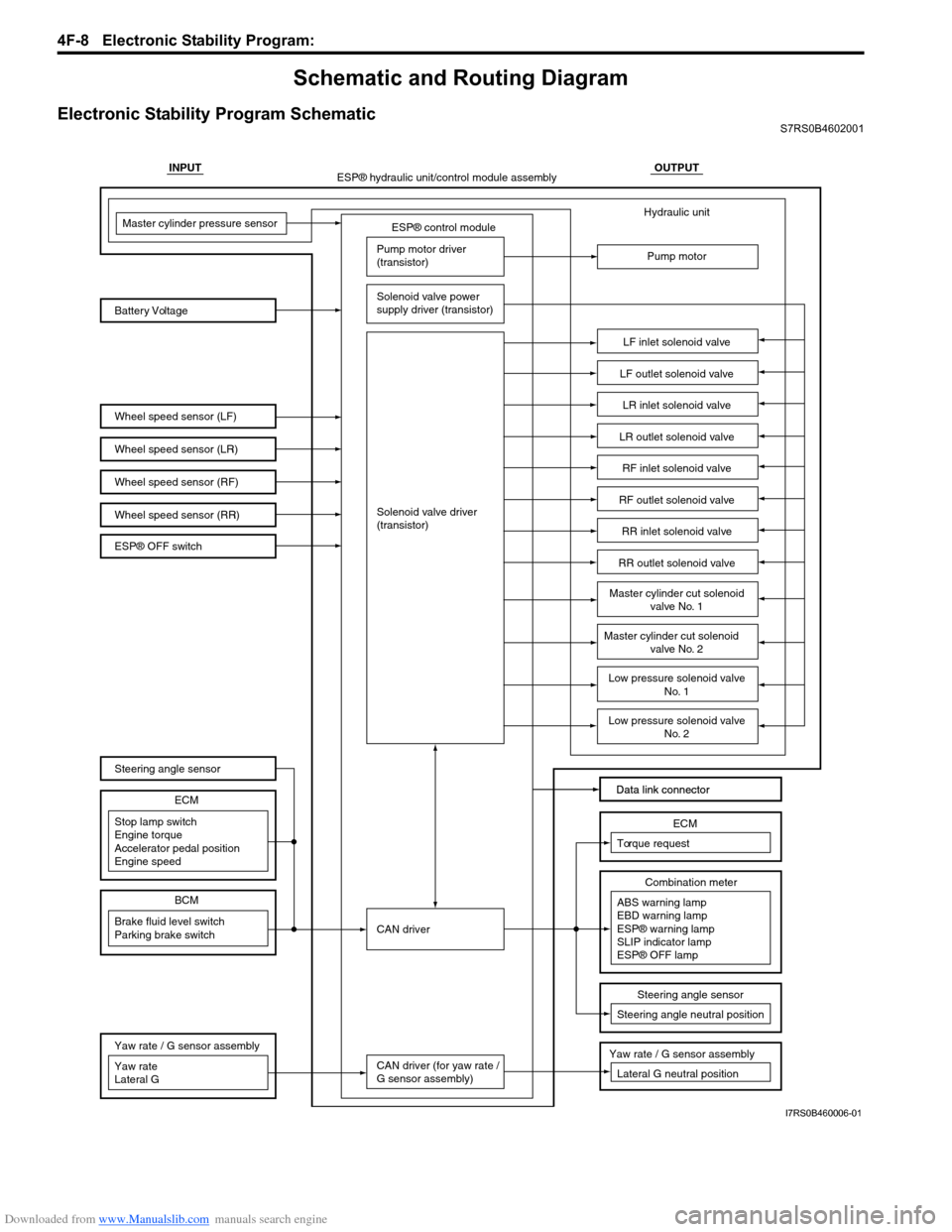

ESP® Control Module Reception Data

CAN Communication System For Electronic Stability Program DescriptionS7RS0B4601005

There is CAN communication system only for ESP ® control module (1) and yaw rate / G sensor assembly (2).

This CAN communication system is independent from other control modules.

ESP ® communicates control data with yaw rate / G sensor assembly as follows.

ESP ® Transmission Data to Yaw Rate / G Sensor Assembly

• Longitudinal G neutral position

• Lateral G neutral position

ESP ® Reception Data from Yaw Rate / G Sensor Assembly

• Vehicle yaw rate signal

• Vehicle longitudinal G signal

• Vehicle lateral G signal

• Yaw rate / G sensor assembly related malfunction

BCM

Receive DATA

ESP® control

moduleECMSteering angle sensor

Engine torque signal

Accelerator pedal position signal

Engine speed signal

Brake pedal switch signal

Brake fluid level switch signal

Parking brake switch signal

Steering angle signal

Steering angle sensor related malfunction

I7RS0B460005-01

2 1

I6JB01460006-01

Page 582 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-8 Electronic Stability Program:

Schematic and Routing Diagram

Electronic Stability Program SchematicS7RS0B4602001

INPUTOUTPUT

ESP® control module

Wheel speed sensor (LF)

Wheel speed sensor (LR)

Wheel speed sensor (RF) Battery VoltageMaster cylinder pressure sensor

Pump motor driver

(transistor)

Solenoid valve power

supply driver (transistor)

Solenoid valve driver

(transistor)

CAN driver

CAN driver (for yaw rate /

G sensor assembly) Hydraulic unit

Pump motor

LF inlet solenoid valve

LF outlet solenoid valve

LR inlet solenoid valve

LR outlet solenoid valve

RF inlet solenoid valve

RF outlet solenoid valve

RR inlet solenoid valve

RR outlet solenoid valve

Data link connector

Data link connector

ESP® hydraulic unit/control module assembly

Wheel speed sensor (RR)

Master cylinder cut solenoid valve No. 1

Master cylinder cut solenoid

valve No. 2

Low pressure solenoid valve No. 1

Low pressure solenoid valveNo. 2

Stop lamp switch

Engine torque

Accelerator pedal position

Engine speed ECM

Brake fluid level switch

Parking brake switch

BCM

Steering angle sensor

ESP® OFF switch

Yaw rate

Lateral G Yaw rate / G sensor assembly

ABS warning lamp

EBD warning lamp

ESP® warning lamp

SLIP indicator lamp

ESP® OFF lampCombination meter

Torque request

ECM

Steering angle neutral positionSteering angle sensor

Yaw rate / G sensor assembly

Lateral G neutral position

I7RS0B460006-01

Page 584 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-10 Electronic Stability Program:

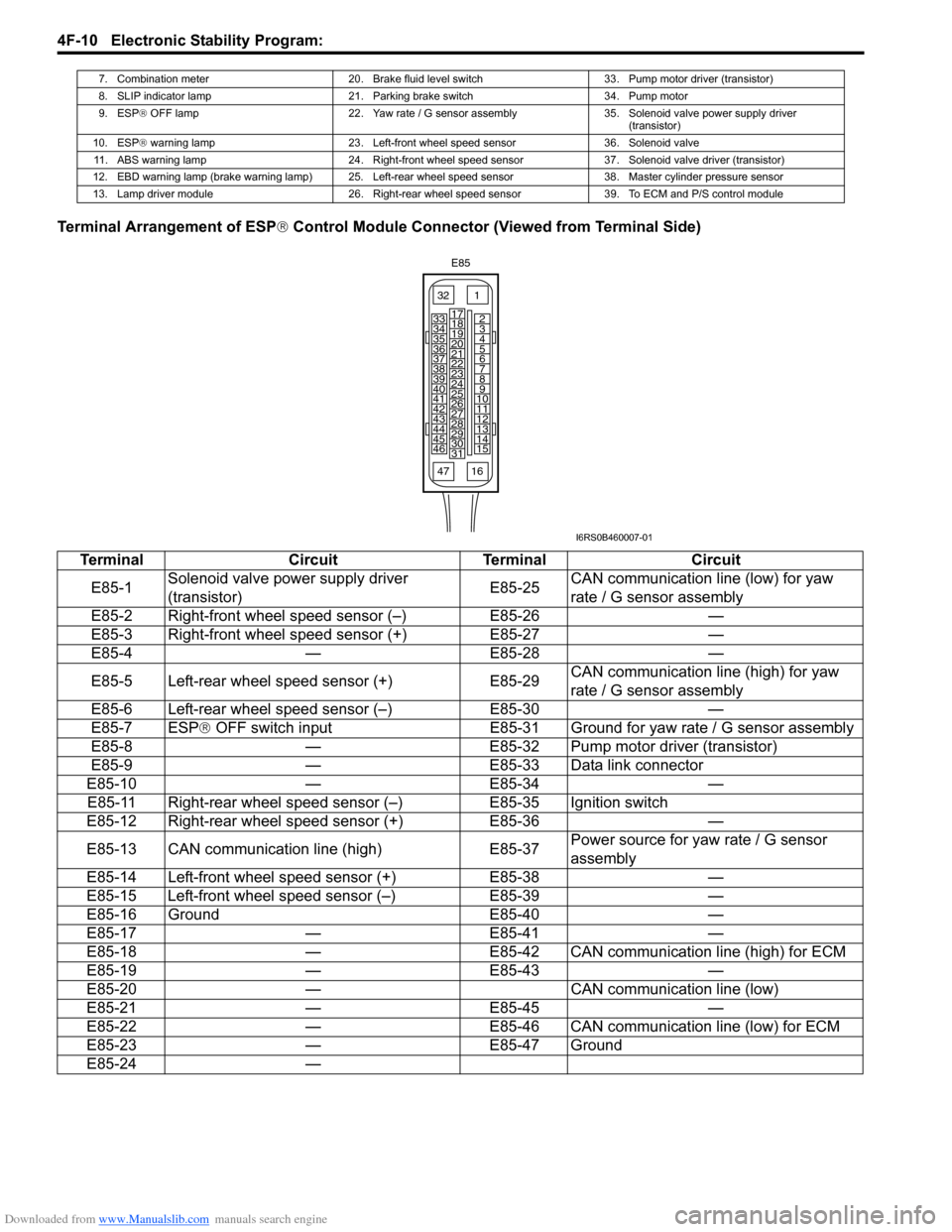

Terminal Arrangement of ESP® Control Module Connector (Viewed from Terminal Side)

7. Combination meter 20. Brake fluid level switch 33. Pump motor driver (transistor)

8. SLIP indicator lamp 21. Parking brake switch 34. Pump motor

9. ESP ® OFF lamp 22. Yaw rate / G sensor assembly 35. Solenoid valve power supply driver

(transistor)

10. ESP ® warning lamp 23. Left-front wheel speed sensor 36. Solenoid valve

11. ABS warning lamp 24. Right-front wheel speed sensor37. Solenoid valve driver (transistor)

12. EBD warning lamp (brake warning lamp) 25. Left-rear wheel speed sensor 38. Master cylinder pressure sensor

13. Lamp driver module 26. Right-rear wheel speed sensor 39. To ECM and P/S control module

Terminal CircuitTerminal Circuit

E85-1 Solenoid valve power supply driver

(transistor) E85-25CAN communication line (low) for yaw

rate / G sensor assembly

E85-2 Right-front wheel speed sensor (–) E85-26—

E85-3 Right-front wheel speed sensor (+) E85-27—

E85-4 —E85-28 —

E85-5 Left-rear wheel speed sensor (+) E85-29CAN communication line (high) for yaw

rate / G sensor assembly

E85-6 Left-rear wheel speed sensor (–) E85-30—

E85-7 ESP® OFF switch input E85-31 Ground for yaw rate / G sensor assembly

E85-8 —E85-32 Pump motor driver (transistor)

E85-9 —E85-33 Data link connector

E85-10 —E85-34 —

E85-11 Right-rear wheel speed sensor (–) E85-35 Ignition switch

E85-12 Right-rear wheel speed sensor (+) E85-36—

E85-13 CAN communication line (high) E85-37Power source for ya

w rate / G sensor

assembly

E85-14 Left-front wheel speed sensor (+) E85-38—

E85-15 Left-front wheel speed sensor (–) E85-39—

E85-16 Ground E85-40—

E85-17 —E85-41 —

E85-18 —E85-42 CAN communication line (high) for ECM

E85-19 —E85-43 —

E85-20 — CAN communication line (low)

E85-21 —E85-45 —

E85-22 —E85-46 CAN communication line (low) for ECM

E85-23 —E85-47 Ground

E85-24 —

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

I6RS0B460007-01

Page 585 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-11

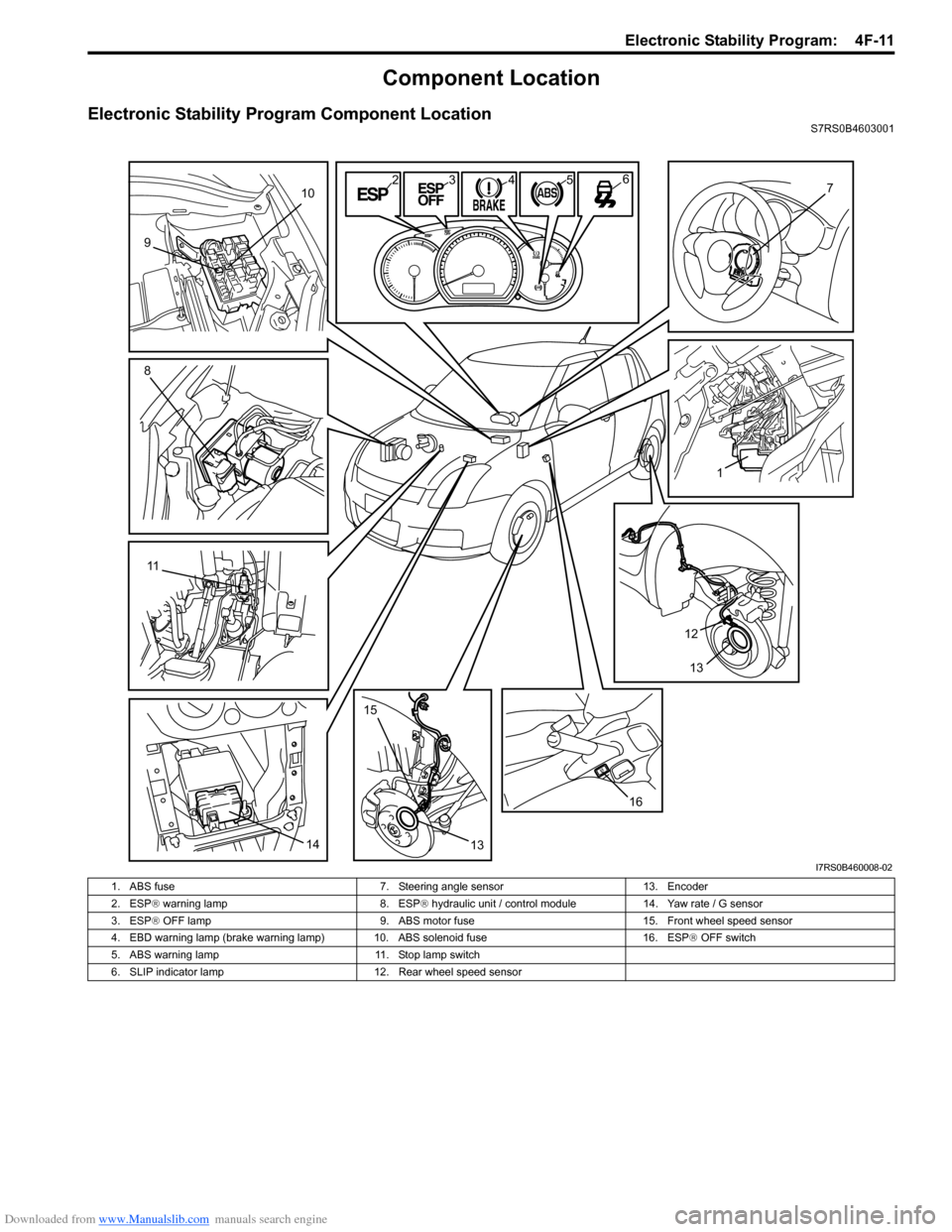

Component Location

Electronic Stability Program Component LocationS7RS0B4603001

10

9

8

11

1415

13 1613

12 1 7

6

5

4

3

2

I7RS0B460008-02

1. ABS fuse 7. Steering angle sensor13. Encoder

2. ESP ® warning lamp 8. ESP® hydraulic unit / control module 14. Yaw rate / G sensor

3. ESP ® OFF lamp 9. ABS motor fuse 15. Front wheel speed sensor

4. EBD warning lamp (brake warning lamp) 10. ABS solenoid fuse 16. ESP® OFF switch

5. ABS warning lamp 11. Stop lamp switch

6. SLIP indicator lamp 12. Rear wheel speed sensor

Page 590 of 1496

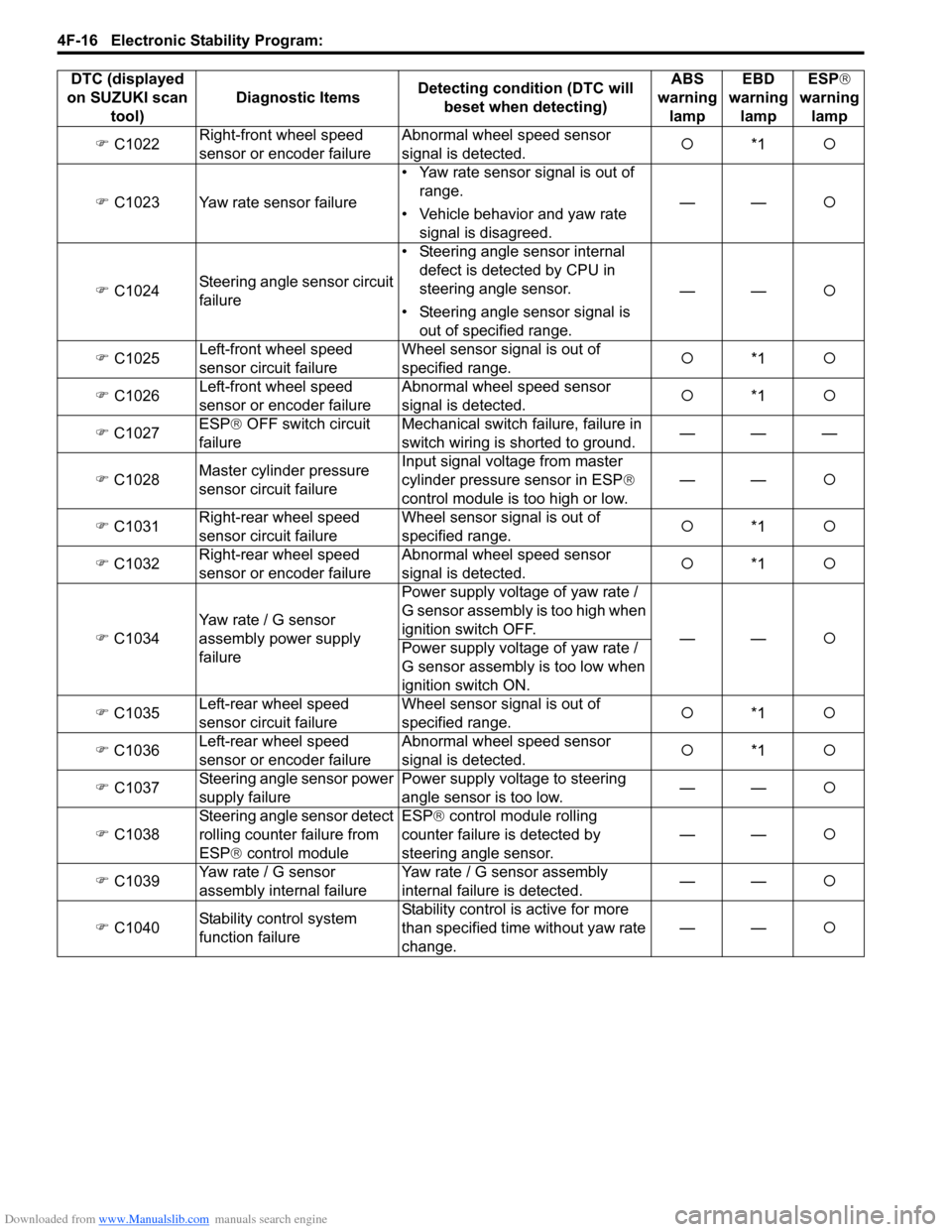

Downloaded from www.Manualslib.com manuals search engine 4F-16 Electronic Stability Program:

�) C1022 Right-front wheel speed

sensor or encoder failure Abnormal wheel speed sensor

signal is detected.

�{

*1 �{

�) C1023 Yaw rate sensor failure • Yaw rate sensor signal is out of

range.

• Vehicle behavior and yaw rate signal is disagreed. ——

�{

�) C1024 Steering angle sensor circuit

failure • Steering angle sensor internal

defect is detected by CPU in

steering angle sensor.

• Steering angle sensor signal is out of specified range. ——

�{

�) C1025 Left-front wheel speed

sensor circuit failure Wheel sensor signal is out of

specified range.

�{

*1 �{

�) C1026 Left-front wheel speed

sensor or encoder failure Abnormal wheel speed sensor

signal is detected.

�{

*1 �{

�) C1027 ESP

® OFF switch circuit

failure Mechanical switch failure, failure in

switch wiring is shorted to ground.

———

�) C1028 Master cylinder pressure

sensor circuit failure Input signal voltage from master

cylinder pressure sensor in ESP

®

control module is too high or low. ——

�{

�) C1031 Right-rear wheel speed

sensor circuit failure Wheel sensor signal is out of

specified range.

�{

*1 �{

�) C1032 Right-rear wheel speed

sensor or encoder failure Abnormal wheel speed sensor

signal is detected.

�{

*1 �{

�) C1034 Yaw rate / G sensor

assembly power supply

failure Power supply voltage of yaw rate /

G sensor assembly is too high when

ignition switch OFF.

——�{

Power supply voltage of yaw rate /

G sensor assembly is too low when

ignition switch ON.

�) C1035 Left-rear wheel speed

sensor circuit failure Wheel sensor signal is out of

specified range.

�{

*1 �{

�) C1036 Lef

t-rear wheel speed

sensor or encoder failure Abnormal wheel speed sensor

signal is detected.

�{

*1 �{

�) C1037 Steering angle sensor power

supply failure Power supply voltage to steering

angle sensor is too low.

——

�{

�) C1038 Steering angle sensor detect

rolling counter failure from

ESP

® control module ESP

® control module rolling

counter failure is detected by

steering angle sensor. ——

�{

�) C1039 Yaw rate / G sensor

assembly internal failure Yaw rate / G sensor assembly

internal failure is detected.

——

�{

�) C1040 Stability control system

function failure Stability control is active for more

than specified time

without yaw rate

change. ——

�{

DTC (displayed

on SUZUKI scan tool) Diagnostic Items

Detecting condition (DTC will

beset when detecting) ABS

warning lamp EBD

warning lamp ESP

®

warning lamp