bcm SUZUKI SWIFT 2008 2.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1019 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-71

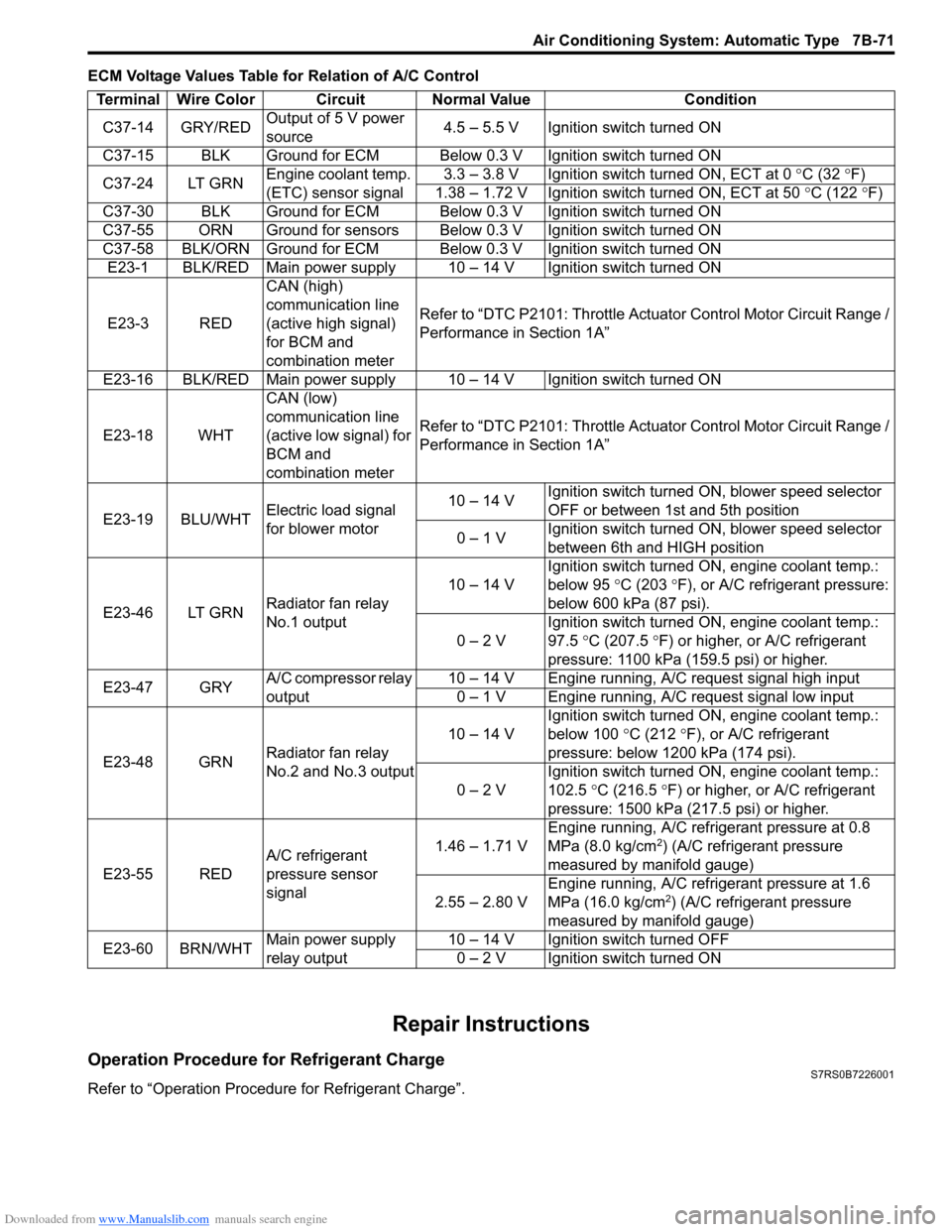

ECM Voltage Values Table for Relation of A/C Control

Repair Instructions

Operation Procedure for Refrigerant ChargeS7RS0B7226001

Refer to “Operation Procedure for Refrigerant Charge”.Terminal Wire Color Circuit Normal Value Condition

C37-14 GRY/RED Output of 5 V power

source 4.5 – 5.5 V Ignition switch turned ON

C37-15 BLK Ground for ECM Below 0.3 V Ignition switch turned ON

C37-24 LT GRN Engine coolant temp.

(ETC) sensor signal 3.3 – 3.8 V Ignition switch turned ON, ECT at 0

°C (32 ° F)

1.38 – 1.72 V Ignition switch turned ON, ECT at 50 °C (122 °F)

C37-30 BLK Ground for ECM Below 0.3 V Ignition switch turned ON

C37-55 ORN Ground for sensors Below 0.3 V Ignition switch turned ON

C37-58 BLK/ORN Ground for ECM Below 0.3 V Ignition switch turned ON E23-1 BLK/RED Main power supply 10 – 14 V Ignition switch turned ON

E23-3 RED CAN (high)

communication line

(active high signal)

for BCM and

combination meterRefer to “DTC P2101: Throttle Actu

ator Control Motor Circuit Range /

Performance in Section 1A”

E23-16 BLK/RED Main power supply 10 – 14 V Ignition switch turned ON

E23-18 WHT CAN (low)

communication line

(active low signal) for

BCM and

combination meterRefer to “DTC P2101: Throttle Actu

ator Control Motor Circuit Range /

Performance in Section 1A”

E23-19 BLU/WHT Electric load signal

for blower motor 10 – 14 V

Ignition switch turned ON, blower speed selector

OFF or between 1st and 5th position

0 – 1 V Ignition switch turned ON, blower speed selector

between 6th and HIGH position

E23-46 LT GRN Radiator fan relay

No.1 output 10 – 14 V

Ignition switch turned ON, engine coolant temp.:

below 95

°C (203 ° F), or A/C refrigerant pressure:

below 600 kPa (87 psi).

0 – 2 V Ignition switch turned ON, engine coolant temp.:

97.5

°C (207.5 °F) or higher, or A/C refrigerant

pressure: 1100 kPa (159.5 psi) or higher.

E23-47 GRY A/C compressor relay

output 10 – 14 V Engine running, A/C request signal high input

0 – 1 V Engine running, A/C request signal low input

E23-48 GRN Radiator fan relay

No.2 and No.3 output 10 – 14 V

Ignition switch turned ON, engine coolant temp.:

below 100

°C (212 °F), or A/C refrigerant

pressure: below 1200 kPa (174 psi).

0 – 2 V Ignition switch turned ON, engine coolant temp.:

102.5

°C (216.5 ° F) or higher, or A/C refrigerant

pressure: 1500 kPa (217.5 psi) or higher.

E23-55 RED A/C refrigerant

pressure sensor

signal 1.46 – 1.71 V

Engine running, A/C refrigerant pressure at 0.8

MPa (8.0 kg/cm

2) (A/C refrigerant pressure

measured by manifold gauge)

2.55 – 2.80 V Engine running, A/C refrigerant pressure at 1.6

MPa (16.0 kg/cm

2) (A/C refrigerant pressure

measured by manifold gauge)

E23-60 BRN/WHT Main power supply

relay output 10 – 14 V Ignition switch turned OFF

0 – 2 V Ignition switch turned ON

Page 1033 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-2

Seat Belt with ELR

The seat belt with emergency locking retractor (ELR) is

designed so that it locks immediately (to prevent the

webbing from being pulled out of the retractor any

further) when any of the following items is detected as

exceeding each set value;

• Speed at which the webbing is pulled out of the retractor.

• Acceleration or deceleration of the vehicle speed.

• Inclination.

Seat Belt with A-ELR

The automatic and emergency locking retractor (A-ELR)

works as an Emergency Locking Retractor (ELR) till its

webbing is pulled all the way out and then on as an

Automatic Locking Retractor (ALR ) till it is retracted fully.

ALR: Automatically locks when the webbing is pulled out

from the retractor and allowed to retract even a little.

Then the webbing can not be pulled out any further,

unless it is wound all the way back into the retractor,

which releases the lock and allows the webbing to be

pulled out.

Seat Belt with ELR and Pretensioner

The seat belt with ELR and a pretensioner has a

pretensioner mechanism whic h operates in linkage with

the air bag in addition to the described ELR.

The pretensioner is incorporated in retractor assembly

and controlled by SDM as one of air bag system

components. It will be activated at the same time as the

driver and passenger air bag module when an impact at

the front of vehicle exceeds the specified value.

When servicing seat belt (retractor assembly) with

pretensioner, be sure to observe all WARNINGS and

CAUTIONS and “Precautions on Service and Diagnosis

of Air Bag System in Section 8B”. CAUTION!

Do not reuse the seat belt pretensioner

(retractor assembly) that has activated.

Replace it with a new seat belt assembly and

buckle together as a set. For checking

procedure of its activation, refer to “Repair

and Inspection Required after Accident in

Section 8B”.

Seat Belt Remainder

When driver’s seat belt is unfastened (under the

following conditions), seat belt reminder light and

warning buzzer inform that driver’s seat belt is

unfastened. Seat belt reminder light located in

combination meter and warning buzzer located inside

BCM operate as follows:

• Seat belt reminder light comes on when driver’s seat belt is unfastened while igni tion key switch is at ON

position.

• If vehicle speed exceeds 15 km/h with seat belt unfastened, warning buzzer operates for

approximately 95 seconds and seat belt reminder light

flashes synchronously with buzzer. When warning

buzzer stops operating, seat belt reminder light is

turned on.

• If driver’s seat belt state is changed from “fastened” to “unfastened” while vehicle speed is above 15 km/h,

warning buzzer operates for approximately 95

seconds and seat belt reminder light flashes

synchronously with buzzer. When warning buzzer

stops operating, seat belt reminder light is turned on.

Diagnostic Information and Procedures

Repair and Inspection Required after AccidentS7RS0B8104001

After an accident, whether the seat belt pretensioner has been activated or not, be sure to perform checks and repairs

described on “Repair and Inspection Required after Accident in Section 8B”.

Page 1045 of 1496

![SUZUKI SWIFT 2008 2.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-7

Schematic and Routing Diagram

Air Bag System Wiring Circuit DiagramS7RS0B8202001

[A]

[B]“E13” “E44”, “G04� SUZUKI SWIFT 2008 2.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-7

Schematic and Routing Diagram

Air Bag System Wiring Circuit DiagramS7RS0B8202001

[A]

[B]“E13” “E44”, “G04�](/img/20/7607/w960_7607-1044.png)

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-7

Schematic and Routing Diagram

Air Bag System Wiring Circuit DiagramS7RS0B8202001

[A]

[B]“E13” “E44”, “G04” “G35” and "L03" \

"L41"

1

2 GRN/RED

GRN GRN/RED

GRN

BLU/RED YEL/RED BLU/RED

YEL/RED

GRN/ORN GRN/YEL

RED

13

PPL/WHT

9 7

8

5

6

10 “L10”

“L11”

“L04”

“G35” “G34”

“G33”

“G28”

“G32”

“L35”

L29-2

L29-27

L29-32 L29-5

L29-6 L29-4

L29-3

L29-8

L29-7

IG

ST

YEL L29-37ADS

WHT/RED

LT GRN/BLK L29-46

L29-47 SD+

SD-

11

WHT/GRN LT GRN

BLK L29-45

L29-44 WL

L29-28

E1 DP-

DP+ P- P+ D- D+

“G10”

“G04”“L29”

18

BLU/ORN

BLU/YEL “L36”

L29-9

L29-10

PP-

PP+

19 17

GRY/RED

GRY

L29-12

L29-11

DS- DS+ “L25”

20

BRN/WHT

BRN

L29-13

L29-14

PS- PS+ “L30”

21

YEL/GRN

YEL/BLU

L29-20

L29-19

DC- DC+ “L18”

22

BLK/YEL

BRN/YEL

L29-21

L29-22

PC- PC+ “L41”

2316

15

14

“L29”

SP+

SP-

“G26”“L32”

“L03”“E44”“E13”

12

ORN

PNK/BLK

GRY/RED

GRY L29-50

L29-51 FD+

FD-

3 4

YEL/BLK

YEL/BLK

GRN RED/BLK

I7RS0A820002-03

[A]: Shorting bar

8. BCM 17. Passenger air bag (inflator) module

[B]: Connector 9. To data link connector (DLC)18. Driver seat belt pretensioner

1. To battery 10. Driver side-sensor (if equipped)19. Passenger seat belt pretensioner

2. Ignition switch 11. Passenger side-sensor (if equipped) 20. Driver side-air bag (inflator) module (if equipped)

3. “AIR BAG” warning light 12. Forward-sensor 21. Passenger side-air bag (inflator) module (if equipped)

4. Light driver 13. Ground for air bag system 22. Driver side curtain-air bag (inflator) module (if equipped)

5. “METER” fuse 14. SDM 23. Passenger side curtain-air bag (inflator) module (if equipped)

6. “A/BAG” fuse 15. Contact coil

7. Junction block assembly 16. Driver air bag (inflator) module

Page 1046 of 1496

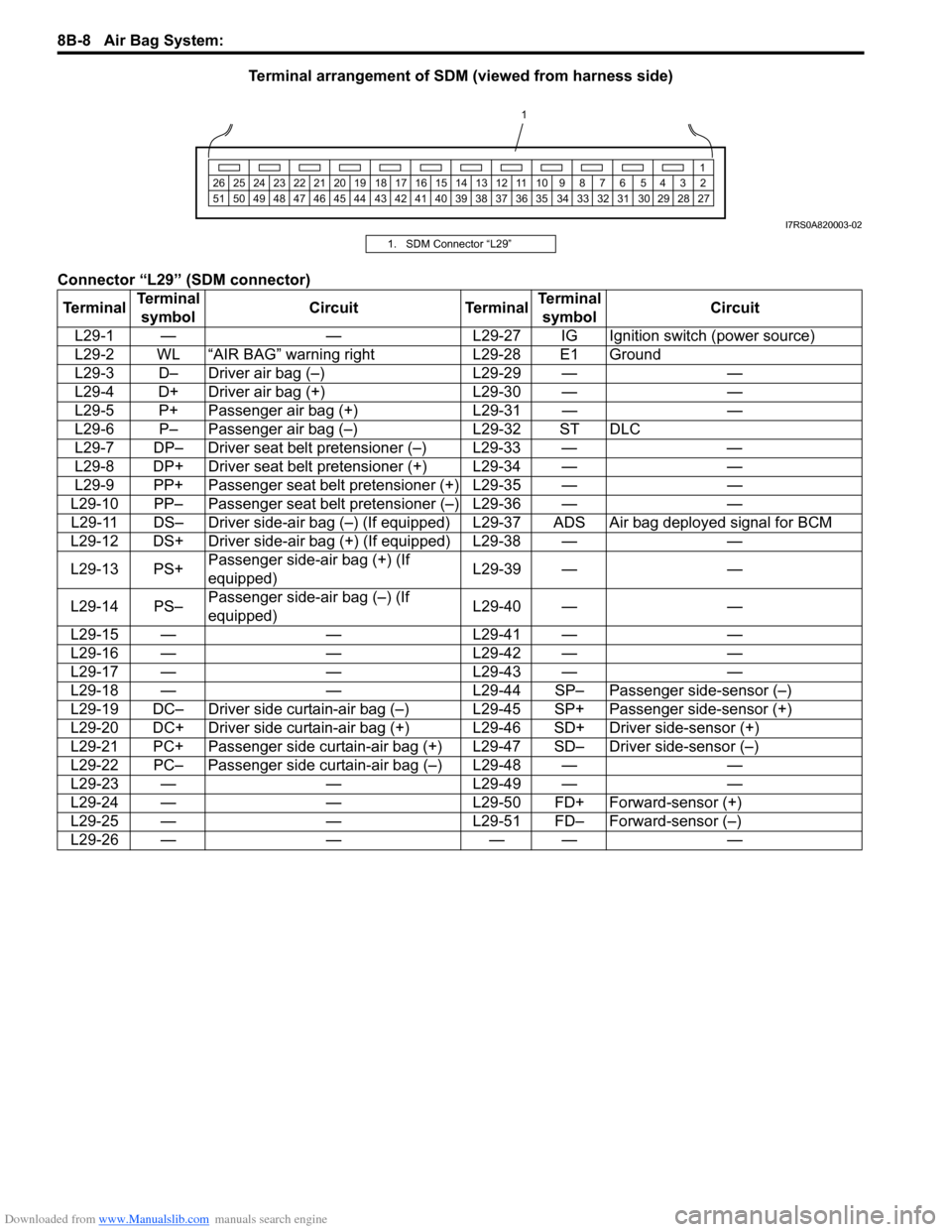

Downloaded from www.Manualslib.com manuals search engine 8B-8 Air Bag System:

Terminal arrangement of SDM (viewed from harness side)

Connector “L29” (SDM connector)

1 2345678910

11

1213141516171819202122232425

272829303132333435363738394041424344454647484950

1

26

51

I7RS0A820003-02

1. SDM Connector “L29”

Terminal Terminal

symbol Circuit Terminal Terminal

symbol Circuit

L29-1 — — L29-27 IG Ignition switch (power source)

L29-2 WL “AIR BAG” warning right L29-28 E1 Ground

L29-3 D– Driver air bag (–) L29-29 — —

L29-4 D+ Driver air bag (+) L29-30 — —

L29-5 P+ Passenger air bag (+) L29-31 — —

L29-6 P– Passenger air bag (–) L29-32 ST DLC

L29-7 DP– Driver seat belt pretensioner (–) L29-33 — —

L29-8 DP+ Driver seat belt pretensioner (+) L29-34 — —

L29-9 PP+ Passenger seat belt pretensioner (+) L29-35 — —

L29-10 PP– Passenger seat belt pretensioner (–) L29-36 — — L29-11 DS– Driver side-air bag (–) (If equipped ) L29-37 ADS Air bag deployed signal for BCM

L29-12 DS+ Driver side-air bag (+) (If equipped) L29-38 — —

L29-13 PS+ Passenger side-air bag (+) (If

equipped) L29-39 — —

L29-14 PS– Passenger side-air bag (–) (If

equipped) L29-40 — —

L29-15 — — L29-41 — —

L29-16 — — L29-42 — —

L29-17 — — L29-43 — —

L29-18 — — L29-44 SP– Passenger side-sensor (–)

L29-19 DC– Driver side curtain-air bag (–) L29-45 SP+ Passenger side-sensor (+)

L29-20 DC+ Driver side curtain-air bag (+) L29-46 SD+ Driver side-sensor (+)

L29-21 PC+ Passenger side curtain-air bag (+) L29-47 SD– Driver side-sensor (–)

L29-22 PC– Passenger side curtain-air bag (–) L29-48 — —

L29-23 — — L29-49 — —

L29-24 — — L29-50 FD+ Forward-sensor (+)

L29-25 — — L29-51 FD– Forward-sensor (–)

L29-26 — — — — —

Page 1048 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-10 Air Bag System:

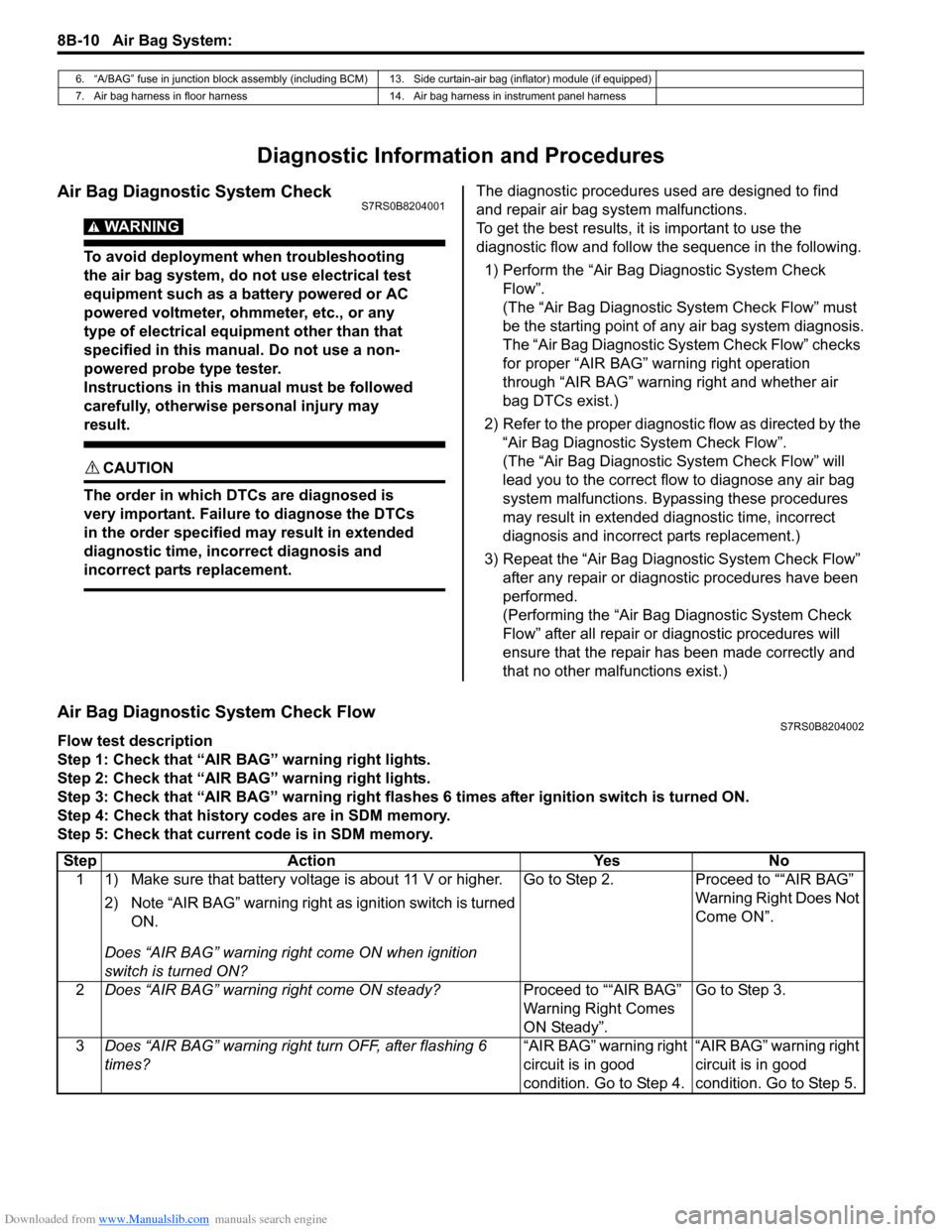

Diagnostic Information and Procedures

Air Bag Diagnostic System CheckS7RS0B8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

The order in which DTCs are diagnosed is

very important. Failure to diagnose the DTCs

in the order specified may result in extended

diagnostic time, incorrect diagnosis and

incorrect parts replacement.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.1) Perform the “Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning right operation

through “AIR BAG” warning right and whether air

bag DTCs exist.)

2) Refer to the proper diagnost ic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow” after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

Air Bag Diagnostic System Check FlowS7RS0B8204002

Flow test description

Step 1: Check that “AIR BAG” warning right lights.

Step 2: Check that “AIR BAG” warning right lights.

Step 3: Check that “AIR BAG” warning right flas hes 6 times after ignition switch is turned ON.

Step 4: Check that history codes are in SDM memory.

Step 5: Check that current code is in SDM memory.

6. “A/BAG” fuse in junction block assembly (including BCM) 13. Side curtain-air bag (inflator) module (if equipped)

7. Air bag harness in floor harness 14. Air bag harness in instrument panel harness

Step Action YesNo

1 1) Make sure that battery voltage is about 11 V or higher.

2) Note “AIR BAG” warning right as ignition switch is turned

ON.

Does “AIR BAG” warning ri ght come ON when ignition

switch is turned ON? Go to Step 2.

Proceed to ““AIR BAG”

Warning Right Does Not

Come ON”.

2 Does “AIR BAG” warning right come ON steady? Proceed to ““AIR BAG”

Warning Right Comes

ON Steady”.Go to Step 3.

3 Does “AIR BAG” warning right turn OFF, after flashing 6

times? “AIR BAG” warning right

circuit is in good

condition. Go to Step 4.“AIR BAG” warning right

circuit is in good

condition. Go to Step 5.

Page 1051 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-13

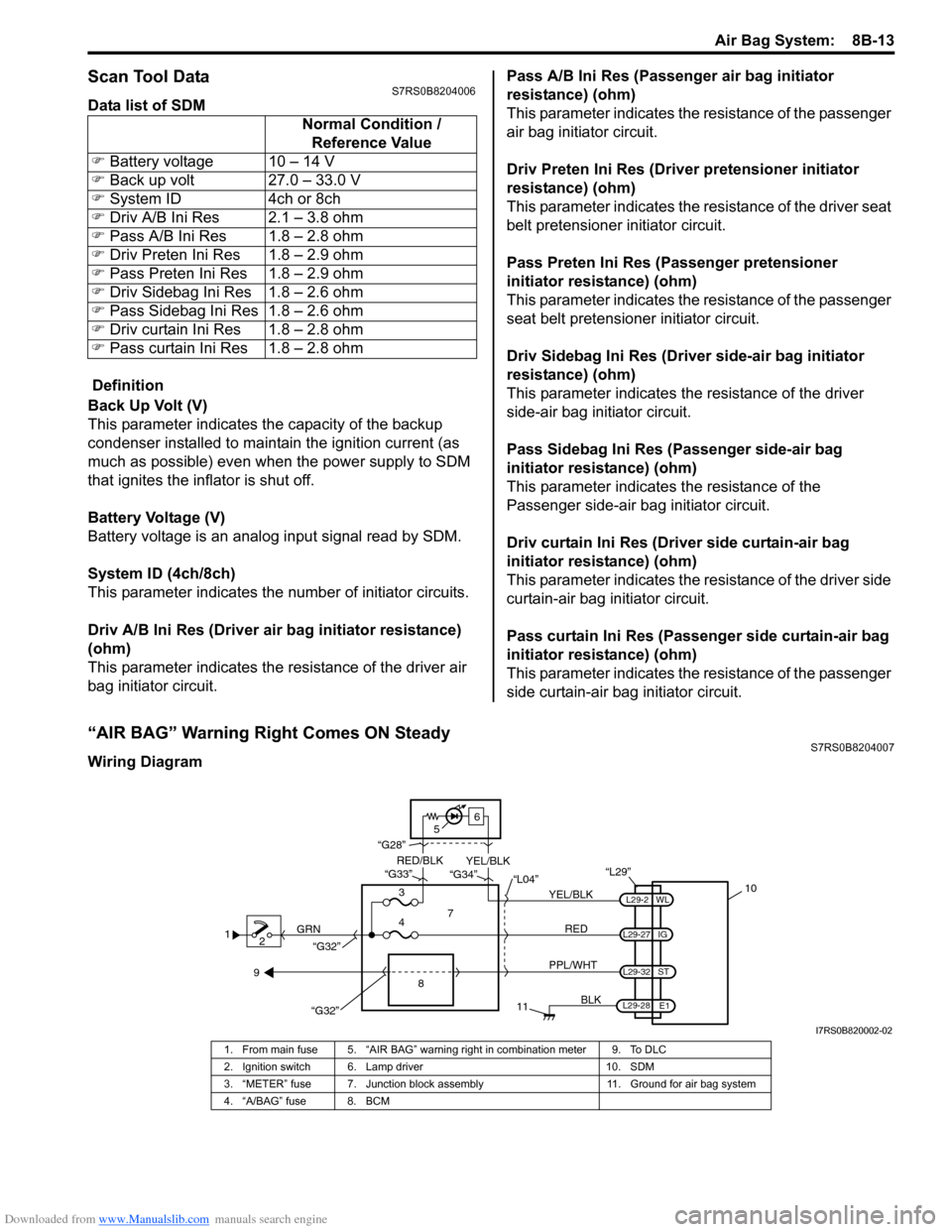

Scan Tool DataS7RS0B8204006

Data list of SDM

Definition

Back Up Volt (V)

This parameter indicates the capacity of the backup

condenser installed to maintain the ignition current (as

much as possible) even when the power supply to SDM

that ignites the inflator is shut off.

Battery Voltage (V)

Battery voltage is an analog input signal read by SDM.

System ID (4ch/8ch)

This parameter indicates the number of initiator circuits.

Driv A/B Ini Res (Driver air bag initiator resistance)

(ohm)

This parameter indicates the resistance of the driver air

bag initiator circuit. Pass A/B Ini Res (Passenger air bag initiator

resistance) (ohm)

This parameter indicates the

resistance of the passenger

air bag initiator circuit.

Driv Preten Ini Res (Dri ver pretensioner initiator

resistance) (ohm)

This parameter indicates the resistance of the driver seat

belt pretensioner initiator circuit.

Pass Preten Ini Res (Passenger pretensioner

initiator resistance) (ohm)

This parameter indicates the resistance of the passenger

seat belt pretensioner initiator circuit.

Driv Sidebag Ini Res (Driver side-air bag initiator

resistance) (ohm)

This parameter indicates the resistance of the driver

side-air bag initiator circuit.

Pass Sidebag Ini Res (Passenger side-air bag

initiator resistance) (ohm)

This parameter indicates the resistance of the

Passenger side-air bag initiator circuit.

Driv curtain Ini Res (Driver side curtain-air bag

initiator resistance) (ohm)

This parameter indicates the re sistance of the driver side

curtain-air bag initiator circuit.

Pass curtain Ini Res (Passenger side curtain-air bag

initiator resistance) (ohm)

This parameter indicates the resistance of the passenger

side curtain-air bag initiator circuit.

“AIR BAG” Warning Right Comes ON SteadyS7RS0B8204007

Wiring Diagram Normal Condition /

Reference Value

�) Battery voltage 10 – 14 V

�) Back up volt 27.0 – 33.0 V

�) System ID 4ch or 8ch

�) Driv A/B Ini Res 2.1 – 3.8 ohm

�) Pass A/B Ini Res 1.8 – 2.8 ohm

�) Driv Preten Ini Res 1.8 – 2.9 ohm

�) Pass Preten Ini Res 1.8 – 2.9 ohm

�) Driv Sidebag Ini Res 1.8 – 2.6 ohm

�) Pass Sidebag Ini Res 1.8 – 2.6 ohm

�) Driv curtain Ini Res 1.8 – 2.8 ohm

�) Pass curtain Ini Res 1.8 – 2.8 ohm

1

2 GRN

11

BLK

L29-27

L29-2

L29-28 WL

E1

IG

L29-32

ST

10

8

“L29”

RED

PPL/WHT

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

“G32”

YEL/BLK

YEL/BLK

RED/BLK

9

I7RS0B820002-02

1. From main fuse 5. “AIR BAG” warning right in combination meter 9. To DLC

2. Ignition switch 6. Lamp driver 10. SDM

3. “METER” fuse 7. Junction block assembly 11. Ground for air bag system

4. “A/BAG” fuse 8. BCM

Page 1053 of 1496

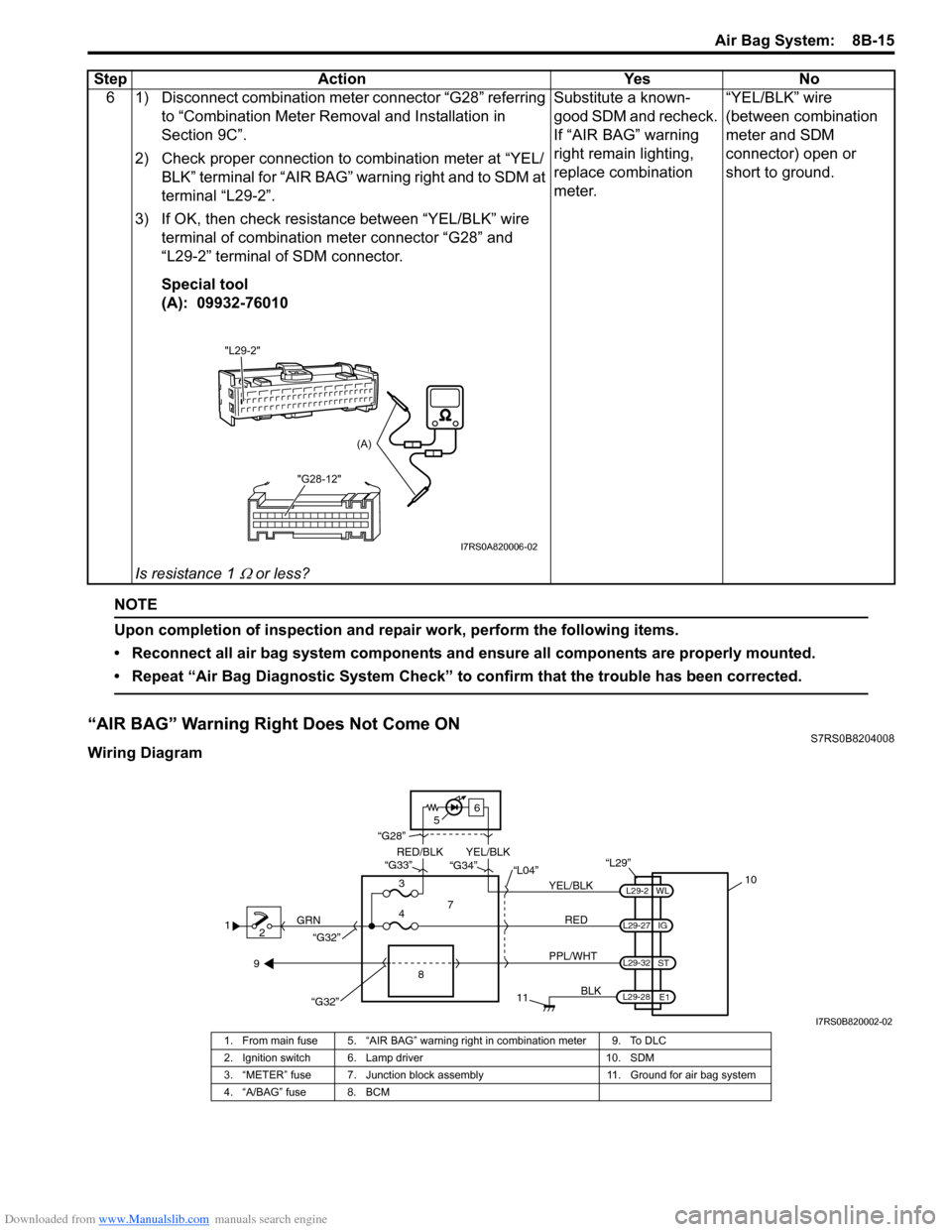

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-15

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

“AIR BAG” Warning Right Does Not Come ONS7RS0B8204008

Wiring Diagram6 1) Disconnect combination meter connector “G28” referring

to “Combination Meter Removal and Installation in

Section 9C”.

2) Check proper connection to combination meter at “YEL/ BLK” terminal for “AIR BAG” warning right and to SDM at

terminal “L29-2”.

3) If OK, then check resistance between “YEL/BLK” wire terminal of combination meter connector “G28” and

“L29-2” terminal of SDM connector.

Special tool

(A): 09932-76010

Is resistance 1

Ω or less? Substitute a known-

good SDM and recheck.

If “AIR BAG” warning

right remain lighting,

replace combination

meter.

“YEL/BLK” wire

(between combination

meter and SDM

connector) open or

short to ground.

Step Action Yes No

"L29-2"

"G28-12"

(A)

I7RS0A820006-02

12 GRN

11

BLK

L29-27

L29-2

L29-28 WL

E1

IG

L29-32

ST

10

8

“L29”

RED

PPL/WHT

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

“G32”

YEL/BLK

YEL/BLK

RED/BLK

9

I7RS0B820002-02

1. From main fuse 5. “AIR BAG” warning right in combination meter 9. To DLC

2. Ignition switch 6. Lamp driver 10. SDM

3. “METER” fuse 7. Junction block assembly 11. Ground for air bag system

4. “A/BAG” fuse 8. BCM

Page 1054 of 1496

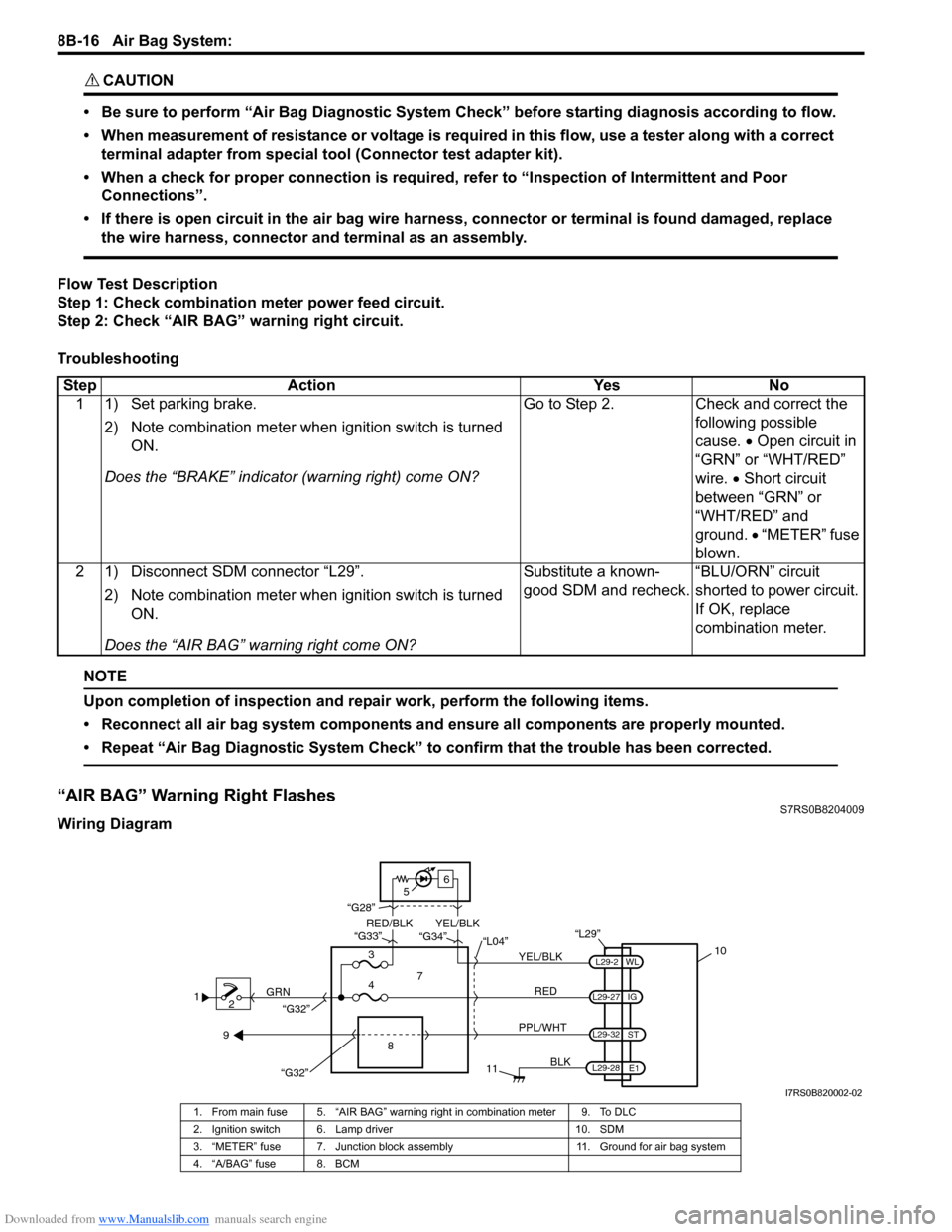

Downloaded from www.Manualslib.com manuals search engine 8B-16 Air Bag System:

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Flow Test Description

Step 1: Check combination meter power feed circuit.

Step 2: Check “AIR BAG” warning right circuit.

Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

“AIR BAG” Warning Right FlashesS7RS0B8204009

Wiring Diagram Step Action Yes No

1 1) Set parking brake.

2) Note combination me ter when ignition switch is turned

ON.

Does the “BRAKE” in dicator (warning right) come ON? Go to Step 2. Check and correct the

following possible

cause. • Open circuit in

“GRN” or “WHT/RED”

wire. • Short circuit

between “GRN” or

“WHT/RED” and

ground. • “METER” fuse

blown.

2 1) Disconnect SDM connector “L29”.

2) Note combination me ter when ignition switch is turned

ON.

Does the “AIR BAG” warning right come ON? Substitute a known-

good SDM and recheck.

“BLU/ORN” circuit

shorted to power circuit.

If OK, replace

combination meter.

1

2 GRN

11

BLK

L29-27

L29-2

L29-28 WL

E1

IG

L29-32

ST

10

8

“L29”

RED

PPL/WHT

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

“G32”

YEL/BLK

YEL/BLK

RED/BLK

9

I7RS0B820002-02

1. From main fuse 5. “AIR BAG” warning right in combination meter 9. To DLC

2. Ignition switch 6. Lamp driver 10. SDM

3. “METER” fuse 7. Junction block assembly 11. Ground for air bag system

4. “A/BAG” fuse 8. BCM

Page 1060 of 1496

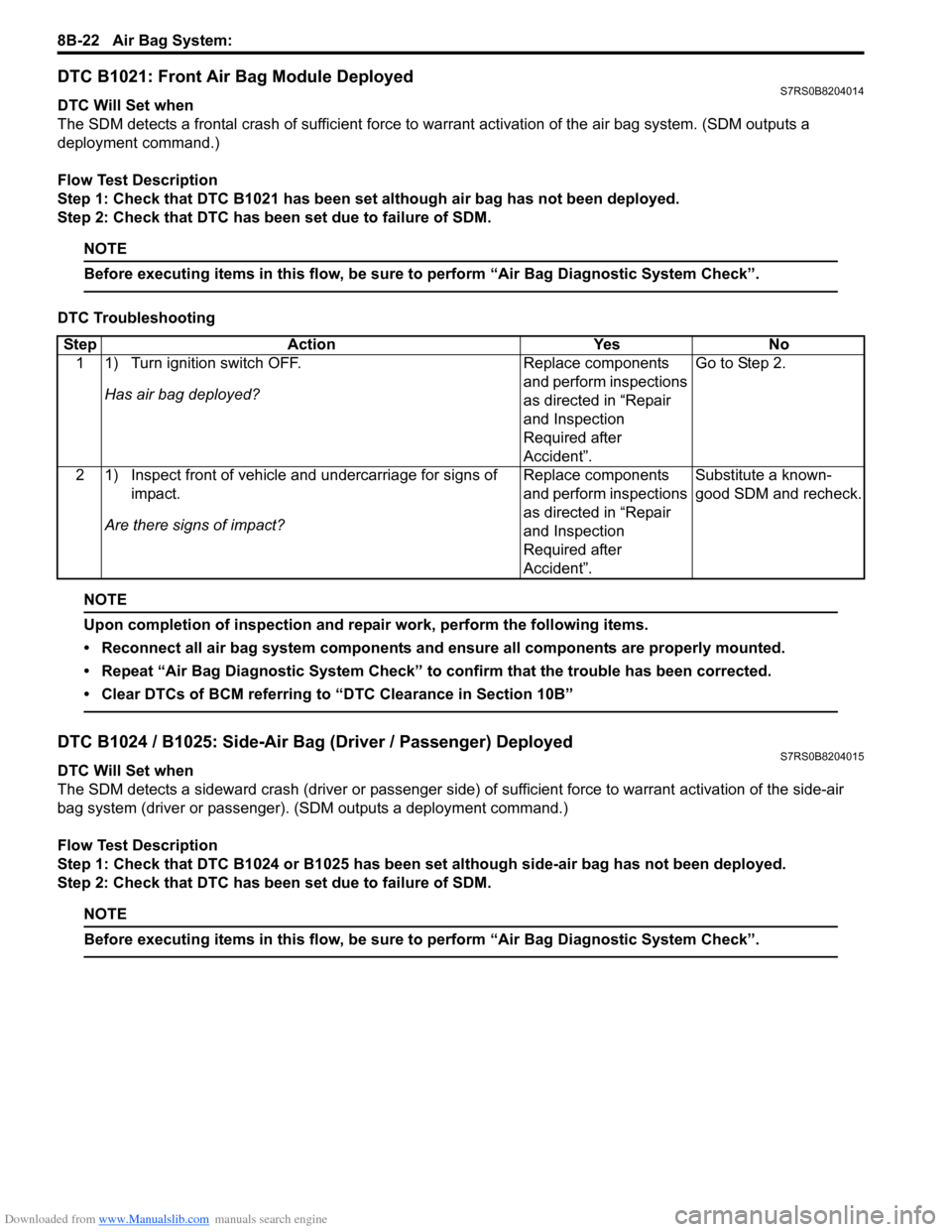

Downloaded from www.Manualslib.com manuals search engine 8B-22 Air Bag System:

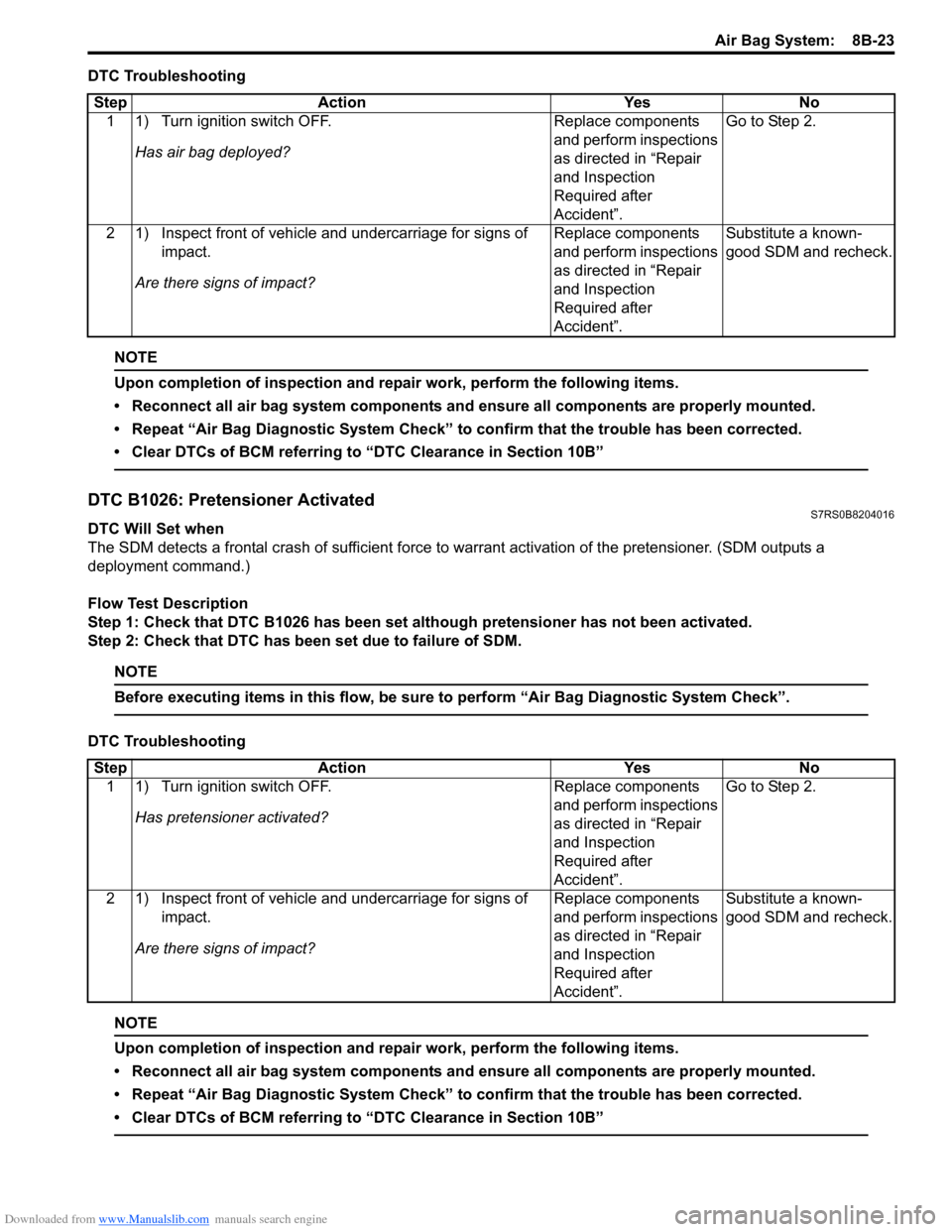

DTC B1021: Front Air Bag Module DeployedS7RS0B8204014

DTC Will Set when

The SDM detects a frontal crash of sufficient force to warrant activation of the air bag system. (SDM outputs a

deployment command.)

Flow Test Description

Step 1: Check that DTC B1021 has been set although air bag has not been deployed.

Step 2: Check that DTC has been set due to failure of SDM.

NOTE

Before executing items in this flow, be sure to perform “Air Bag Diagnostic System Check”.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

• Clear DTCs of BCM referring to “DTC Clearance in Section 10B”

DTC B1024 / B1025: Side-Air Bag (Driver / Passenger) DeployedS7RS0B8204015

DTC Will Set when

The SDM detects a sideward crash (driver or passenger side) of sufficient force to warrant activation of the side-air

bag system (driver or pa ssenger). (SDM outputs a deployment command.)

Flow Test Description

Step 1: Check that DTC B1024 or B1025 has been set although side-air bag has not been deployed.

Step 2: Check that DTC has been set due to failure of SDM.

NOTE

Before executing items in this flow, be sure to perform “Air Bag Diagnostic System Check”.

Step Action YesNo

1 1) Turn ignition switch OFF.

Has air bag deployed? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Go to Step 2.

2 1) Inspect front of vehicle and undercarriage for signs of impact.

Are there signs of impact? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Substitute a known-

good SDM and recheck.

Page 1061 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-23

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

• Clear DTCs of BCM referring to “DTC Clearance in Section 10B”

DTC B1026: Pretensioner ActivatedS7RS0B8204016

DTC Will Set when

The SDM detects a frontal crash of sufficient force to warrant activation of the pr etensioner. (SDM outputs a

deployment command.)

Flow Test Description

Step 1: Check that DTC B1026 has been set although pretensioner has not been activated.

Step 2: Check that DTC has been set due to failure of SDM.

NOTE

Before executing items in this flow, be sure to perform “Air Bag Diagnostic System Check”.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

• Clear DTCs of BCM referring to “DTC Clearance in Section 10B”

StepAction YesNo

1 1) Turn ignition switch OFF.

Has air bag deployed? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Go to Step 2.

2 1) Inspect front of vehicle and undercarriage for signs of impact.

Are there signs of impact? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Substitute a known-

good SDM and recheck.

Step

Action YesNo

1 1) Turn ignition switch OFF.

Has pretensioner activated? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Go to Step 2.

2 1) Inspect front of vehicle and undercarriage for signs of impact.

Are there signs of impact? Replace components

and perform inspections

as directed in “Repair

and Inspection

Required after

Accident”.Substitute a known-

good SDM and recheck.